Automatic tying and loosing shoes

a technology of automatic tying and loosing shoes, applied in the field of shoes, to achieve the effect of low fault ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

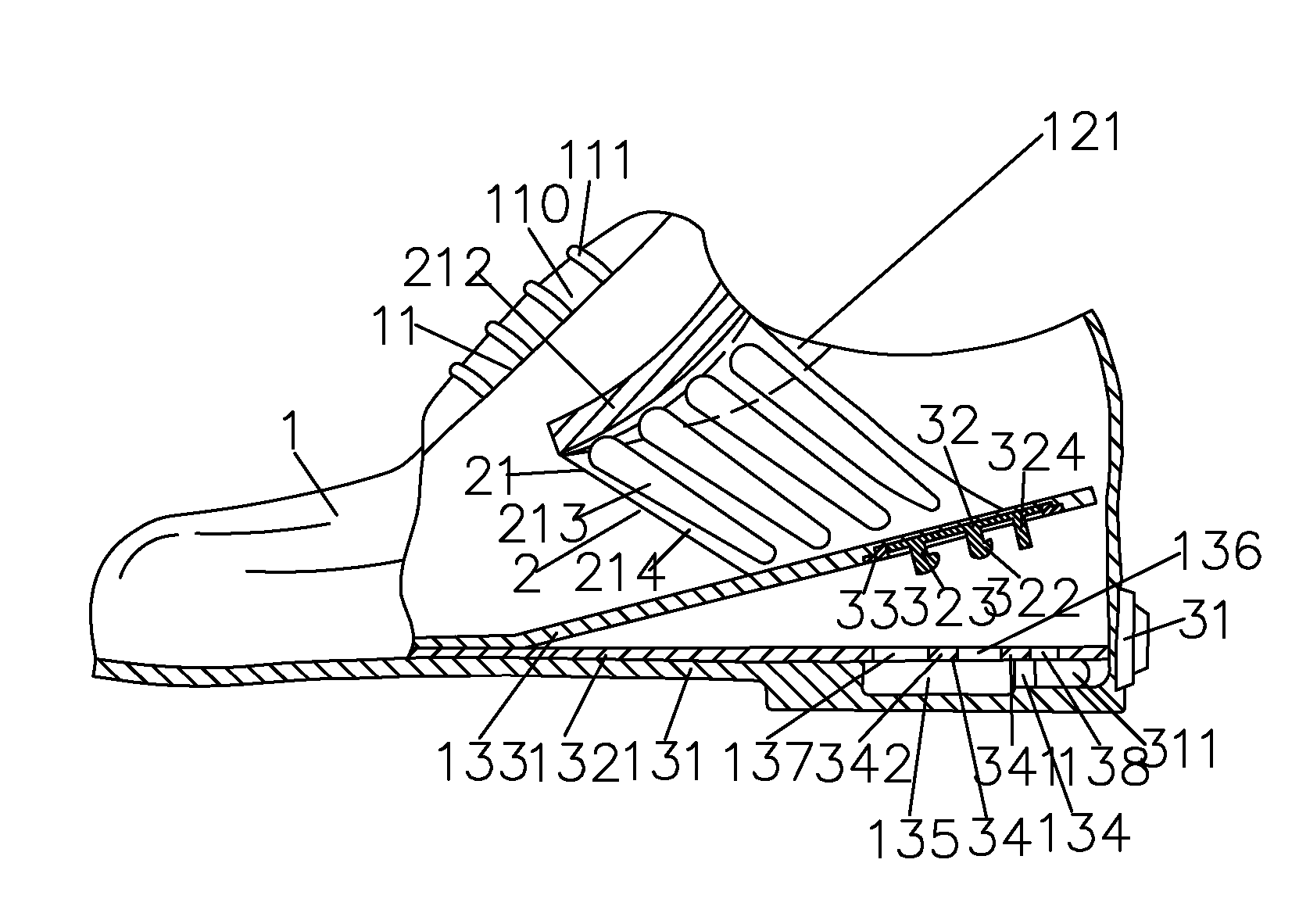

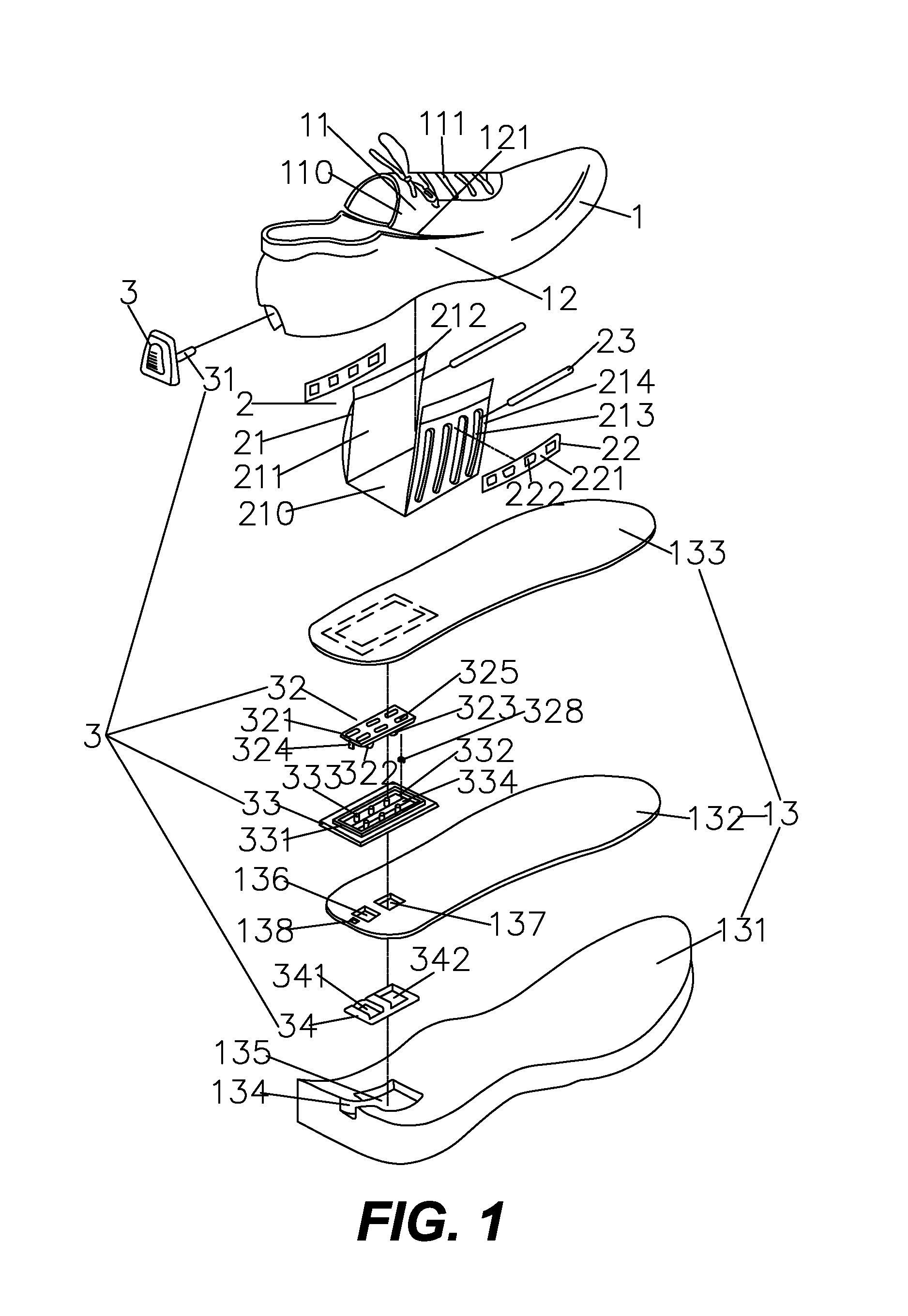

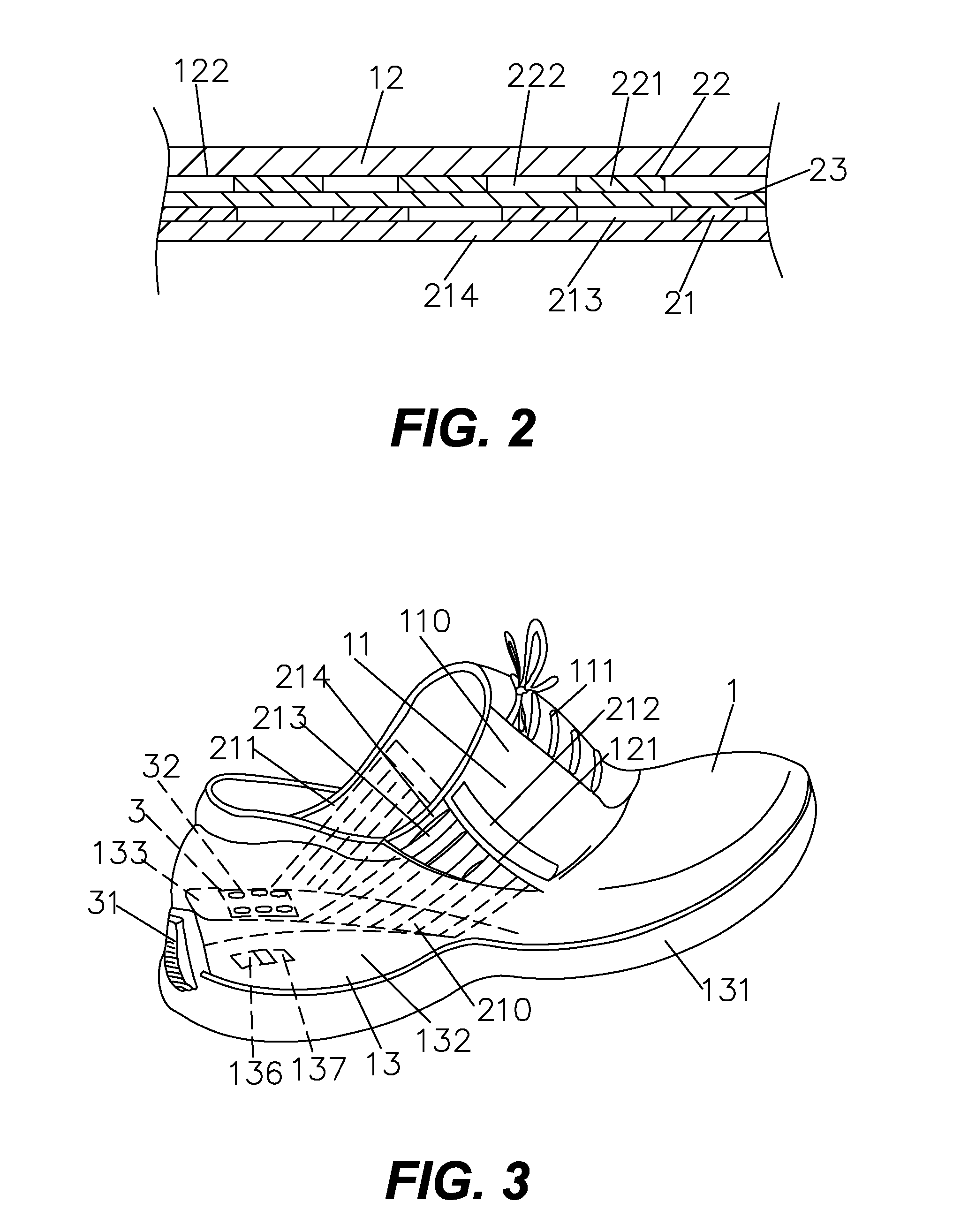

[0038] Referring to FIG. 1 to FIG. 4, the first embodiment provided by the present invention is typically comprised of a shoe-body 1, an action regulating mechanism 2 installed into the inside of the upper 12 of the shoe-body 1, and a control mechanism 3 mounted on the inside of the shoe-sole 13 of the shoe-body 1, as shown in FIG. 1.

[0039] Said shoe-body 1 is constructed of tongue portion 11, upper portions 12 and shoe-sole 13 overlapping together. Wherein:

[0040] Said tongue portion 11 includes a tongue 110 and an attachment 111 further designed into decorative lace, or Nylon sticking band and so on, for adjusting the slack of the tongue 110 further to meeting the different foot of users.

[0041] Said upper 12 has a mouthing portion 121 formed on the interface to the tongue 110 at any position between the said tongue 110 and the decorative lace 111, thereby decision the area of the tongue 110 and the moving distance of the action regulating mechanism 2 for cooperating to the actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com