Cooling die for fuse box cover body

A fuse box and cover technology, applied in the field of mold processing, can solve problems such as long cooling time, achieve the effect of improving molding efficiency and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

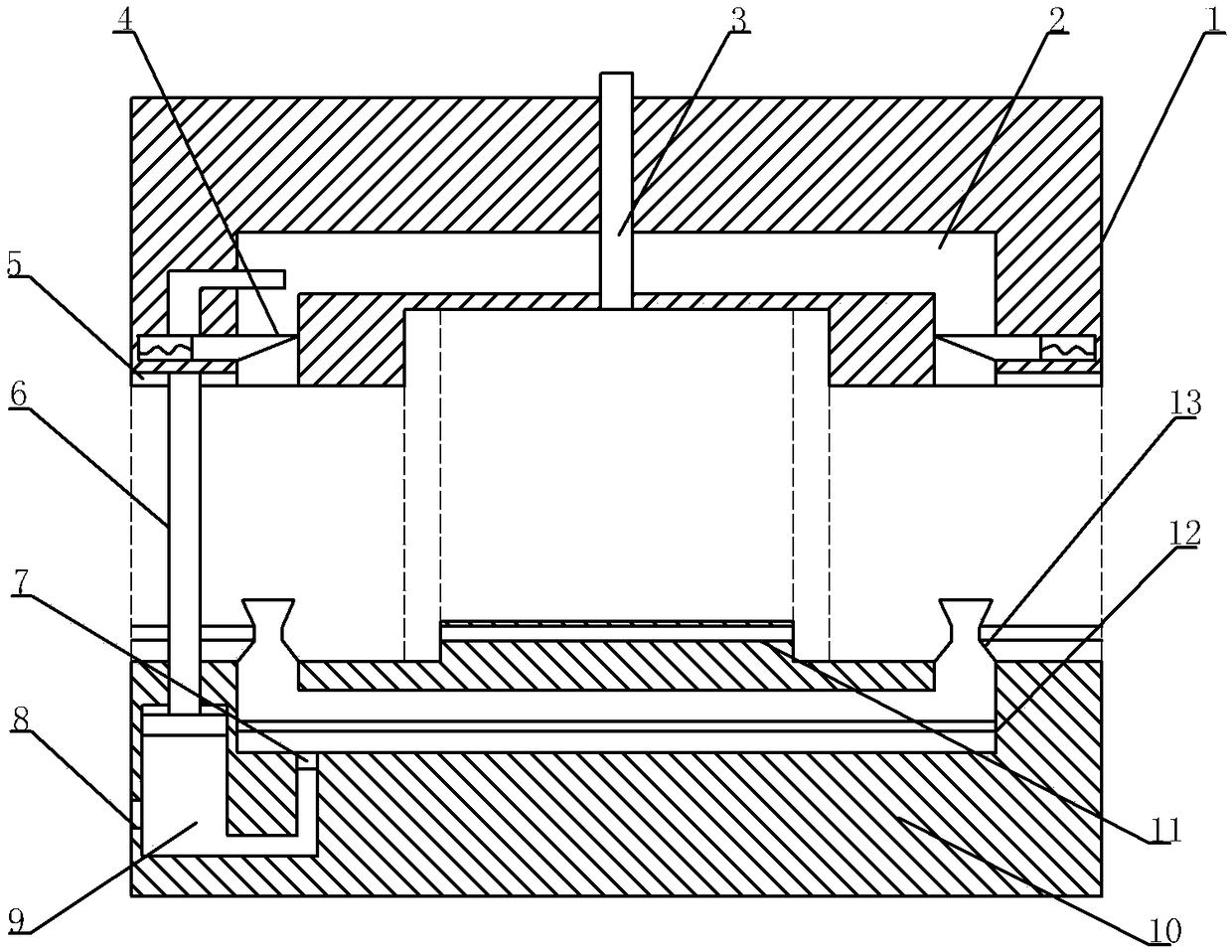

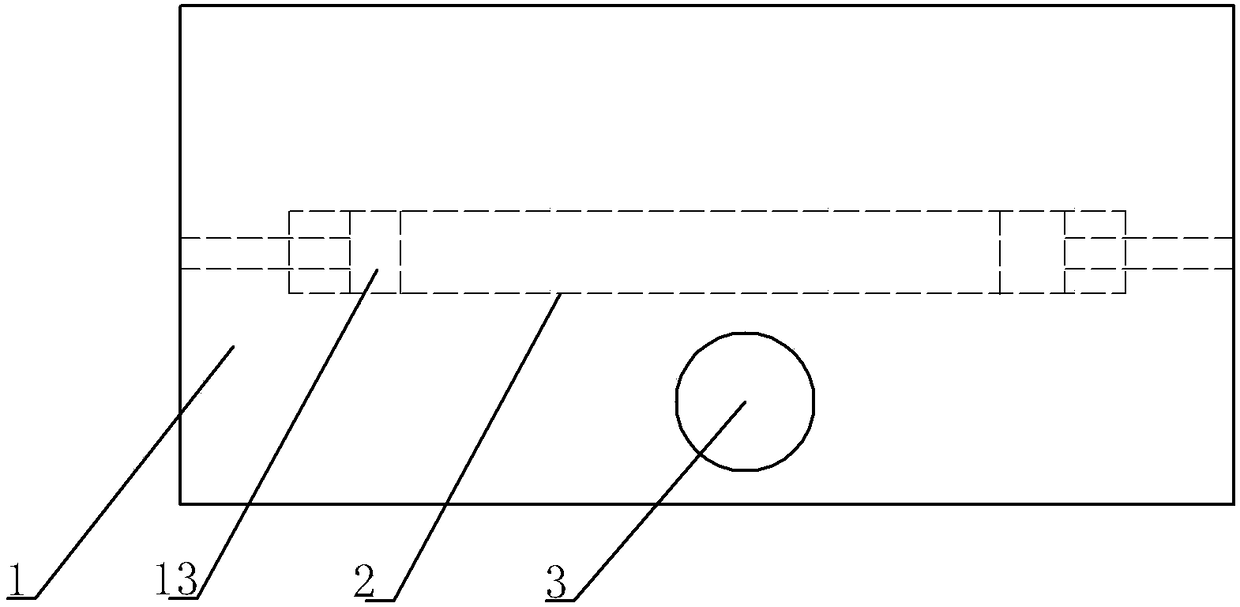

[0021] as attached figure 1 And attached figure 2 As shown, a cooling mold for fuse box cover includes a frame, an upper mold 1 and a lower mold 10, the upper mold 1 is a concave mold and is slidably connected with the frame, and the upper mold 1 can slide vertically on the frame. Lower mold 10 is punch and is fixed with frame. When the upper mold 1 and the lower mold 10 are engaged, a molding cavity is formed between the upper mold 1 and the lower mold 10 . The upper mold 1 is provided with an injection port 3 connected to the molding cavity, through which the thermoplastic is injected into the molding cavity. The upper mold 1 is provided with a cooling channel 2 to prevent the plastic melt from entering the cooling channel 2. The cooling channel 2 and the thickness of the side wall of the molding cavity is 3cm. Both ends of the cooling channel 2 are provided with wedges 4 slidably connected to the upper mold 1 , and the wedges 4 can slide horizontally relative to the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com