Anti-reversion shoulder pad rubber composition

A rubber composition and anti-reversion technology, applied in the rubber field, can solve problems such as not very obvious effects, and achieve the effects of reducing the heat generation of the tire shoulder, improving the service life, and improving the anti-reversion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

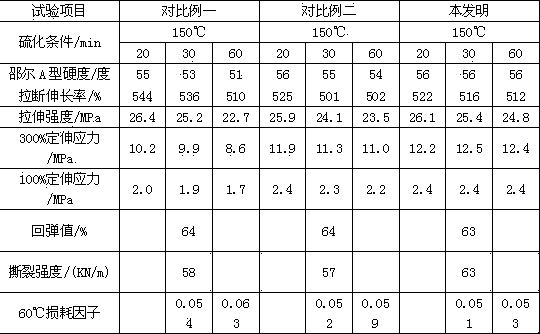

[0009] Below in conjunction with embodiment the present invention will be further described:

[0010] The invention is characterized by adopting the following raw materials in parts by weight: 100 parts by weight of natural rubber, 25-40 parts by weight of carbon black, 5-10 parts by weight of white carbon black, 3-5 parts by organic silicon mixture TESPT, 3-6 parts by weight of zinc oxide, 1.5 parts by stearic acid ~2.5, Super Tackifying Resin 1~2, Antiaging Agent 4020 1~2.5, Antiaging Agent RD 0.5~1.5, Insoluble Sulfur 1~2.5, Accelerator NS 0.5~2, Antiscorch Agent CTP 0.2, Hexamethylene-1 , 6-dithiosulfate disodium salt. Two parts of crystal water (HTS) 0.5 to 2.5.

[0011] Preferably, the carbon black is preferably N375 and N660, where N375 is 10-15 parts by weight, and N660 is 15-25 parts by weight.

[0012] Preferably, the disodium salt of hexamethylene-1,6-bisthiosulfate. Two parts of crystal water (HTS) is 1-2 parts.

[0013] In the present invention, a balanced vulca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com