Feed system and feed method of calcium carbide furnace

A feeding system and feeding method technology, applied in the direction of climate sustainability, carbide, calcium carbide, etc., can solve the problem of damage to motors, reducer bearings, driving wheel couplings, guide wheels, and excessive CO concentration in the feeding system , prone to CO poisoning and other problems, to achieve the effect of reducing failure rate, improving economic benefits and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

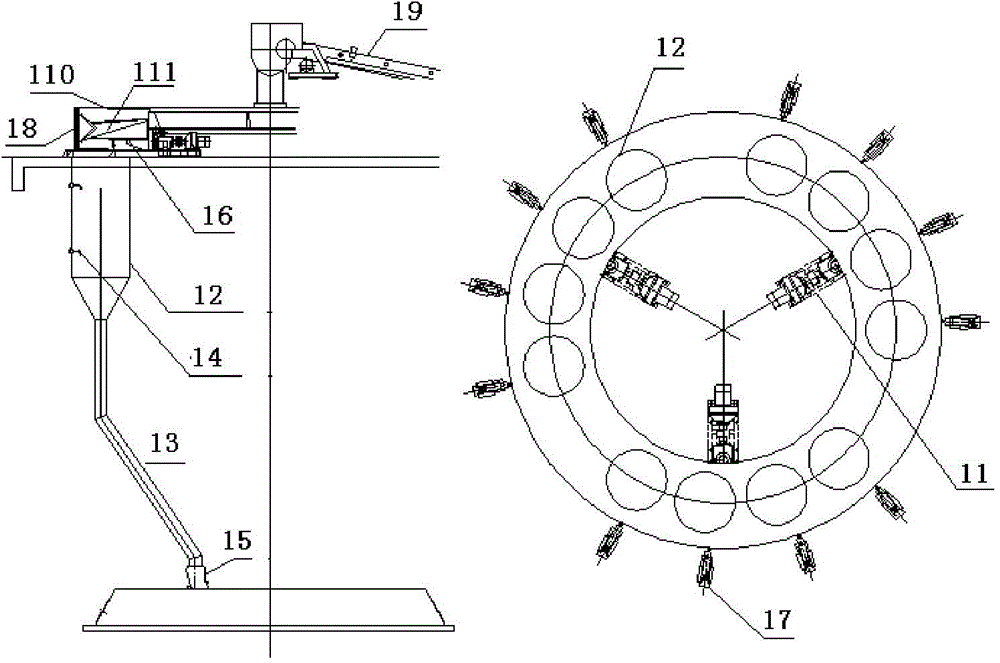

Embodiment 1

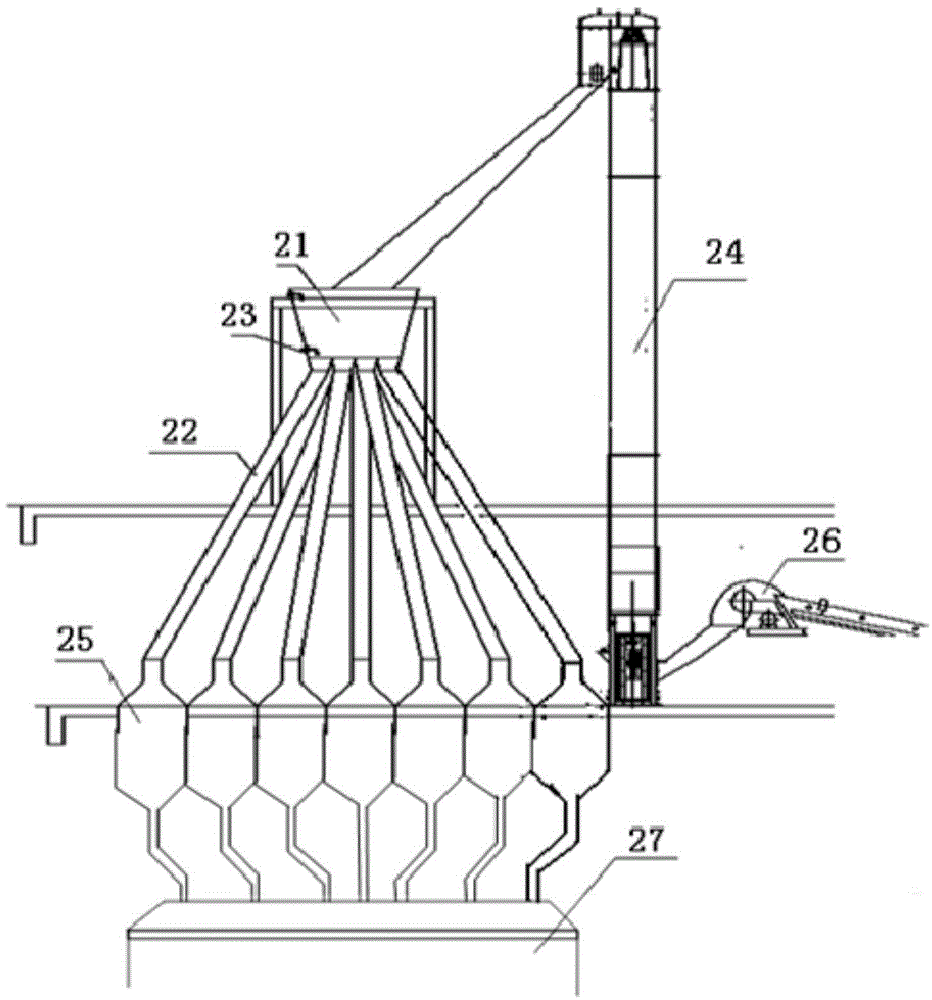

[0028] figure 2 A schematic diagram of a calcium carbide furnace feeding system showing an embodiment of the present invention, see figure 2 , the calcium carbide furnace feeding system includes a sequentially connected feeding device 24 , a storage device 21 for freely distributing raw materials depending on the gravity of the raw materials, and a plurality of feeding devices 25 . The feeding device 24 is used to transport the raw materials on the ground to the storage device 21. In this embodiment, a bucket elevator is preferably used to realize it. Of course, it can also be realized by using a belt conveyor with a large inclination angle. The present invention does not do anything to realize this. limit.

[0029] The material storage device 21 is used to store the raw material and automatically distributes the raw material to the plurality of feeding devices 25 by the gravity of the raw material itself. The feeding device 25 is connected with the material storage device ...

Embodiment 2

[0033] The feeding method of the calcium carbide furnace feeding system in the first embodiment of the present invention comprises the following steps:

[0034] S1: The belt conveyor transports the raw materials from the batching station to the feeding device;

[0035] S2: The feeding device transports the raw materials to the storage device;

[0036] S3: The storage device distributes the stored raw materials to each feeding device relying on the gravity of the raw materials themselves.

[0037] S4: The raw material in the feeding device enters the calcium carbide furnace under its own gravity.

[0038] The calcium carbide furnace feeding system provided by the present invention can replace the current feeding system in the calcium carbide industry. The original circular feeding system with power equipment is replaced by a storage device and a material guide device, and the raw materials are added to the feed by their own weight. The purpose of feeding is achieved in the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com