Composite stainless steel pipe for hydraulic pipeline and production process thereof

A technology for stainless steel pipes and hydraulic pipelines, applied in the direction of anti-corrosion/anti-rust protection of pipes, pipes/pipe joints/fittings, pipes, etc. Smoothness, burr reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-2 The application is described in further detail.

[0044] The embodiment of the present application discloses a stainless steel pipe for a hydraulic pipeline and a production process thereof.

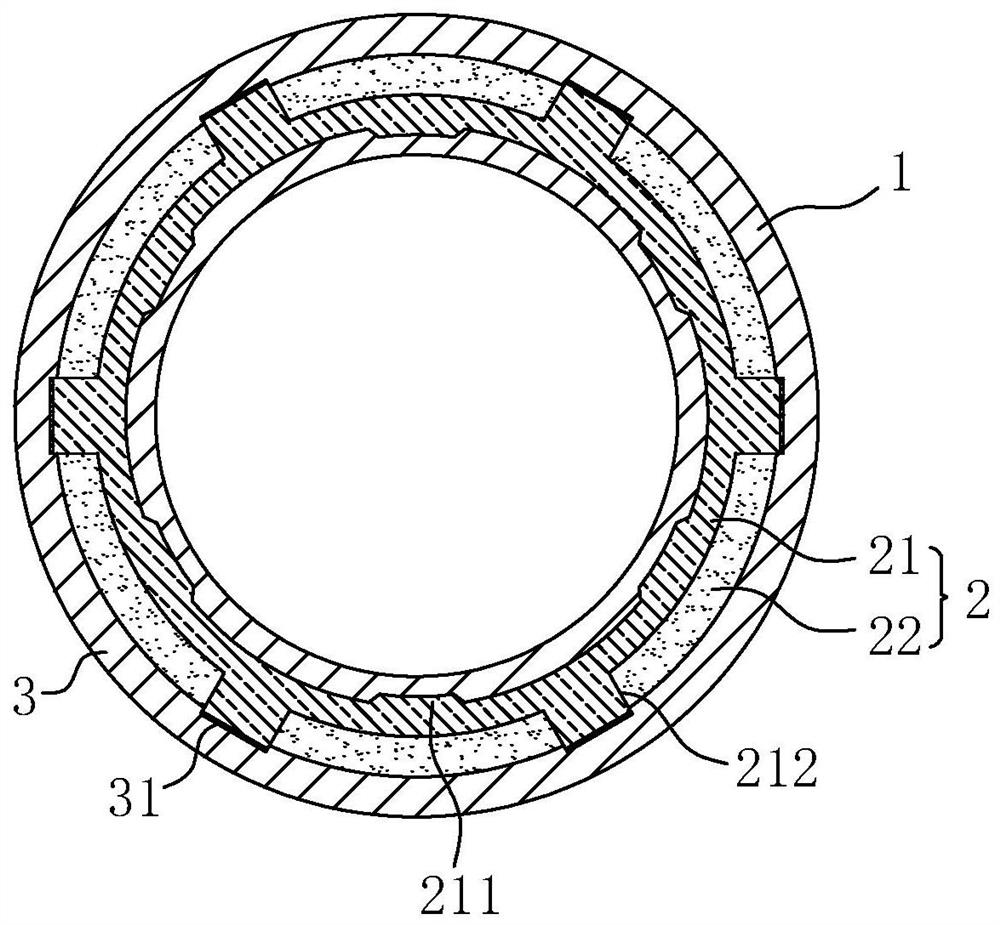

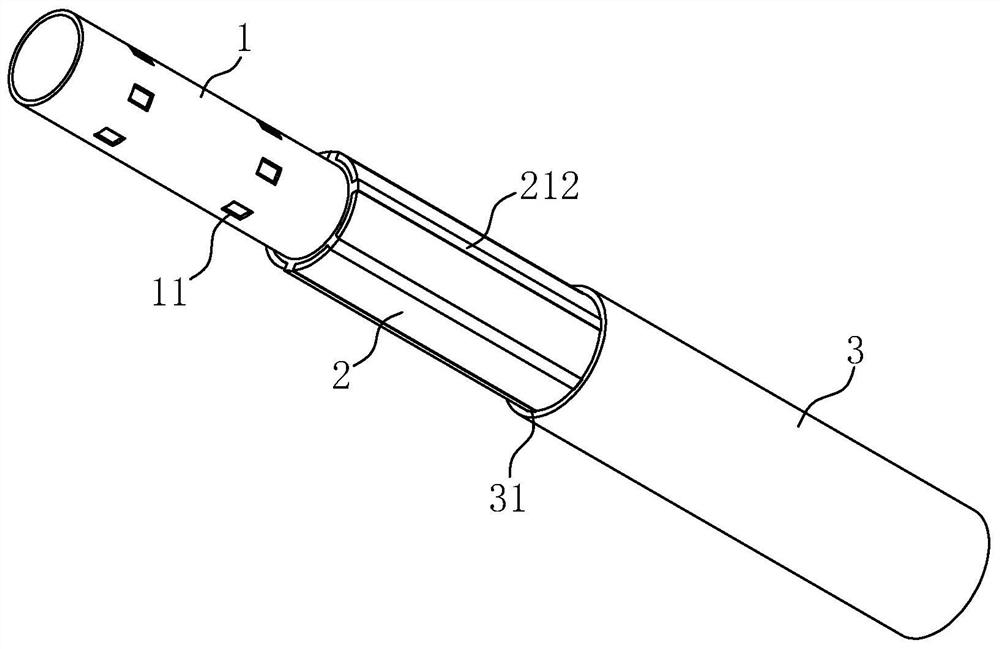

[0045] refer to figure 1 and figure 2 The stainless steel pipe for hydraulic pipelines includes an inner lining layer 1, an intermediate layer 2 and an outer layer 3 that are sequentially sleeved and fixed from the inside to the outside. The intermediate layer 2 includes a steel skeleton 21 and an aluminum alloy layer 22 covering the surface of the steel skeleton 21. The inner lining layer 1 is welded and fixed to the middle layer 2, and the middle layer 2 is welded and fixed to the outer layer 3.

[0046] refer to figure 1 and figure 2 , the inner lining layer 1 is a circular stainless steel tube as a whole, and the material of the stainless steel can be any one of ferritic stainless steel, austenitic stainless steel, austenitic-ferrit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com