Tread rubber for all-steel snow tire and preparation method of tread rubber

A technology for snow tires and tread rubber, which is applied in the field of rubber, can solve the problems of falling blocks and low hardness of tread rubber, and achieve the effects of reducing heat generation, improving tear resistance, and improving flex resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

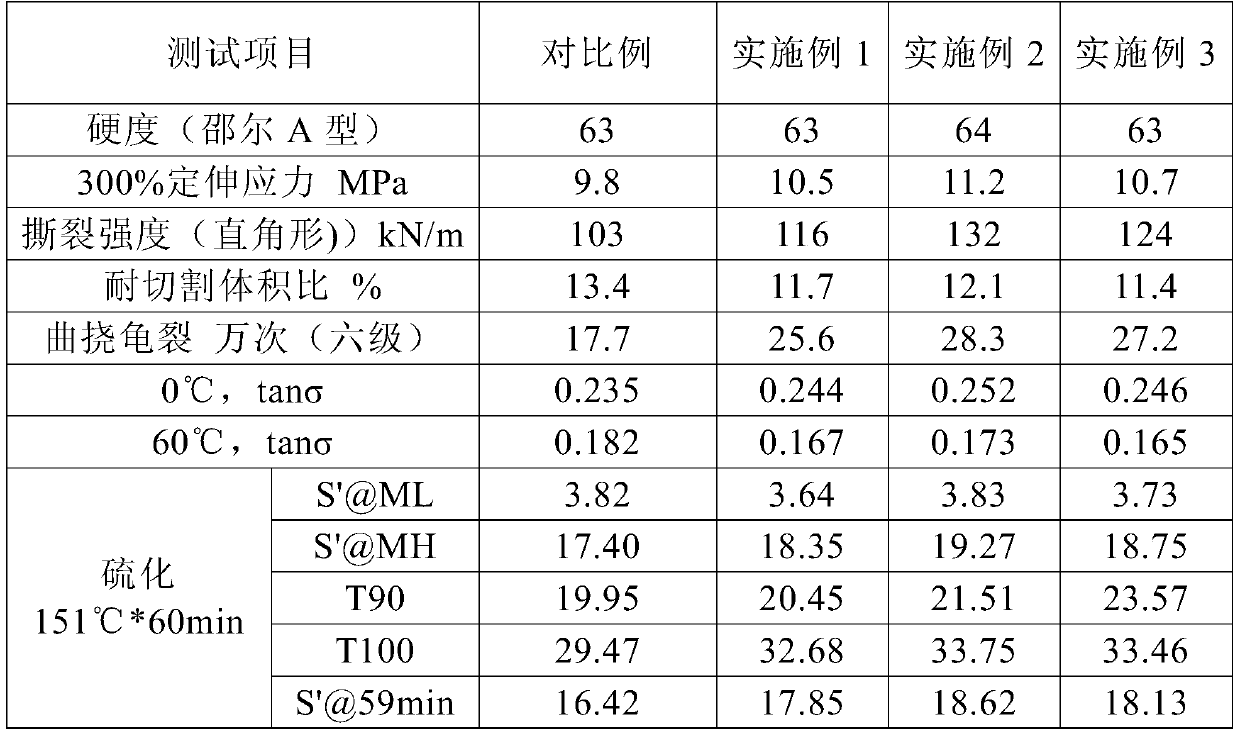

Examples

Embodiment 1

[0022] A preparation method of all-steel snow tire tread rubber, the addition of raw materials is calculated in parts by weight, comprising the following steps:

[0023] (1) One-stage mixing: 78 parts of natural rubber, 15 parts of ESBR, 8 parts of trans isoprene rubber, 41 parts of N115 carbon black, 0.3 parts of graphene oxide, 6 parts of HD165MP white carbon black, 0.8 parts of silane coupling agent Put Si69, 3 parts of phenol-modified DCPD resin, 3.5 parts of zinc oxide, and 2 parts of stearic acid into the internal mixer for mastication, the pressure of the top bolt is 5.5MPa, the rotor speed is 50r / min, and the glue discharge temperature is 160°C , the time is 160s, to obtain a section of mixed rubber;

[0024] (2) Two-stage mixing: Put the first-stage compound rubber obtained in step (1), 6 parts of N115 carbon black, 1.3 parts of antioxidant RD, 1.7 parts of antioxidant 4020, and 1 part of rubber protective wax into the internal mixer for mixing , the upper bolt press...

Embodiment 2

[0028] A preparation method of all-steel snow tire tread rubber, the addition of raw materials is calculated in parts by weight, comprising the following steps:

[0029] (1) One-stage mixing: 80 parts of natural rubber, 13 parts of SSBR, 7 parts of trans isoprene rubber, 20 parts of N115 carbon black, 20 parts of N134 carbon black, 0.35 parts of graphene oxide, 12 parts of HD165MP white carbon black, 1.2 parts of silane coupling agent Si69, 5 parts of phenol-modified DCPD resin, 3.5 parts of zinc oxide, and 2.5 parts of stearic acid are put into the internal mixer for masticating. 50r / min, the glue discharge temperature is 160°C, and the time is 160s, and a section of mixed rubber is obtained;

[0030] (2) Two-stage mixing: Put the first-stage compound rubber obtained in step (1), 5 parts of N134 carbon black, 1.2 parts of antioxidant RD, 1.6 parts of antioxidant 4020, and 1.2 parts of rubber protective wax into the internal mixer for mixing , the upper bolt pressure of the i...

Embodiment 3

[0034] A preparation method of all-steel snow tire tread rubber, the addition of raw materials is calculated in parts by weight, comprising the following steps:

[0035] (1) One-stage mixing: 70 parts of natural rubber, 20 parts of SSBR, 10 parts of trans isoprene rubber, 30 parts of N115 carbon black, 10 parts of N134 carbon black, 0.25 parts of graphene oxide, 10 parts of HD175MP white carbon black, 1 part of silane coupling agent Si69, 4 parts of phenol-modified DCPD resin, 4 parts of zinc oxide, and 3 parts of stearic acid were put into the internal mixer for mastication. 50r / min, the glue discharge temperature is 160°C, and the time is 160s, and a section of mixed rubber is obtained;

[0036] (2) Two-stage mixing: Put the first-stage compound rubber obtained in step (1), 6 parts of N115 carbon black, 1.2 parts of antioxidant RD, 1.8 parts of antioxidant 4020, and 1.2 parts of rubber protective wax into the internal mixer for mixing , the upper bolt pressure of the intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com