Novel carbon black dispersing agent for rubber and preparation method thereof

A technology of dispersant and carbon black, applied in dyeing low molecular organic compound treatment, dyeing high molecular organic compound treatment, fibrous filler, etc., can solve the problem of poor self-adhesion, poor abrasion resistance and poor abrasion resistance and other problems, to achieve the effect of improving reversion resistance and heat resistance, improving fluidity and extrusion rate, and simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

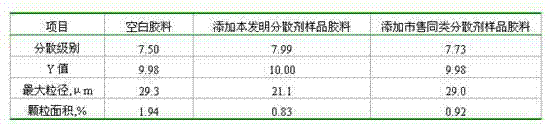

Examples

Embodiment 1

[0036] A kind of carbon black dispersion agent for rubber, is made up of the raw material of following mass percent:

[0037] Polyethylene wax (WAX-420P) 10 parts Zinc stearate 15 parts Stearic acid (1801) 20 parts Polyethylene glycol 400 10 parts Pentaerythritol tetrastearate 45 parts.

[0038] Preparation method: Stir and melt polyethylene wax (WAX-420P), stearic acid (1801), polyethylene glycol 400, and pentaerythritol tetrastearate at 100°C, then add stearic acid at a temperature of 130°C Zinc is stirred and melted, added once every ten minutes, three additions are completed, poured out and cooled to form a tablet to obtain a new type of carbon black dispersant for rubber. For the preparation process flow chart, see figure 1 .

Embodiment 2

[0040] A kind of carbon black dispersion agent for rubber, is made up of the raw material of following mass percent:

[0041] Polyethylene wax (WAX-420P) 15 parts Zinc stearate 20 parts Stearic acid (1801) 25 parts Polyethylene glycol 400 10 parts Pentaerythritol tetrastearate 30 parts.

[0042] Preparation method: Stir and melt polyethylene wax (WAX-420P), stearic acid (1801), polyethylene glycol 400, and pentaerythritol tetrastearate at 110°C, then add stearin at 140°C Zinc acid is stirred and melted, added once every ten minutes, after three additions, melted and granulated to obtain a new type of carbon black dispersant for rubber.

Embodiment 3

[0044] A kind of carbon black dispersion agent for rubber, is made up of the raw material of following mass percent:

[0045] Polyethylene wax (WAX-420P) 30 parts Zinc stearate 20 parts Stearic acid (1801) 10 parts Polyethylene glycol 400 (PEG 400) 10 parts Pentaerythritol tetrastearate 30 parts.

[0046] Preparation method: Stir and melt polyethylene wax (WAX-420P), stearic acid (1801), polyethylene glycol 400, and pentaerythritol tetrastearate at 105°C, and then add stearin at a temperature of 130°C Stir and melt the acid zinc, add once every ten minutes, add three times, and finally pour it out and cool it to make tablets or granulate to obtain a new type of carbon black dispersant for rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com