Forming method of lithium titanate battery

A technology of lithium titanate battery and formation method, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, climate sustainability, etc., can solve the problems of reduced energy density, uneven dispersion, unfavorable practical applications, etc., and achieve improved cycle performance , Guarantee the effect of battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Lithium nickel cobalt manganese oxide is used as the positive electrode material, and lithium titanate is used as the negative electrode material.

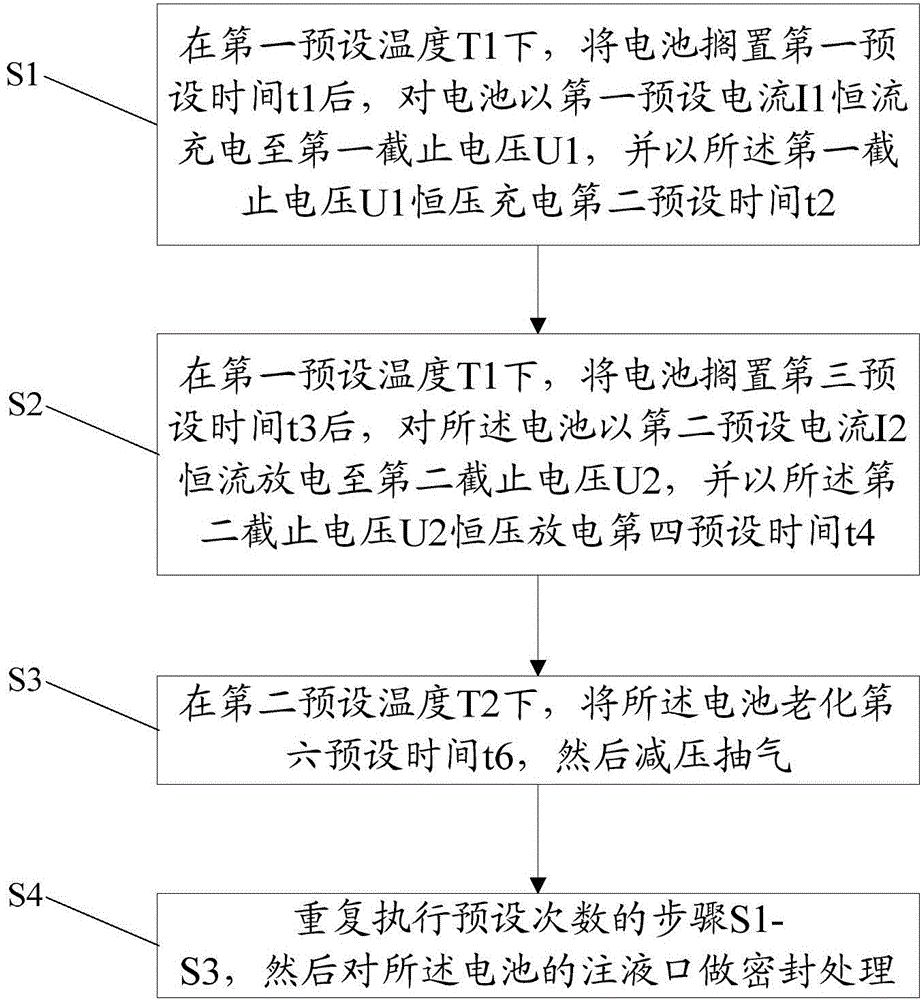

[0052] Place the battery in the formation cabinet for formation, adjust the temperature to 60°C, let it stand at a constant temperature for 5 minutes, then charge it with a constant current of 0.2C to 2.6V, then charge it with a constant voltage for 4 hours, let it stand for 10 minutes, and charge it with a constant current of 0.2C to 2.6V. Current discharge to 1.4V, then discharge at constant voltage for 4h, stand still for 10min, then age at high temperature 30℃ for 20h, decompress and exhaust, cycle 2 times; keep at constant temperature for 5min, then charge to 2.9V with a constant current of 1C, and then Charge at constant voltage for 2 hours, let it stand for 5 minutes, discharge at constant current of 1C to 1.7V, discharge at constant voltage for 2 hours, age at 30°C for 10 hours, depressurize and exhaust, cycle 3 time...

Embodiment 2

[0054] Lithium nickel cobalt manganese oxide is used as the positive electrode material, and lithium titanate is used as the negative electrode material.

[0055] Place the battery in the formation cabinet for formation, adjust the temperature to 80°C, let it stand at a constant temperature for 1 hour, then charge it with a constant current of 1C to 2.9V, then charge it with a constant voltage for 2 hours, let it stand for 10 minutes, and discharge it with a constant current of 1C To 1.7V, then constant voltage discharge for 2h, high temperature 40°C aging for 10h, decompression and exhaust, cycle 4 times, seal, activation is complete.

Embodiment 3

[0057] Lithium nickel cobalt manganese oxide is used as the positive electrode material, and lithium titanate is used as the negative electrode material.

[0058] Place the battery in the formation cabinet for formation, adjust the temperature to 120°C, keep it at a constant temperature for 2 hours, then charge it at a constant current of 1C to 2.9V, then charge it at a constant voltage for 2 hours, let it stand for 1 hour, and discharge it at a constant current of 2C To 1.7V, then constant voltage discharge for 4h, high temperature 60°C aging for 4h, decompression and exhaust, cycle 3 times, seal, activation is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com