Rubber material and preparation method thereof

A technology of rubber materials and natural rubber, which is applied in the field of rubber materials, can solve the problems that it is difficult to meet the technical requirements of automobiles, natural rubber materials are not resistant to high temperature thermal oxygen aging, ozone resistance, and poor weather resistance, so as to achieve easy implementation and improve durability. High temperature thermal oxygen aging ability, the effect of prolonging the service life of high temperature fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

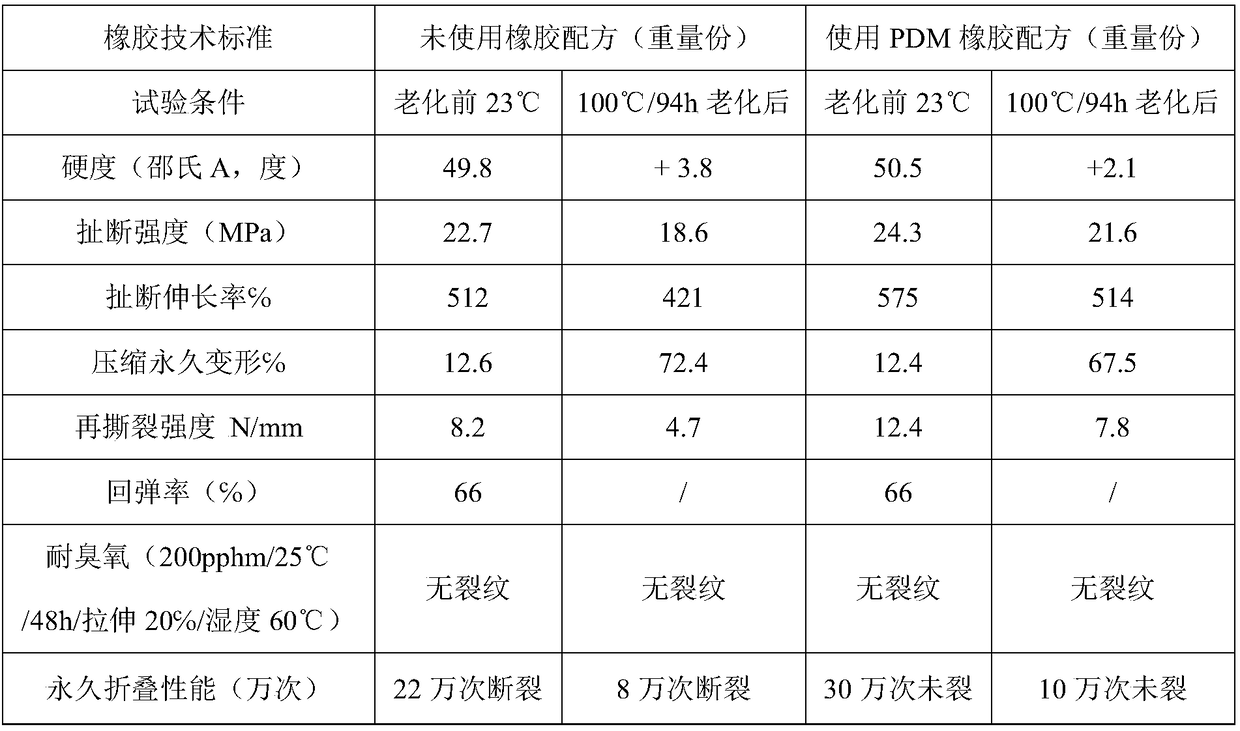

[0018] The rubber material of the present invention uses part of PDM as auxiliary vulcanizing agent and effective modifier in the natural rubber sulfur vulcanization system to achieve the purpose of improving the high temperature resistance, heat resistance and oxygen aging resistance of natural rubber.

[0019] The raw materials of the rubber material include: 100 parts by weight of natural rubber, 0.5-1.5 parts by weight of sulfur, 0.5-1.5 parts by weight of PDM, 1-2.5 parts by weight of vulcanization aid, 5-10 parts by weight of anti-aging agent, 4-10 parts by weight of zinc oxide The parts by weight are 4-8 parts by weight of white carbon black, 10-30 parts by weight of carbon black, and 4-8 parts by weight of softener. The vulcanizing agent, vulcanization aid, anti-aging agent, zinc oxide and white carbon black are all called fine materials, and the carbon black and softener are all called coarse materials. The vulcanization aid can be MBT (2-mercaptobenzothiazole), MBTS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com