Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Faster molding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

Anhydrous resin bonding agent for fireproof material and preparation method thereof

ActiveCN101538451AViscosity can be controlled and adjustedGood adaptability to molding processAldehyde/ketone condensation polymer adhesivesBrickRefractory

The invention discloses an anhydrous resin bonding agent for a fireproof material and a preparation method thereof. The anhydrous resin bonding agent is characterized in that after phenol and aldehyde are synthetized into phenol aldehyde linear resin under the action of an acid composite catalyst, a solvent without hydroxide radicals is added for dissolving; and isocyanate is used for modifying to prepare the anhydrous resin bonding agent. The anhydrous resin bonding agent for the fireproof material contain no water, has moderate viscosity, generate no water in the process of solidifying and is particularly suitable for manufacturing alkaline fireproof material products containing calcium, such as magnesia-calcium bricks, dolomite bricks, and the like. The alkaline fireproof material products have long storage time, no easy aquation, no generation of volumetric expansion and high product strength and effectively improve the quality of the fireproof material.

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

Method for preparing carbon fiber reinforced thermoplastic composite material

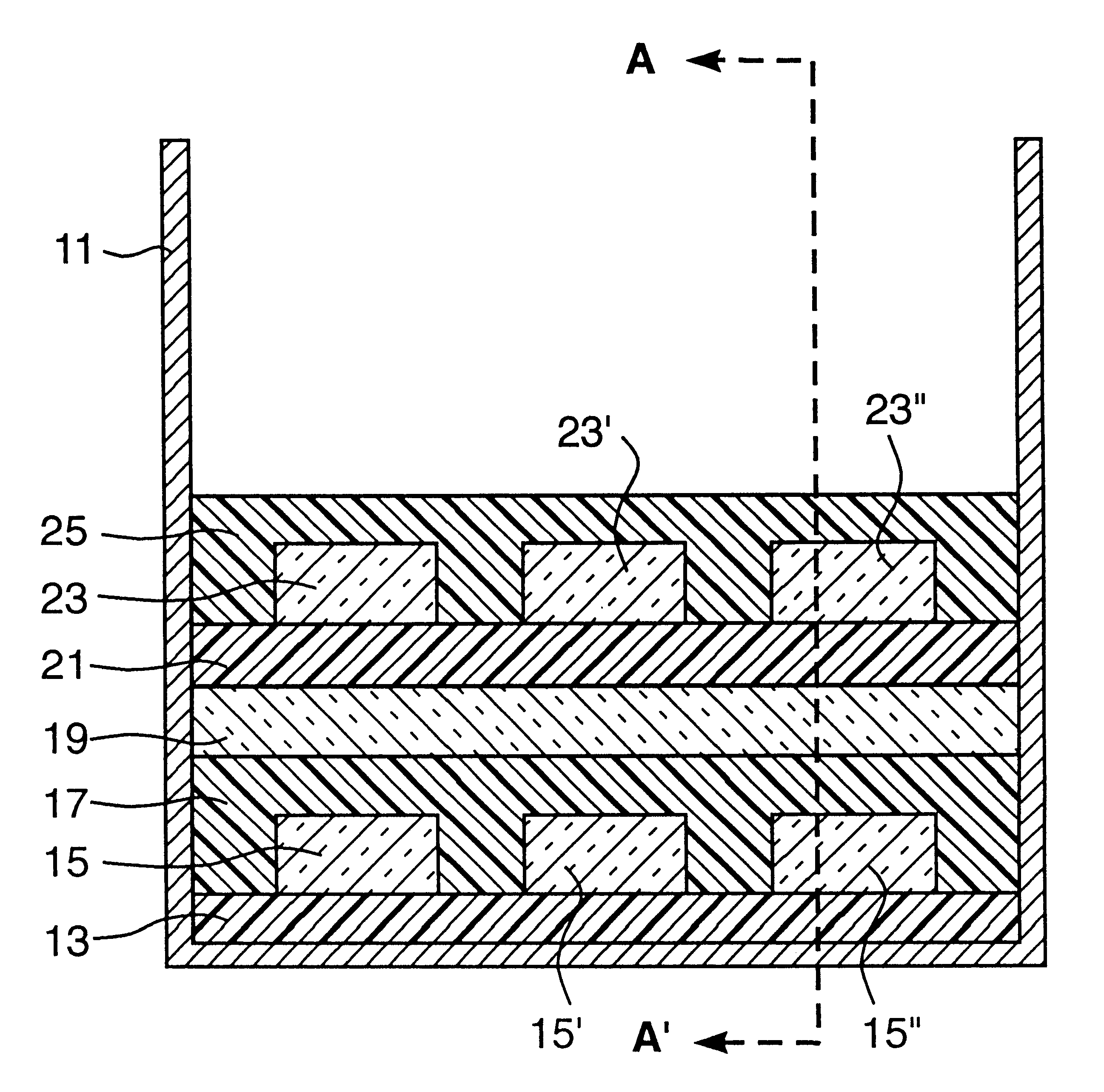

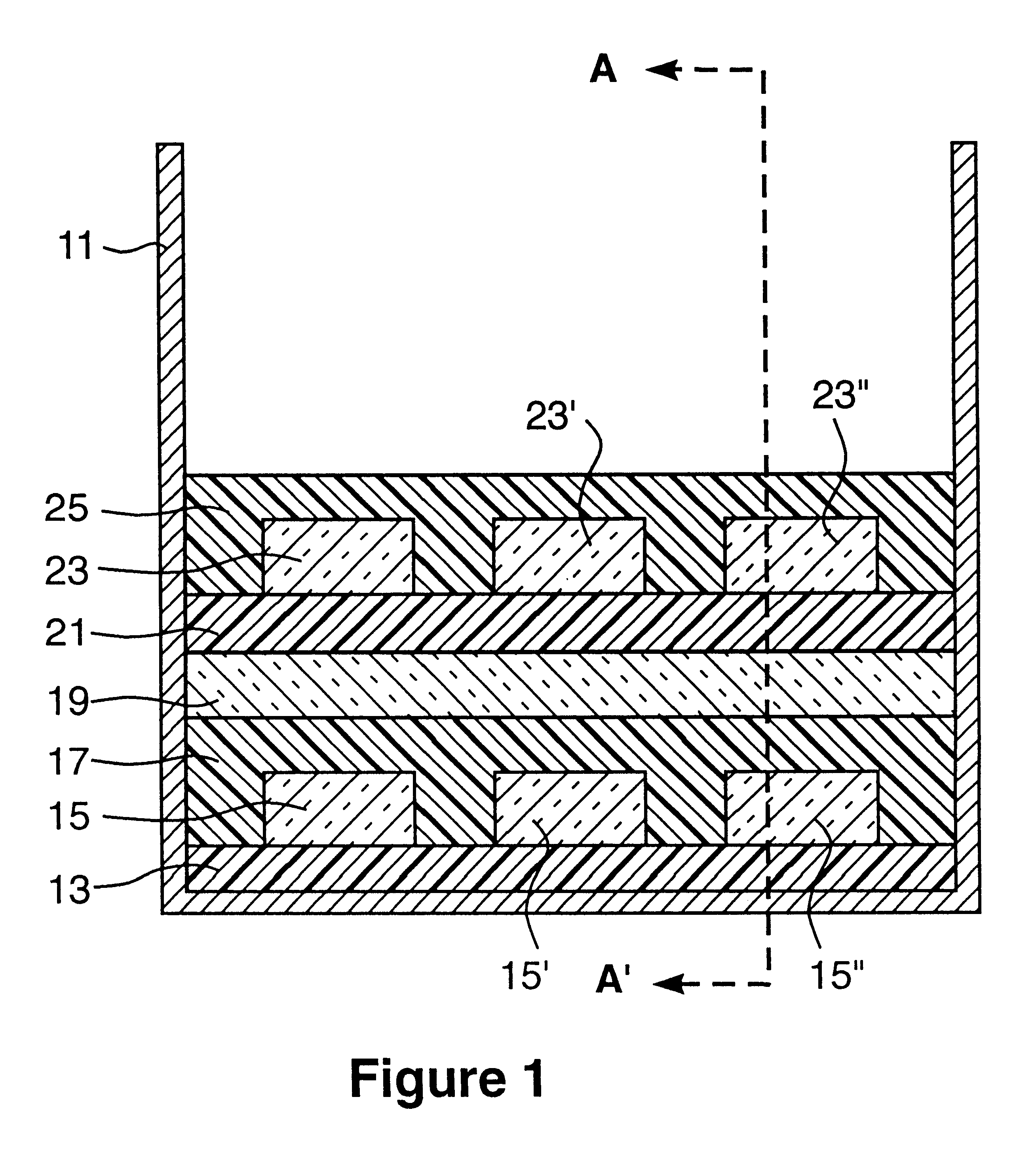

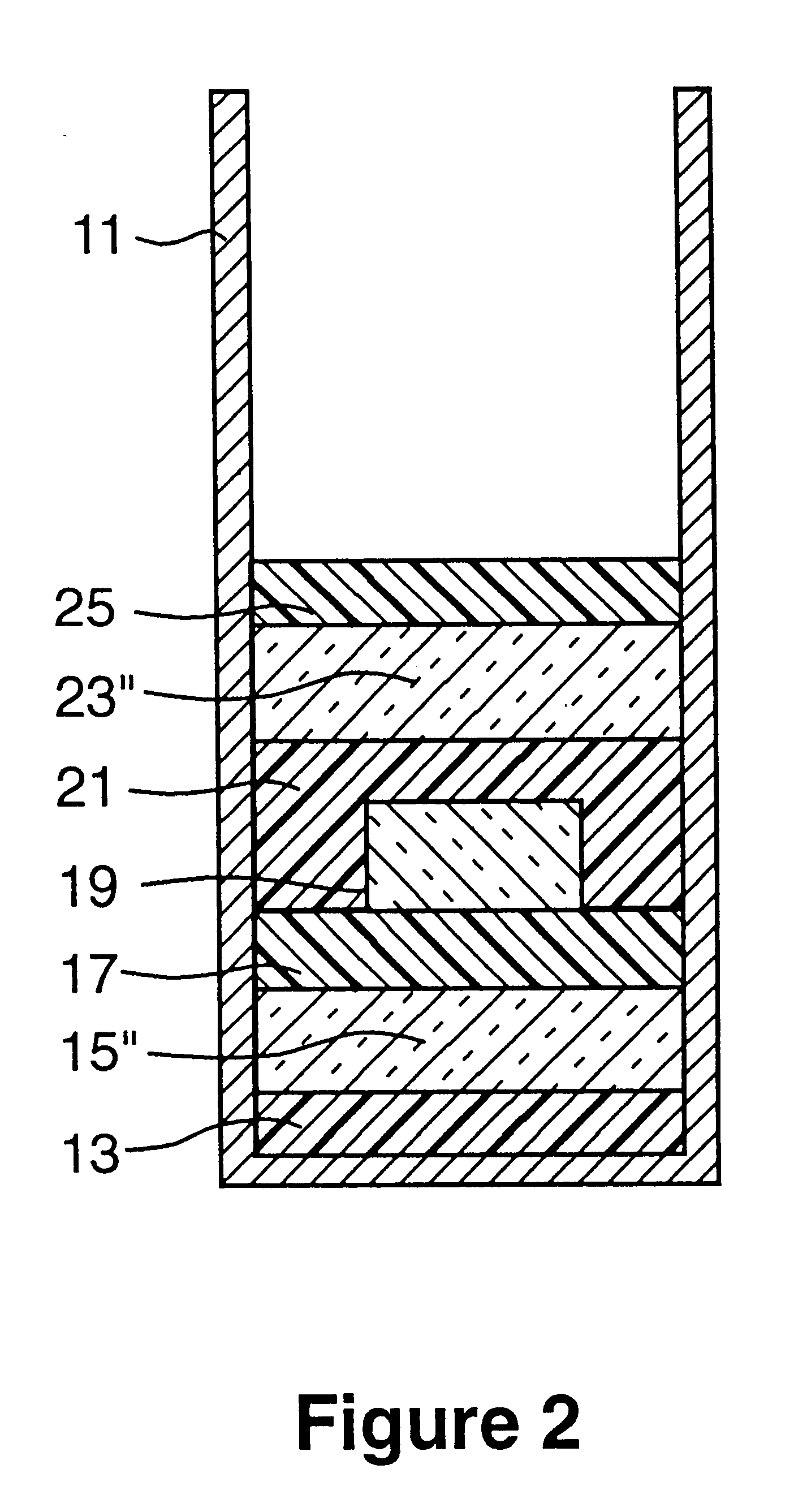

The invention discloses a method for preparing a carbon fiber reinforced thermoplastic composite material, which comprises the following steps: 1)alternatively paving carbon fiber and thermoplastic resin in a die, wherein a bottom layer and a top layer of the die are thermoplastic resin, closing the die and applying pressure; 2)accessing power supply to a carbon fiber layer, rapidly heating under current effect, when the temperature is higher than the melting point of thermoplastic resin, fusing thermoplastic resin, dipping carbon fiber under pressure; and 3)breaking power, cooling the die, and then opening the die to obtain the carbon fiber reinforced thermoplastic composite material. The method takes carbon fiber as a heat-generating body, the electrothermal conversion efficiency can reach as high as more than 90%, and the energy saving effect is obvious; simultaneously, carbon fiber is capable of melting thermoplastic resin and completing dipping, and has the advantages of short moulding time and good dipping effect, formation of good cross section of thermoplastic resin and fiber can be realized, composite material performance is increased, and processing of product with large thickness can be realized in short time.

Owner:蓝星纤维(北京)有限公司

Polymer gel molds

InactiveUS6365082B1Easy and inexpensive to fabricateNot prone to problemCeramic shaping apparatusCoatingsPolymer sciencePolymer gel

Owner:LOCKHEED MARTIN ENERGY SYST INC

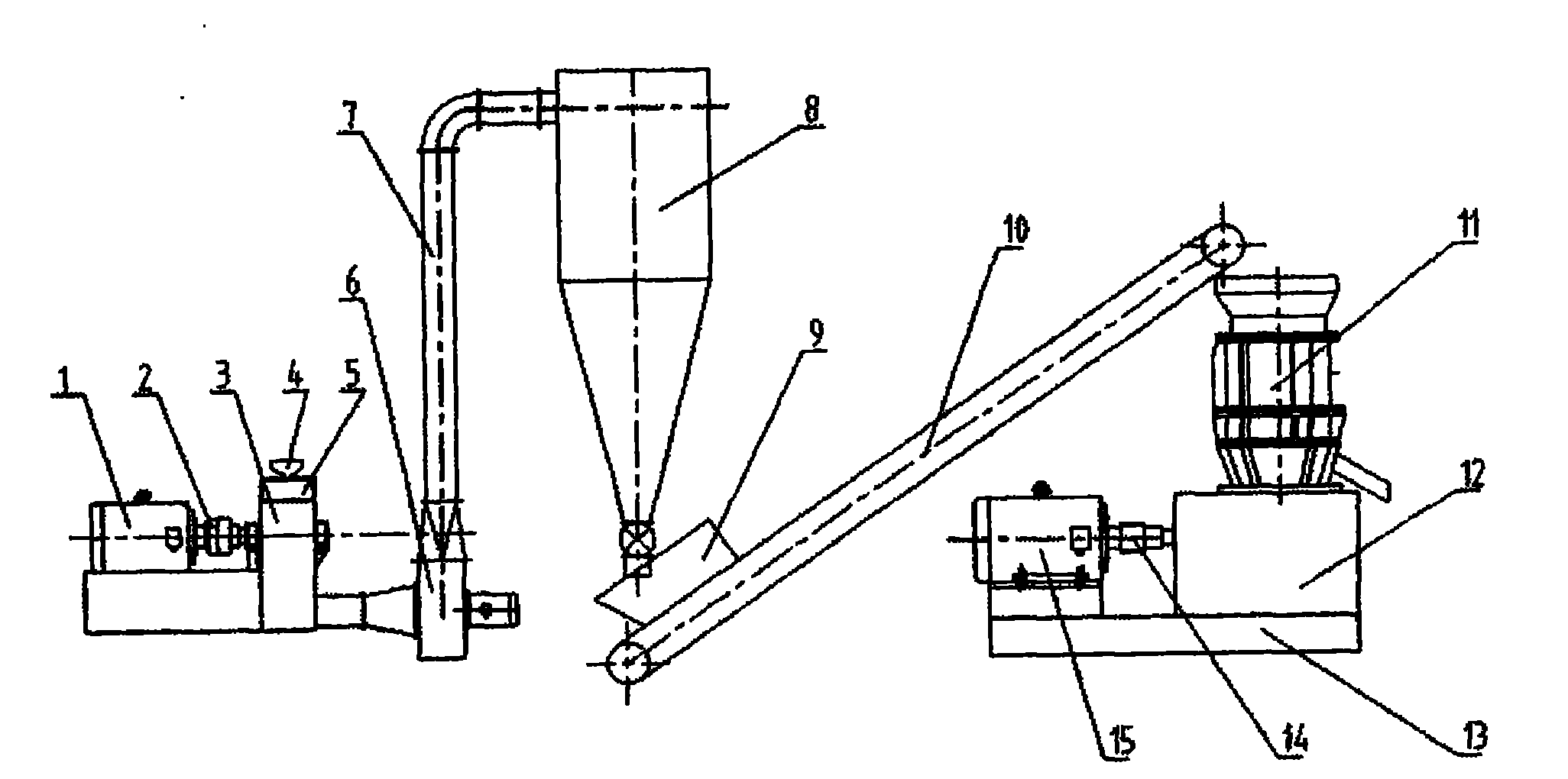

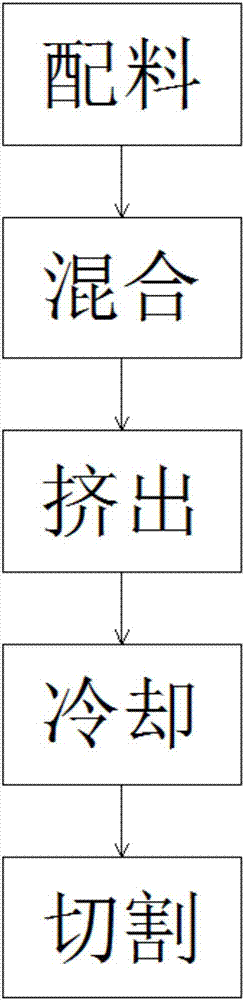

Biomass granulation system and device

ActiveCN101797490ACalorific value stableNo alkali corrosion problemBiofuelsSolid fuelsSlagEngineering

The invention discloses a biomass granulation system and a biomass granulation device. Biomass is delivered to a crusher to be crushed, the crushed biomass is pumped out through a blower and fed into a cyclone dust collector to perform gas-solid separation, and the separated material is made into granules through a biomass granulator; pulverized coal or diatomite can be added into the biomass delivered to the crusher; a temperature sensor is arranged in a molding cavity, the biomass granulator is driven by a variable frequency motor, and the rotating speed of the variable frequency motor is automatically adjusted through a monitored temperature signal; and a straight hole or a conical-straight composite through hole is formed on a flat die of the granulator. The biomass and the additive can be mixed while crushing, so the mixing uniformity of different materials is improved; the provided temperature sensor adjusts the rotating speed of the variable frequency motor and stabilizes the water content of the biomass molding granules; and the straight hole or the conical-straight composite through hole is formed on the flat die of the granulator, the molding time of the biomass granules is prolonged, the molding intensity is increased, and the slag dropping defect of the current granulator is overcome.

Owner:邢献军

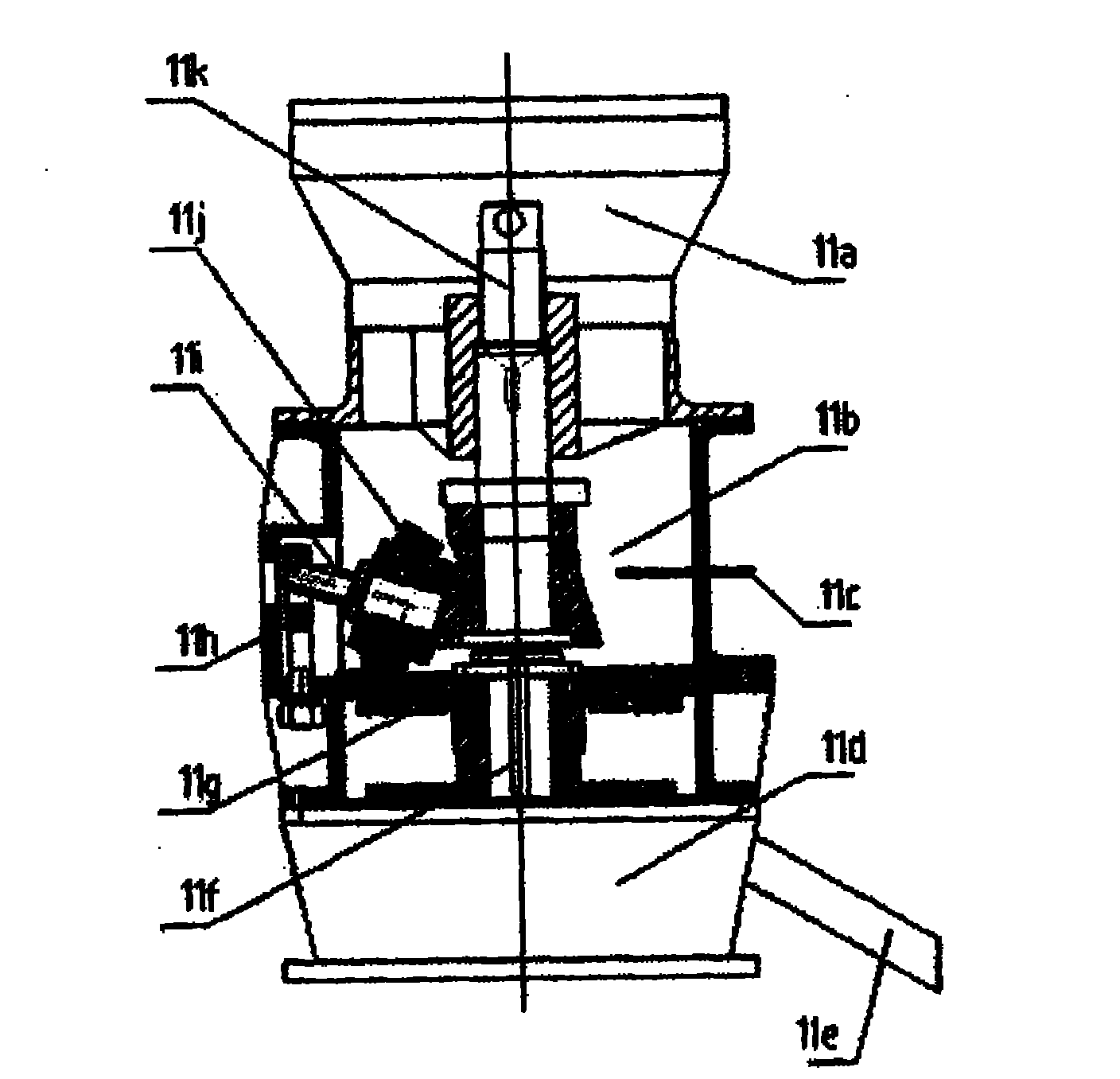

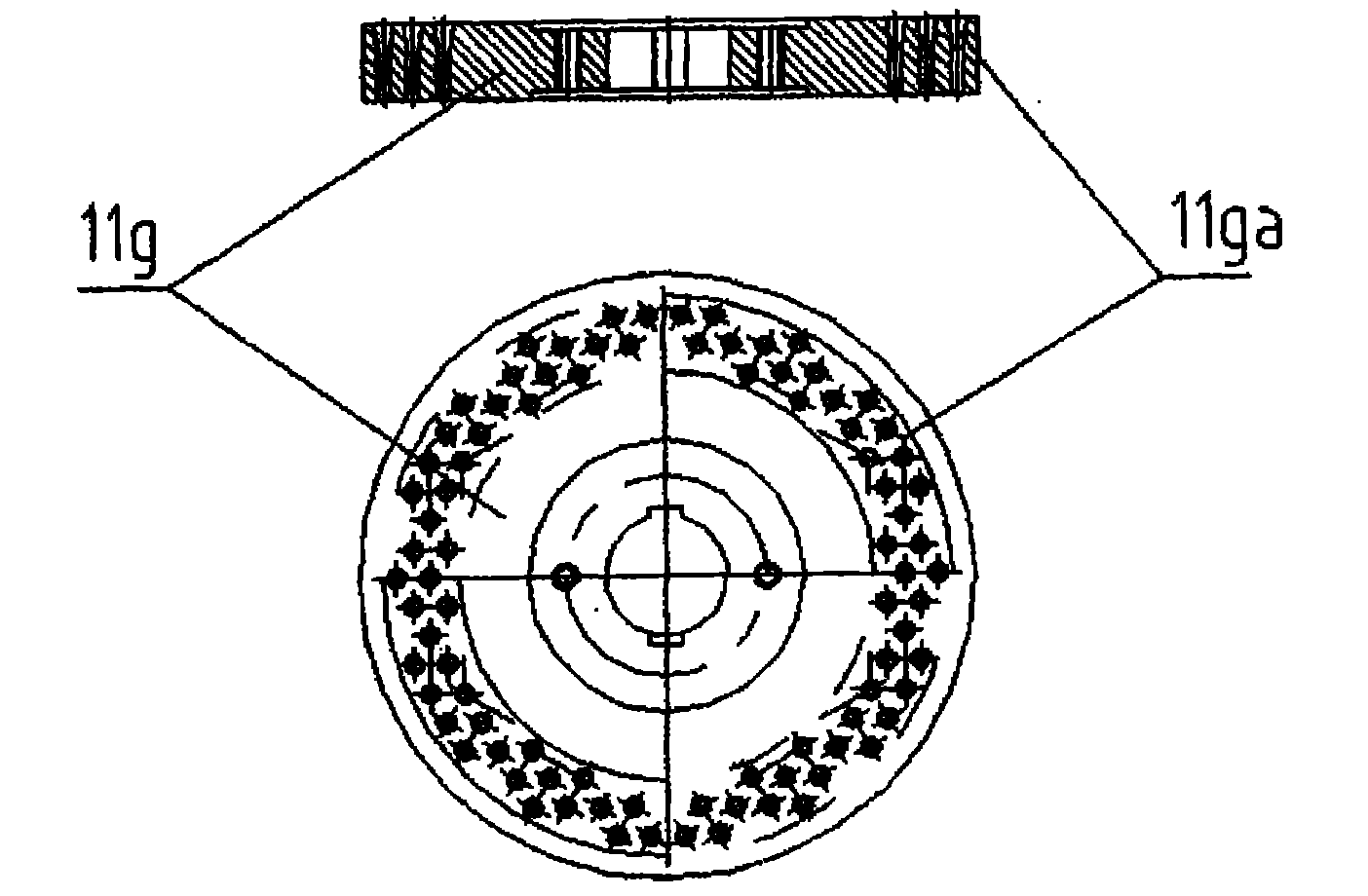

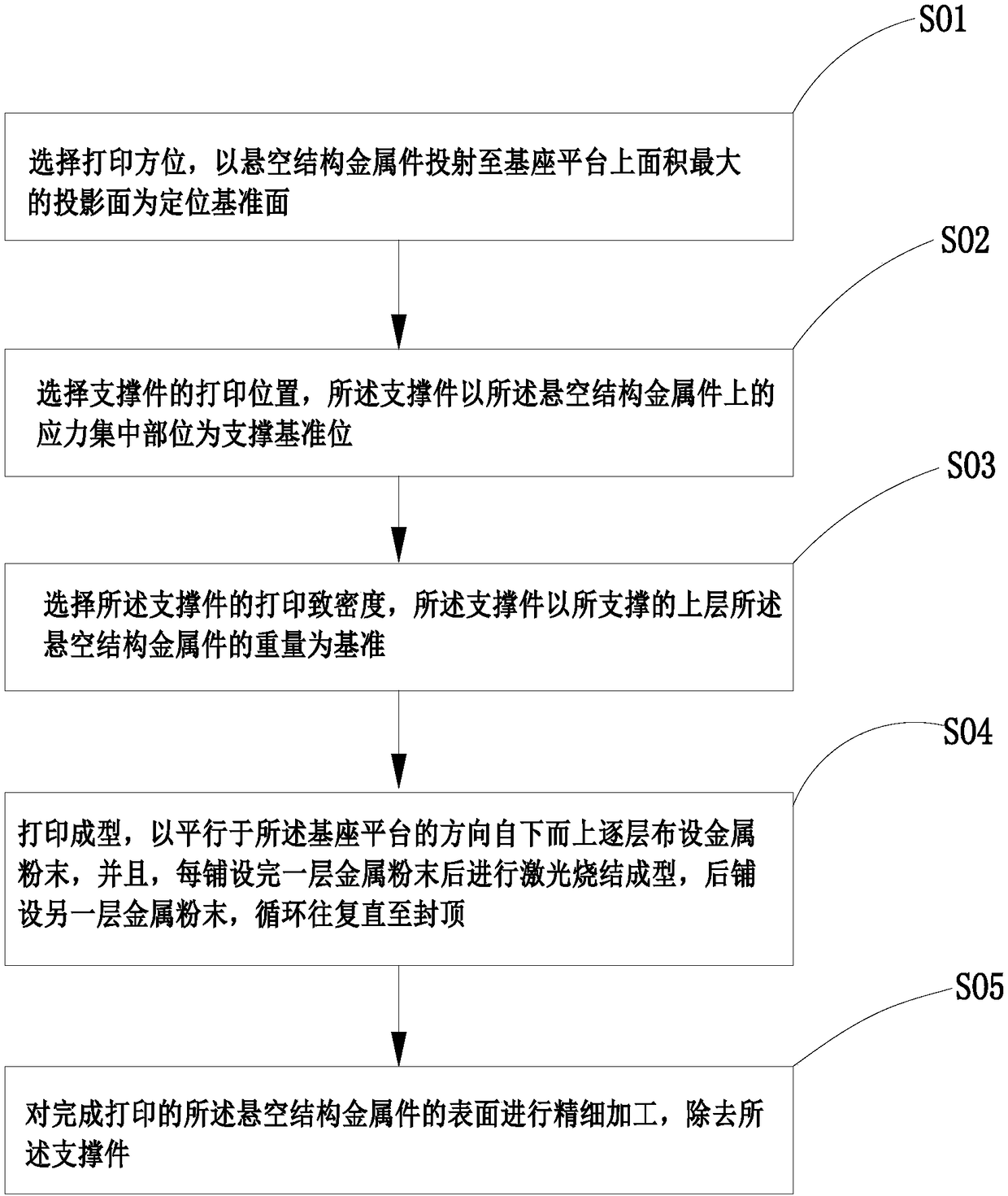

3D printing method of metal part of hollowed structure

ActiveCN109420761AGuaranteed stabilityReduce the occurrence of cantilever beam structuresAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringForming processes

The invention relates to the technical field of 3D printing manufacturing, and provides a 3D printing method of a metal part of a hollowed structure. The 3D printing method comprises the following steps that firstly, a printing orientation is selected, and refers to the placement orientation of the metal part of the hollowed structure on a base platform; secondly, a printing position of a supporting part is selected, and the supporting part takes a stress concentrated part on the metal part of the hollowed structure as a supporting reference position; thirdly, the printing density of the supporting part is selected, and the supporting part take weight of the supported upper-layer the metal part of the hollowed structure as a benchmark; and finally, after early-stage preparation work is completed, printing forming is conducted in the following printing forming process, metal powder is laid layer by layer from bottom to top in the direction parallel to the base platform, laser sinteringforming is carried out after each layer of metal powder is laid, another layer of metal powder is laid after sintering is completed, the steps are carried out repeatedly until the last layer of metalpowder of the metal part of the hollowed structure is sintered, and then capping is carried out.

Owner:SHENZHEN SILVER BASIS TECH

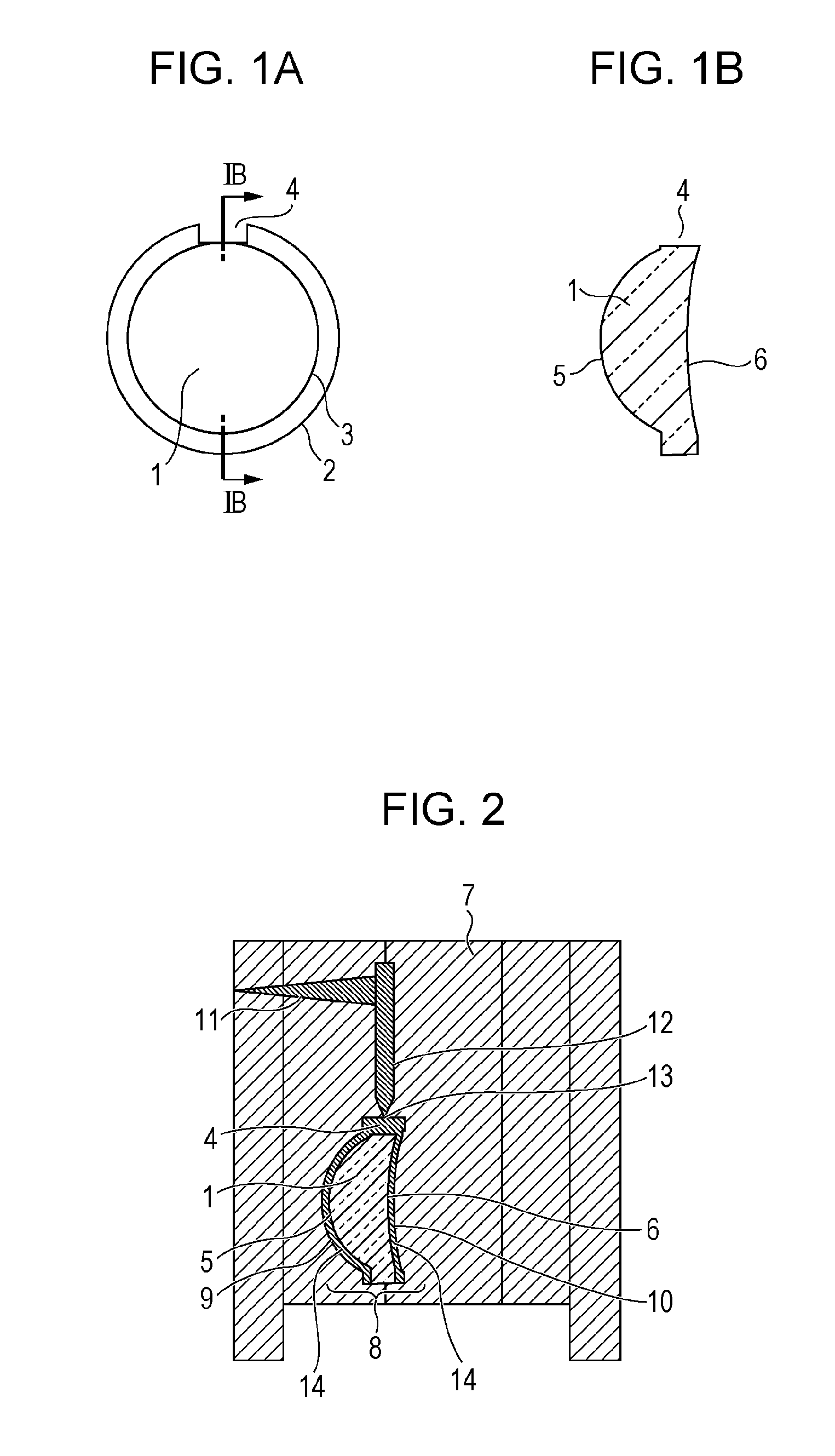

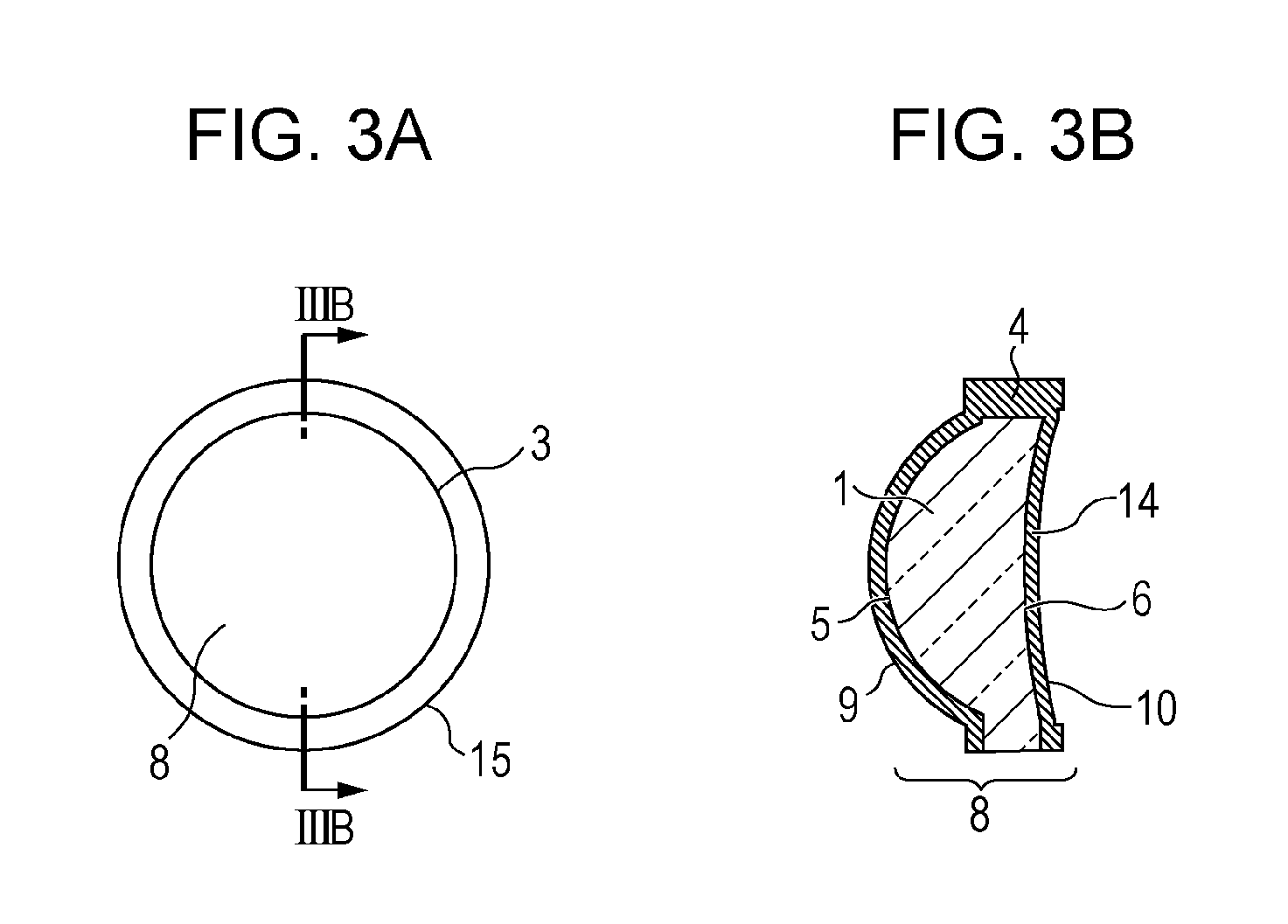

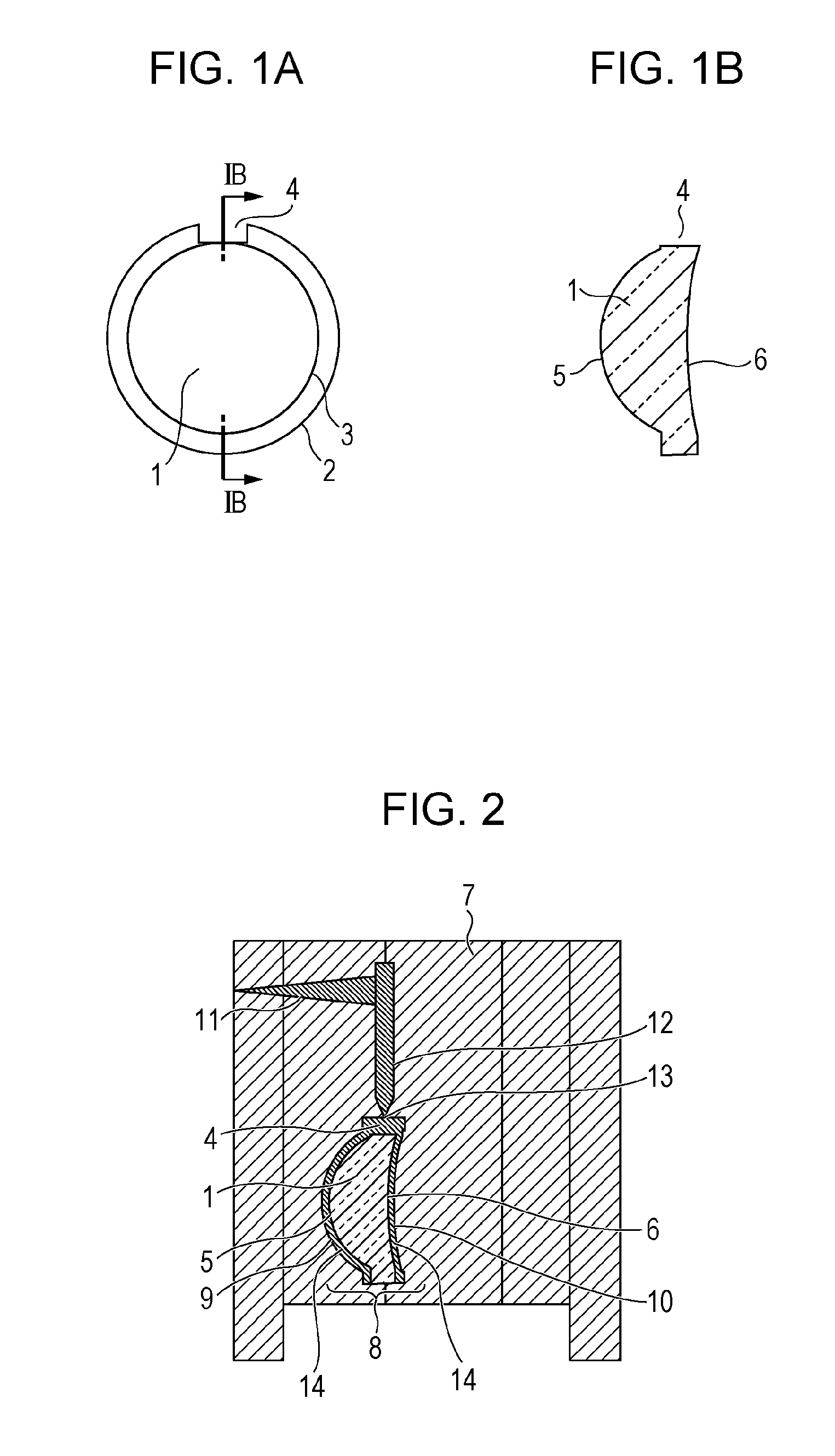

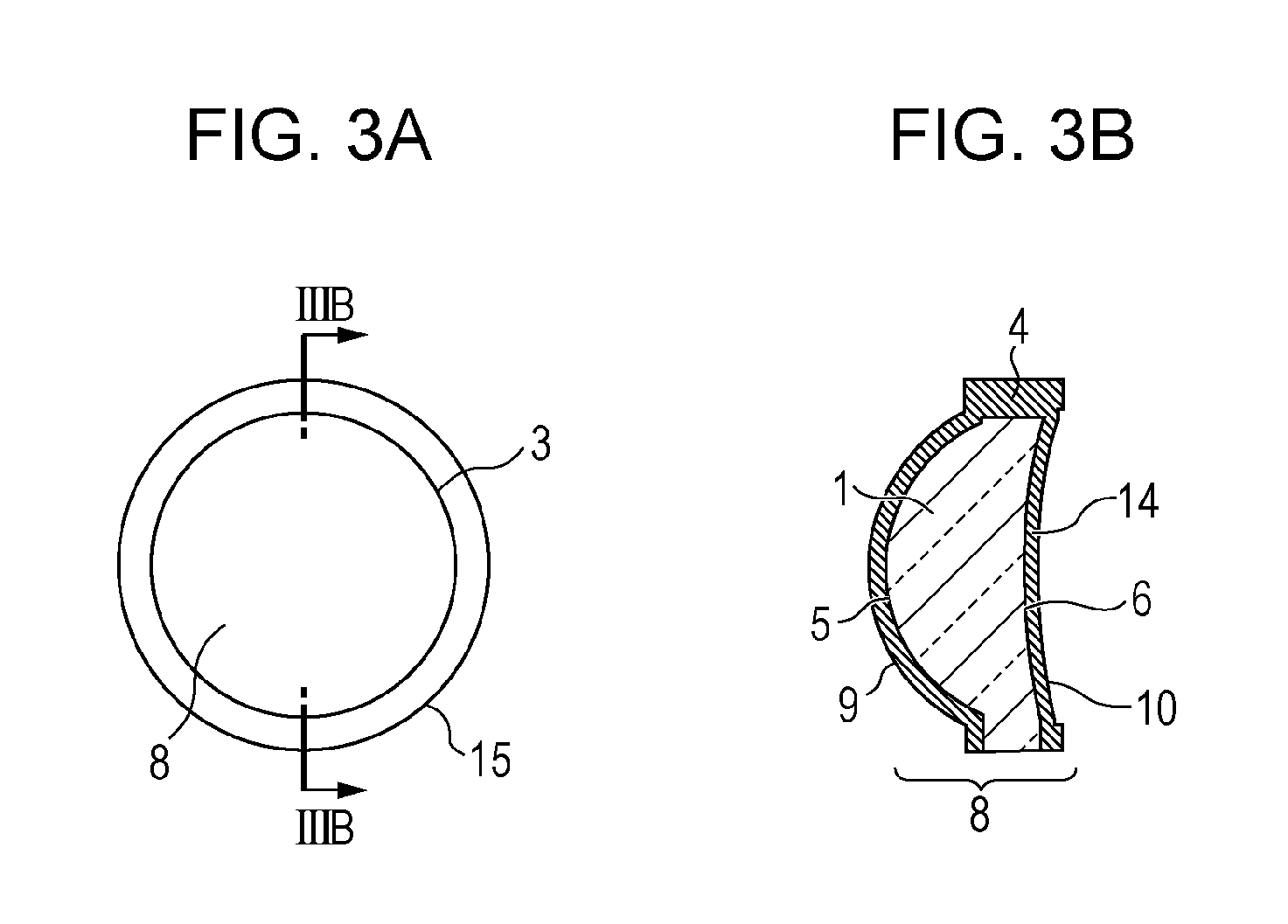

Optical component and method of making the same

ActiveUS20120224267A1Small sizeIncreasing molding timeOptical articlesMountingsBiomedical engineeringEngineering

Owner:CANON KK

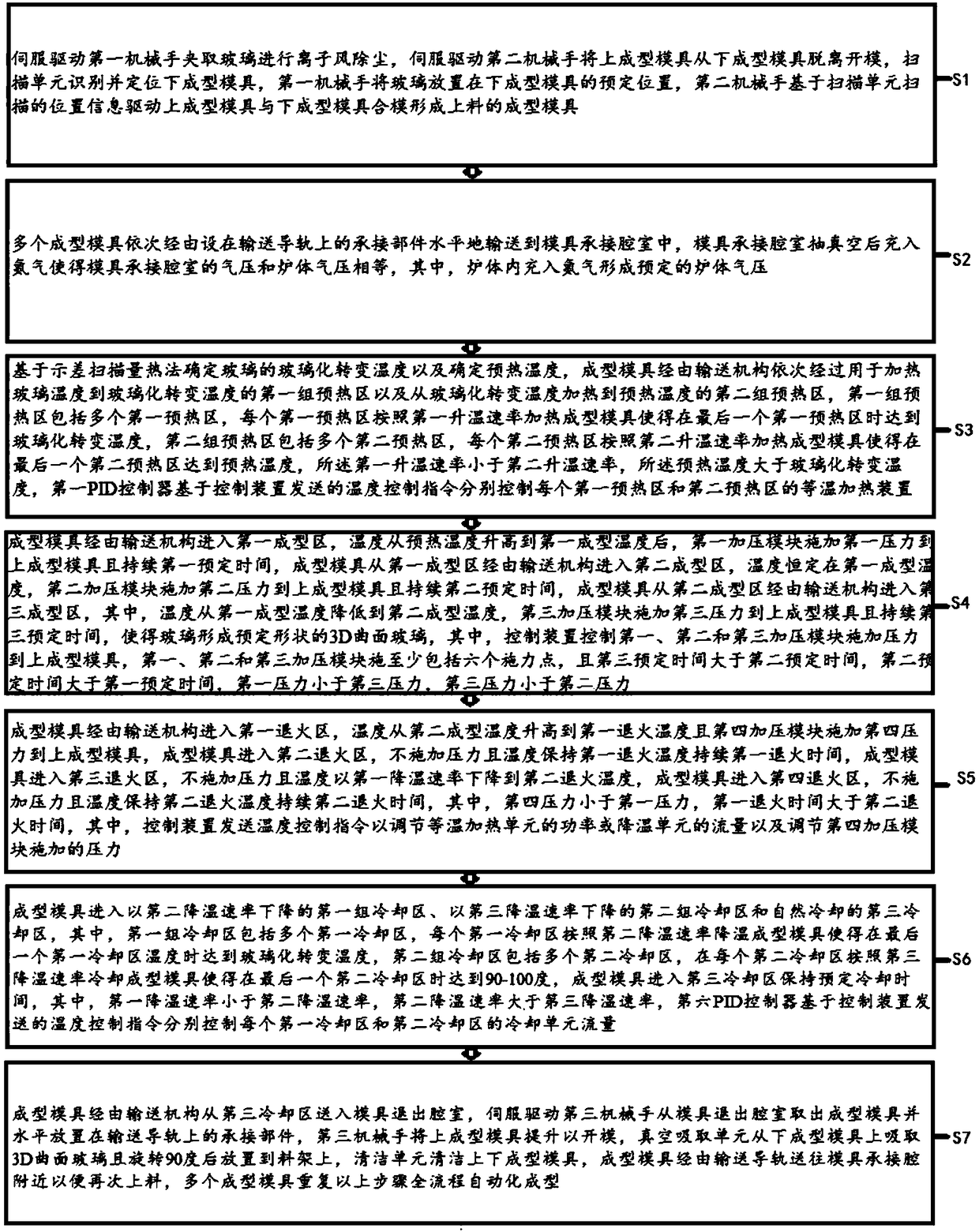

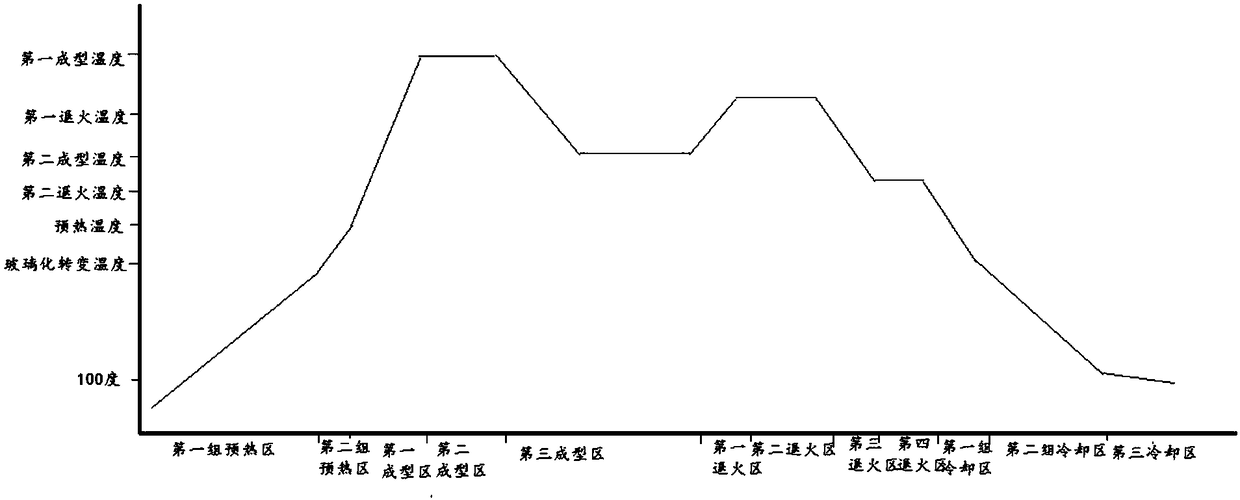

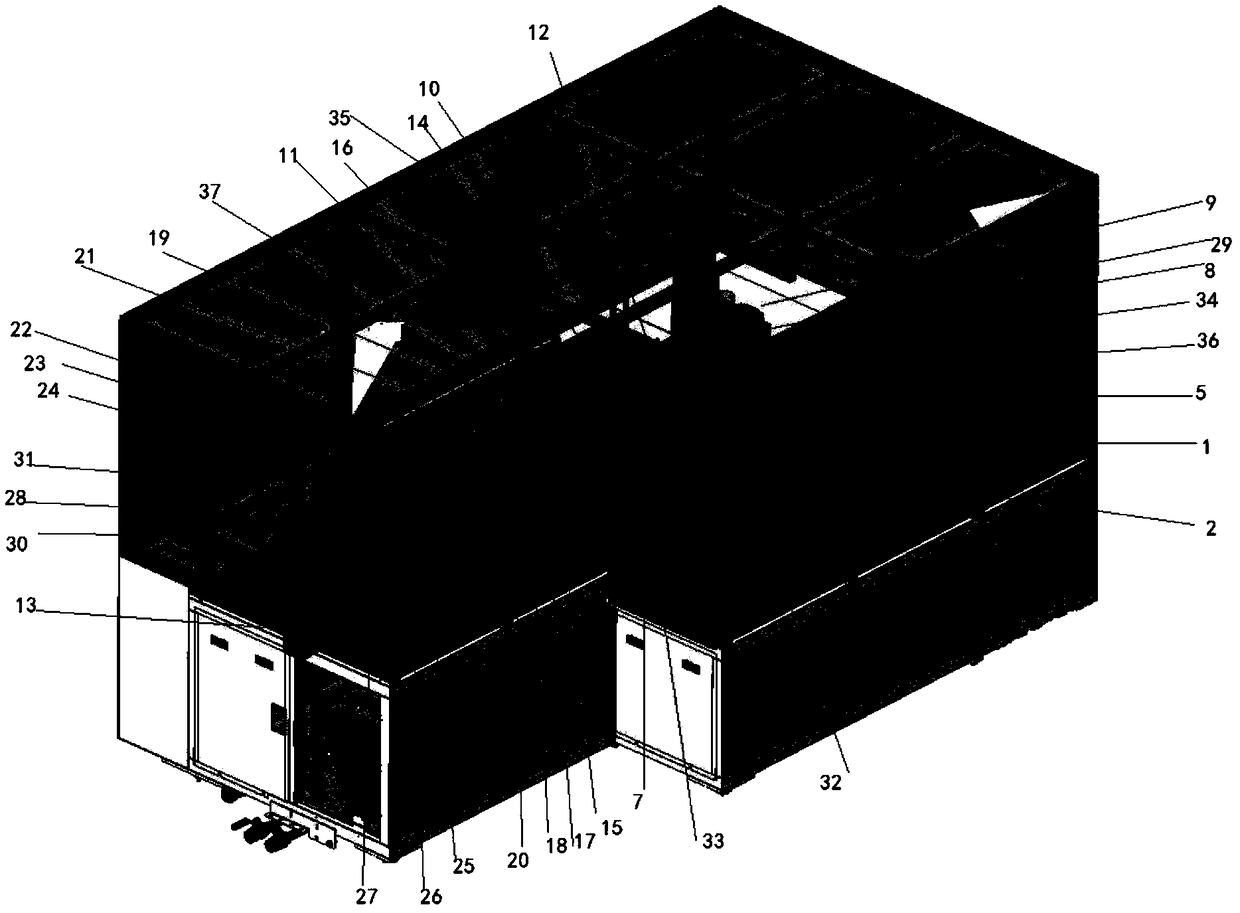

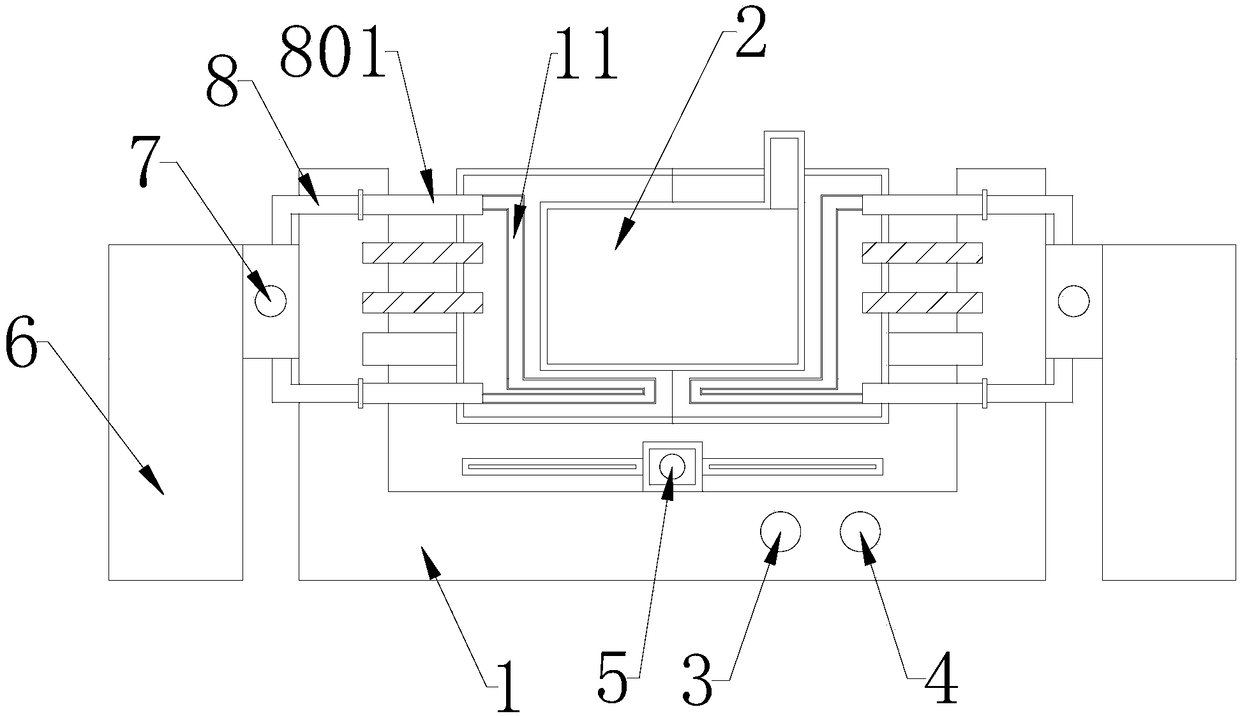

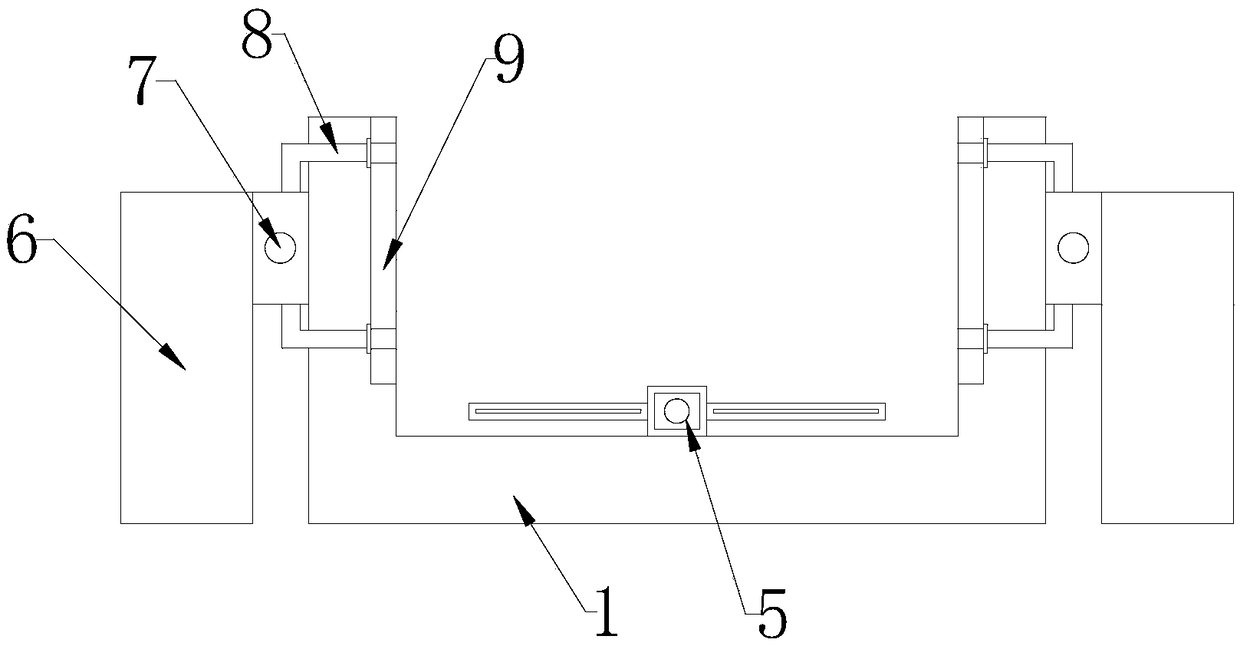

Forming method of 3D curved glass, forming system and 3D curved glass

InactiveCN108585452AAvoid the risk of splinteringSoften evenly and fullyGlass reforming apparatusNitrogenEngineering

The invention discloses a forming method of 3D curved glass, a forming system and the 3D curved glass. The forming method of the 3D curved glass comprises the following steps: a second manipulator (2)performs die assembling on the basis of position information scanned by a scanning unit (5) to form forming dies (6) for loading materials; the multiple forming dies (6) are horizontally conveyed into a die carrying cavity (8) in sequence; after being vacuumized, the die carrying cavity (8) is filled with nitrogen to enable gas pressure in the die carrying cavity (8) to be equal to that of a furnace body (9); the forming dies (6) pass through a first group of preheating regions (10) for heating glass from a temperature to a glass transition temperature and a second group of preheating regions(11) for heating the glass from the glass transition temperature to a preheating temperature in sequence through a conveying mechanism; after being formed, annealed and cooled, the forming dies (6) are conveyed to a position near to the die carrying die (8) through a conveying guide rail (7) for material reloading; the multiple forming dies (6) are repeatedly subjected to the processes to realizeautomatic forming in the whole procedure.

Owner:深圳市太平洋自动化设备有限公司

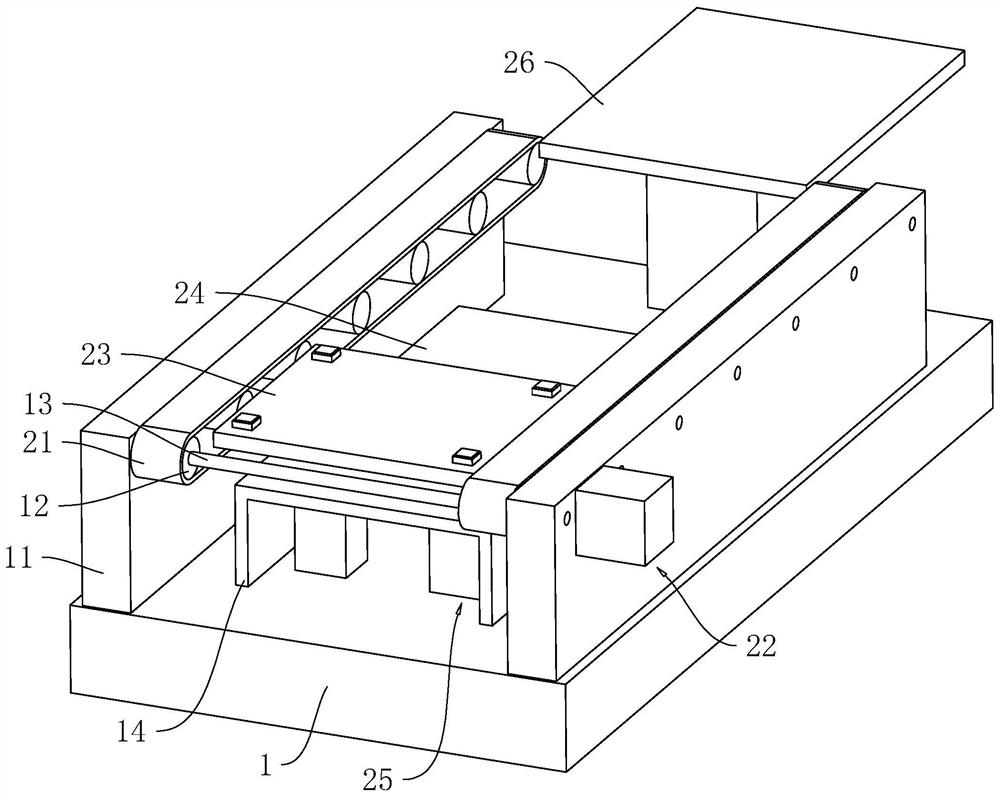

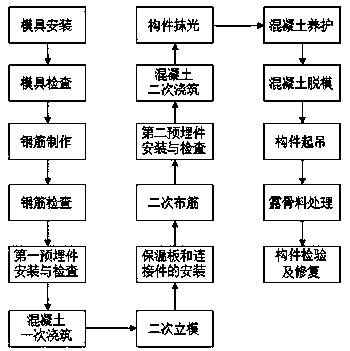

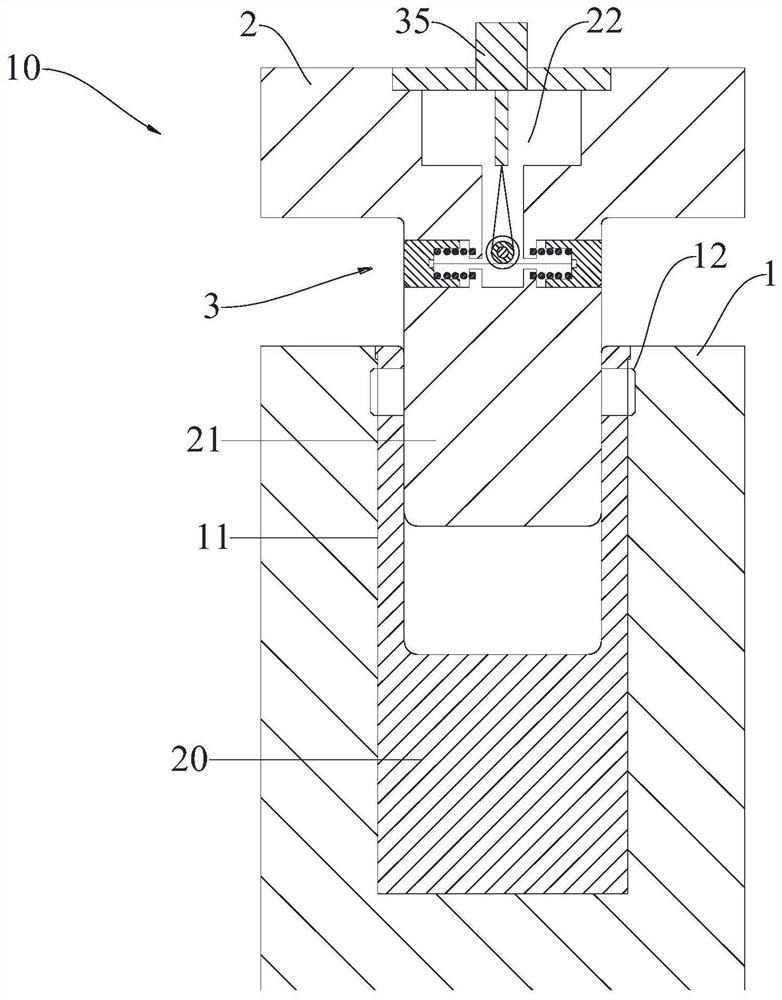

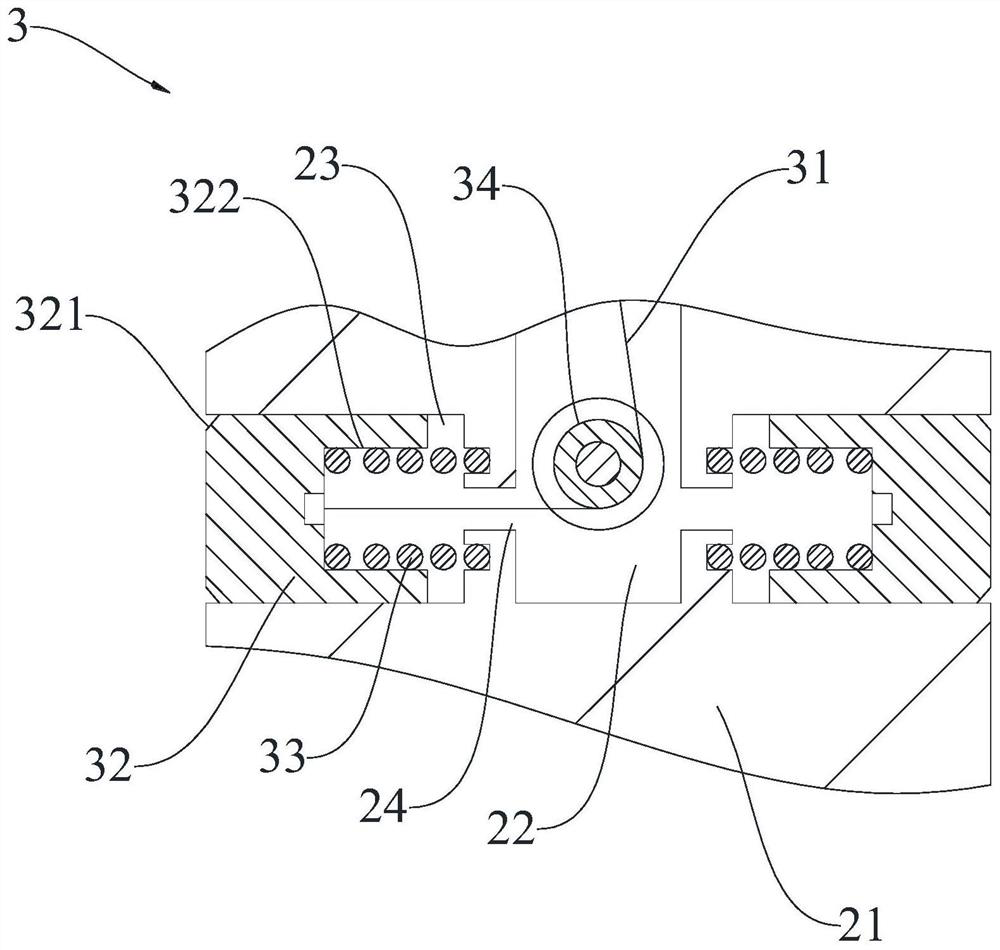

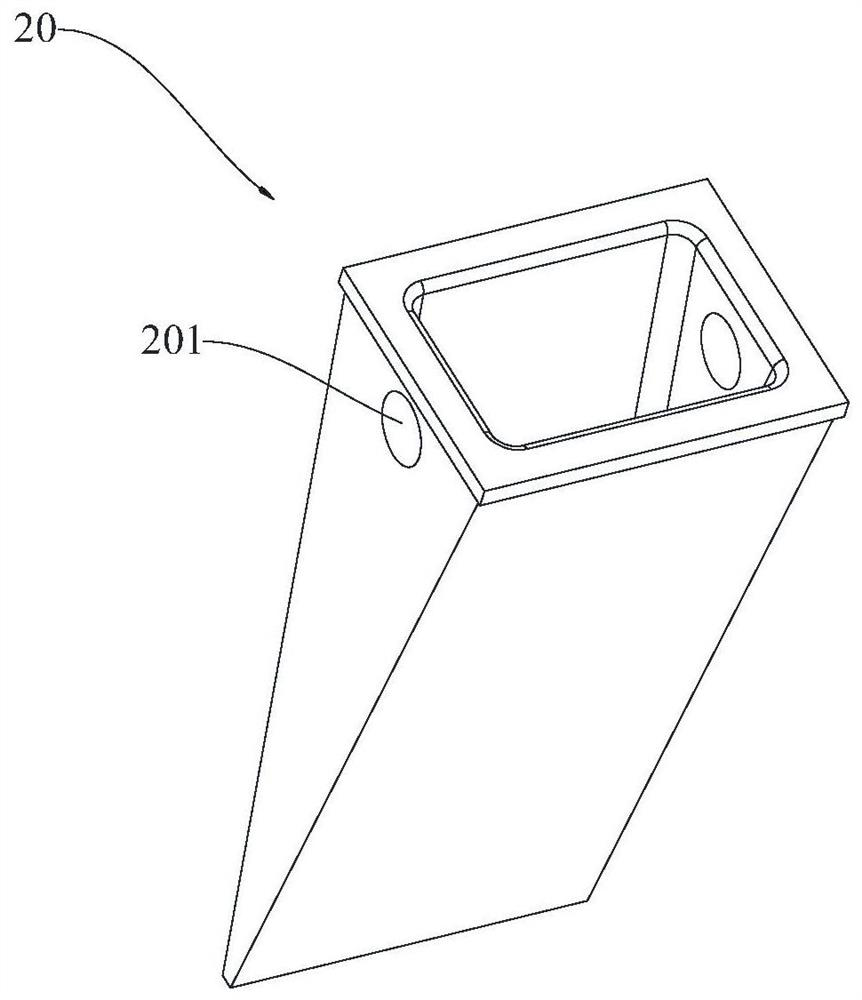

Production device and process for prefabricated part

ActiveCN112045821AImprove production efficiency is lowShorten the timeCeramic shaping plantsRebarMechanical engineering

The invention relates to a production device and process for a prefabricated part. The production device comprises a rack; a conveying mechanism is arranged on the rack, and the conveying mechanism comprises a conveying belt, a driving piece, a first lifting table, a second lifting table, a lifting assembly and a receiving table; the conveying belt is arranged on the rack; the driving piece is arranged on the rack; and the first lifting table and the second lifting table are both slidably arranged on the rack, the lifting assembly is arranged on the rack, the receiving table is arranged on therack, and a mold can move to the receiving table. A reinforcing steel bar is mounted on the mold, after mounting is completed, the lifting assembly is started to place the mold on the conveying belt,the mold is moved to the second lifting table, the lifting assembly is started to drive the mold to get away from the conveying belt, then a filling mechanism is started to pour concrete into the mold, thus the mold does not need to be manually placed on the filling mechanism, the time is saved, and the problem of low production efficiency of the prefabricated part is solved.

Owner:浙江三杰建筑产业化有限公司

Mine efficient filling retaining wall and construction method thereof

ActiveCN108757024AGuaranteed StrengthShort construction periodMaterial fill-upWater filterBlocking layer

The invention discloses a mine efficient filling retaining wall and a construction method thereof. The mine efficient filling retaining wall comprises a skeleton structure layer, blocking layers and aconcrete layer. The skeleton structure layer comprises longitudinal ribs, transverse ribs, a top plate and a metal mesh. The blocking layers are connected with the skeleton structure layer, and the concrete layer is located between the blocking layers. The blocking layers adopt jute bags. The concrete layer is made of sprayed concrete. A sprayed concrete thickness point stick, a filling pipe, anoverflow pipe and a water filtering pipe are arranged on the top plate. The sprayed concrete thickness point stick penetrates through the metal mesh to be located in the concrete layer. Materials suchas down-hole wasted steel and the jute bags are sufficiently utilized, meanwhile the construction method further has the advantages of short construction period, simple technological process, convenient operation and the like, the filling efficiency can be effectively improved, and thus safe, economical and efficient production work of a filling mining method is achieved.

Owner:GUIZHOU JINFENG MINING

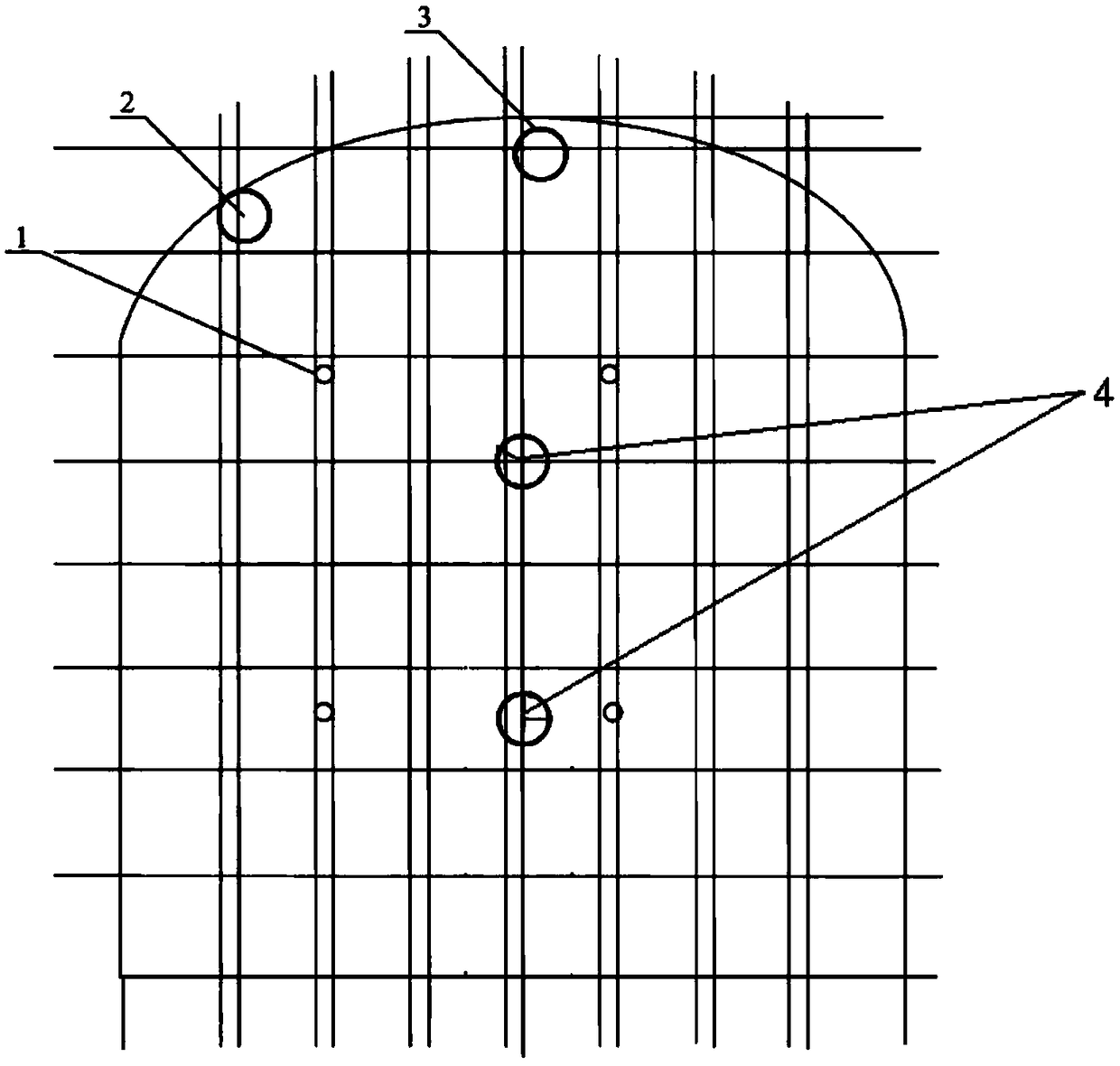

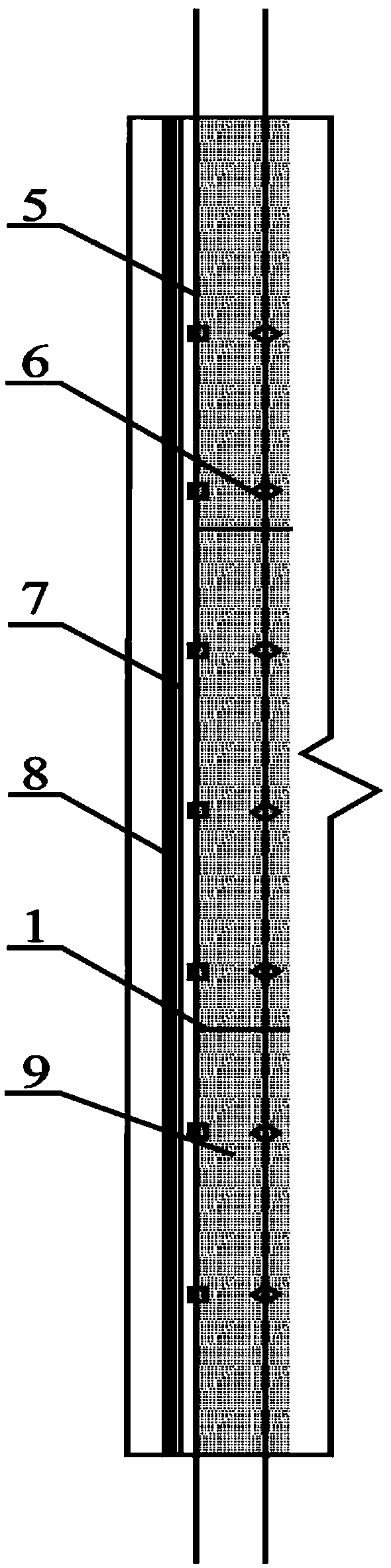

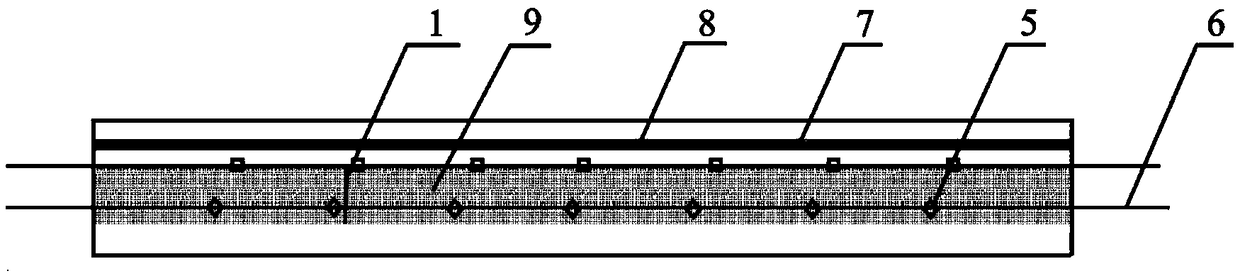

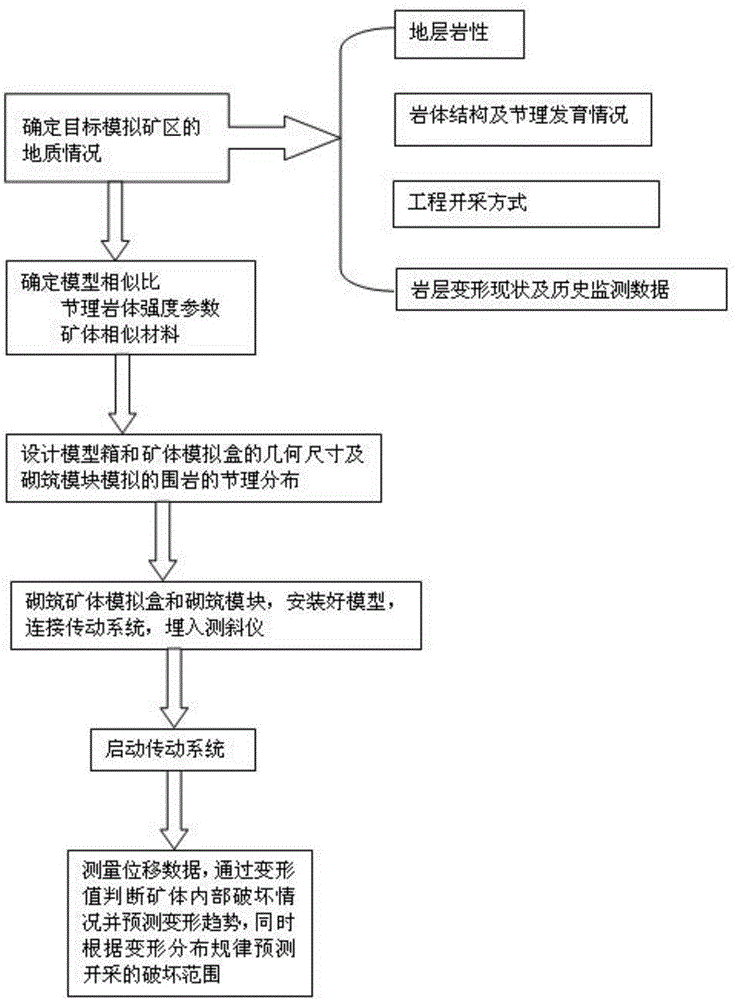

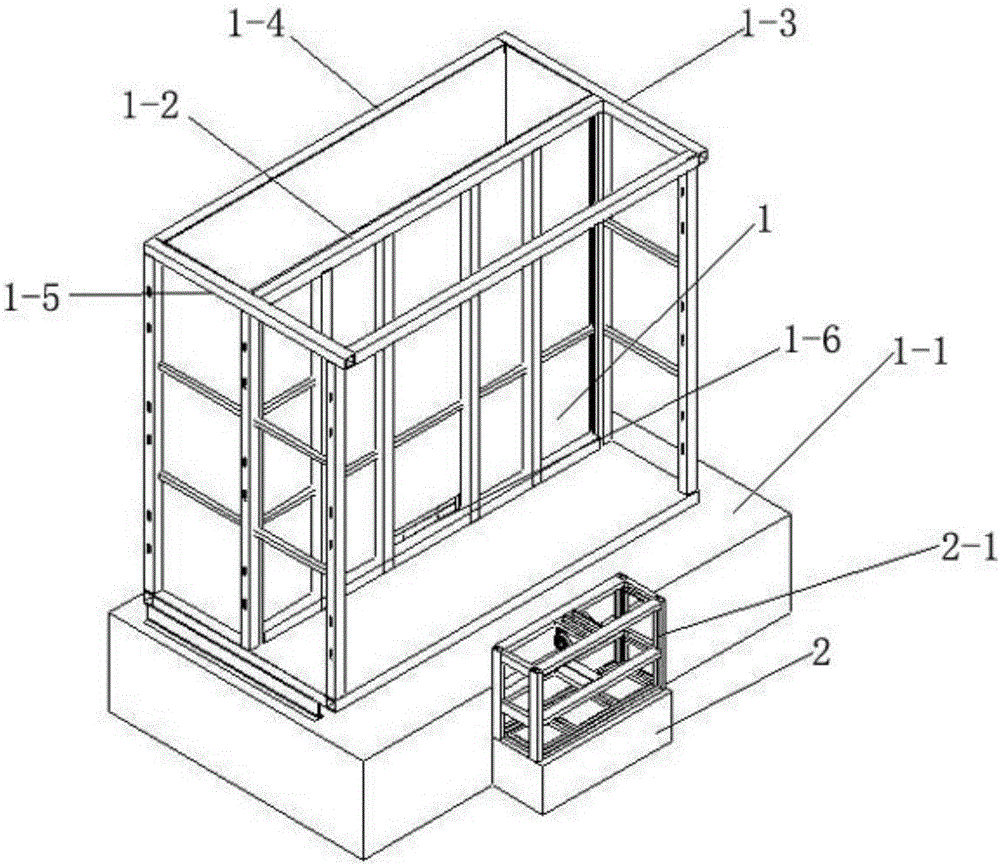

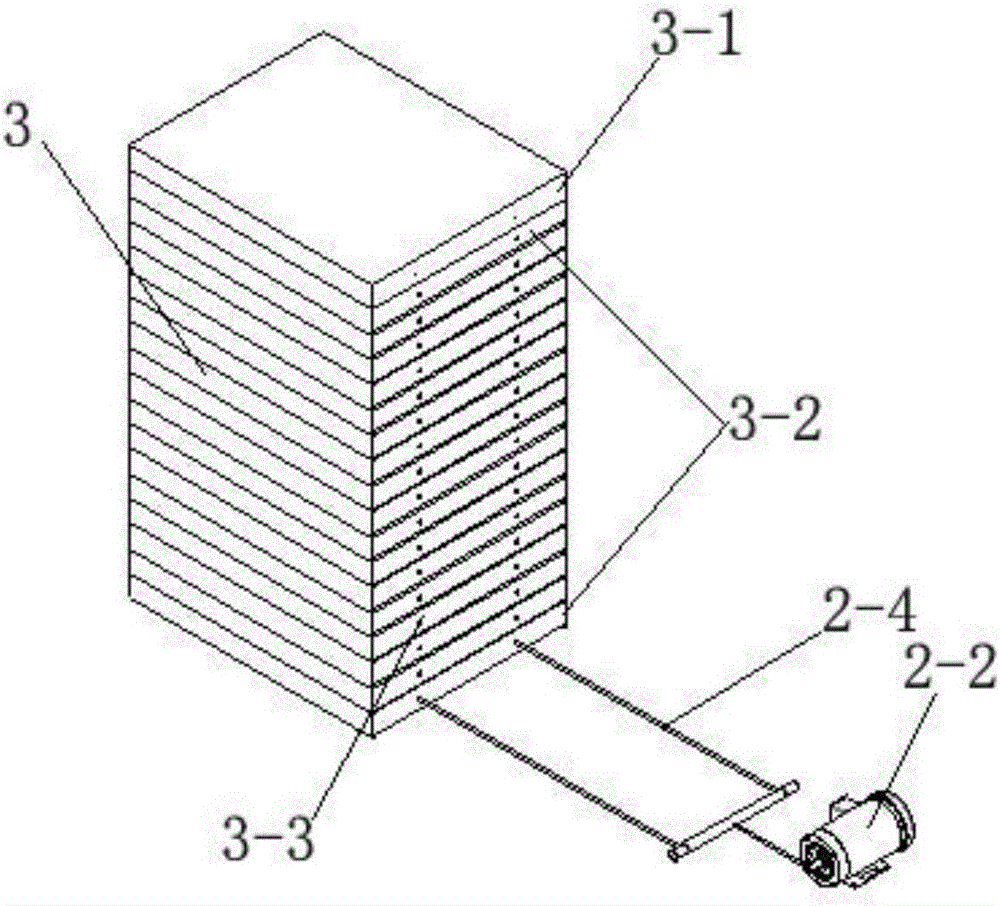

Device and method of simulating iron ore open pit-into-underground mining induced strata movement

ActiveCN106323658AImprove efficiency and safetyEasy to makeStructural/machines measurementPhysical modelMineralogy

The invention belongs to the technical field of mining rock mass mechanics engineering, and specifically relates to a device and a method of simulating iron ore open pit-into-underground mining induced strata movement. According to the device, a 3D physical model taking the actual joint fissure condition of a rock mass into consideration is built by use of a most similar material proportioning plan, so as to reproduce the whole process of strata movement and destruction induced by mining and the laws of deformation and destruction and to provide reasonable and effective suggestions for the prevention and control of geological disasters in a mine environment.

Owner:ANSTEEL GRP MINING CO LTD

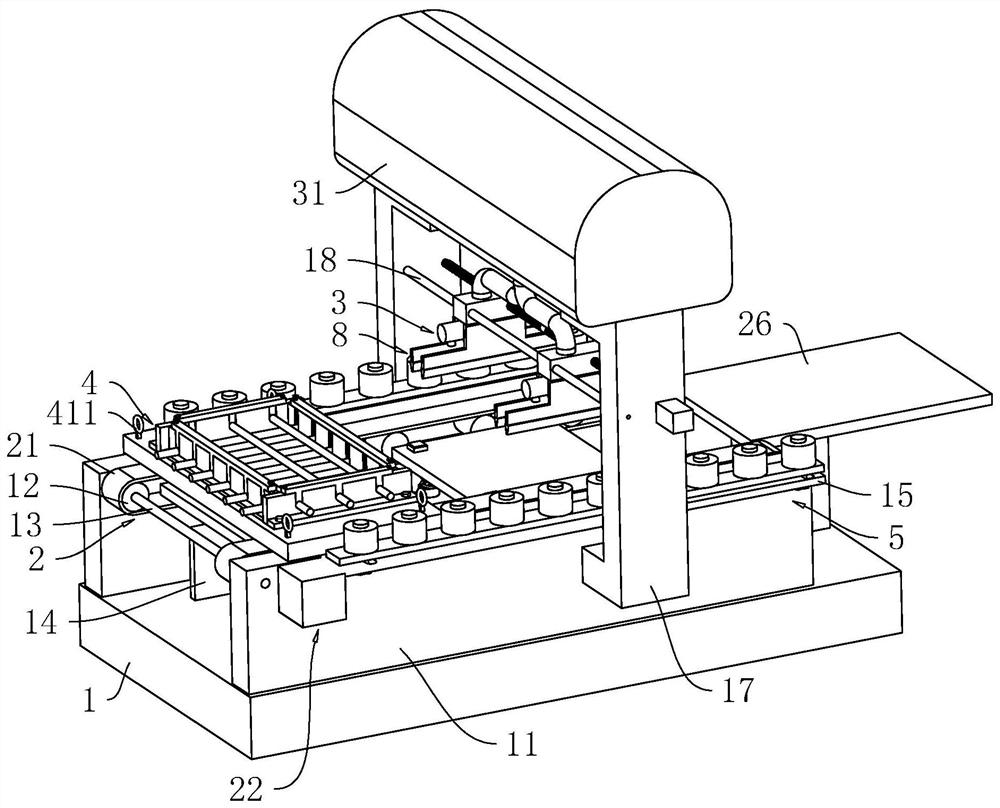

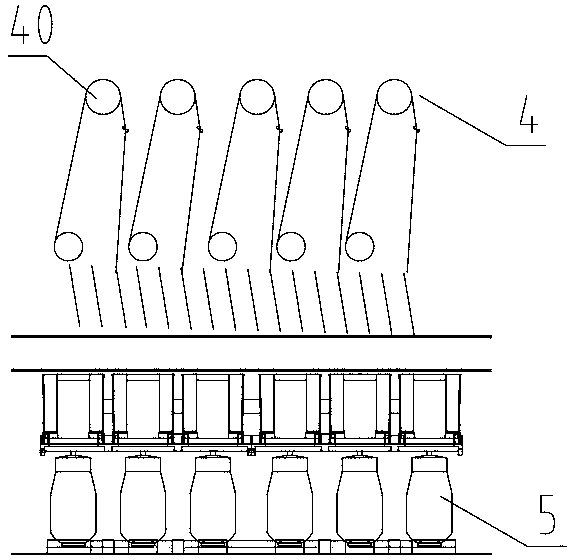

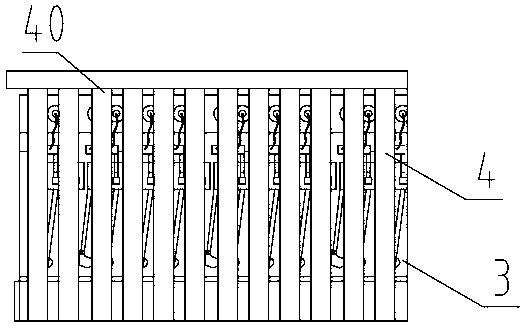

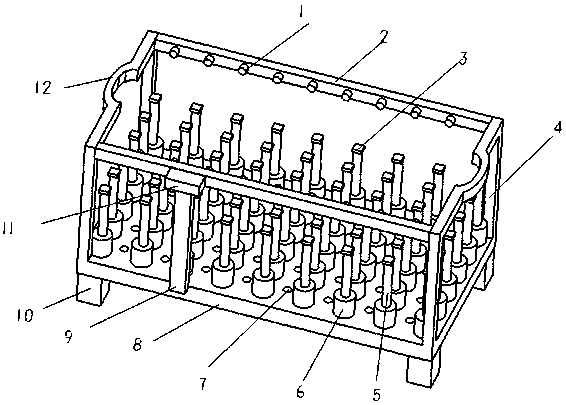

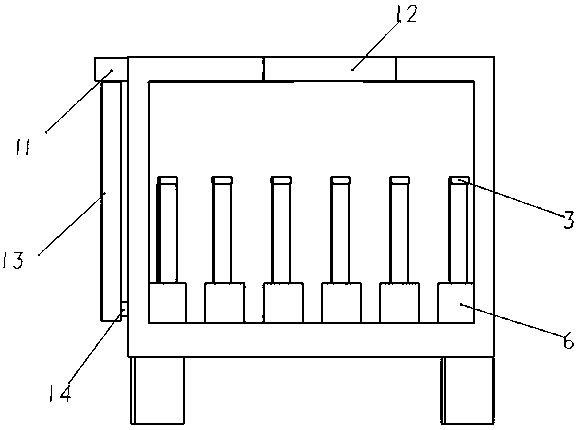

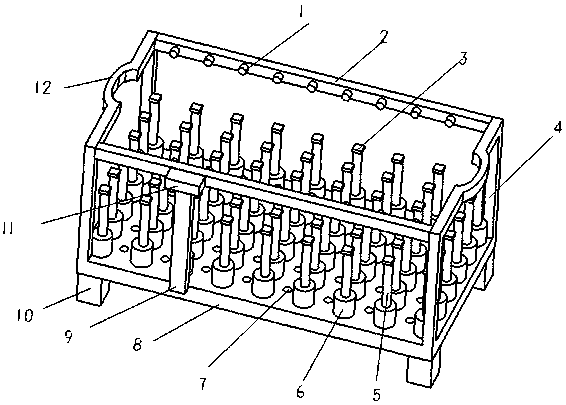

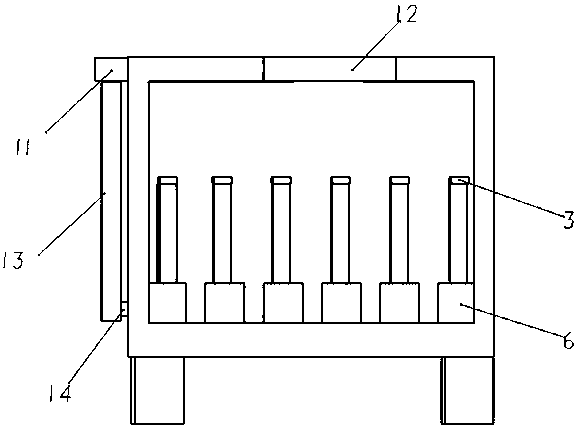

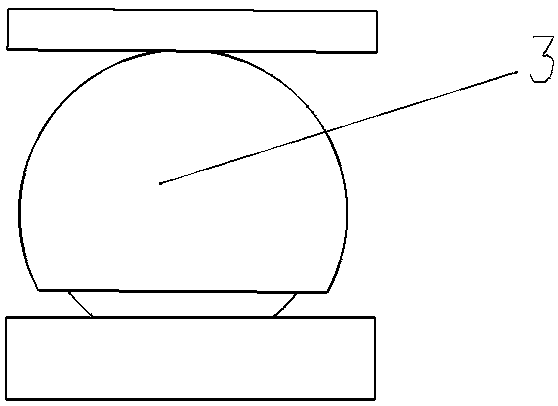

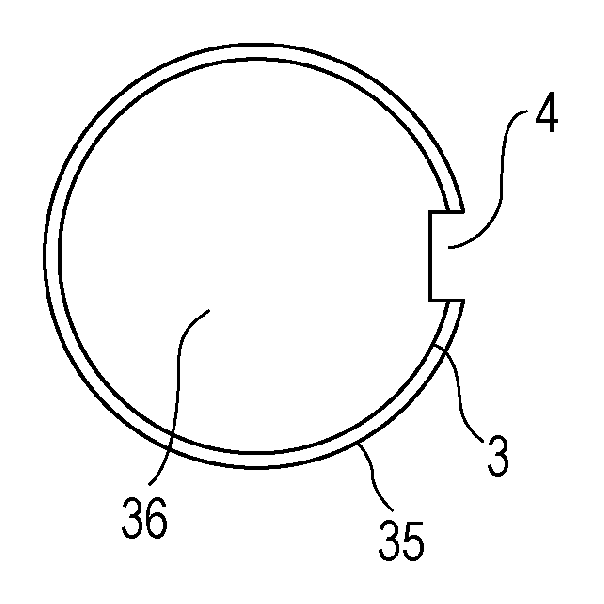

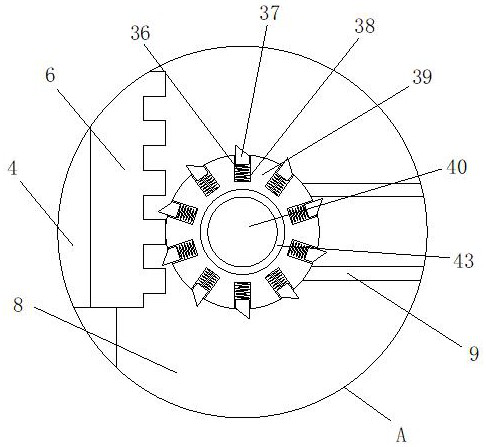

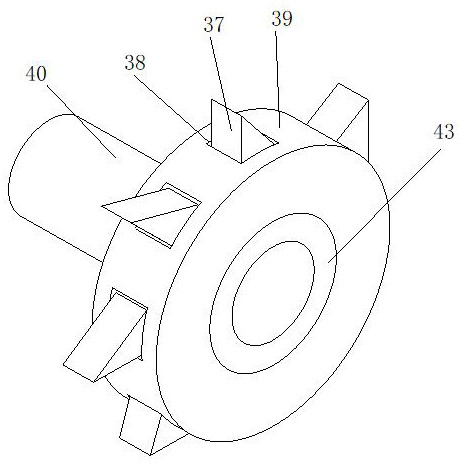

Novel semi-continuous high-speed spinning machine

ActiveCN103409825AEasy to operateControllableArtificial thread manufacturing machinesWet spinning methodsEngineeringSpin speed

The invention relates to a novel semi-continuous high-speed spinning machine which comprises a rack, a glue supply device, a filament strip forming device, a spinning device and a winding device. The spinning device comprises a spinning roller which is transversely arranged relative to the operating surface of a spinning face, and the two ends of the spinning roller are fixed on the rack. The novel semi-continuous high-speed spinning machine improves spinning speed, ensures that filament strips are sufficiently reacted, and then achieves the purposes of ensuring the quality of the filament strips, improving production efficiency and reducing spinning cost.

Owner:YIBIN HIEST FIBER +2

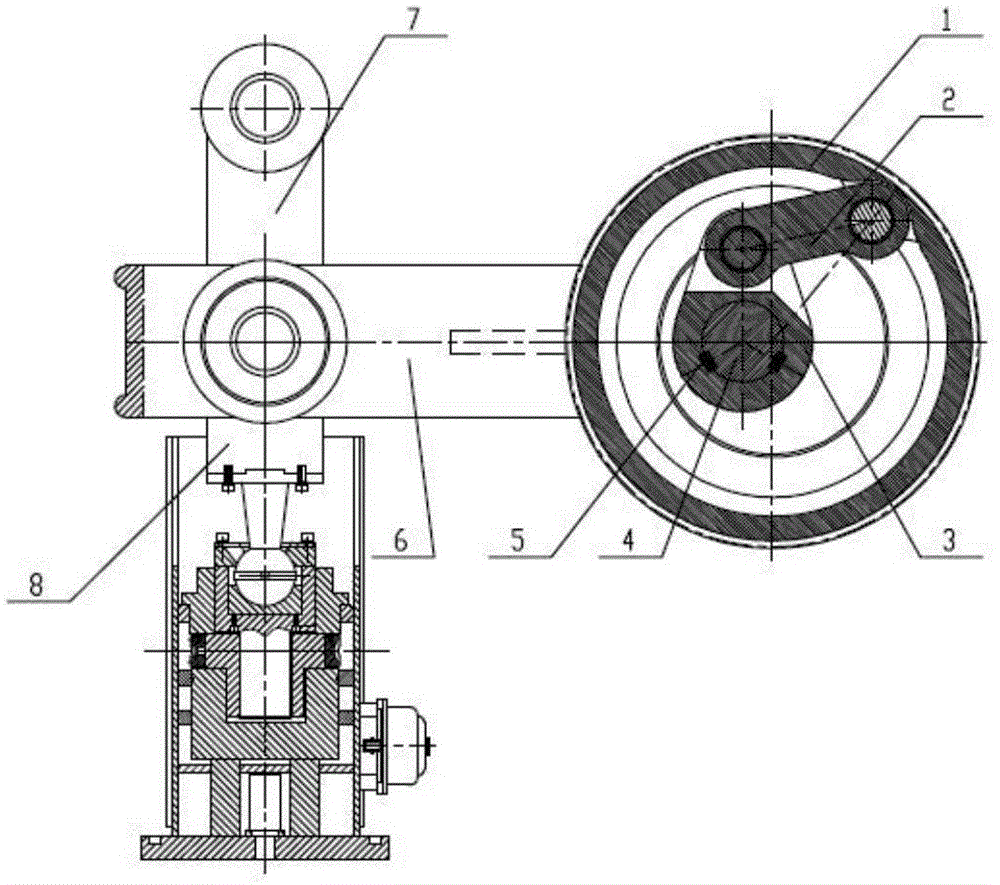

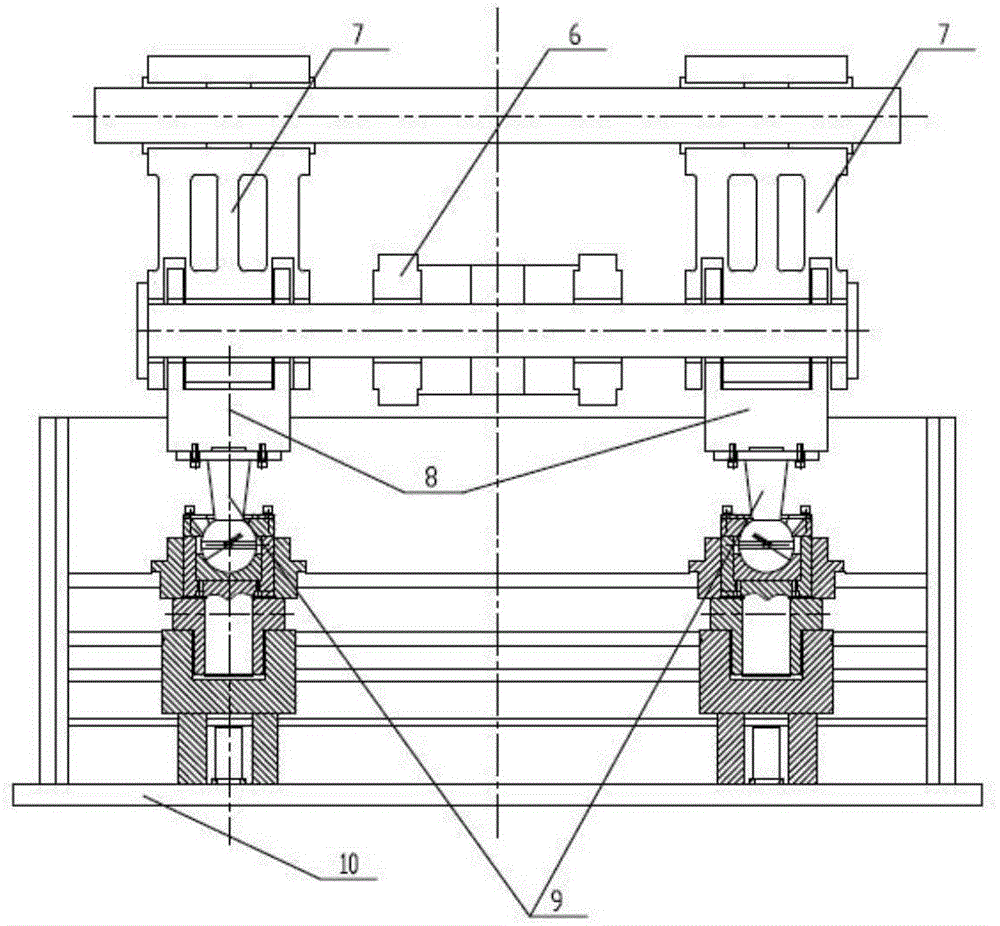

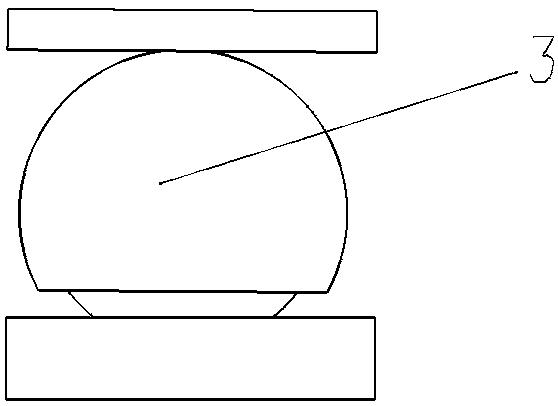

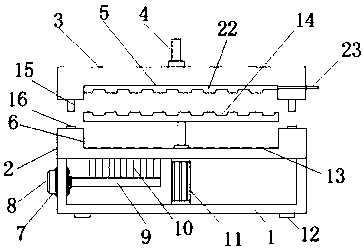

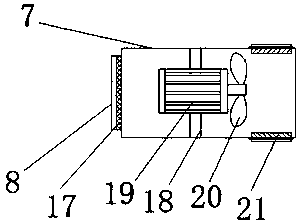

Transmission device of press

The invention relates to a transmission device of a press. The transmission device comprises a gear wheel, a connecting rod I, a rocker, a crankshaft, a key, a connecting rod II, upper toggle rods, lower toggle rods, ball screws and a slider body, wherein the gear wheel is connected with the connecting rod I and the rocker through hinge pins; the rocker is fixedly connected with the crankshaft through the key; the crankshaft is fixedly connected with the connecting rod II; the upper toggle rods are fixedly connected onto a press body and fixedly connected with the connecting rod II; the lower toggle rods are fixedly connected with the ball screws; the ball screws are fixedly connected onto the slider body. A slider can stay at about 50 degrees at a lower dead point through a unique operation curve of a multi-point toggle rod mechanism, the metal molding time is increased to the greatest extent, and plastic deformation of metal is better facilitated.

Owner:YANGZHOU FORGING MACHINE TOOL

Modeling method by using novel ship bracket device and novel ship supporting frame device

The invention discloses a modeling method by using a novel ship bracket device. According to the modeling method, molding and demolding can be conducted on the bottom of a ship. The modeling method includes the steps that an epoxy resin mixture is molded on a plastic mold ship bracket and a miscellaneous material layer, then mold pressing is conducted on the epoxy resin mixture through a ship bottom mold to form a new ship supporting frame, the integrity of a ship body can be observed from the ship bracket, and a good inspection effect is achieved for construction of the ship bottom; the height of a hydraulic device on the molded ship bracket can be adjusted according to the shape of desired modeling, and meanwhile, by being matched with a steering device, a prototype of a bottom mold is established; and according to the different needs, the bottom outline and lines of a model to be established are adjusted, and after demolding is conducted, secondary curing and mechanical machining and testing are conducted. According to the modeling method, modeling adjusting is conducted aiming at the ship bottoms of different shapes, an air drying device can speed up the molding time of the mold, a washing device can wash the equipment automatically, and the modeling method has the characteristics of being diversified in molding effect, simple and novel in operation.

Owner:李春洪

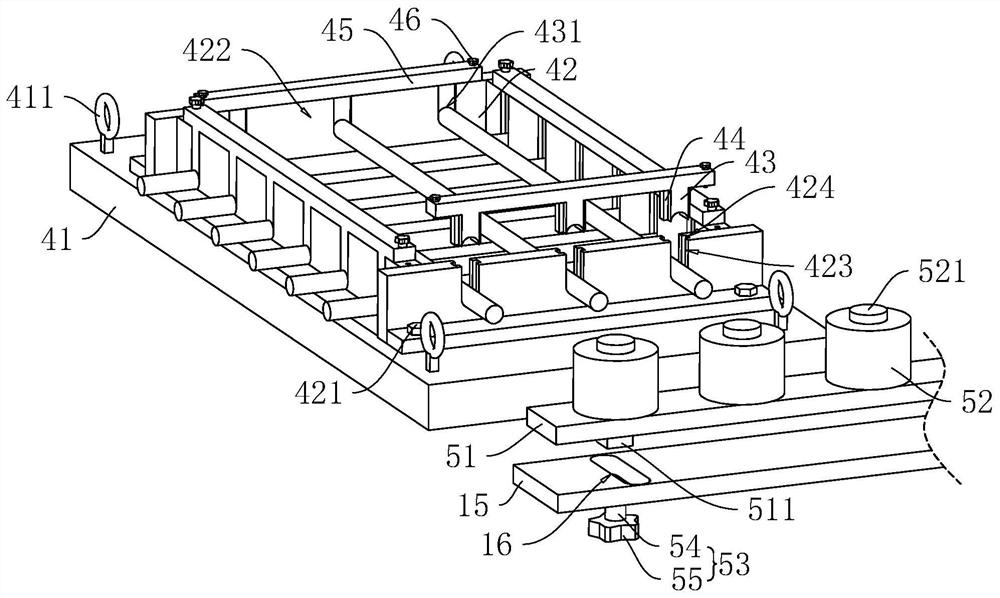

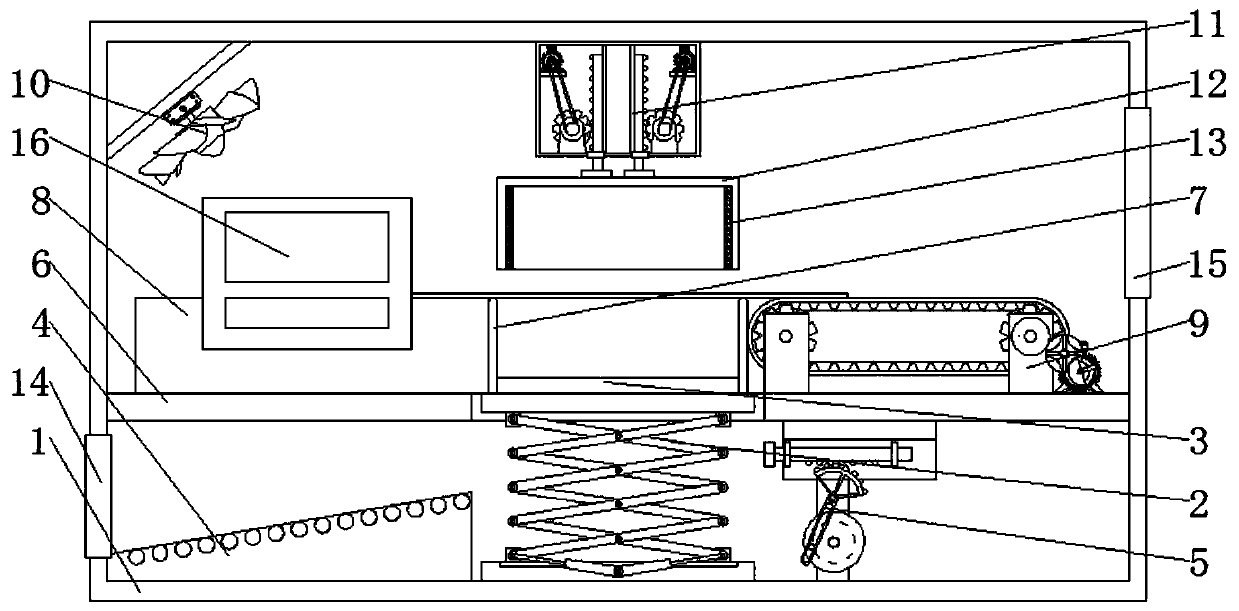

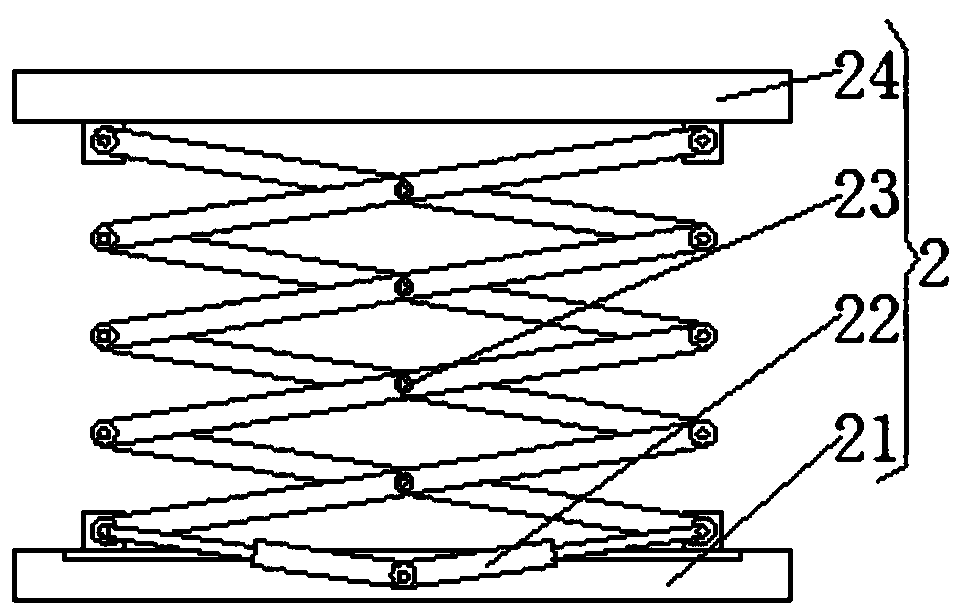

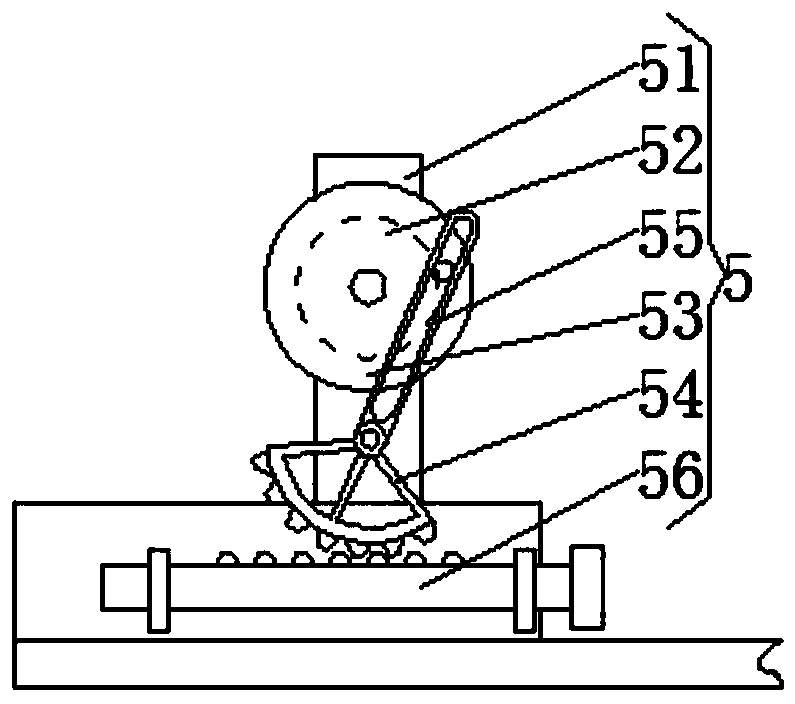

Sheet metal cabinet forming device

InactiveCN110976593AAdhesivelyFaster molding timeMetal-working feeding devicesPositioning devicesEngineeringPhysics

The invention discloses a sheet metal cabinet forming device, and relates to the technical field of packing boxes. The device comprises a box body, wherein a lifting adjusting device is fixedly connected to the middle position of the bottom of an inner cavity of the box body, the side, away from the bottom of the inner cavity of the box body, of the lifting adjusting device is fixedly connected with a forming bottom plate, supporting transverse plates fixedly connected to the middles of the inner walls of the two sides of the box body, the position, located above the forming bottom plate, at the tops of the supporting transverse plates is fixedly connected with a forming lower die, the position, located on the right side of the forming lower die, at the tops of the supporting transverse plates is fixedly connected with a conveying device, the position, located above the forming lower die, at the top of the inner cavity of the box body is fixedly connected with a pressure device, the bottom of the pressure device is fixedly connected with a forming upper die, and the inner surface of the forming upper die is provided with a heater. According to the device, by heating and prolongingthe forming time, the packaging boxes are bonded more closely with one another, the phenomena of degumming and the like are avoided, and the product quality is guaranteed.

Owner:滁州市朝友精密制造有限公司

Hoop composite insulating brick or building block and manufacturing and building methods thereof

The invention discloses a hoop composite insulating brick or building block and manufacturing and using methods thereof. The hoop composite insulating brick or building block is characterized in that: the brick or building block comprises an inner blade block and an outer blade block, wherein a thermal insulation body is arranged between the inner blade block and the outer blade block; the inner blade block and the outer blade block are provided with a top face and a bedding face respectively; at least two hollow holes are formed in the inner blade block and the outer blade block respectively; and a hoop passes through the hollow holes in the inner and outer blade blocks to integrally connect the inner blade block, the outer blade block and the thermal insulation body. In the hoop composite insulating brick or building block, a heat (cold) bridge caused by a brick wall and a built mortar joint in the wall is completely blocked, so that a thermal insulation wall which meets the wall energy-saving requirement is formed after the wall is built, wall thermal insulation construction is prevented from being performed once again, and consequently construction cost is greatly saved; the inner and outer blade blocks are tied by using the hoop, so that the reliable connection of the inner and outer blade blocks is ensured; by adjusting the thickness of the thermal insulation body, the wall energy-saving requirements of different areas can be met; and the thermal insulation body is positioned in the block, so the durability of the thermal insulation body is the same as that of the wall.

Owner:上海奥伯应用技术工程有限公司

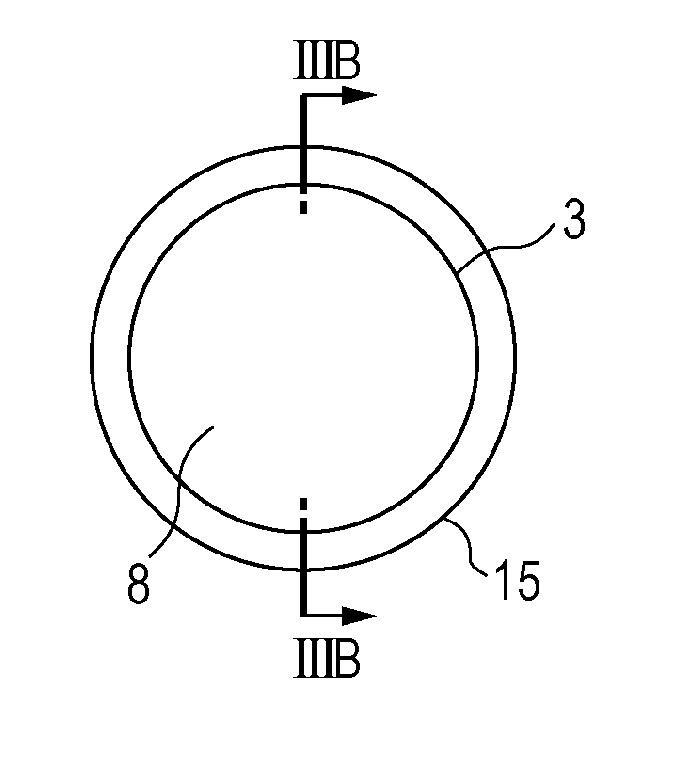

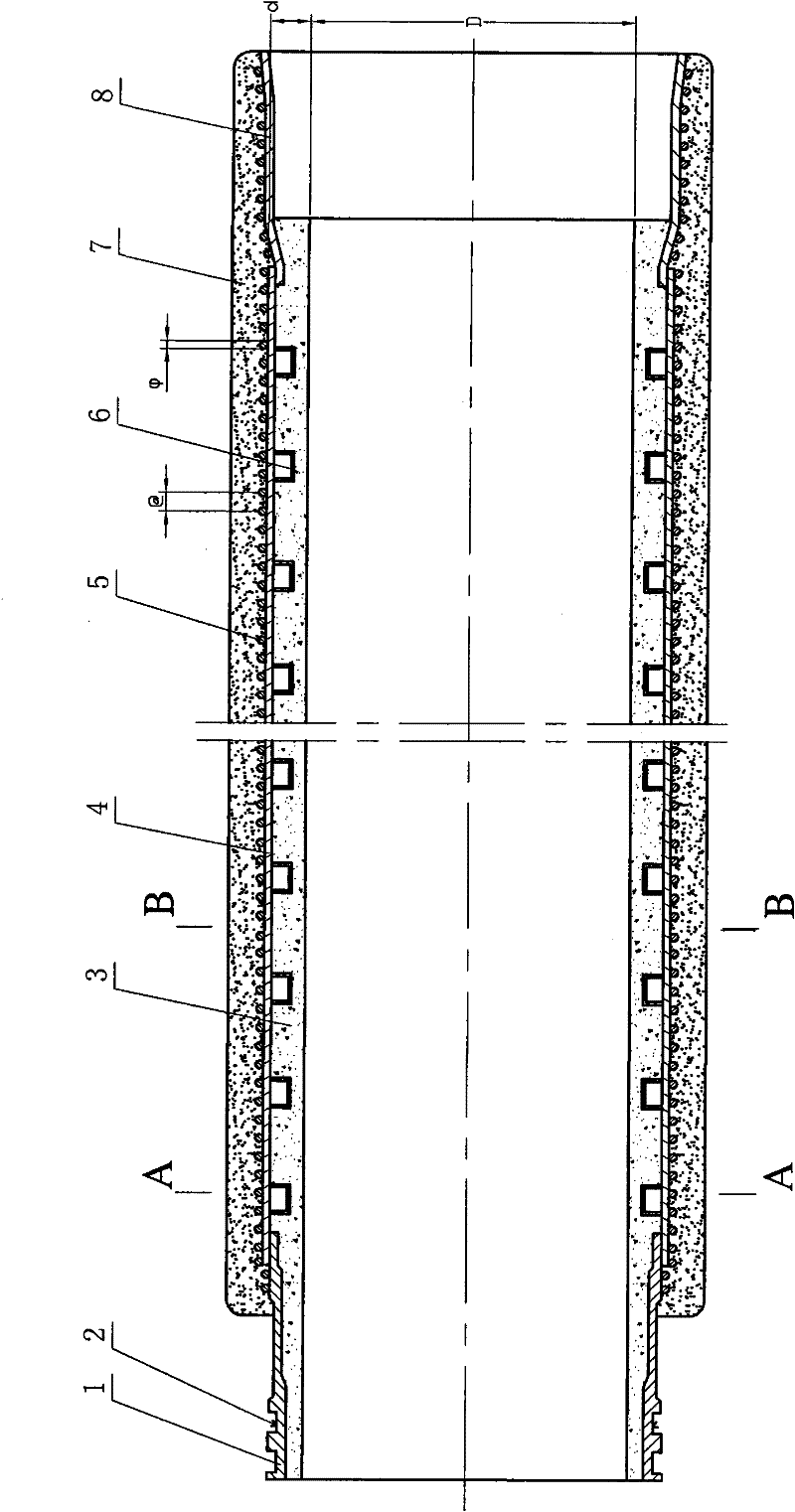

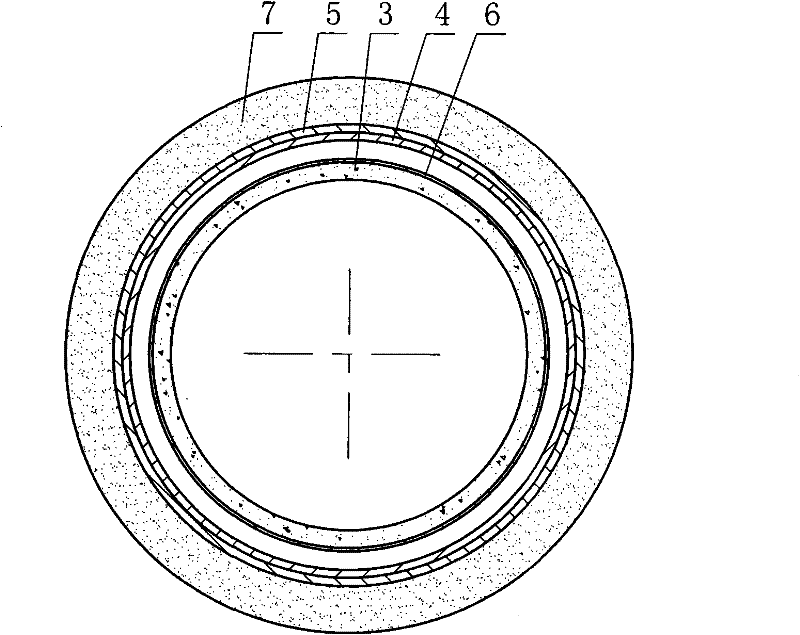

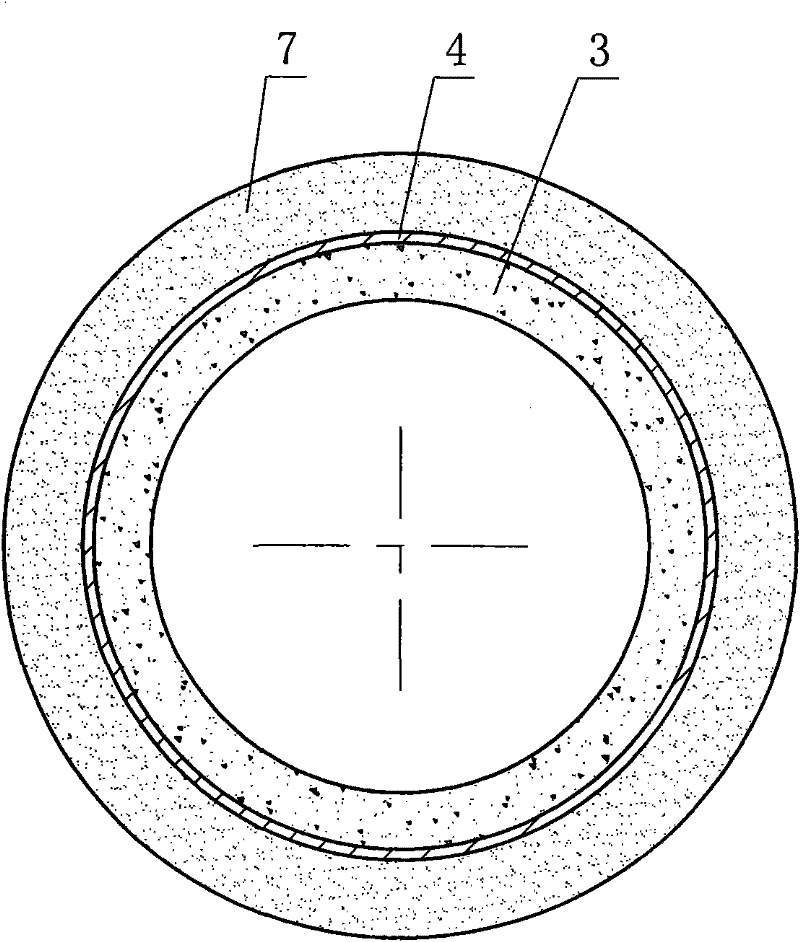

Steel fiber reinforced concrete pipe with ribbed thin wall

The invention relates to a steel fiber reinforced concrete pipe with a ribbed thin wall. The steel fiber reinforced concrete pipe provided by the invention is composes of a mouthing, a socket, a steel fiber reinforced concrete pipe core with a steel cylinder, a prestressed wire and a protective layer, wherein the mouthing and the socket are respectively coaxially fixed on the two ends of the steel fiber reinforced concrete pipe core with the steel cylinder, the external wall of the steel fiber reinforced concrete pipe core with the steel cylinder is fixedly provided with the protective layer, and the prestressed wire is wound on the external wall of the steel fiber reinforced concrete pipe core with the steel cylinder between the external wall and the protective layer; and the ratio of the wall thickness d of the steel fiber reinforced concrete pipe core with the steel cylinder and the inner diameter D of the pipe core is mu, wherein 1 / 32<mu<1 / 16, the thread pitch of the prestressed wire is @ mm, the diameter of the prestressed wire is phi mm, 2phi<=@<=50, and an annular steel rib is coaxially welded on the steel cylinder. The steel fiber reinforced concrete pipe with the ribbed thin wall provided by the invention has the advantages of simple integral structure, scientific and reasonable design, simple production process, higher production efficiency, thin pipe wall, light weight, distinct external pressure bearing capability, good impermeability and lower transportation and construction cost.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

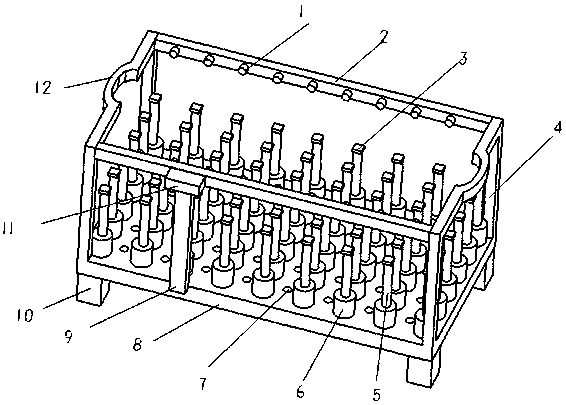

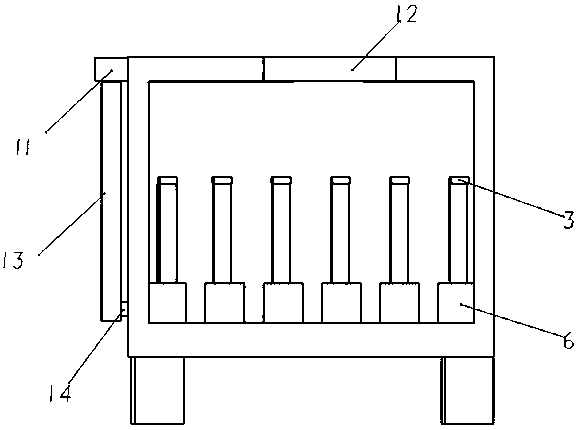

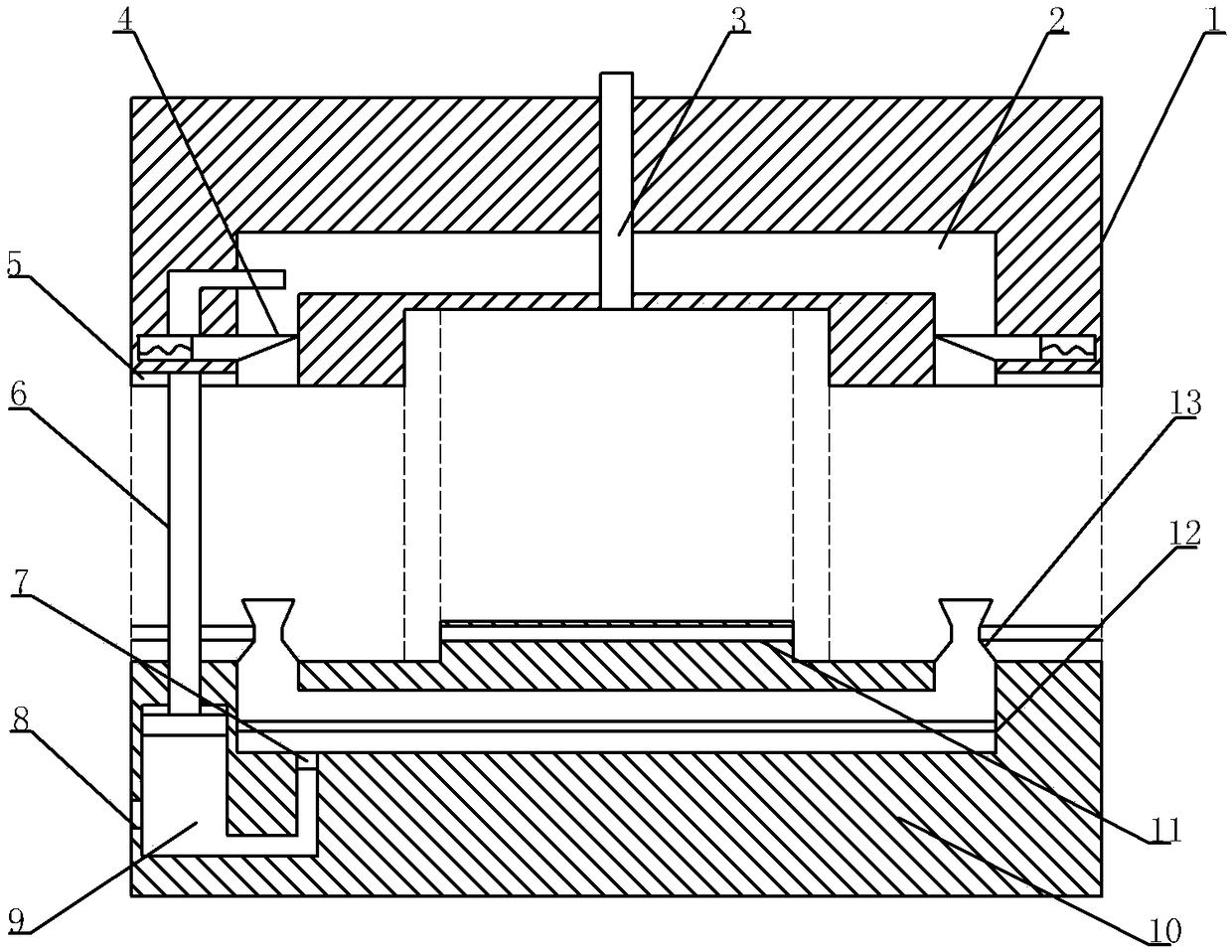

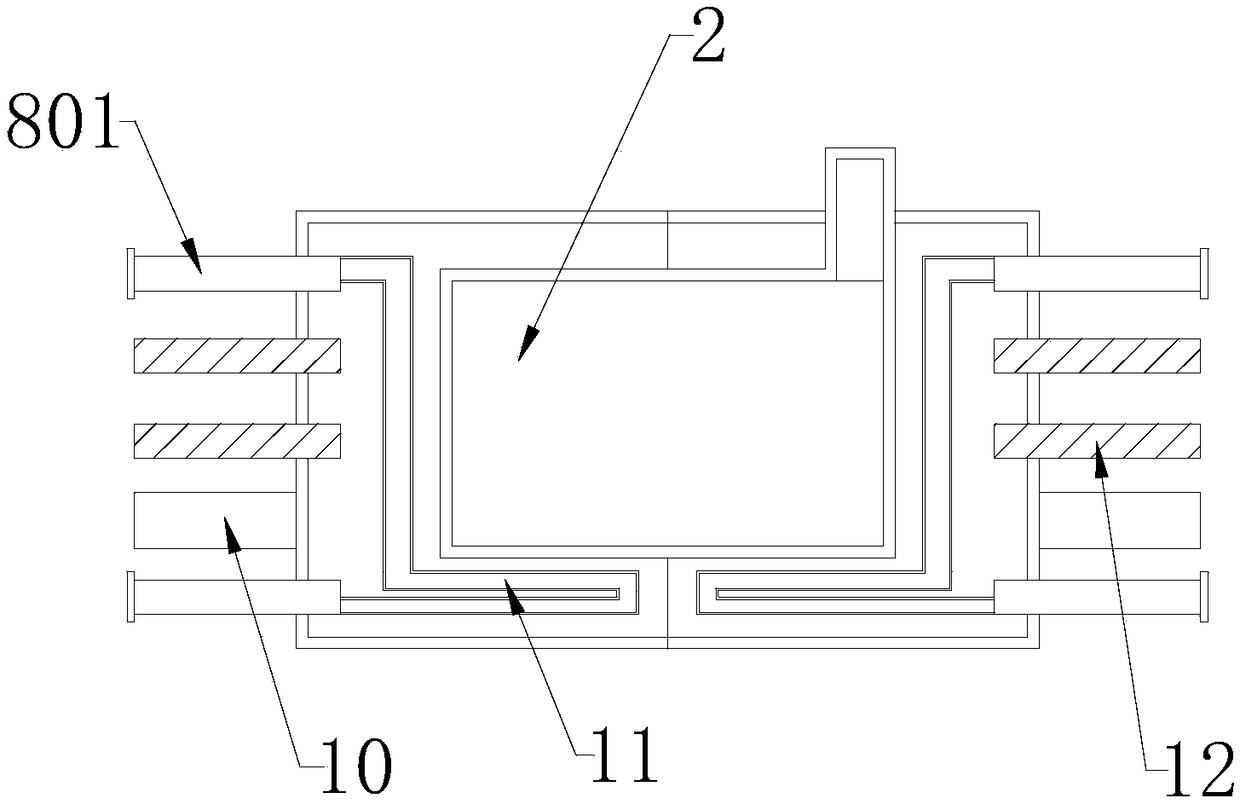

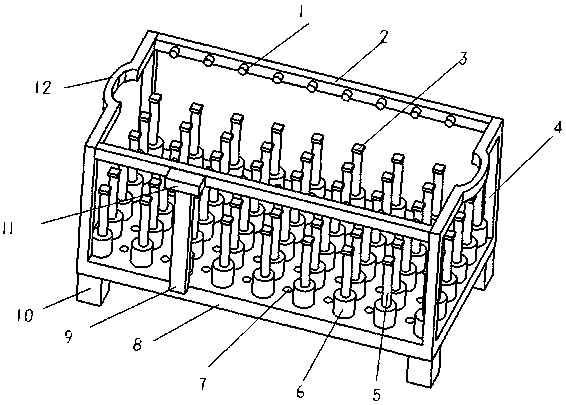

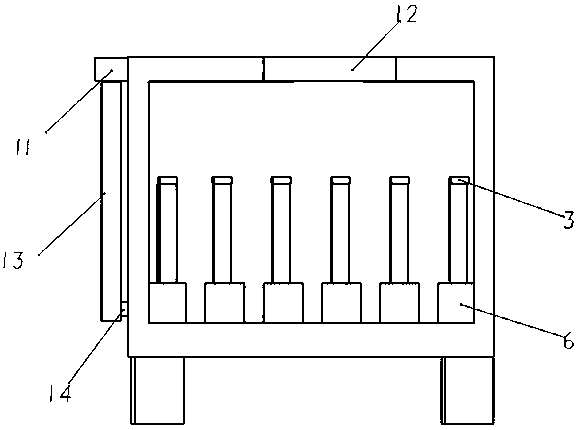

Cooling die for fuse box cover body

The invention relates to the technical field of die processing and discloses a cooling die for a fuse box cover body. The cooling die comprises a rack, an upper die and a lower die; the upper die is aconcave die; the lower die is a convex die; a formation cavity is formed between the upper die and the lower die when the upper die is locked with the lower die; the upper die is provided with an injection molding hole which is communicated with the formation cavity and is internally provided with a cooling channel; the lower die is internally provided with a water storage channel and an air cavity; the water storage channel is internally provided with a pushing plate; venturi pipes are arranged at the two ends of the water storage channel respectively and are communicated with the water storage channel; an air pipe which is communicated with each venturi pipe is arranged at a throat pipe of each venturi pipe; the air cavity is internally provided with a sliding plate which is in verticalsliding connection with the lower die; the air cavity below the sliding plate is communicated with the water storage channel below the pushing plate, and an electromagnetic valve is arranged at the communication part; the sliding plate is provided with a connection rod; one end of the connection rod is arranged in the cooling channel; the air cavity below the sliding plate is provided with an airinlet one-way valve; and a bulge of the upper die is provided with a heat conduction sheet which extends into the air cavity. The cooling die is simple in structure and can rapidly perform cooling ona product in the die.

Owner:CHONGQING YINSHENG MOLD

Ship bottom model modeling method and molding ship bracket

InactiveCN107932810AImprove smoothnessFaster molding timeVessel partsDomestic articlesEpoxyOrganic solvent

The invention discloses a ship bottom model modeling method, and by means of the method, molding and demolding can be performed on the bottom of ships. The method comprises the steps that molding is performed on epoxy resin mixed materials utilizing a molding ship bracket and a mixed material layer, then mold pressing is performed on the epoxy resin mixed materials by a ship bottom mold to form anew ship bracket, the integrity of a ship body can be observed from the ship bracket, and a good testing effect for building the bottom of ships is achieved. According to the ship bottom model modeling method and the molding ship bracket, the adjustment of modeling is performed for ship bottoms of different shapes, the molding time of a mold can be shortened by air drying devices, and automatic cleaning can be performed on equipment by a cleaning device; any organic solvents are not contained, the ship bottom model modeling method and the molding ship bracket are environment friendly and freeof pollution, production and construction operations are simple, construction tools can be cleaned by water, the degree of safety is high in the processes of transportation, storage and use, raw materials have wide sources, the production cost is low, the production is clean, and the requirements of the current environmental protection are met; and the ship bottom model modeling method and the molding ship bracket have the characteristics of being diversified in molding effect and simple and novel to operate.

Owner:李春洪

Method for modeling by using plastic mold ship bracket device and plastic mold ship bracket device

InactiveCN107901311AImprove smoothnessFaster molding timeVessel designingDomestic articlesEpoxyHeat resistance

The invention discloses a method for modeling by using a plastic mold ship bracket device. The method can be used for carrying out shaping and demoulding on the bottom of the ship. The device comprisea plastic mold vessel bracket and a mixed material layer which is used for shaping the epoxy resin mixture, a ship bottom die is used for carrying out die pressing on the epoxy resin mixture to forma new ship bracket, the integrity of a hull can be observed from the ship bracket, a good inspection effect on building ship bottom is acquired. The bottom contour and the line of the model to be modeled are adjusted according to different requirements, and then curing and demolding are carried out after the plastic mold is molded; secondary curing, mechanical manufacturing and inspection are conducted after demoulding. According to the method for modeling by using a plastic mold ship bracket device and plastic mold ship bracket device, modeling adjustment is carried out on the ship bottom according to different shapes, an air drying device can accelerate the forming time of the mold, and the cleaning device can automatically clean the equipment; the organic silicon modified epoxy resin can be used for improving the heat resistance, and the method and the device have the characteristics of being diversified in shaping effect, simple and novel in operation and the like.

Owner:李春洪

Optical component and method of making the same

Owner:CANON KK

Novel casting device for cylinder head

InactiveCN108994260AQuick installationAvoid damageFoundry mouldsFoundry coresThermal energyCylinder head

The invention provides a novel casting device for a cylinder head. The novel casting device comprises a base, a mold cavity, a water-cooling switch and an air-cooling switch. The mold cavity is movably connected above the base. The water-cooling switch and the air-cooling switch are fixedly connected to the front end of the base. Clamping grooves are formed in the inner walls of the base. Connecting water pipes are arranged at the upper ends and the lower ends of the clamping grooves, and the connecting water pipes penetrate through the side surface of the base. According to the novel castingdevice, water in a water tank is pumped into the connecting water pipes by water pumps, the water of the connecting water pipes flows into conveying water pipes and into circulating water pipes, and the circulating water pipes are in contact with the inside of the mold cavity, so that the heat energy in the mold cavity can be absorbed, the mold cavity is rapidly cooled, and then the water flows tothe water tank through the circulating water pipes, the conveying water pipes and the connecting water pipes; and by cooling the inside of the mold cavity, the forming time in the mold cavity is shortened, the working efficiency is improved, and the novel casting device is suitable for the production and use of the novel casting device for the cylinder head and has good development prospect.

Owner:繁昌县亘通智能装备有限公司

High-fluidity high-temperature nylon material and preparation method

InactiveCN107141789AImprove high temperature resistanceImprove liquidityGlass fiberTemperature resistance

Owner:LUHE SHOUCHUANG PLASTIC HARDWARE PROD

A kind of non-steam curing concrete prefabricated component and its forming method

ActiveCN108249846BImprove internal densityIncrease surface smoothnessCeramic shaping apparatusCement mixing apparatusCrazingUltimate tensile strength

The invention relates to a steaming-free concrete prefabricated assembly. The steaming-free concrete prefabricated assembly is characterized in that an inorganic-organic composite early strength agentand a nucleus-type early strength agent are simultaneously added to a concrete prefabricated assembly raw material according to a certain proportion to improve the early strength of the concrete prefabricated assembly, so that a steaming process can be avoided, energy consumption is reduced, energy is saved, the internal compactness of the concrete is improved, the flatness of the concrete surface is increased, crack formation is avoided, the later strength of the concrete is maintained, and the overall strength of the concrete is improved.

Owner:镇江建科建设科技有限公司

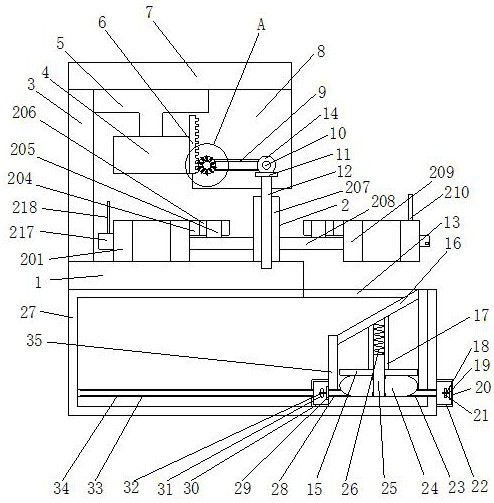

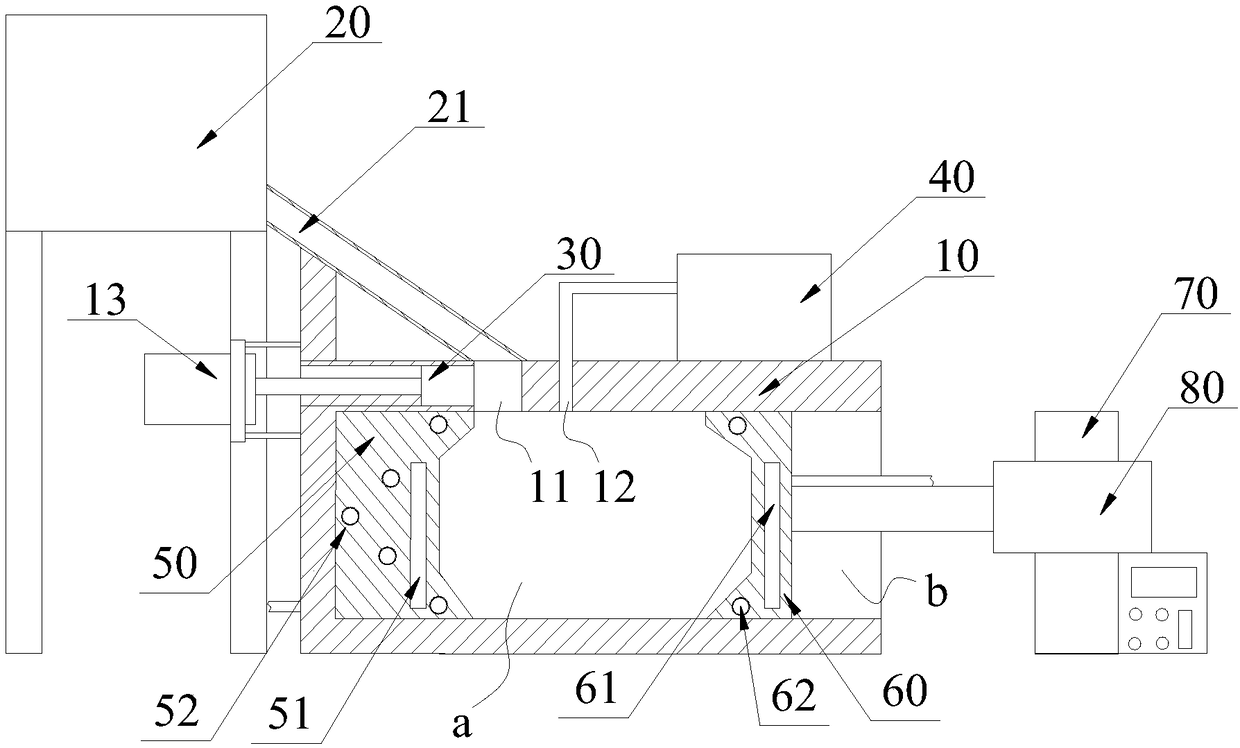

Automatic hot forging press for forming high-toughness aluminum alloy and working method thereof

InactiveCN111804863AImprove the press forming effectImprove work efficiencyForging/hammering/pressing machinesCircular discGear wheel

The invention relates to the technical field of aluminum alloy production and discloses an automatic hot forging press for forming high-toughness aluminum alloy and a working method thereof. A gear arotates clockwise to drive a gear b to rotate anticlockwise, so that a rotating rod can be driven to rotate, a rotating column can be driven to rotate, two connecting strips can be driven to rotate soas to exchange positions, and two semicircular modules a are driven to exchange positions; meanwhile, two semicircular modules b can be driven to exchange positions through two connecting blocks, andwhen a rack moves downwards, teeth can be driven to move towards a clamping groove when contacting the teeth, so that a disc cannot be driven to rotate; and such repeated, after the aluminum alloy ispressed, an upper pressing die moves upwards to drive the formed aluminum alloy to rotate to the right, and the other semicircular modules b and the semicircular modules a are replaced below the upper pressing die, so that the previous aluminum alloy can be taken down when the next aluminum alloy is pressed, and the production is speeded up.

Owner:无锡元基精密机械有限公司

Aluminum alloy piece die-casting machine

The invention relates to an aluminum alloy piece die-casting machine which comprises a body, a feeding pipe, an injection puncher pin, a vacuum pump, a fixed die, a movable die, an installing column and a first air cylinder, one end of the feeding pipe is connected with the body, a molten aluminum furnace is connected to the end, far away from the body, of the feeding pipe, the injection puncher pin is arranged in the body, the vacuum pump is connected with the body, the fixed die is arranged in the body, a first heating bar and a plurality of water pipes are arranged in the fixed die, the first heating bar is arranged inside the fixed die, the multiple first water pipes are evenly arranged inside the fixed die, the movable die is arranged at an opening, a second heating bar and a plurality of second water pipes are arranged in the movable die, the second heating bar is arranged inside the movable die, the multiple second water pipes are evenly arranged inside the movable die, the installing column is arranged on the side, away from the body, of the opening, the first air cylinder is fixedly installed on the installing column, the output end of the first air cylinder is fixedly connected with the movable die, and the movable die is in sliding connection to the interior of the body through the first air cylinder.

Owner:广德盛源电器有限公司

Membrane panel forming mold

The invention discloses a membrane panel forming mold. The membrane panel forming mold comprises a supporting frame. The four corners of the bottom end of the supporting frame are all fixedly providedwith bases. The top end of the supporting frame is fixedly provided with a lower mold shell. The middle portion of the top end of the lower mold shell is provided with a lower mold groove. An upper mold shell is placed at the top end of the lower mold shell. The middle portion of the bottom end of the upper mold shell is provided with an upper mold groove. An upper mold plate is fixed to the interior of the upper mold groove. A glue filling pipe is mounted on the middle portion of the top end of the upper mold shell. A push rod motor is fixed to the bottom end of the interior of the supporting frame. An air hood penetrates through the left end of the supporting frame. A rack is connected to the interior of the air hood. A motor is mounted on the rack. According to the membrane panel forming mold, a lower mold plate is connected with a push rod of the push rod motor; after completion of molding, the upper mold shell is opened, the push rod motor can be started to drive the lower mold plate to rise to enable a molded membrane panel to move out of the lower mold groove. The membrane panel forming mold facilitates demolding of the membrane panel, greatly improves the demolding convenience and is suitable for extensive application and popularization.

Owner:滁州市印科模塑有限责任公司

Modeling method of epoxy resin ship bottom model and molding ship bracket device

The invention discloses a modeling method of an epoxy resin ship bottom model. The modeling method can perform molding and demolding on the bottom of a ship and comprises the steps that shaping is carried out on an epoxy resin mixed material through a molding ship bracket and an impurity material layer, then mold pressing is carried out on the epoxy resin mixed material through a ship bottom moldto form a new ship bracket, integrity of a ship body can be observed from the ship bracket, and a good inspection effect on ship bottom building can be achieved. According to the modeling method of the epoxy resin ship bottom model and a molding ship bracket device, modeling can be adjusted according to ship bottoms in different shapes, forming time of a mold can be shortened by an air drying device, and a cleaning device can automatically clean equipment; and the modeling method and the molding ship bracket device have the advantages of being high in durability and development performance, not prone to being affected by the environment, capable of keeping high image density even being used for a long period of time and capable of inhabiting occurrence of fog, excellent in image reproducibility, diversified in shaping effect, easy to operate, novel and the like.

Owner:李春洪

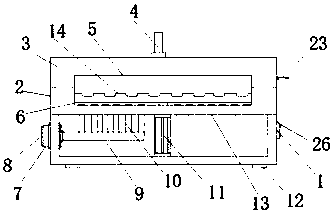

Automatic carton bonding device

InactiveCN104029419ASmooth transmissionSimple structureBox making operationsPaper-makingWork periodCarton

An automatic carton bonding device structurally comprises a rotary table, a baffle, a belt, a brush, a bonding table, a rocker arm, a solid block and belt pulleys. The baffle is fixed above the rotary table. A gap is formed between the baffle and the upper surface of the rotary table. The belt is installed on the belt pulleys. The brush is installed above the belt. The bonding table is arranged at one end of the belt. The solid block is arranged on the rocker arm above the bonding table. The rocker arm is also arranged at one end of the belt. The automatic carton bonding device is simple in structure, transmission is stable and free of noise, the buffering function and the vibration absorption function can be achieved, thin and vulnerable parts and components can be protected against damage under an overload circumstance, and therefore the function of safety protection is achieved; the whole process is automatically conducted, so that working time is saved, and working efficiency is improved.

Owner:潘明强

Forging bucket tooth casting, forging and quenching integrated production process

ActiveCN112170774APromote ruptureImprove toughnessMetal-working apparatusFurnace typesTemperingMechanical engineering

The invention discloses a forging bucket tooth casting, forging and quenching integrated production process. The forging bucket tooth casting, forging and quenching integrated production process comprises a casting step, a water toughening step, a material adding step, a forging step, a trimming step and a quenching step. After a trimmed casting is washed clean, low-temperature tempering and quenching are conducted, and therefore a bucket tooth is obtained. According to the forging bucket tooth casting, forging and quenching integrated production process, casting and forging are combined, thenumber of air holes of the bucket tooth is reduced, the toughness, impact resistance, abrasion resistance and other mechanical properties of the bucket tooth are improved, and meanwhile the productioncost can be saved.

Owner:浙江继望锻造科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com