Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

144results about How to "The feeding process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

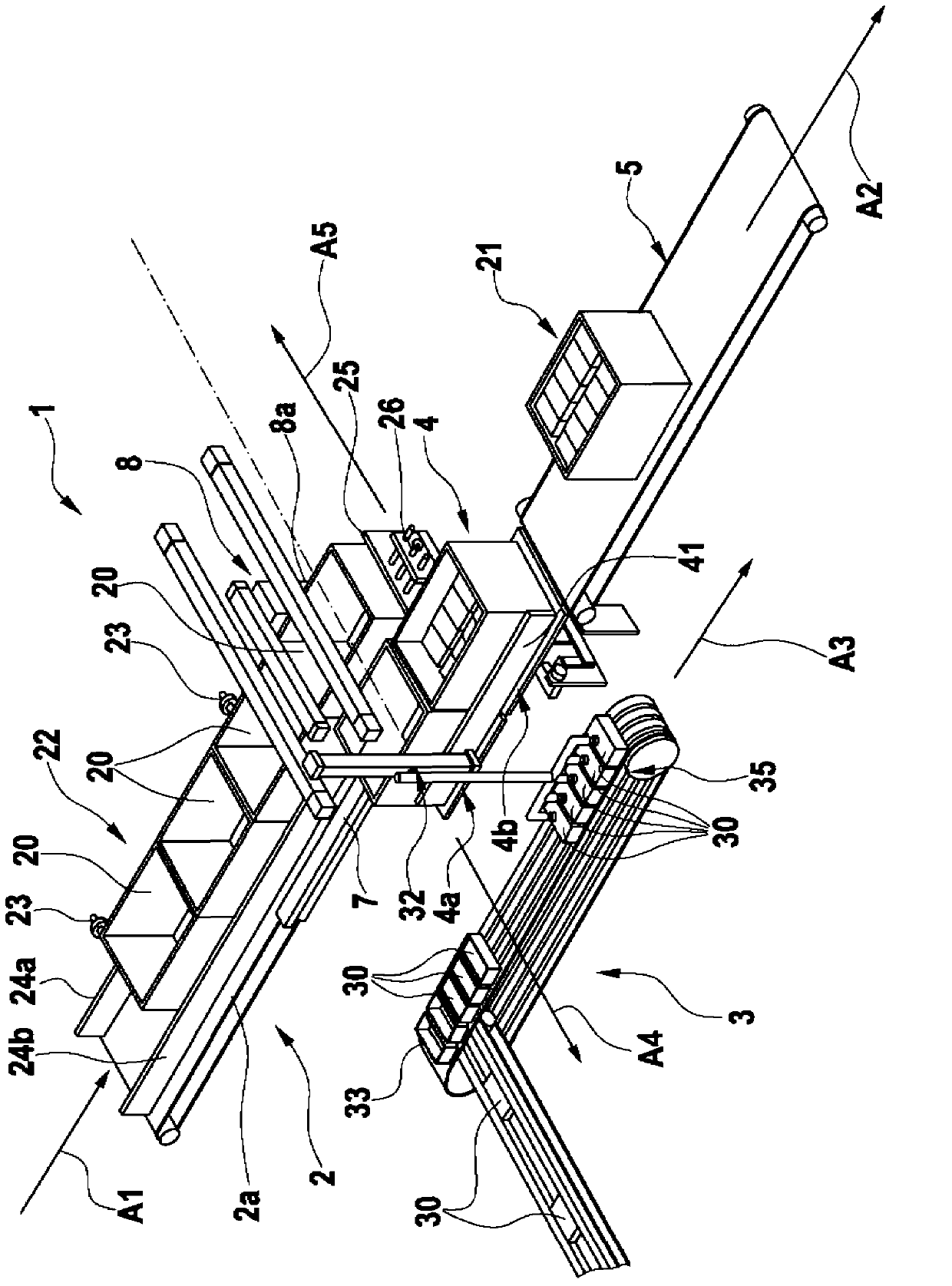

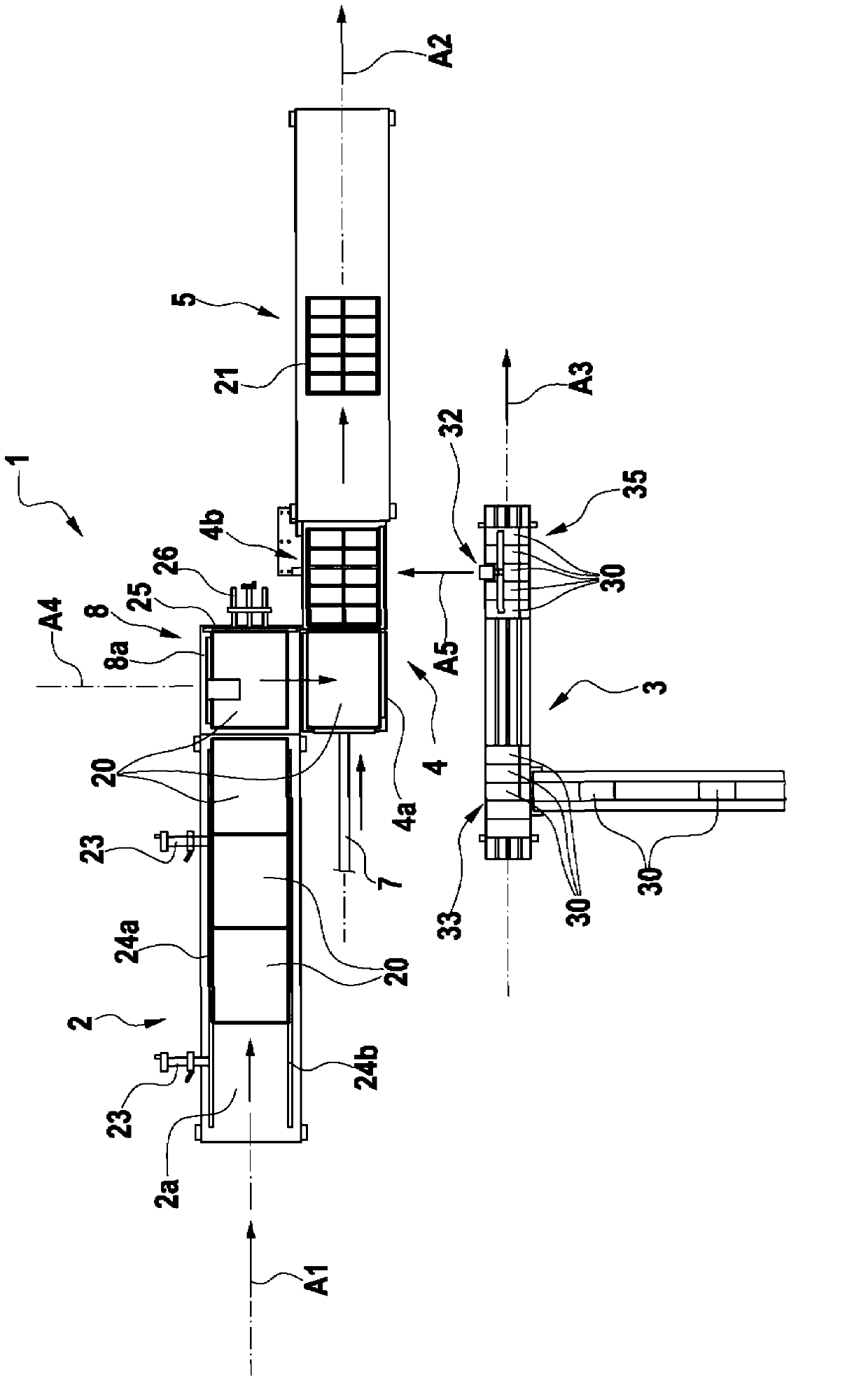

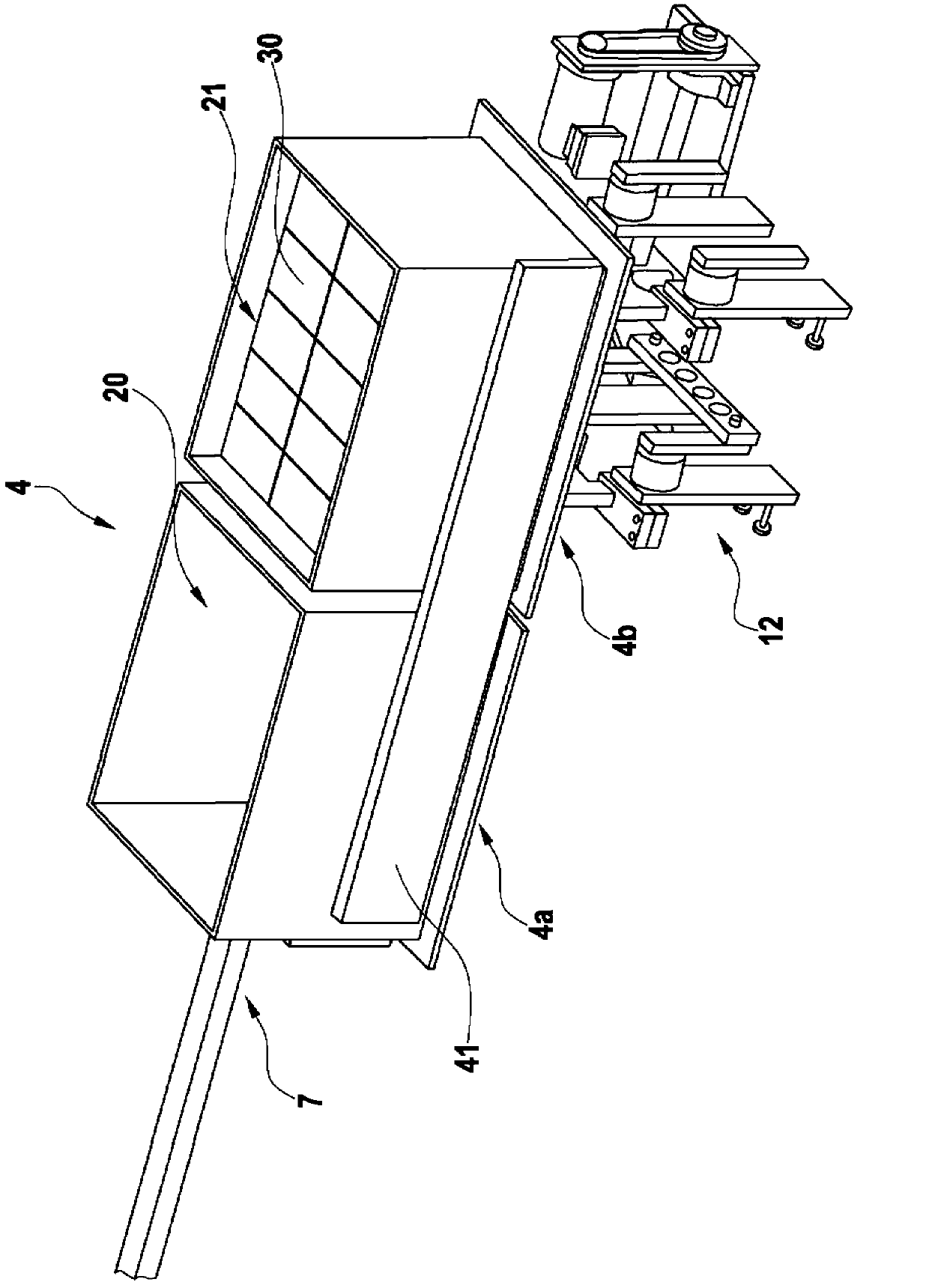

Packaging device

InactiveCN103298696AShort cycle timeContinuous packaging stepsIndividual articlesMechanical engineeringCardboard box

The invention relates to a modularly constructed packaging device, comprising: a package feed (2) for feeding empty packages (20), a product feed (3) for feeding products (30, 40), a loading station (4), in which the products are packed into the empty package in order to provide a packaging container (21), and a cardboard-box discharge (5), which leads away the packaging container.

Owner:ROBERT BOSCH GMBH

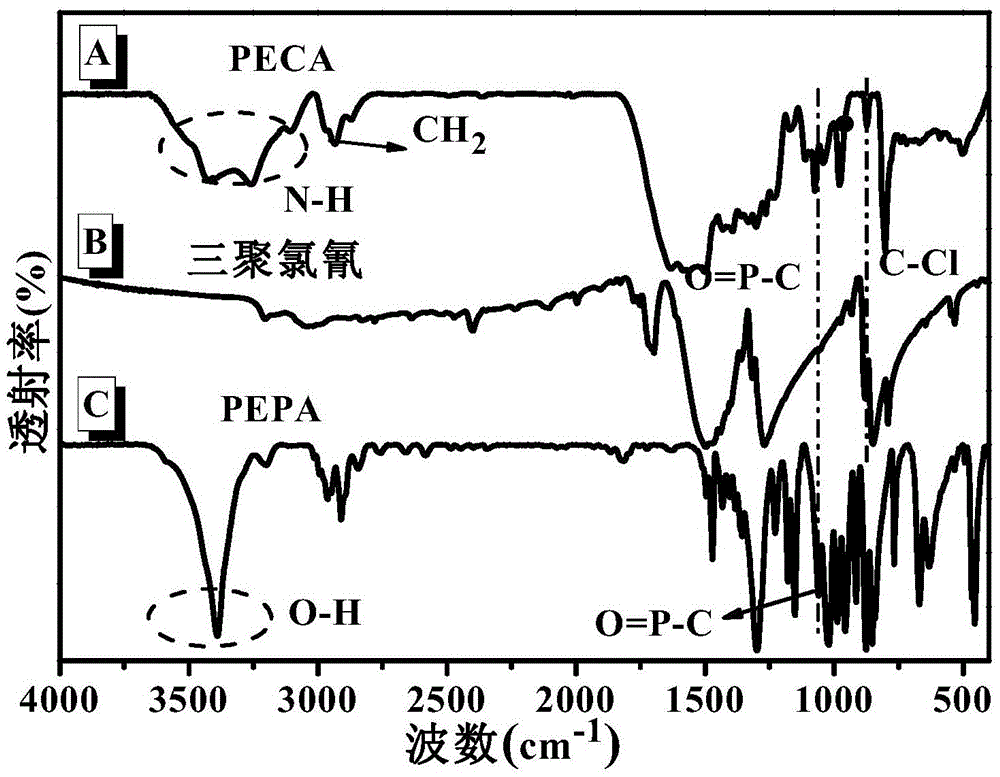

Single-component phosphor-nitrogen double-ring cage-shaped macromolecular intumescent flame retardant as well as preparation method and application thereof

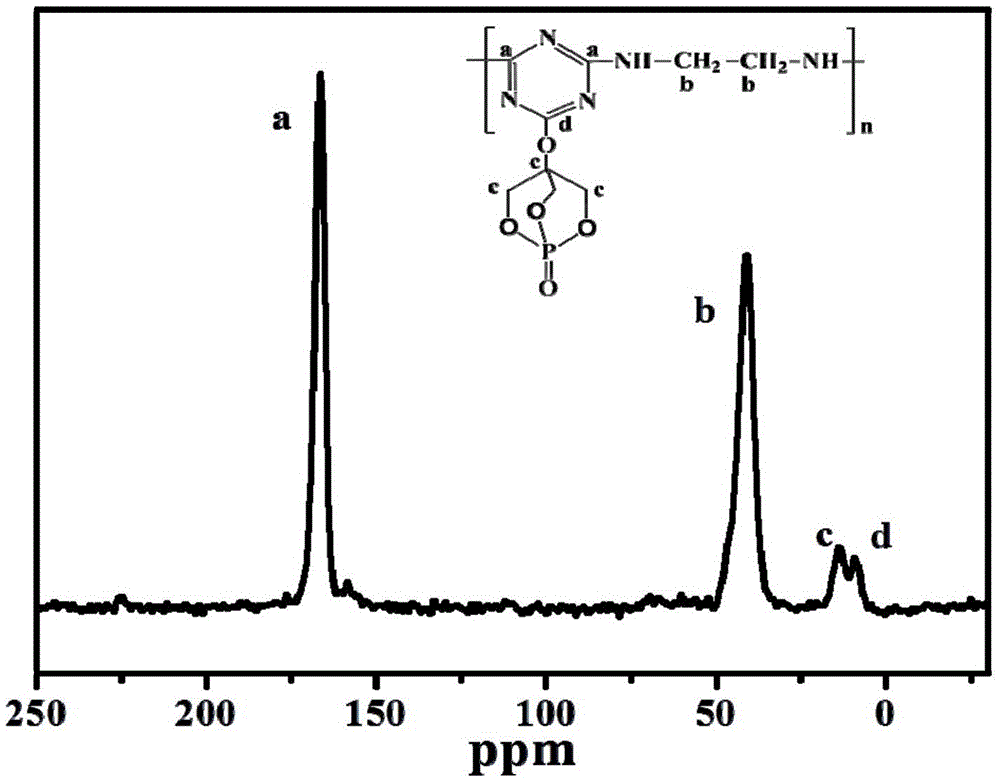

The invention discloses a single-component phosphor-nitrogen double-ring cage-shaped macromolecular intumescent flame retardant as well as a preparation method and an application thereof. the preparation method comprises the following steps: at 90-110 DEG C, a nucleophilic substitution reaction is carried out between pentaerythritol and phosphorous oxychloride, and PEPA is obtained; a reaction between PEPA and cyanuric chloride is carried out at -5-10 DEG C for 3-6 hours, a reaction between a product and a diamine compound is carried out at 50-60 DEG C for 5-10 hours, and then a reaction between the product and the diamine compound is carried out at 90-110 DEG C for 5-10 hours; finally the single-component phosphor-nitrogen double-ring cage-shaped macromolecular intumescent flame retardant is obtained for flame retardant modification of polymers. Compared with the prior art, the prepared single-component macromolecular intumescent flame retardant has the advantages of high flame retardation efficiency, good compatibility with polymers, etc.; the intumescent flame retardant whose weight is 20-25 wt% of polypropylene can be added into the polypropylene for endowing the polypropylene with good flame retardation performance, and the intumescent flame retardant can be widely applied to the fields of internal and external decorative parts of automobiles, furniture and electric appliances, wires and cables, building material, etc.

Owner:SOUTH CHINA UNIV OF TECH

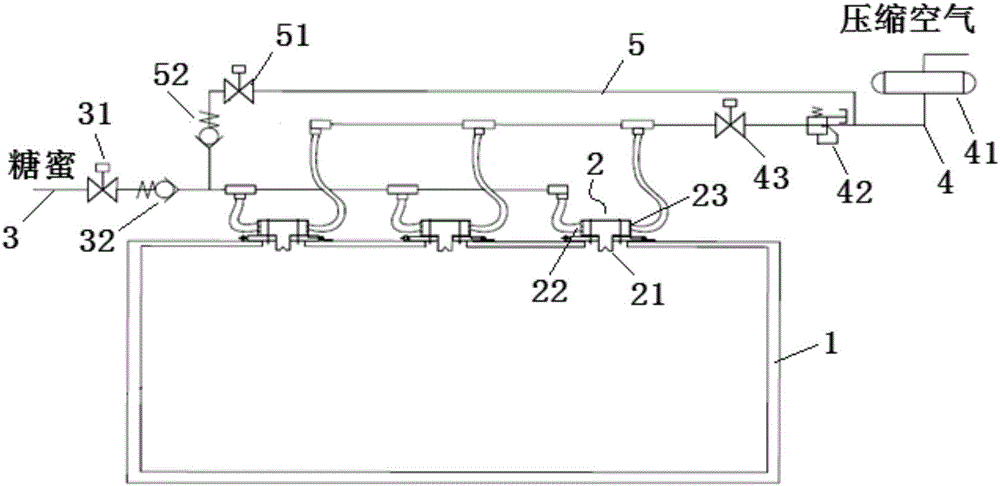

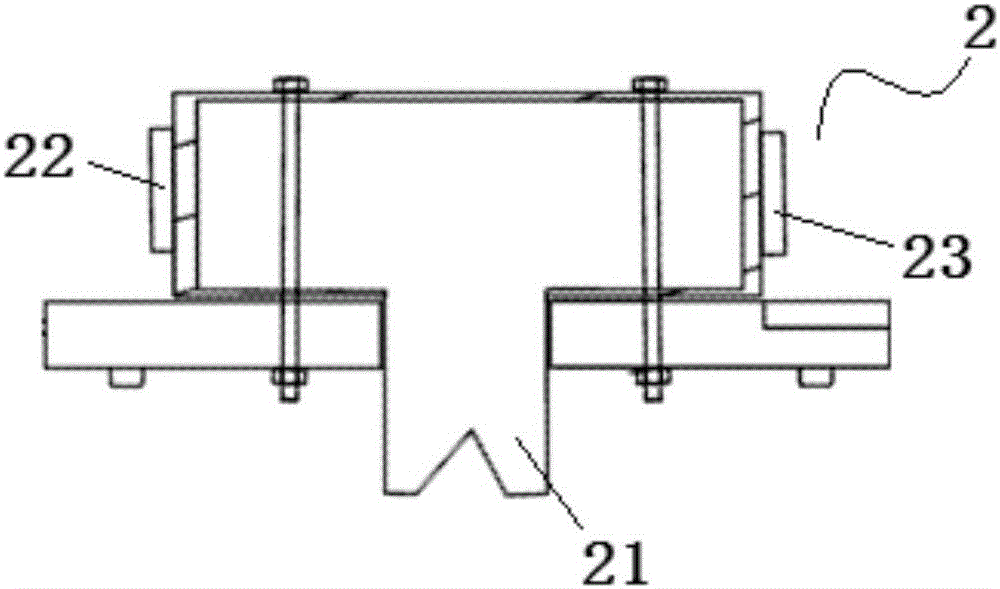

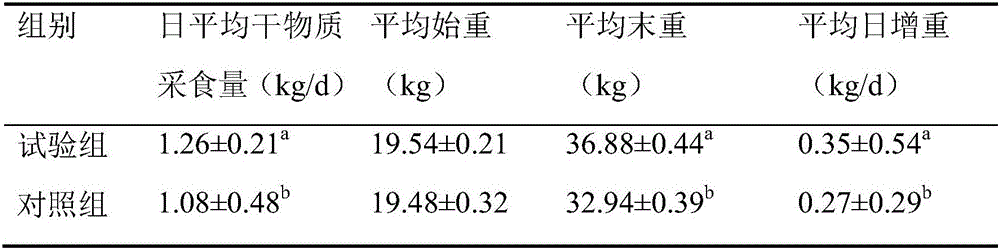

Total mixed pellet feed for meat sheep and manufacturing method and application of feed

InactiveCN106376738AImprove palatabilityIncrease feed intakeFood processingAnimal feeding stuffSodium bicarbonateSlurry

The invention discloses total mixed pellet feed for meat sheep and a manufacturing method and application of the feed. The feed comprises: 20.00-40.00% of straw, 0.00-30.00% of caragana korshinskii, 0.00-30.00% of sunflower shells, 0.00-30.00% of leymus chinensis, 10.00-30.00% of corn, 5.00-10.00% of molasses, 5.00-8.00% of soybean meal, 0.00-10.00% of cottonseed meal, 0.00-5.00% of sesame meal, 0.00-15.00% of maize germ meal, 0.00-5.00% of rapeseed meal, 0.00-8.00% of corn bran with slurry, 0.00-3.00% of wheat bran, 0.00-5.00% of rice bran, 0.00-20.00% of corn distiller's dried grains with soluble, 0.00-3.00% of bentonite, 0.40-0.80% of salt, 0.10-0.50% of calcium hydrogen phosphate, 0.50-1.50% of stone flour, 0.00-0.80% of slow-release protein, 0.50-1.50% of sodium bicarbonate, 0.04-0.08% of a mildew inhibitor, 0.40-0.50% of ammonium chloride, 1.00-3.00% of Chinese herbal medicine premix and 0.80-1.50% of meet goat fattening premix. The feed can replace common refined feeding and roughage, the breeding process is simplified, the breeding cost is saved, and the total mixed pellet feed can prevent the occurrence of rumen acidosis and urinary calculus of meet sheep.

Owner:BEIJING JIUZHOU DADI BIOLOGICAL TECH GRP

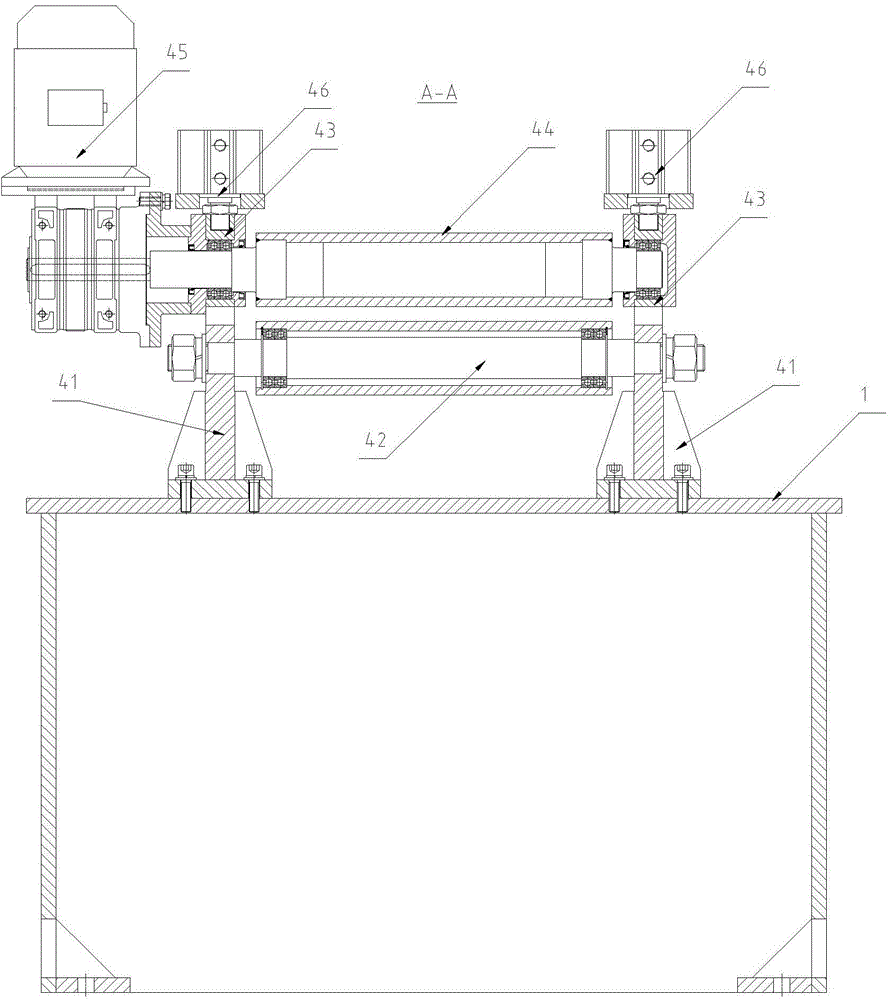

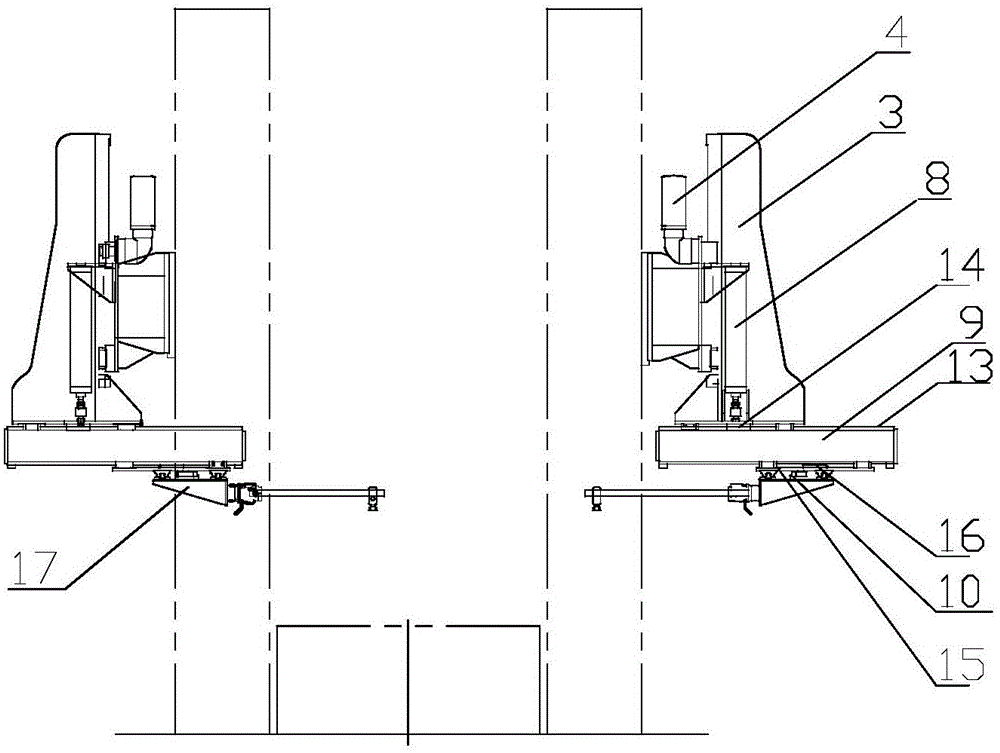

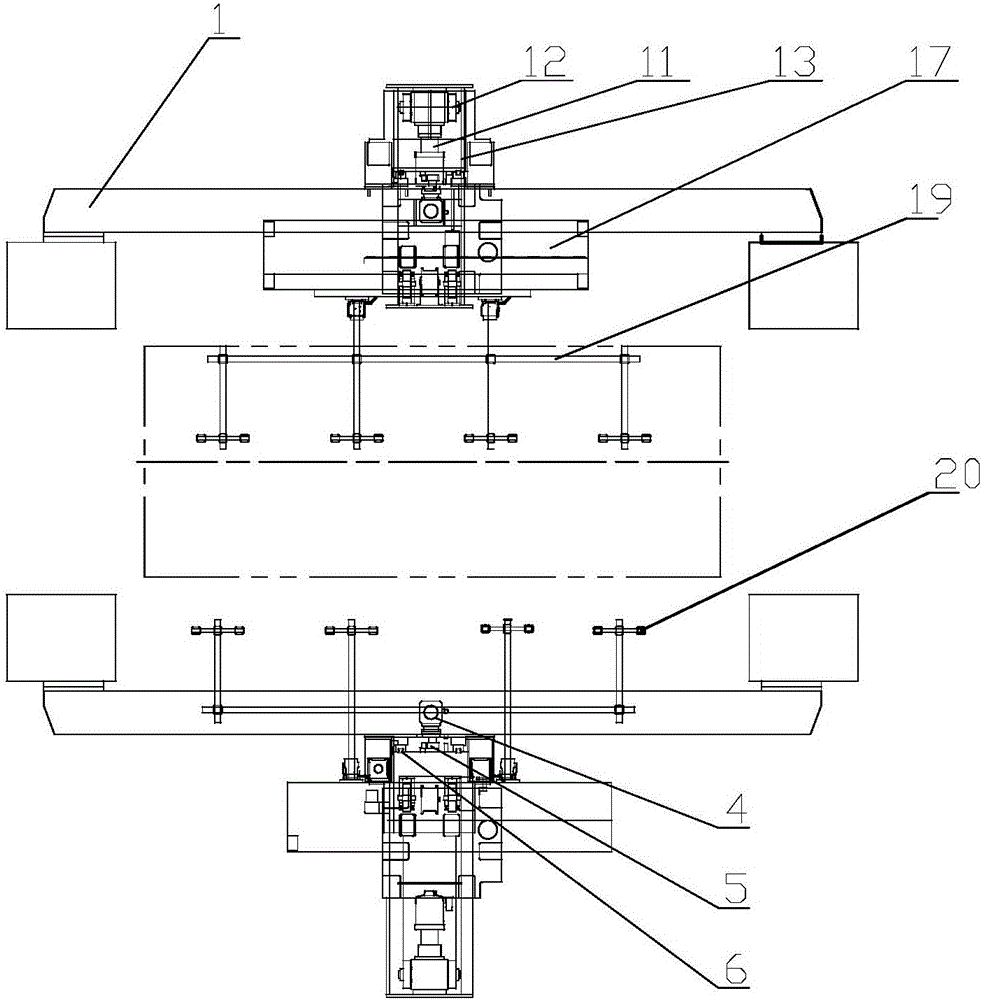

Butt welding platform for steel band

ActiveCN104384803AEasy deliveryReduce resistanceWelding/cutting auxillary devicesAuxillary welding devicesForce outputPiston rod

The invention discloses a butt welding platform capable of automatically adjusting the position of a steel band on the platform and enabling the steel band to be smoothly conveyed. The butt welding platform comprises a base, wherein a clamping butting device is arranged on the base; guide devices are respectively arranged on two sides of the clamping butting device on the base; a clamping conveying device is arranged on one side, which is far away from the clamping butting device, of each of the two guide devices on the base and comprises two brackets arranged on the base; a lower pressing roller is erected between the brackets; sliding chutes are formed in the middle of the brackets; sliding blocks are arranged in the sliding chutes; an upper pressing roller matched with the lower pressing roller is erected between the sliding blocks on the two brackets; one end of the upper pressing roller is connected with a force output shaft of a clamping conveying motor arranged on the sliding block at the end; stroke-adjustable pressurization cylinders are arranged on the tops of the brackets; through holes communicated with the sliding chutes are formed in the upper parts of the brackets; the end parts of piston rods of the pressurization cylinders penetrate through the through holes and are connected with the sliding blocks.

Owner:张家港市中悦冶金设备科技有限公司

Method for culturing maggot by utilizing manure slurry

The invention belongs to the technical field of animal manure comprehensive utilization and culture, and relates to a method for culturing maggot by utilizing livestock and poultry manure slurry. The method comprises the following steps: collecting animal manure in a temporary animal manure lagoon; fermenting effective microorganism (EM) strain, or enzymatic microorganism, or mixed strains of the EM strain and the enzymatic microorganism to ensure that the manure slurry is liquefied to form liquefied manure slurry; putting putrescent food in an outdoor fly concentrated position; putting collected seed maggot on a net chain above a fly cage to collect fly eggs and maggot; and maintaining the temperature of diluted manure slurry in a maggot culture pond, introducing oxygen to ensure that the maggot is cultured for 3 to 4 days and developed into imagochrysalis, and capturing by utilizing a net bag. The culture process has the advantaages of simple process, high animal manure utilization, safe and reliable equipment, high maggot culture benefit, large comprehensive utilization value, high quality of maggot and light environmental pollution, and can be used for large-scale industrial culture.

Owner:QINGDAO ZHONGREN PHARMA

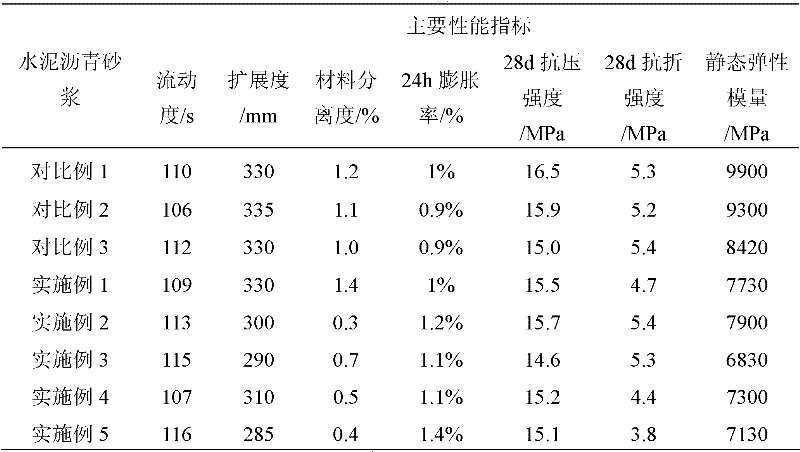

Cement asphalt mortar with high elastic damping

The invention provides a cement asphalt mortar. The cement asphalt mortar comprises cement, an expanding agent, sand, emulsified bitumen, water, a water reducer, an antifoaming agent, aluminum powder and rubber powder; The mass part ratio of cement to expanding agent to sand to emulsified bitumen to water to water reducer to antifoaming agent to aluminum powder to rubber powder is 90: (5-15): (100-180): (25-45): (15-30): (0.1-1.5): (0.01-0.15): (0.001-0.02): (1-20). According to the invention, rubber powder recovered by old tire can replace of partial emulsified bitumen or sand, under the condition of keeping certain intensity, the rubber powder has better damping performance than that of asphalt, simultaneously the rubber powder has low temperature sensitivity and is capable of keeping good damping performance under the various temperature; the adopted polypropylene fiber is capable of improving the uniformity of a cement asphalt mortar mixture, substantially raising the workability of the cement asphalt mortar mixture and enhancing the crack resistance and volume stability of the mortar.

Owner:CHINA NAT OFFSHORE OIL CORP +2

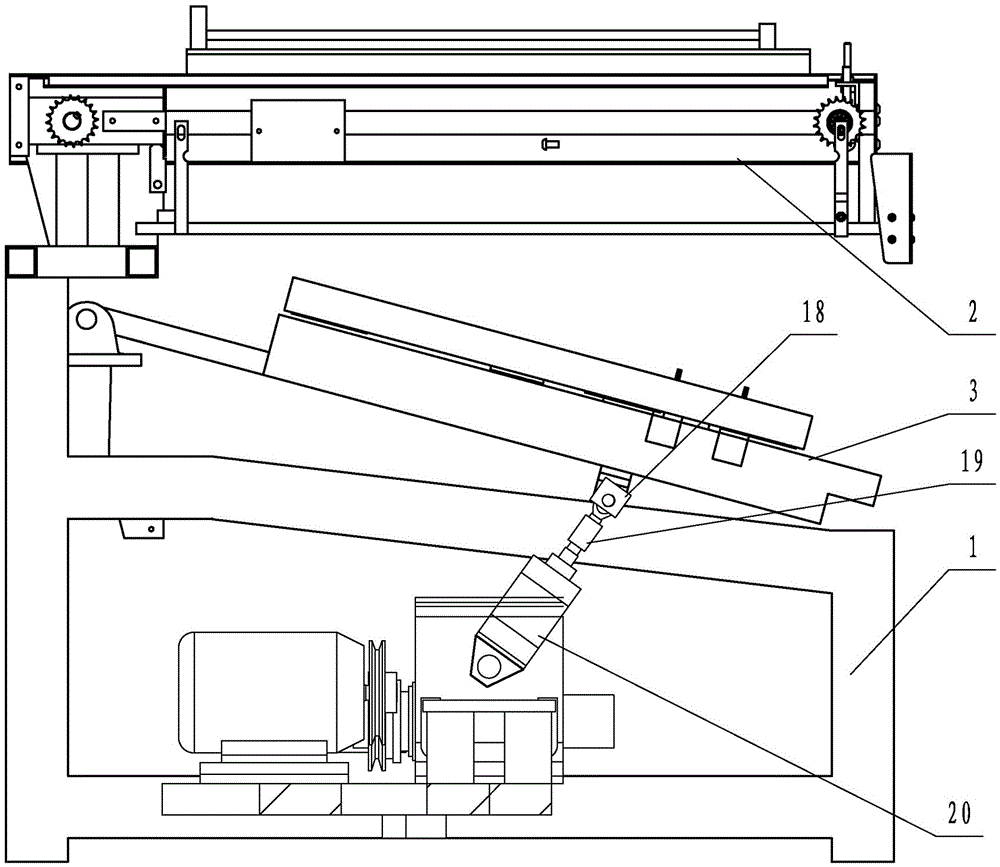

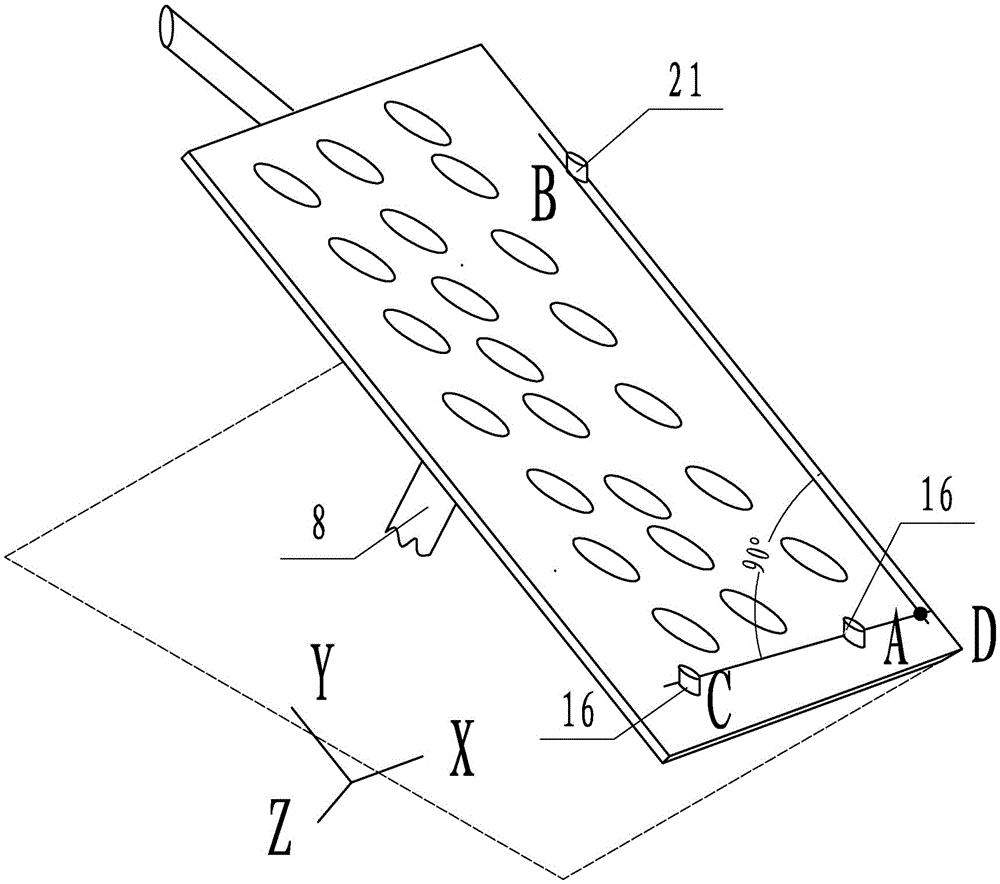

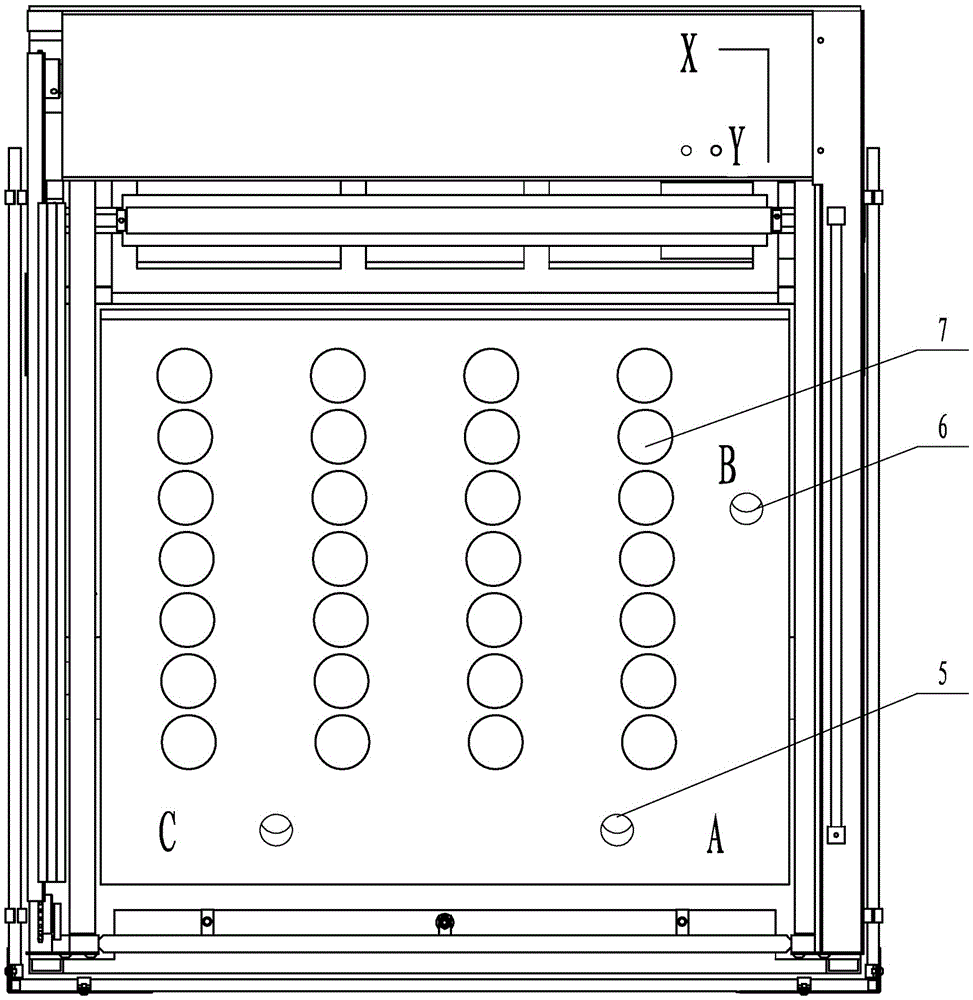

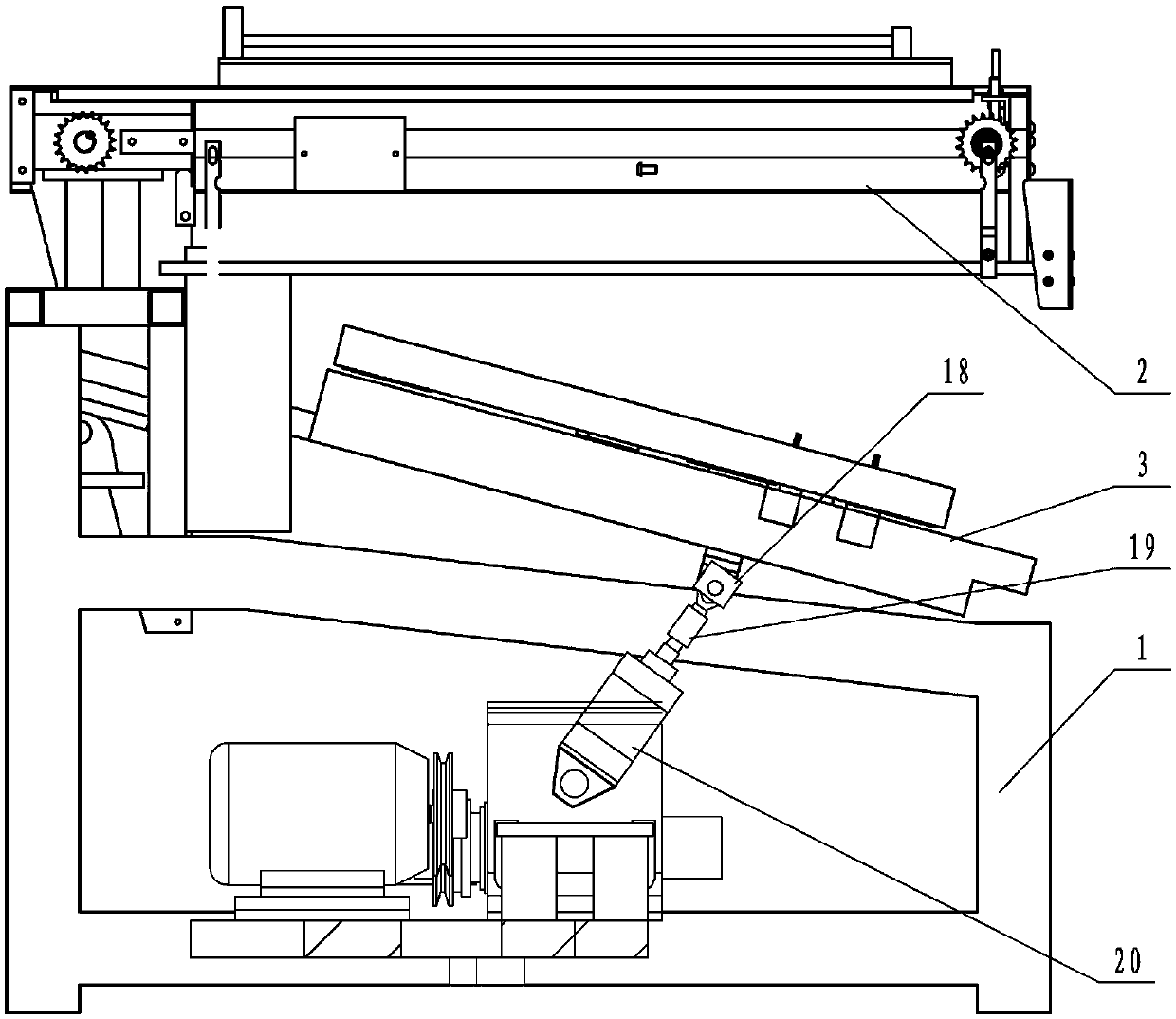

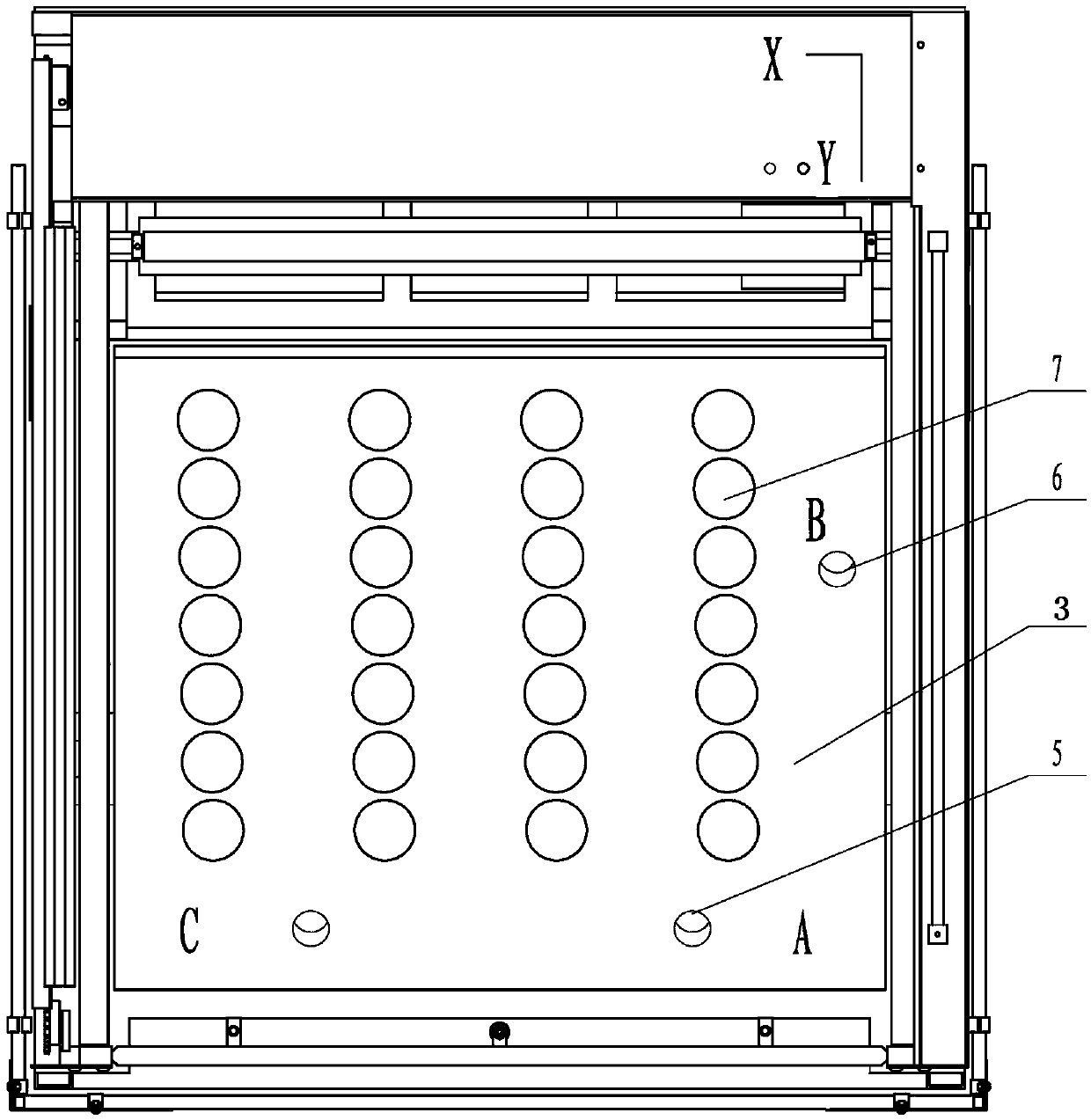

Screen printing machine for achieving inclined gravity feeding and automatic positioning

The invention relates to a screen printing machine for achieving inclined gravity feeding and automatic positioning. The screen printing machine comprises a machine frame, a print head, a placement platform, a Y-direction positioning pin and an X-direction positioning pin. The labor intensity is greatly lowered, labor is saved, the cost is reduced, the alignment precision is high, and the printing quality is high, so that feeding is simple and easy to learn, the training cost is reduced, the reject rate is reduced, and working efficiency is improved.

Owner:张永胜

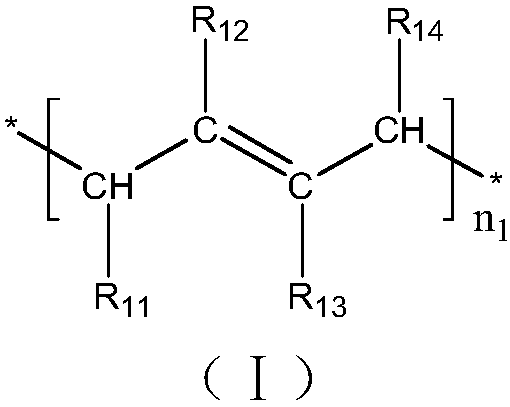

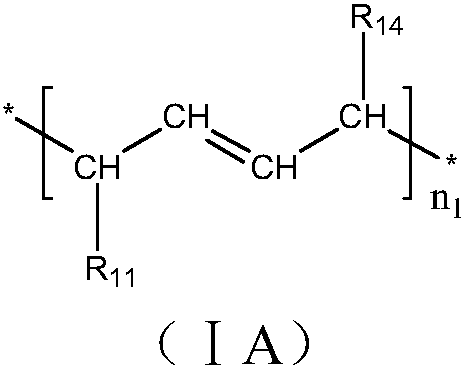

Binder and secondary battery

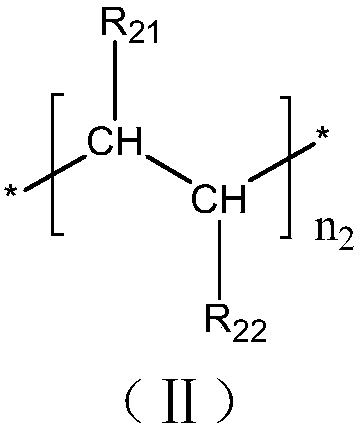

InactiveCN108987751ADoes not dry out and crackAvoid technical problems of drying and crackingCell electrodesSecondary cellsCrystallographyPlasticizer

The present invention relates to the field of secondary battery materials, particularly to a binder and a secondary battery using the binder, wherein the binder is a polymer containing a poly conjugated diene structure unit, an aromatic group substituted polyalkenyl structure unit, an ester group or acyloxy substituted polyalkenyl structure unit and a polar group-substituted polyalkenyl structureunit, and the polar group is at least one selected from a hydroxyl group, a carboxyl group, a sulfonic acid group and an amide group. According to the present invention, by combining the four structure units, the electrode sheet using the binder cannot produce the dry cracking phenomenon during the rapid coating, such that the technical problem that the electrode sheet is subjected to dry crackingduring the rapid coating under the premise of no adding of the plasticizer can be avoided while the coating rate and the yield can be simultaneously improved, and the feeding process can be simplified, and the performance of the battery cannot be deteriorated.

Owner:CONTEMPORARY AMPEREX TECH CO

Breeding and egg taking method of self-destructing insects

The invention discloses a breeding and egg taking method of self-destruction insects. The method comprises the steps that a breeding box is produced first, the breeding box is provided with a big-end-up transparent plastic box body, and a ventilation window is formed in the side surface of the box body; a sponge block is arranged in the transparent plastic box body, and a folded paper slip which is folded into a wave shape and arranged along the inner wall of the box is arranged in the transparent plastic box body, wherein the length of the paper slip is 200 mm, and the height of the paper slip is 20 mm. The breeding and egg taking method is used for breeding self-destructing insects such as harmonia axyridis indoors, larvas are bred collectively in small quantity, pupas are collected andsubjected to collective eclosion, and the insects are bred in single pair after eclosion, and the wave-shaped folded paper is place in the breeding box so that egg taking can be conducted collectivelyand conveniently.

Owner:INST OF PLANT PROTECTION FAAS

Automatic floor tile sticking device for building construction and using method of device

ActiveCN111677251AAvoid uneven layingReduce operating proceduresBuilding constructionsArchitectural engineeringWorkbench

The invention discloses an automatic floor tile sticking device for building construction and a using method of the device, and belongs to the technical field of building construction equipment. According to the automatic floor tile sticking device for building construction and the using method of the device, the automatic floor tile sticking device comprises two bases, the outer walls of the twobases are connected with guide rails, the tops of the bases are connected with a workbench, the outer wall of the workbench is connected with a feeding mechanism, the top of the workbench is connectedwith a fixed seat, the outer wall of the workbench is connected with a mortar box, the outer wall of the fixed seat is slidably connected with a placing plate, the feeding mechanism is connected withthe mortar box and the placing plate, fixing plates are connected to the outer walls of the two guide rails, a supporting seat is connected between the two fixing plates, a tile sticking mechanism isconnected to the top of the supporting seat, and a mortar screeding mechanism is slidably connected to the outer walls of the guide rails. According to the technical scheme, floor tiles and mortar can be synchronously fed, meanwhile, screeding of the mortar can be realized in the tile sticking preparation process, so that the operation procedures can be reduced, the labor intensity can be alleviated, and the working efficiency can be improved.

Owner:云南建设装饰集团有限公司

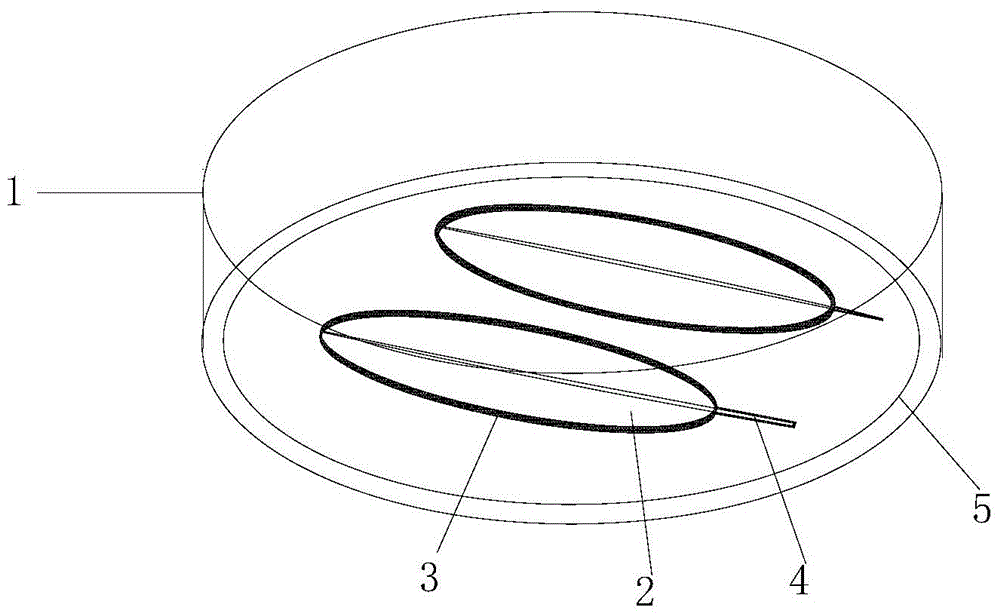

Indoor isolation feeder for spider mites

InactiveCN104472437APrevent escapeDoes not cause drowningAnimal husbandryTemperature controlPredation

The invention discloses an indoor isolation feeder for spider mites; the indoor isolation feeder comprises a culture dish which is composed of a bottom wall and a lateral wall and is open at one end, host leaves placed in the culture dish and protective isolation parts for preventing the escaping of the spider mites; the protective isolation parts are of wet bar-shaped structures around the leaves. The leaves utilized for feeding the spider mites are capable of preventing the spider mites from escaping and from being drowned; meanwhile, the technical problems in leaf feeding and water isolation feeding can be solved; the indoor isolation feeder for spider mites is simple in structure, does not need to utilize other complex escaping prevention measures and has the characteristics of being good in moisture retention, long in refreshing time of leaves, easy in temperature control, strong in operability and controllable in activity range of insects; the feeding process is simplified and the feeder can be used for performing indoor culturing experiments, indoor fertility and host selectivity experiments of the spider mites, pesticide efficacy and toxicity measurement as well as accurate measurement of predation quantity of natural enemies; the indoor isolation feeder solves the error problem caused by epitrophy and phototropism of insects to the experimental operation and solves the experimental errors caused by partial spider mites remaining at the top of a mite cultivating shade when the mite cultivating shade is utilized to perform an experiment in the prior art; the experimental errors are reduced and the experimental accuracy is improved.

Owner:CITRUS RES INST OF CHINESE ACAD OF AGRI SCI

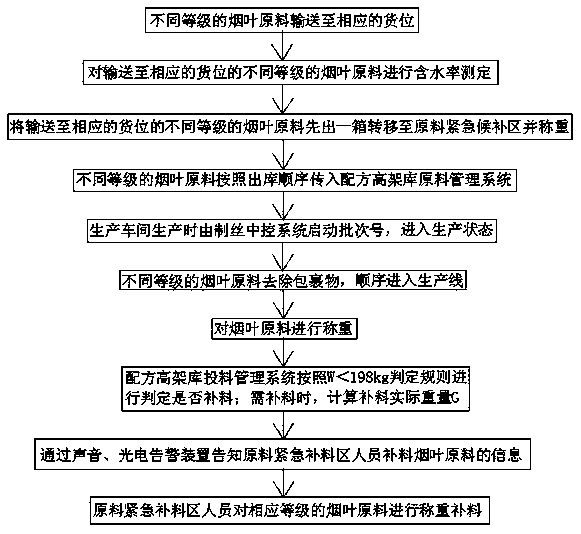

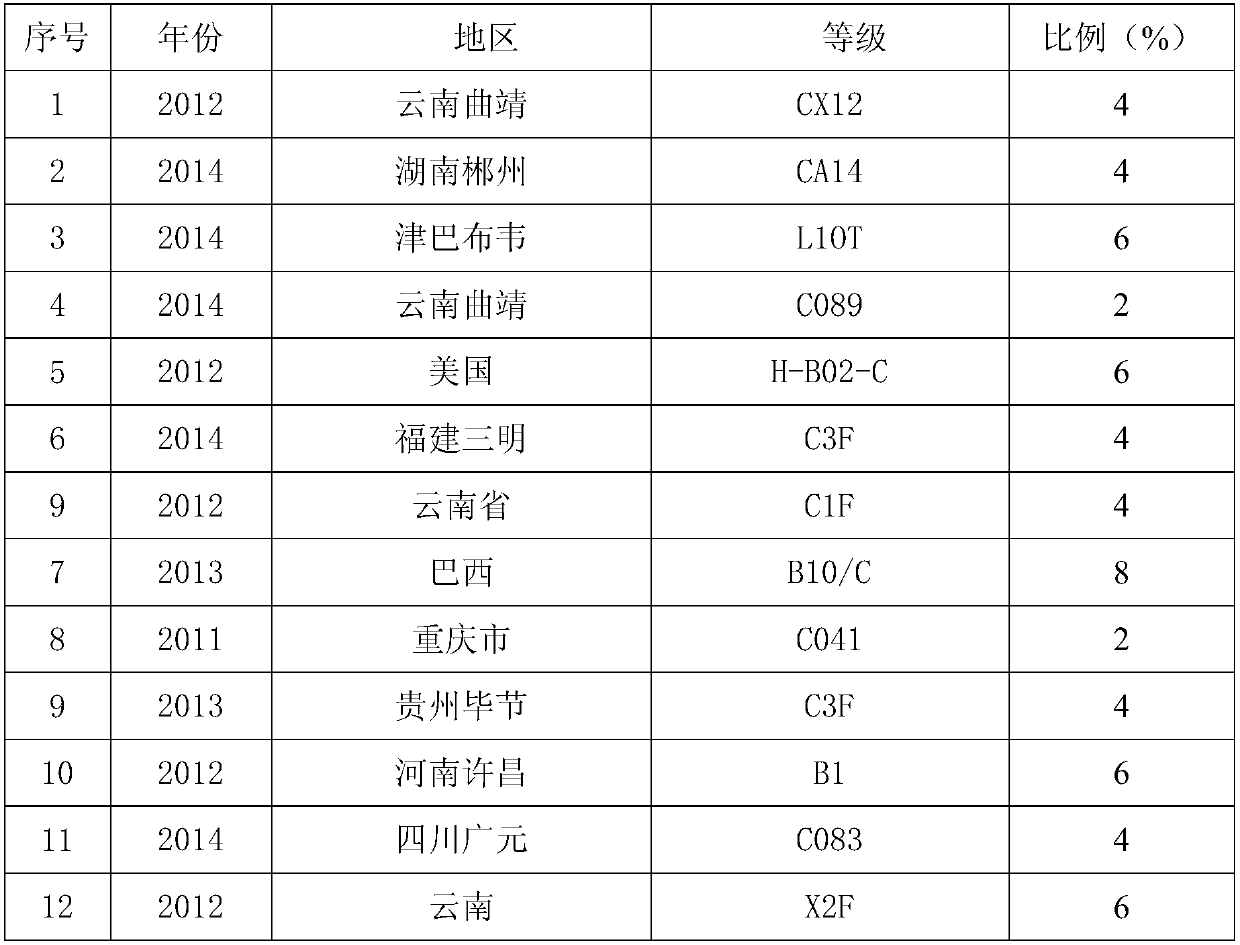

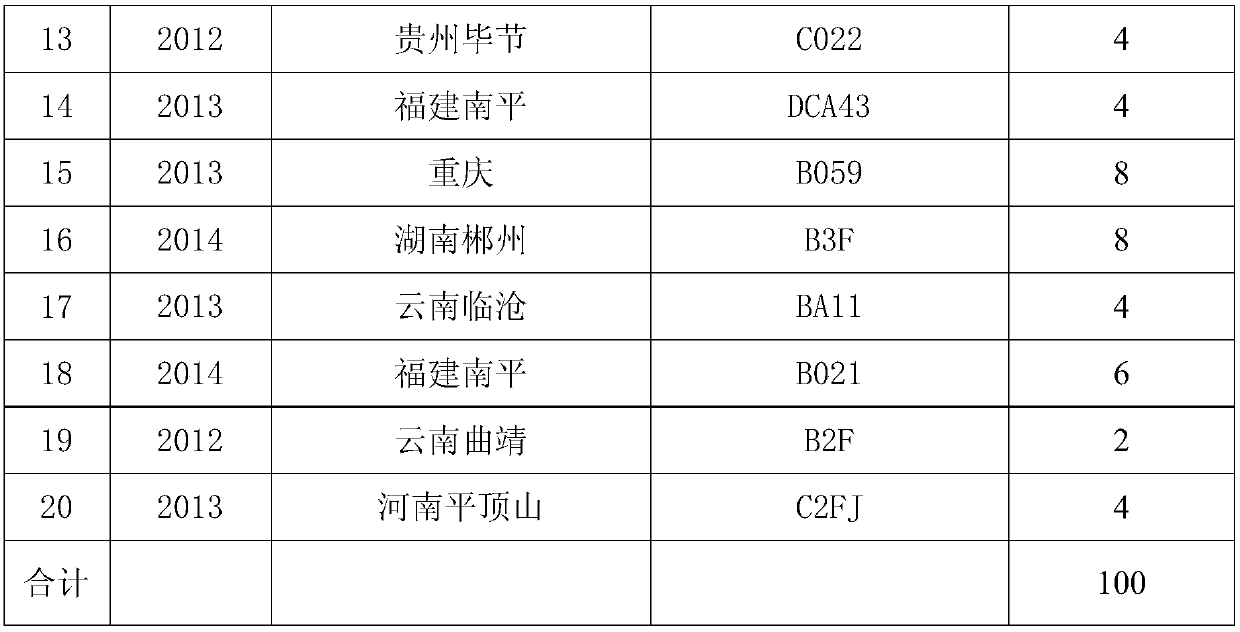

Cigarette feed deviation alarm and feed batch method

ActiveCN109674078ASimplify the feeding processIncrease productivityTobacco preparationProcess engineeringEngineering

The invention provides a cigarette feed deviation alarm and feed batch method. The moisture content in tobacco can be detected, real-time feed batch can be realized when the tobacco quality is insufficient, the feeding process is simplified, the condition that the tobacco raw materials are crushed due to manual bag breaking, weighing and re-packing can be avoided, the production efficiency is effectively improved, and the raw materials are saved. The feeding precision is improved, and the influence of the moisture content of the tobacco raw materials on the feeding weight is eliminated; and the efficiency of the conventional equipment and system is fully achieved, and the automation degree and efficiency are greatly improved; and the manual cost is saved.

Owner:CHINA TOBACCO HENAN IND

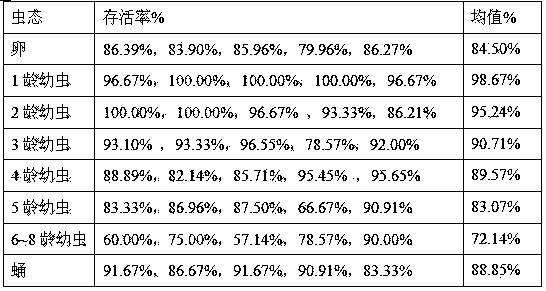

Method for feeding a large number of laboratory test populations of Opisina arenosella Walkers

ActiveCN104186430AIncrease the number of pairsIncrease success rateAnimal husbandryAnimal scienceMating

The invention belongs to the technical field of insect feeding and particularly discloses a method for feeding a large number of laboratory test populations of Opisina arenosella Walkers. The method is an improvement on an existing method for feeding the Opisina arenosella Walkers according to mating and oviposition characteristics of the Opisina arenosella Walkers. Mating space is enlarged, and the number of matched pairs of male and female Opisina arenosella Walkers is increased, so that female Opisina arenosella Walkers are stimulated to oviposit. In addition, the number of places where the female Opisina arenosella Walkers can oviposit is increased, the oviposition area is enlarged, and the survival rate of ova is increased. Tedious procedures of collecting ova through independent test tubes and leaf replacement during larva feeding are simplified, workload is decreased greatly, and the large number of standard test populations of Opisina arenosella Walkers with a high survival rate and simplified procedures can be obtained truly.

Owner:COCONUT RES INST OF CHINESE ACAD OF TROPICAL AGRI SCI +1

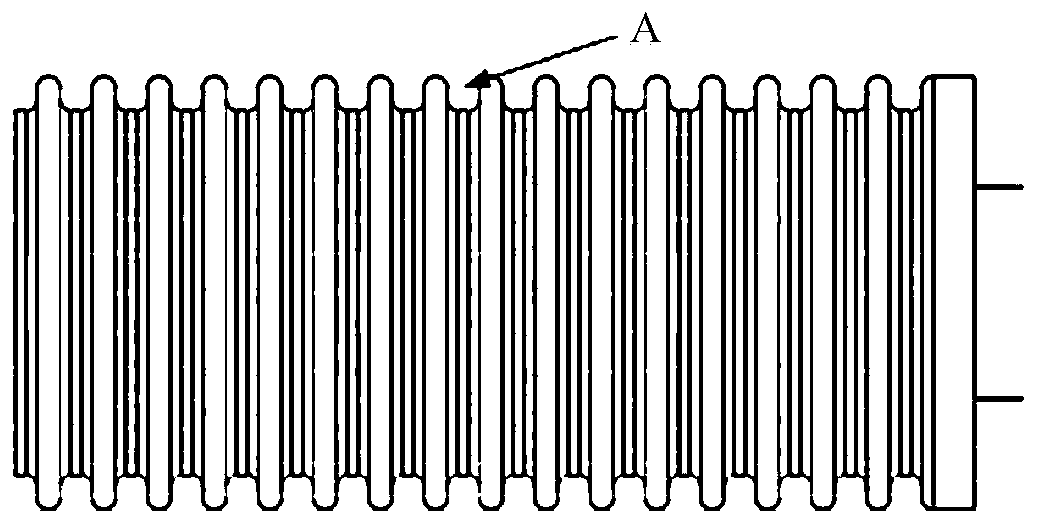

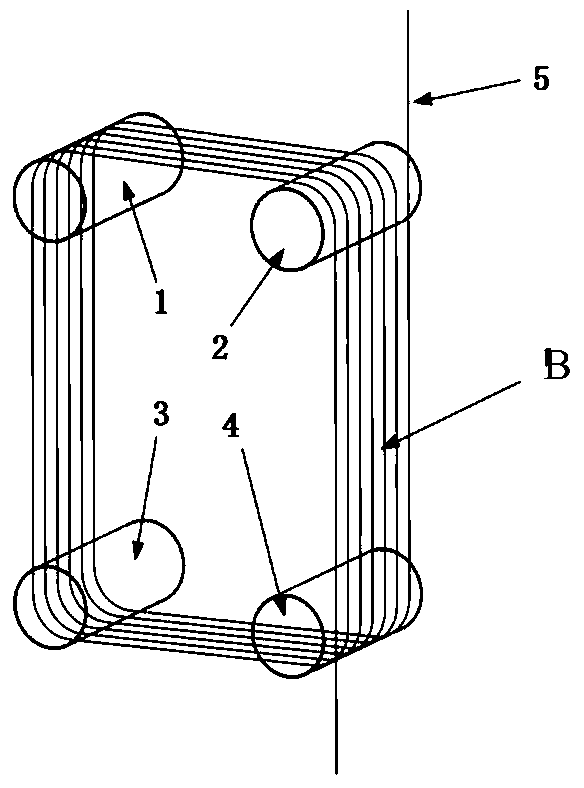

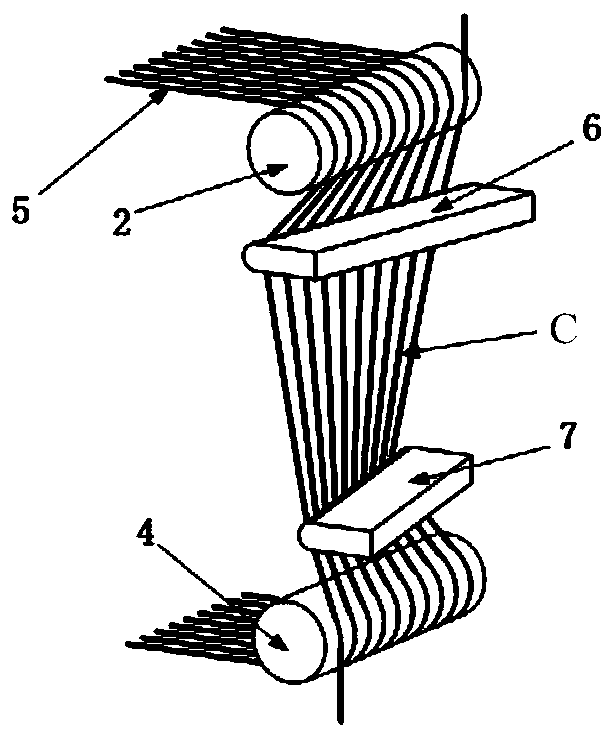

Straight-line curved surface multi-wire electric discharge machining method

ActiveCN109967810ASimplify the difficulty of planningImprove processing efficiencyElectric dischargeWear resistant

The invention discloses a straight-line curved surface multi-wire electric discharge machining method. The machining method comprises the following steps that a plurality of multi-grooved wire rollersare manufactured, grooves are required to just wrap electrode wires to be wound, so that radial run-out of the electrode wires during the wire conveying process is limited, and the distance between every two adjacent grooves is smaller than the sum of the diameter of each electrode wire and a discharging gap during machining; the multi-grooved wire rollers are mounted on a wire electric dischargemachining machine tool, the electrode wires are coiled one by one to form an electrode wire parallel wire mesh, and the two ends of the electrode wires are connected to a wire storage barrel; at theupper end and the lower end of the electrode wire parallel wire mesh surface, contact jacking is carried out on the electrode wire parallel wire mesh, a curved surface sample strip plate is composed of a wear-resistant material, and the electrode wire parallel wire mesh surface is changed into a straight-line curved surface from the plane according to the edge fluctuation of the curved surface sample strip plate or the fact that the edge included angles among the curved surface sample strip plates are different; a wire electric discharge machining auxiliary condition is started; and one-way feeding is carried out on a metal plate workpiece which is installed on a machining platform to be machined so as to obtain a straight-line curved surface conforming to the electrode wire mesh on the metal plate workpiece after machining is completed.

Owner:XIAMEN UNIV

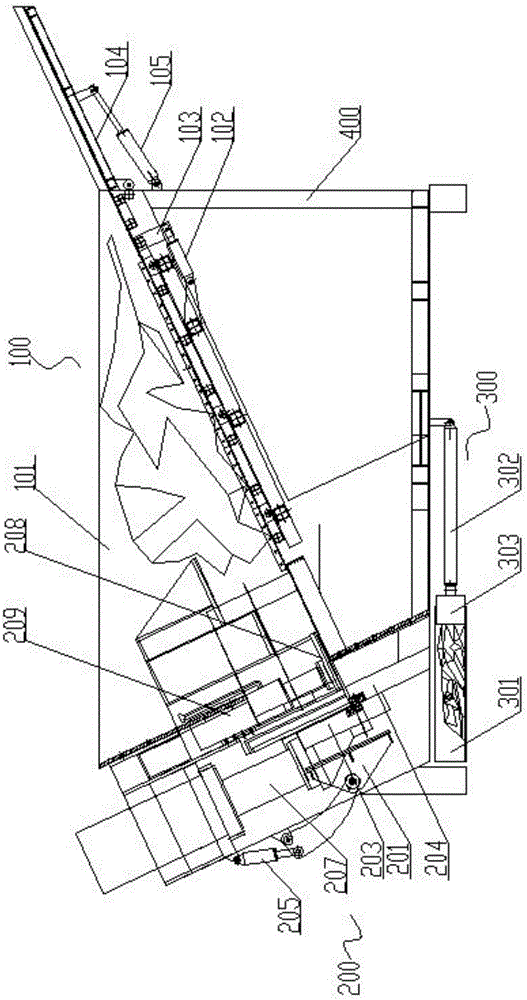

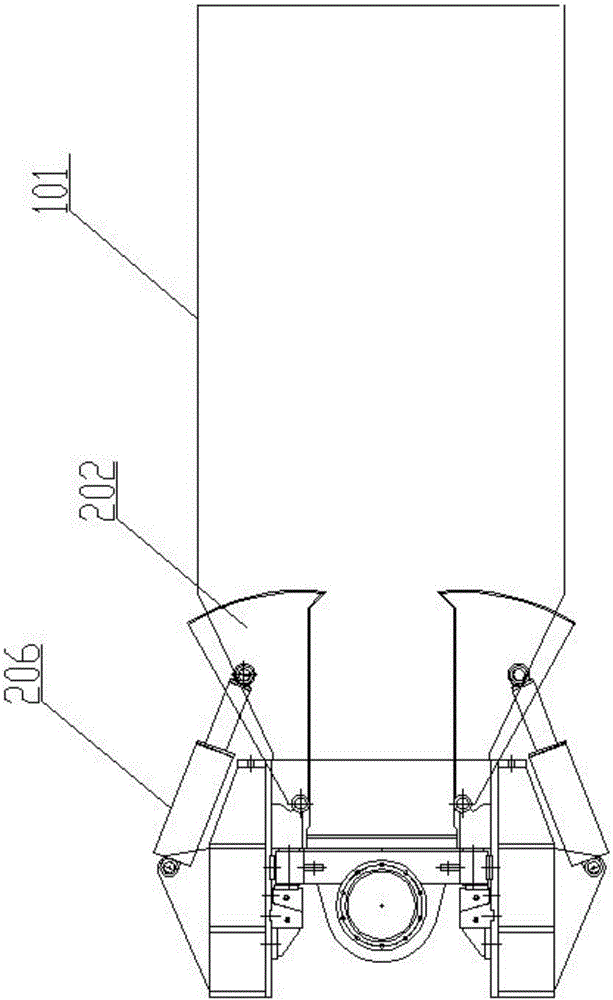

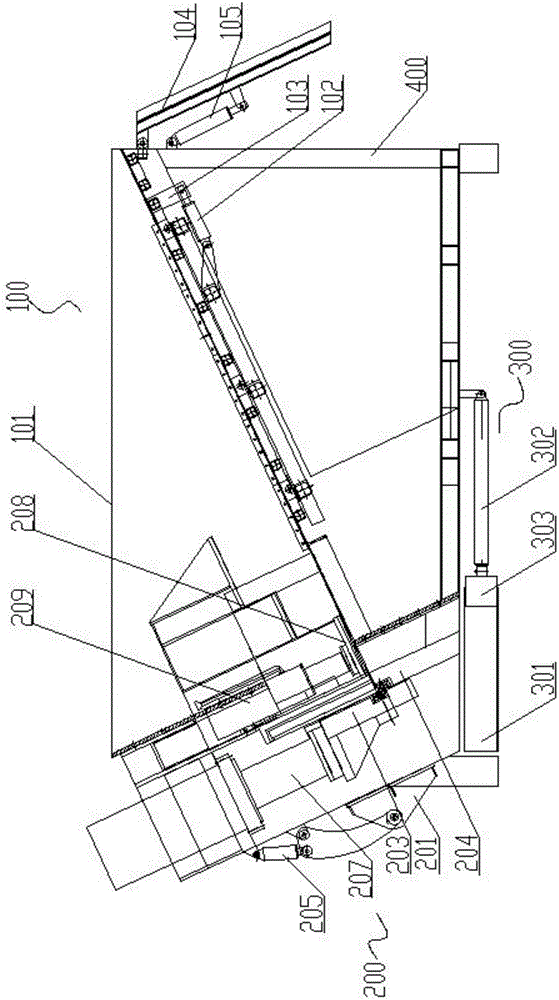

Hydraulic control system of vertical shearing machine

ActiveCN106112090AImprove securityEasy to automateServomotor componentsServomotorsControl systemSlide plate

The invention relates to a hydraulic control system of a vertical shearing machine. The hydraulic control system is characterized by comprising a first valve block (1), a second valve block (2), a third valve block (3), a fourth valve block (4), a fifth valve block (5), a first valve block oil inlet pipeline (6), a third valve block oil inlet pipeline (7), a fourth valve block oil inlet pipeline (8), a fifth valve block oil inlet pipeline (9), a material pressing plate oil cylinder (209), a shearing cutter oil cylinder (207), two side extrusion plate oil cylinders (206), a discharging oil cylinder (302), an extension plate oil cylinder (106), a sliding plate vibration oil cylinder (102) and a material baffle oil cylinder (205). The vertical shearing machine has the beneficial effects that automatic operation is facilitated, the production efficiency and the safety coefficient are high, and the number of employees is small.

Owner:江苏高德液压机械有限公司

Cultivation method of mango chicken

ActiveCN103329851ANo pollution in the processTimely disinfectionAnimal feeding stuffPoultry farmerMango fruit

The invention relates to the technical field of poultry farming, in particular to a cultivation method of mango chicken. The cultivation method comprises the following steps: beginning to feed mature mango fruit two month before fed chicken is going on the market according to a conventional method; reducing the feeding amount of daily foodstuff of chicken and additionally feeding more mango fruit by controlling during the feeding process, wherein the mango fruit accounts for 70-80% in a proportion of daily ordinary foodstuff of chicken to mango fruit; and continuously feeding more than two months after beginning to feed the mongo fruit. Through the implementation of the cultivation method, the production condition during the implementation process is simple, and the raw materials are wide in source, easily obtained and low in price. Chicken like eating the fed mongo; moreover, the weighting effect is obvious and the meat quality is greatly improved after the chicken eat mongo through a plurality of functions and effects of mongo. The cultivated chicken is delicious in meat quality and fragrant and sweet in mouth feel. Meanwhile, the cultivated chicken is extremely low in production cost; however, the cultivated chicken is high in quality, unique in characteristic, good in chicken market prospect and high in selling price, so that the feeders are profitable.

Owner:安徽桧元素生物科技有限公司

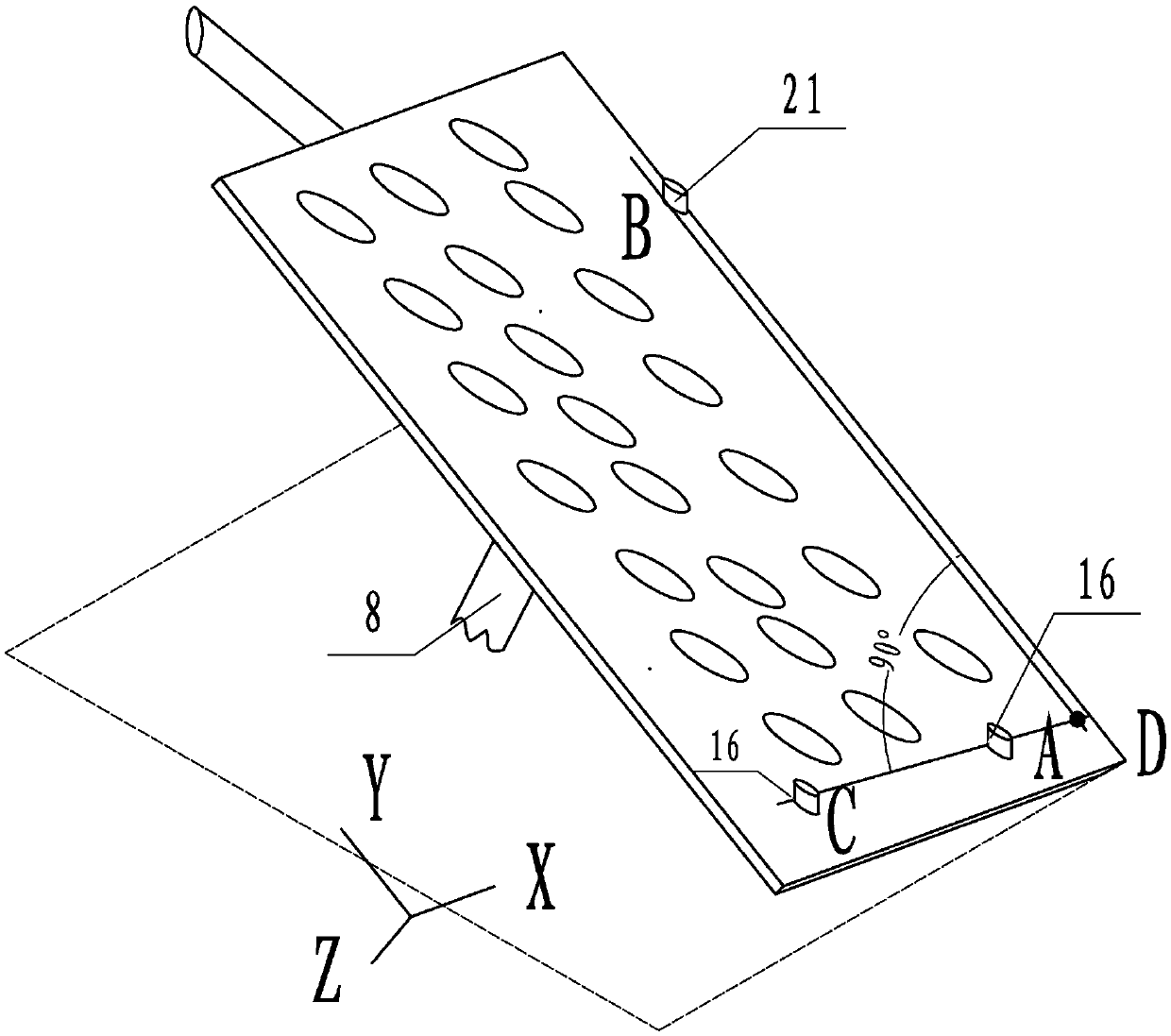

Screen printing machine for conveying materials in inclined rotating manner

The invention relates to a screen printing machine for conveying materials in an inclined rotating manner. The screen printing machine comprises a stander, a printing head arranged on the stander and a material blanking platform buckled with the printing head, wherein the material blanking platform comprises a material blanking platform inclined towards a horizontal plane during material conveying; at least two Y-directional positioning pins are arranged on the material blanking platform in a telescopic manner along the Z direction; contacts between the two Y-directional positioning pins and a printed product are respectively a point A and a point C; the lower ends of the Y-directional positioning pins are connected with rotary stretching devices of Y-directional pins; the lower ends of X-directional positioning pins are connected with stretching devices of X-directional pins. The screen printing machine greatly reduces the labor intensity, saves manpower, reduces the cost, and is high in alignment precision and high in printing quality, so that material conveying is simple and easy to learn, the training cost is reduced, the defective percentage is reduced, and the working efficiency is improved.

Owner:张永胜

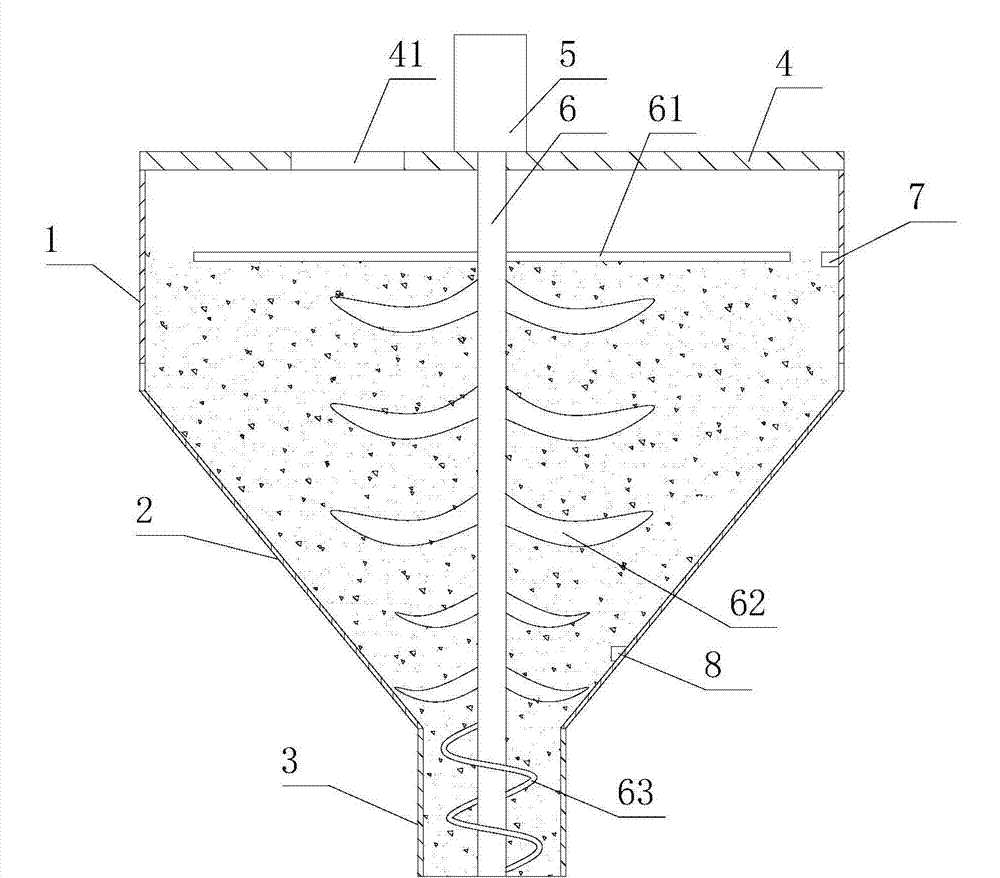

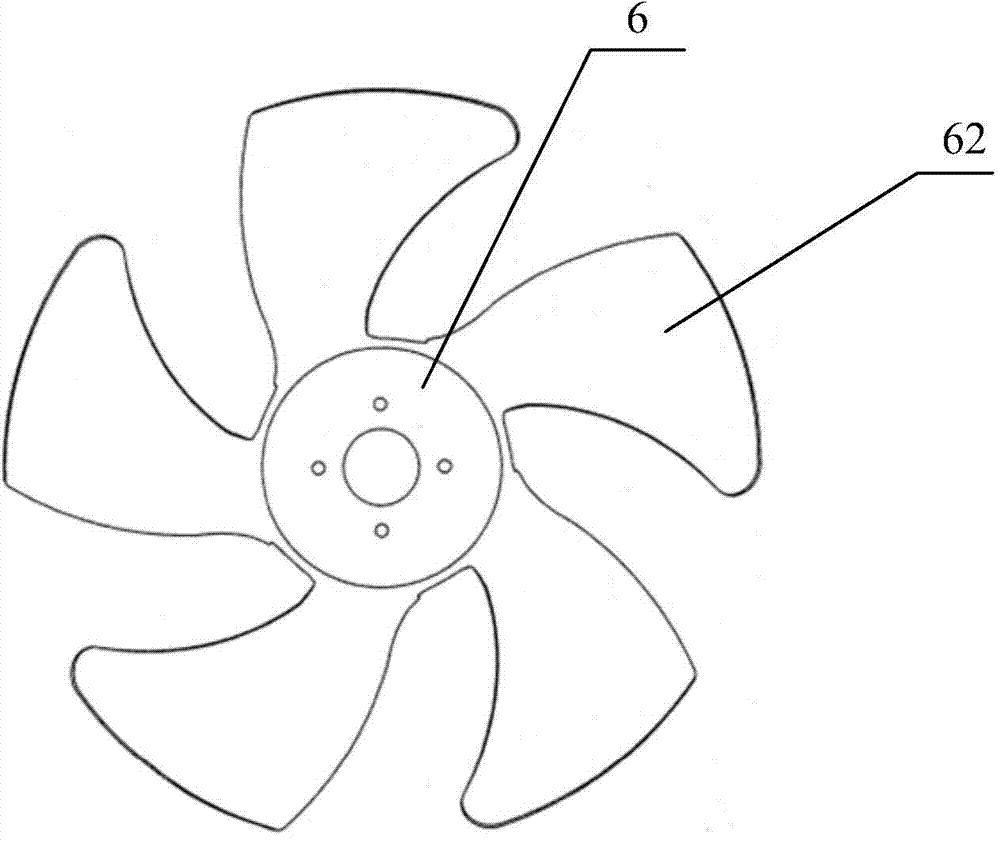

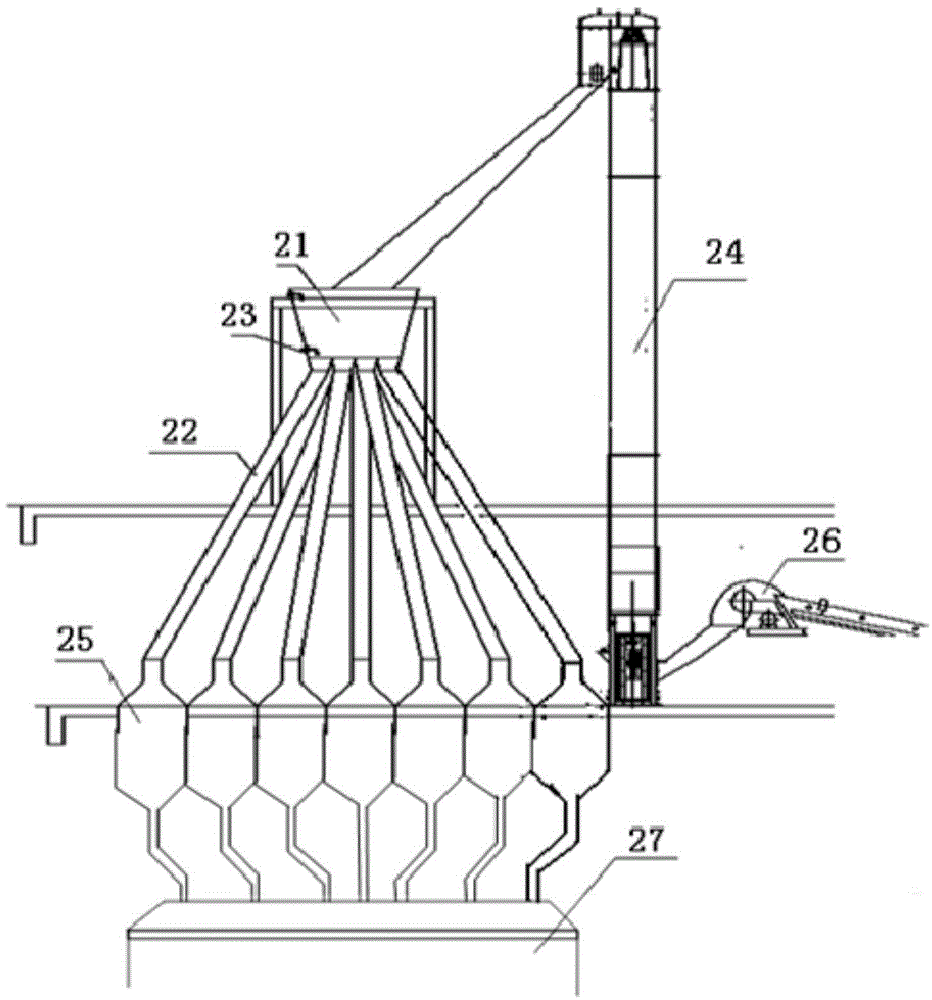

Feeding hopper of extruding machine

The invention discloses a feeding hopper of an extruding machine. The feeding hopper comprises a hopper body, wherein the hopper body comprises an inverted-cone-shaped storing section and an annular discharging section; the storing section and the discharging section are coaxially arranged; the top of the storing section is provided with a cover plate, the cover plate is provided with a feed port, and the top of the cover plate is provided with a driving motor; the driving motor is connected with a main shaft which is arranged in a manner of stretching into the hopper body, the main shaft is provided with multiple groups of loose blade structures at intervals, the loose blade structures are positioned in the storing section, and each loose blade structure comprises at least four loose blades which are uniformly distributed in an annular manner, and each loose blade is arranged in an inclined manner; the blade surface of each loose blade is arranged in a manner of facing the rotating direction of the main shaft, the tail end of the main shaft is provided with a helical blade, and the helical blade is positioned in the discharging section. The feeding hopper of the extruding machine, provided by the invention, has the advantages that the feed is easy, and the power consumption is low.

Owner:昆山市华浦塑业有限公司

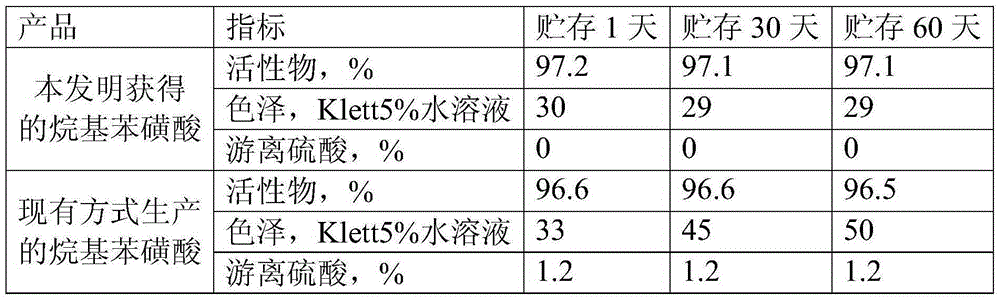

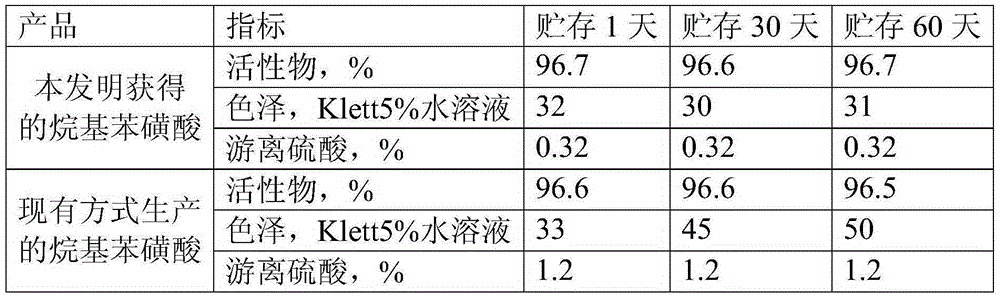

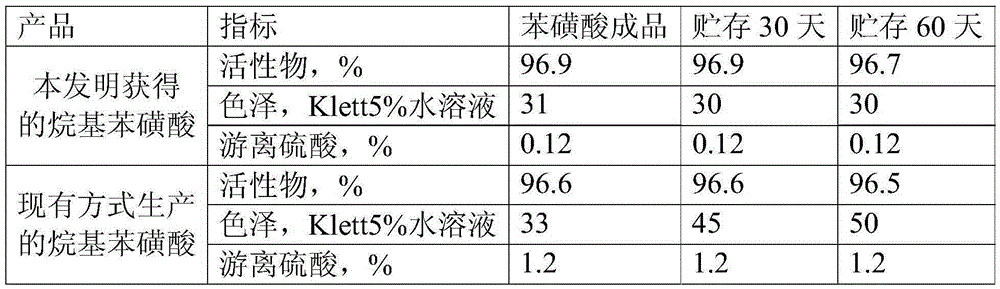

Method for continuous production of high-quality alkyl benzene sulfonic acid

ActiveCN105294513ALess irritatingGood colorOrganic compound preparationSulfonic acid preparationComing outBenzene

The invention relates to a method for continuous production of high-quality alkyl benzene sulfonic acid. The purpose comprises that the alkyl benzene sulfonic acid prepared by the method provided by the invention can reduce irritation caused by the presence of free sulfonic acid and also can improve the problem that the color and luster of alkyl benzene sulfonic acid is darkened in a process of storage. The technical scheme comprises that the method for continuous production of the high-quality alkyl benzene sulfonic acid includes the following steps: 1) sulfonating and aging alkyl benzene to obtain an anhydride, and allowing the anhydride to enter a homogeneous system simultaneously with a calcium ionic aqueous emulsion or aqueous solution according to a certain proportion online, wherein the feeding amount of the anhydride is determined by the sulfonation capacity; 2) homogenizing and mixing the material according to a certain homogenizing speed through a homogenizing pump, then allowing the material to enter a hydrolysis stay column, and further carrying out an aging reaction, wherein the certain homogenizing speed is 500-3000 rpm, the reaction time is 5-60 min, and the reaction temperature is 30-60 DEG C; and 3) separating the material coming out of the hydrolysis stay column to remove calcium sulfate in the material, and thus obtaining the high-quality alkyl benzene sulfonic acid product.

Owner:ZANYU TECH GRP CO LTD +1

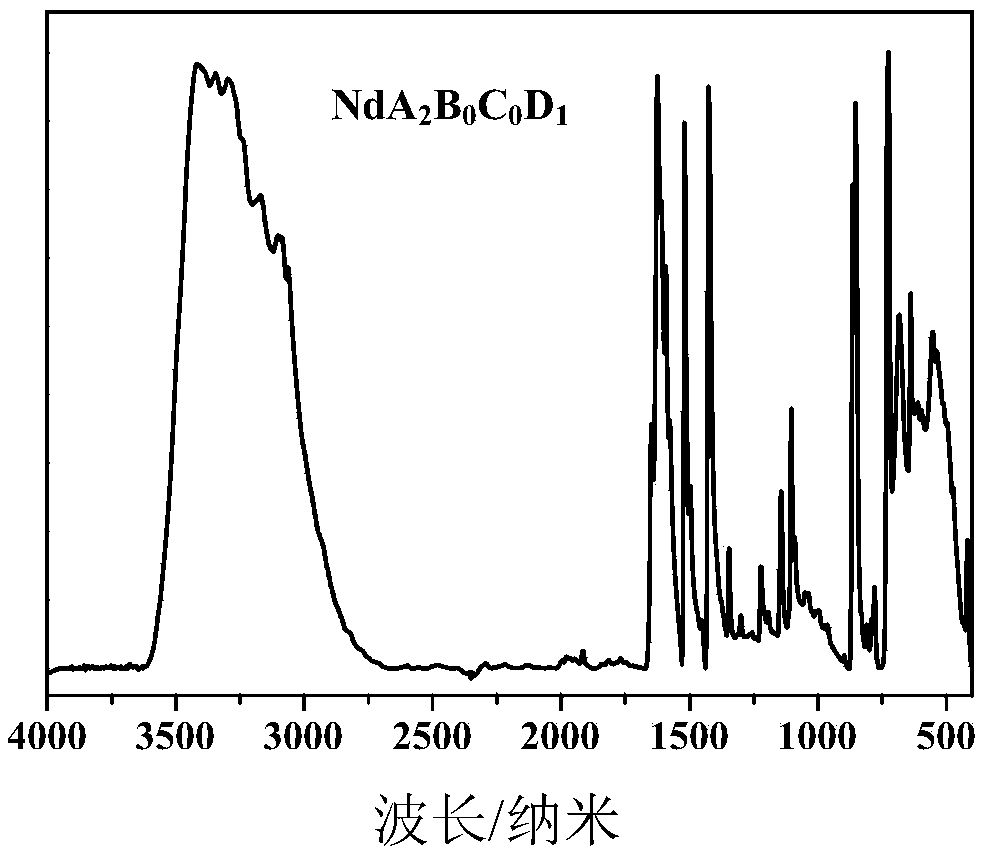

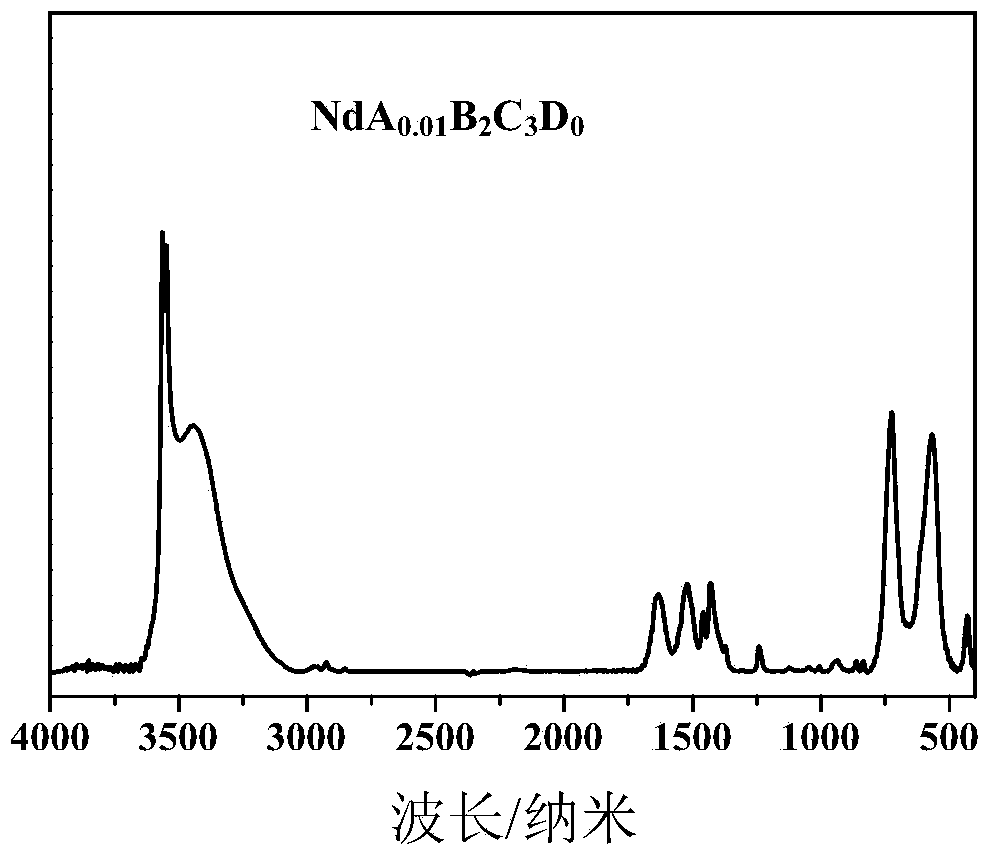

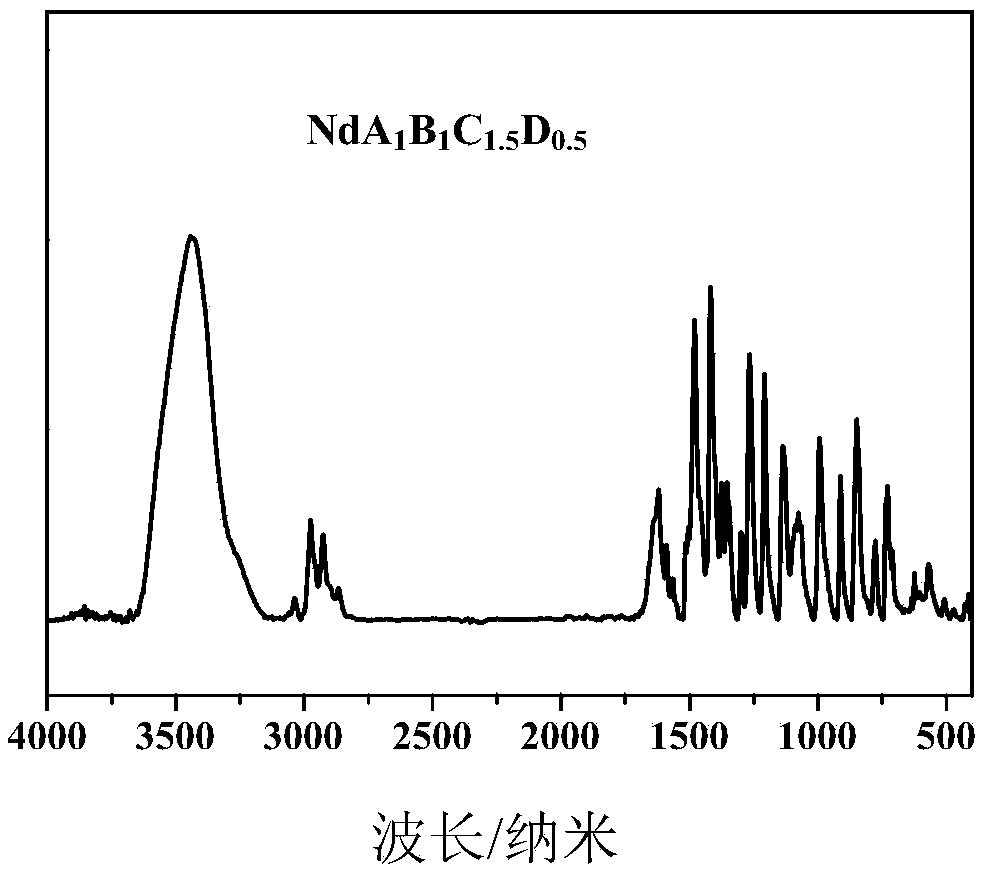

Preparation method of Nd-based multi-ligand vulcanization accelerator

ActiveCN103819716ABest promotion effectReduce dosageGroup 3/13 element organic compoundsRare-earth elementChemistry

The invention discloses an Nd-based multi-ligand vulcanization accelerator and a preparation method thereof. In synthesis, an Nd element is used as a rare earth element, and four ligands are contained; the ligand 1 and the ligand 2 are accelerator radicals with good vulcanization acceleration effects, the ligand 3 is phenanthroline capable of forming strong coordination with the rare earth element, and the ligand 4 is acrylic acid capable of improving the solubility of the accelerator in a sizing material. The preparation method is simple, convenient and feasible, does not need inert gas shielding, is mild in preparation process condition, and has no harmful gas generation. The multi-ligand rare earth vulcanization accelerator has good solubility in rubber, and is long in vulcanization and scorching time, good in vulcanization curve flatness, non-toxic, odorless and pollution-free. The vulcanization accelerator can replace a currently used zinc oxide, stearic acid and accelerator combination system, and is applicable to high performance tires and other rubber products.

Owner:BEIJING UNIV OF CHEM TECH

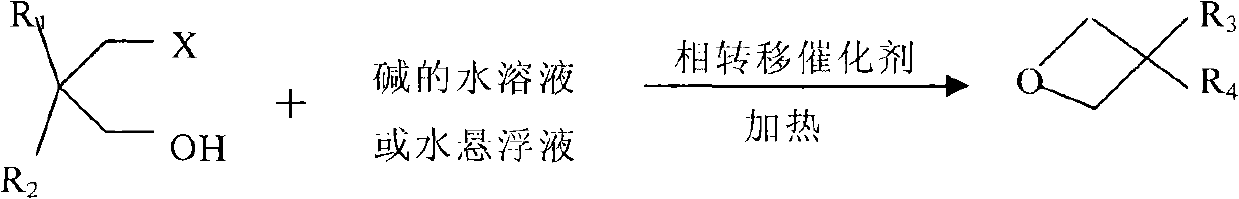

Synthesis method for oxetane compounds

ActiveCN102212044AReduce pollutionThe feeding process is simpleOrganic chemistryChemistryPhase-transfer catalyst

The invention provides a novel synthesis method for oxetane compounds, which comprises the following steps: adding 3-halo-1-propanol shown in formula (1) or an ester thereof used as a raw material in the presence of an alkaline water solution or water suspension, adding a proper amount of phase transfer catalyst, heating to carry out phase transfer reaction, removing hydrogen halide, and carrying out cyclization reaction to obtain products shown in formula (2) at high yield. According to the invention, no organic solvent is used during the reaction process; the reaction system only contains the alkaline water solution and the small amount of phase transfer catalyst besides the raw material; and the process is simple and feasible, has the advantages of low cost, no solvent recovery, few byproducts, easy refining of crude products, relative environmental friendliness, high yield and high equipment utilization rate, and facilitates the industrial mass production of oxetane.

Owner:赵燕 +1

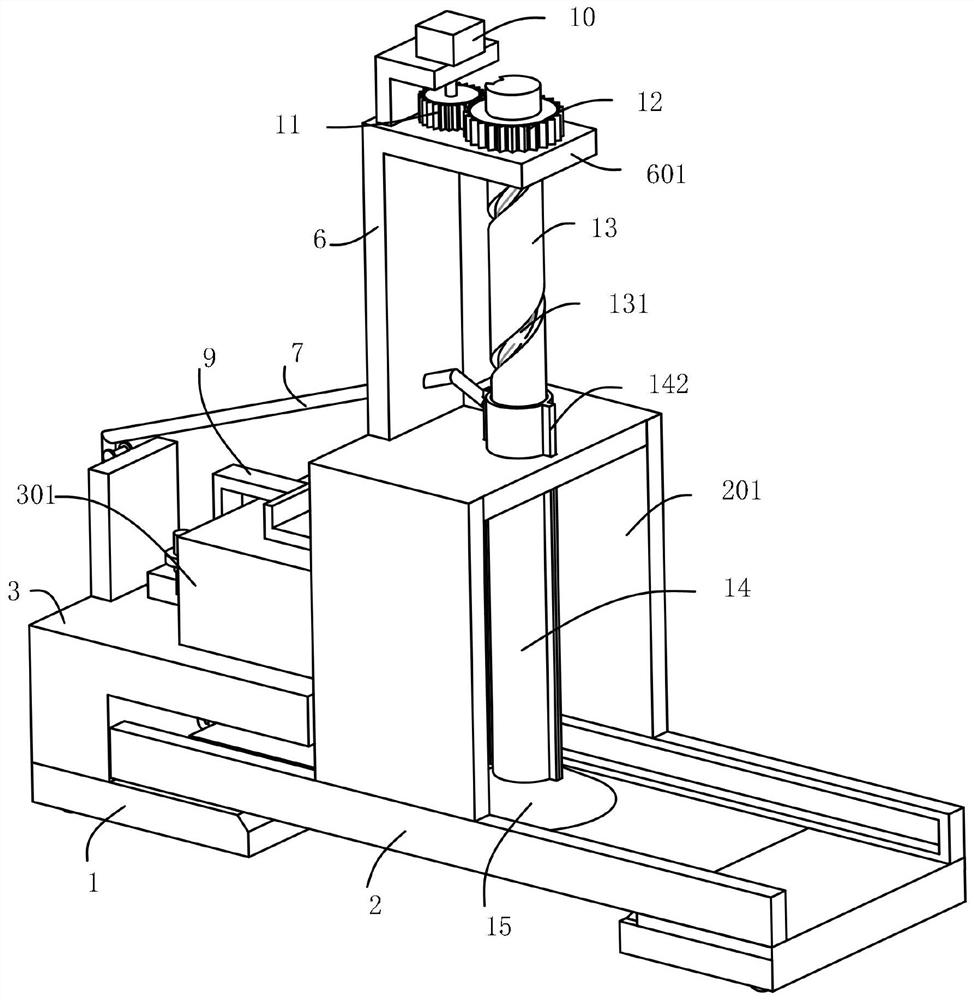

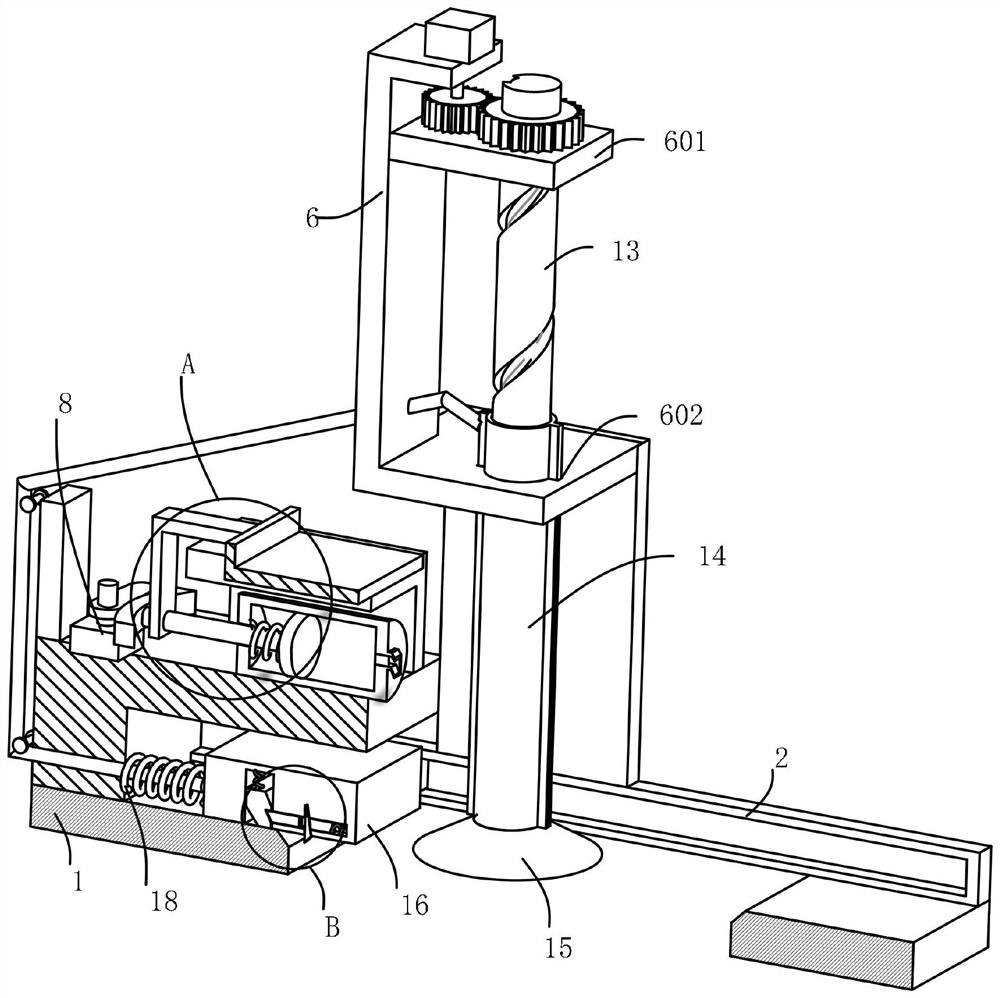

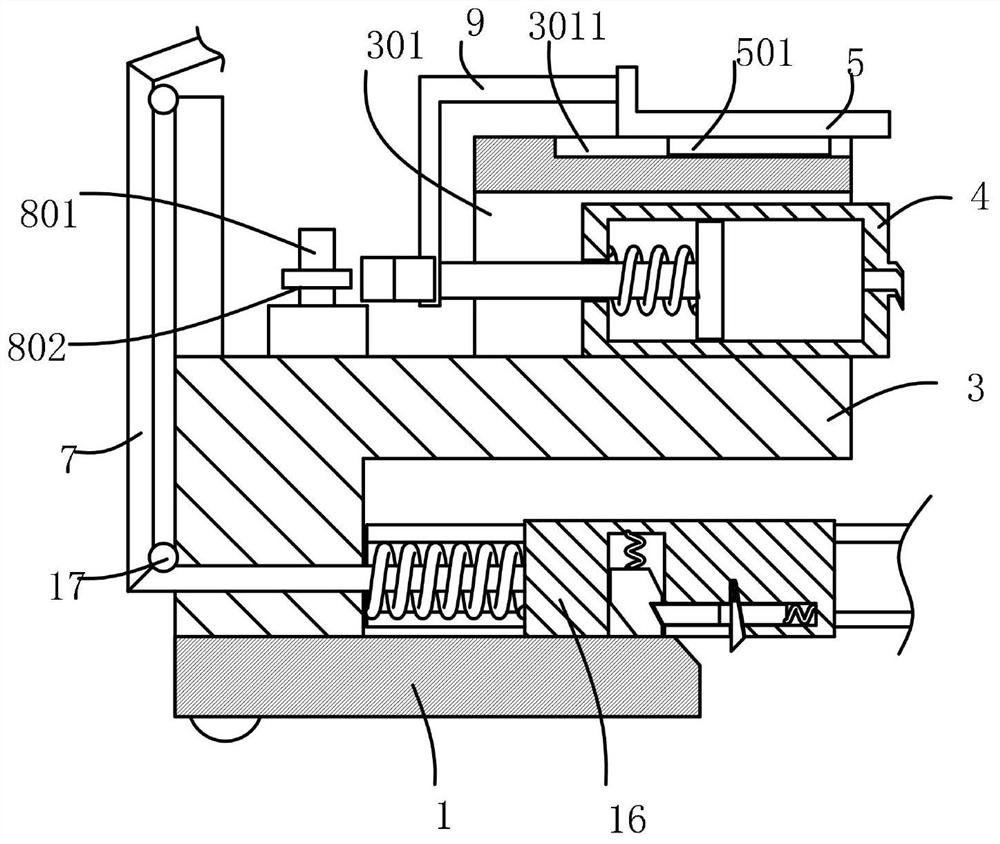

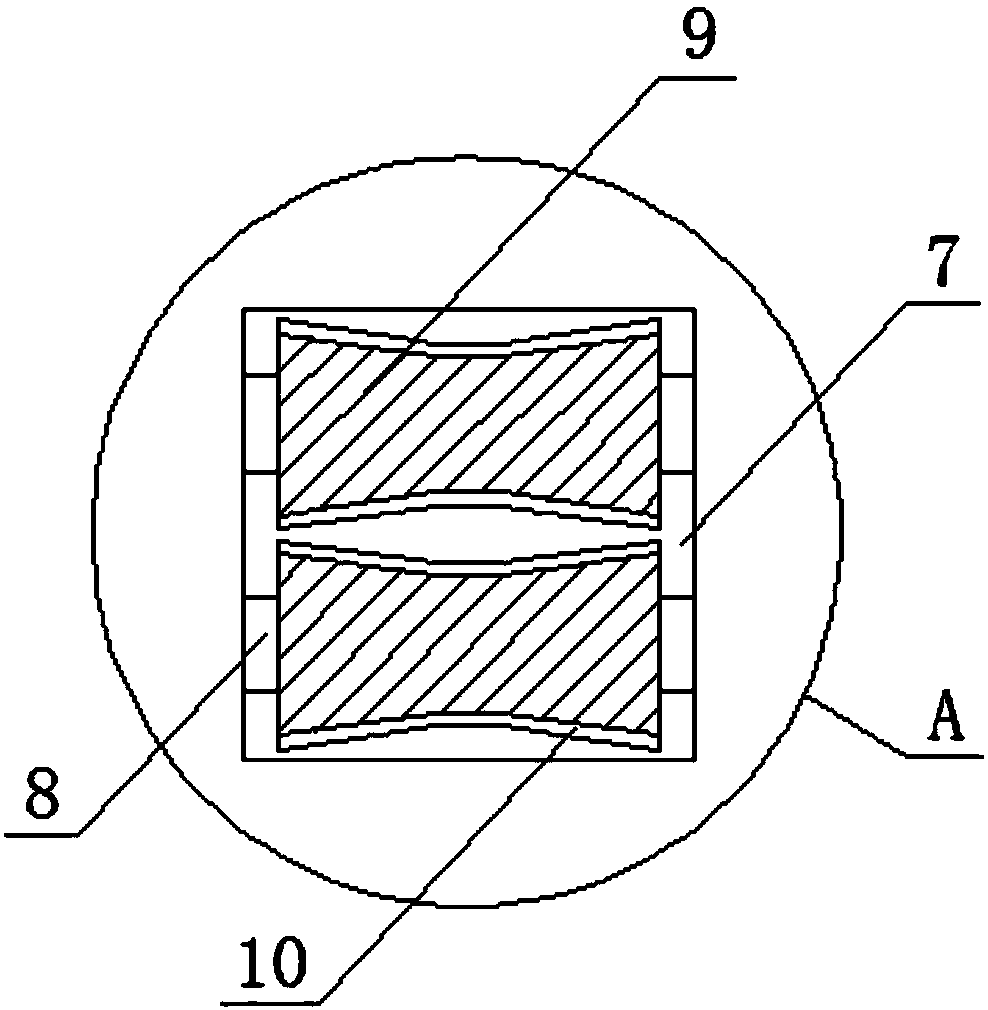

Automatic feeding device for small bearings

InactiveCN112338490ASave transfer structureThe feeding process is simpleMetal working apparatusConveyor partsRobot handControl engineering

The invention discloses an automatic feeding device for small bearings. The automatic feeding device comprises a frame body, a bearing storage bin, a limiting stopping mechanism, a driving connectingrod mechanism and a bearing transferring rail, the storage bin is arranged on the frame body, and the limiting stopping mechanism, the driving connecting rod mechanism and the bearing transferring rail are sequentially arranged above the storage bin from top to bottom and are coordinated with one another for transferring. The automatic feeding device has the advantages that bearings can be first orderly placed in the bearing storage bin in multiple rows and multiple columns through a mechanical arm or manual work, multi-batch feeding at a time used for automatic rotor assembly of one shift ormultiple shifts is realized, the bearings slide along a slope of the storage bin for feeding through the gravity of the bearings, the gravity of the bearings is fully utilized for generating movementkinetic energy, short-distance movement of the whole row of bearings is realized, and therefore a complex transferring structure is removed, and the feeding procedure is simplified.

Owner:FGLS ELECTRIC CO LTD

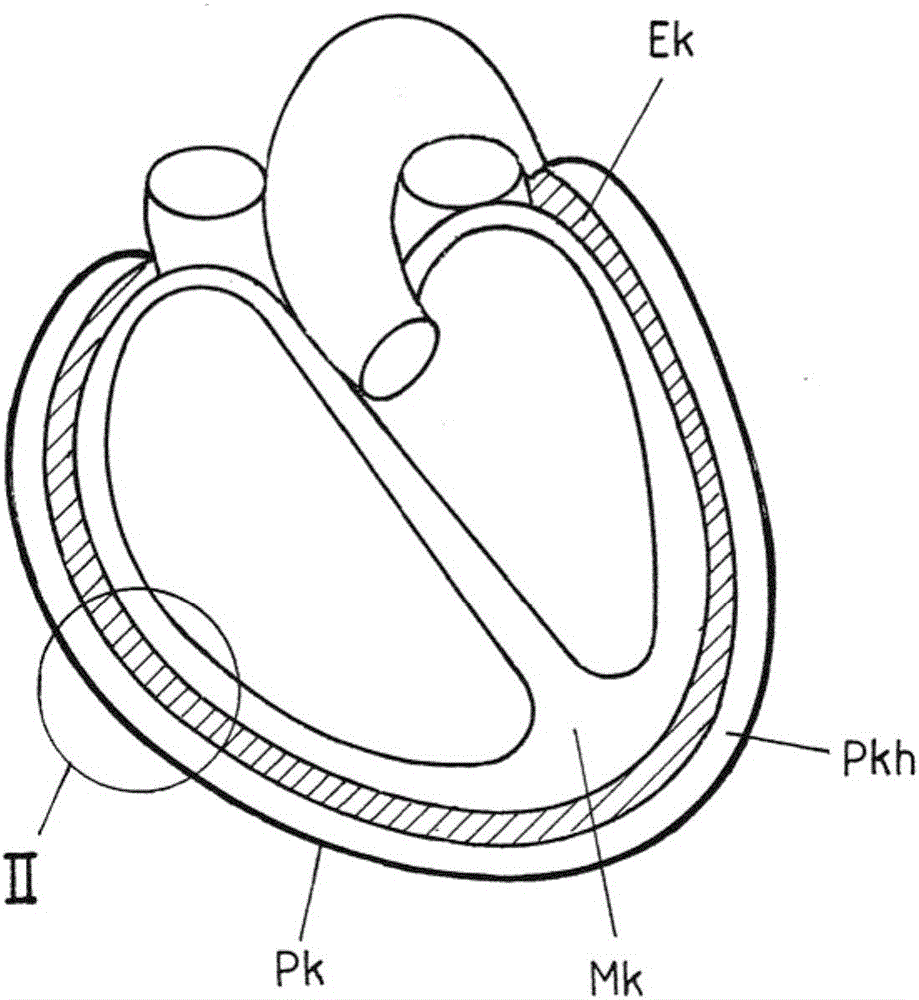

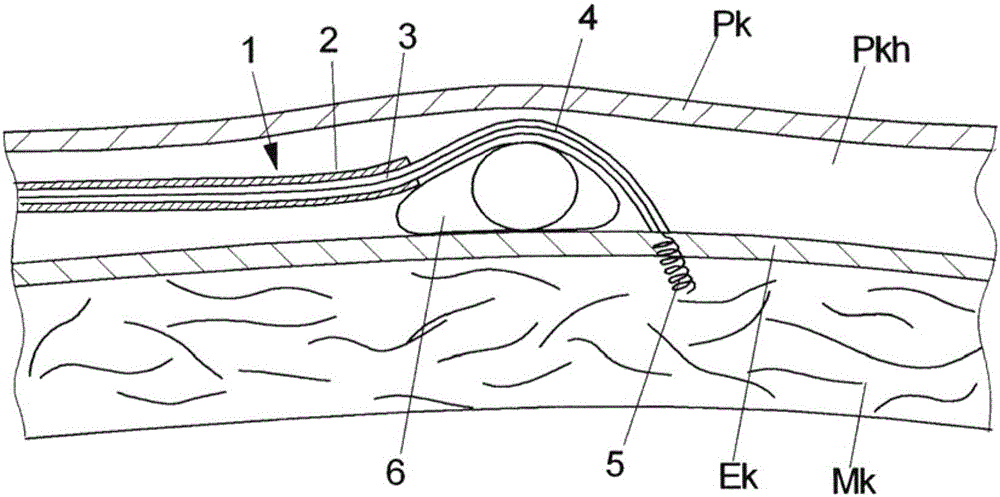

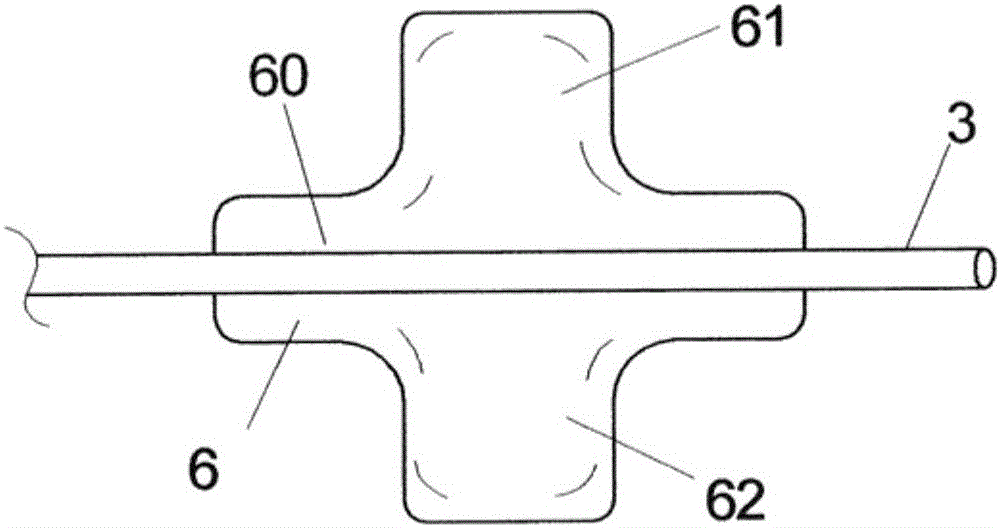

Device for the transcutaneous implantation of epicardial pacemaker electrodes

ActiveCN105848709AThe feeding process is simpleEpicardial electrodesTransvascular endocardial electrodesCardiac pacemaker electrodeBiomedical engineering

The invention relates to a device for the transcutaneous implantation of an epicardial pacemaker electrode (5), which is guided in a tubular, flexible external catheter (2) of an implantation catheter (1) that can be inserted into the gap of the pericardium (Pkh). According to the invention, the distal end portion of the electrode (4) is connected to a shape-variable element (6) for aligning, in particular for adjusting the implantation angle, and for stabilizing, in particular for laterally stabilizing the electrode (5).

Owner:DEUTES HERZZENT BERLIN

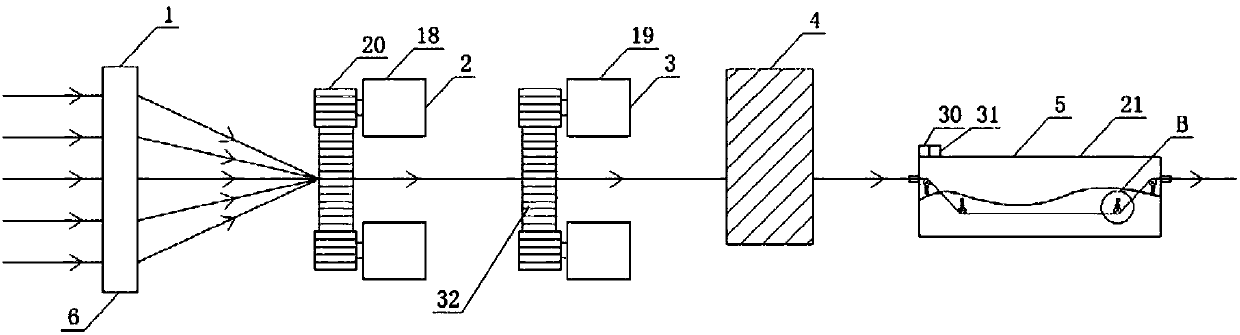

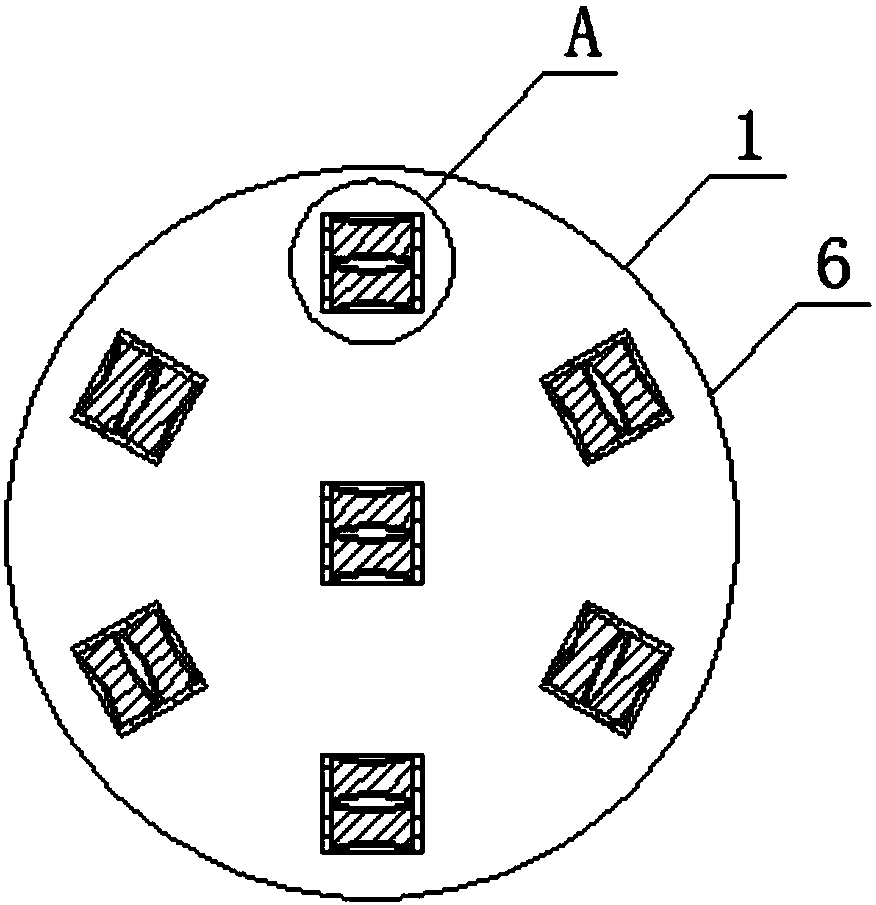

Cable production device

InactiveCN108039249AThe feeding process is simpleReduce lossApparatus for feeding conductors/cablesInsulating conductors/cablesFeed pressureFault rate

The invention discloses a cable production device comprising a material feeding mechanism. One side of the material feeding mechanism is provided with a first twisting mechanism. One side of the firsttwisting mechanism is provided with a second twisting mechanism. One side of the second twisting mechanism is provided with a wrapping mechanism. One side of the wrapping mechanism is provided with acooling mechanism. The material feeding mechanism comprises a material feeding carrier which is provided with a material feeding slot. The material feeding slot is internally provided with material feeding rotating rods which are provided with material feeding pressure rollers. The external side of the material feeding pressure rollers is provided with a protective layer which is provided with antiskid projections. The material feeding mechanism is arranged so that the material feeding process is enabled to be simpler and lighter, loss of the raw cables caused by the material feeding processcan be reduced, the fault rate can be reduced, the cable quality can be enhanced and the unnecessary economic loss can be avoided.

Owner:安徽电信实业集团有限公司器贸分公司

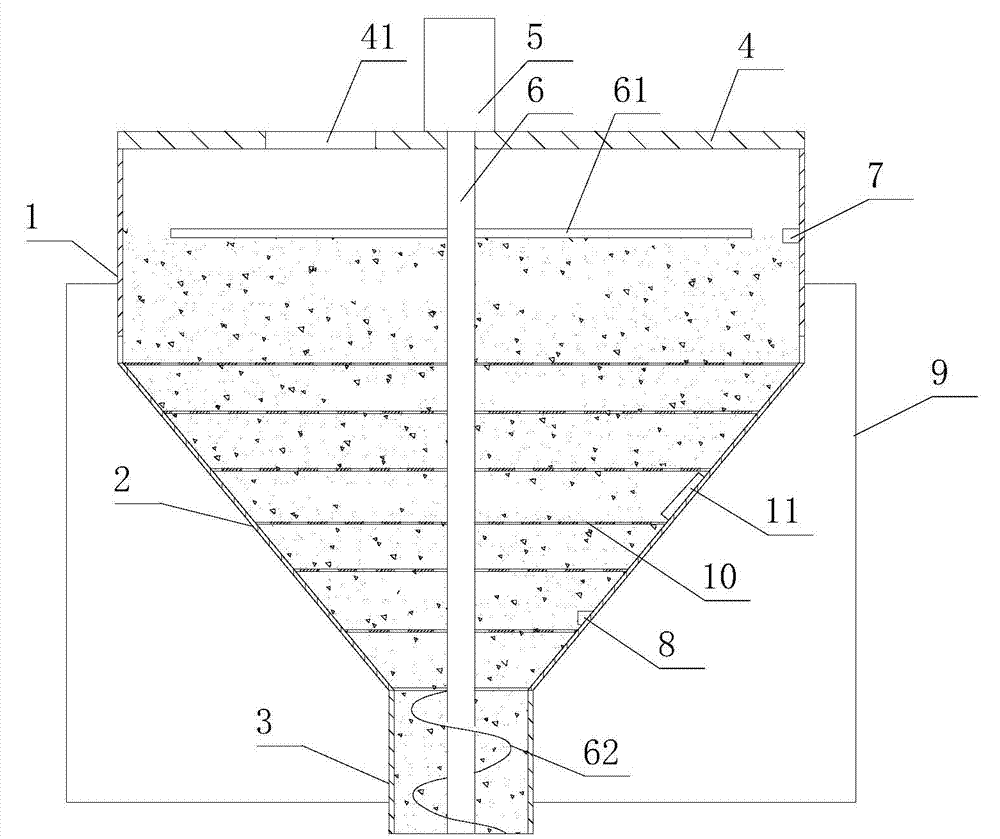

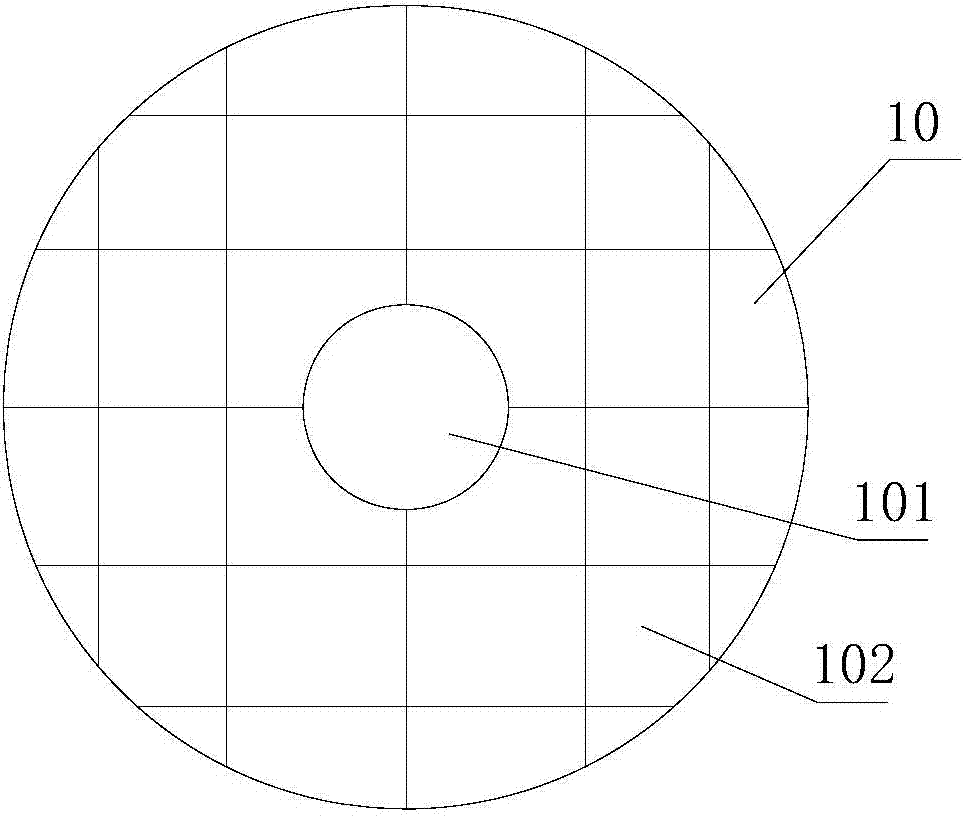

Feeding device capable of vibrating

The invention discloses a feeding device capable of vibrating. The feeding device comprises a bucket body, wherein the bucket body comprises a circular-ring shaped charging section, an inverted cone-shaped material storage section and a circular-ring shaped discharging section which are coaxially arranged; the top end of the material storage section is flexibly connected with the charging section; the bottom end of the material storage section is flexibly connected with the discharging section; a rack is arranged outside the charging section; the rack is connected with the outer side of the charging section; a vibrator is arranged on the side wall of the material storage section; the material storage section is provided with a plurality of screen meshes which are arranged at intervals from top to bottom and are in detachable connection; sieve pores of adjacent two screen meshes are arranged in a staggered manner; shaft through holes are formed at centers of the screen meshes; a cover plate is arranged on the top of the charging section; the cover plate is provided with a charging hole; a drive motor is arranged on the top of the cover plate; the drive motor is connected with a main shaft; the main shaft extends into the bucket body and passes through the shaft through holes to reach the discharging section; a spiral blade is arranged at the tail end of the main shaft; and the spiral blade is arranged in the discharging section. The feeding device capable of vibrating can be used for avoiding material accumulation and is easy for feeding.

Owner:昆山市华浦塑业有限公司

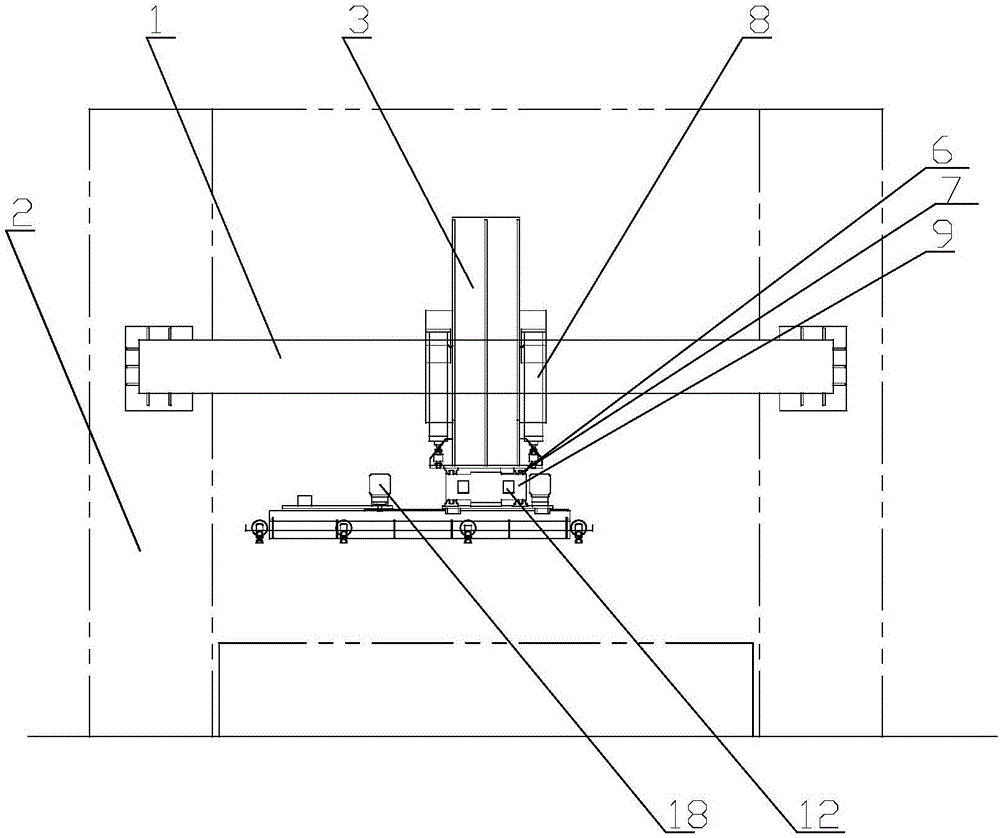

Multi-station automatic feeding device

InactiveCN105964819AReasonable designInnovative designMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention relates to the technical field of industrial automation, in particular to a multi-station automatic feeding device. The automatic feeding device comprises two parallel beams. The two ends of each beam are fixed between two supporting devices located on the same side of a station. One beam is located on the left side of the station, and the other beam is located on the right side of the station. A Z-axis displacement device capable of moving up and down is arranged at the middle portions of the beams. The bottom end of the Z-axis displacement device is connected with a Y-axis displacement device capable of moving front and back. The bottom of the Y-axis displacement device is connected with an X-axis displacement device capable of moving left and right. The front side of the bottom of the X-axis displacement device is connected with a workpiece picking device. Thus, the multi-station automatic feeding device is reasonable and novel in structural design, full-automatic mechanical control is adopted, the labor cost is saved, people are released from high-strength labor, the work efficiency is high, and the danger coefficient is low; and meanwhile the positioning precision is high, and the good quality stability of a finished product manufactured through a punching machine is guaranteed.

Owner:JINAN FOUND AUTOMATION EQUIP

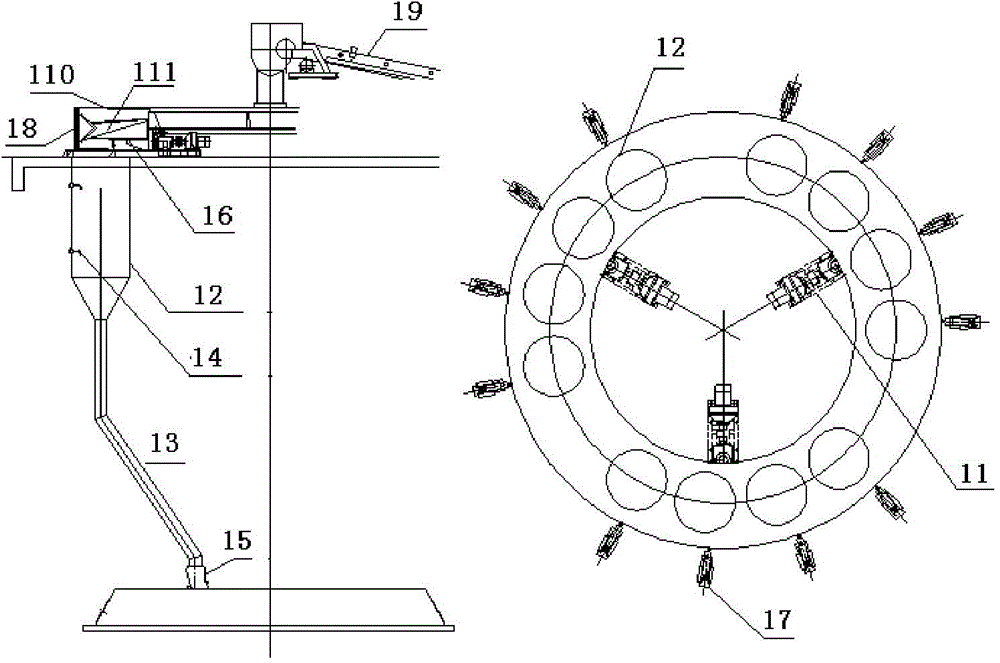

Feed system and feed method of calcium carbide furnace

InactiveCN104876220ALow failure rateReduce pollutionChemical industryCalcium carbideProcess engineeringPower equipment

The invention relates to feed system and feed method of a calcium carbide furnace. The feed system comprises a material loading device, a material storage device and a plurality of feed devices which are sequentially connected, wherein the material storage device is capable of freely distributing raw materials depending on the gravity of the raw materials; the material loading device is used for delivering the raw materials positioned on the ground to the material storage device; the material storage device is used for storing the raw materials and automatically distributing the raw materials to the plurality of feed devices respectively depending on the self gravity of the raw materials; and the feed device is connected with the calcium carbid furnace. The feed system disclosed by the invention can be used for effectively reducing the generation of a safety accident of the feed system in an calcium carbide industry, reducing the failure rate of the feed system and preventing the pollution of a production environment, is simple in process and convenient to operate, and has no complicated power equipment used in the prior art, thus saving the energy sources and increasing the economic benefit of calcium carbide production.

Owner:内蒙古鄂尔多斯电力冶金集团股份有限公司

Crab feeding device based on solar energy

InactiveCN106234277ASimplify the feeding processSave energyClimate change adaptationAgricultural fishingElectricityMaterial resources

The invention discloses a crab feeding device based on solar energy and relates to the technical field of crab feeding. The crab feeding device comprises a feeding pond frame, wherein a cement filling layer is arranged in the feeding pond frame, a group of positioning and clamping slots are formed in the feeding pond frame, a group of ramps are arranged at the bottom end of the feeding pond frame, one end of each ramp is fixedly connected with the feeding pond frame through a rotating shaft, the other ends of the ramps are connected with the positioning and clamping slots, automatic feeding devices are arranged at two ends of the feeding pond frame and electrically connected with a solar power supplying device, a young crab temporary rearing device is arranged at one end of the feeding pond frame, and a temporary rearing box is connected with a lifting device. With the adoption of the integrated structure of biological feed boxes, the young crab rearing box and a feeding box frame, integrated feeding is realized, the feeding process is simplified, energy is saved through solar power supply, the young crab rearing box can be lifted up and down, meanwhile, new young crabs can adapt to the pond, and a large quantity of manpower and material resources are saved.

Owner:苏州市阳澄湖楼上楼大闸蟹养殖有限公司

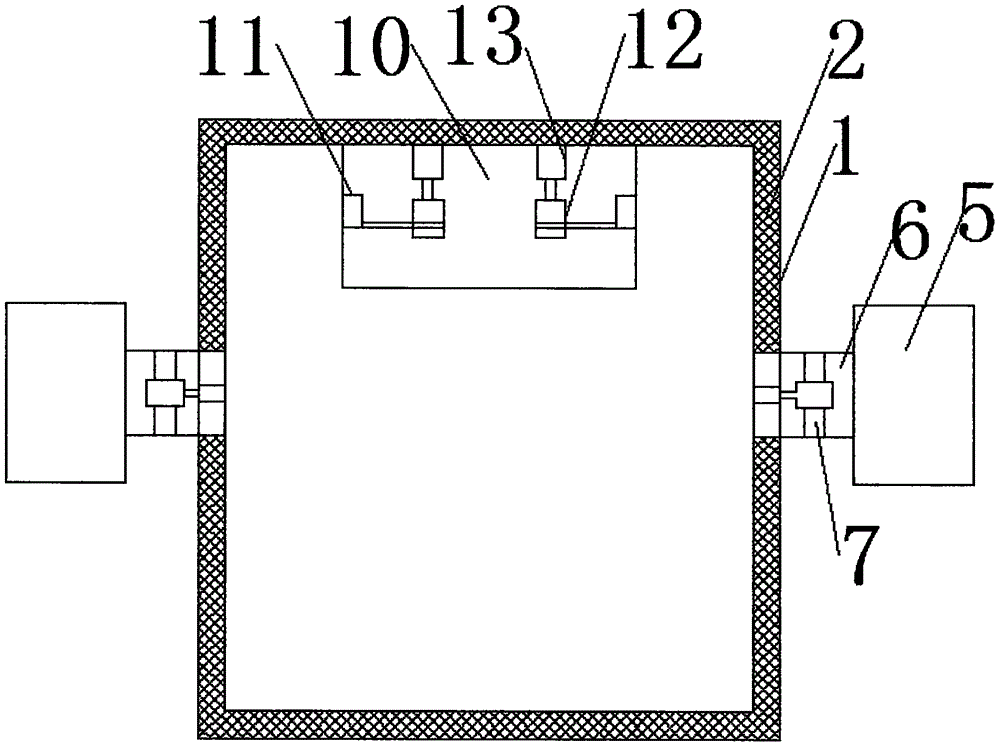

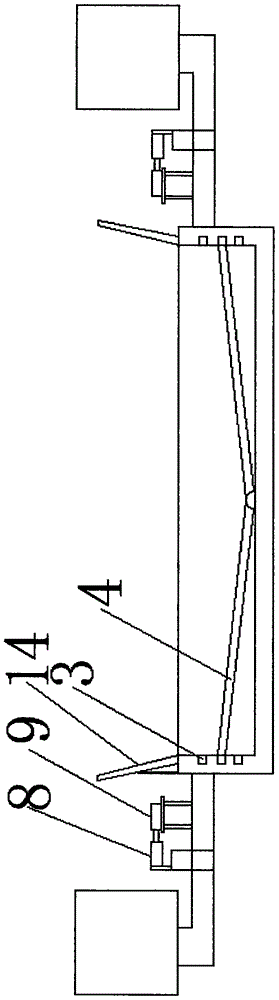

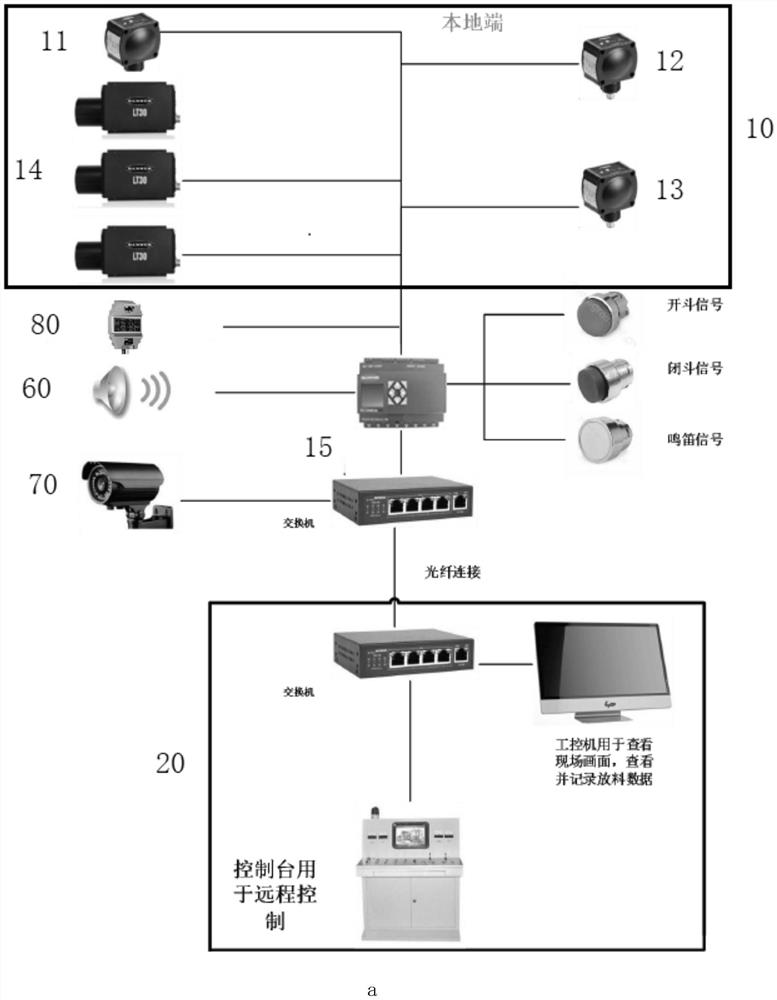

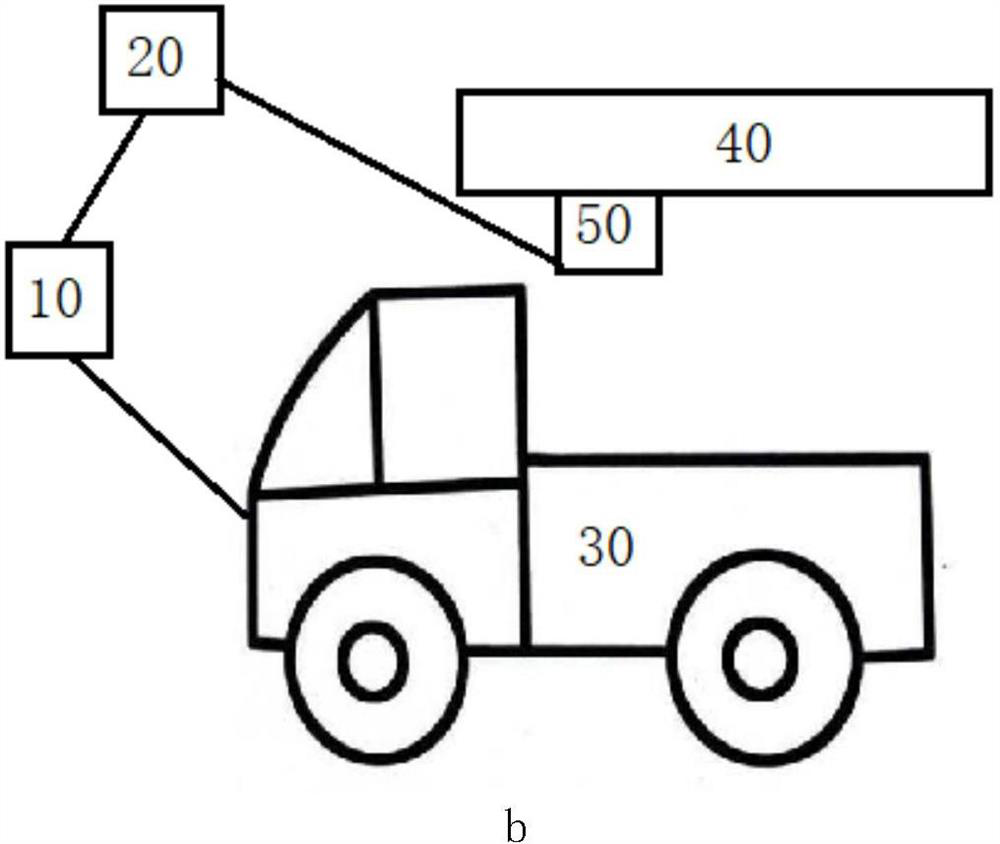

Control method for automatic material receiving of truck

PendingCN113620074AReduce labor costsUnloading is simpleConveyorsControl devices for conveyorsTruckRoboty

The invention provides a control system and method for automatic material receiving of a truck. The control system comprises a signal acquisition unit, a controller and a vehicle, wherein the signal acquisition unit is in signal connection with the vehicle, and obtains the type information, the position information and the material receiving amount information of the vehicle; the signal acquisition unit is in signal connection with the controller so as to send or receive signals, the signal acquisition unit and / or the controller are / is in signal connection with a bin opening robot, and the bin opening robot is used for regulating and controlling the opening and closing states of a stock bin so as to start and stop discharging operation; and after the system judges that the obtained information meets the requirement, the opening and closing states of the stock bin are regulated and controlled through the bin opening robot, and automatic discharging and receiving operation is achieved. The labor cost is saved, discharging becomes simple and efficient, and an accurate and controllable solution is provided for fixed-point material receiving of the truck.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

Environment-friendly phosphor-nitrogen single-component expansion type flame retardant and preparation method thereof

ActiveCN107090100AReduce pollutionMeeting the Demand for High-Performance Flame RetardantsChemical reactionFire retardant

The invention discloses an environment-friendly phosphor-nitrogen single-component expansion type flame retardant and a preparation method thereof. The environment-friendly phosphor-nitrogen single-component expansion type flame retardant takes a dehydrating agent as an acid source, and takes a nitrogen-containing foaming agent as a gas source and takes a char-forming agent as a carbon source, and chemical reaction is performed in an organic solvent to synthesize a three-dimensional macromolecular structure. The environment-friendly phosphor-nitrogen single-component expansion type flame retardant effectively overcomes the defects that a micromolecule expansion type flame retardant is liable to migrate, is liable to absorb humidity, is poor in compatibility with polymer matrix and the like, does not contain halogen, is small in environmental pollution; and the environment-friendly phosphor-nitrogen single-component expansion type flame retardant which integrates the carbon source, the acid source and the gas source can meet requirements, on high-performance flame retardant, of people, and also can simplify a feeding process in a processing process, and saves cost; and the production process is simple and easy to control, is relatively low in requirement on production equipment and is relativley high in yield.

Owner:上海兴怀化工技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com