Cigarette feed deviation alarm and feed batch method

A technology of deviation alarming and feeding materials, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems such as the inability of the smoke box to enter smoothly, affect the production efficiency, and the deformation of the smoke box, so as to save labor costs, improve production efficiency, and save raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] The technical solution of the present invention will be further explained below with specific examples (feeding deviation alarm and feeding method of Golden Leaf (Lotto) products), so that those skilled in the art can further understand the technical solution of the present invention:

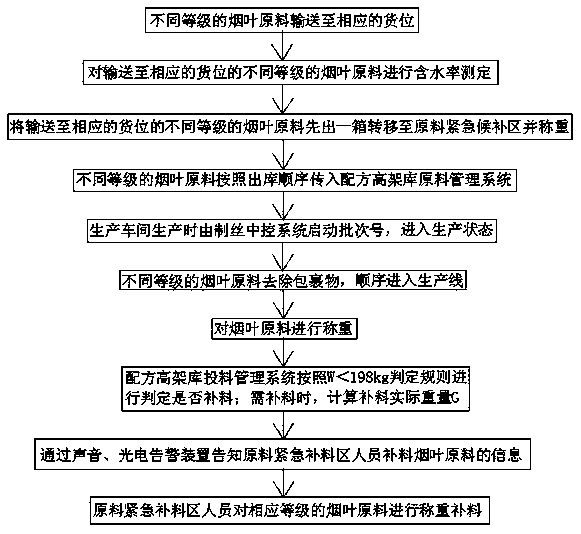

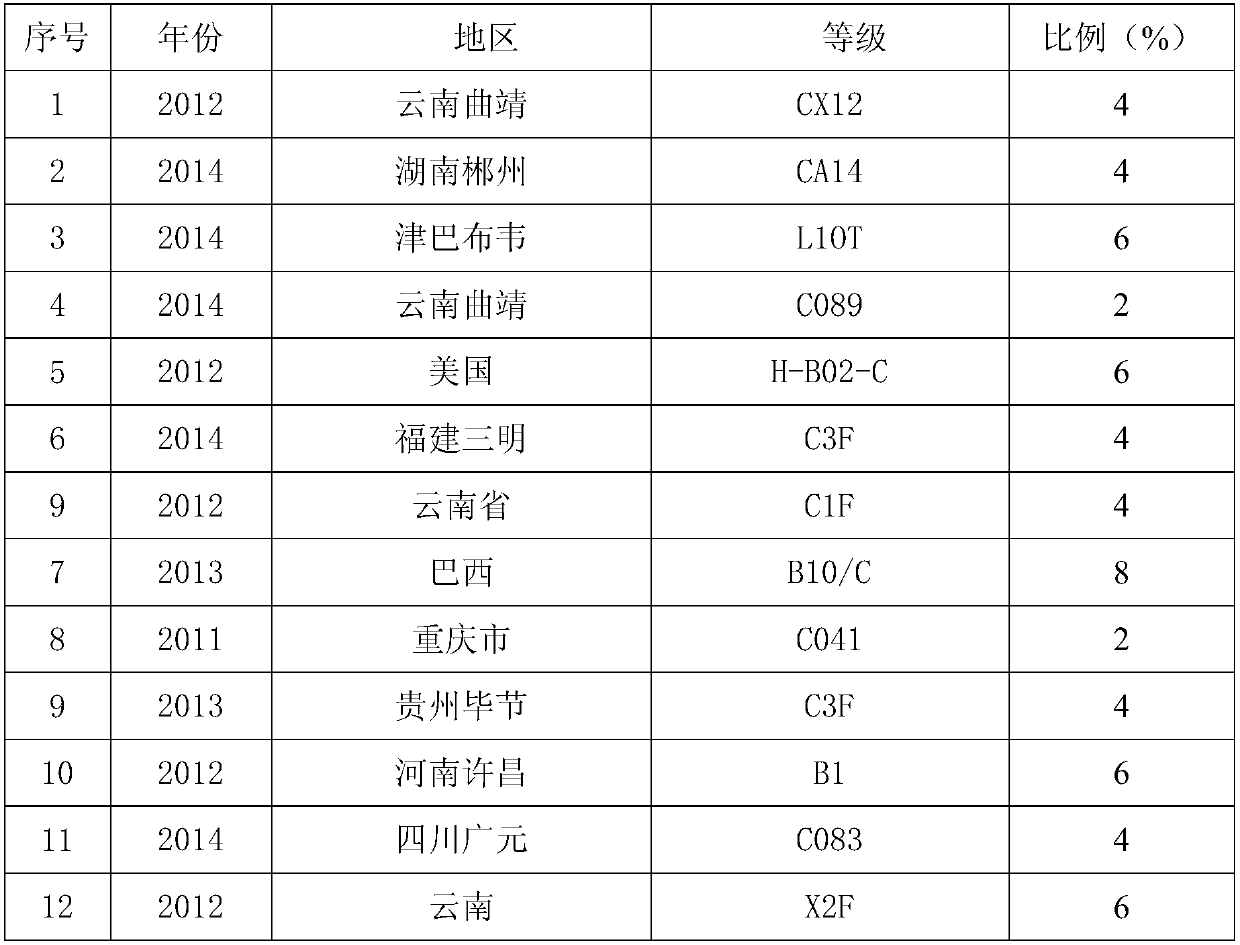

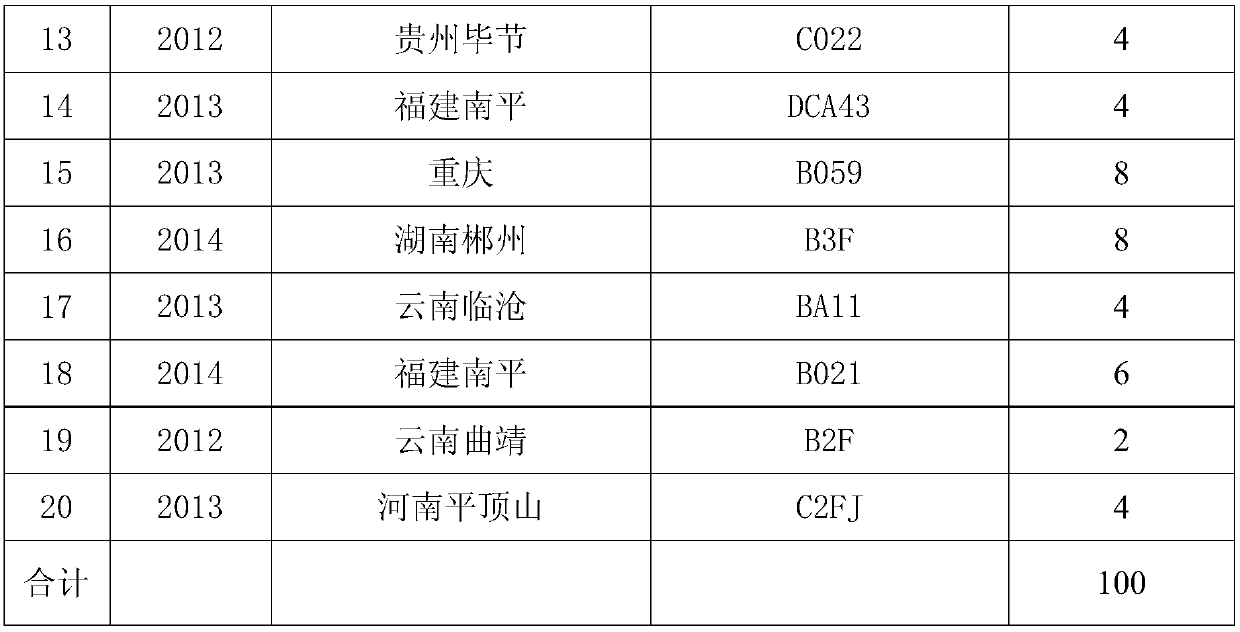

[0065] Step 1: Input the Golden Leaf (Lotto) product formula list into the formula raw material elevated warehouse; organize different grades of tobacco leaf raw materials in batches according to the formula elevated warehouse raw material formula system, start the formula elevated warehouse raw material storage system, and process different grades of tobacco leaf raw materials After scanning the code for identification, the tobacco leaf raw materials of different grades are transported to the corresponding storage positions; the following Table 1 is the product formula list of Golden Leaf (Lotto);

[0066]

[0067]

[0068] Table 1: Golden Leaf (Lotto) Product Formula List

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com