Tubular membrane based on nuclear pore membrane as well as preparation method and application thereof

A technology of nuclear pore membranes and tubular membranes, applied in the field of nuclear pore membranes, tubular membranes based on nuclear pore membranes and their preparation, can solve the problems of low filtration accuracy, limited material selection of tubular membranes, and engineering applications of nuclear pore membranes Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a tubular membrane based on a nuclear pore membrane, comprising the following steps:

[0033] Prepare materials, prepare nuclear pore membranes and non-woven fabrics;

[0034] Composite, the nuclear pore membrane is composited with the non-woven fabric, and the nuclear pore membrane is composited on the inner side and / or the reverse side of the non-woven fabric;

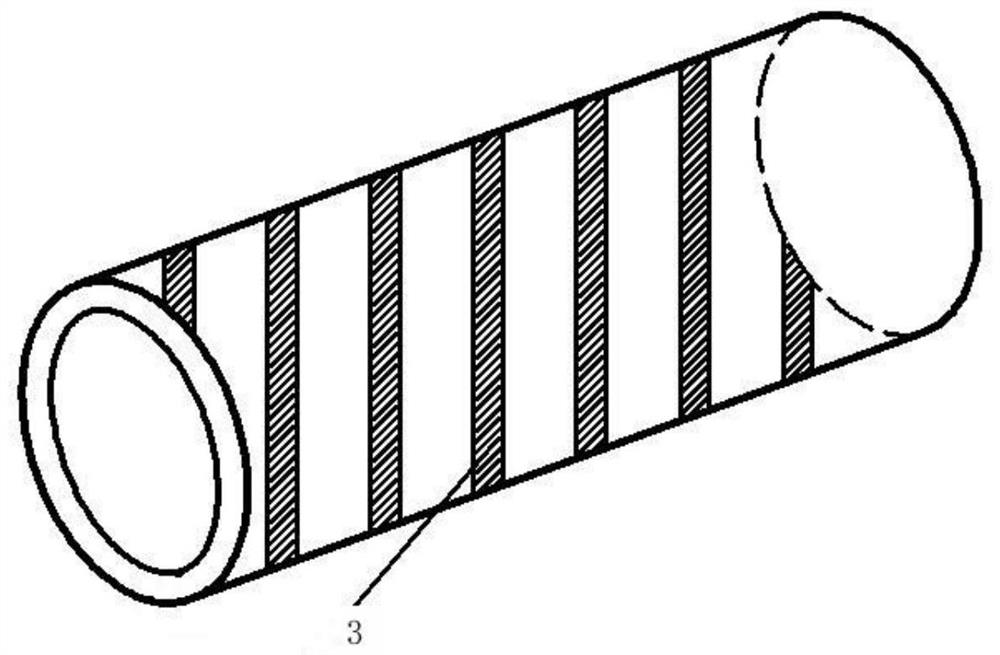

[0035] Cutting, cutting the composited film into narrow strips, the width of the narrow strips is 1-20 mm;

[0036]Rolling tube, according to the need, roll the composite film cut into narrow strips into a cylindrical tube film at a certain angle, the diameter of the tube tube film is 6mm-8mm, and the angle is 30°-60°; There is an overlapping position between the films, and the overlapping position is sealed and welded by ultrasonic waves, and the width of the weld seam at the overlapping position is 1-3 mm.

[0037] The compounding method in the above steps is h...

specific Embodiment 1

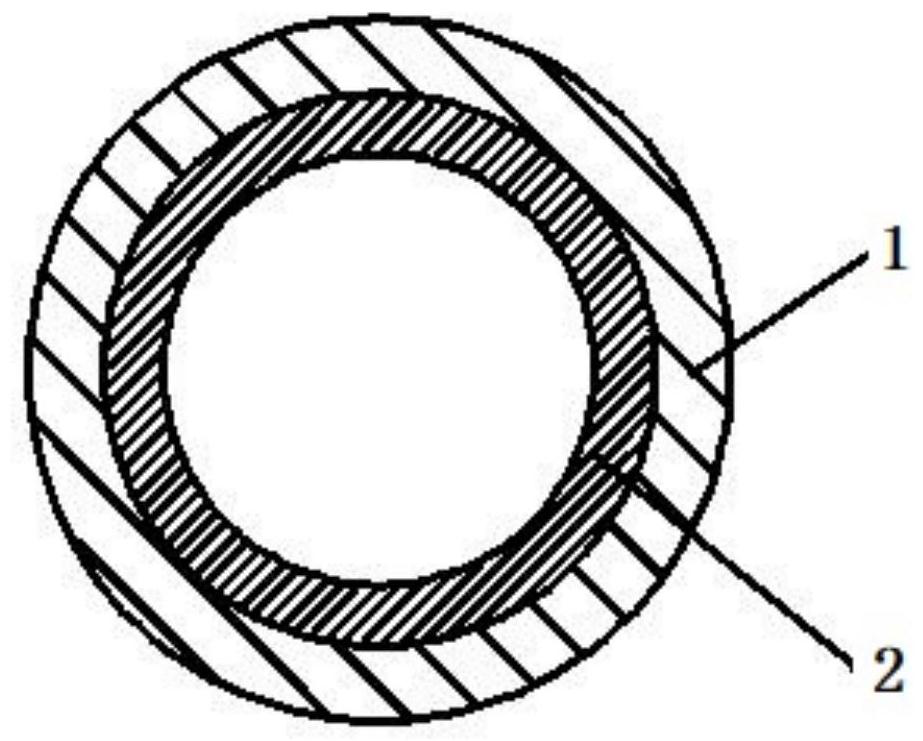

[0040] This embodiment provides a tubular membrane based on a nuclear pore membrane, including a composite material. The composite material is rolled into a tubular tubular membrane at an acute angle, and the overlap is sealed by ultrasonic welding. The composite material includes a support layer and a core. Porous film layer, the support layer is PET non-woven fabric, the nuclear pore film layer is hot-compressed on the inner side of the support layer, and the pores that play a screening role are distributed in the nuclear pore film layer, and the adjacent composite There is an overlapping position between the materials, and the width of the overlapping position is 2 mm. The composite material is rolled into a tubular tube film at 45°, and the overlapping is sealed by ultrasonic welding.

[0041] The material of the nuclear pore membrane layer is PET, the thickness of the nuclear pore membrane layer is 15 microns, the pore diameter is 15 microns, and the pore density is 2×10 ...

specific Embodiment 2

[0048] This embodiment provides a tubular membrane based on a nuclear pore membrane, including a composite material. The composite material is rolled into a tubular tubular membrane at an acute angle, and the overlap is sealed by ultrasonic welding. The composite material includes a support layer and a core. Porous film layer, the support layer is PP non-woven fabric, the nuclear pore film layer is hot-compressed on the inner side of the support layer, and the pores that play a screening role are distributed in the nuclear pore film layer, and the adjacent composite There is an overlapping position between the materials, and the width of the overlapping position is 3 millimeters. The composite material is rolled into a cylindrical tubular film at 30°, and the overlapping position is sealed by ultrasonic welding.

[0049] The material of the nuclear pore membrane layer is PP, the thickness of the nuclear pore membrane is 15 microns, the pore diameter is 15 microns, and the pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com