Modeling method of epoxy resin ship bottom model and molding ship bracket device

A technology of epoxy resin and modeling method, used in household components, household appliances, other household appliances, etc., can solve the problems of poor machining performance, long production cycle, complex process, etc., to achieve faster molding time, convenient installation, Effects of high image density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

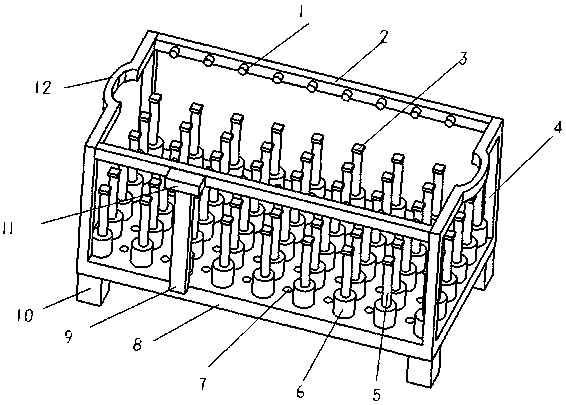

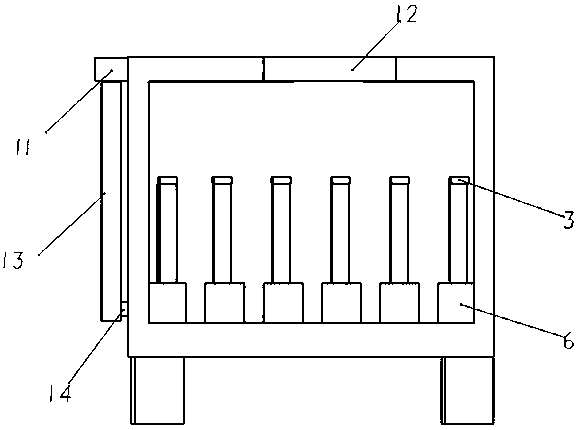

[0029] like figure 1 Shown, a kind of modeling method of epoxy resin ship bottom model, comprises the following steps:

[0030] Step 1, place a large-scale plastic cloth with good airtightness on the molded ship bracket, and connect end to end with stoppers and sealant around the plastic cloth;

[0031] Step 2, the plastic cloth is covered with at least two layers of plastic film, and then at least two layers of kapok, shredded paper and flexible chains are spread on the film to form a miscellaneous material layer, and the miscellaneous material layer Cover the top with plastic film;

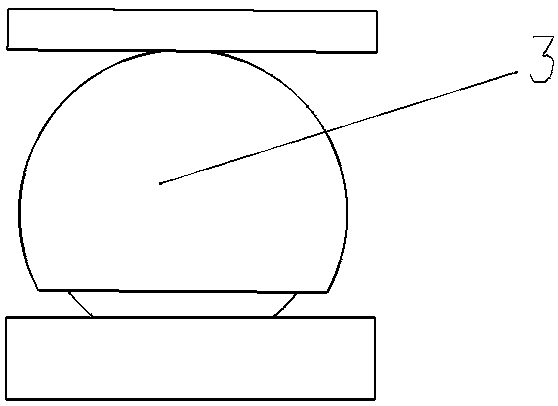

[0032] Step 3: Put in the ship bottom mold to be molded, adjust the height of the hydraulic device on the molded ship bracket according to the bottom shape of the ship bottom mold, and at the same time cooperate with the steering limit device to establish a prototype of the bottom shape of the ship bottom, and place the molded ship bracket After adjusting the outline and lines of the bottom of t...

Embodiment 2

[0041] The structure and principle of this embodiment 2 are basically the same as that of embodiment 1, the difference is that the order of operation is changed, the epoxy resin mixture is first poured into the molded ship bracket, and then the height of the hydraulic device of the molded ship bracket is adjusted. Form the desired shape for the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com