A kind of preparation method of europium-based multi-ligand rubber vulcanization accelerator

A technology for rubber vulcanization and multi-ligand, which is applied in the synthesis field of europium-based multi-ligand vulcanization accelerator, can solve problems such as poor solubility, achieve simplified process, good reversion resistance, and simple and easy preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of accelerator:

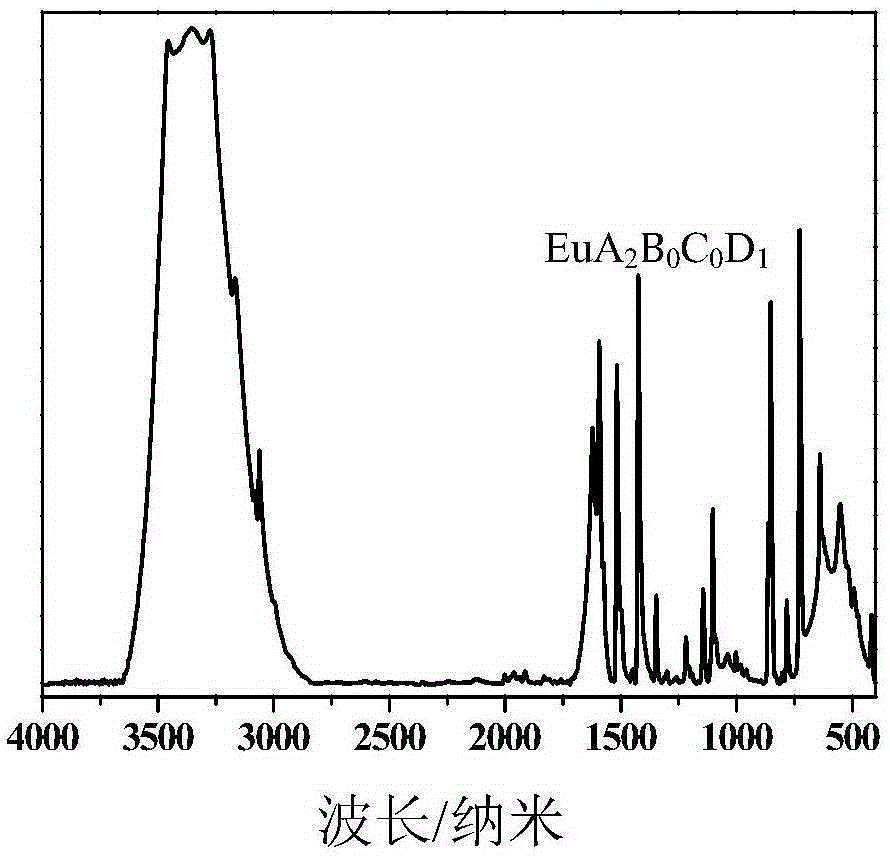

[0044] 0.01molEuCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.02mol N-cyclohexyl-2-benzothiazole sulfenamide in absolute ethanol solution at 60°C, dissolve 0.01mol triethanolamine in absolute ethanol at 60°C in solution. Fully mix the dehydrated ethanol solution of N-cyclohexyl-2-benzothiazole sulfenamide and the dehydrated ethanol solution of triethanolamine to obtain a mixed solution. Then the above mixed solution was added dropwise to EuCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2 Dry in a desiccant desiccator at 20°C to constant mass to obtain a light yellow powder, the target product EuA 2 B 0 C 0 D. 1 .

Embodiment 2

[0046] The preparation method of accelerator:

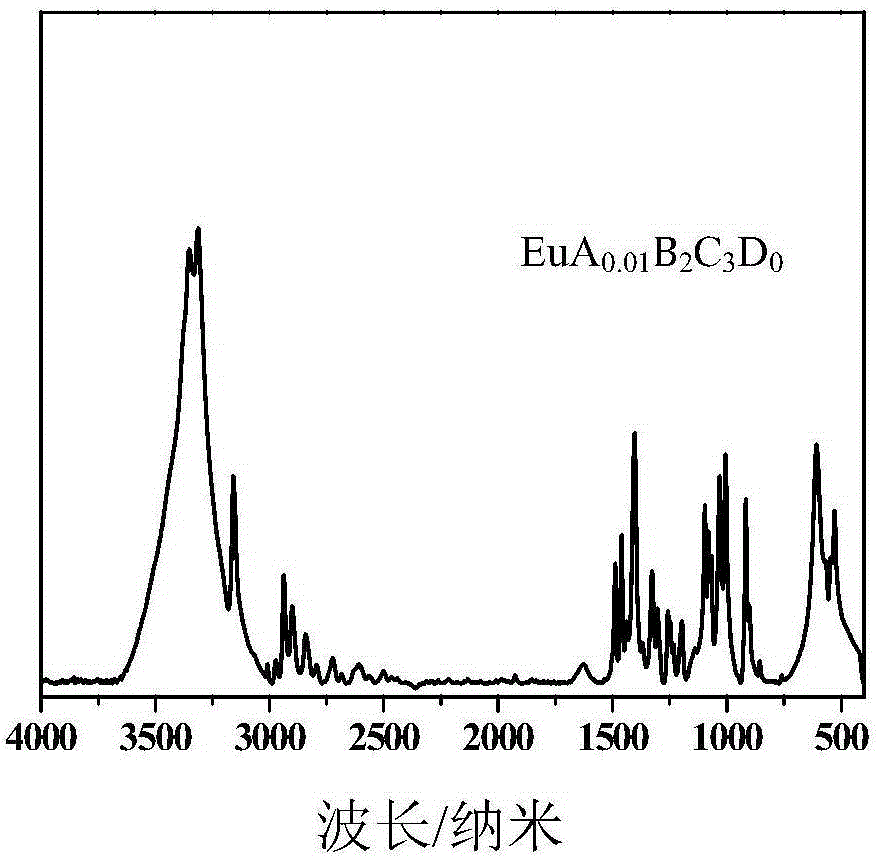

[0047] 0.01molEuCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.0001mol N-cyclohexyl-2-benzothiazole sulfenamide in absolute ethanol solution at 60°C, dissolve 0.02mol thiourea in absolute ethanol at 60°C In the solution, 0.03mol citric acid was dissolved in absolute ethanol solution at 60°C. The dehydrated ethanol solution of N-cyclohexyl-2-benzothiazole sulfenamide, the dehydrated ethanol solution of thiourea and the dehydrated alcohol solution of citric acid are thoroughly mixed to obtain a mixed solution. Then the above mixed solution was added dropwise to EuCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2Dry in a desiccant desiccator at 20°C to constant mass to obtain a light yellow powder, the target product EuA 0.01 B 2 C 3 D. 0 .

Embodiment 3

[0049] The preparation method of accelerator:

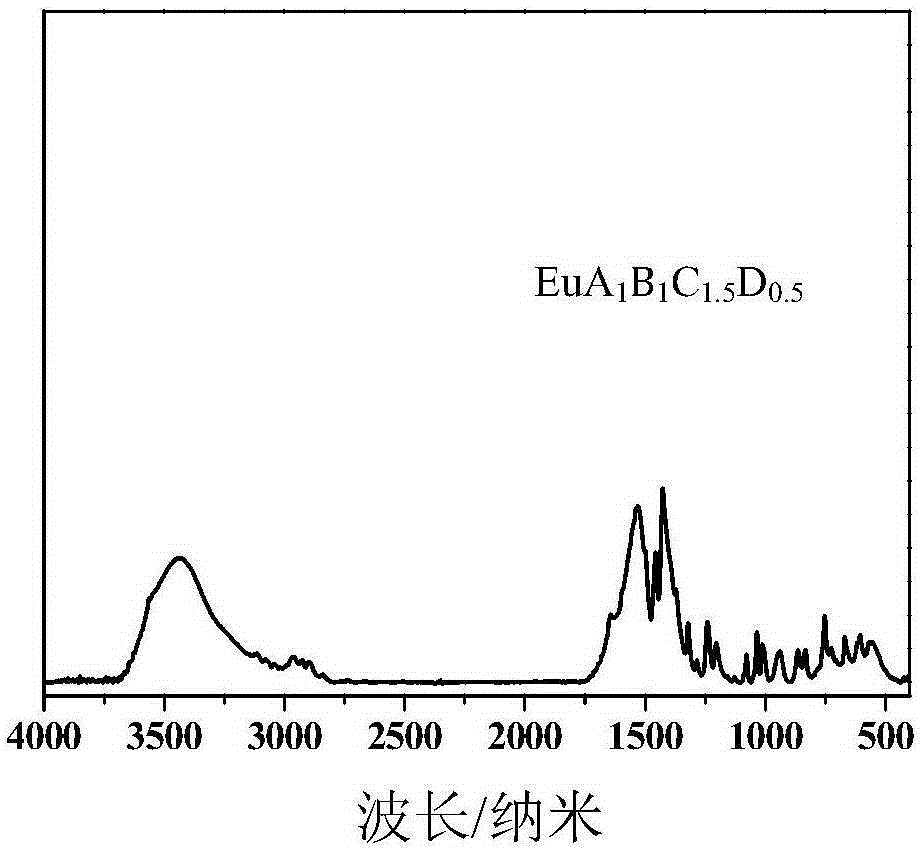

[0050] 0.01molEuCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.01mol N-cyclohexyl-2-benzothiazole sulfenamide in absolute ethanol solution at 60°C, dissolve 0.01mol thiourea in absolute ethanol at 60°C In the solution, 0.015 mol of citric acid was dissolved in the absolute ethanol solution at 60° C., and 0.005 mol of triethanolamine was dissolved in the absolute ethanol solution at 60° C. Fully mix the dehydrated ethanol solution of N-cyclohexyl-2-benzothiazole sulfenamide, the dehydrated ethanol solution of thiourea, the dehydrated ethanol solution of citric acid and the dehydrated alcohol solution of triethanolamine to obtain a mixed solution. Then the above mixed solution was added dropwise to EuCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2 Dry in a desiccant desiccator at 20°C to constant mass to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com