A kind of non-steam curing concrete prefabricated component and its forming method

A technology of prefabricated components and concrete, which is applied in the field of building materials, can solve the problems of small dispersion, large size and unfavorable crystal new organisms, and achieve the effects of stable strength, improved internal compactness, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

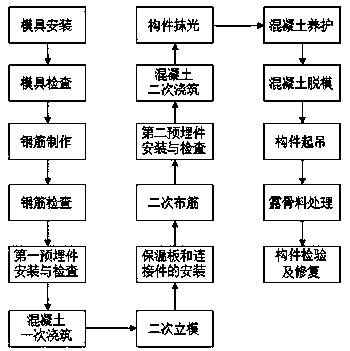

[0046] Such as figure 1 As shown, a non-steamed concrete prefabricated component, at the same time, the inorganic-organic composite accelerator and the crystal nucleus type accelerator are added to the raw material of the concrete prefabricated component in a certain proportion to improve its early strength, wherein each cubic meter of concrete Prefabricated element raw materials are formed from the following components:

[0047] 42.5 Ordinary Portland cement: 227.5Kg;

[0048] Inorganic-organic composite early strength agent: 1%~5% of the total mass of cement;

[0049] Crystal nucleation early strength agent: 10~15% of the total mass of cement;

[0050] Sand: 750Kg;

[0051]Pebbles: 290Kg;

[0052] Large stones: 760Kg;

[0053] Water: 150Kg;

[0054] Superplasticizer: 3Kg;

[0055] The preparation method of the raw material of the non-steamed concrete prefabricated component includes the following steps: use a forced mixer, first dry mix and then wet mix, first add lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com