Circulating spraying type waste gas absorption tower

A technology of circulating spraying and absorption towers, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of insufficient utilization of treatment liquid, etc., and achieve the effect of prolonging the exhaust gas velocity and prolonging the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

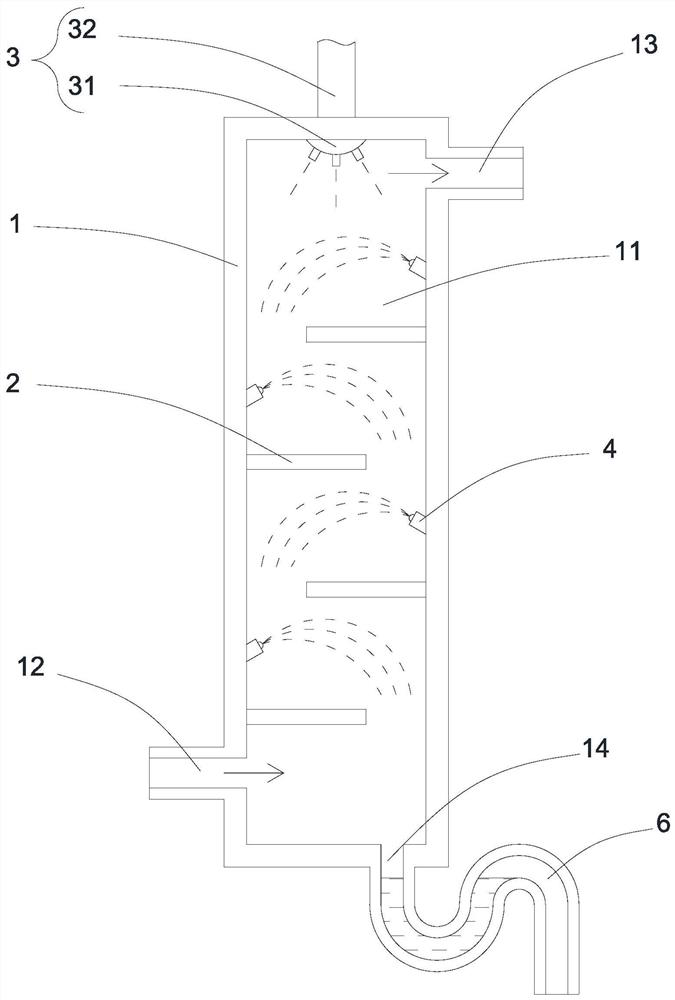

[0022] See Figure 1 to Figure 3 , The circulating spray waste gas absorption tower includes a tower body 1, a baffle plate 2, a main spray device 3 and a secondary spray device 4.

[0023] An absorption chamber 11 is formed inside the tower body 1, and an air inlet 12, an air outlet 13, and a liquid discharge port 14 communicating with the absorption chamber 11 are opened on the tower body 1. The exhaust gas enters the absorption chamber 11 from the air inlet 12, and the The treatment liquid in the absorption chamber 11 is discharged from the gas outlet 13 after being treated, and the used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com