Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Fine pore size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

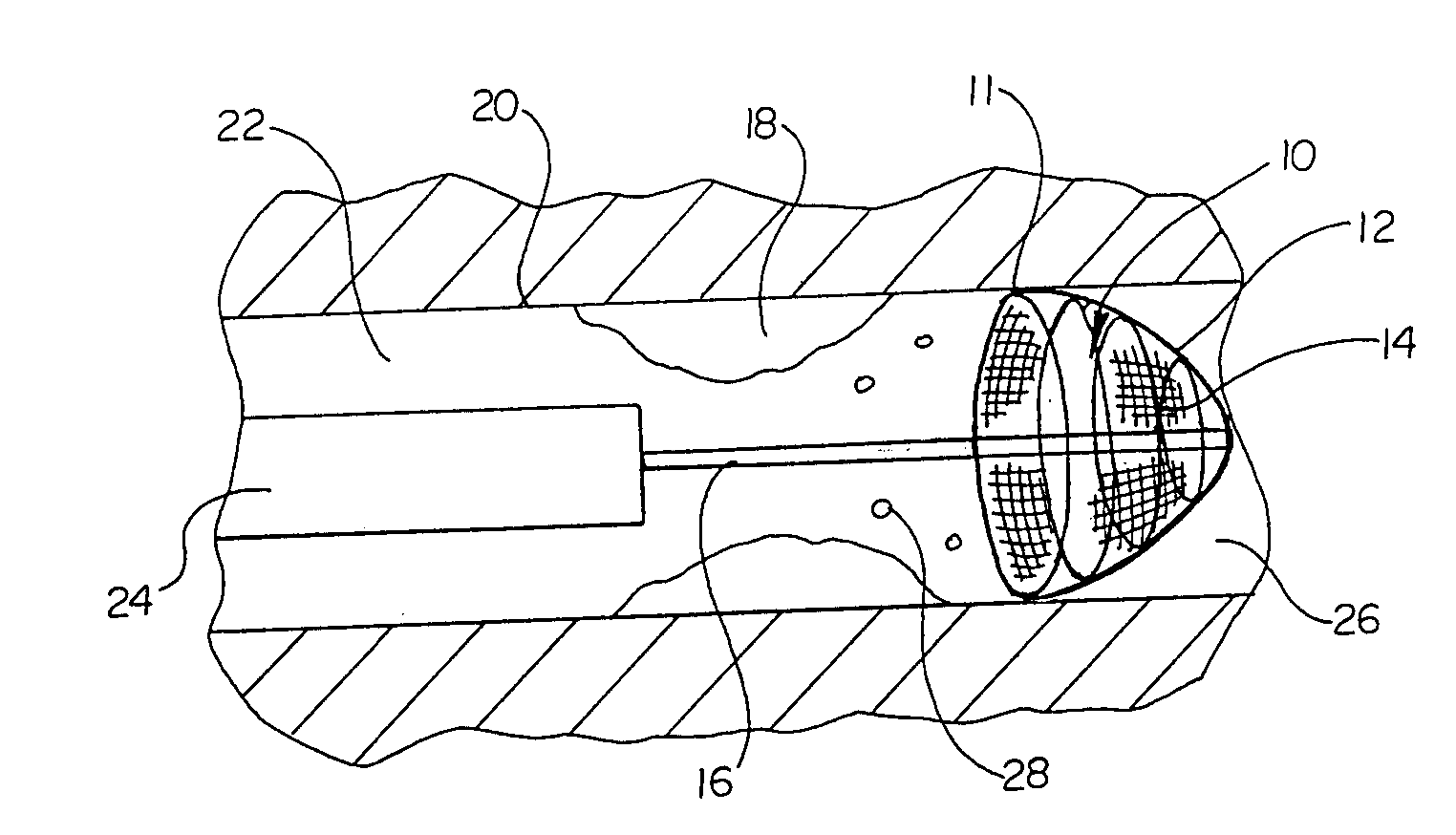

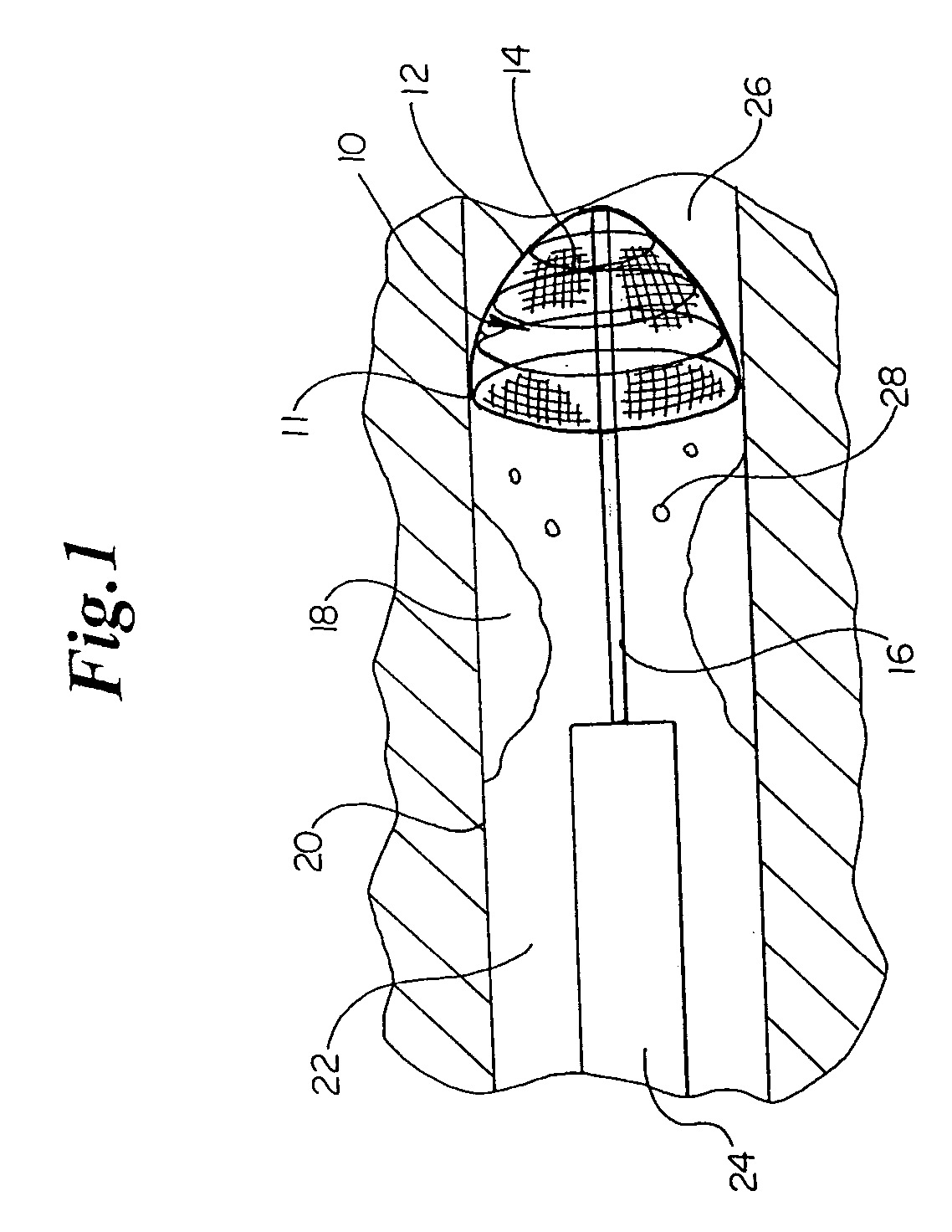

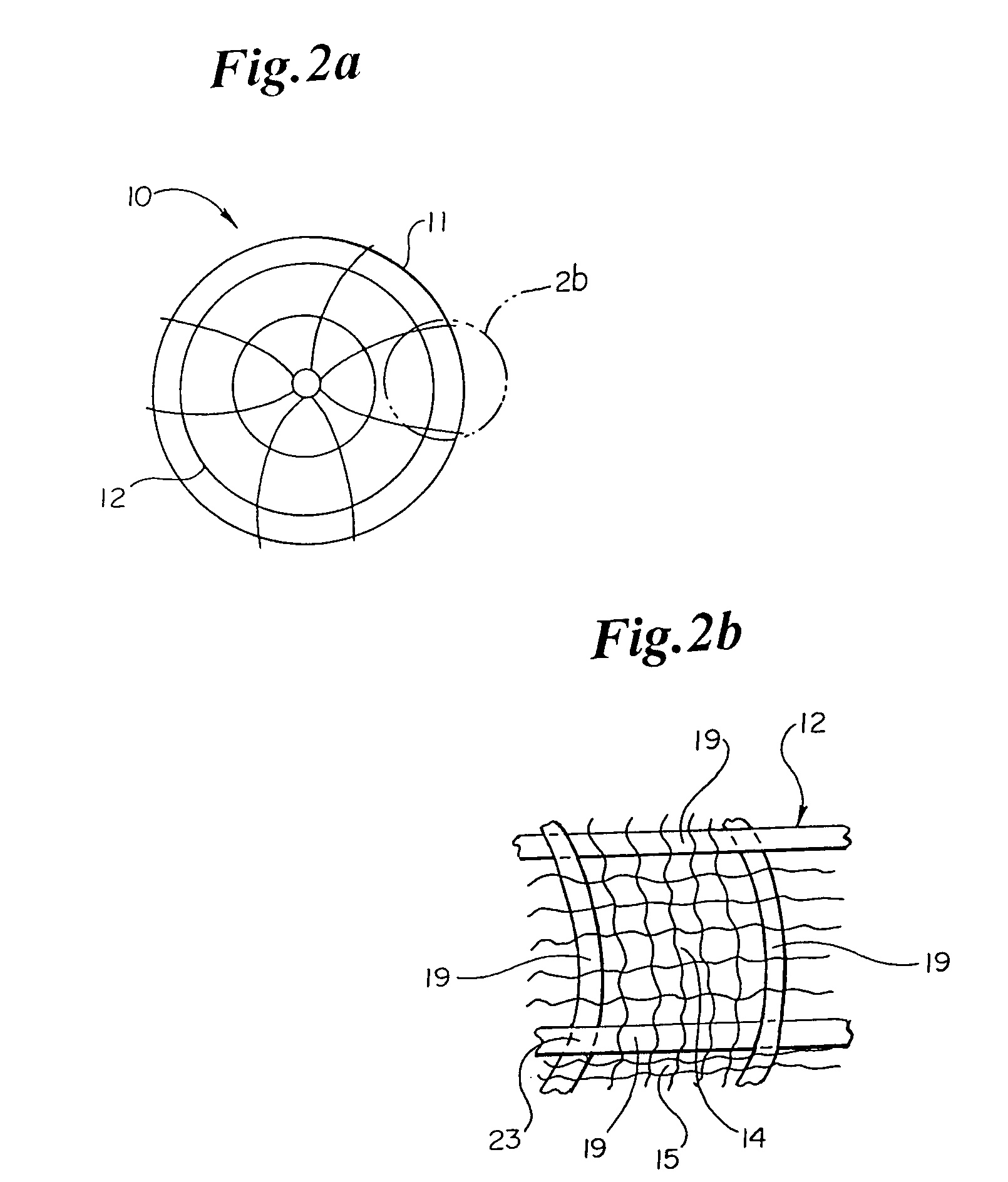

Distal protection device with electrospun polymer fiber matrix

The present invention relates to a protection device for use in a lumen of a patient's body. The protection device has a fiber matrix electrospun about an expandable and collapsible wire frame. In the collapsed configuration the protection device may be advanced within a lumen. In the expanded configuration, the protection device is able to engage the walls of the lumen wherein, the fiber matrix forms a plurality of pores for preventing the passage of particulate material and allow fluid to flow through.

Owner:EV3

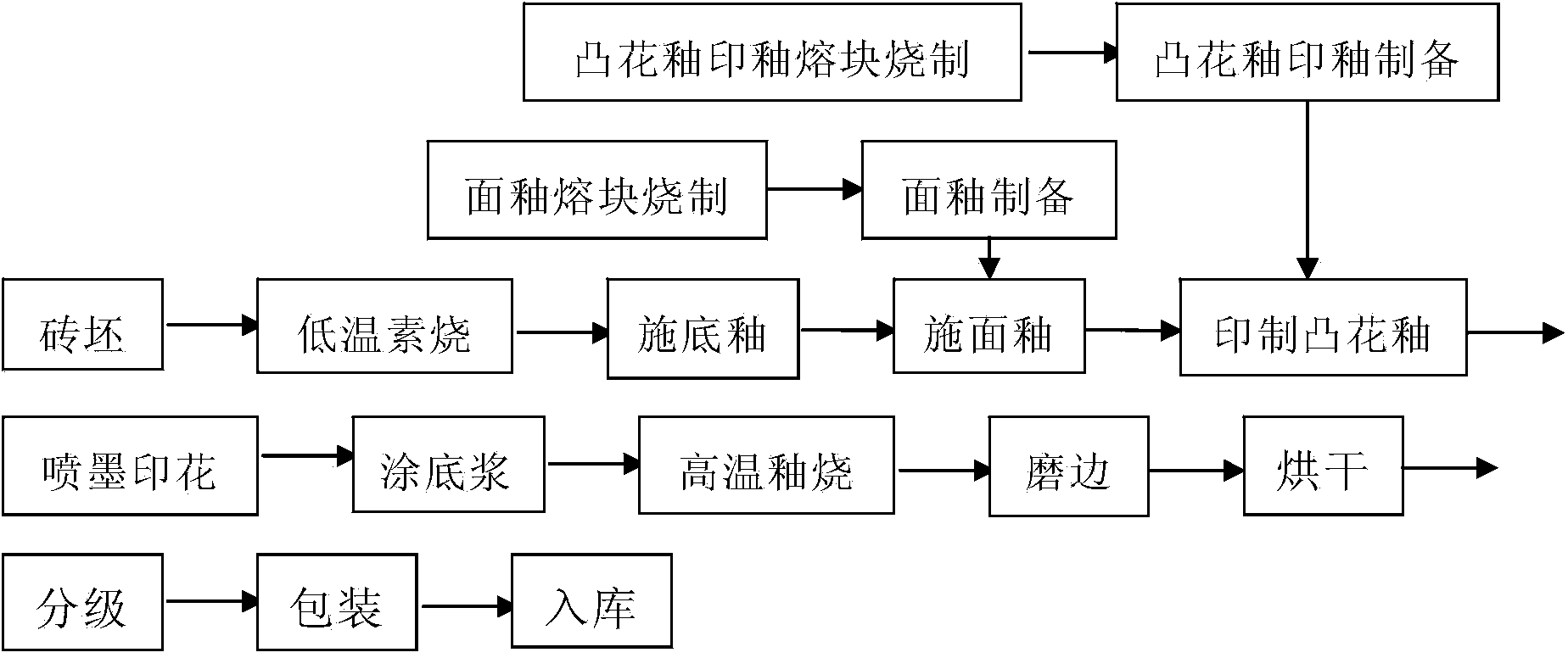

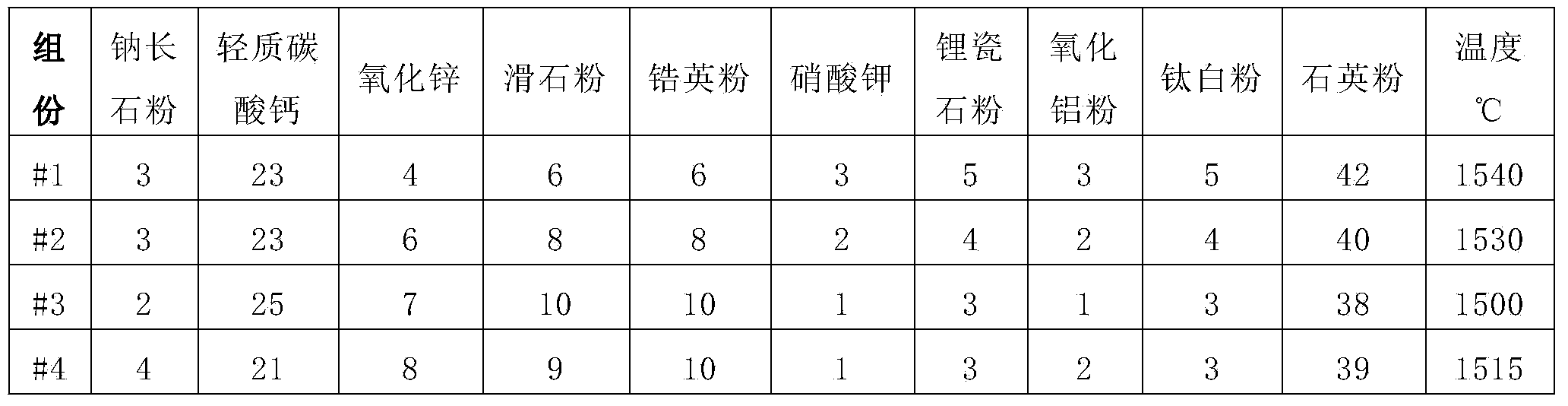

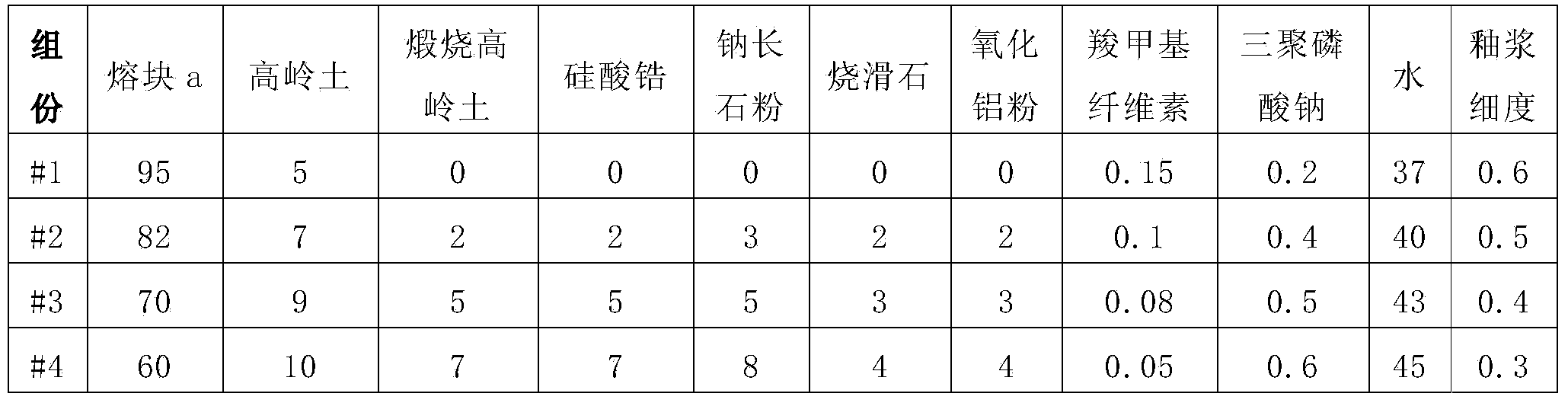

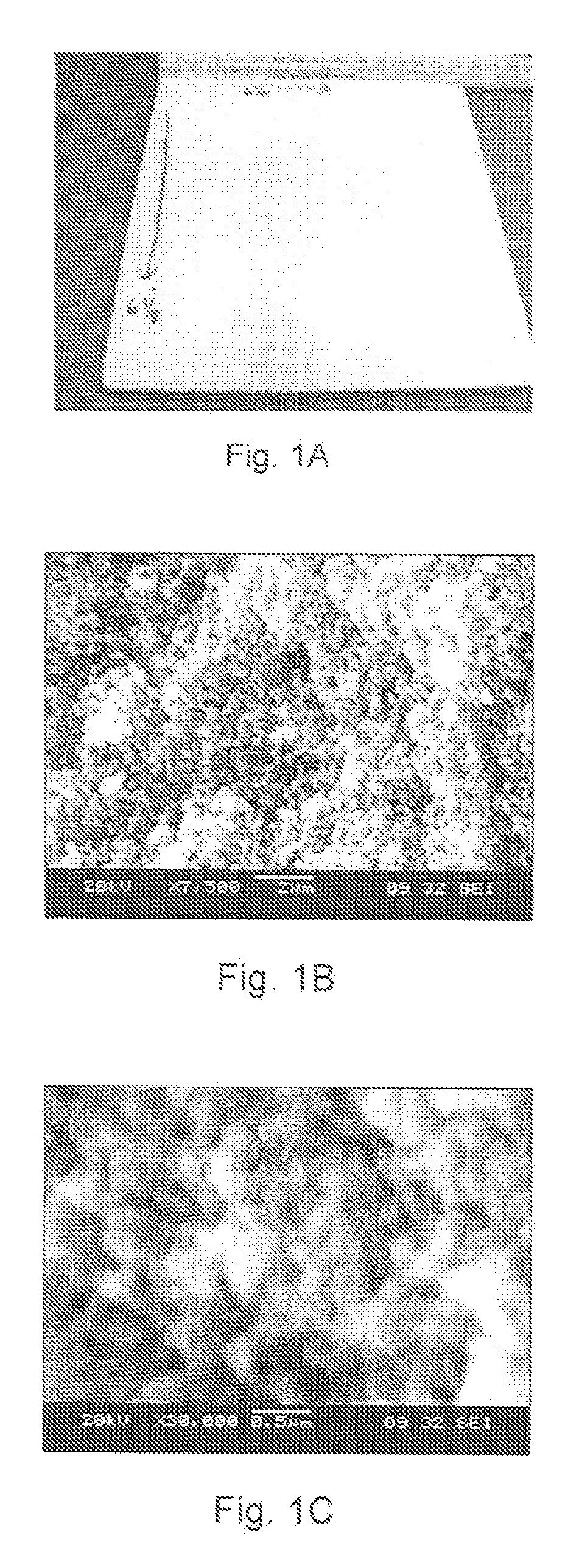

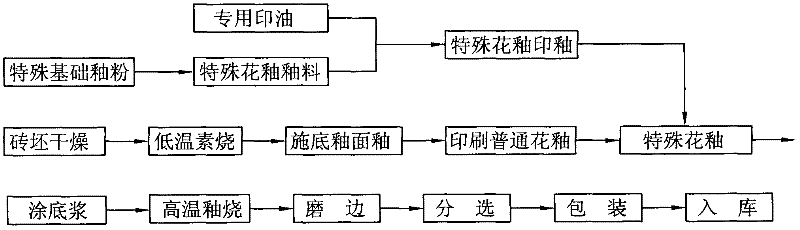

Glazed tile with wallpaper or bark-shaped surface and concave and convex effect and preparation method

The invention discloses glazed tile with wallpaper or bark-shaped surface and concave and convex effect and a preparation method. According to the invention, a product which is a glazed tile with wallpaper or bark-shaped surface and concave and convex effect is obtained by optimizing the composition of an overglaze frit and an overglaze formula, as well as the composition of a convex fancy glaze printed glaze frit and a convex fancy glaze printed glaze formula, printing the convex fancy glaze printed glaze on a green body coated with underglaze and overglaze through a special rubber roller or screen printing plate, and then enabling patterns of convex fancy glaze to keep original printing appearance after being fired at a high temperature and protrude on the surface of inkjet patterns through inkjet printing and high-temperature firing. Further, by mixing with optimized ceramic rubber roller printing ink, through the special rubber roller with optimized design or the screen printing plate with optimized mesh count, the surface gloss of the obtained glazed tile with wallpaper or bark-shaped surface and concave and convex effect is 15-40, the convex fancy glaze has good performance, the protruding height is greater than or equal to 0.8mm, and the convex fancy glaze does not adsorb pollution, so that the decorative patterns formed by inkjet printing are not damaged, and the disadvantage of single decoration style of an existing glazed tile is overcome.

Owner:GUANGDONG WINTO CERAMICS +3

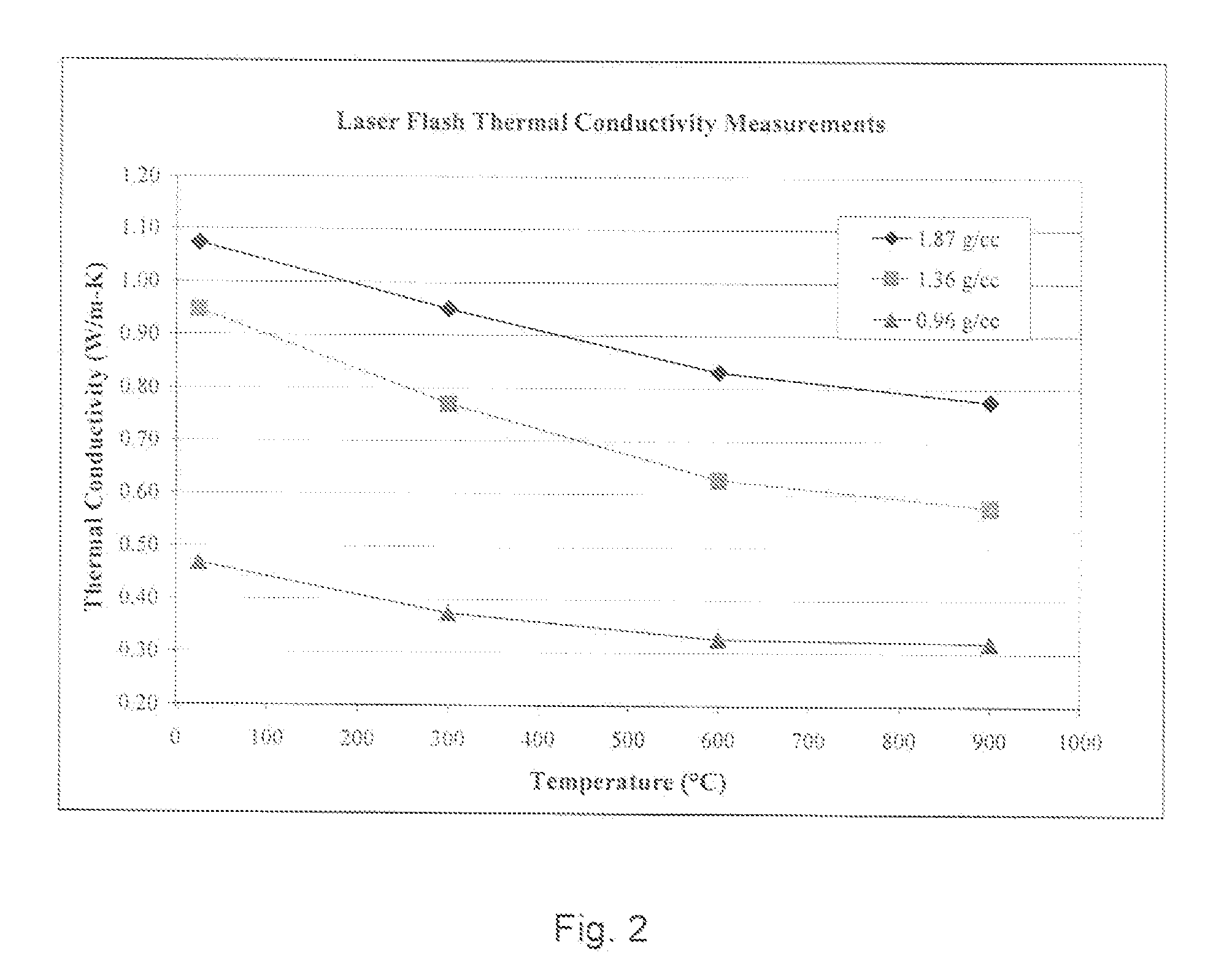

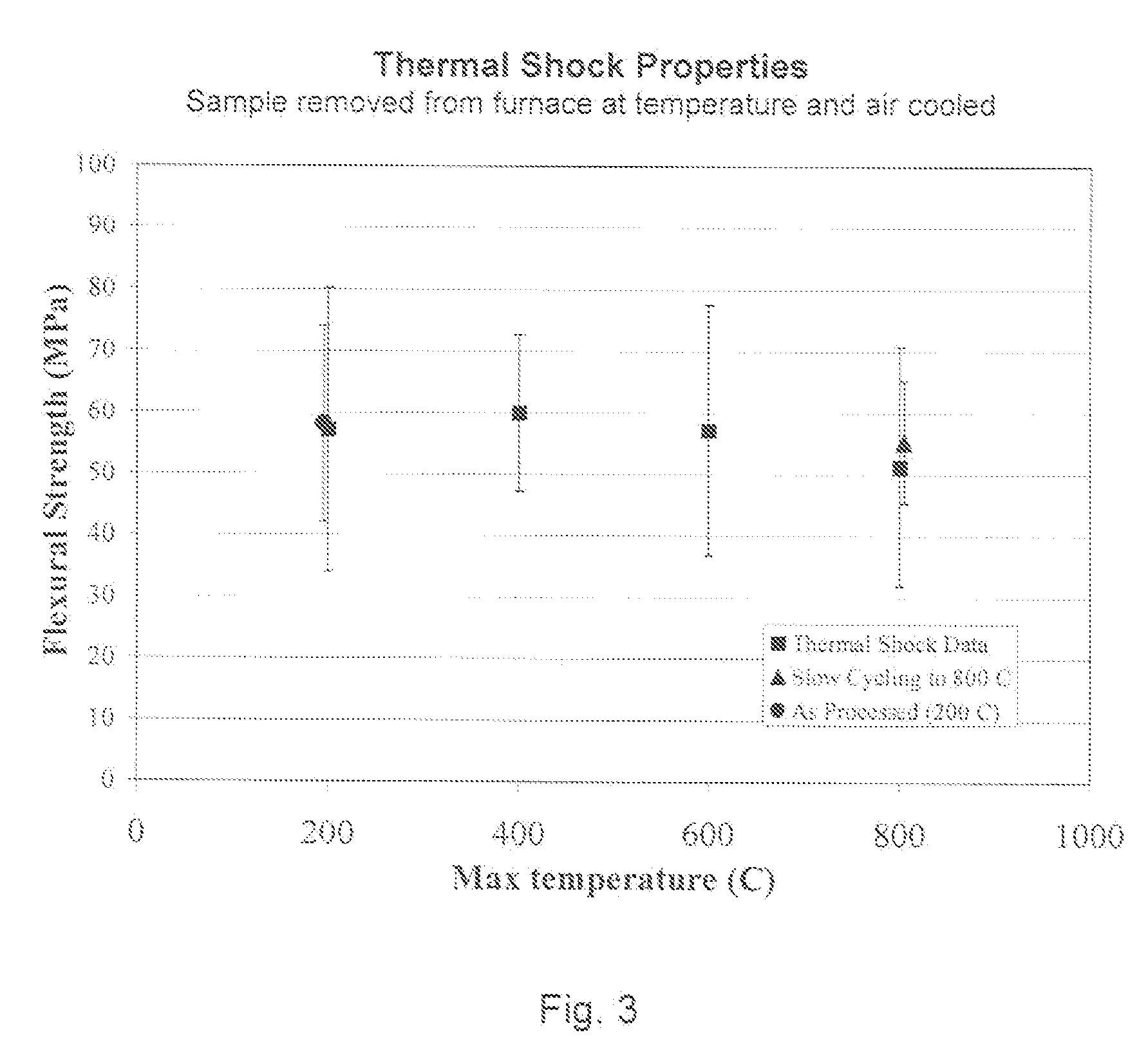

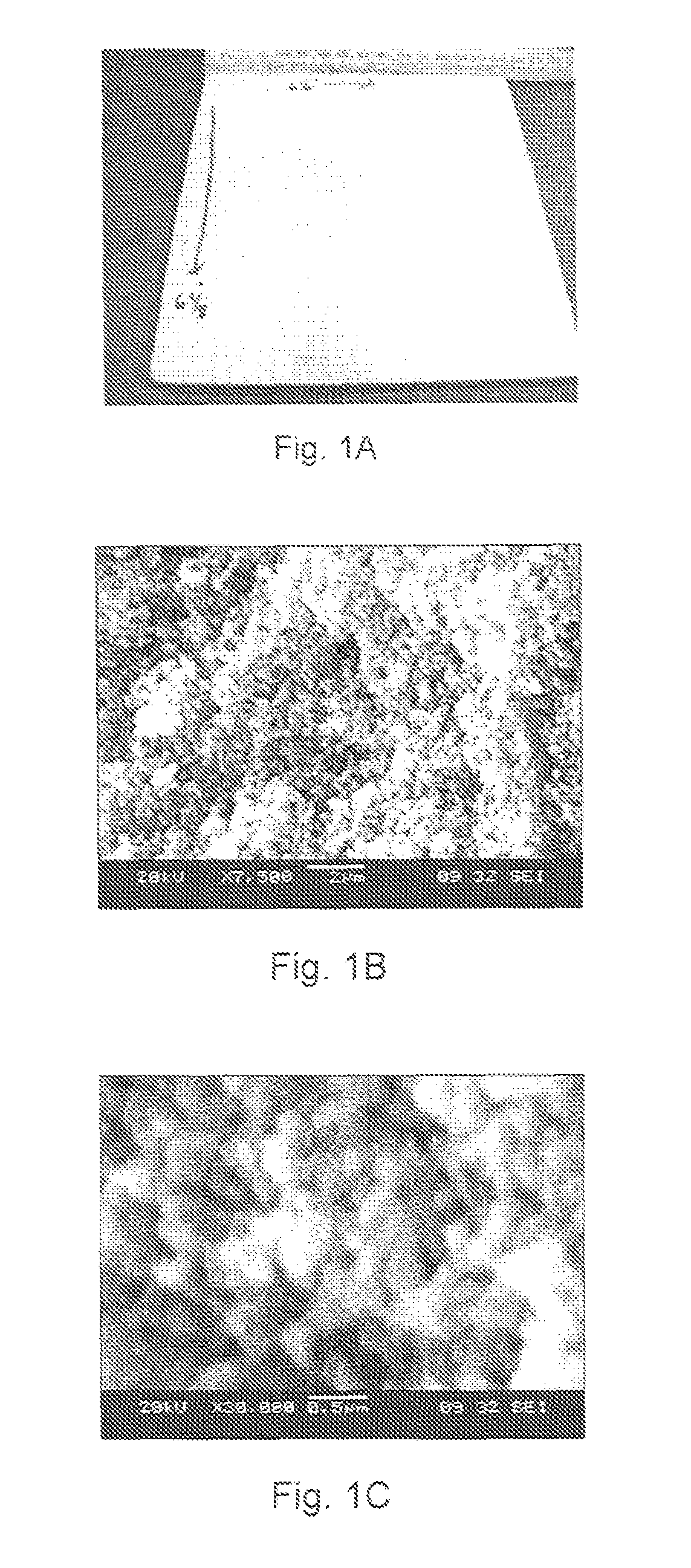

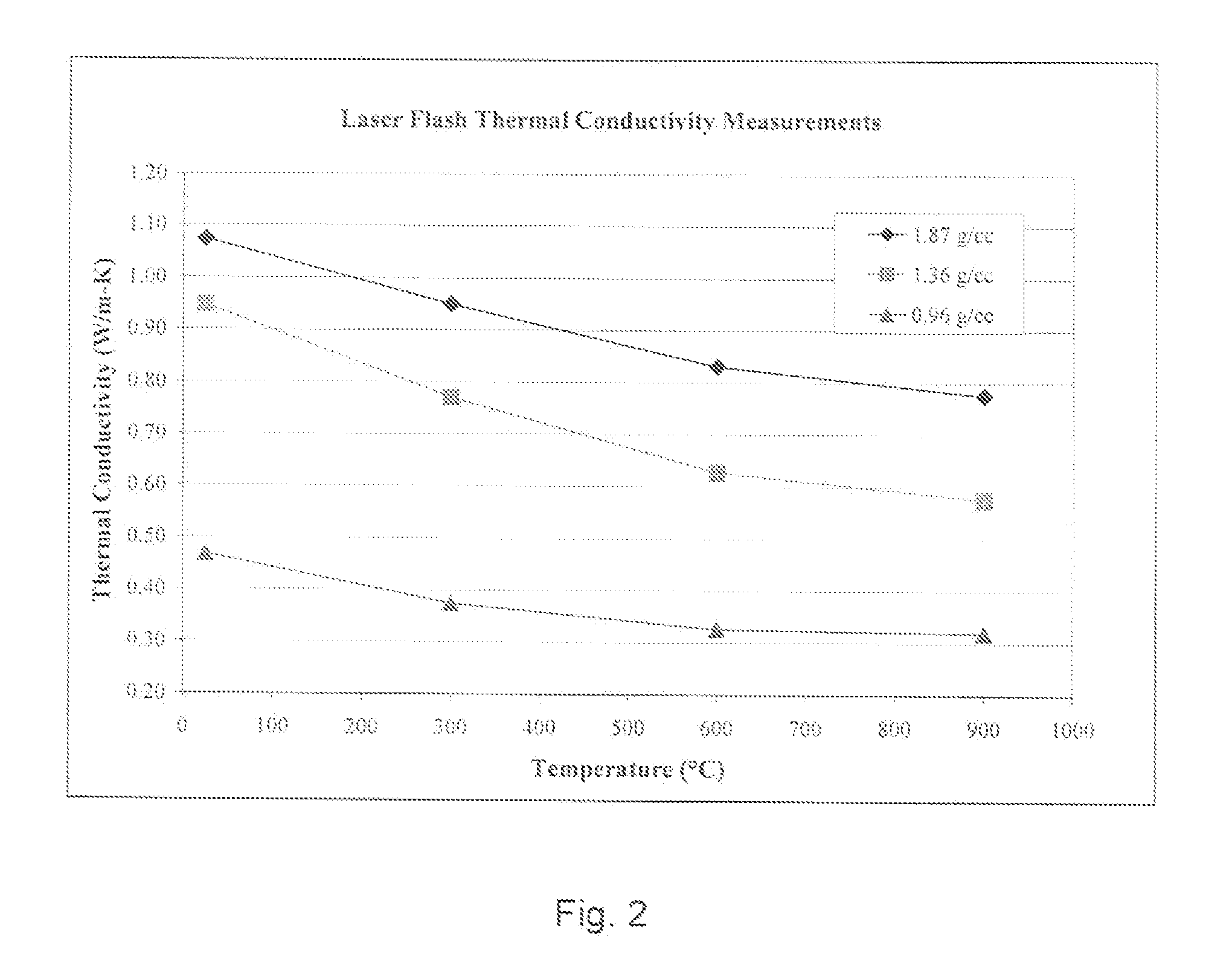

Process for making ceramic insulation

InactiveUS20090295045A1Low costImprove performanceFinal product manufactureCeramic shaping apparatusPorosityFuel cells

A method is provided for producing insulation materials and insulation for high temperature applications using novel castable and powder-based ceramics. The ceramic components produced using the proposed process offers (i) a fine porosity (from nano-to micro scale); (ii) a superior strength-to-weight ratio; and (iii) flexibility in designing multilayered features offering multifunctionality which will increase the service lifetime of insulation and refractory components used in the solid oxide fuel cell, direct carbon fuel cell, furnace, metal melting, glass, chemical, paper / pulp, automobile, industrial heating, coal, and power generation industries. Further, the ceramic components made using this method may have net-shape and / or net-size advantages with minimum post machining requirements.

Owner:CERAMTEC

Nonwoven fabric sheet and method for producing same

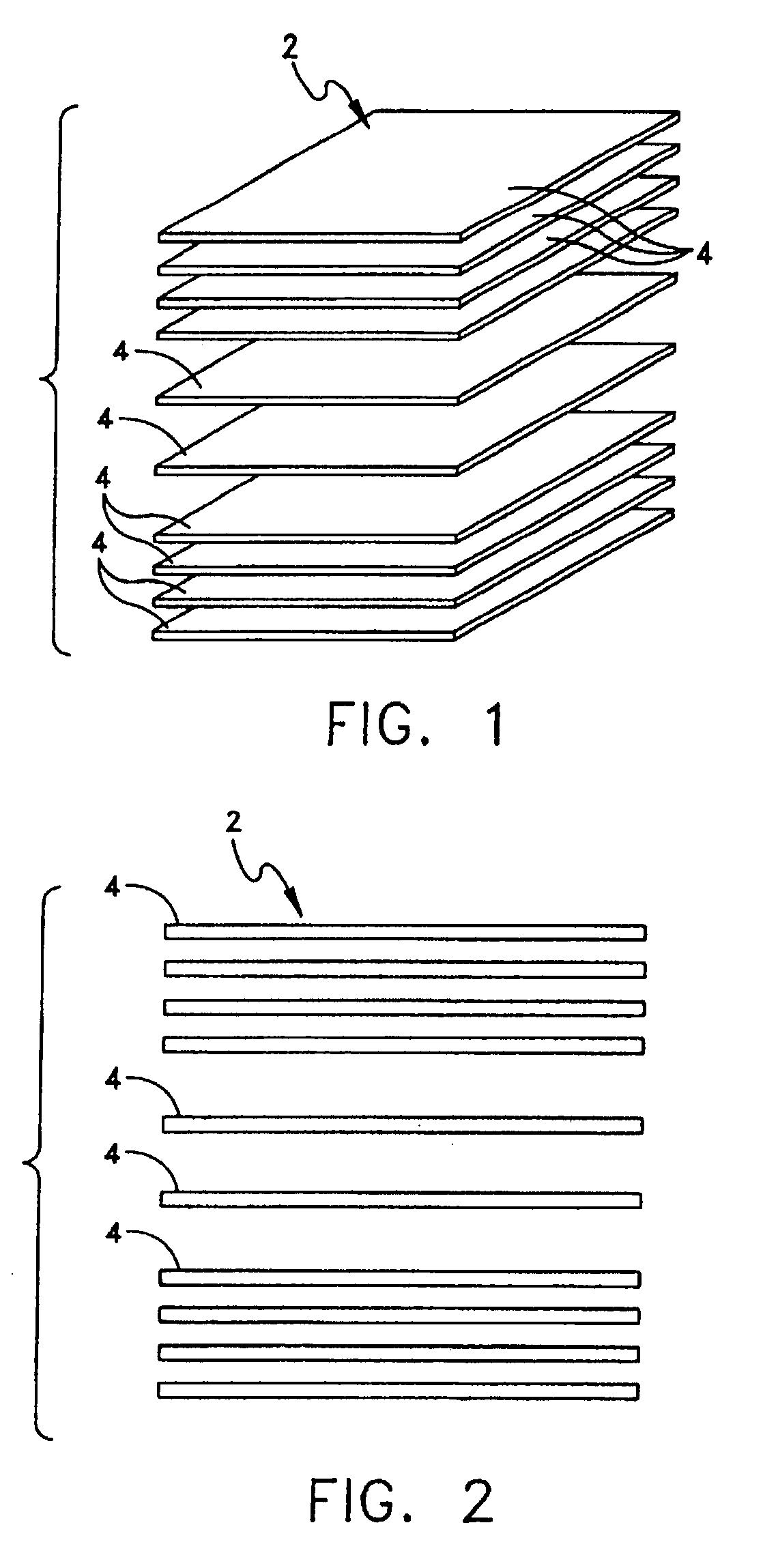

InactiveUS20070184256A1High porosityUniform pore size distributionLayered productsCeramic shaping apparatusPorosityPolymer science

The nonwoven fabric sheet of the present invention is characterized by a porosity in the range of 0.3 to 0.7 and an average pore size in the range of 0.5 μm to 5.0 μm. The nonwoven fabric sheet of the present invention preferably has a maximum pore size (μm) / average pore size (μm) ratio of 1.30 or lower. The nonwoven fabric sheet of the present invention is obtained by press-molding a nonwoven fabric at a temperature lower than the melting point of the thermoplastic resin which constitutes the nonwoven fabric sheet. According to the present invention, there is provided a nonwoven fabric sheet that has a high porosity, small uniform pore sizes and excellent productivity, which can suitably be used in various applications such as filters, light diffusing material, liquid absorber and heat insulating materials; and a method for producing the nonwoven fabric sheet.

Owner:MITSUI CHEM INC

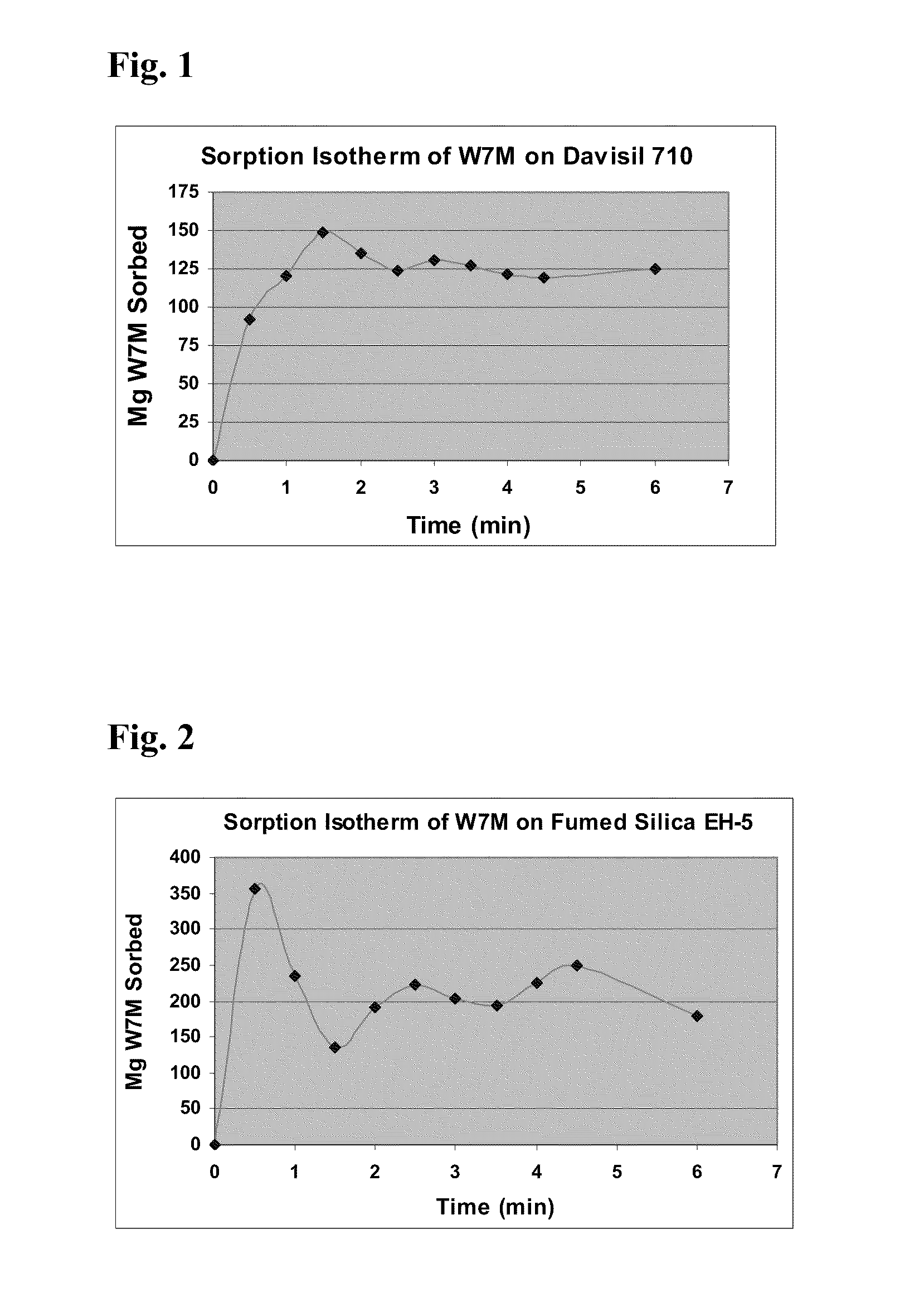

Packaging Material Such as Film, Fiber, Woven and Nonwoven Fabric with Adsorbancy

ActiveUS20110072967A1Promote absorptionReduce charge effectOther chemical processesIsotope separationSorbentCyclodextrin

The invention relates to compositions that can be used to adsorb low concentration, preferably, for example less than 15 ppm, of unwanted or target substances. Typically the absorbance can be from an enclosed vapor phase. Such absorbency is accomplished in a contained substantially enclosed gaseous volume or atmosphere using a composition comprising a cyclodextrin compound and a polyethylenimine that can have an absorbency capability for low concentrations of unwanted or target substances. Such absorbency can be obtained with thermoplastic materials used in the form of bulk polymer or a film, fiber, web, woven fabric, nonwoven fabric, sheet, packaging and other such structures including or surrounding the enclosed volume. The adsorbent of the invention is typically used in the context of an enclosed volume, also known as an enclosed ambient vapor phase that contains the adsorbent of the invention and the unwanted or target substances at a concentration that is not desirable. The concentration should be reduced to non-offensive sensed limits or a limit that does not produce a biological response.

Owner:VERDANT TECH LLC

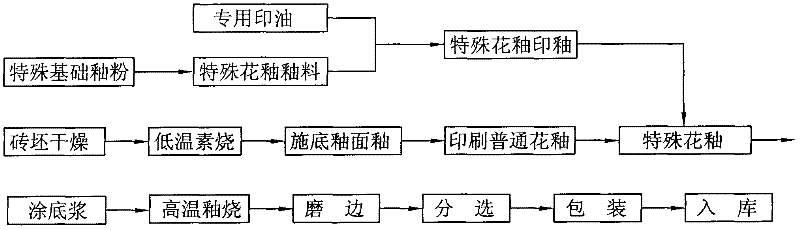

Preparation method and intermediate product of optical relievo illusion glazed brick

The invention relates to a preparation method of an optical relievo illusion glazed brick, which comprises the following steps: A. preparation of special basic glaze powder; B. preparation of special fancy glaze material; C. preparation of special fancy glaze printing glaze; D. special fancy glaze printing; and E. product firing system. By optimizing the compositions of the special basic glaze powder, special fancy glaze material, printing oil and special fancy glaze printing glaze as well as the firing technique and the like, optimized special rubber rollers or printing silk screen plate with optimized meshes can be used for printing the special fancy glaze on the base glaze, surface glaze and common fancy glaze green body, and the green body is fired at high temperature, so that the special fancy glaze pattern sinks into the common surface glaze and fancy glaze. The obtained product does not have the special fancy glaze pattern when viewed from the front side, but has the clear delicate pattern with relievo illusion effect when viewed from the lateral side, thereby achieving the dreamy illusion effect. The special fancy glaze has favorable transparency, does not destroy the original decorative pattern, and overcomes the defect of single decorative style in the existing glazed brick.

Owner:GUANGDONG WINTO CERAMICS +1

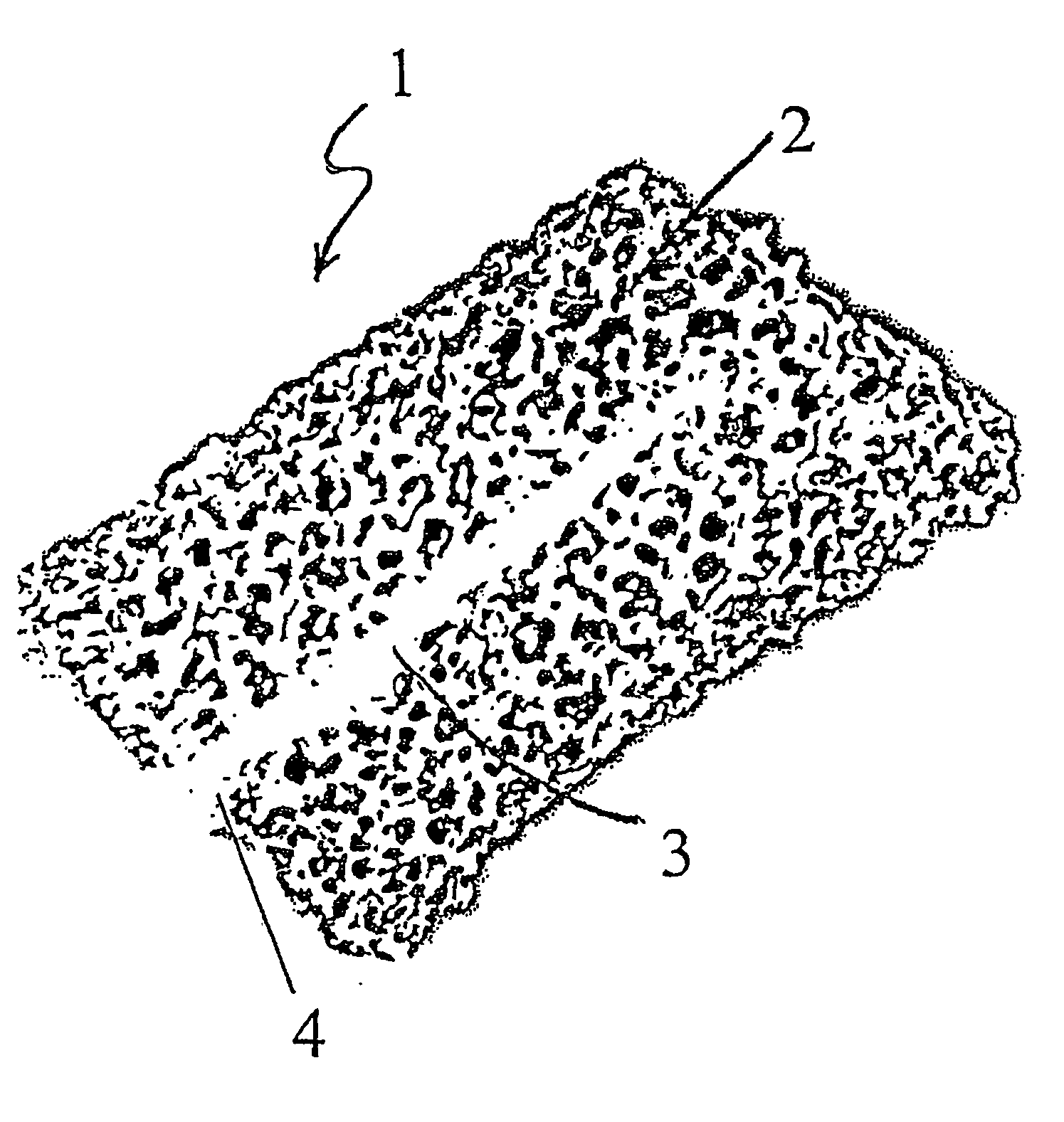

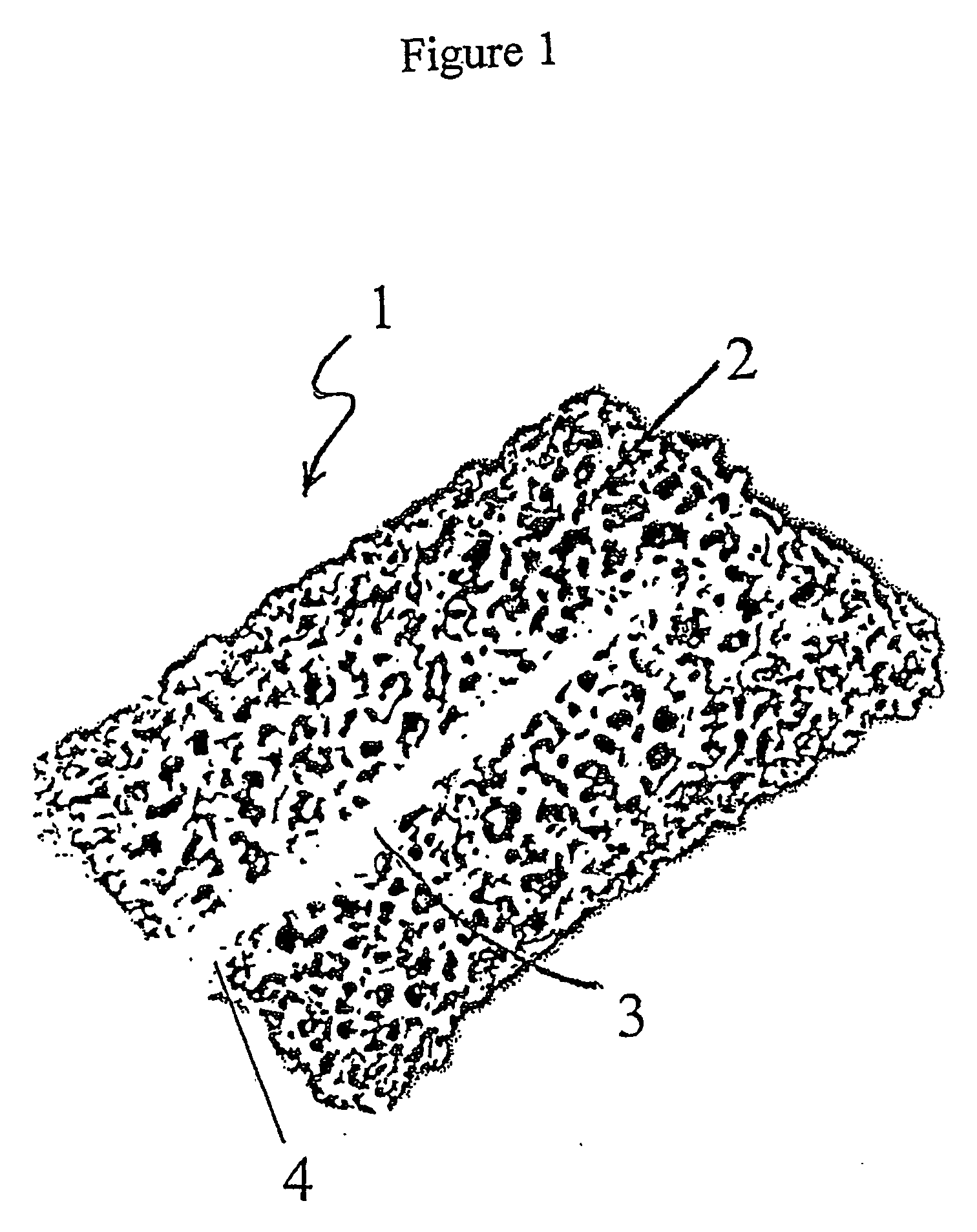

Method for treatment of ischaemic tissue

InactiveUS20070056595A1Maintain functional integrityStimulate and restore functionDiagnosticsSurgical needlesSurgeryBiology

A method for treating ischaemic tissue comprising cutting the tissue to form a wound, and locating a sponge-like element (1) structured to receive blood and to comply with the movement of the tissue, in contact with a source of blood whereby the element (1) receives blood from the source of blood to thereby promote tissue growth and angiogenesis throughout and beyond the element (1).

Owner:MCLACHLAN CRAIG

Process for making ceramic insulation

InactiveUS7628951B1Low costImprove performanceFinal product manufactureCeramic shaping apparatusPorosityDirect carbon fuel cell

A method is provided for producing insulation materials and insulation for high temperature applications using novel castable and powder-based ceramics. The ceramic components produced using the proposed process offers (i) a fine porosity (from nano-to micro scale); (ii) a superior strength-to-weight ratio; and (iii) flexibility in designing multilayered features offering multifunctionality which will increase the service lifetime of insulation and refractory components used in the solid oxide fuel cell, direct carbon fuel cell, furnace, metal melting, glass, chemical, paper / pulp, automobile, industrial heating, coal, and power generation industries. Further, the ceramic components made using this method may have net-shape and / or net-size advantages with minimum post machining requirements.

Owner:CERAMTEC

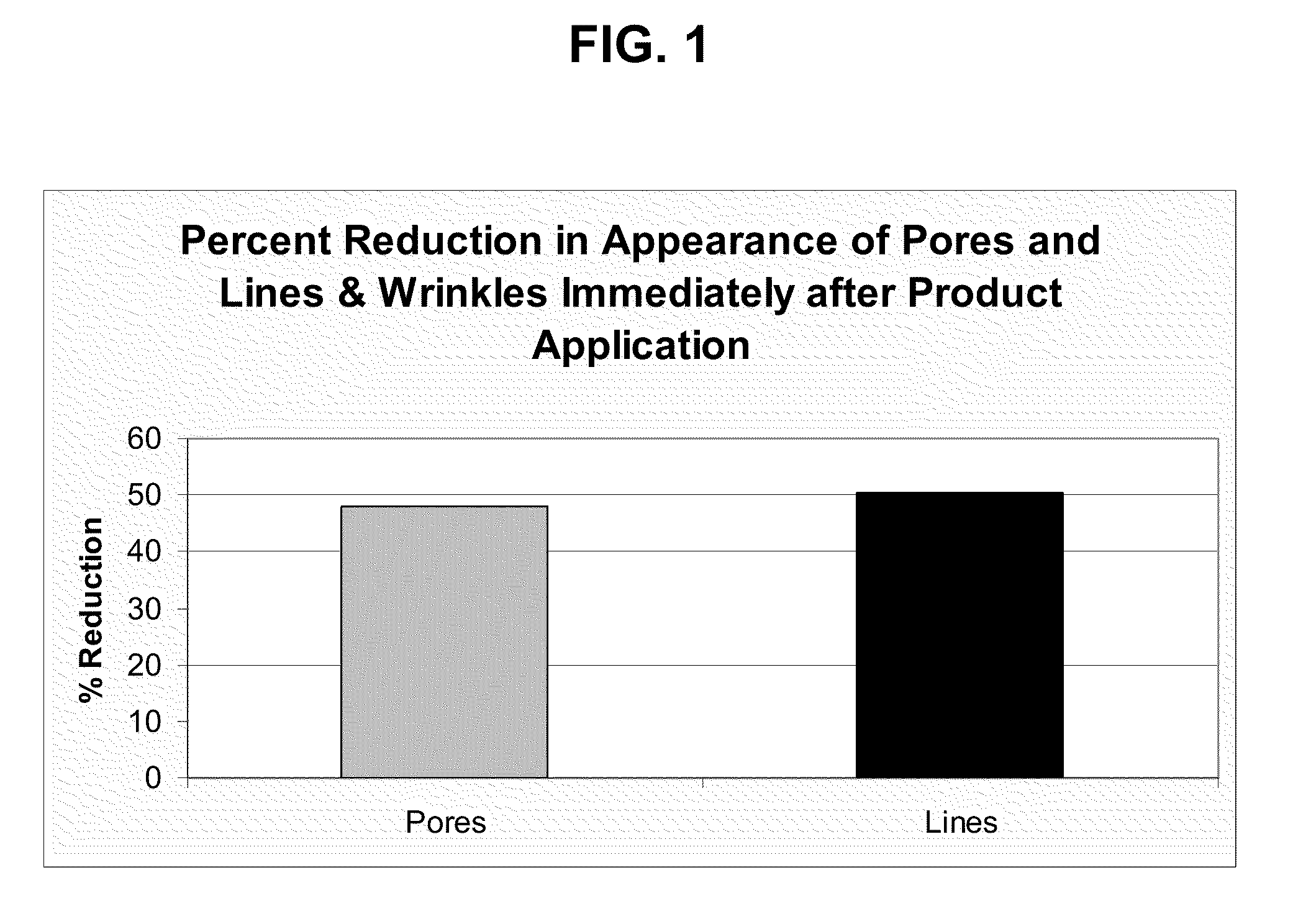

Cosmetic Composition For Diminishing The Appearance Of Lines And Pores

InactiveUS20110123579A1Nice appearanceFine pore sizeCosmetic preparationsBiocideWrinkle skinEmulsion

Owner:ELC MANAGEMENT LLC

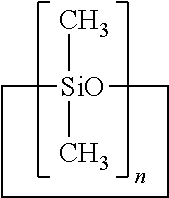

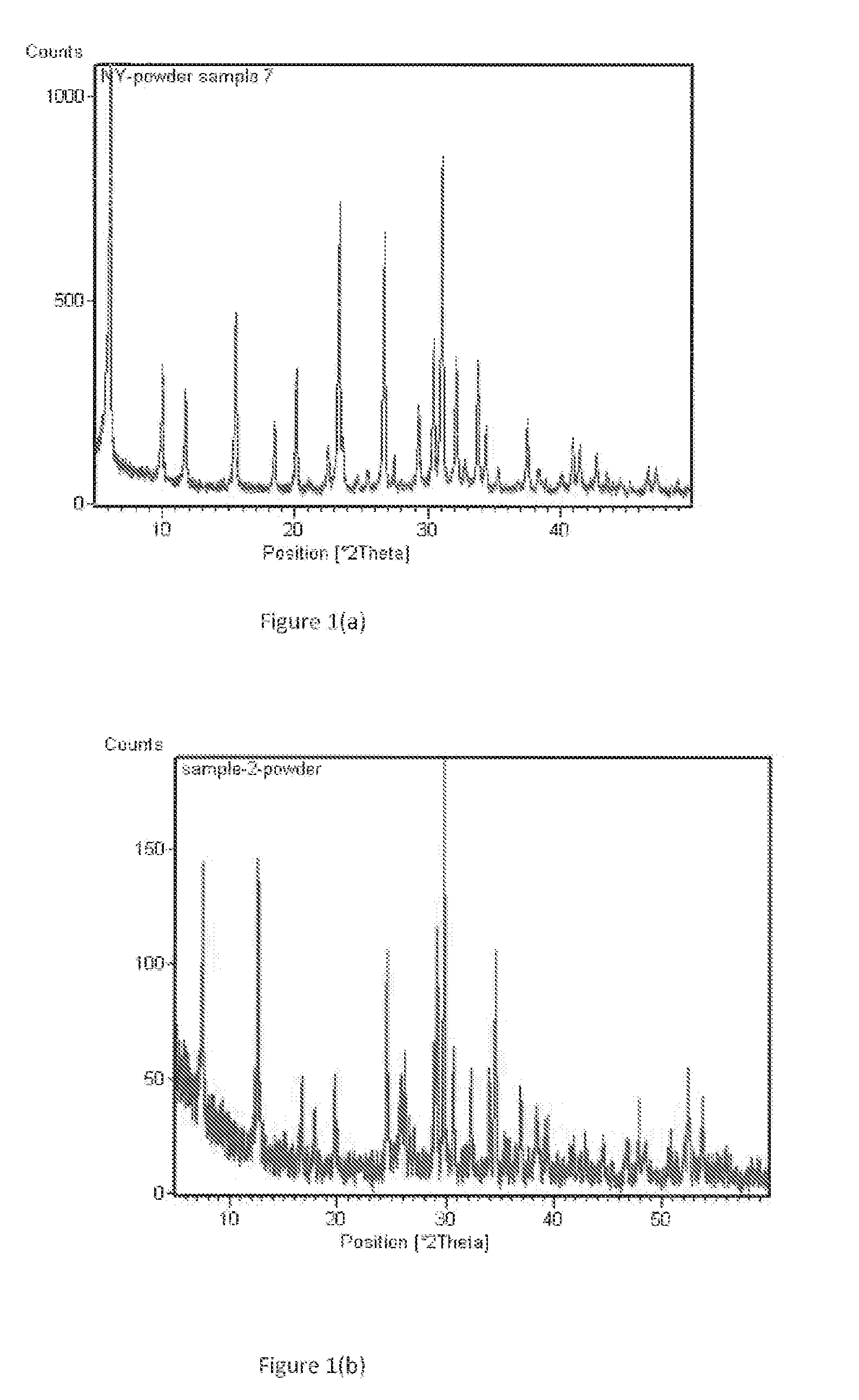

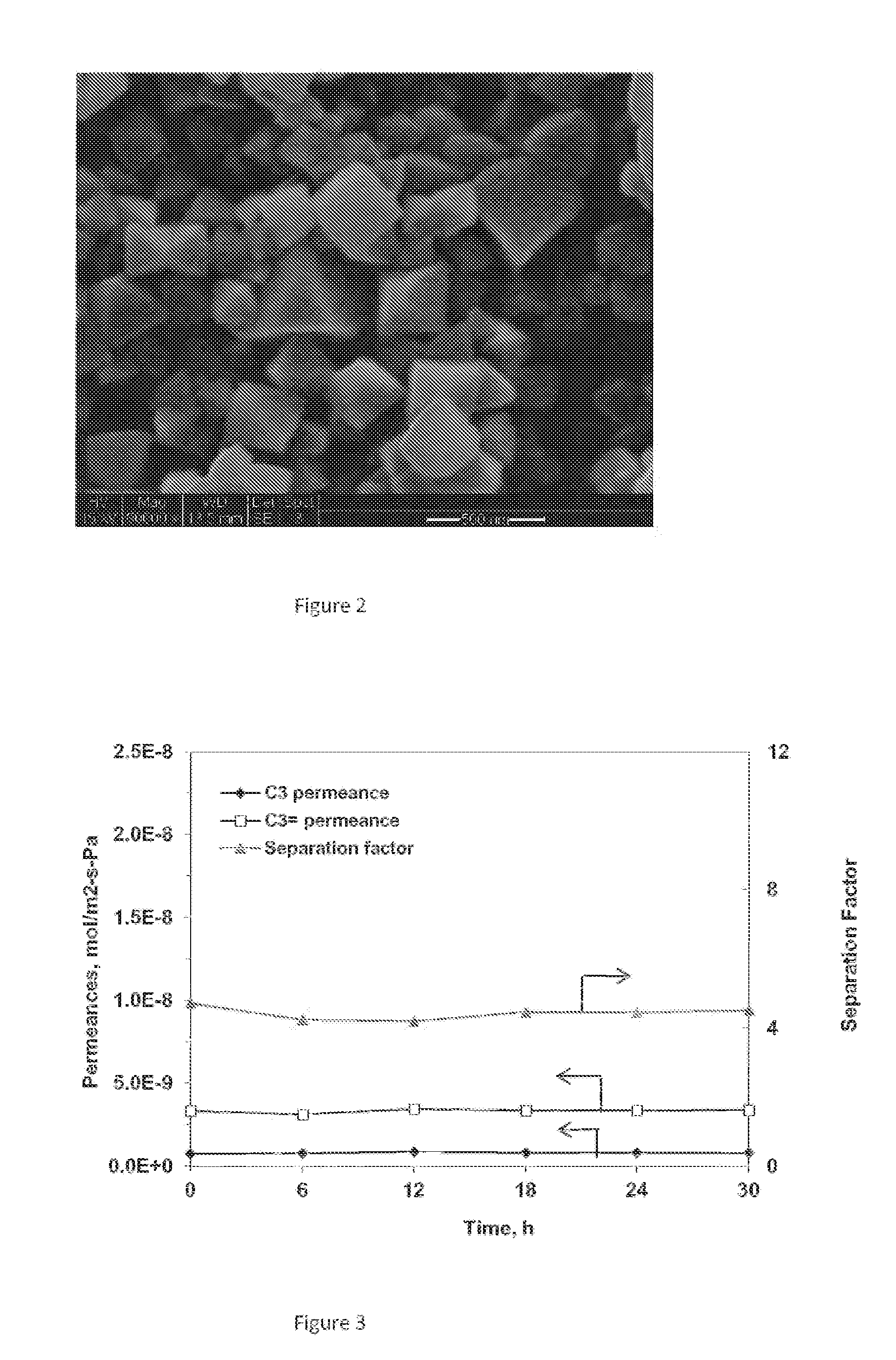

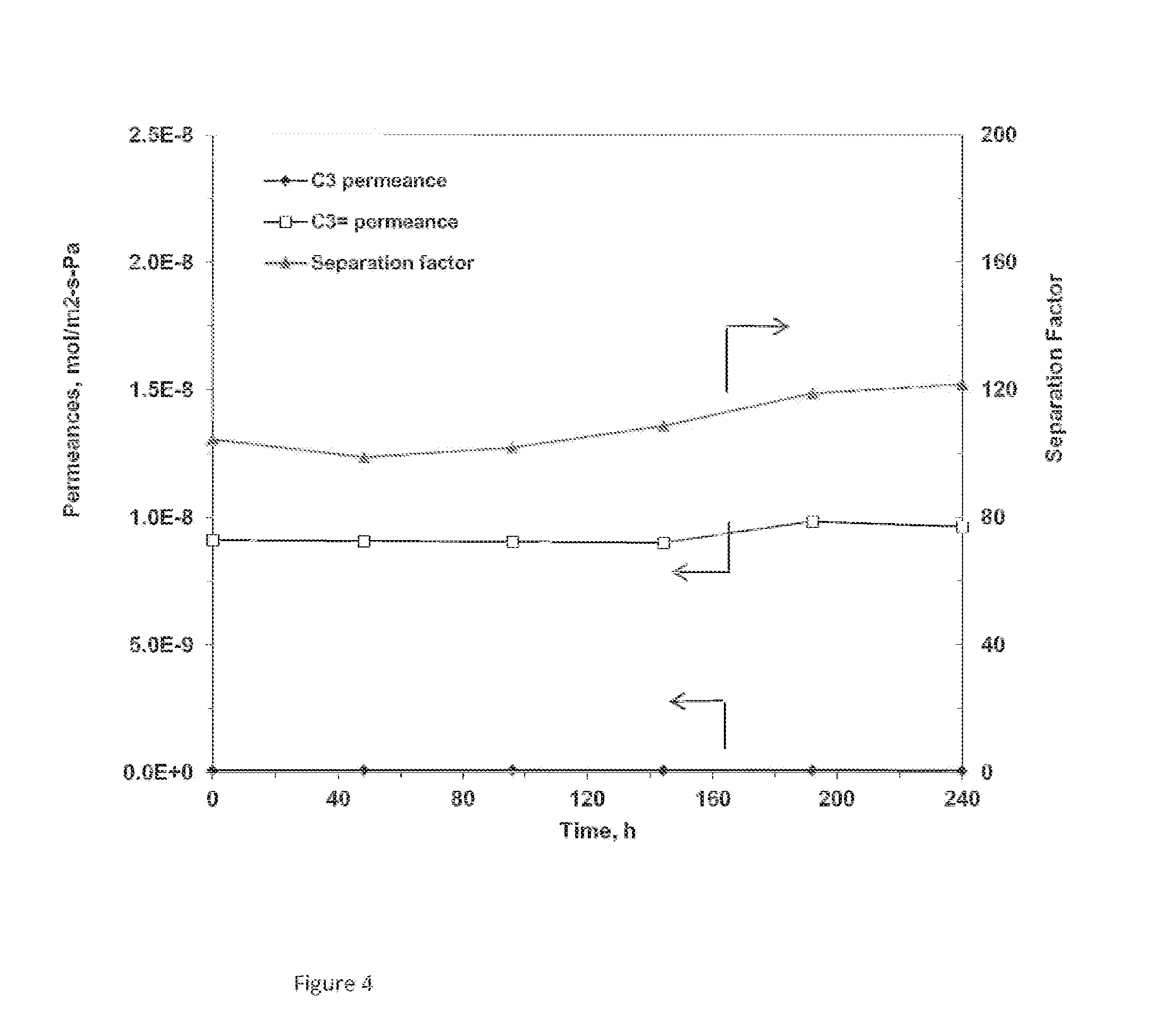

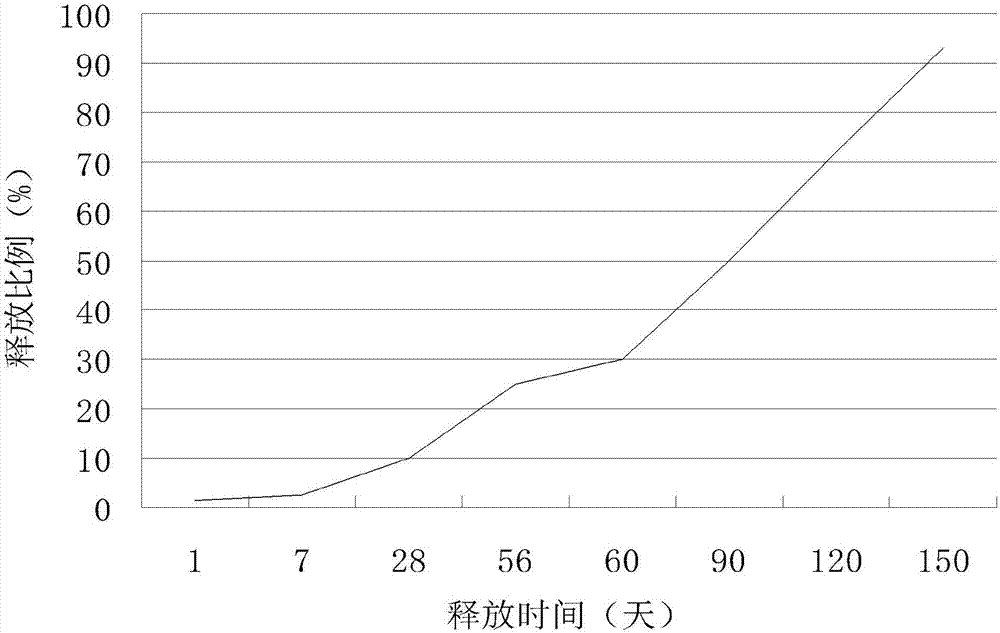

Composite membranes for olefin/paraffin separation

ActiveUS20150321141A1Improve olefin selectivityStrong ion exchange performanceSemi-permeable membranesMembranesPorous substrateMolecular sieve

This invention presents a metal-doped zeolite membrane-based apparatus containing molecular sieving zeolite thin film on the seeded porous substrate. The metal-doped zeolite membrane exhibits high selectivity to olefin over paraffins. The membrane is synthesized by seed coating and secondary growth method, followed by metal doping and post treatment processes.

Owner:BETTERGY

Packaging material such as film, fiber, woven and nonwoven fabric with adsorbancy

ActiveUS8152902B2Improve adsorption capacityEnhance and increase surface area of surfaceOther chemical processesIsotope separationSorbentCyclodextrin

The invention relates to compositions that can be used to adsorb low concentration, preferably, for example less than 15 ppm, of unwanted or target substances. Typically the absorbance can be from an enclosed vapor phase. Such absorbency is accomplished in a contained substantially enclosed gaseous volume or atmosphere using a composition comprising a cyclodextrin compound and a polyethylenimine that can have an absorbency capability for low concentrations of unwanted or target substances. Such absorbency can be obtained with thermoplastic materials used in the form of bulk polymer or a film, fiber, web, woven fabric, nonwoven fabric, sheet, packaging and other such structures including or surrounding the enclosed volume. The adsorbent of the invention is typically used in the context of an enclosed volume, also known as an enclosed ambient vapor phase that contains the adsorbent of the invention and the unwanted or target substances at a concentration that is not desirable. The concentration should be reduced to non-offensive sensed limits or a limit that does not produce a biological response.

Owner:VERDANT TECH LLC

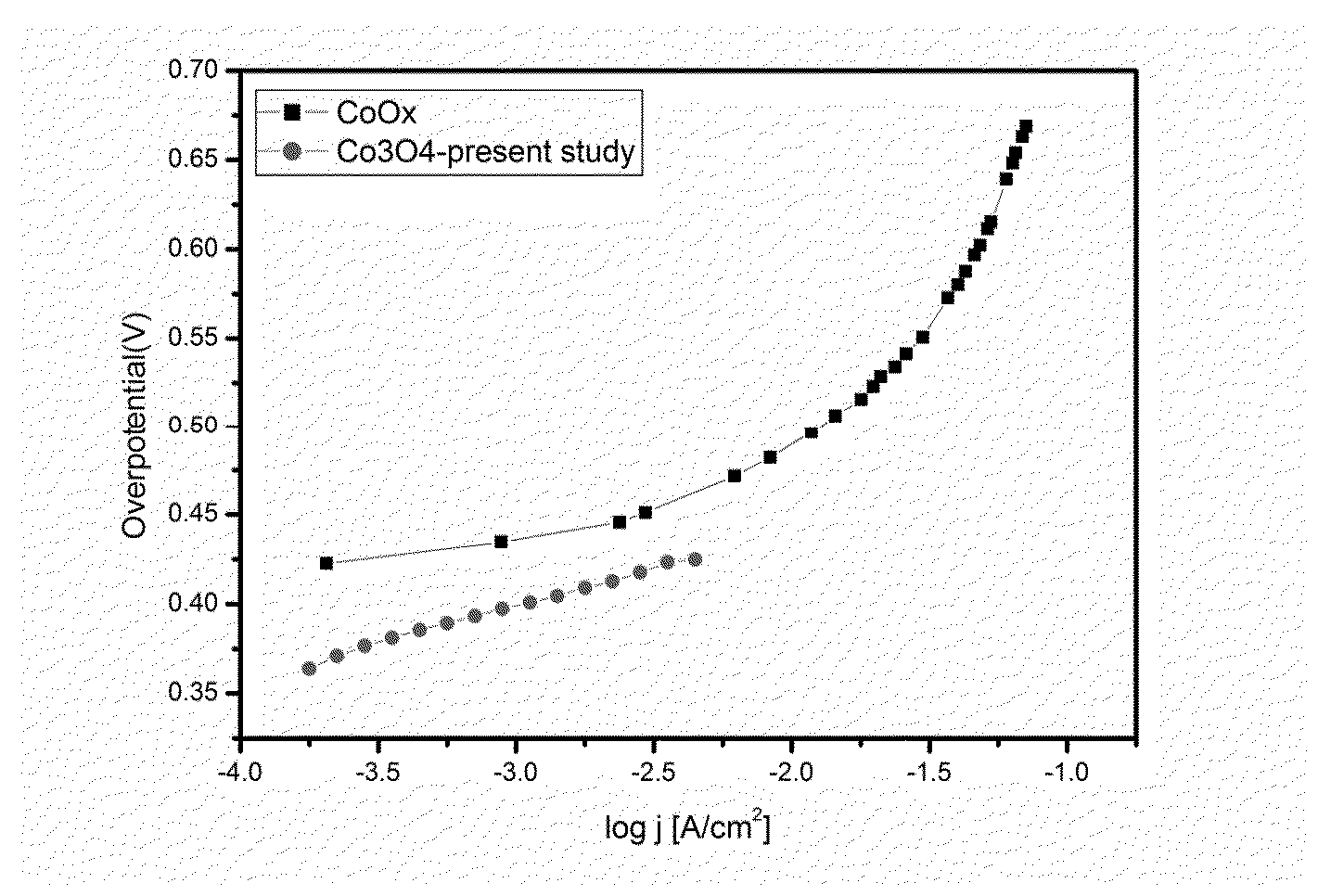

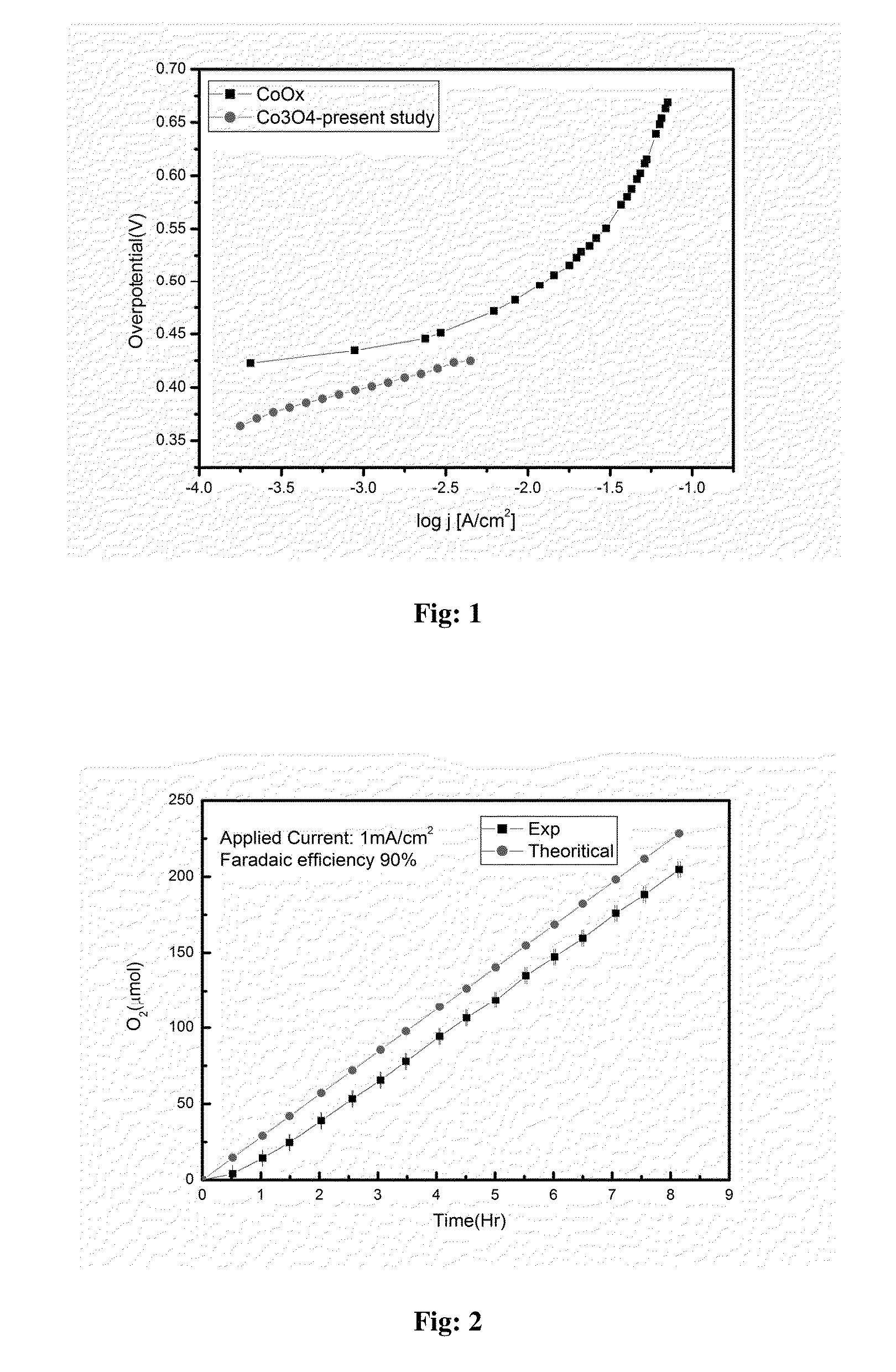

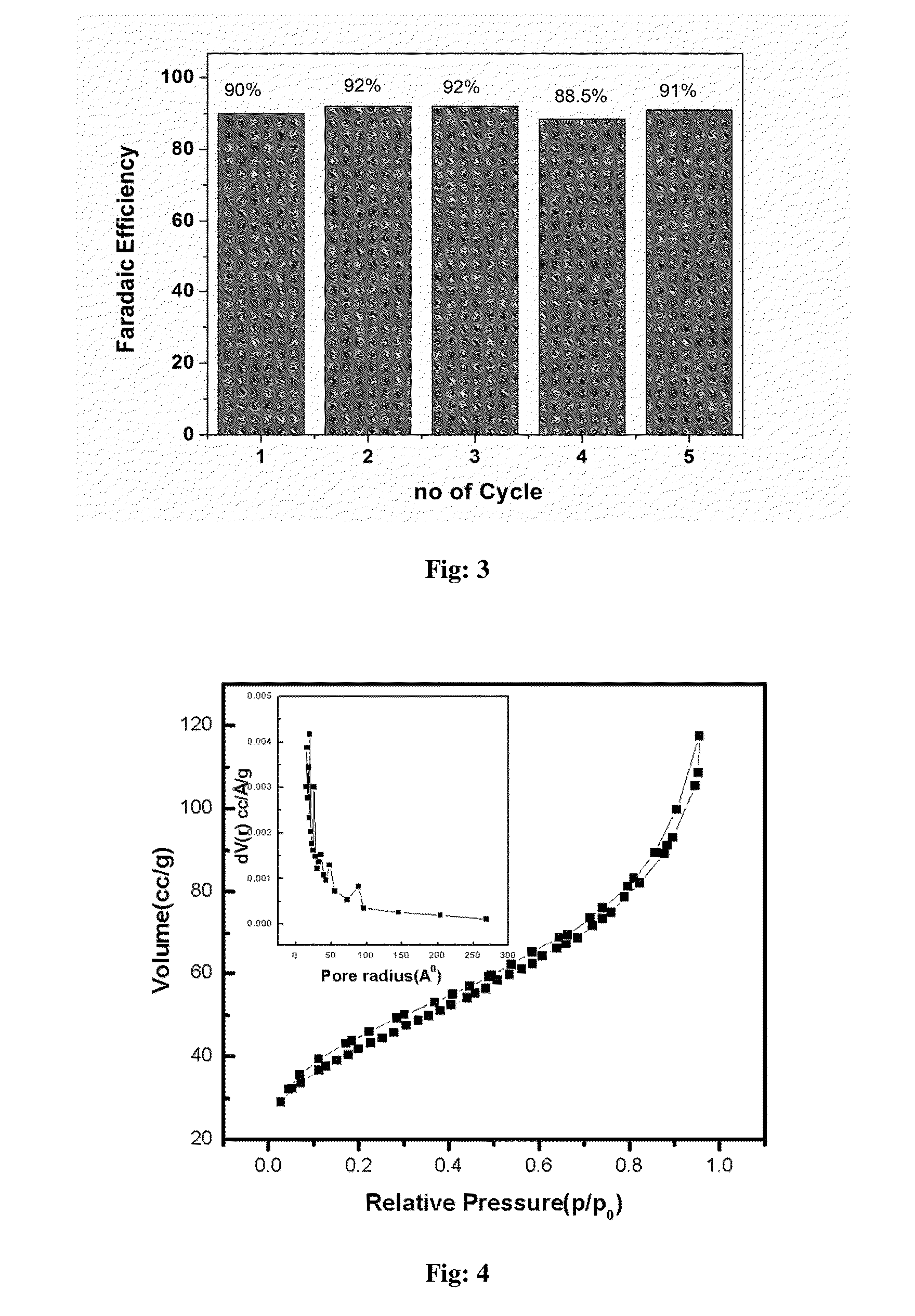

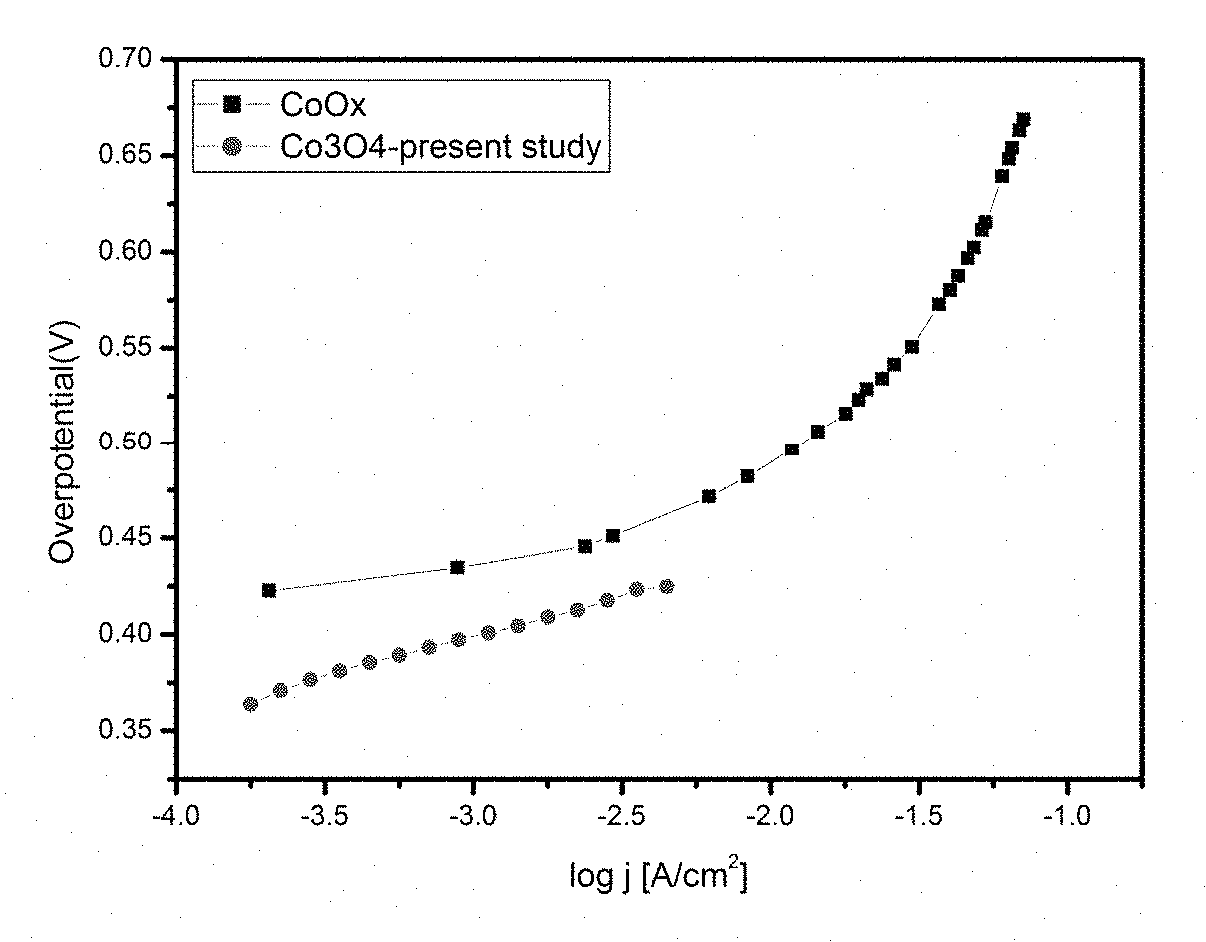

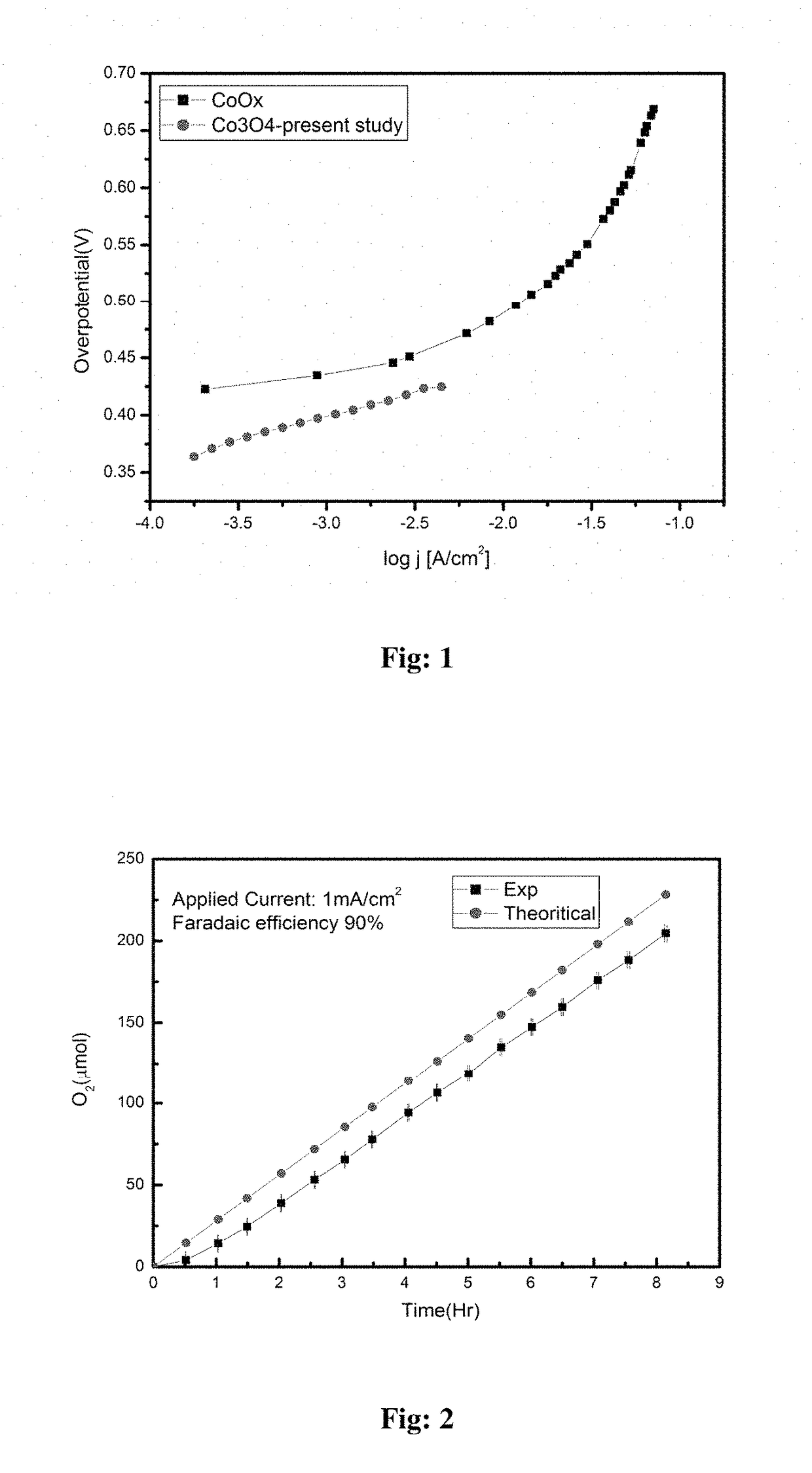

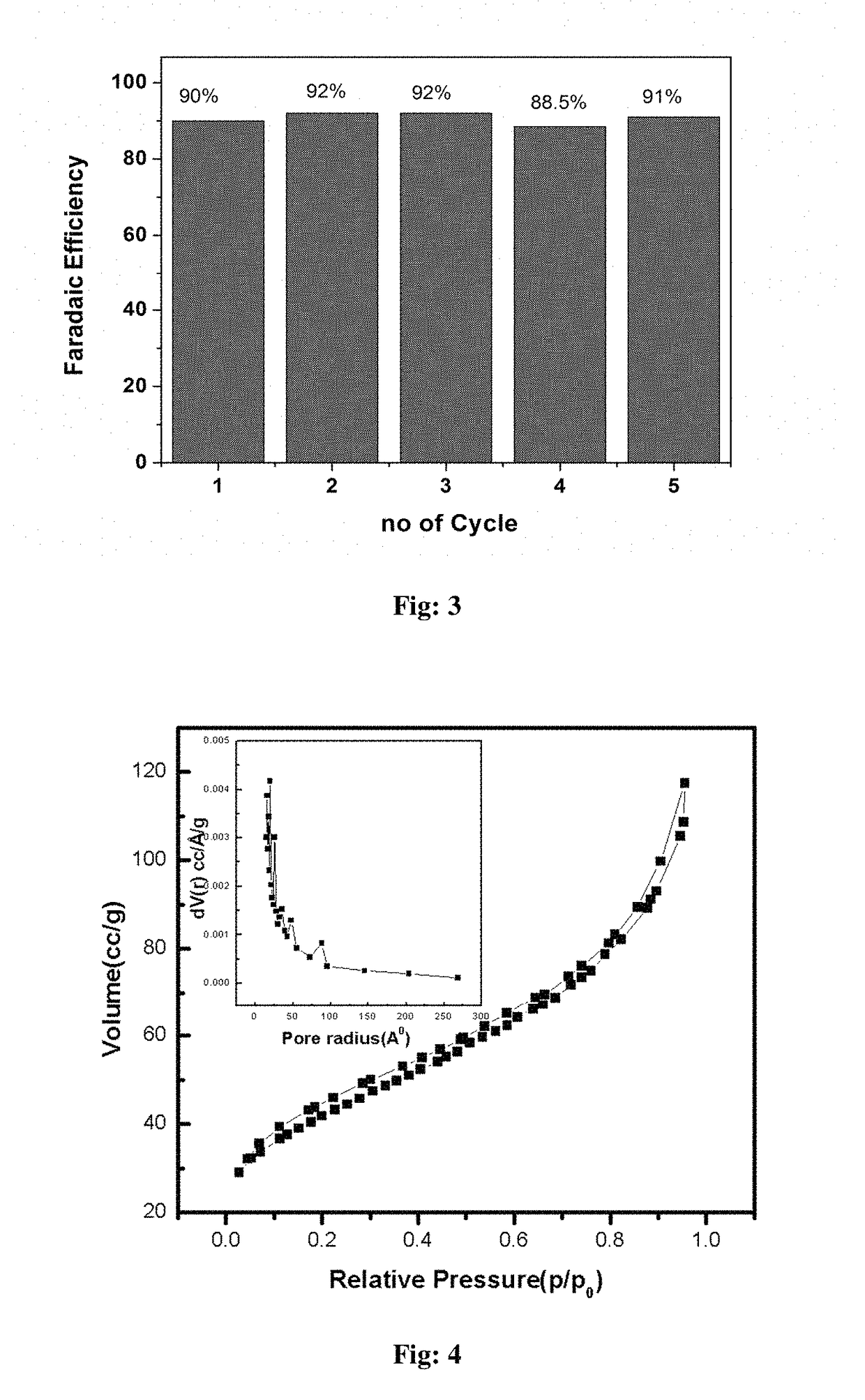

ELECTROCHEMICAL PROCESS FOR WATER SPLITTING USING POROUS Co3O4 NANORODS

InactiveUS20150136614A1Reduce overpotentialHigh exchange current densityElectrodesExchange current densityPhysical chemistry

The present invention discloses an electrochemical process for water splitting for production of oxygen using porous Co3O4 nanorods with a considerably low overpotential and high exchange current density. The present invention further discloses a simple, industrially feasible process of for preparation of said nanostructured porous cobalt oxide catalyst thereof.

Owner:COUNCIL OF SCI & IND RES

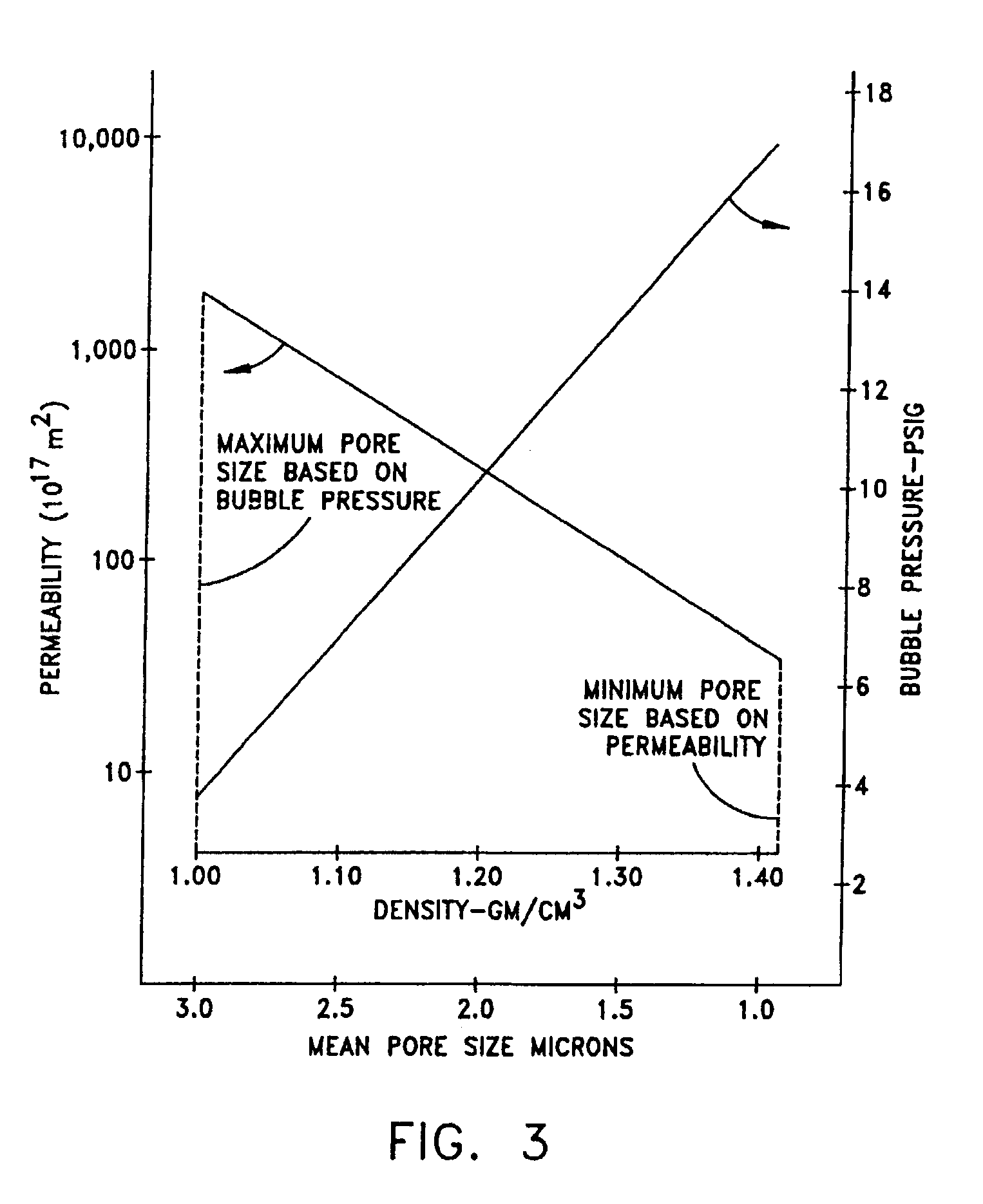

Method of using a water transport plate

InactiveUSRE39348E1Improve balanceHigh open porositySolid electrolytesFinal product manufacturePorosityFuel cells

A water transport plate is provided with optimized physical characteristics to greatly improve fuel cell operation. In a preferred method of manufacturing, graphite powder, reinforcing fibers, cellulosic fibers, and a thermosetting resin are mixed with a liquid to form a slurry and showered onto a screen to form a planar sheet which is dried to form paper. The paper is cut into the desired size and is laid-up. The lay-up is laminated with pressure and heat, carbonized, and graphitized to form a water transport plate for later machining as desired. The finished water transport plate exhibits optimal physical characteristics for bubble pressure, water permeability, median pore size, porosity, thru-plane resistivity and compressive yield strength.

Owner:AUDI AG

Composite membranes for olefin/paraffin separation

ActiveUS9649601B2Improve olefin selectivityStrong ion exchange performanceSemi-permeable membranesMembranesPorous substrateMolecular sieve

This invention presents a metal-doped zeolite membrane-based apparatus containing molecular sieving zeolite thin film on the seeded porous substrate. The metal-doped zeolite membrane exhibits high selectivity to olefin over paraffins. The membrane is synthesized by seed coating and secondary growth method, followed by metal doping and post treatment processes.

Owner:BETTERGY

Fragrant sterilizing-type pea-hull composite cat litter and preparation method thereof

InactiveCN106386525AImprove antibacterial propertiesImprove adsorption capacityAnimal housingSodium bicarbonateLiving environment

The invention belongs to the technical field of a process for a cat litter, and specifically relates to a fragrant sterilizing-type pea-hull composite cat litter and a preparation method thereof. According to the invention, pea hulls are capable of emitting slightly sweet and fragrant smells in the process of processing, so the prepared cat litter by the invention has pea-hull fragrance, low density and good water absorptivity, bulkiness, antibacterial properties and adsorption properties, is biodegradable, green and environmentally friendly, and effectively improves the living environment of a cat; meanwhile, regularly-cleaned cat litter is poured into soil and can play the role of improving soil, and the regularly-cleaned cat litter contains animal manure, thereby being able to be used as an organic fertilizer, so resources are saved. The preparation method provided by the invention has the following advantages: through mutual compounding effects of the pea hulls with filled-type wood, an antibacterial agent, sodium bicarbonate and a binder, and by adopting a vertical-type ring die granulating machine, the prepared cat litter has uniform particle size, small pore size and good bulkiness; strong adsorption of the cat litter to manure odor is guaranteed; meanwhile, the yield is large; and production efficiency is improved.

Owner:YANTAI CHINA PET FOODS GRP

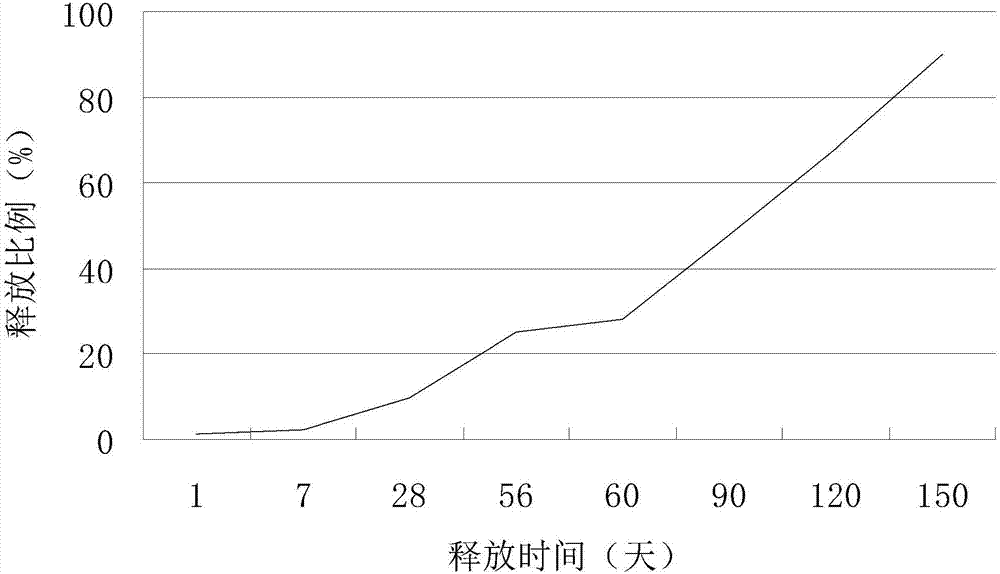

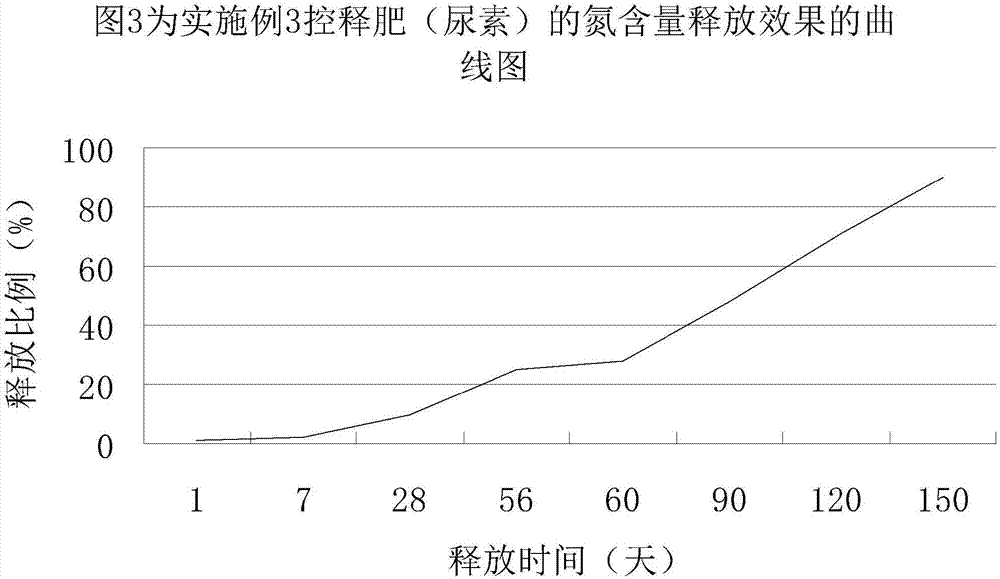

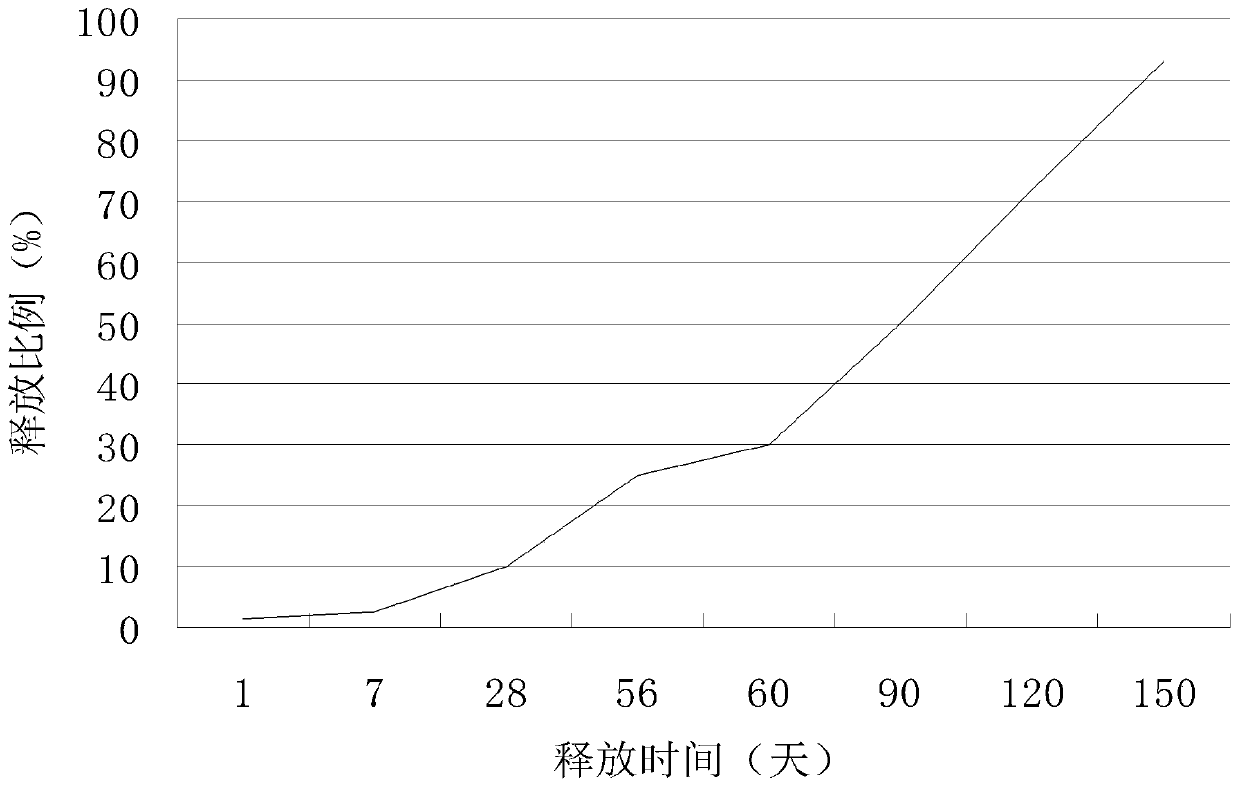

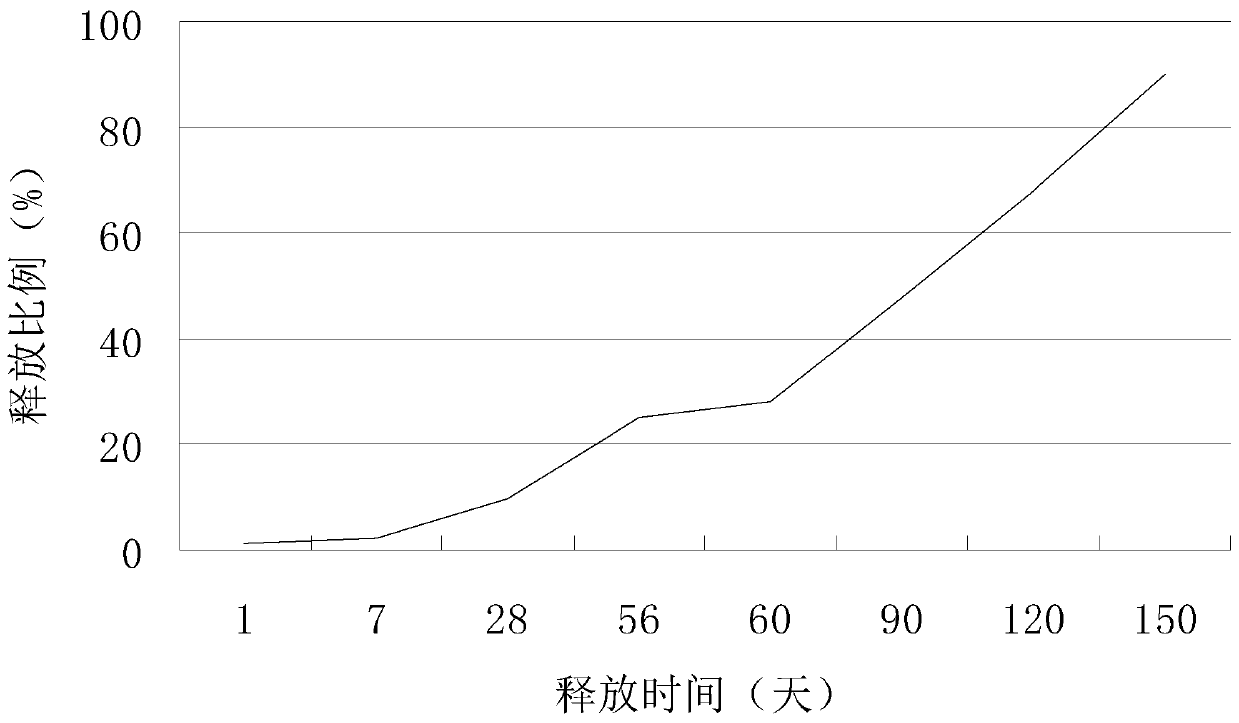

Bio-based aromatic hydrocarbon polyester polyol for controlled-release fertilizer and application thereof

ActiveCN107383347AModerate viscosityReduce dosageLayered/coated fertilisersFertilizer mixturesVacuum extractionGlycerol

The invention discloses bio-based aromatic hydrocarbon polyester polyol for controlled-release fertilizer. The bio-based aromatic hydrocarbon polyester polyol is characterized by being synthesized according to a method comprising the following steps: sucking fatty acid (1mol), diethylene glycol (2mol), glycerol (2mol) and the like into a reaction kettle in vacuum according to a sequence; adding terephthalic acid (3mol), phthalic anhydride (2mol) and trimethylol propane (2mol) from a solid feeding hole in the reaction kettle; after stirring in the reaction kettle for 1h, displacing air in the reaction kettle once with nitrogen gas; slowly raising the temperature of the reaction kettle to 180 DEG C to 240 DEG C, carrying out esterification reaction to distill water and maintaining the temperature for 4h; when the temperature of the top of an esterification tower is lower than about 95 DEG C and no water is discharged, sampling and testing an acid value; when the acid value is less than 15mgKOH / g, supplementing a catalyst Tio2 / SO4-2 solid super acid which accounts for 0.03 percent of the total amount; continually keeping heat and reacting for 1h; then carrying out vacuum extraction for about 2h and controlling the vacuum degree to be -0.085mPa to -0.095mPa; when the acid value is less than 2mgKOH / g, the reaction is completed; then cooling and filtering and packaging to obtain a bio-based aromatic hydrocarbon polyester polyol finished product.

Owner:张家港晟新和新材料有限公司

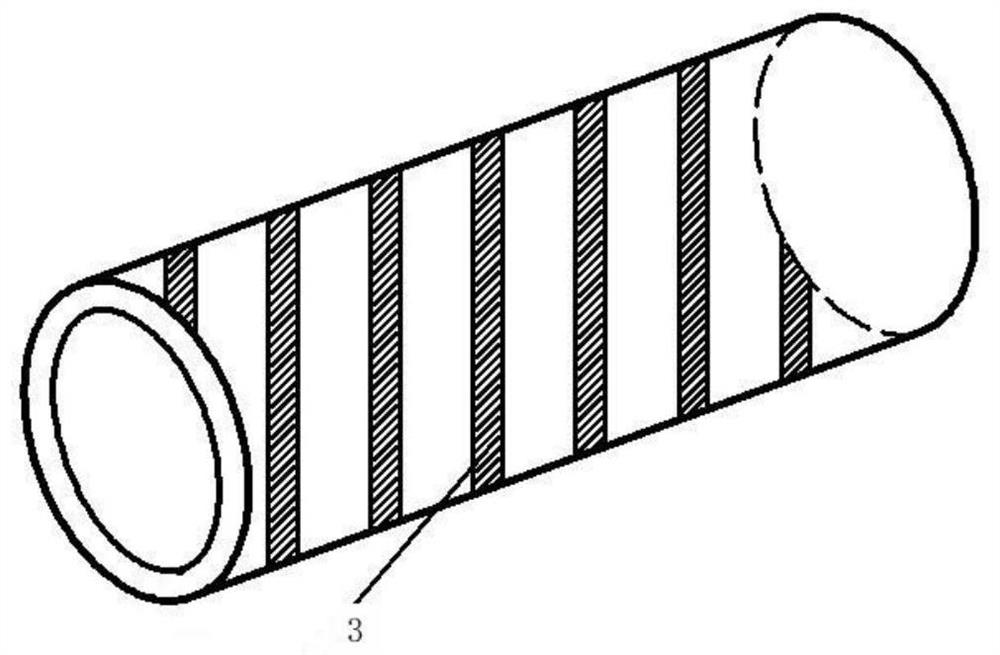

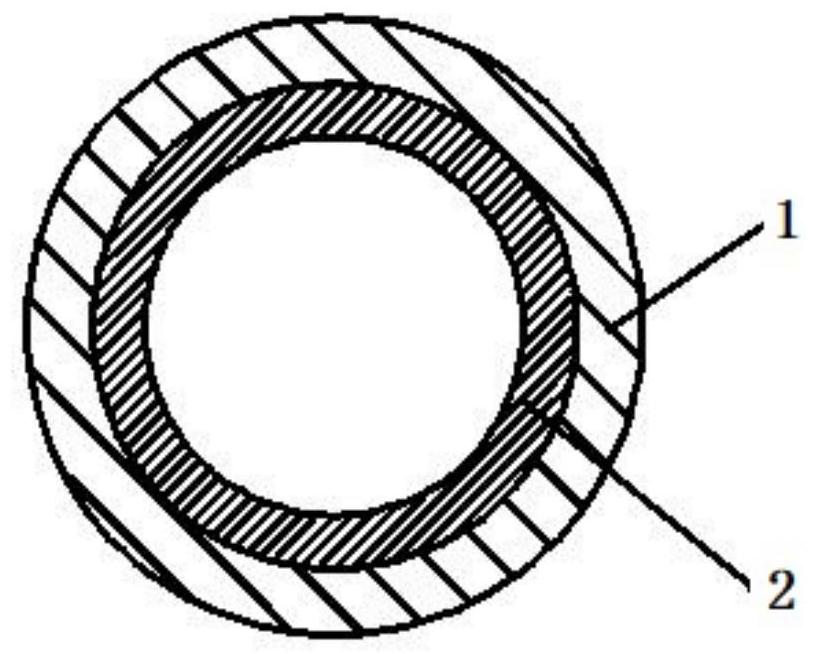

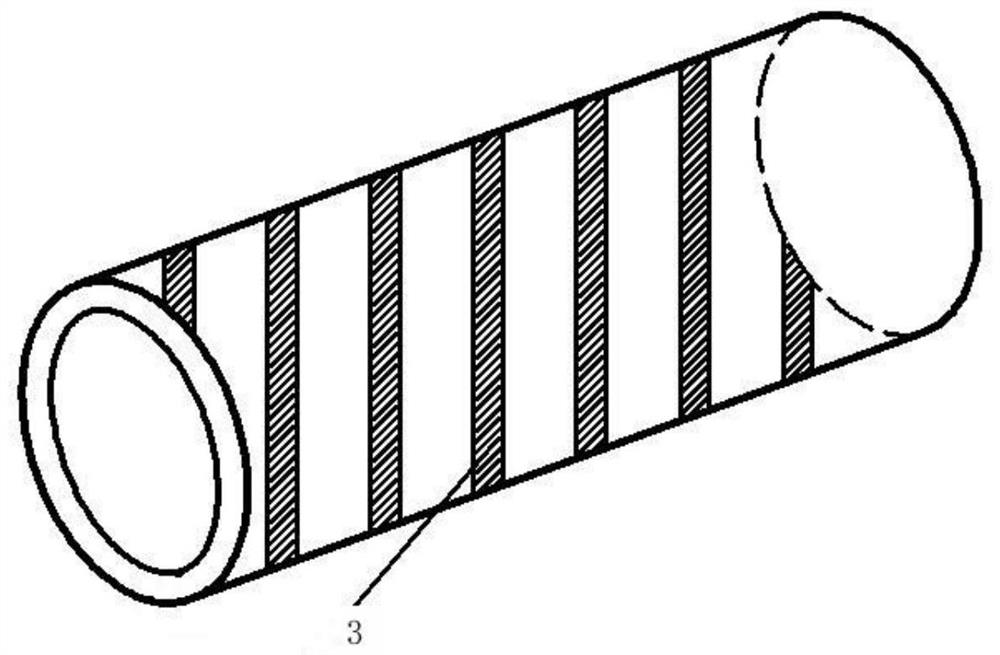

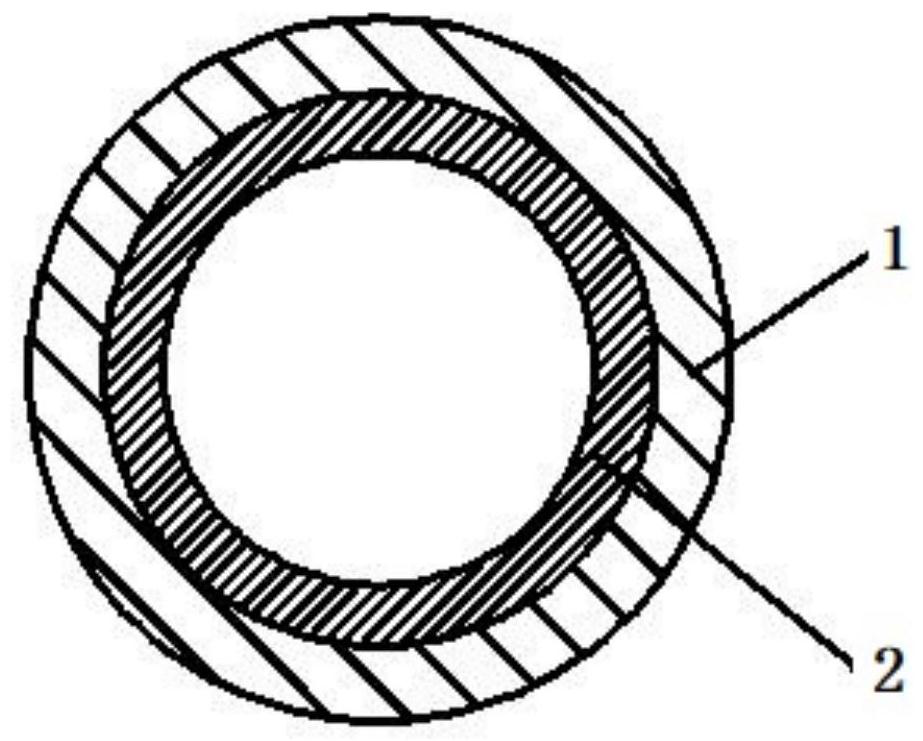

Tubular film based on nuclear track film and application

InactiveCN111841331AIncrease selectionSimple processWater aerationUltrafiltrationThermodynamicsFilm base

The invention relates to a tubular film based on a nuclear track film and application. The tubular film based on the nuclear track film comprises a composite material, the composite material is woundto form a tubular structure and comprises a supporting layer and a nuclear track film layer, the nuclear track film layer is compounded on the outer side or the inner side and the outer side of the supporting layer in a hot pressing mode, pore channels playing a screening role are distributed in the nuclear track film layer, the inner diameter of the channels is larger than 2 mm, and the thicknessof the channel wall is larger than or equal to 10 micrometers. Through hot-pressing compounding, the nuclear track film is successfully applied to the tubular film, the length of the tubular film isnot limited, the minimum pore diameter of the tubular film can reach 0.01 mm, the filtering precision of the tubular film is improved, the bearing pressure value is larger, and the engineering application range is wide. According to the invention, the types of tubular film materials are broadened, the tubular film adopts a new material, the physical and chemical properties of the tubular film areimproved, and a solution is provided for the engineering application of the nuclear track film.

Owner:惠州市科近离子膜材料研究院 +1

Nonwoven fabric sheet and method for producing same

ActiveUS20100148390A1High porosityUniform pore size distributionWoven fabricsNon-woven fabricsPolymer scienceNonwoven fabric

The nonwoven fabric sheet of the present invention is characterized by a porosity in the range of 0.3 to 0.7 and an average pore size in the range of 0.5 μm to 5.0 μm. The nonwoven fabric sheet of the present invention preferably has a maximum pore size (μm) / average pore size (μm) ratio of 1.30 or lower. The nonwoven fabric sheet of the present invention is obtained by press-molding a nonwoven fabric at a temperature lower than the melting point of the thermoplastic resin which constitutes the nonwoven fabric sheet. According to the present invention, there is provided a nonwoven fabric sheet that has a high porosity, small uniform pore sizes and excellent productivity, which can suitably be used in various applications such as filters, light diffusing material, liquid absorber and heat insulating materials; and a method for producing the nonwoven fabric sheet.

Owner:MITSUI CHEM INC

Drafting method for preparation of mesophase pitch fiber precursor

InactiveCN108265337AReduce frequencyReduce the number of timesSpinnerette packsStretch-spinning methodsFiberMetallurgy

The invention discloses a drafting method for preparation of a mesophase pitch fiber precursor. Mesophase pitch is extruded by a spinneret plate in a spinning assembly, a certain length of retarded cooling area is arranged behind the spinneret plate, finally, drafting is performed under the joint action of gravity and a drafting roll, and the mesophase pitch fiber precursor is formed. Drafting isperformed by use of gravity and tension applied by the drafting roll, the frequency of turning of the precursor is reduced, so that precursor breaking and damage in the spinning process are effectively reduced, and precursor damage is prevented through a spinning channel. The drafting method is applicable to continuous drafting of precursors in the continuous spinning process of mesophase pitch fiber, the mesophase pitch fiber precursor with a small diameter can be obtained, and the obtained precursor has higher strength.

Owner:西安天运新材料科技有限公司

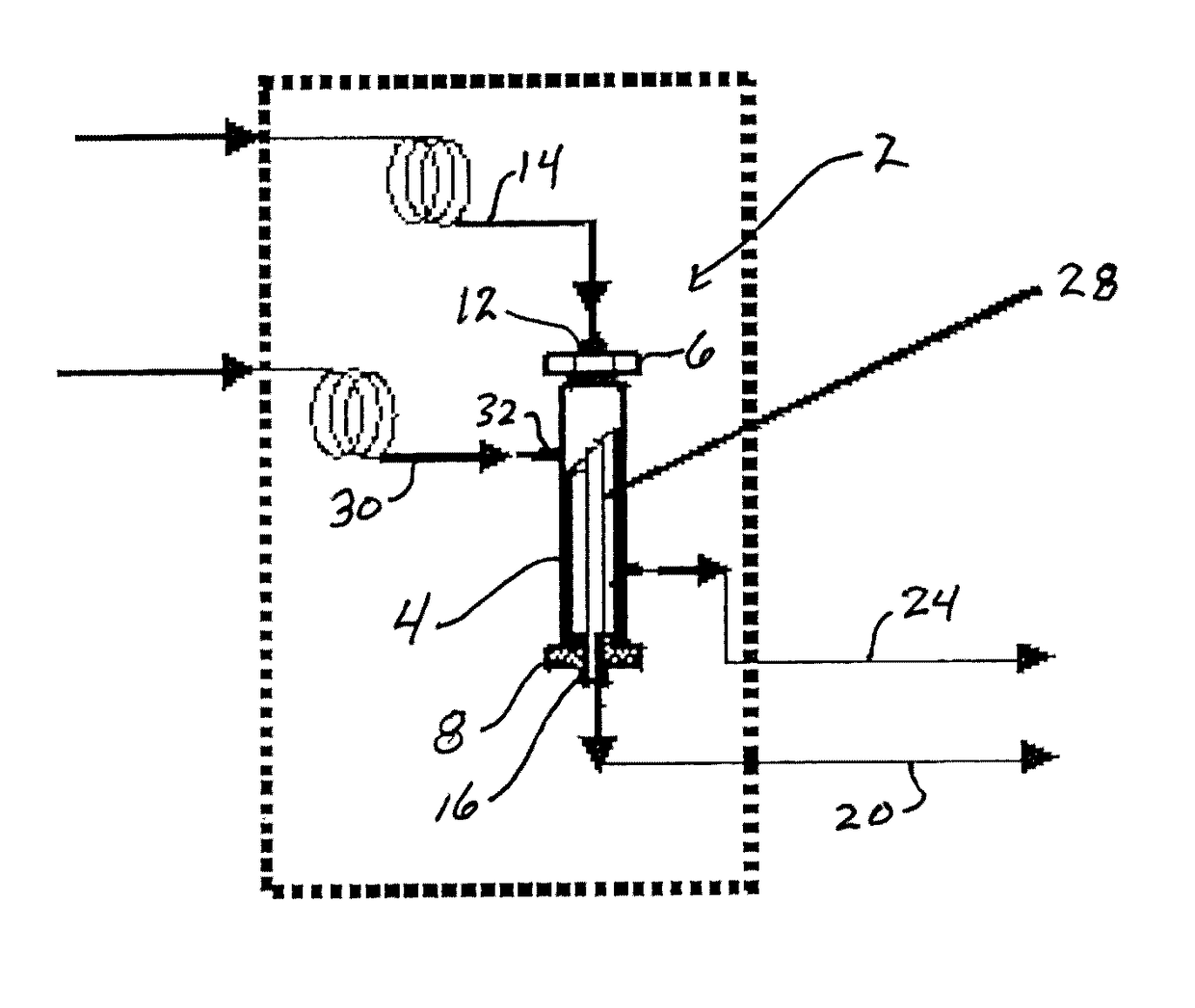

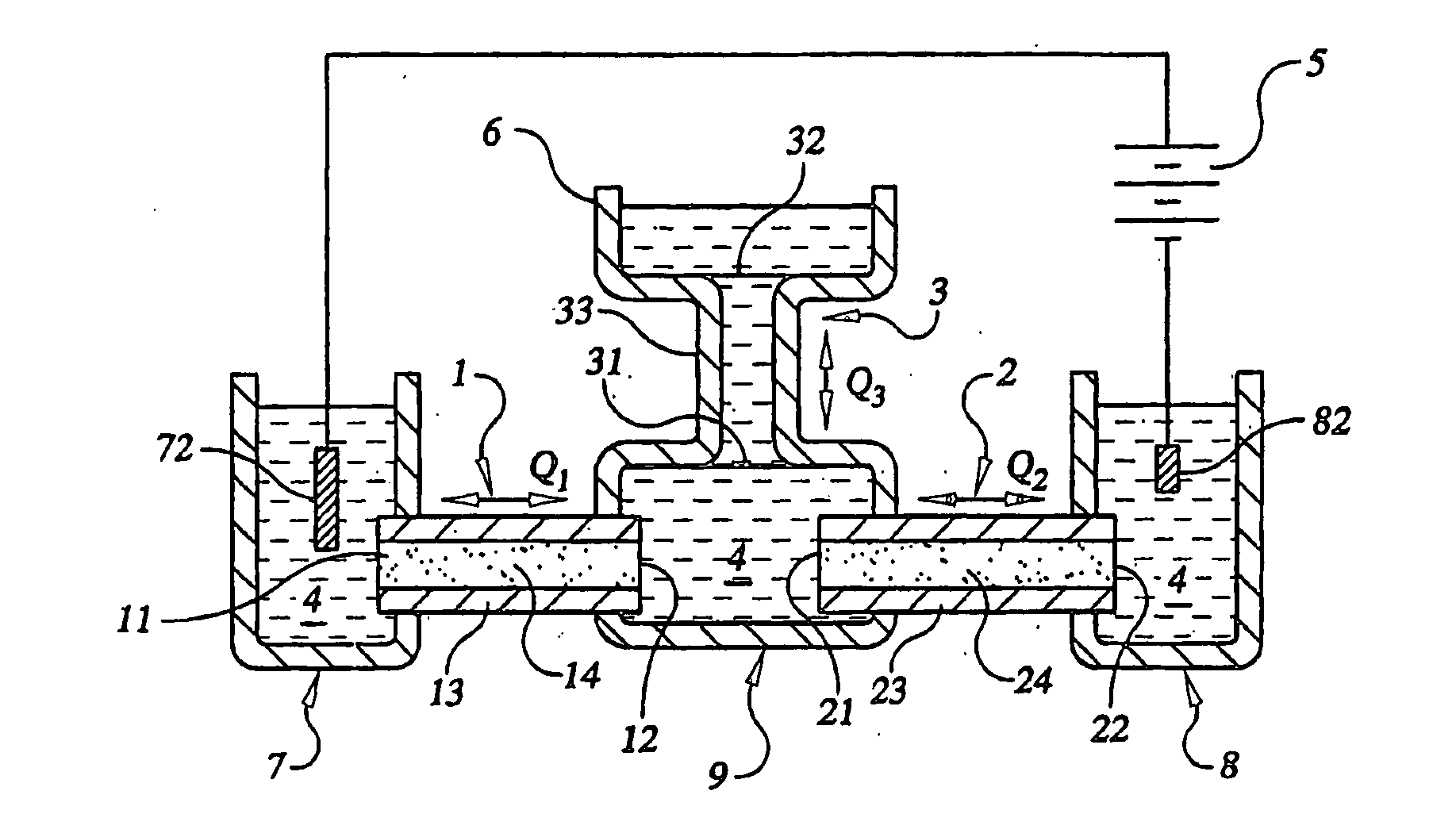

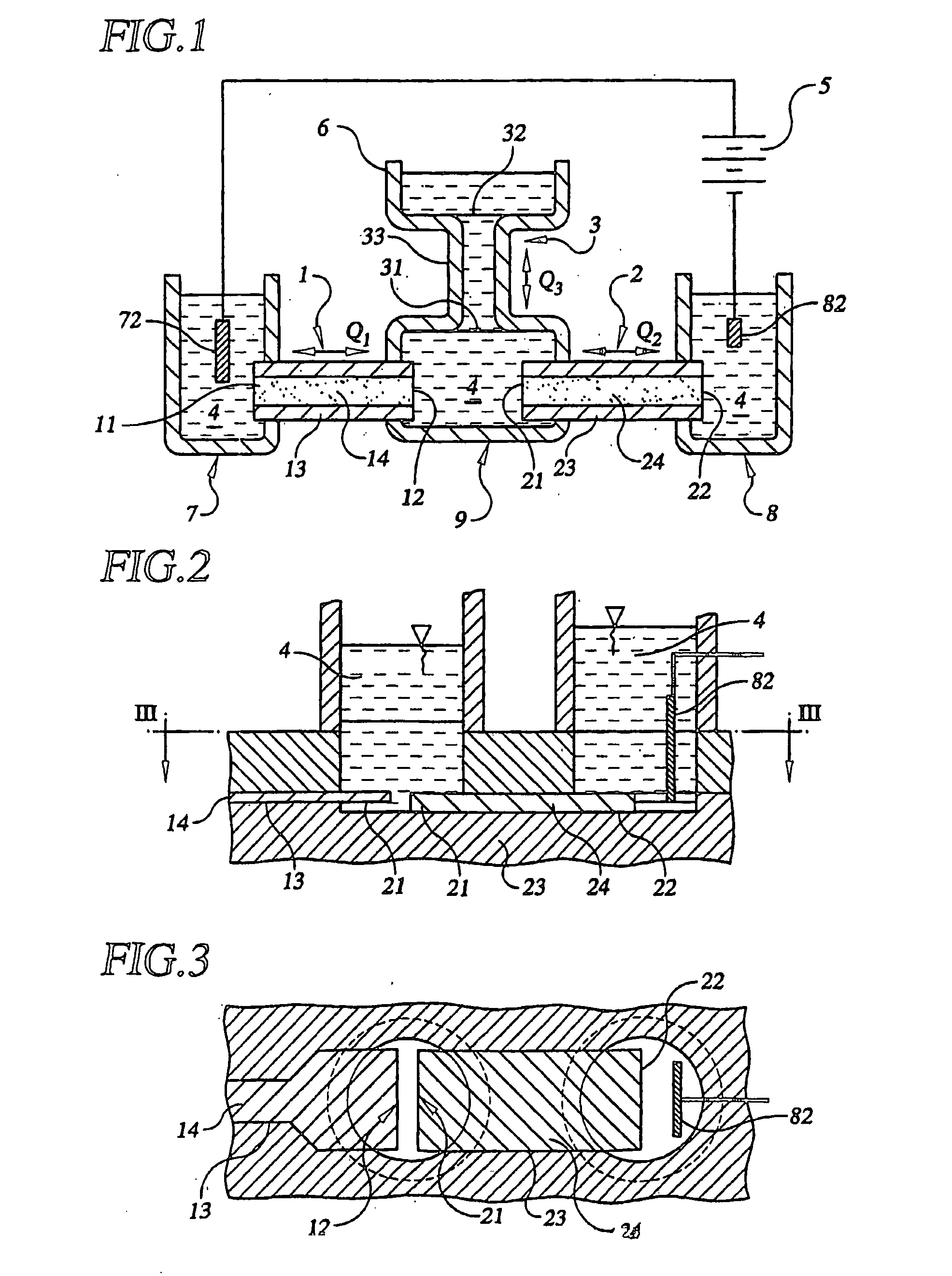

Electroosmotic flow systems

Owner:EKSIGENT TECH

Aromatic sterilization type birch compound cat litter and preparation method thereof

InactiveCN106332791AImprove antibacterial propertiesImprove adsorption capacityAnimal housingSodium bicarbonateFeces

The invention belongs to the technical field of cat litter process, and in particular relates to aromatic sterilization type birch compound cat litter and a preparation method thereof. In a processing process, birch emits a slight fragrant and sweet smell; the cat litter prepared by the method has the fragrance of the birch, is low in density, has good water absorption, bulkiness, antibacterial property and adsorption property, is biodegradable, green and environmental-friendly, and can effectively improve the living environment of cats; the regularly cleaned cat litter can play a role in improving the soil after being put into the soil, and can be used as organic fertilizer so as to save resources due to containing animal feces. According to the preparation method provided by the invention, the birch is compounded with filling type wood, an antibacterial agent, sodium hydrogen carbonate and a binding agent for realizing a synergistic effect; a vertical ring die granulator is adopted, so that the prepared cat litter is uniform in particle size, tiny in aperture and good in bulkiness, and the strong absorption of the cat litter for the odor of the feces is guaranteed; furthermore, the yield is high, and the production efficiency is increased.

Owner:YANTAI CHINA PET FOODS GRP

Porous filtration film

InactiveCN104174301AMany holesFine pore sizeSemi-permeable membranesVinyl acetateArray data structure

The invention discloses a porous filtration film. The porous filtration film comprises the following raw materials in parts by weight: 20-40 parts of polyvinyl chloride, 15-30 parts of vinyl acetate, 5-10 parts of porous fibers, 10-30 parts of an organic solvent, 1-5 parts of a heat stabilizer and 1-3 parts of a surfactant. A preparation method of the porous filtration film comprises the following steps: adding the polyvinyl chloride, the vinyl acetate and the porous fibers into the organic solvent according to the parts by weight, simultaneously and uniformly mixing, stirring, adding the heat stabilizer and the surfactant, continuously stirring so as to obtain a spraying film slurry solution, and coagulating the spraying film to obtain a finished product. The preparation method of the porous filtration film is simple in process and convenient to operate; and the prepared porous filtration film is small in aperture, large in number and high in filtration efficiency.

Owner:SUQIAN RONGJIN INFORMATION TECH

A kind of bio-based aromatic hydrocarbon polyester polyol for controlled release fertilizer and application thereof

ActiveCN107383347BLow costPromote degradationLayered/coated fertilisersFertilizer mixturesVacuum extractionGlycerol

The invention discloses bio-based aromatic hydrocarbon polyester polyol for controlled-release fertilizer. The bio-based aromatic hydrocarbon polyester polyol is characterized by being synthesized according to a method comprising the following steps: sucking fatty acid (1mol), diethylene glycol (2mol), glycerol (2mol) and the like into a reaction kettle in vacuum according to a sequence; adding terephthalic acid (3mol), phthalic anhydride (2mol) and trimethylol propane (2mol) from a solid feeding hole in the reaction kettle; after stirring in the reaction kettle for 1h, displacing air in the reaction kettle once with nitrogen gas; slowly raising the temperature of the reaction kettle to 180 DEG C to 240 DEG C, carrying out esterification reaction to distill water and maintaining the temperature for 4h; when the temperature of the top of an esterification tower is lower than about 95 DEG C and no water is discharged, sampling and testing an acid value; when the acid value is less than 15mgKOH / g, supplementing a catalyst Tio2 / SO4-2 solid super acid which accounts for 0.03 percent of the total amount; continually keeping heat and reacting for 1h; then carrying out vacuum extraction for about 2h and controlling the vacuum degree to be -0.085mPa to -0.095mPa; when the acid value is less than 2mgKOH / g, the reaction is completed; then cooling and filtering and packaging to obtain a bio-based aromatic hydrocarbon polyester polyol finished product.

Owner:张家港晟新和新材料有限公司

Tubular membrane based on nuclear pore membrane as well as preparation method and application thereof

InactiveCN111804155AIncrease selectionSimple processSemi-permeable membranesWater aerationAcute angleEngineering

The invention relates to a tubular membrane based on a nuclear pore membrane as well as a preparation method and application of the tubular membrane. The tubular membrane based on the nuclear pore membrane comprises a composite material, the composite material is rolled into a cylindrical pipe membrane according to an acute angle, and overlapping parts are welded and sealed through ultrasonic waves. The composite material comprises a supporting layer and a nuclear pore membrane layer, wherein the nuclear pore membrane layer is compounded on the inner side and / or the outer side of the supporting layer in a hot pressing mode, pore channels playing a role in screening are distributed in the nuclear pore membrane layer, the inner diameter of the pipe is larger than 2 mm, and the thickness of the pipe wall is larger than or equal to 10 micrometers. Through hot-pressing compounding, the nuclear pore membrane is successfully applied to the tubular membrane, the length of the tubular membraneis not limited, the minimum pore diameter of the tubular membrane can reach 0.01 mm, the filtering precision of the tubular membrane is improved, the bearing pressure value is larger, and the engineering application range is wide. According to the invention, the tubular membrane material variety and the preparation process are broadened, the tubular membrane adopts a new material, the physical andchemical properties of the tubular membrane are improved, and a solution is provided for the engineering application of the nuclear pore membrane.

Owner:惠州市科近离子膜材料研究院 +1

Fragrant degerming pea wood composite cat litter and preparation method for same

InactiveCN106376471AImprove antibacterial propertiesImprove adsorption capacityAnimal housingSodium bicarbonateFeces

The invention belongs to the technical field of cat litter technology and in particular relates to a fragrant degerming pea wood composite cat litter and a preparation method for the same. Pea wood can give out weak fragrant smell during the processing, so the cat litter made of the pea wood is fragrant and has low density, great water absorbing capacity, filling power, bacteria resistance and absorbing ability; and the cat litter can be biodegraded, thereby being green and environment-protective, so lift environment of cats can be effectively improved; cat litters can be regularly cast into soil, so soil can be improved; containing animal waste, the cat litter can work as organic fertilizer, so resource can be saved. In the preparation method, pea wood is matched with filling wood material, antibacterial agent, sodium bicarbonate and binders; a vertical circular mold granulator is applied, so particle size of cat litter particles is even and fine; great fluffiness can be achieved, so the cat litter has great absorbing capacity for excrement odor; and great yield can be provided, and production efficiency can be improved.

Owner:YANTAI CHINA PET FOODS GRP

Foaming agent and dispersant combinations for gypsum compositions

A lightweight gypsum compositions gypsum composition with good water resistance having a low water-to-stucco ratio, high flowability, and mechanical strength. The gypsum composition includes a cationic agent, an anionic agent, an aqueous stucco slurry containing a stucco, a water reducing dispersant, and water. The cationic agent may operate as a foaming agent, and the anionic agent may operate as a foam stabilizer.

Owner:ALLIED FOAM TECH

Aroma degerming apricot-wood composite litter box and preparing method thereof

InactiveCN106342705AImprove antibacterial propertiesImprove adsorption capacityAnimal housingSodium bicarbonateAnimal science

The invention belongs to technical field of litter box, especially relates to an aroma degerming apricot-wood composite litter box and a preparing method thereof. Apricot-wood can emit slight fragrant and sweet smell in processing. The litter boxis featured in small density, good water-absorbing quality, filling power, antibacterial property and absorptive property. The litter box is capable of biodegradation and environmental protection, to effectively improve living environment of cat. The regularly removed litter box can improve soil and animal waste can act as organic fertilizer, which saves resources. The preparing methodis to make apricot-wood, filling wood, antibacterial agent, sodium bicarbonate and binder react, and adopt vertical circular mould granulator to make litter box particles have uniform size, tiny aperture, and good filling power, which guarantees strong absorption of abnormal taste of excrement and has big output and production efficiency.

Owner:YANTAI CHINA PET FOODS GRP

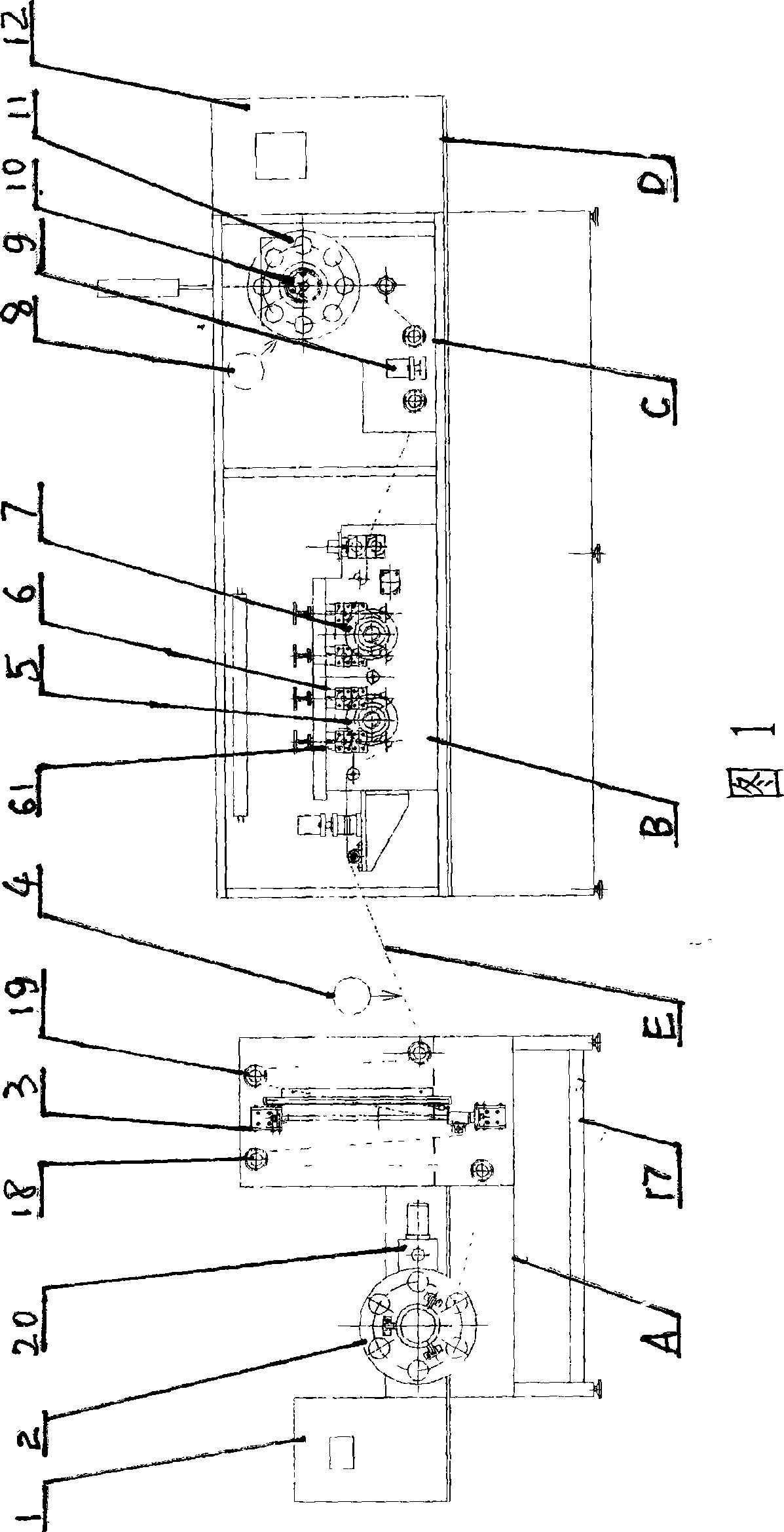

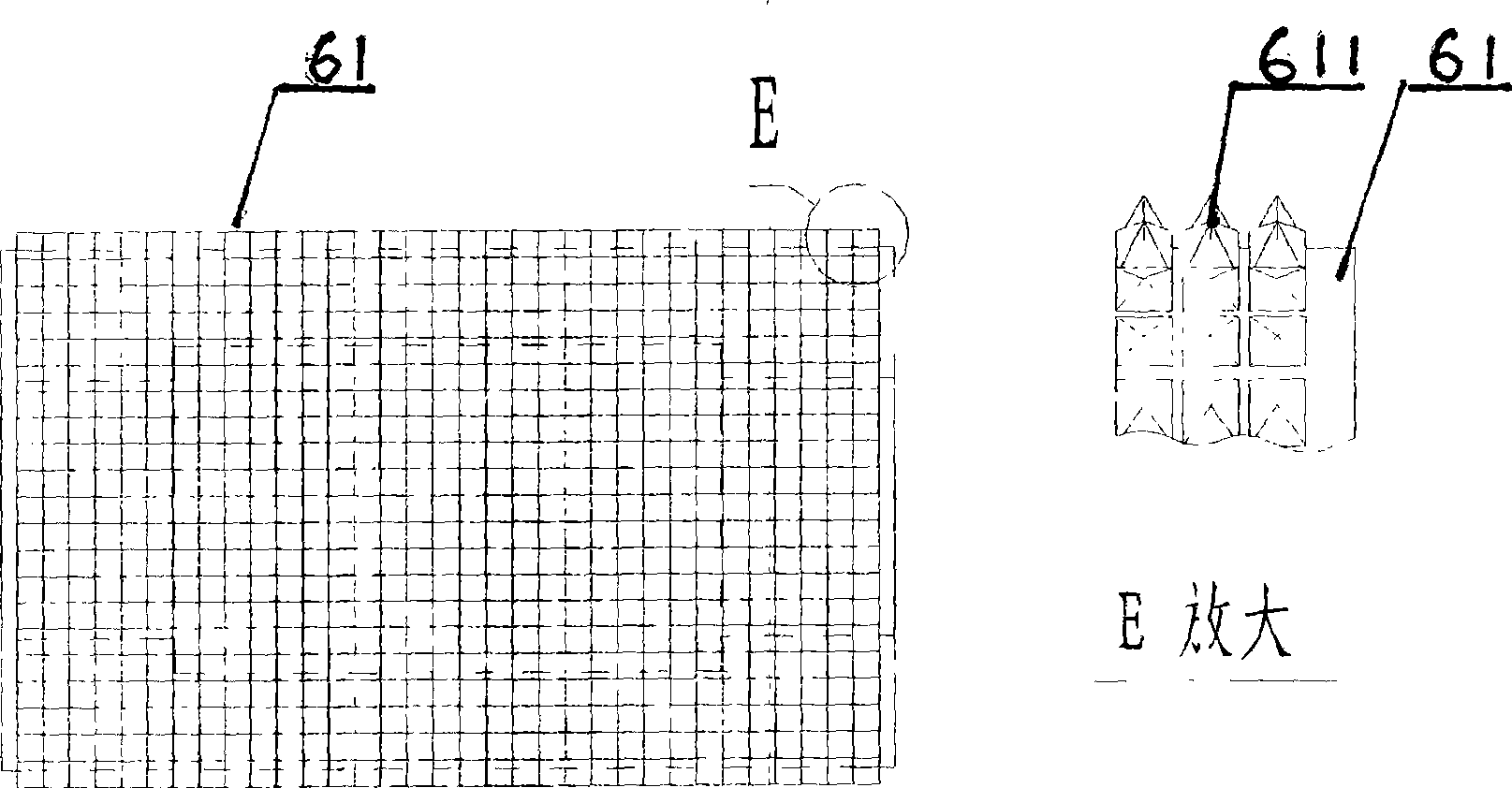

Apparatus for preparing Two-sided micropore burr steel belt

ActiveCN101038961BIncrease packing capacityImprove the fixing strengthPerforating toolsElectrode manufacturing processesFiberPunching

The invention provides a double-side micro-hole burr steel belt and manufacturing method and device thereof, wherein the double-side micro-hole burr steel belt molding device is invented based on the principle of holing by the double rollers opposite rolling, and the key is that the invention uses a group of holing rollers instead of traditional convex and concave die structure, and the holing rollers are in pure rolling state, the steel belt passes through the rollers form the gap between the rollers to be holed to form micro-holes, the burrs on the hole edge are respectively bended to opposite to from fiber-shaped burr on the surface of the steel belt. The holing rollers can be divided into two types, one type roller is equably disposed with geometrical teeth, whose shapes includes rectangle, taper, trigon or pyramid, on its surface, and another type roller is provided with geometrical annular slot, whose slot angle is trigon or rectangle, on its surface; according to the process requirement, the rollers can combine with that of another type, or combines with that of the same type. The holed steel belt made in this manner has hole shape arranged in various forms, and the hole diameter is very small and compact, the density of the burr hole is up to 625 pre square centimeter, and the burr on the surface of the steel belt is fiber-shaped; and the production speed is 20 times faster than that of the traditional punching die.

Owner:高宁宁

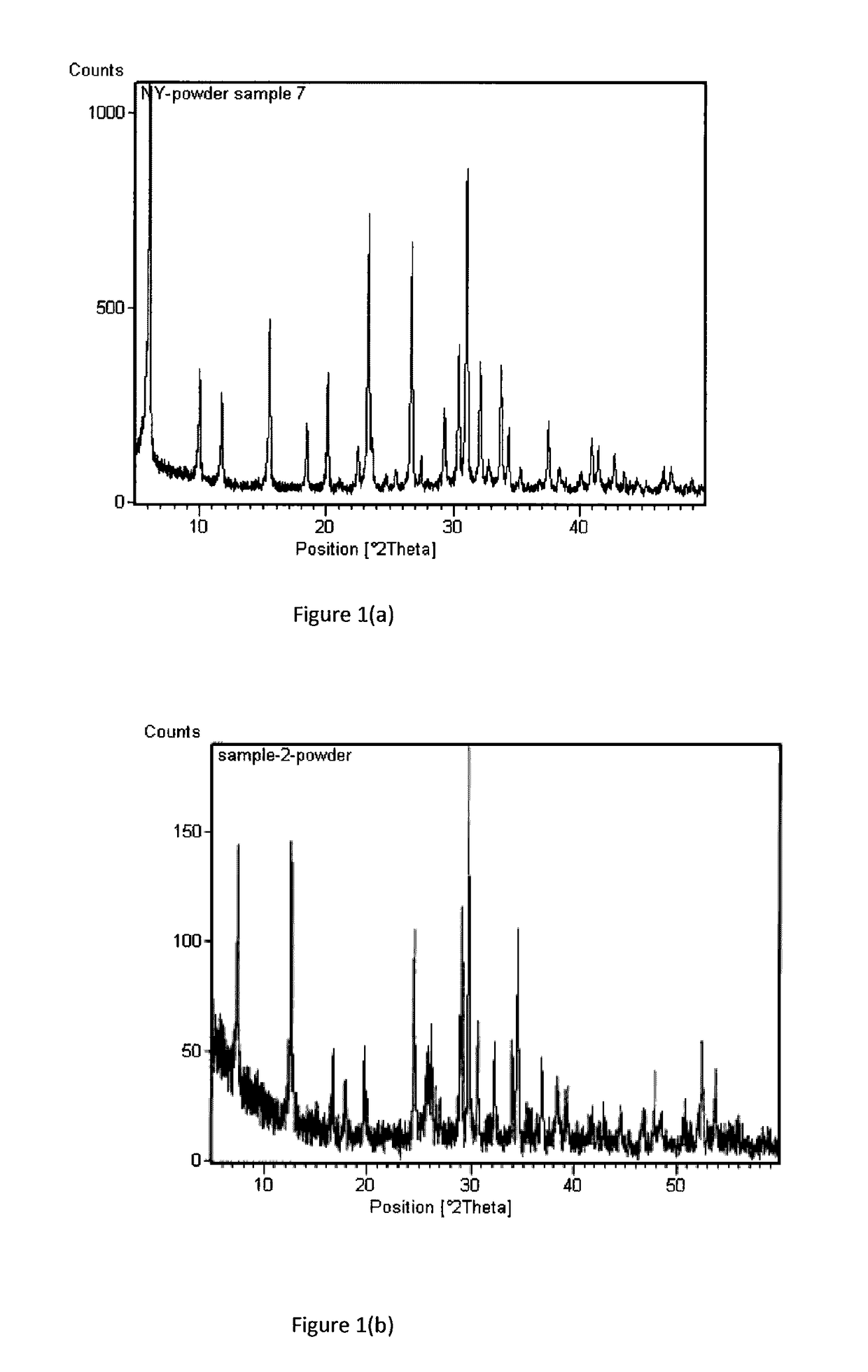

Electrochemical process for water splitting using porous Co3O4 nanorods

InactiveUS9879354B2Efficient and cost-effectiveReduce overpotentialElectrode shape/formsExchange current densityPhysical chemistry

The present invention discloses an electrochemical process for water splitting for production of oxygen using porous Co3O4 nanorods with a considerably low overpotential and high exchange current density. The present invention further discloses a simple, industrially feasible process of for preparation of said nanostructured porous cobalt oxide catalyst thereof.

Owner:COUNCIL OF SCI & IND RES

Preparation method of graphene composite PP filter membrane

PendingCN111530303AExtended service lifeImprove anti-pollution performanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolypropylenePolymer chemistry

The invention discloses a preparation method of a graphene composite PP filter membrane. The preparation method comprises the following steps: firstly, grafting and compounding graphene and polypropylene to prepare graphene composite PP master batch, then adding the master batch and an additive into a polypropylene melt extruder to prepare a graphene composite PP single-layer membrane, and superposing and hot-pressing the membranes to prepare the graphene composite PP filter membrane. Compared with a common membrane, the graphene composite PP membrane has the advantages that the pore diameteris small, the adsorption performance is just good, impurities in water can be effectively blocked, and a good filtering effect is achieved.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com