High-fluidity high-temperature nylon material and preparation method

A high-fluidity, high-temperature technology, applied in the field of nylon materials, can solve the problems of poor high-temperature resistance and fluidity of nylon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

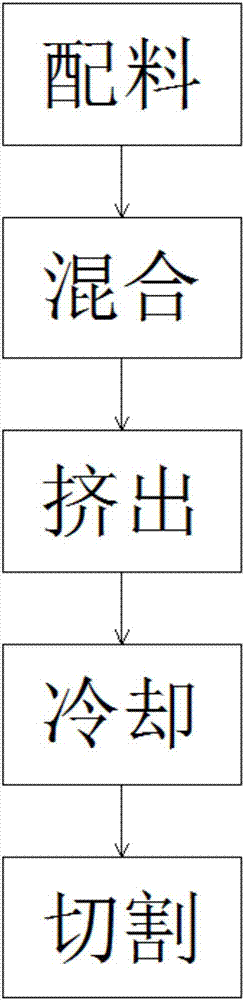

Method used

Image

Examples

Embodiment 1

[0025] High-fluidity high-temperature nylon material is characterized in that it is mainly made of raw material PA46, glass fiber, stabilizer, nucleating agent, grafted POE and lubricant, wherein the weight percentage of PA46 in the raw material is 40%, glass The weight percentage of fiber in the raw material is 42%, the weight percentage of the stabilizer in the raw material is 3%, the weight percentage of the nucleating agent in the raw material is 2%, and the weight percentage of grafted POE in the raw material Percent composition is 11%, and the weight percent composition of lubricant in raw material is 2%,

[0026] Further, the glass fibers are alkali-free glass fibers.

[0027] Further, the stabilizer is a high temperature resistant hindered amine antioxidant.

[0028] Further, the nucleating agent is aryl sulfonate.

[0029] Further, the grafted POE is maleic anhydride grafted POE.

[0030] Further, the lubricant is stearamide.

[0031] The preparation method of the...

Embodiment 2

[0044] High-fluidity high-temperature nylon material is characterized in that it is mainly made of raw material PA46, glass fiber, stabilizer, nucleating agent, grafted POE and lubricant, wherein the weight percentage of PA46 in the raw material is 85%, glass The weight percentage of fiber in raw material is 12%, the weight percentage of stabilizer in raw material is 0.5%, the weight percentage of nucleating agent in raw material is 0.5%, and the weight percentage of grafted POE in raw material The percentage content is 1.5~11%, and the weight percentage content of the lubricant in the raw material is 0.5~2%,

[0045] Further, the glass fibers are alkali-free glass fibers.

[0046] Further, the stabilizer is a high temperature resistant hindered amine antioxidant.

[0047] Further, the nucleating agent is aryl sulfonate.

[0048] Further, the grafted POE is maleic anhydride grafted POE.

[0049] Further, the lubricant is stearamide.

[0050] The preparation method of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com