Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Fully consumed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

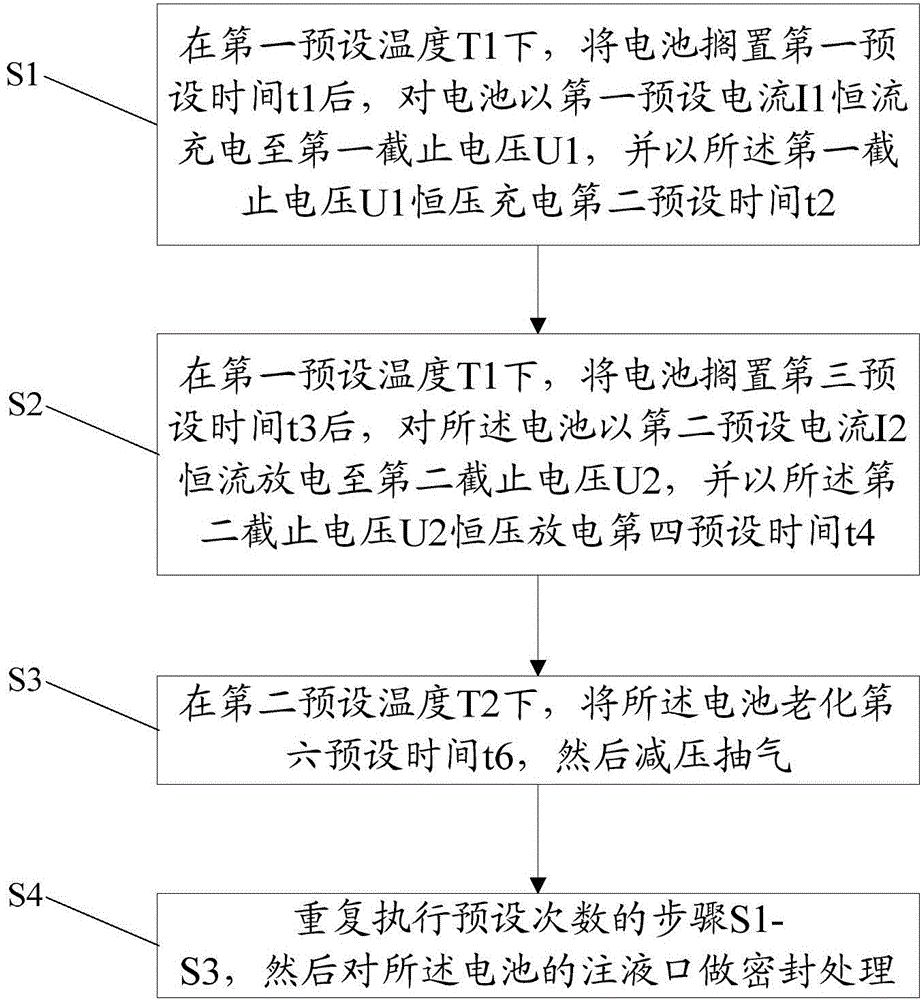

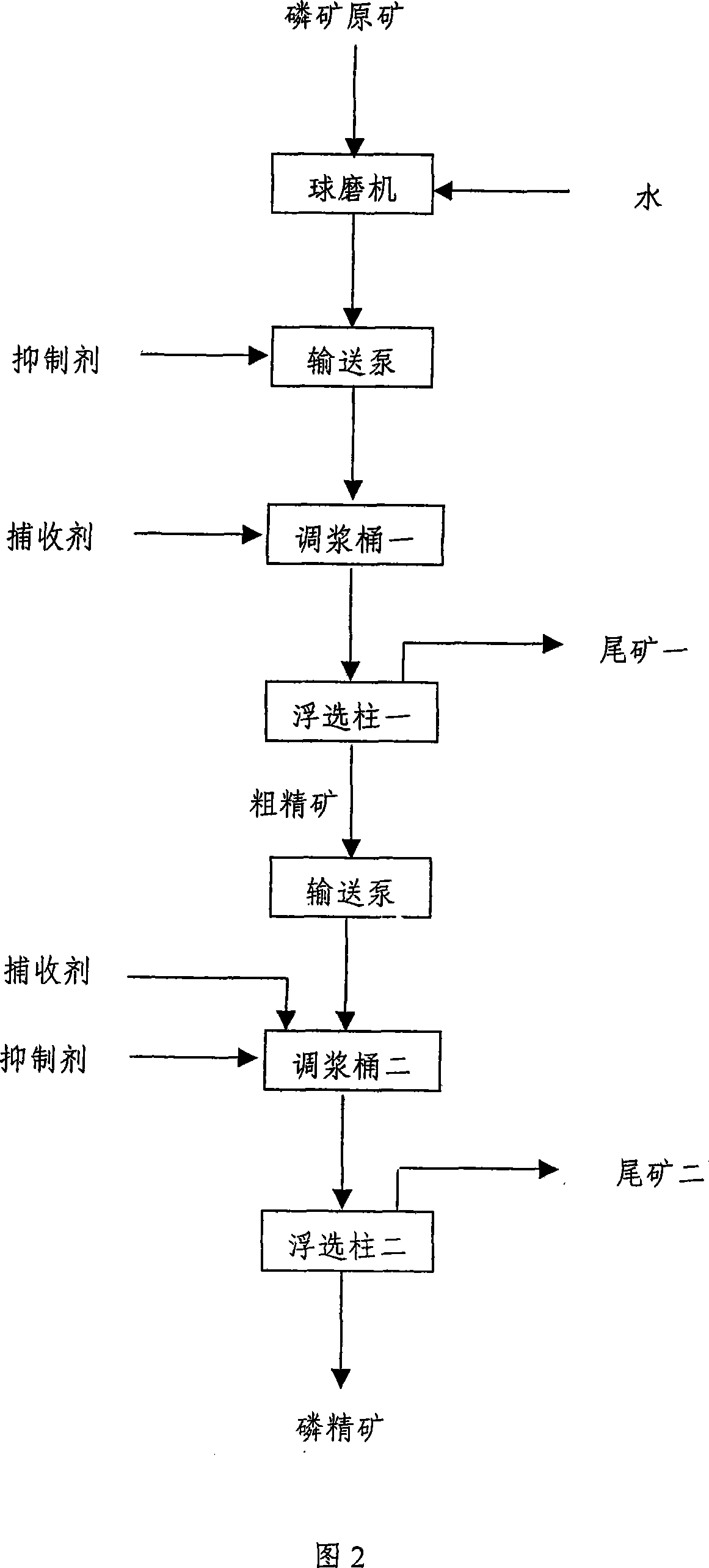

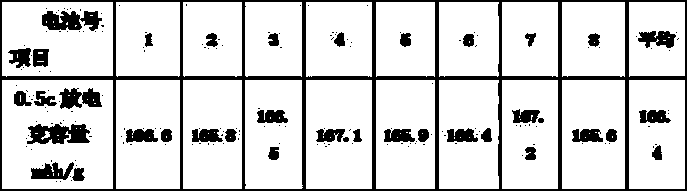

Forming method of lithium titanate battery

ActiveCN104409780AImprove cycle performanceGuaranteed capacityFinal product manufactureElectrolyte accumulators manufactureEngineeringVoltage

The invention discloses a forming method of a lithium titanate battery. The forming method comprises the following steps: S1, lying the battery for first preset time t1 at first preset temperature T1, charging the battery with first preset current I1 constantly until reaching first cut-off voltage, and charging the battery with U1 constantly for second preset time t2; S2, lying the battery for third preset time t3 at the first preset temperature T1, discharging the battery with second preset current I2 constantly until reaching second cut-off voltage, and discharging the battery with U2 for fourth preset time t4; S3, aging the battery for sixth preset time t6 at second preset temperature T2, reducing the pressure and exhausting air; S4, carrying out the step S1 to the step 3 repeatedly for preset frequency, and sealing a liquid filling opening of the battery. According to the forming method of the lithium titanate battery, water in the battery is consumed completely and is generated into gas to be discharged from the battery, so that the capacity of the battery can be ensured, and the cycle performance of the lithium titanate battery can be improved.

Owner:HEBEI YINLONG NEW ENERGY +1

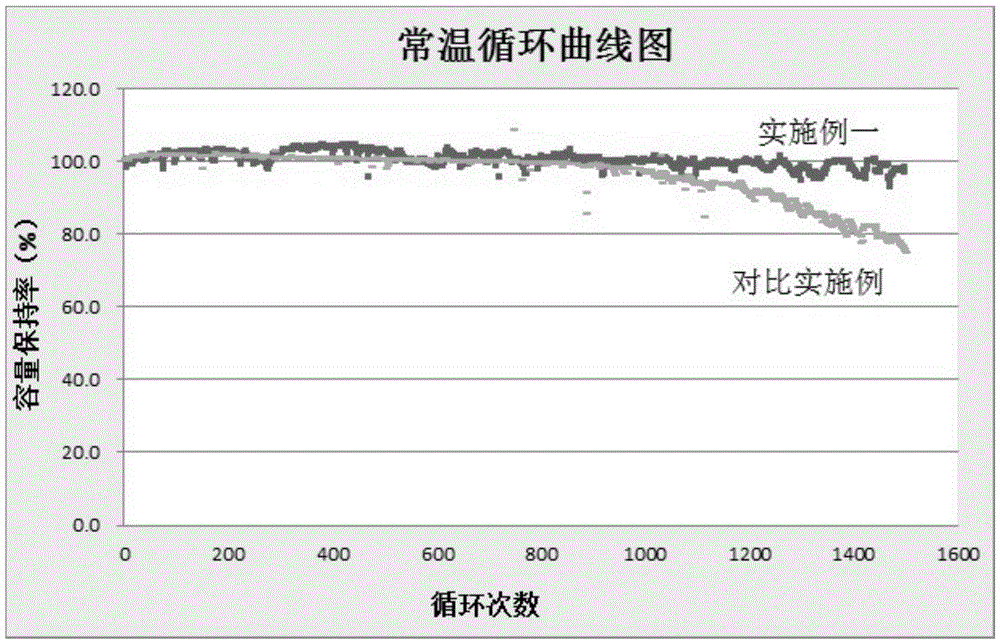

Method for demagging from phosphate ore

ActiveCN101049584ATo removeAchieve the effect of removing magnesium impurities in phosphate rockFlotationSludgePhosphoric acid

A process for removing Mg from phosphorus ore in order to prepare phosphoric acid by wet method features use of static microbubble floatation column, and includes such steps as breaking the crude phosphorus ore, grinding, classifying, mineralizing by mixing the reverse floatation chemical with ore sludge, and floatating in said static microbubble floatation column while conditioning the ore sludge to obtain the bubble-phase tailings and low-Mg phosphorus ore concentrate from the column bottom.

Owner:YUNNAN CHEM RES INST

Process for producing nano zinc oxide by using crude zinc oxide

InactiveCN103482680AAvoid pollutionRealize comprehensive utilizationMaterial nanotechnologyZinc oxides/hydroxidesZinc hydroxideZno nanoparticles

The invention relates to a process for producing nano zinc oxide by using crude zinc oxide. The process comprises the procedures of leaching, purifying, precipitating and calcining; the leaching procedure comprises the steps of adopting the crude zinc oxide as a material, reacting with hydrochloric acid and producing a coarse zinc chloride solution; the purifying procedure comprises the steps of controlling the pH value properly of the coarse zinc chloride solution obtained in the leaching procedure, adding sodium hypochlorite to carry out primary oxidation for removing impurities, adding zinc powder to carry out secondary replacement for removing impurities and obtaining a refined zinc chlorine solution; and the precipitating procedure comprises the step of reacting the refined zinc chlorine solution obtained in the purifying procedure and a sodium hydroxide solution, producing zinc hydroxide slurry, and then filtering, washing and drying the slurry to obtain zinc hydroxide; calcining the zinc hydroxide obtained in the precipitating procedure to obtain active zinc oxide. The process had the advantages that comprehensive utilization and sustainable development of resources are realized and the economic, environmental and social benefits are good.

Owner:JIYUAN VOCATIONAL & TECHN COLLEGE

Semi-red mud water permeable brick and preparation method thereof

The invention relates to a semi-red mud water permeable brick which comprises 40-50 parts of red mud; 5-10 parts of a silicon-aluminum additive; 40-50 parts of an additional aggregate; 5-8 parts of flux and 5-8 parts of an auxiliary adhesive. The semi-red mud water permeable brick has large red mud consumption, can cooperatively treat solid wastes in industries such as ceramics, refractory materials, metallurgy and the like, and is low in cost, high in safety and attractive in appearance, and all technical requirements conform to industry standard requirements of water permeable bricks.

Owner:SHANDONG UNIV OF TECH

Delicacy hoisin sauce

The invention provides delicacy hoisin sauce. The hoisin sauce is prepared by the steps of with 10 as a base rate, respectively weighing the delicacies of wild bamboo shoots, mountain mushrooms, haw and phyllanthus emblica according to a proportion of (5-7) to (6-5) to (4-3) to (3-2), crushing and stirring the delicacies into a delicacy mixture, respectively weighing the seafood of oyster, sea crab, prawn and conch according to a proportion of (5-6) to (4-5) to (2-3) to ( 2-1), and crushing and stirring the seafood into a seafood mixture, respectively weighing the additives of tomato, chili, pepper, anise, ginger, table salt and rice vinegar according to a proportion of (3-4) to (4-2) to (2-3) to (3-2) to (2-1) to (1-2) to ( 0.4-0.2), and crushing and uniformly mixing the additives into an additive mixture, with 100 as the base rate, weighing the delicacy mixture, the seafood mixture and the additive mixture according to a proportion of (8-7) to (7-6) to (0.5-0.3), and stirring uniformly to form mixed sauce, heating and cooking the mixed sauce for 50-60 minutes, filling a bottle with the mixed sauce, sealing to improve the quality for 5-7 days to obtain the delicacy hoisin sauce which has rich delicacy and seafood flavors and has high quality and is delicious.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

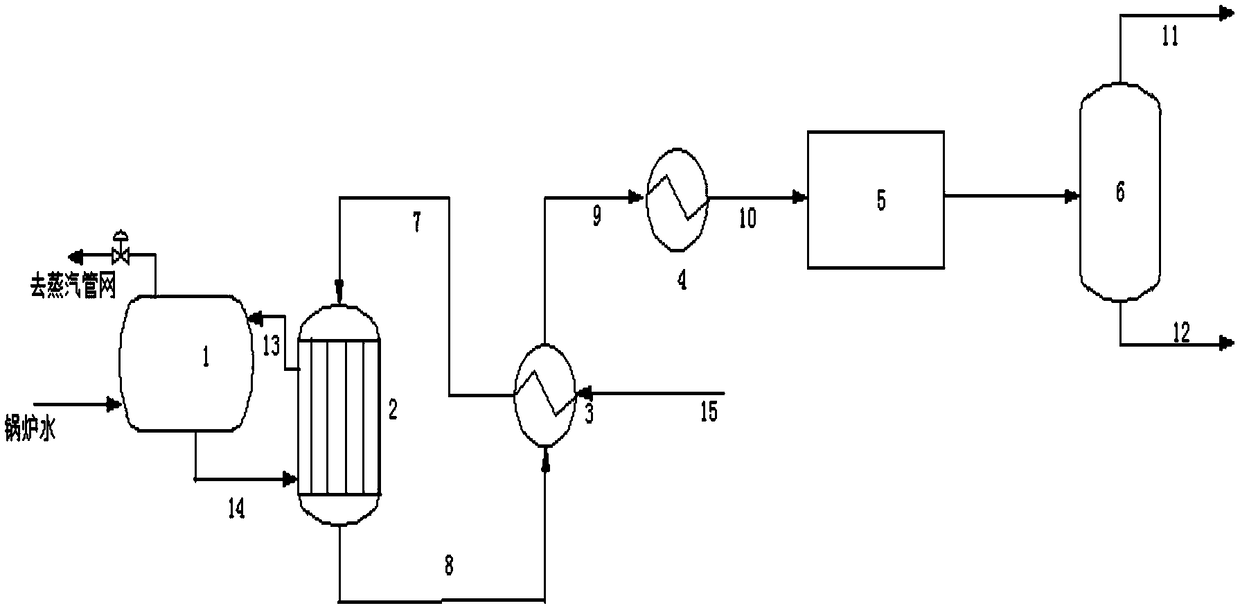

Method for treating oxygen-containing tail gas in ethylene glycol production device

InactiveCN109364750ALower oxygen levelsFully consumedOrganic compound preparationChemical industryEthylene oxideCatalytic oxidation

The invention relates to a method for treating oxygen-containing tail gas in an ethylene glycol production device. The problems that in the prior art, the oxygen-containing tail gas treating is high in cost, large in energy consumption and low in safety, and pollutes the environment are mainly solved. According to the method for treating the oxygen-containing tail gas in the ethylene glycol production device, by adopting the technical scheme that the oxygen-containing tail gas from the ethylene oxide-ethylene glycol device enters a shell and tube reactor through a gas-gas heat exchanger and generates a catalytic oxidation reaction on the tube side under the effect of a noble metal catalyst, thus oxygen in the tail gas sufficiently reacts with ethylene, and the oxygen in the tail gas is removed; and then the treated tail gas is cooled through a cooler and then enters an ethylene recovering unit, and after the ethylene is removed, the tail gas enters a liquid separating tank to be subjected to subsequent treatment, the problems are solved well, and the method can be used for treating the oxygen-containing tail gas in the ethylene glycol production device.

Owner:SINOPEC SHANGHAI ENG +1

Racing horse feed

InactiveCN110037179AGuaranteed healthy growthImprove palatabilityFood processingAnimal feeding stuffBiologyNutrient

The invention discloses a racing horse feed, and belongs to the field of horse feeds. According to key points of the technical scheme, the racing horse feed is composed of the following ingredients inparts by weight: 20-60kg of tablet-compressed oat, 7-21kg of helianthus annus, 5-15kg of soybean oil, 5-15kg of molasses, 1.5-4.5kg of tablet-compressed soybeans, 1-3kg of tablet-compressed black beans, 0.03-0.09kg of ethoxyquin, and 50-150kg of novel base particles. The racing horse feed is capable of achieving the effect of making nutrients of the horses more balanced.

Owner:北京宝麟马业科技有限公司

Shutdown control method of fuel cell system, fuel cell system and vehicle

ActiveCN113809366AFully consumedGuaranteed hydrogen concentrationMotive system fuel cellsThermodynamicsFuel cells

The invention relates to the field of fuel cells, in particular to a shutdown control method of a fuel cell system, the fuel cell system and a vehicle. The method comprises the following steps: closing an inlet / outlet at the air side of the fuel cell stack, and keeping the pressure at the hydrogen side of the fuel cell stack constant; switching on an output circuit of the fuel cell stack, and obtaining hydrogen accumulated flow input from the hydrogen side; and determining whether to close the fuel cell system according to the relationship between the hydrogen accumulated flow and a preset threshold value. According to the invention, the contradiction that the fuel cell system is insufficient in shutdown oxidation gas consumption and short in standing time and is high in tail discharge hydrogen concentration of next startup in the shutdown oxidation gas consumption process is solved; and it can be guaranteed that shutdown control meets the safety of oxygen consumption and hydrogen emission in the whole life cycle and under the abnormal condition.

Owner:BEIJING SINOHYTEC

Natural high-quality paste for blacking hair and growing hair

InactiveCN104546593AUnique preparation technologyCost green high qualityCosmetic preparationsHair cosmeticsRice strawHerb

The invention discloses a natural high-quality paste for blacking hair and growing hair. The natural high-quality paste is prepared by the following steps: firstly, thoroughly airing partial selected main materials and auxiliary materials by virtue of a frying machine or manpower; on the basis of 10, weighing the following main materials: black mulberry, black wolfberry, black rose, carbon black oil, ilex latifolia thumb, cacumen biotae and rice straw ashes at the ratio of (6-7) to (5-6) to (3-4) to (4-3) to (3-2) to (2-3) to (2-3), crushing, refining and slightly sieving to form main material powder; and weighing the following auxiliary materials: pine needle leaves, mint leaves and vanilla at the ratio of (0.8-0.7) to (0.6-0.7) to (0.5-0.6), crushing, refining and slightly sieving to form auxiliary material powder; on the basis of 100, weighing the main material powder, the auxiliary material powder, rice vinegar and camellia oil at the ratio of (8-9) to (2-3) to (3-2) to (2-3), and stirring evenly to form mixed paste; heating, stewing, and sterilizing the obtained mixed paste for 1-2 hours; and packing and sealing to obtain the natural high-quality paste for blacking hair and growing hair, which is high in quality, high in grade, natural, black and bright, and is capable of finishing hair dyeing, hot oil treatment, hair care, hair growth and the like for men and women once.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

Method for preparing calcium chloride through carbide slag and hydrochloric acid

InactiveCN103303957AReduce Calcium Chloride ContentIncrease profitCalcium/strontium/barium chloridesPhysical chemistryEngineering

The invention discloses a method for preparing calcium chloride through carbide slag and hydrochloric acid, and belongs to the technical field of chlor-alkali production. The method comprises the following steps of: reacting hydrochloric acid with carbide slag; filtering to obtain refined calcium chloride brine and calcium chloride brine sludge; washing the calcium chloride brine sludge with water; filtering; preparing hydrochloric acid by the obtained calcium chloride freshwater salt absorbing hydrogen chloride; and preparing calcium chloride through calcium-chloride-containing hydrochloric acid instead of part of hydrochloric acid. According to the method for preparing calcium chloride through the carbide slag and hydrochloric acid, the calcium chloride brine sludge is washed with water in order to recover the calcium chloride; the recovery rate of the calcium chloride under such method can reach 96% compared with the traditional process with the recovery rate of the calcium chloride of 70%; the production cost can be effectively decreased; the calcium chloride content in the brine sludge is greatly decreased through the washing, so that the influence of the loss of calcium chloride to the surrounding environment is reduced. The byproduct naming hydrogen chloride is fully consumed during recovering the calcium chloride, so that the production capacity of a chlor-alkali production is also improved.

Owner:SICHUAN PROVINCE JINLU RESIN

Temperature-resistant salt-resistant low-tension foam oil-displacing agent as well as preparation method and application thereof

ActiveCN113025297AExcellent oil-water interface propertiesProminent foamOrganic compound preparationFluid removalPolymer scienceCarboxylic acid

The invention discloses a temperature-resistant salt-resistant low-tension foam oil-displacing agent. The foam oil-displacing agent mainly comprises fatty alcohol polyoxyethylene ether carboxylate, and also comprises fatty alcohol-polyoxyethylene ether. The product has excellent oil-water interface property and outstanding foam performance, and is especially suitable for a foam flooding technology in the field of tertiary oil recovery. The invention also discloses a preparation method of the foam oil-displacing agent, the whole synthesis process of the method is continuously completed in a reaction kettle, any additional separation and purification process is not needed, a terminal product is directly formed, and the method has the advantages of simple process, economy, environmental friendliness and the like. The invention also discloses application of the foam oil-displacing agent.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for avoiding blackening of negative electrode pin-flexible connection of lithium ion battery

InactiveCN111799521AAvoid generatingAvoid corrosion and blackeningFinal product manufactureSecondary cells charging/dischargingElectrical batteryPhysical chemistry

The invention relates to a method for avoiding blackening of a negative electrode pin-flexible connection of a lithium ion battery. The method comprises the following step of pre-charging the lithiumion battery subjected to liquid injection for 30-60 seconds under the condition of 0.5-1 C. Through the pre-charging step, trace water in the electrolyte of the lithium ion battery after liquid injection can be rapidly consumed, the trace water is prevented from reacting with the fluorine-containing lithium salt in the electrolyte to generate sufficient HF, therefore, oxidation of HF to the negative electrode pin-flexible connection in subsequent high-temperature standing and charging and discharging processes is avoided, the effect of avoiding corrosion and blackening of the negative electrode pin-flexible connection of the lithium ion battery is achieved, the DCIR of the lithium ion battery after circulation is reduced, the first effect of the lithium ion battery is improved, and the cycle life of the lithium ion battery is prolonged.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

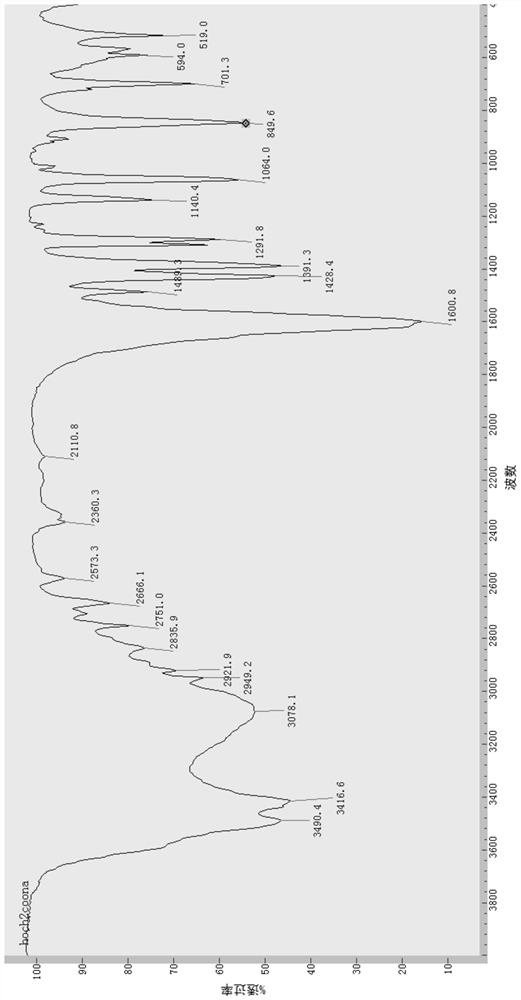

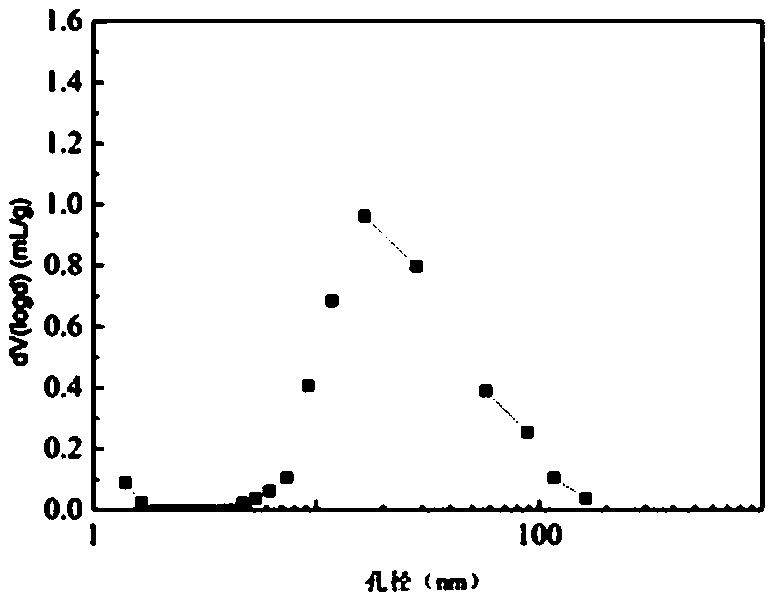

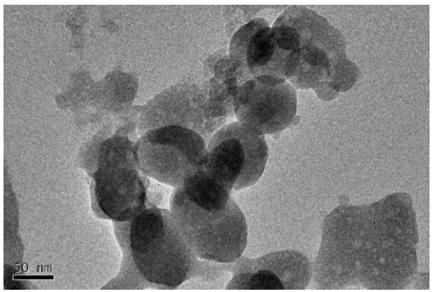

Preparation method of spherical silicon dioxide nano-particles

The invention provides a preparation method of spherical silicon dioxide nano-particles. The preparation method comprises the following steps of vertically dispersing nitrogen into a flowing sodium silicate solution through a microporous membrane to obtain a precursor solution; and vertically dispersing a sulfuric acid solution into the flowing precursor solution through the microporous membrane,and performing precipitation reaction and ageing to obtain the spherical silicon dioxide nano-particles, wherein the initial flow rate of the sulfuric acid solution passing through the microporous membrane is 5-30 mL / min, the flow rate of the sulfuric acid solution passing through the microporous membrane is increased by one time per 1-2 min, each increase amplitude is 0.1-10 mL / min, and the finalflow rate is 12-40 mL / min. According to records of the embodiment of the invention, the particle size of the silicon dioxide nano-particles prepared by the preparation method provided by the invention is 20-80 nm, and the degree of sphericity is good.

Owner:TSINGHUA UNIV +1

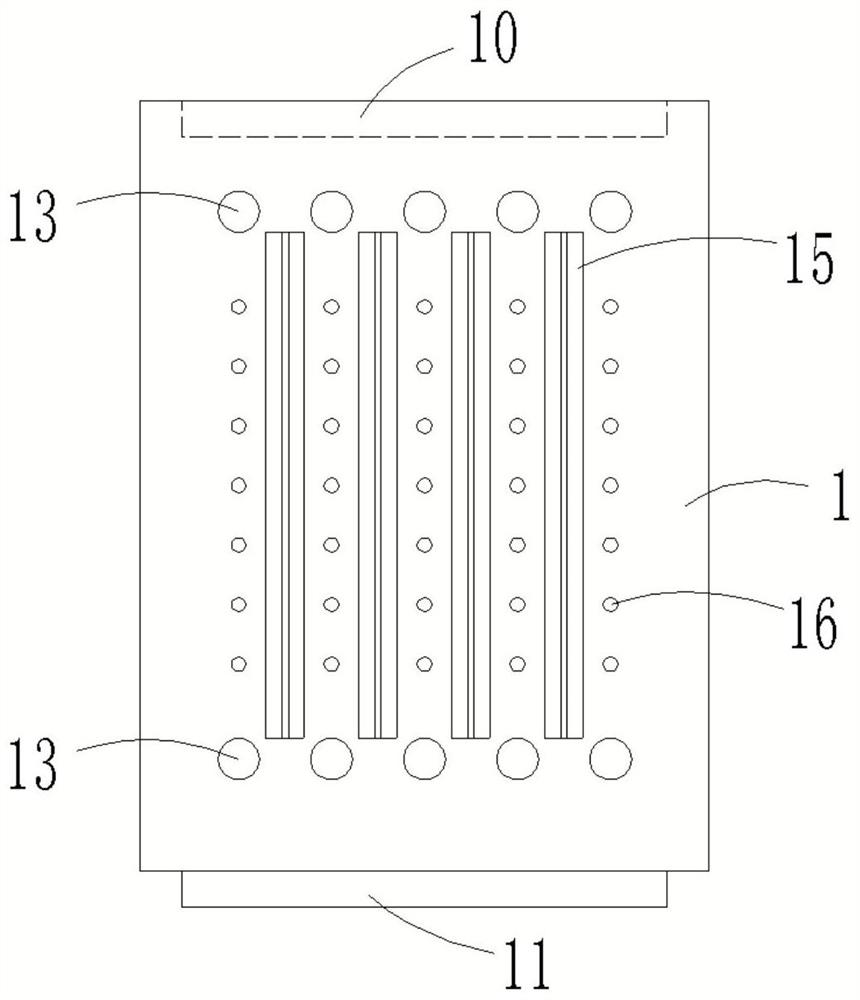

Nitrogen and phosphorus removal device and method for simultaneously treating domestic sewage and nitrate wastewater by fully utilizing an internal carbon source

ActiveCN113415884AImprove carbon source utilizationStable nitrogen and phosphorus removalWater treatment parameter controlWater treatment compoundsElectron donorSludge

The invention discloses a nitrogen and phosphorus removal device and method for simultaneously treating domestic sewage and nitrate wastewater by fully utilizing an internal carbon source, and belongs to the field of wastewater treatment. Sewage enters an AOA-SBR, anaerobic stirring is carried out, glycogen accumulating bacteria (GAOs) take in organic matter and store the organic matter as an internal carbon source (PHAs), and phosphorus accumulating bacteria (PAOs) store the PHAs and release phosphorus at the same time; the sewage enters a low-oxygen aeration stage (180 minutes), synchronous nitrification and denitrification is carried out, meanwhile, phosphorus uptake by PAOs is carried out, and denitrifying phosphorus removal is carried out by using nitrification products by denitrifying phosphorus-accumulating bacteria (DPAOs); nitrate wastewater with the same volume as discharged sludge is pumpedafter aeration, then an anoxic stage is enabled, denitrifying glycogen-accumulating bacteria (DGAOs) perform denitrification by using the internal carbon source, and perform endogenous denitrification by using the PHAs and NO3 <-> as an electron donor and an electron acceptor respectively, so as to achieve the purpose of deep nitrogen and phosphorus removal. The device is simple and easy to start, simple and convenient to operate, low in energy consumption, capable of treating domestic sewage and nitrate wastewater at the same time, good in nitrogen and phosphorus removal effect and low in sludge yield.

Owner:BEIJING UNIV OF TECH

Copper and copper alloy efficient melting method

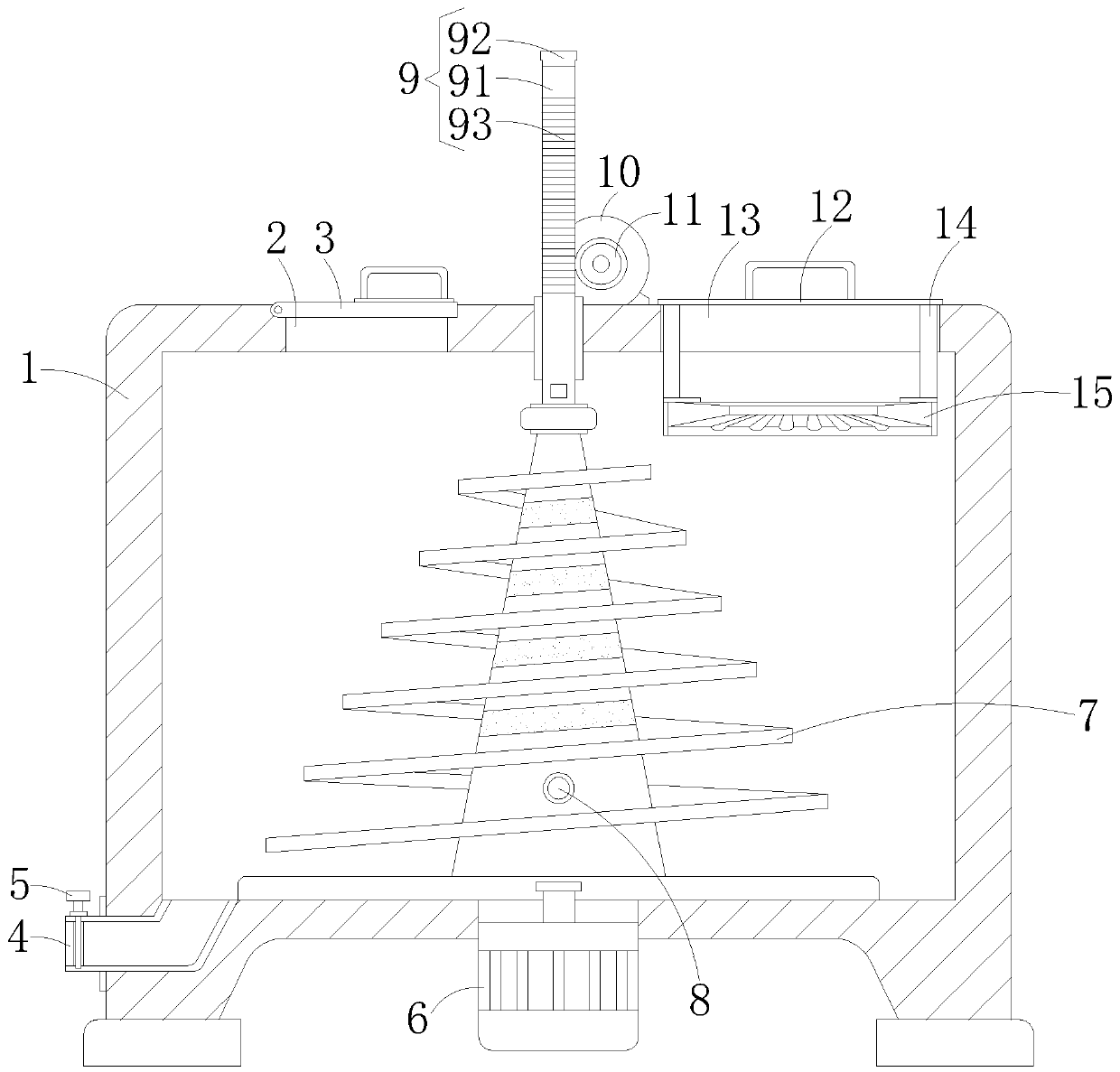

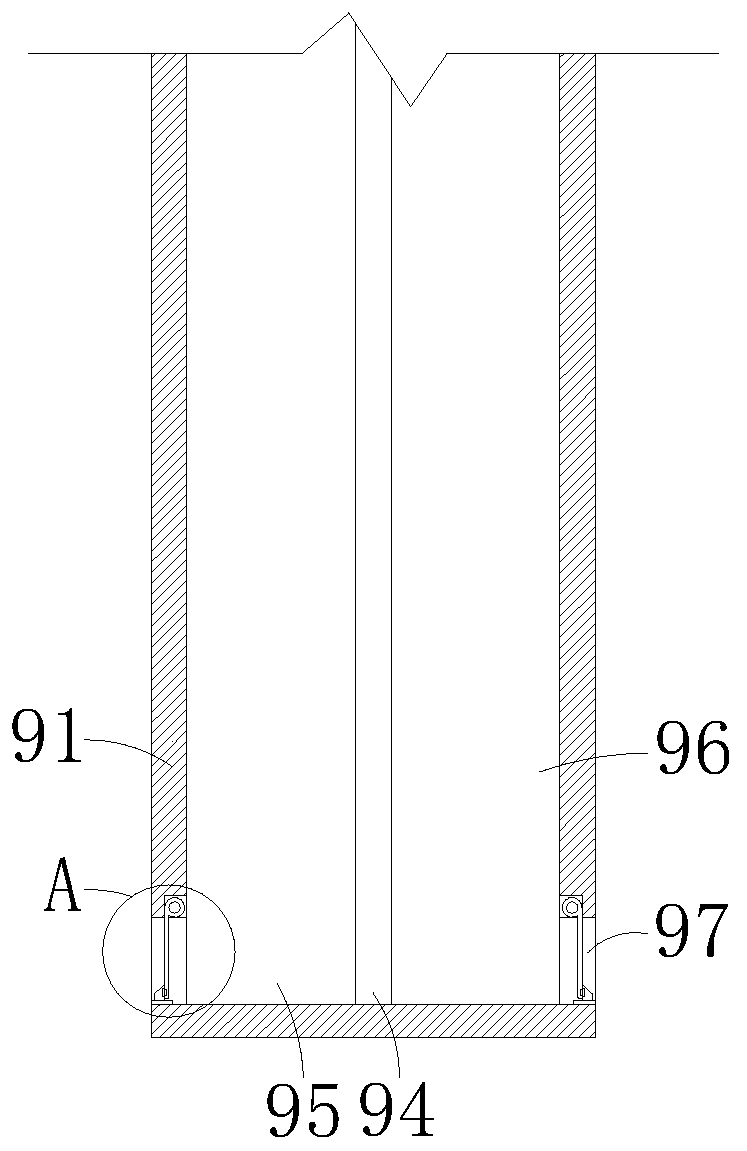

ActiveCN110396618ABurn fullyBurn quicklyCharge composition/stateCharge manipulationCombustion chamberFlue gas

The invention relates to the technical field of casting, in particular to a copper and copper alloy efficient melting method. Smelting equipment used in the casting method comprises a shell, an auxiliary structure, a feeding structure, a flue gas discharging structure, a gas inlet structure, a smelting furnace body, a partition structure and a heat preservation layer, wherein the shell for providing protection and heat preservation is internally connected with the smelting furnace body used for melting copper and copper alloy. Flue gas generated by combusting coal fuel in a combustion chamberis fully and quickly discharged through the flue gas discharging structure, so that the coal fuel is fully and quickly combusted, the partition structure fully and quickly absorbs heat, the melting efficiency of the copper in a smelting chamber is improved; and meanwhile, the flue gas discharging structure is matched with the gas inlet structure, the oxygen entering amount in the combustion chamber is reduced in the flue gas discharging process, oxygen is fully contacted with the coal fuel, the coal fuel is fully combusted while the oxygen is rapidly consumed, so that the coal utilization rateis increased, the amount of oxygen discharged along with the flue gas is reduced, and the flue gas is fully and quickly discharged while the oxygen waste is avoided.

Owner:江西盛凯铜业有限公司

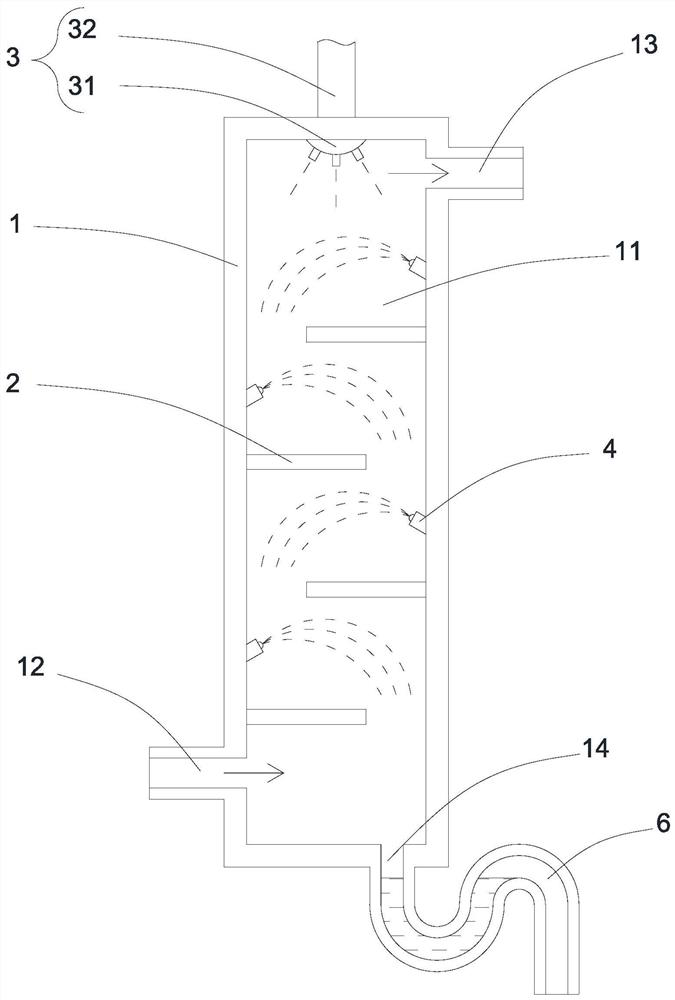

Circulating spraying type waste gas absorption tower

PendingCN113332833AExhaust gas velocity extensionIncrease contact timeDispersed particle separationExhaust fumesMechanical engineering

The invention relates to a circulating spraying type waste gas absorption tower which comprises a tower body, a baffle, a main spraying device and a secondary spraying device. An absorption cavity is formed in the tower body, and a gas inlet, a gas outlet and a liquid outlet which are communicated with the absorption cavity are formed in the tower body; the baffle is arranged in the absorption cavity and forms a gap for waste gas circulation with the inner wall of the absorption cavity; the main spraying device comprises a main spraying head arranged at the top of the absorption cavity and a liquid inlet pipe communicated with the main spraying head, and treatment liquid in the liquid inlet pipe can be sprayed into the absorption cavity from the main spraying head; the secondary spraying device comprises a liquid pumping pipe, a liquid pump and a secondary spray head, the liquid inlet end of the liquid pumping pipe is arranged on the baffle, the liquid outlet end of the liquid pumping pipe is communicated with the secondary spray head, and the liquid pump is arranged on the liquid pumping pipe. Compared with the prior art, the circulating spraying type waste gas absorption tower has the advantages that the treatment liquid falling on the baffle plate is sprayed out again through the secondary spraying device, is in contact with waste gas and absorbs harmful substances in the waste gas, so that the utilization rate of the treatment liquid is increased, and the waste gas absorption effect is improved.

Owner:JINGMEN GEM NEW MATERIAL

Partition rod with damping

PendingCN111030017ADampen breeze vibrationsSuppress Ice DancingMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsEngineeringShock absorber

The invention provides a partition rod with damping. The partition rod comprises a conducting wire clamp for clamping a conducting wire, a frame body and filling particles, wherein the conducting wireclamp is fixedly connected with the frame body, the frame body is provided with a hollow particle damping filling cavity, and the filling particles are located in the particle damping filling cavityand do not fill the particle damping filling cavity. According to the invention, by introducing a particle damping technology, the damping of a conducting wire-shock absorber system is increased, thevibration mechanical energy of a conducting wire is fully consumed, and the conducting wire and auxiliary fittings are protected.

Owner:CHINA ELECTRIC POWER RES INST +2

Formation method of lithium titanate battery

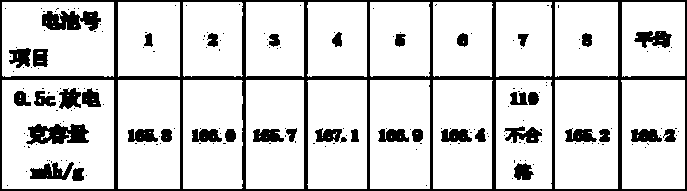

ActiveCN104409780BImprove cycle performanceGuaranteed capacityFinal product manufactureElectrolyte accumulators manufacturePower flowBattery capacity

The invention discloses a method for forming a lithium titanate battery, comprising the following steps: S1. At a first preset temperature T1, after the battery is placed on hold for a first preset time t1, the battery is kept at a first preset current I1 S2, at the first preset temperature T1, after the battery is put on hold for a third preset time t3, the battery is charged with the second preset time t3. Set the current I2 to constant current discharge to the second cut-off voltage U2, and discharge the constant voltage U2 for the fourth preset time t4; S3, at the second preset temperature T2, age the battery for the sixth preset time t6, reduce the pressure and pump and S4, repeating the steps S1-S3 for a preset number of times, and then sealing the liquid injection port of the battery. The chemical formation method of the lithium titanate battery of the present invention enables the water in the battery to be fully consumed, and the generated gas is discharged from the outside of the battery, which can ensure the battery capacity and improve the cycle performance of the lithium titanate battery.

Owner:HEBEI YINLONG NEW ENERGY +1

Overhead conductor wide-frequency-domain dynamic vibration reduction device based on electromagnetic damping technology

PendingCN113048187AImprove self-dampingReduced bending strainDevices for damping mechanical oscillationsVibration dampersMagnetic dampingMetal sheet

The invention provides an overhead conductor wide-frequency-domain dynamic vibration reduction device based on an electromagnetic damping technology. The overhead conductor wide-frequency-domain dynamic vibration reduction device comprises a hollow shell, permanent magnets and an induction metal sheet, wherein the permanent magnets and the induction metal sheet are located in the middle of the interior of the shell; one of the permanent magnets or the induction metal sheet is rigidly connected with the inner wall of the shell, and the other one of the permanent magnets or the induction metal sheet is flexibly connected with the inner wall of the shell; and under the action of vibration, the permanent magnets and the induction metal sheet perform relative displacement to generate electromagnetic damping to convert and consume the vibration mechanical energy of a conductor. While the device converts and consumes energy, the device also has the functions of improving the self-damping of the conductor, increasing the galloping threshold value of a bundle conductor, reducing the dynamic bending strain of the conductor at the outlets of suspension and strain clamps, and the like.

Owner:CHINA ELECTRIC POWER RES INST +1

Slag-corrosion-resistant high-strength furnace-melting brick for gasification melting furnace and preparation method of furnace-melting brick

PendingCN113548901AHigh compressive strengthImprove withstand voltage characteristicsClaywaresBrickSlag

The invention discloses a slag-corrosion-resistant high-strength furnace-melting brick for a gasification melting furnace and a preparation method of the furnace-melting brick. The furnace-melting brick is composed of flint clay, coagulated stone, andalusite, magnesium-rich spinel, siliceous shale, gibbsite, water-washed kaolin, alpha-Al2O3 micro powder, zinc oxide, nano carbon black, titanium dioxide, yttrium oxalate, a sintering aid, a composite water reducing agent, a binding agent and purified water. The preparation method comprises the steps: pretreatment: crushing and mixing the raw materials respectively; pressing and forming: putting the pretreated material into a brick making machine mold, pressing into a wet blank, and curing; and roasting: roasting the wet blank in a tunnel roasting kiln to obtain a finished product of the high-strength furnace-melting brick. The process is reasonable in design, and the high-strength furnace-melting brick prepared through the method has high slag corrosion resistance and structural strength and is suitable for large-scale popularization.

Owner:宜兴市海科窑炉工程有限公司

Method for preparing calcium chloride through carbide slag and hydrochloric acid

InactiveCN103303957BReduce Calcium Chloride ContentIncrease profitCalcium/strontium/barium chloridesPhysical chemistryChloride

Owner:SICHUAN PROVINCE JINLU RESIN

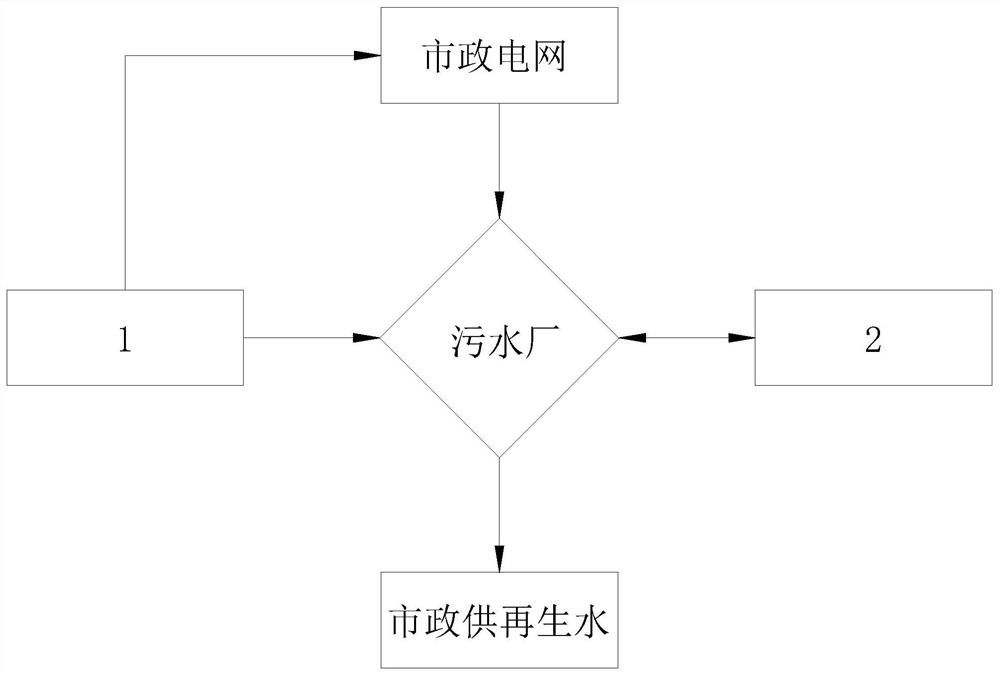

Renewable energy comprehensive utilization system of sewage plant

PendingCN111817340AFully consumedReduce consumptionLighting and heating apparatusSingle network parallel feeding arrangementsMunicipal sewagePhotovoltaic electricity

The invention discloses a renewable energy comprehensive utilization system of a sewage plant. The system comprises a photovoltaic power generation system and a sewage heat source heating and refrigerating system, the photovoltaic power generation system supplies power to sewage treatment, the sewage heat source heating and refrigerating system and a municipal power grid, and the sewage heat source heating and refrigerating system supplies cold and heat sources to a sewage plant. According to the invention, the solar energy of a sewage plant and the waste heat of municipal sewage are fully utilized; according to the electric energy consumption and photovoltaic power generation characteristics of a sewage plant, a photovoltaic power generation installed capacity optimal model is established, solar energy is fully utilized, the electric energy consumption of the sewage plant is reduced, meanwhile, the construction cost of photovoltaic equipment is saved, and environmental pollution caused by coal-fired power generation is reduced. Meanwhile, the seasonal temperature change characteristic of municipal sewage is utilized, the sewage supplies cold and heat to the sewage plant, energy consumption of the sewage plant is further reduced, and renewable energy sources of the sewage plant are fully utilized.

Owner:HUADIAN WATER TECH CO LTD +1

Penicillin fermentation liquid continuous culture method

ActiveCN108796024ARaise the fermentation unitTake advantage ofMicroorganism based processesFermentationWastewaterFermentation broth

The invention provides a penicillin fermentation liquid continuous culture method, which comprises the following steps of (a) setting a primary, secondary, tertiary and fourth fermentation tanks; (b)bringing and putting excessive fermentation liquid being 20 thousand to 50 thousand mu / mL in a normal fermentation tank into the primary fermentation tank to be cultured in a sterile way; (c) bringingand putting excessive fermentation liquid being 50 thousand to 80 thousand mu / mL in the normal fermentation tank and fermentation liquid being 50 thousand to 80 thousand mu / mL in the primary fermentation tank into the secondary fermentation tank to be cultured in a sterile way; (d) bringing and putting excessive fermentation liquid being 80 thousand to 110 thousand mu / mL in the normal fermentation tank and fermentation liquid being 80 thousand to 110 thousand mu / mL in the secondary fermentation tank into the tertiary fermentation tank to be cultured in a sterile way; (e) bringing and puttingexcessive fermentation liquid being greater than 110 thousand mu / mL in the normal fermentation tank and fermentation liquid being greater than 110 thousand mu / mL in the tertiary fermentation tank intothe fourth fermentation tank to be cultured in a sterile way; (f) performing filtering after the culture on the fermentation liquid in the fourth fermentation tank. The fermentation unit of the penicillin bringing and putting fermentation liquid is greatly improved; the COD concentration in the fermentation waste water is obviously reduced; the environmental-friendly cost is reduced.

Owner:NORTH CHINA PHARMA COMPANY

A kind of assembly method of button type lithium ion battery

ActiveCN103618112BImprove pass rateImprove consistencyFinal product manufactureCylindrical casing cells/batteryMaterial consumptionPass rate

The invention discloses an assembly method of a button-type lithium-ion battery. The positive electrode battery case of the button battery is placed flat on the copper plate of the resistance welding machine, the positive electrode sheet is placed in the center of the positive electrode battery case, and then the resistance welding machine is adjusted. Voltage, the tip of the carbon rod is welded to the positive battery case on the edge of the positive electrode sheet, so that the positive electrode sheet can be firmly in contact with the positive electrode battery case and the position is not easy to change, so that the assembled battery has a high pass rate, and the battery The consistency of performance has been significantly improved, reflecting the original basic electrochemical performance of the positive electrode material, and can make full use of the positive electrode material; the present invention is a qualitative leap in mass production as a whole, which improves the pass rate of button batteries , Material consumption is reduced, battery performance is improved, which effectively reduces the production cost of the enterprise, improves the product quality, and increases the enterprise benefit.

Owner:HENAN FUSEN NEW ENERGY TECH

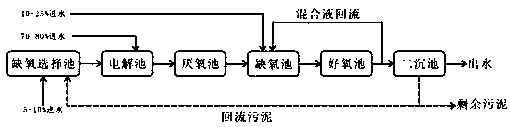

Sewage denitrification and dephosphorization device and process based on improved AAO

ActiveCN110217939AReduce or eliminate the impact of the anaerobic phosphorus release processReduce or eliminate the impactWater contaminantsWater/sewage treatmentSludgeWater quality

The invention relates to a sewage denitrification and dephosphorization device and process based on improved AAO. The device includes an anoxic selective tank, an electrolytic tank, an anaerobic tank,an anoxic tank, an aerobic tank and a secondary settling tank which are arranged in order along the sewage flowing direction. An operation mode of feeding water at multiple points of the anoxic selective tank, the electrolytic tank and the anoxic tank is achieved. Before returned sludge is returned to the anaerobic tank, the anoxic selective tank is additionally arranged, thus reducing or eliminating influences of nitrates on anaerobic phosphorus releasing. The electrolytic tank is additionally arranged on a water feeding pipeline of the anaerobic tank, and the residence time is generally controlled within half an hour, and therefore, on the one hand, dissolved oxygen in the sewage can be consumed while preserving sufficient carbon sources, ensuring that the sewage entering the anaerobictank meets anaerobic conditions; and on the other hand, a situation that the sewage in the anaerobic tank is influenced by a low pH and further effective phosphorus release of phosphorus-accumulatingbacteria, nitrification of nitrifying bacteria and denitrifying denitrification of denitrifying bacteria are influenced can be avoided. Quality indicators of discharged water by the device and the process all meet and exceed the national emission standard level A standard in China.

Owner:皇宝(福建)环保工程投资有限公司

Assembling method of button-type lithium ion battery

ActiveCN103618112AImprove pass rateImprove consistencyFinal product manufactureCylindrical casing cells/batteryButton batteryLithium-ion battery

The invention discloses an assembling method of a button-type lithium ion battery. The assembling method comprises the following steps of horizontally placing a button battery positive electrode battery shell on a copper plate of a resistance welding machine, placing a positive plate right in the center of the positive electrode battery shell, then adjusting the voltage of the resistance welding machine, welding a sharp part of a carbon rod onto the positive battery shell on the edge of the positive plate, enabling the positive plate to be firmly contacted with the positive electrode battery shell, and enabling the position of the positive plate not to be easily changed. An assembled battery has high qualification rate, the consistency of the battery performance can be obviously improved, the original basic electrochemical performance of the positive electrode material can be reflected, and the positive electrode material can be adequately utilized. By adopting the assembling method, the mass production can be integrally improved, the qualification rate of the button battery can be increased, the consumption of materials can be reduced, the battery performance can be improved, the production cost of enterprises can be effectively reduced, the product quality can be improved, and the corporate benefit can be increased.

Owner:HENAN FUSEN NEW ENERGY TECH

Lithium porcelain stone tailings defluorination device based on solvent flotation method

The invention discloses a lithium porcelain stone tailings defluorination device based on a solvent flotation method, which relates to the technical field of lithium porcelain stone processing. The lithium porcelain stone tailings defluorination device based on a solvent flotation method comprises a body, a driving motor, an accelerating mechanism, a one-way valve, a feeding mechanism, a rotatingmotor, a gear, a cover plate, a port, a connecting rod and a collecting mechanism, wherein the driving motor is fixedly installed in the middle part of the bottom of the body, and the output shaft ofthe driving motor penetrates the middle part of the bottom of the body and is fixedly connected with the middle part of the bottom of the accelerating mechanism. The lithium porcelain stone tailings defluorination device based on a solvent flotation method uses a rotating spiral plate surface to drive the boric acid in the falling process to rotate spirally upwards and float, thus achieving the effect of promoting the full reaction between the boric acid and the solvent. At the same time, when the accelerating mechanism rotates counterclockwise, the solvent in the body also rotates counterclockwise, and the collecting mechanism cooperates with the collecting mechanism to effectively collect the flotation substance of the liquid surface.

Owner:李异洪

Method for demagging from phosphate ore

Owner:YUNNAN CHEM RES INST

L-shaped lithium ion battery and formation method thereof

InactiveCN108899600AIncrease in sizeIncrease capacitySecondary cells charging/dischargingEngineeringLithium-ion battery

The invention provides an L-shaped lithium ion battery and a formation method thereof. The battery comprises a battery cell, a shell coating outside the battery cell and an electrolyte filled in the shell, wherein the battery cell is manufactured by means of a laminating process and comprises an L-shaped positive plate, an L-shaped negative plate and an L-shaped diaphragm arranged between the L-shaped positive plate and the L-shaped negative plate. According to the L-shaped lithium ion battery and the formation method thereof provided by the invention, on the one hand, the capacity of the battery is increased effectively, so that the time of endurance is prolonged and the capacity of endurance of the battery is ensured; and on the other hand, the inflating problem of the battery is solvedthoroughly, so that the performance of the battery in a follow-up using process is ensured.

Owner:CHINA ELECTRIC POWER RES INST +1

A kind of copper and copper alloy high-efficiency melting and casting method

ActiveCN110396618BBurn fullyBurn quicklyCharge composition/stateCharge manipulationCombustion chamberInsulation layer

The invention relates to the technical field of melting and casting, in particular to a high-efficiency melting and casting method for copper and copper alloys. The melting equipment used in the method includes a shell, an auxiliary structure, a feeding structure, a smoke exhaust structure, an air intake structure, and a melting furnace body , a partition structure and an insulation layer, the shell for providing protection and insulation is connected to the body of the smelting furnace for melting copper and copper alloys; the flue gas produced by burning the coal fuel in the combustion chamber through the smoke exhaust structure Sufficient and rapid discharge, so that the coal fuel can be fully and quickly burned, so that the partition structure can fully and quickly absorb heat, and improve the melting efficiency of copper inside the smelting chamber. Oxygen intake, so that oxygen can fully contact with coal fuel, so that coal fuel can be fully burned while oxygen is consumed quickly, improve the utilization rate of coal, reduce the amount of oxygen that is discharged together with flue gas, and make flue gas fully while avoiding oxygen waste was quickly expelled.

Owner:江西盛凯铜业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com