Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Fast polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

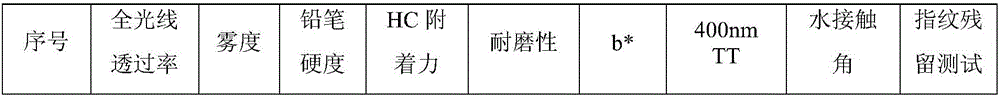

Anti-fingerprint coating liquid and anti-fingerprint hardening film

ActiveCN106433411AImprove the level ofIncrease smoothnessEpoxy resin coatingsOrganic solventFluoride

The invention provides an anti-fingerprint coating liquid and an anti-fingerprint hardening film. The anti-fingerprint coating liquid is prepared from components, in percentage by weight, 20%-50% of fluorine-containing acrylic acid prepolymers, 10%-40% of matrix resin, 1%-5% of a photoinitiator and 30%-50% of an organic solvent. The components of the anti-fingerprint coating liquid are limited in the content range, the fluorine-containing acrylic acid prepolymers can be rapidly subjected to a polymerization reaction under the action of the photoinitiator through UV illumination, fluoride elements float on the surface of the matrix resin, the fluorine-containing aid is added to improve the content of the fluoride elements on the surface and improve the levelling property of the coating liquid, after the anti-fingerprint coating liquid is cured to form an anti-fingerprint coating, the smooth degree and the wear resistance of the surface of the anti-fingerprint coating can be improved, and the anti-fingerprint coating has better hydrophobic performance.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

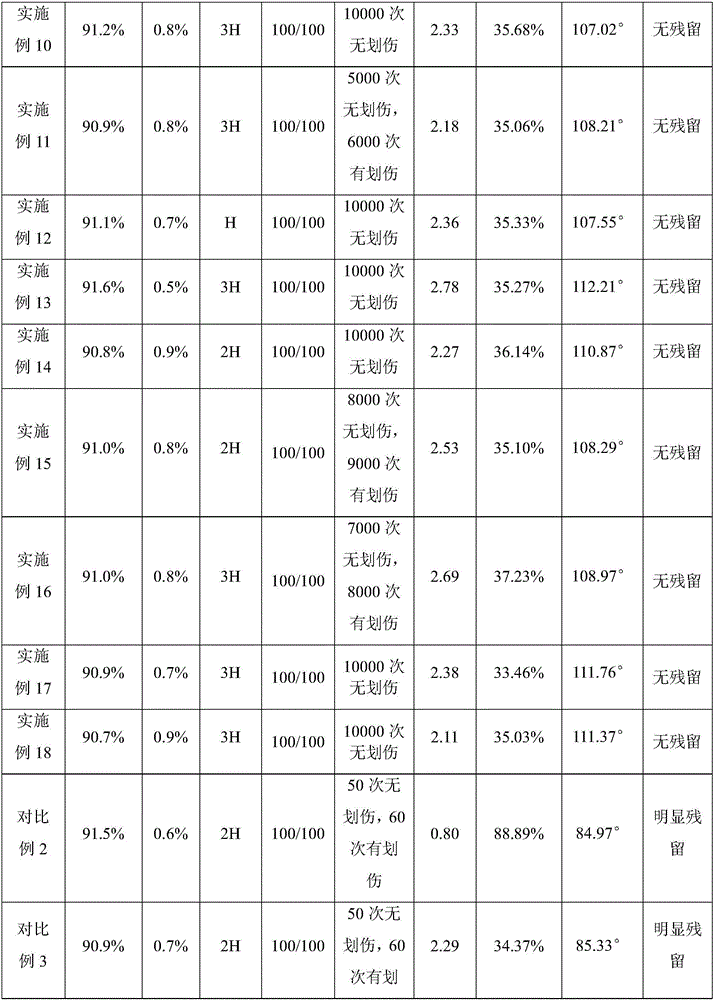

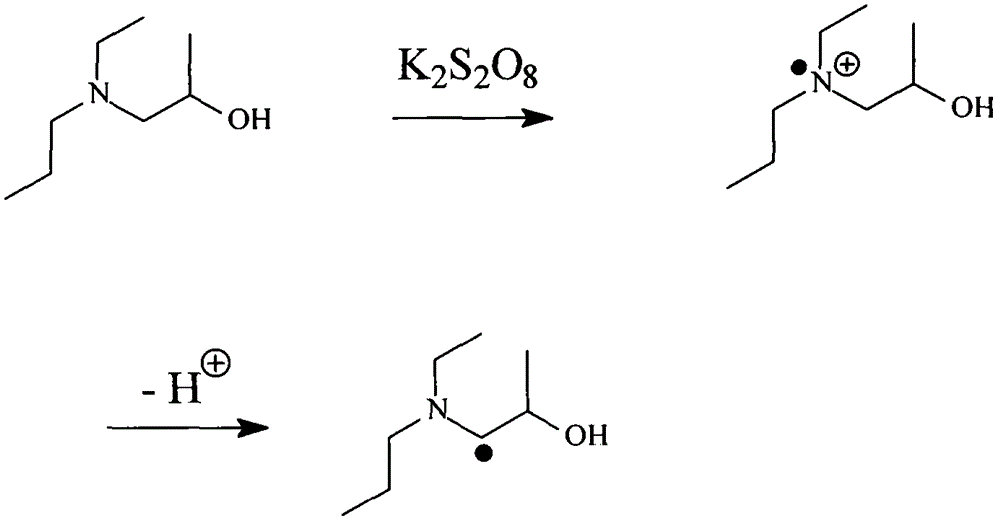

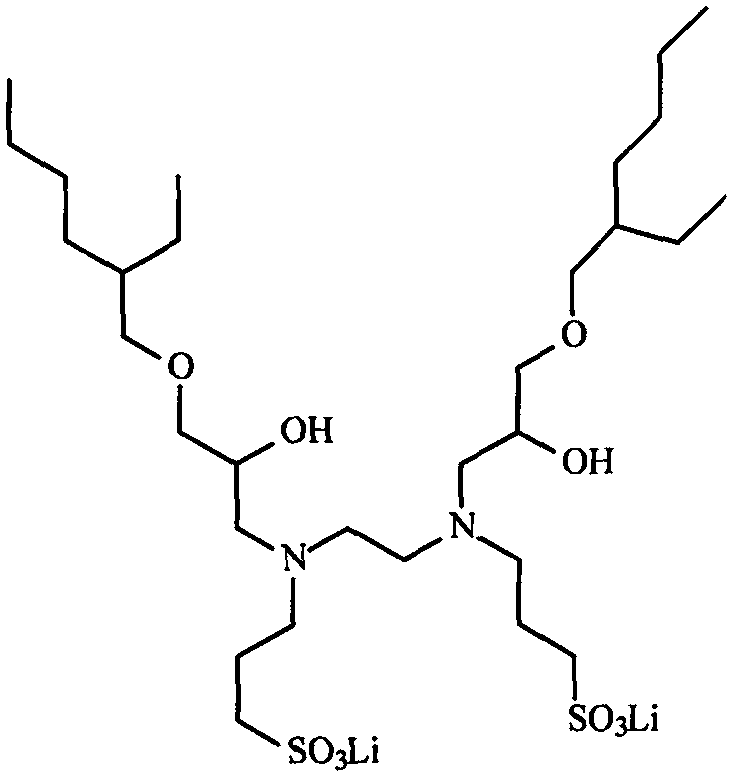

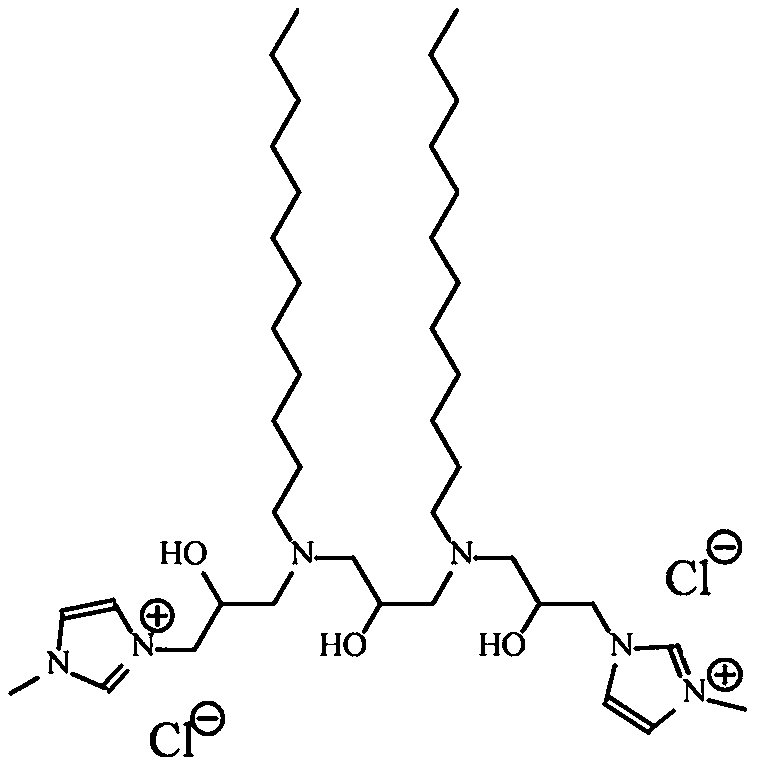

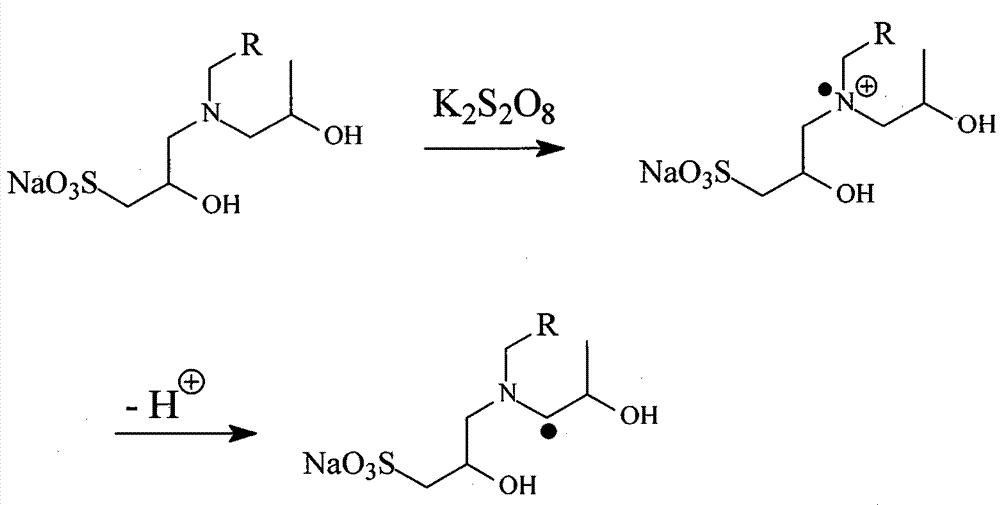

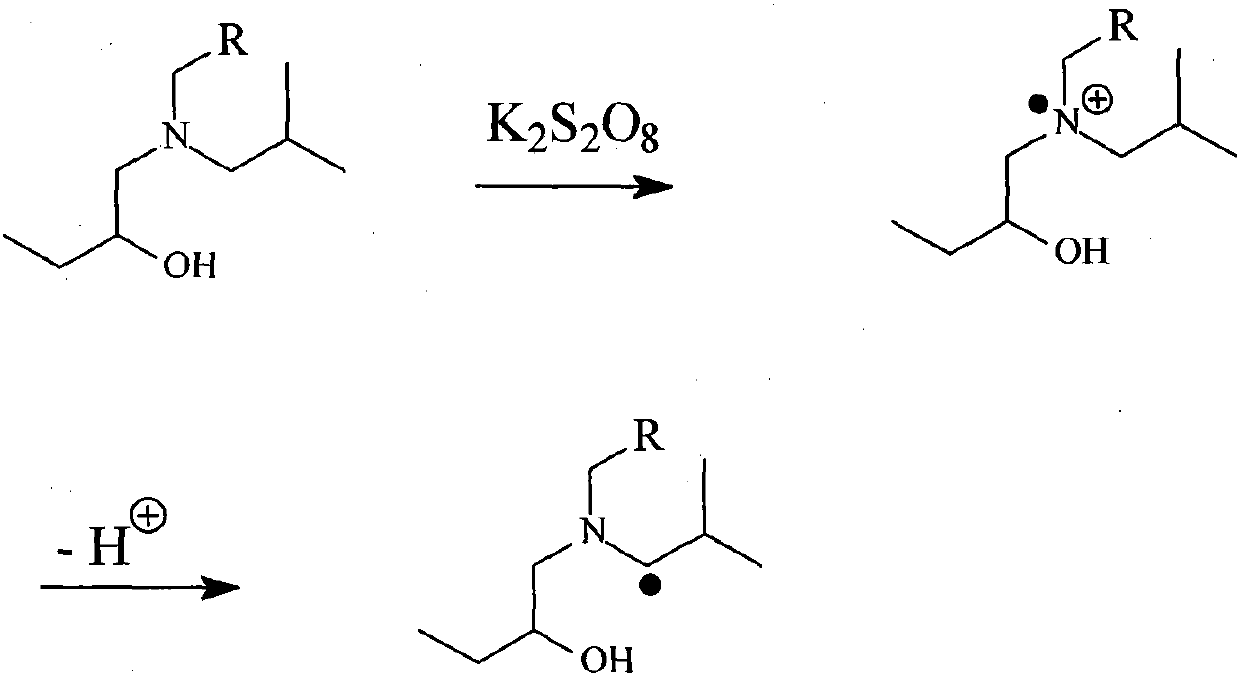

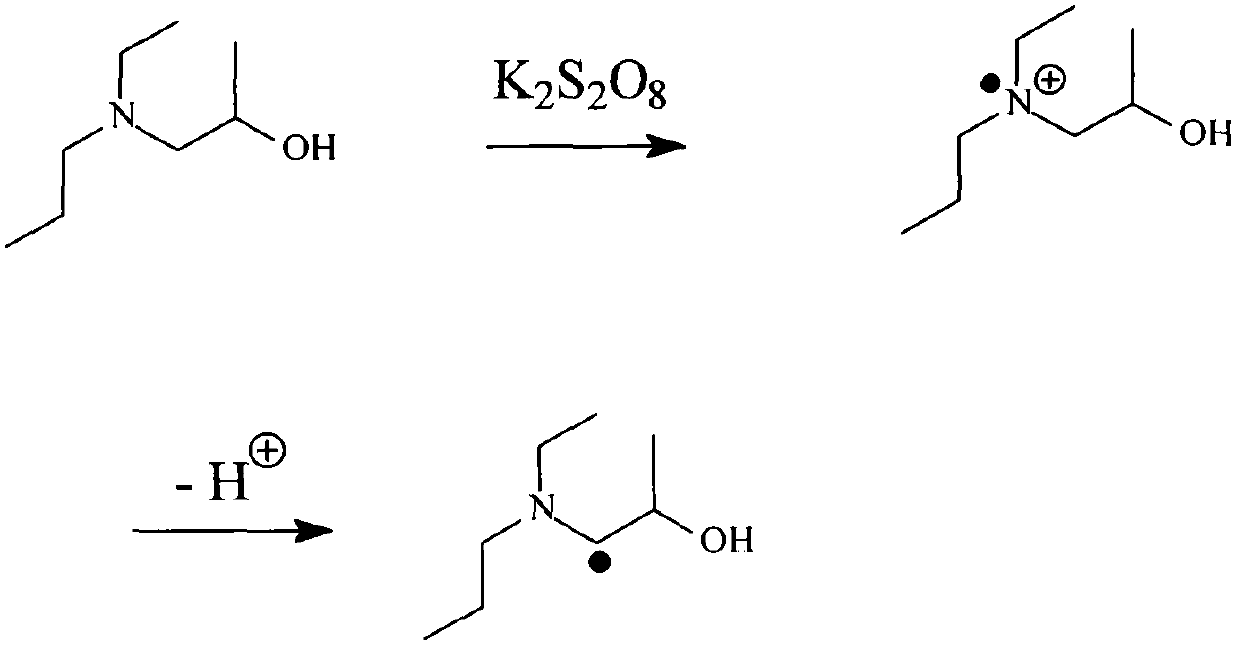

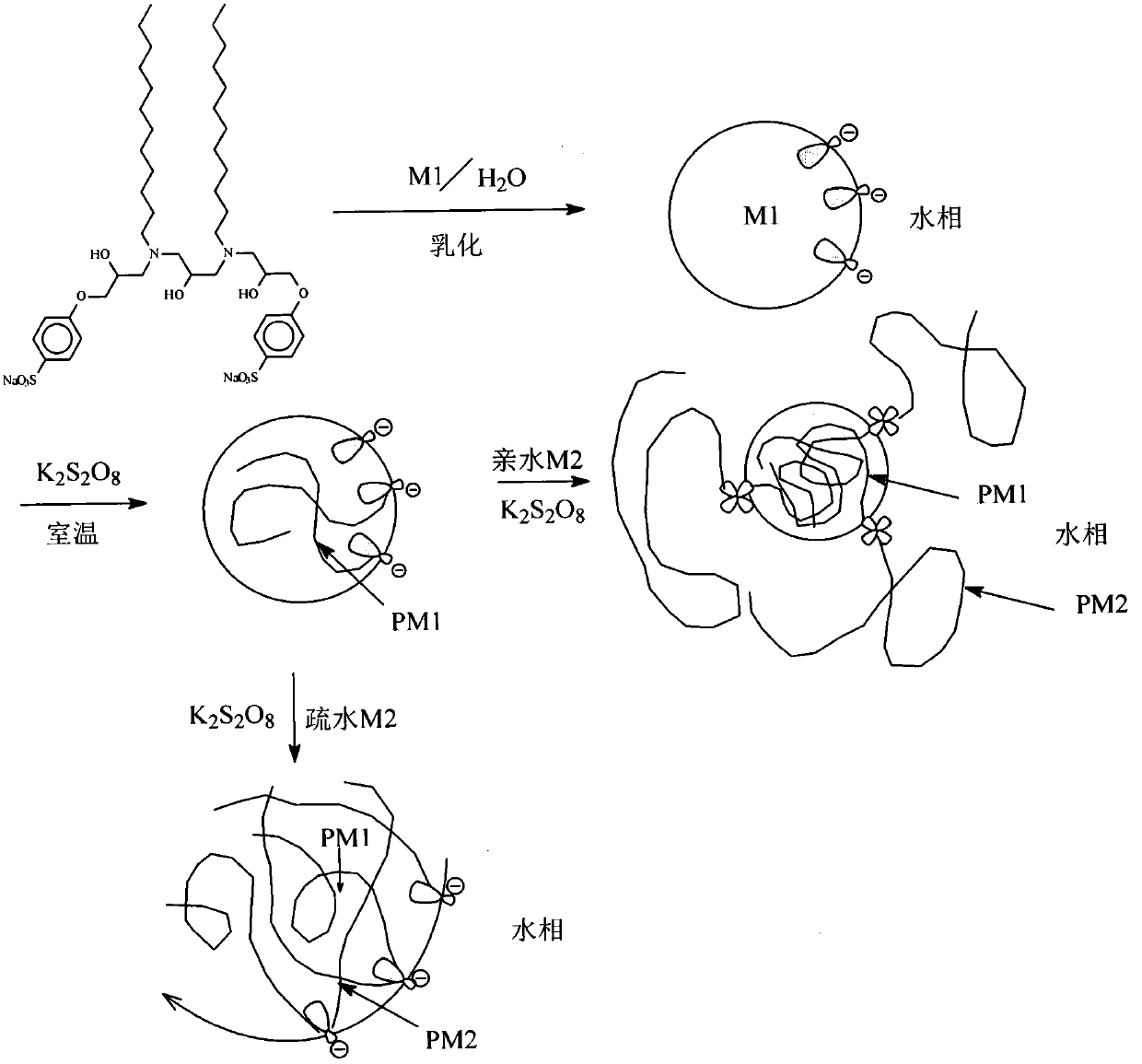

Gemini surface activity initiator and preparation method thereof

ActiveCN105884939AComposition is easy to controlOptimal Control StructureOrganic compound preparationAmino-hyroxy compound preparationPotassium persulfateCarvacryl acetate

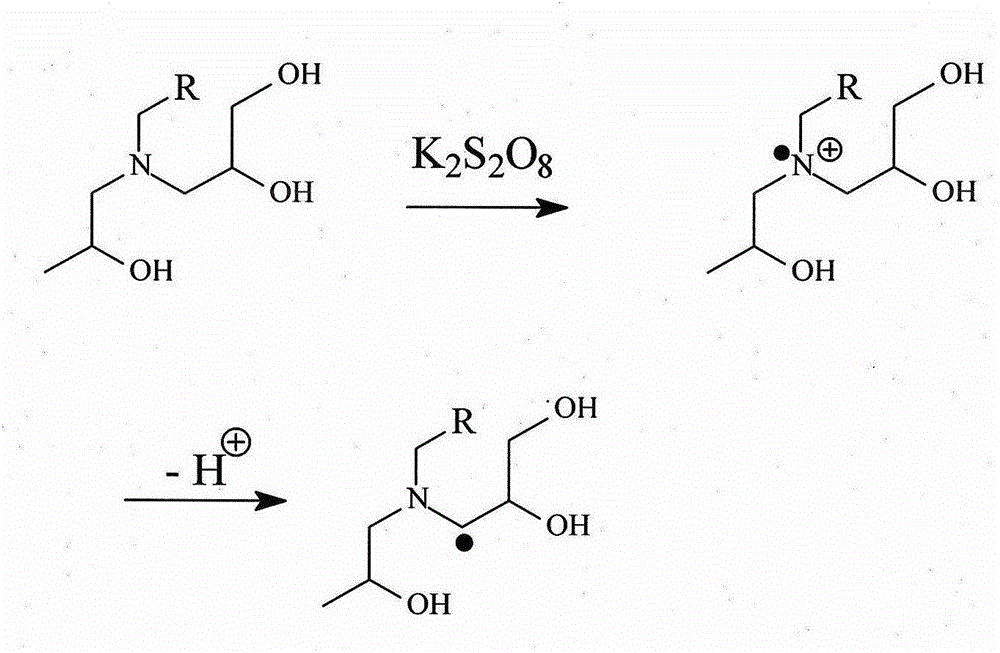

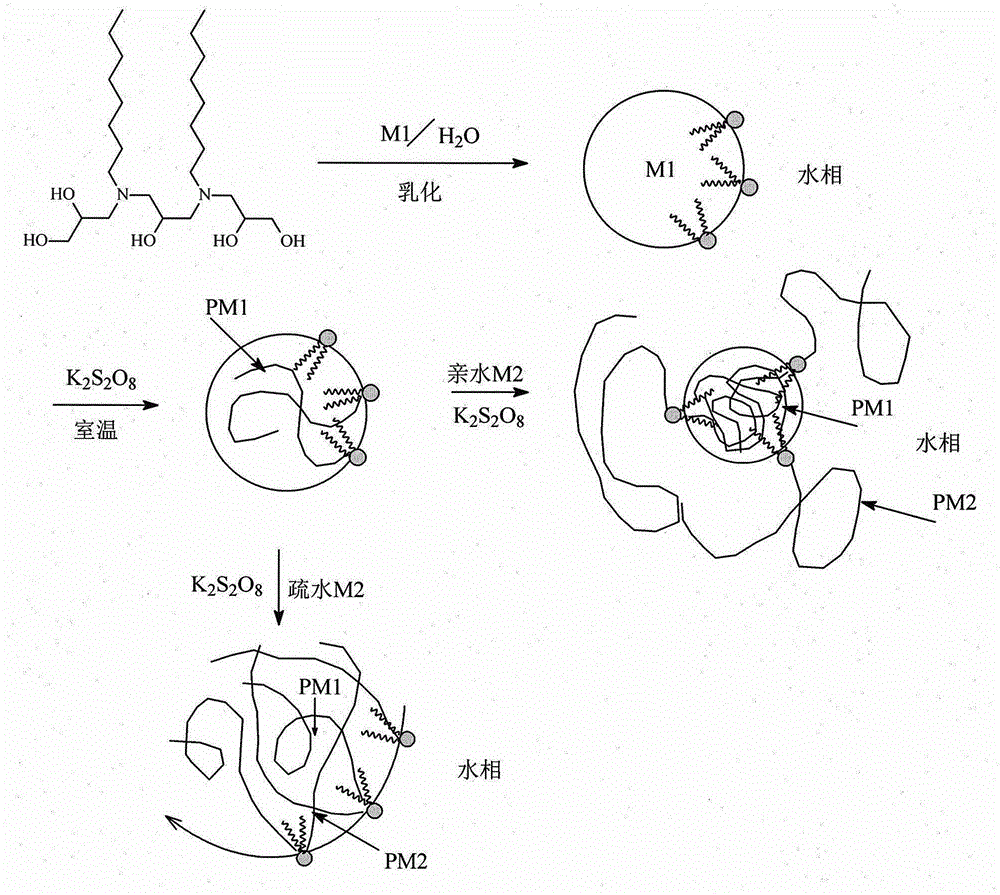

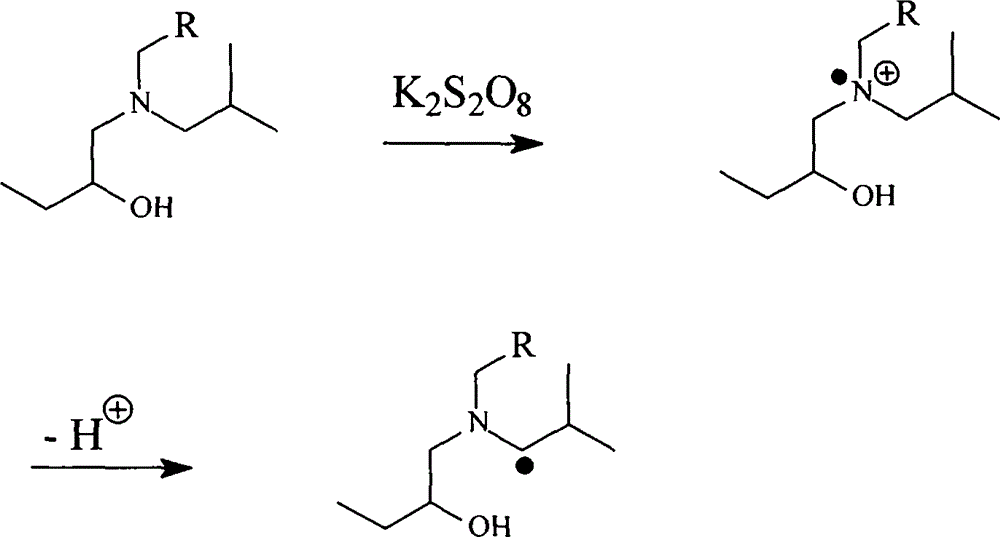

The invention relates to a gemini surface activity initiator and a preparation method thereof. An amphiphilic compound containing polyhydroxyl amine and dioctyl groups is firstly synthesized, the compound has the high characteristics of emulsifying oily monomers, hydrophilic tertiary amine can generate a redox reaction with potassium persulfate at room temperature, cation free radicals are firstly formed on nitrogen atoms and then converted into carbon free radicals at the adjacent positions, generation of the free radicals can be repeated for multiple times and flexibly controlled, a serially-initiated multiphase concatenating polymerization mode is achieved, polymerization of styrene and vinyl acetate and polymerization of styrene and acrylamide are initiated on a water-oil interface in sequence, and then a segmented copolymer is obtained. Experiments prove that the feed ratio of monomers is quite consistent with the component ratio of the copolymer, that is to say, the initiation efficiency of the initiator is very high, this mode of polymerization reaction is mild and controllable in condition and low in energy consumption, no other organic solvent or emulsifier is used, the product is pure, and the requirements of green chemistry are totally met.

Owner:NINGBO UNIV

Liquid aromatic amine epoxy resin curing agent and preparation method thereof

InactiveCN102532486ALow toxicityGood high temperature mechanical propertiesOrganic compound preparationAmino-hyroxy compound preparationEpoxyHeat resistance

The invention discloses a liquid aromatic amine epoxy resin curing agent and a preparation method thereof. The liquid aromatic amine epoxy resin curing agent comprises the following components by weight percentage: 70-98 percent of solid aromatic amine and 2-30 percent of low-viscosity aliphatic epoxy resin. The preparation method comprises the following steps of: adding solid aromatic amine with a weight percentage of 70-98 percent in a reaction vessel, raising the temperature to a melting point above, starting an agitator after the material is molten, reducing the temperature to a melting point plus or minus 3 DEG C and dripping the low-viscosity aliphatic epoxy resin with a weight percentage of 2-30 percent for 2-3 batches through an overhead tank; agitating and reacting for 1-2 hours after the end of dripping, reducing the temperature to 50-60 DEG C, and filtering and discharging to obtain the liquid aromatic amine epoxy resin curing agent. The liquid aromatic amine epoxy resin curing agent and the preparation method thereof have the beneficial effects that the liquid aromatic amine epoxy resin curing agent prepared according to the invention can be mutually dissolved with the epoxy resin nearby the room temperature, the quicker polymerization reaction of the aromatic amine with the epoxy resin in the rubber mixing process can be avoided, and the characteristics of small toxicity, excellent curing substance heat resistance and good high-temperature mechanical property of the aromatic amine curing agent are kept.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

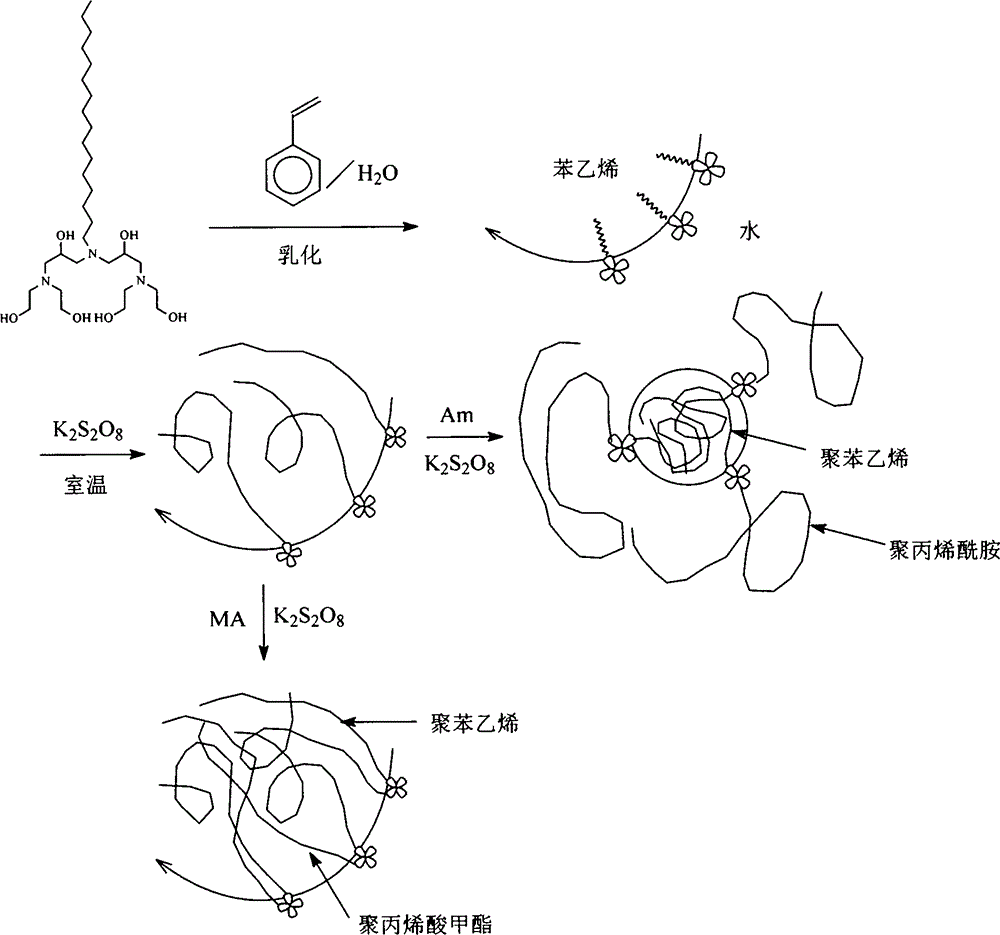

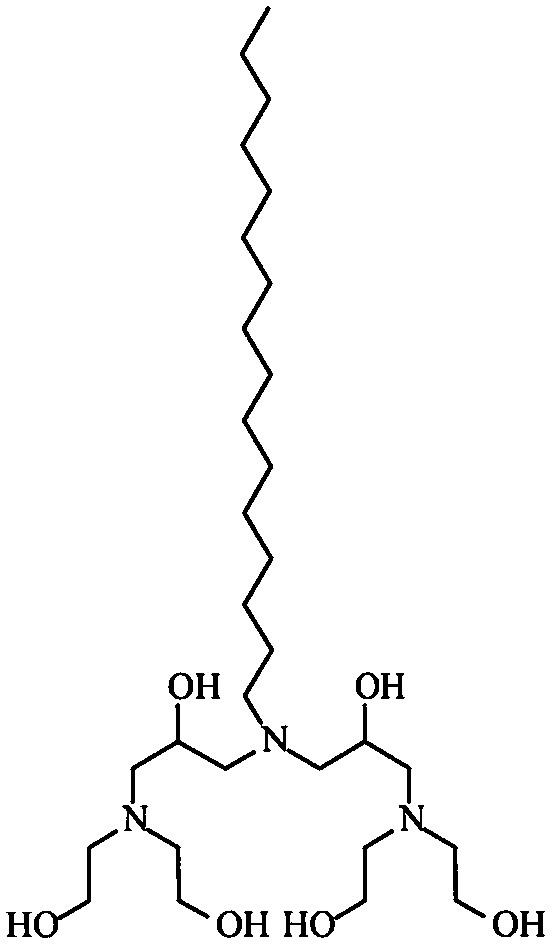

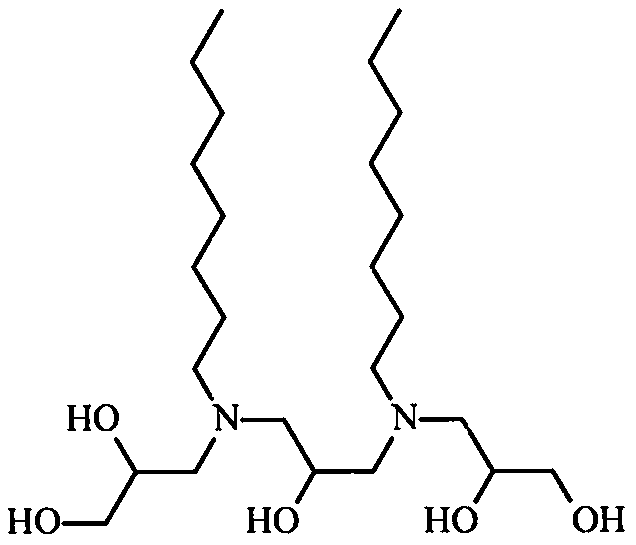

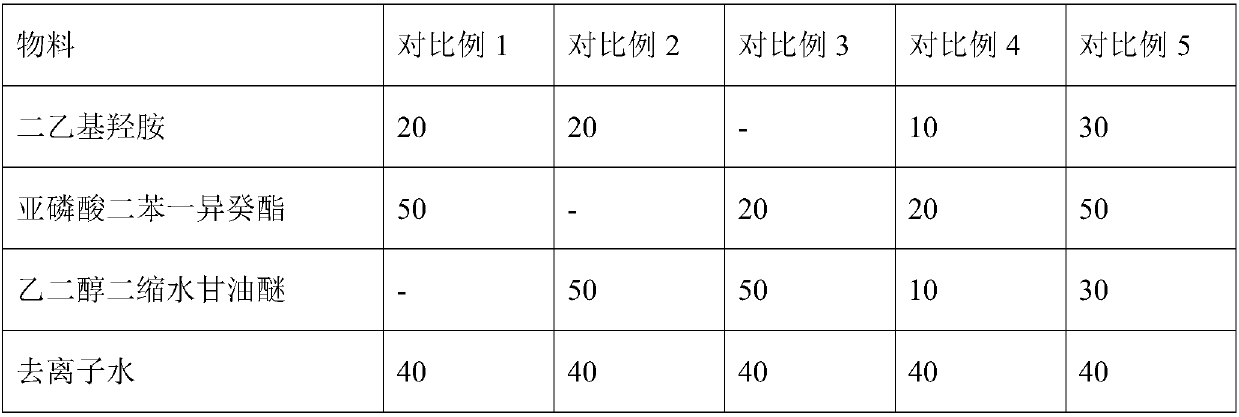

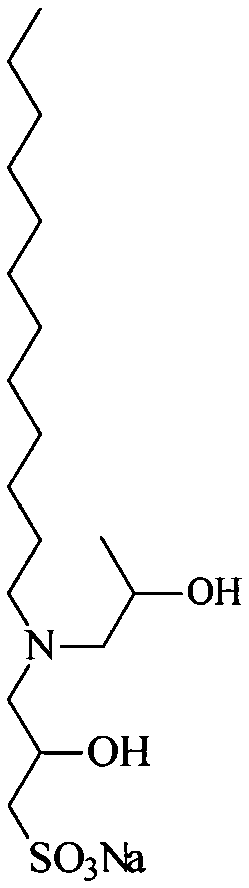

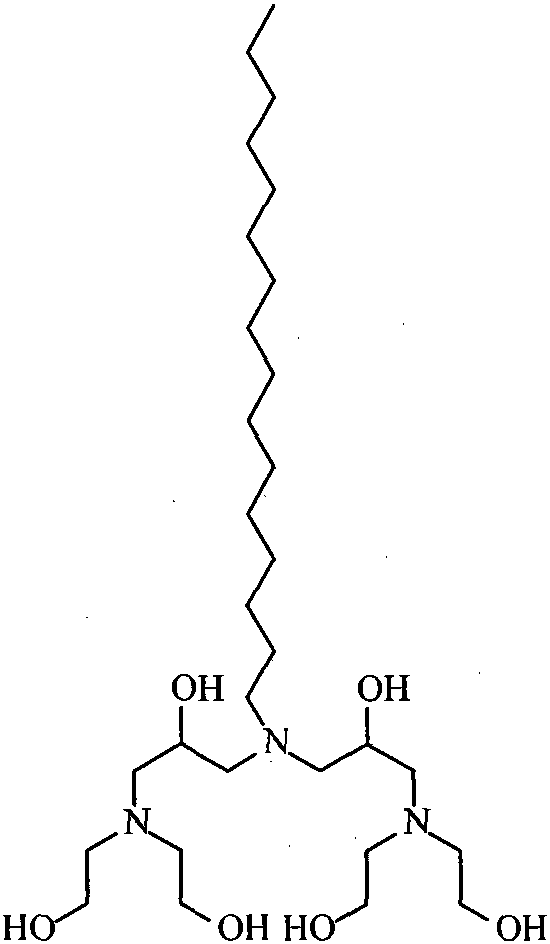

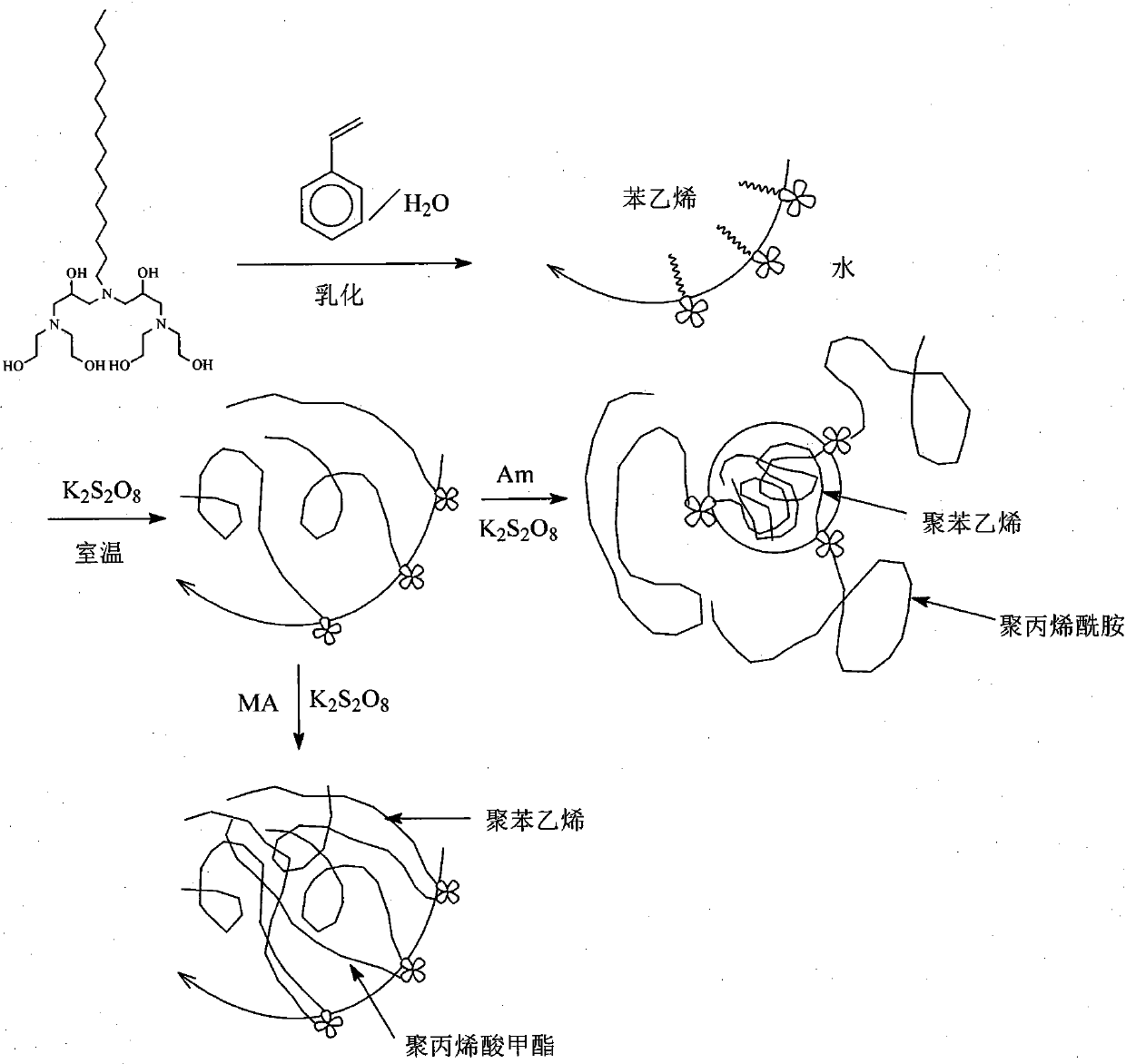

Polyhydroxy polyamine surface activity initiator and preparing method thereof

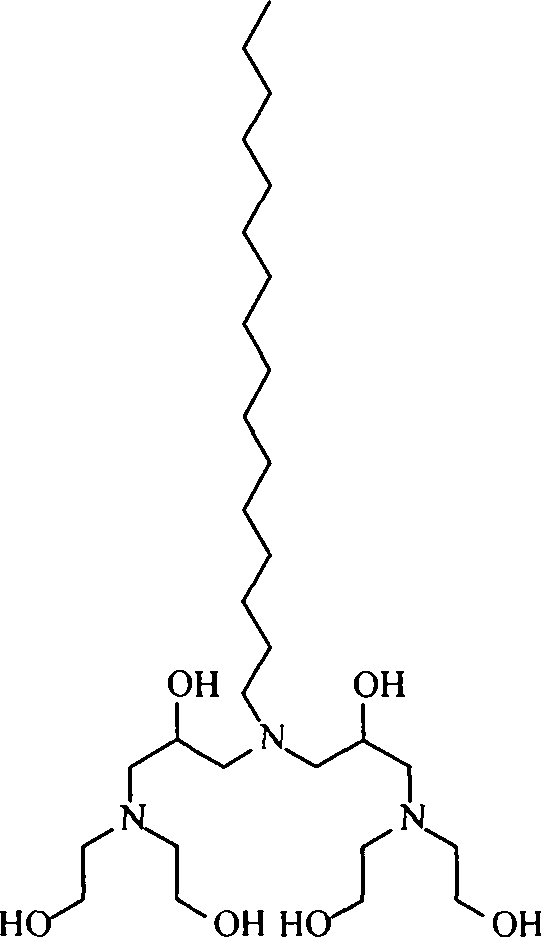

ActiveCN105884624APerformance impactNo leakageOrganic compound preparationTransportation and packagingPotassium persulfateGreen chemistry

The invention discloses a polyhydroxy polyamine surface activity initiator and a preparing method thereof. A tri-tert amine compound containing polyhydroxy group and cetyl group is synthesized and is made to have the characteristics of a surfactant; meanwhile, redox reaction can be conducted between tertiary amine and potassium persulfate at normal temperature, cation free radicals are formed on nitrogen atoms firstly and then converted into carbon free radicals at adjacent positions, free radicals can be generated repeatedly under flexible control, multiphase tandem connection polymerization can be achieved, polymerization between styrene and methyl acrylate and polymerization between styrene and acrylamide are triggerned on a water / oil interface in sequence, and a corresponding segmented copolymer is obtained; experiments prove that the rate of charge of a monomer is quite consistent with the component ratio of the copolymer, which implies that the ignition efficiency of the initiator is high. The polymerization reaction condition of the mode is mild and controllable, energy consumption is low, no other organic solvent or emulgator is used, the product is pure, and the requirement of green chemistry is completely met.

Owner:NINGBO UNIV

Production method of silicon dioxide aerogel functional material

InactiveCN109851380AHigh compressive strengthImprove physical crosslink strengthCeramicwareLayered structureIon

The invention relates to a production method of a silicon dioxide aerogel functional material, and belongs to the technical field of aerogel. According to the production method of the silicon dioxideaerogel functional material, through carbonization treatment, the silicon dioxide aerogel functional material is produced, not only can an original nano-porous network structure be maintained, but also the silicon dioxide aerogel functional material has a plurality of excellent property such as a high specific surface area, low mass density and nanoscale continuous pores, and the mechanical performance is good; and montmorillonoid is a two-dimensional molecular-sieve-like porous substance, due to the fact that the montmorillonoid has performance of a large specific surface area, large adsorption capability and the like, the montmorillonoid is applied to a wide variety of aspects of adsorption, hydrogen storage, catalysis, bioseparation, electron devices, chromosorb supports and the like, through carbonization treatment, the swelling capability of a layered structure and exchangeable performance of positive ions of the montmorillonoid are used for inserting the inorganic positive ions into layers of the montmorillonoid, and the layers of the montmorillonoid are distracted to form two-dimensional pore channels with openings, so that the adsorption capability and the mechanical performance of the silicon dioxide aerogel functional material are improved.

Owner:谢吉萍

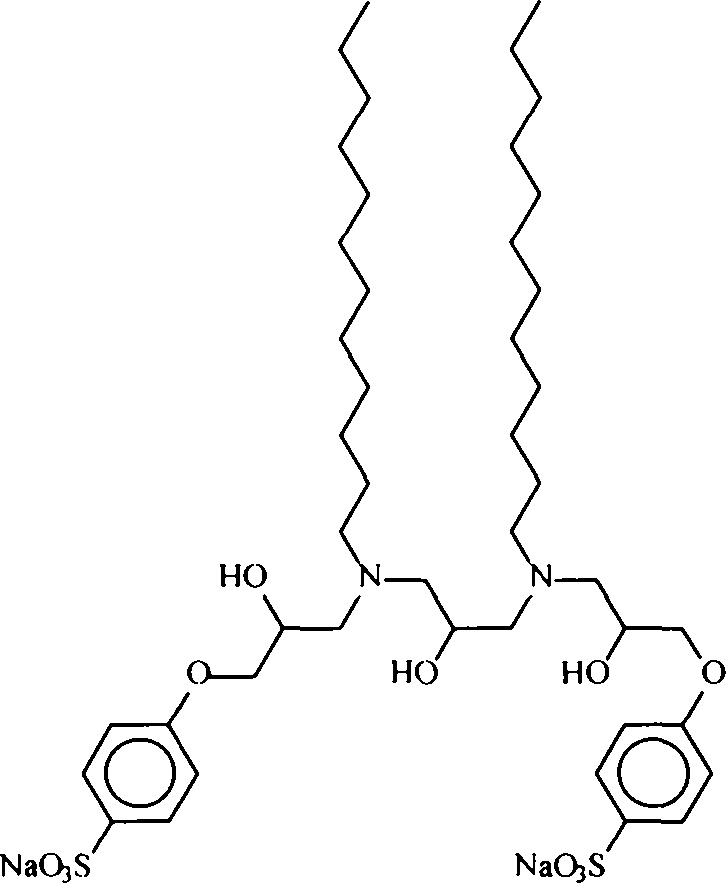

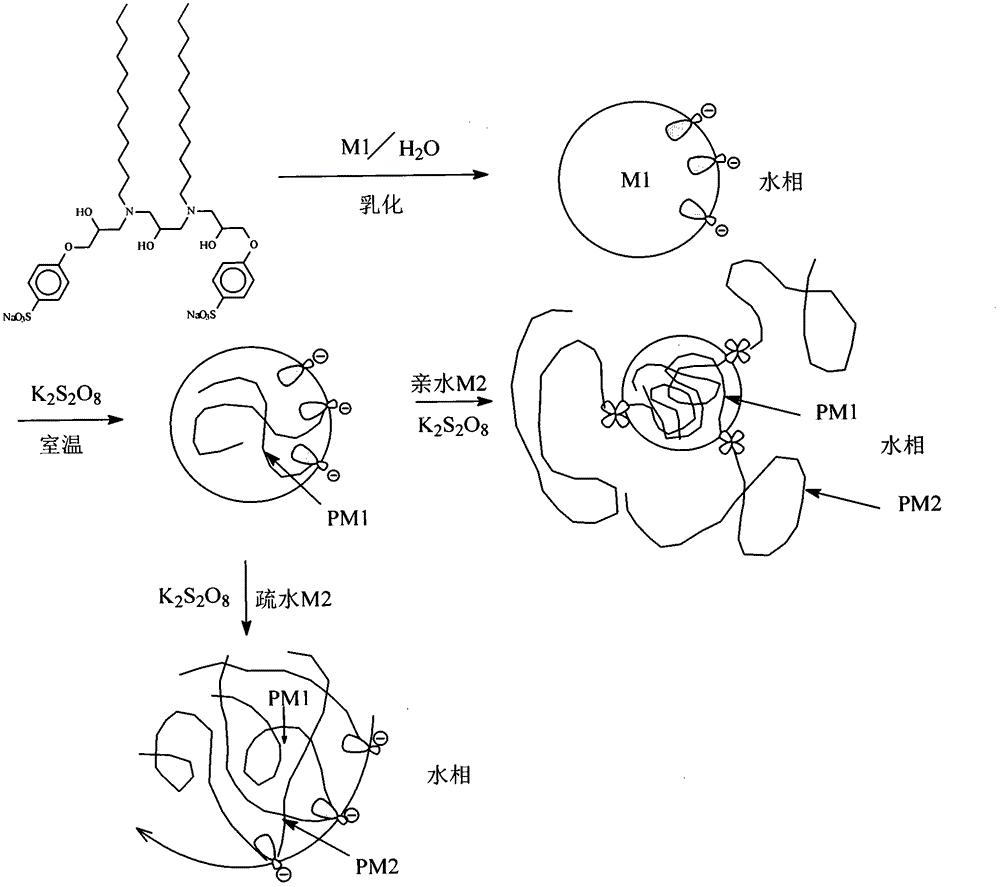

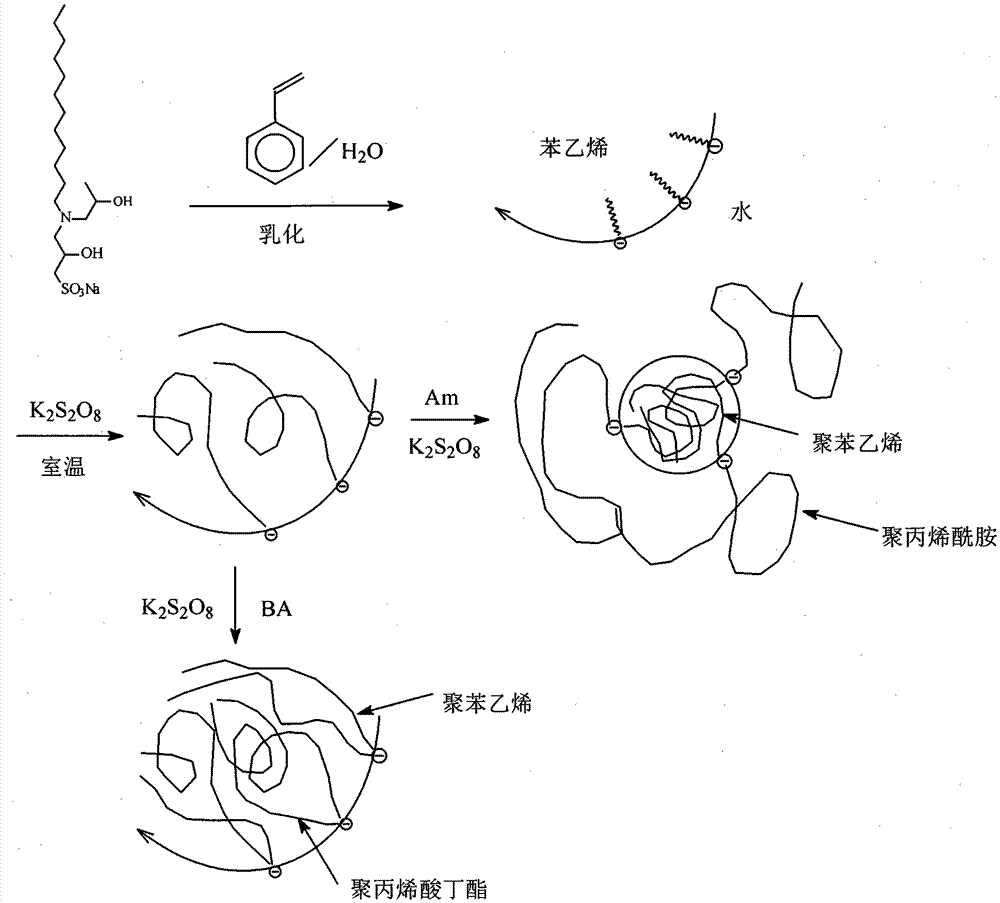

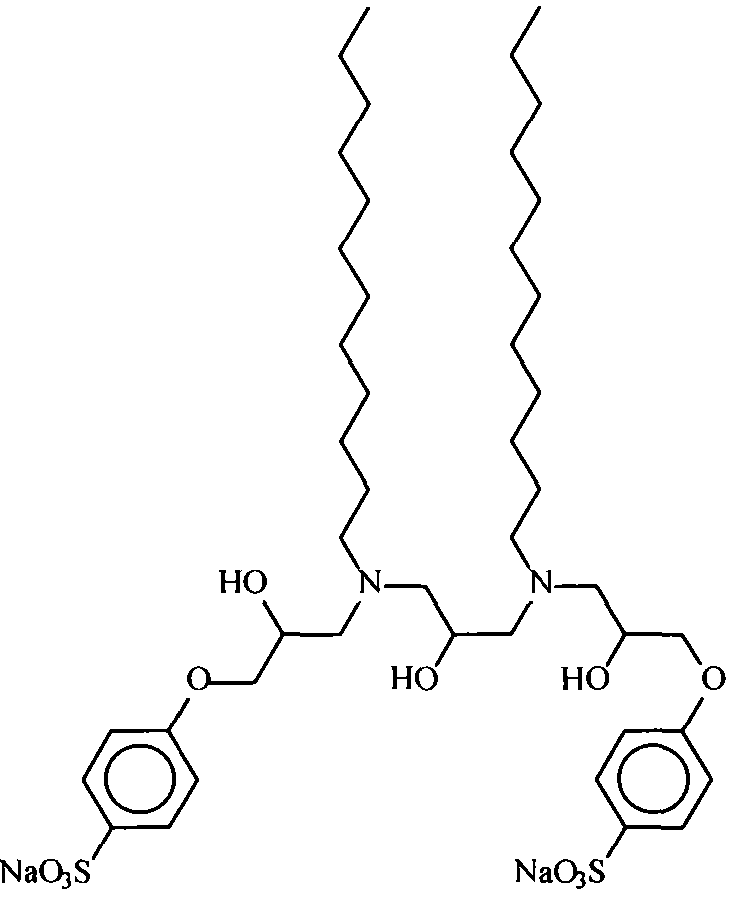

Bi-benzene-sulfonate interface initiator and preparing method thereof

ActiveCN105884940AComposition is easy to controlOptimal Control StructureSulfonic acids salts preparationPotassium peroxodisulfateGreen chemistry

The invention relates to a bi-benzene-sulfonate interface initiator and a preparing method thereof. A tertiary amine compound with bi-benzene-sulfonate anions and bi-dodecyl is synthesized, and the characteristics of a surfactant are shown; meanwhile, tertiary amine and potassium peroxodisulfate can be subjected to a redox reaction at the normal temperature, cation free radicals are formed on nitrogen atoms and then converted into carbon free radicals at adjacent positions, generating of the free radicals can be repeated, control is flexible, multi-phase concatenation polymerization is achieved, polymerization of styrene and butyl acrylate and polymerization of styrene and N,N-dimethyl acrylamide are sequentially triggered on a water / oil interface, and a multi-segmented copolymer is obtained. An experiment proves that the feeding ratio of monomer and the composition ratio of the copolymer are quite coincident, it shows that the triggering efficiency of the initiator is high, the polymerization reaction in the mode is moderate and controllable in condition and low in energy consumption, other organic solvents and emulsifiers are avoided, the product is pure, and the requirements of green chemistry are completely met.

Owner:NINGBO UNIV

Preparation method of solvent type cumyl peroxyneodecanoate (CNP)

InactiveCN102443079AOvercoming activityOvercome the disadvantage of high toxicityOrganic compound preparationPeroxy compound preparationAlkaneChloride

The invention relates to a preparation method of an initiator for synthesizing a high polymer, in particular to a preparation method of solvent type cumyl peroxyneodecanoate (CNP). According to the technical scheme of the invention, the preparation method of the solvent type CNP comprises the following steps of: mixing octyl decanoyl chloride with an alkaline solution and cumyl hydroperoxide, stirring and reacting at the temperature of 10-40 DEG C; and washing a reaction product to neutral, and adding an alkane solvent to obtain the solvent type CNP. Due to the adoption of the method for preparing the solvent type CNP provided by the invention, the process flow is simplified, the complex requirements on reaction equipment are eliminated, a reaction can be undergone in a mild and safe condition, the product content and yield can be increased greatly, and the yield can be over 95 percent.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

Preparation method of emulsion type cumyl peroxyneodecanoate (CNP)

InactiveCN102443080AOvercoming low activityThe polymerization reaction is stableOrganic chemistryCumene hydroperoxideEmulsion

The invention relates to a preparation method of an initiator for polymer synthesis, and in particular relates to a preparation method of emulsion type cumyl peroxyneodecanoate (CNP). The invention adopts a technical scheme that: the preparation method comprises the following steps: mixing and stirring octyl-decanoyl chloride, an alkaline solution and cumene hydroperoxide at a temperature of between 10 and 40 DEG C to react; and adding proper an antifreezing agent, an emulsifier, a dispersing agent and deionized water, and mixing to prepare a homogenous solution, namely emulsion type cumyl peroxyneodecanoate (CNP). The product prepared by using the method provided by the invention has greatly improved content and yield, and is convenient for storage and transportation. According to the method, the process is simplified, complicated requirement to reaction equipment is overcome, the reaction is carried out in a milder and safer condition, and the product yield is over 95 percent.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

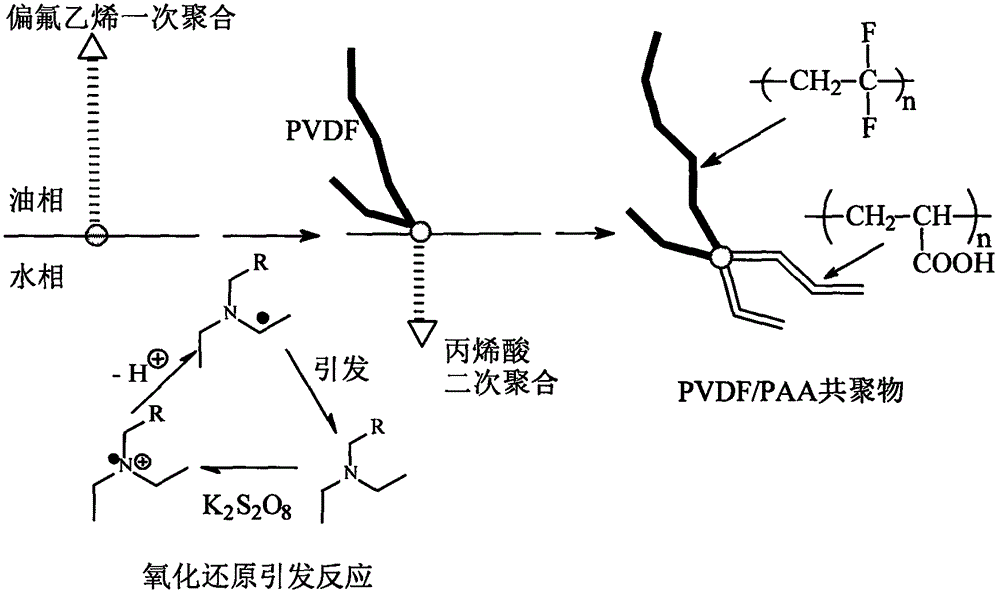

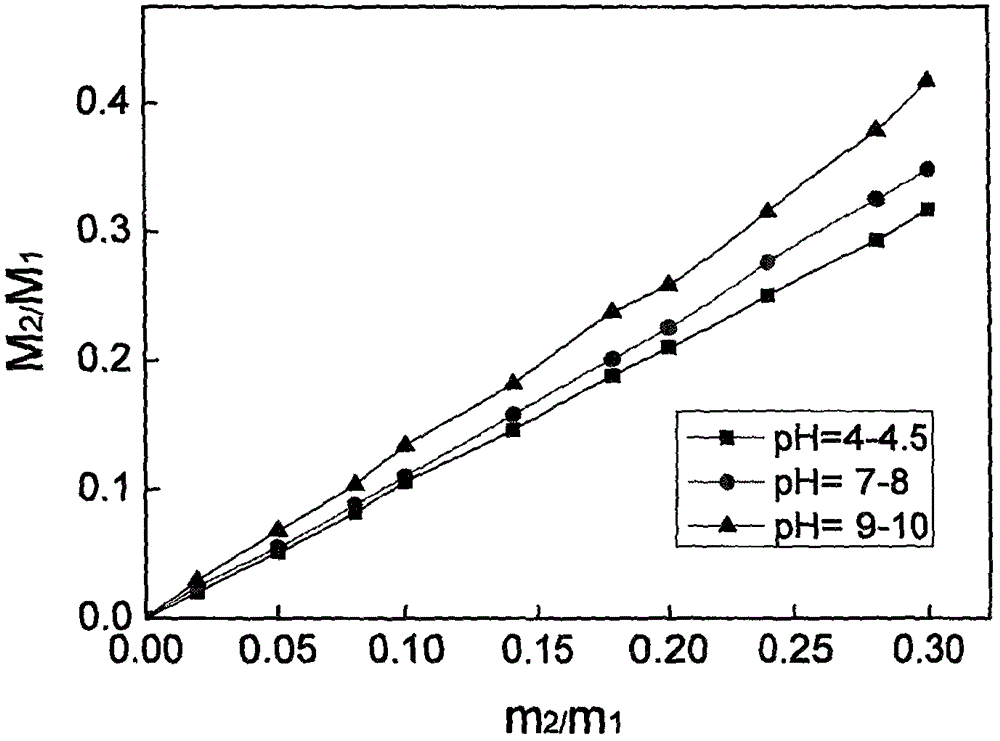

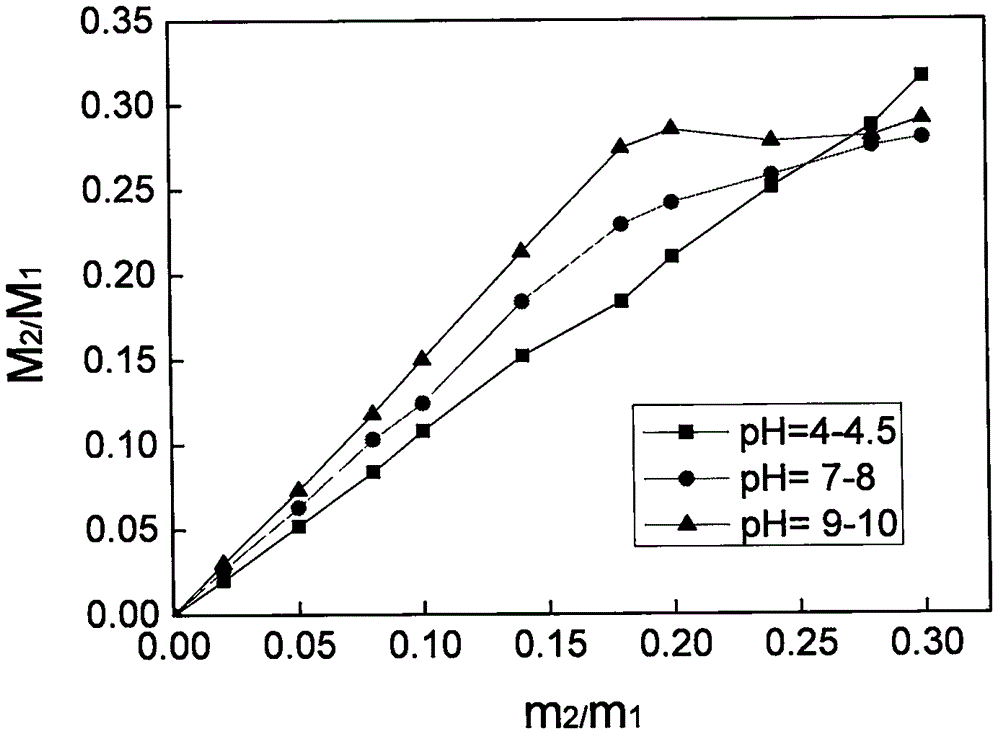

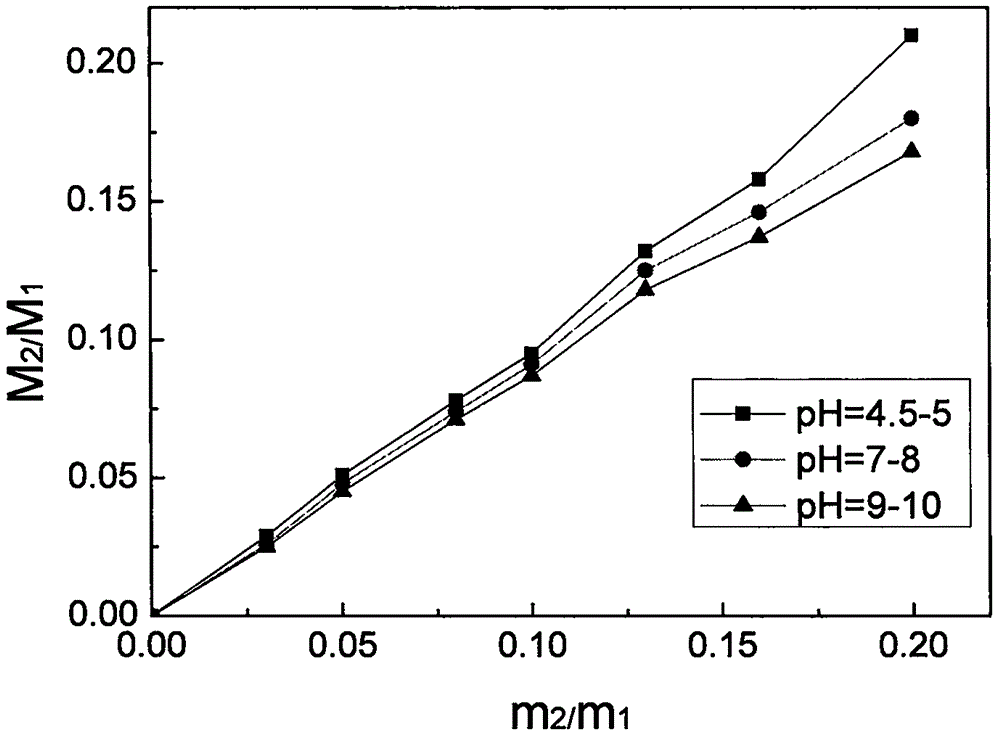

Green preparing method of anionic polyvinylidene fluoride membrane material

ActiveCN106543388AComposition is easy to controlOptimal Control StructurePotassium persulfateOrganic solvent

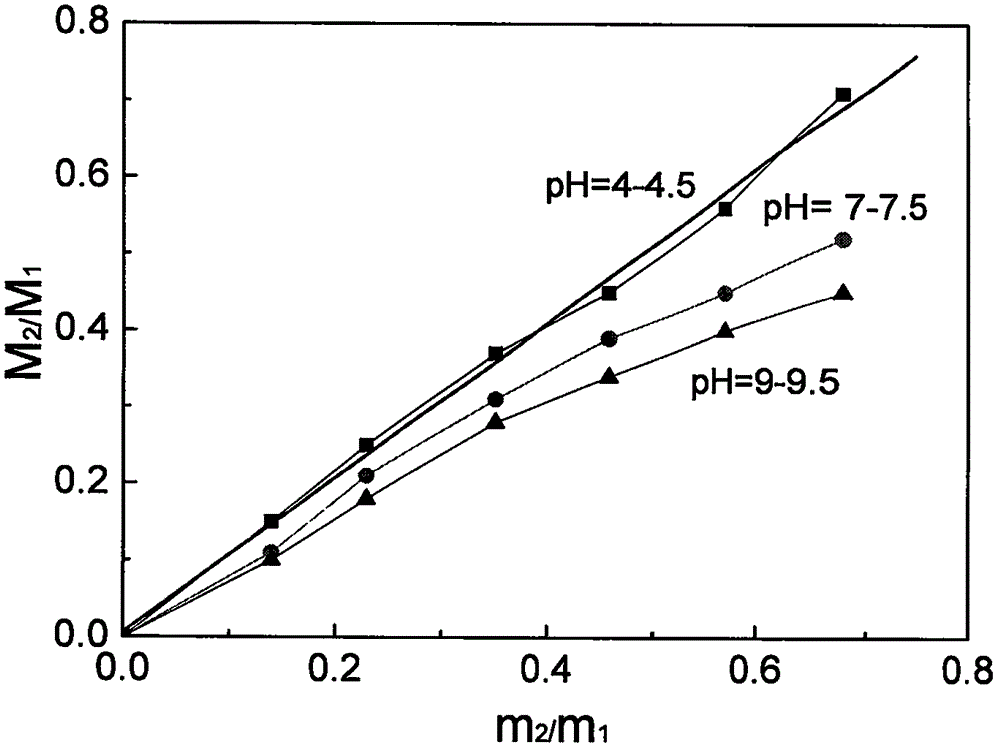

The invention relates to a green preparing method of vinylidene fluoride / acrylic copolymer which is used as a separating membrane material. A copolymer synthetic technique is formed based on polymerization of free radicals in aqueous / oil two phase interface, a gemini type anionic surface activity initiator is specially used to be subjected to redox reaction with potassium persulfate at normal temperature, generation of free radicals in the interface is repeated for a lot of times, an independent polymerization reaction between vinylidene fluoride and acrylic acid is triggered, and a multi-segment copolymer is formed by connecting two kinds of chain segments through a initiator molecular. Experiments show that when a pH value of an aqueous-phase medium is in the range of 4.0-4.5, the material feeding ratio of a monomer coincides exactly with a component ratio of the copolymer, the content of acrylic chain segments in the copolymer is adjustable in the range of 5-25 wt.%, and the polymerization reaction in this mode is mild and controllable in condition, and low in energy consumption; meanwhile, other organic solvents and emulgators are not needed, products are pure, and the thus the preparing method of the anionic polyvinylidene fluoride membrane material totally conforms to demands for green chemistry.

Owner:NINGBO UNIV

Cationic polymerization method for vinyl monomer

The invention discloses a cationic polymerization method for vinyl monomer. In the method, a reaction medium, the vinyl monomer, an initiator, lewis acid and an additive are used, wherein the reaction medium is a mixed reaction medium comprising an organic solvent and water or completely water; the organic solvent is at least one selected from alkane, naphthenic hydrocarbon and halogenated hydrocarbon; the lewis acid is one or a mixture of substances which accord with a general formula of MXn or YRn-mXm; the additive is an oxygen atom and nitrogen atom-containing organic compound; the molar ratio of the lewis acid to the additive to the monomer is 1.0*10<-3> to 3.2*10<-2>:1.0*10<-3> to 3.0*10<-1>:1; and the materials are reacted at the temperature of between -100 and 50 DE C for 0.5 minute to 2 hours to form a polymerization product, namely polymer with molecular weight of 10<5>. The method can simplifies the process flow, saves the production cost, and has great significance and considerable market application value.

Owner:BEIJING UNIV OF CHEM TECH

Ultraviolet-cured transparent finishing coat with high colouring capacity for carpentry

InactiveCN104559748AIncrease dosageConvenient and quick escapePolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolHigh concentration

The technical scheme for realizing the objective of the invention is as follows: an ultraviolet-cured transparent finishing coat with high colouring capacity for carpentry is composed of the following ingredients in parts by weight: 15-25 parts of urethane acrylate, 10-15 parts of epoxy acrylate, 5-10 parts of tripropylene glycol diacrylate, 5-10 parts of trimethylolpropane triacrylate, 5-15 parts of pentaerythritol triacrylate, 5-10 parts of a photoinitiator, 5-10 parts of active amine, 0.5-1.0 part of a dispersant, 0.5-1.0 part of a defoamer, 0.5-1.0 part of a leveller, 3-5 parts of wear-resistant powder, 3-5 parts of matt powder and 10-20 parts of an oily dye. The high-concentration oily dye is used in the ultraviolet-cured transparent finishing coat disclosed by the invention as a breakthrough, meanwhile, the dosage of active amine is increased in a formula, thus greatly solving the problem of achieving the high colouring capacity in one step, ensuring the adhesion force of the finishing coat, achieving the purpose of curing a coating film, and increasing the production efficiency.

Owner:FUJIAN DEZHIXIAN ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

Preparation method of emulsion type tert-butyl peroxyneo-caprate (BNP)

ActiveCN102443078AOvercoming complex requirementsQuality improvementOrganic compound preparationPeroxy compound preparationAnti freezingEmulsion

The invention relates to a preparation method of an initiator for synthesizing a high polymer, in particular to a preparation method of emulsion type tert-butyl peroxyneo-caprate (BNP). According to the technical scheme of the invention, the preparation method of the emulsion type BNP comprises the following steps of: mixing octyl decanoyl chloride with an alkaline solution and tert-butyl hydrogen peroxide, stirring and reacting at the temperature of 10-40 DEG C; separating a mother liquor; and mixing a reaction product with a homogenized liquid prepared from an anti-freezing agent, an emulsifier, a dispersant and deionized water to obtain the emulsion type BNP. Due to the adoption of the method provided by the invention, the product content and yield are increased greatly, and convenience is brought to storage and transportation. Due to the adoption of the method, the process flow is simplified, the complex requirements on reaction equipment are eliminated, a reaction can be undergone under the mild and safe condition, and the product yield can be over 95 percent.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

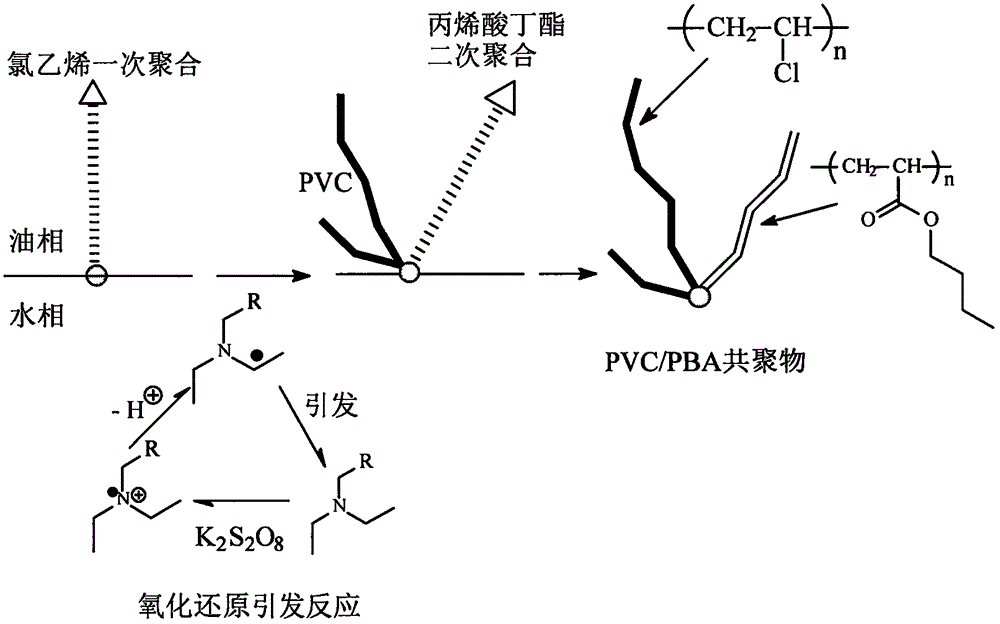

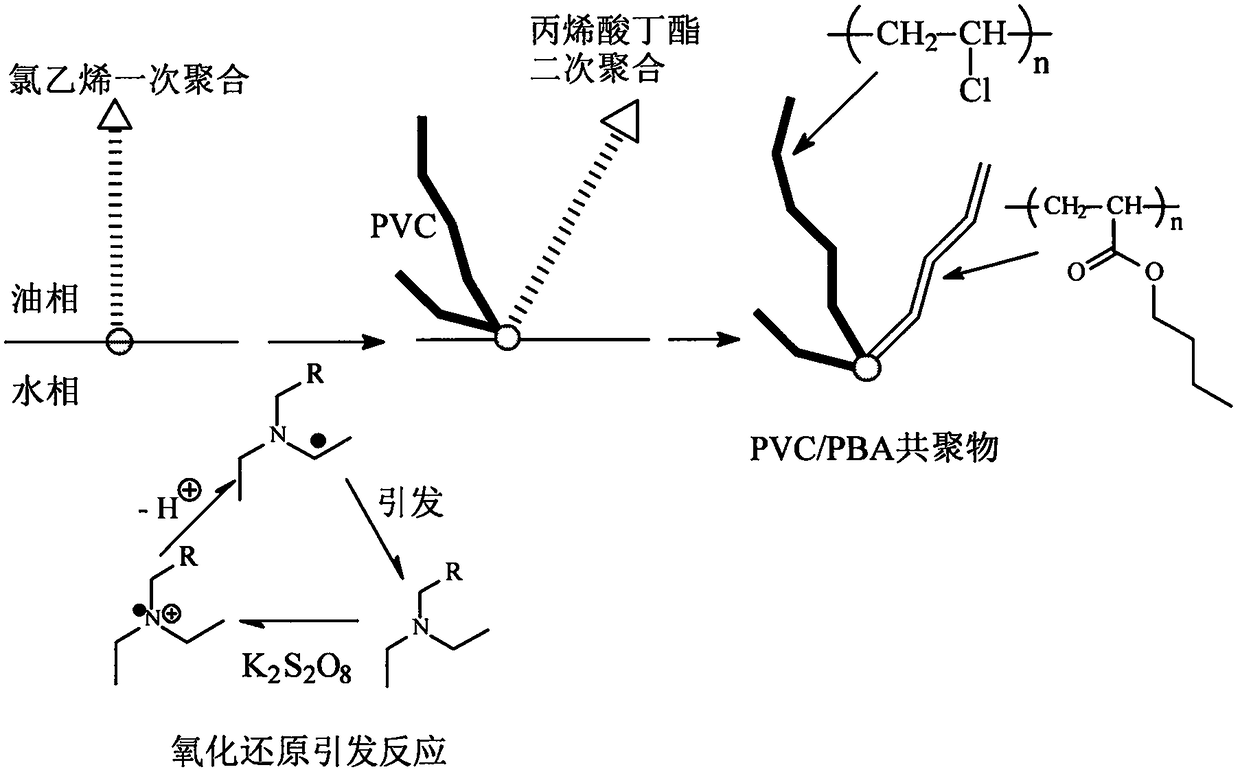

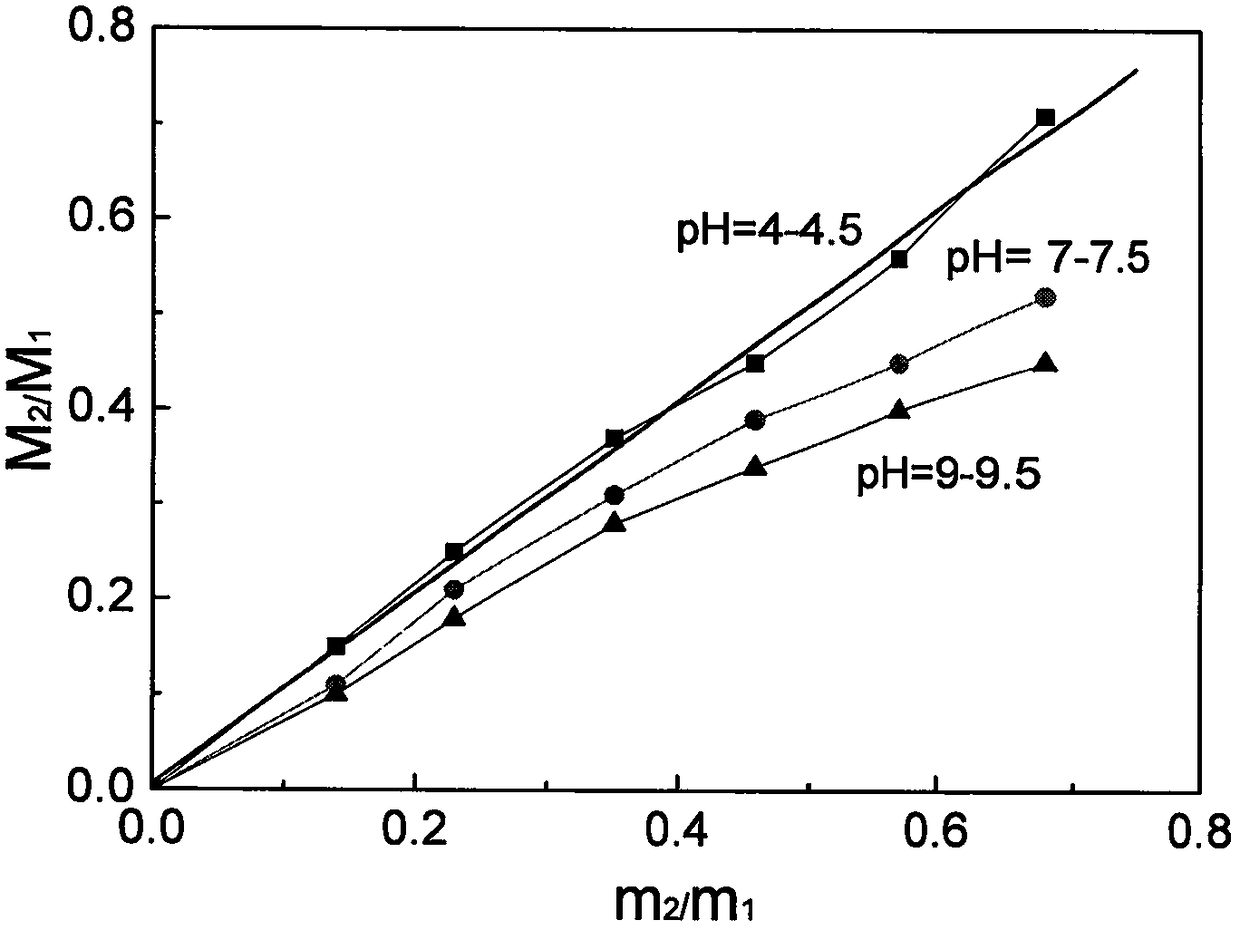

Green chemical preparation method of vinyl chloride/butyl acrylate copolymer

The invention relates to a green preparation method of a vinyl chloride / butyl acrylate copolymer used as a thermoplastic elastomer. The preparation method is based on a synthesis technology of a copolymer formed by interfacial free-radical polymerization of water / oil two-phases. Based on a copolymer synthesis technology through water / oil two-phase interfacial free-radical polymerization, a polyhydroxy polyamine surface active initiator and potassium persulphate are subjected to an oxidation reduction reaction at normal temperature, free radicals are repeatedly generated on the interface and independent polymerization of vinyl chloride and butyl acrylate is initiated. Through molecules of the initiator, two chain segments are connected in series so as to form a poly-segment copolymer. It is proved through experiments that pH of an aqueous medium is within the range of 4-4.5, feed ratio of a monomer is very consistent with composition ratio of the copolymer and content of the butyl acrylate chain segments in the copolymer is adjustable within the range of 10-42wt%. According to the mode of polymerization reaction, conditions are mild and controllable, energy consumption is low, other organic solvents or emulsifiers are not used, and the product is pure. The method completely meets the requirement of green chemistry.

Owner:NINGBO UNIV

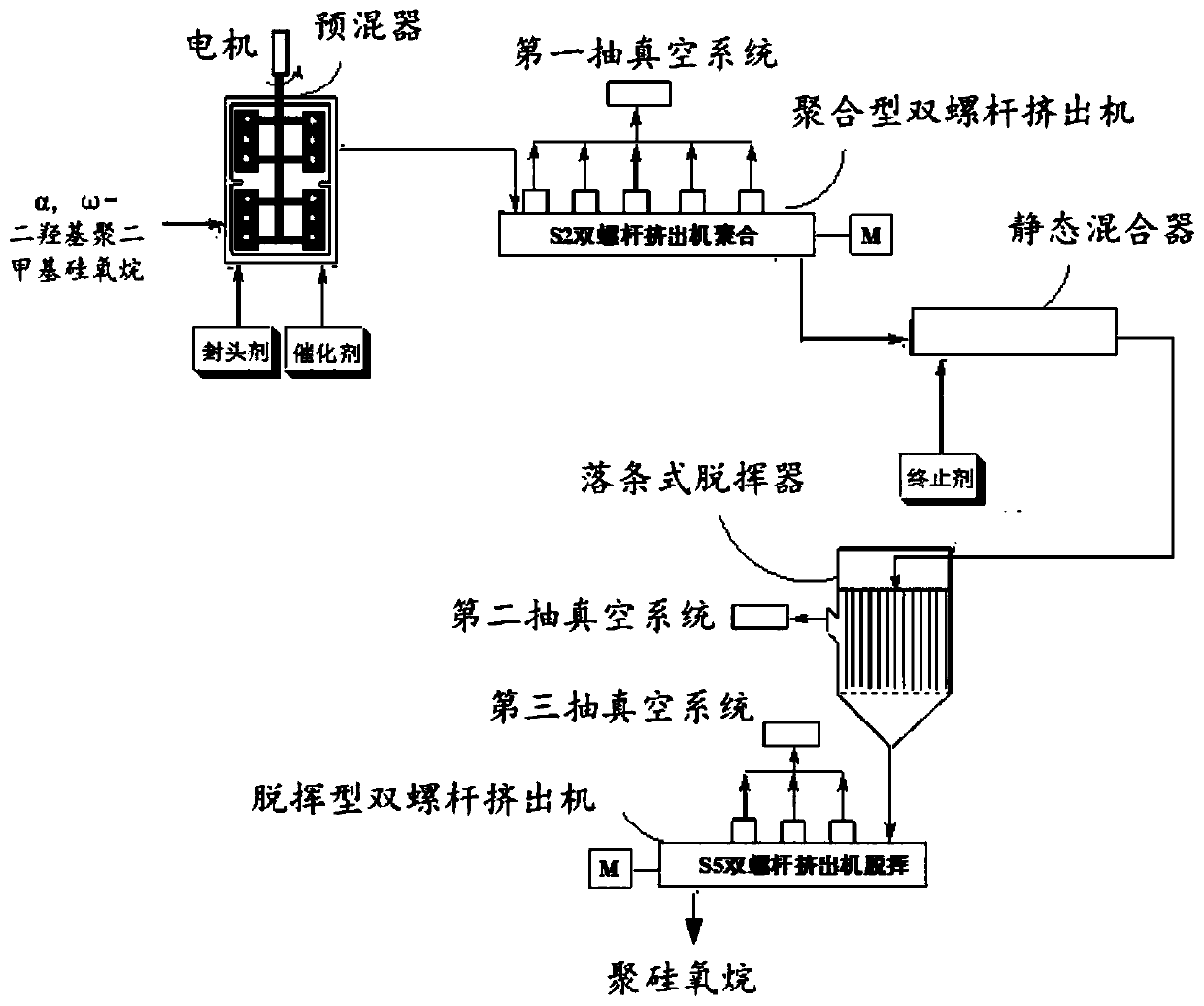

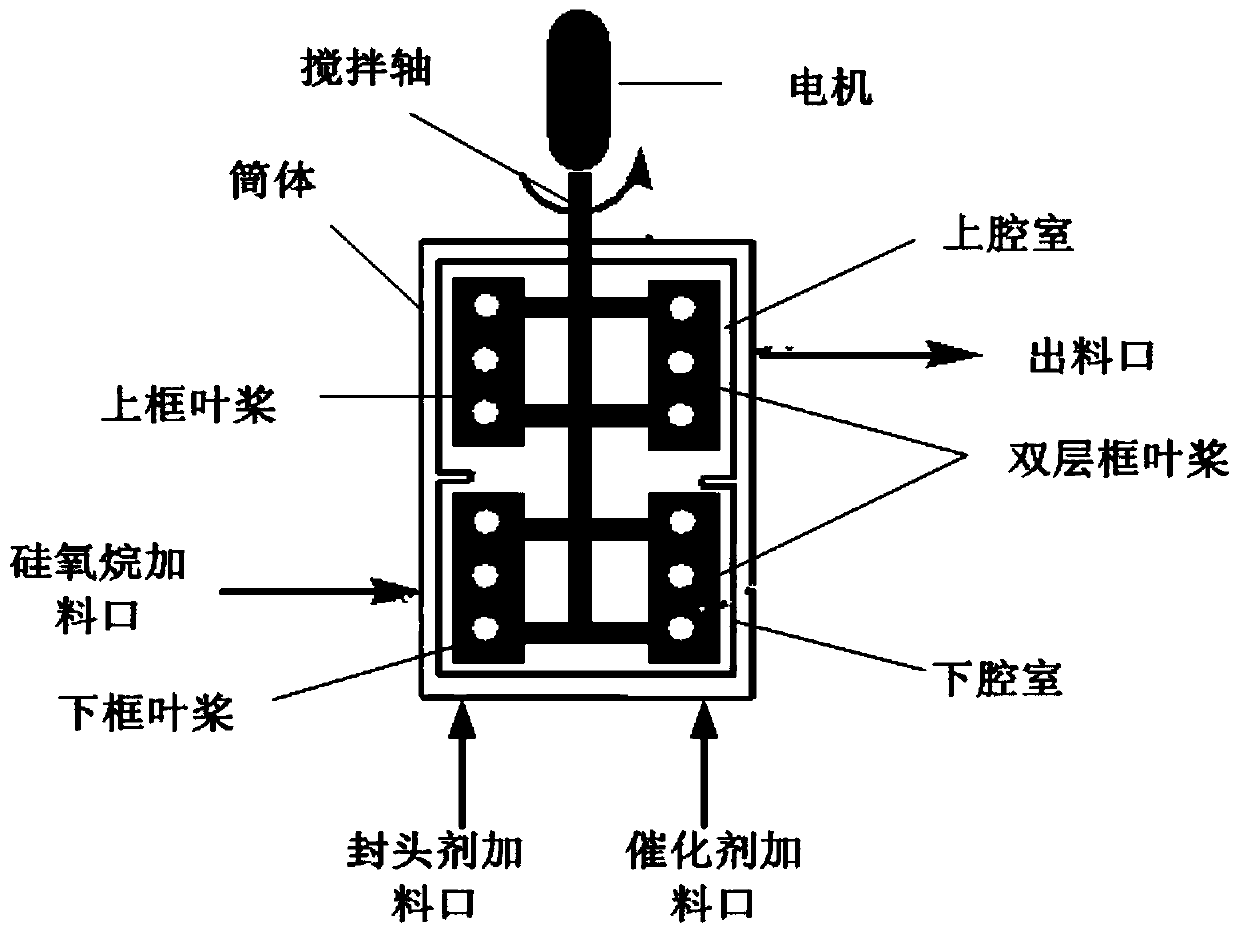

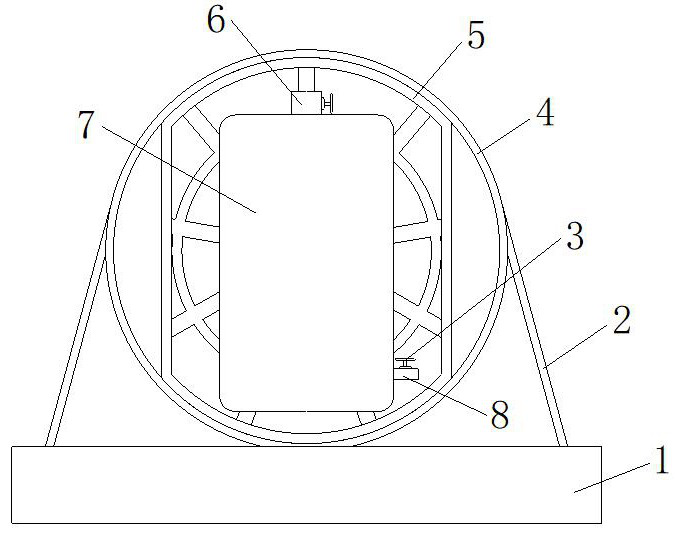

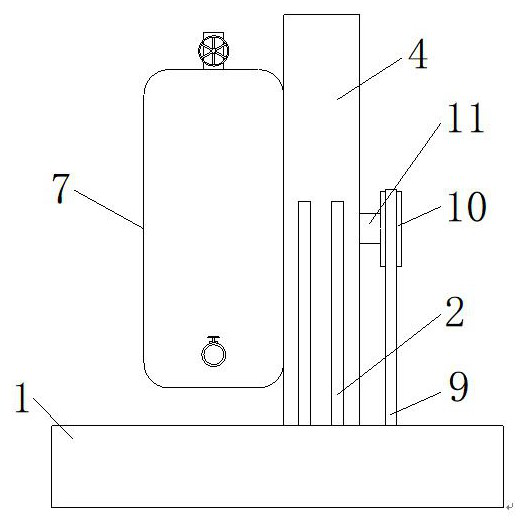

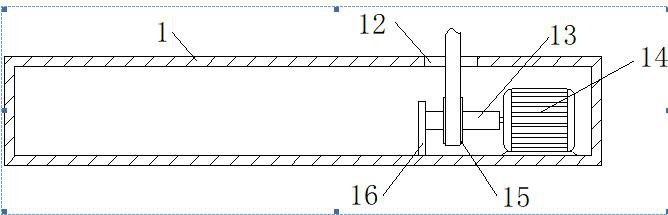

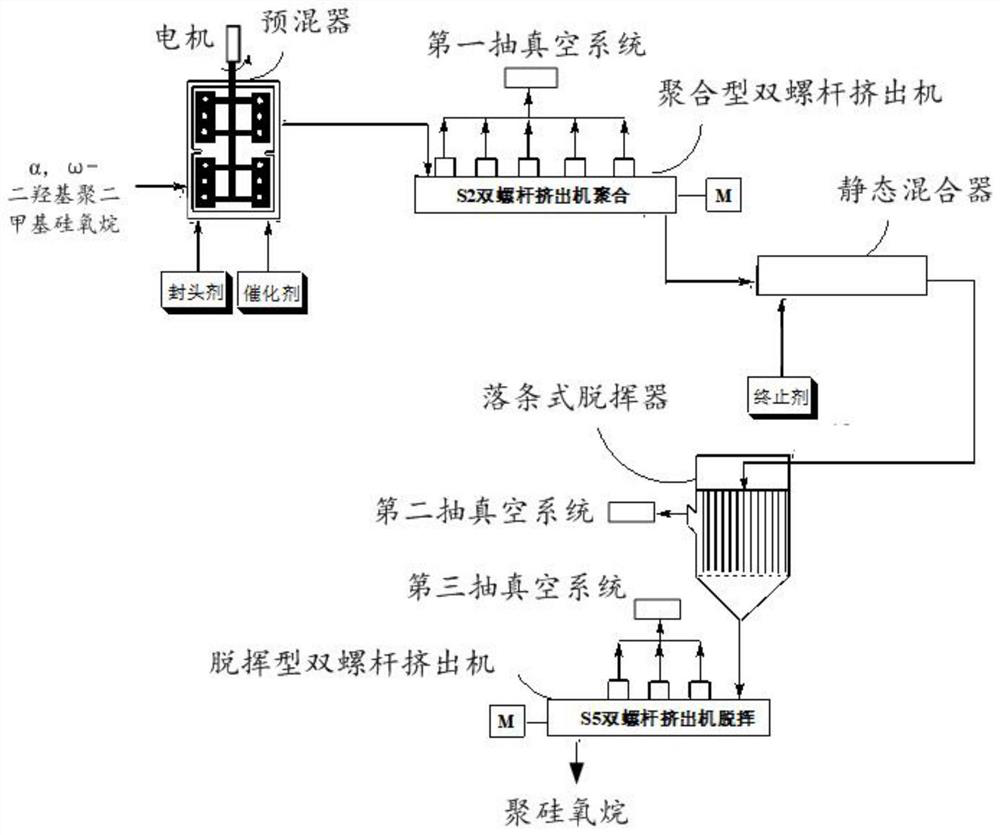

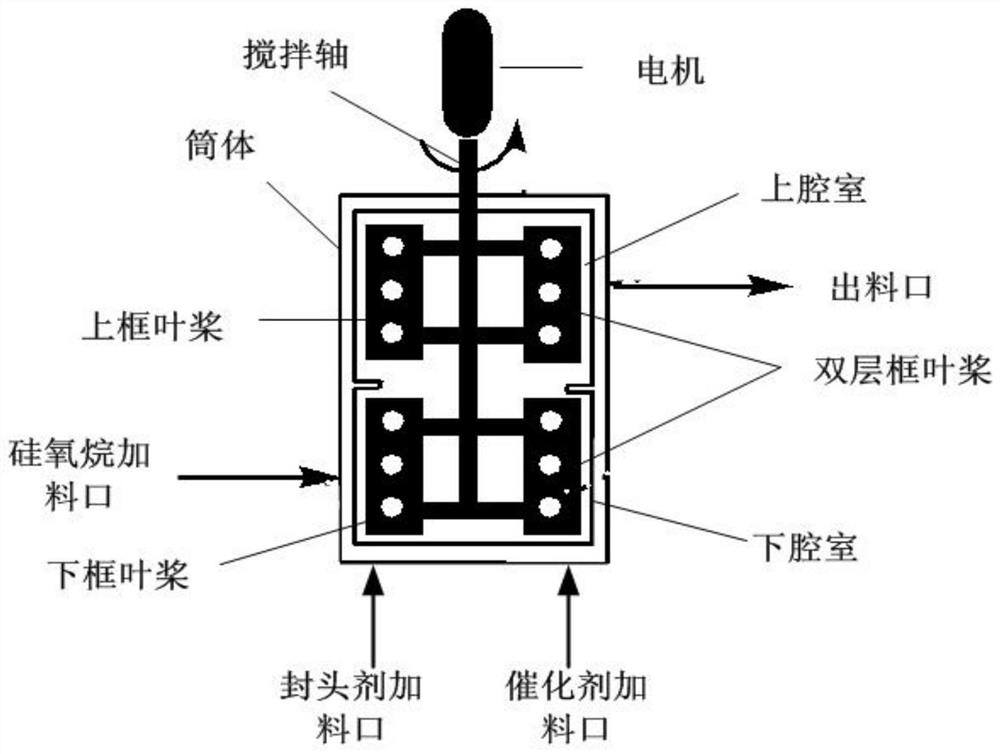

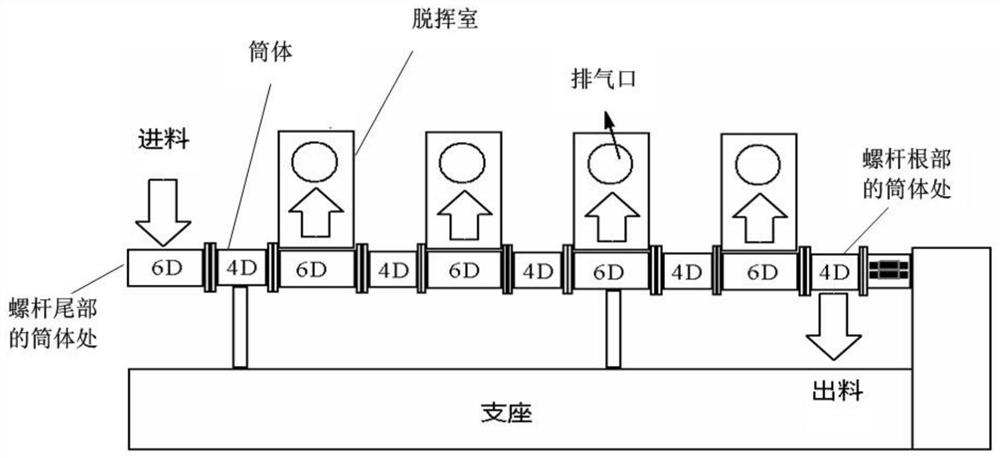

Continuous production system and production method of polysiloxane

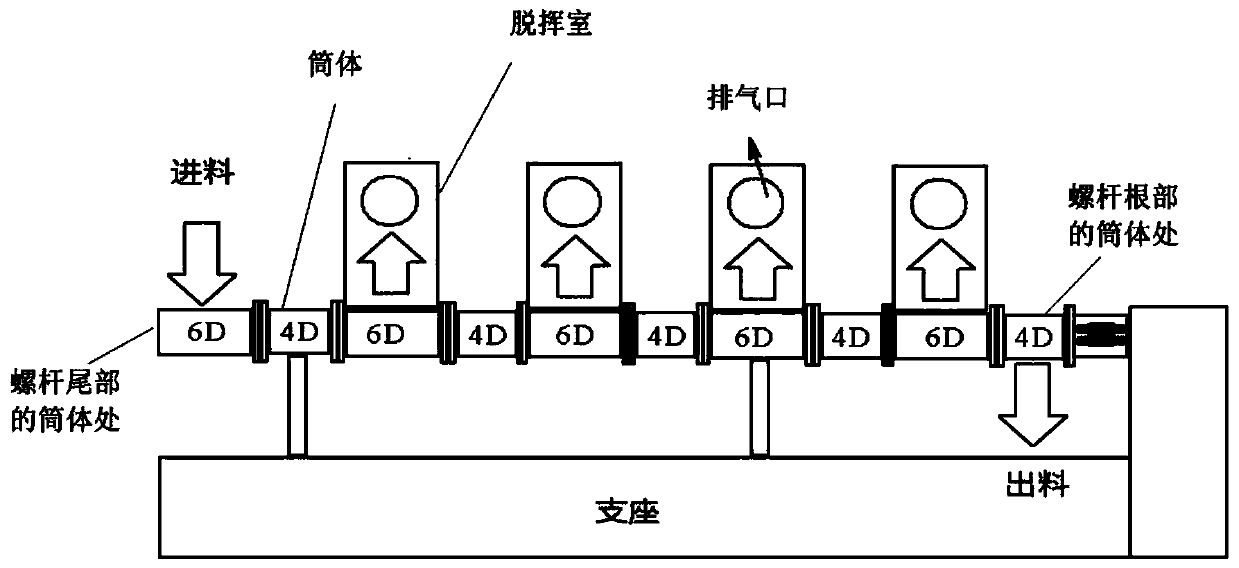

ActiveCN111574714AOvercoming Difficult Stirring ProblemsFacilitate continuous productionPolymer scienceEngineering

The invention relates to the technical field of silicone rubber production and relates a continuous production system and method of polysiloxane. The continuous production system for polysiloxane comprises a premixer, a polymerization type double-screw extruder connected with a discharge hole of the premixer, a first vacuumizing system connected with an exhaust port of the polymerization type double-screw extruder, a static mixer connected with a discharge hole of the polymerization type double-screw extruder, a falling strip type devolatilization device connected with a discharge hole of thestatic mixer, a second vacuumizing system connected with a vacuum hole of the strip falling type devolatilization device, a devolatilization type double-screw extruder connected with a discharge holeof the strip falling type devolatilization device, and a third vacuumizing system connected with a vacuum port of the devolatilization type double-screw extruder. Finally, the produced polysiloxane isrelatively high in viscosity and relatively low in volatile component.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

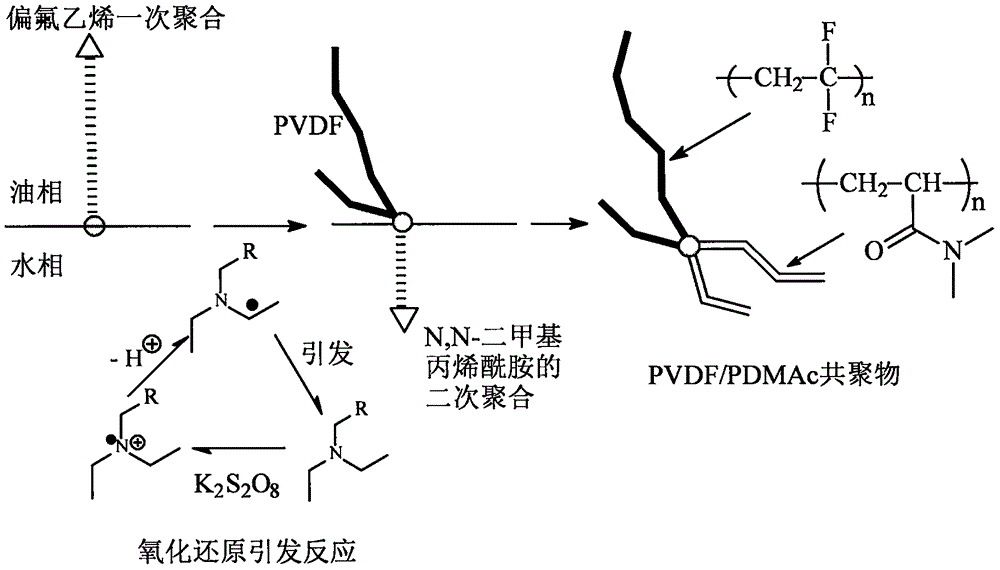

Method for preparing hydrophilic polyvinylidene fluoride membrane materials in green manner

ActiveCN106496465ABroaden the development spaceThe polymerization reaction conditions are mild and controllablePolyvinylidene fluorideMethacrylamide

The invention relates to a method for preparing vinylidene fluoride / N, N-dimethylacrylamide copolymers in a green manner. The vinylidene fluoride / N, N-dimethylacrylamide copolymers are used as separation membrane materials. The method has the advantages that the method is a copolymer synthesis technology based on water / oil two-phase interfacial free radical polymerization, oxidation-reduction reaction is carried out by special Gemini surface active initiators and potassium persulfate at the normal temperature, free radicals are repeatedly generated on interfaces, independent polymerization reaction between vinylidene fluoride and N, N-dimethylacrylamide is initiated, two types of chain segments are connected with each other by initiator molecules in series to form the segmented copolymers, the feed ratios of monomers are extremely consistent with component ratios of the copolymers when pH (potential of hydrogen) values of water-phase media are within the ranges of 4.0-4.5 as proved by experiments, the content of N, N-dimethylacrylamide chain segments in the copolymers is adjustable in the ranges of 5-25 wt.%, polymerization reaction conditions in the modes are mild and controllable, the method is low in energy consumption, other organic solvents or emulsifiers can be omitted, products are pure, and requirements on green chemistry can be completely met.

Owner:NINGBO UNIV

Hydroxymethyl acrylamide-acrylate copolymer toughened and modified polylactic acid material and preparation method thereof

The invention discloses a hydroxymethyl acrylamide-acrylate copolymer toughened and modified polylactic acid material and a preparation method thereof. The hydroxymethyl acrylamide-acrylate copolymer serving as a toughening agent accounts for 5 to 15 percent of the weight of the material; and the material is a transparent material of which the tensile strength is 36 to 50Mpa, the breaking elongation is 40 to 350 percent, and the Izod impact strength is 5 to 17KJ / m<2>. The invention also discloses a method for preparing the polylactic acid material. Because the hydroxymethyl acrylamide-acrylate copolymer serving as the toughening agent can form a fine granular disperse phase in polylactic acid to play a role in toughening similar to rubber particles, the material has the advantages of small additive amount, high toughening efficiency, little influence on the strength, high machining flowability, transparency, rigidity and heat resistance, quick polymerization reaction, short production cycle, simple process control, low cost and easy industrial popularization and application.

Owner:SICHUAN UNIV

Preparation method of solvent type tert-butyl peroxyneo-caprate (BNP)

ActiveCN102442933AOvercoming complex requirementsQuality improvementOrganic compound preparationPeroxy compound preparationAlkaneChloride

The invention relates to a preparation method of an initiator for synthesizing a high polymer, in particular to a preparation method of solvent type tert-butyl peroxyneo-caprate (BNP). According to the technical scheme of the invention, the preparation method of the solvent type BNP comprises the following steps of: mixing octyl decanoyl chloride with an alkaline solution and tert-butyl hydrogen peroxide, stirring and reacting at the temperature of 10-40 DEG C; separating a mother liquor; and washing a reaction product to the neutral state and adding an alkane solvent to obtain the solvent type BNP. Due to the adoption of the method for preparing the solvent type BNP provided by the invention, the process flow is simplified, the complex requirements on reaction equipment are eliminated, a reaction is undergone in the mild and safe environment, the product content and yield are increased greatly, and the yield can be over 95 percent.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

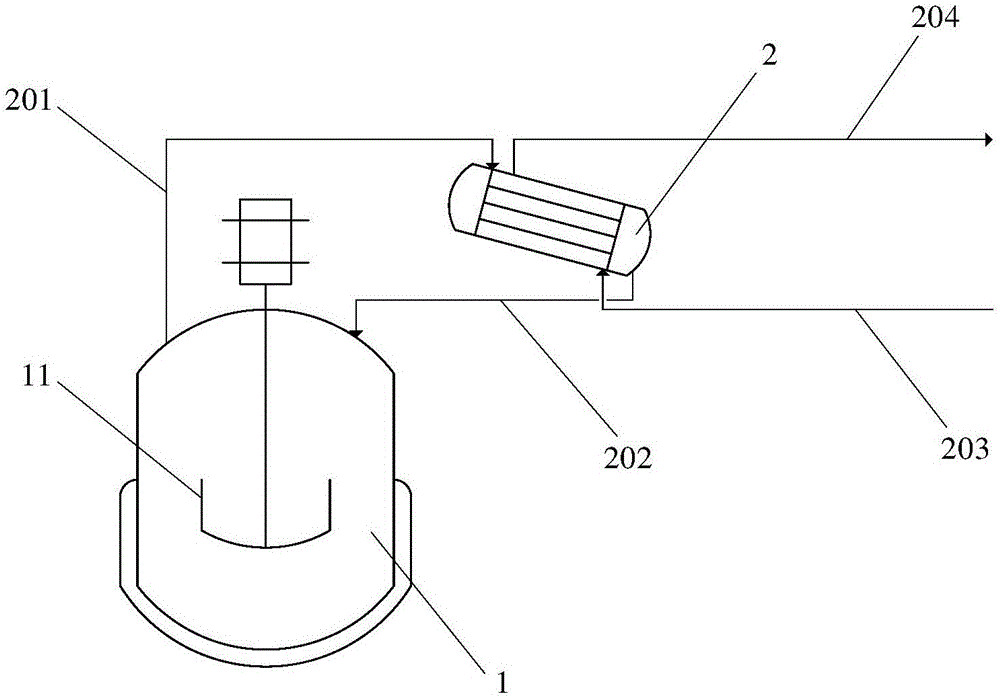

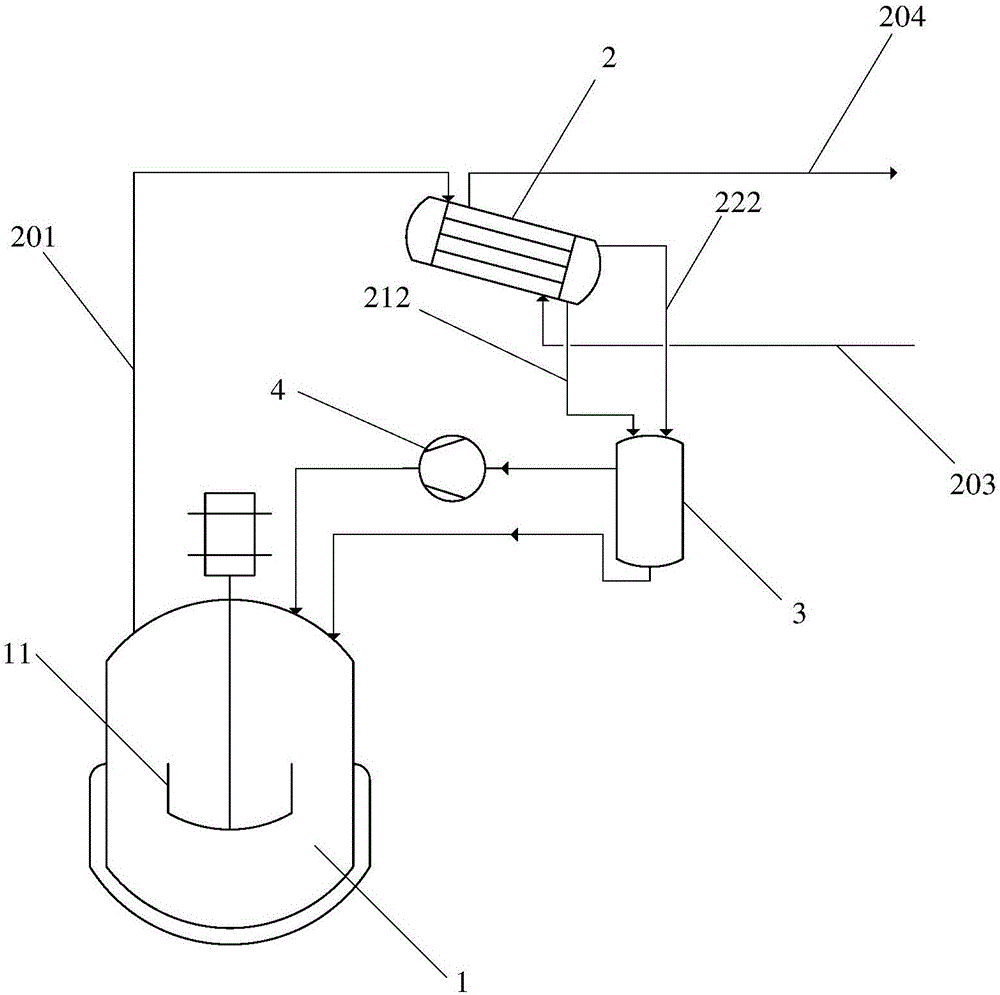

Butane-1 polymerization reaction kettle and butene-1 polymerization reaction heating method

ActiveCN106084098AAchieve coolingReduce the temperatureProcess control/regulationChemical/physical/physico-chemical stationary reactorsButeneReflux

The invention discloses a butene-1 polymerization reaction kettle and a butene-1 polymerization reaction heating method, relates to the technical field of chemical engineering, and aims at decreasing the temperature gradient of reaction materials in the radial direction of the reaction kettle and increasing the polymerization speed and the polymerization degree of polybutylene-1. The butene-1 polymerization reaction kettle comprises a reaction kettle body and a condenser; the reaction kettle body is provided with a stirring device, the heat absorption side of the condenser is communicated with a refrigerant circulating pipeline, a steam outlet of the reaction kettle body and a heat release side inlet of the condenser are connected through an air extraction pipeline, and a heat release side outlet of the condenser is connected with a reflux inlet of the reaction kettle body through a reflux pipeline; the air extraction pipeline extracts saturated steam of a butene-1 polymerization reaction system in the reaction kettle body, wherein butene monomer steam is contained in the saturated steam. The butene-1 polymerization reaction heating method is applied to the butene-1 polymerization reaction kettle. The butene-1 polymerization reaction kettle is applied to polybutylene-1 production.

Owner:山东省滕州瑞达化工有限公司

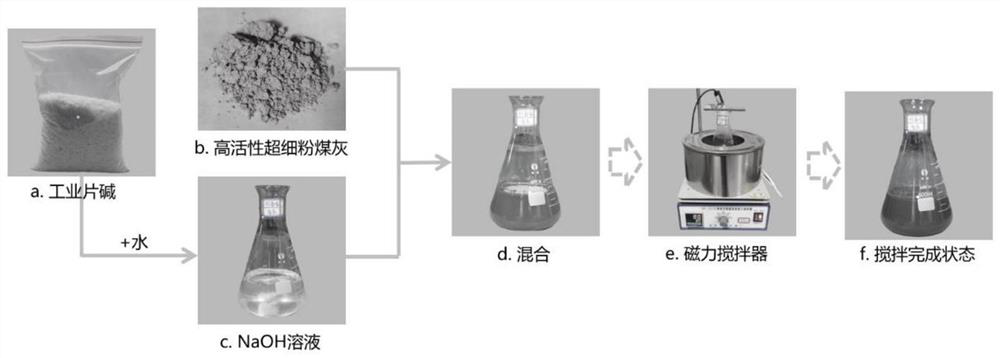

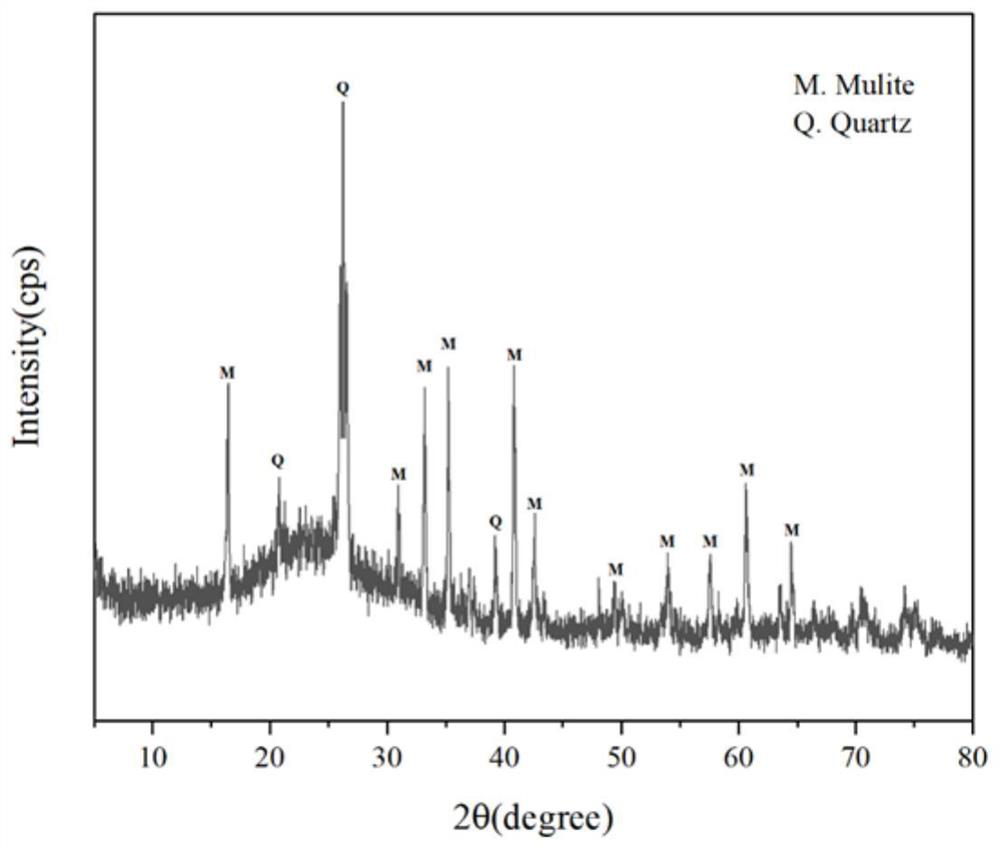

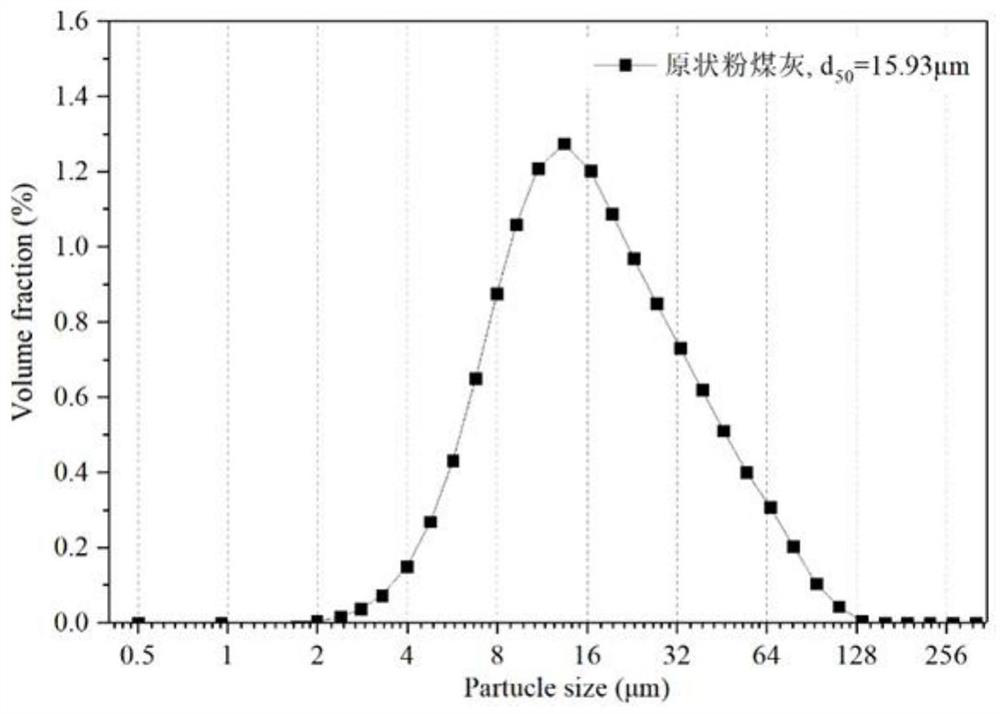

Quick-setting high-alkali-activated fly ash cementing material capable of being maintained at normal temperature and preparation method of quick-setting high-alkali-activated fly ash cementing material

ActiveCN114436549AHelp adsorptionIncrease the rate of polymerizationCement productionPhysical chemistryHigh activity

The invention relates to the technical field of building materials, in particular to a quick-setting high-alkali-activated fly ash cementing material capable of being maintained at normal temperature and a preparation method of the quick-setting high-alkali-activated fly ash cementing material. The raw materials comprise the following components in parts by weight: 30-50 parts of undisturbed fly ash, 50-70 parts of high-activity superfine fly ash and 12-18 parts of sodium hydroxide. Based on the premise that a raw material system and a preparation process are simplified and feasible, under an existing raw material system, through pretreatment of fly ash and a sodium hydroxide exciting agent, AAFA which is rapid in setting and high in strength under normal-temperature curing is prepared, the AAFA is rapidly set under the normal-temperature condition, high early-stage and later-stage strength is obtained, an existing high-temperature curing step is omitted, and the production cost is reduced. And the application of the device in on-site constructional engineering is expanded.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

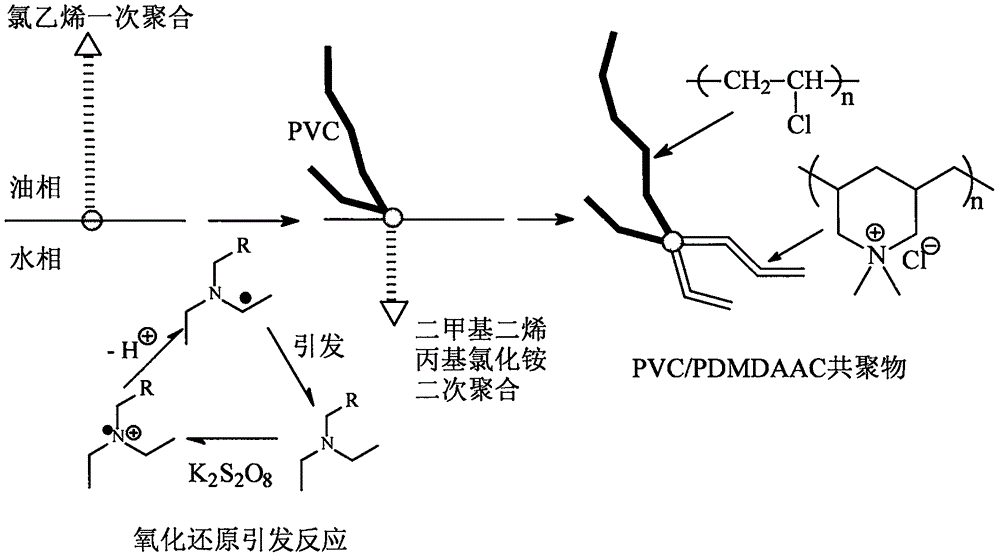

Green preparation method of cationic type polyvinyl chloride membrane material

ActiveCN106519156AImprove securityComposition is easy to controlSemi-permeable membranesPotassium persulfatePolyvinyl chloride

The invention provides a green preparation method of a vinyl chloride / dimethyl diallyl ammonium chloride copolymer which is used as a separating membrane material. The green preparation method is a copolymer synthesizing technology based on a water / oil two-phase interfacial free-radical polymerization. The green preparation method is characterized in that a cationic surface active initiator is specifically used and subjected to oxidation-reduction reaction with potassium persulfate under normal temperature; the oxidation-reduction reaction is repeated at a plurality of times so as to generate free radicals on an interface, and the independent polymerization reaction of vinyl chloride and dimethyl diallyl ammonium chloride is initiated; the two chain segments are connected in series through initiator molecules, thus obtaining a segmented copolymer. The experiment shows that when the pH of a water phase medium is 4.5 to 5, the rate of charge of monomer is consistent with the component ratio of the copolymer; the content of dimethyl diallyl ammonium chloride chain segment in the copolymer can be adjusted between 5-16wt.%; the polymerizing reaction under such mode is mild and controllable in condition, low in energy consumption, free of other organic solvents and emulsifiers, and pure in products, and completely meets the requirement of green chemistry.

Owner:NINGBO UNIV

Hydroxymethyl acrylamide-acrylate copolymer toughened and modified polylactic acid material and preparation method thereof

The invention discloses a hydroxymethyl acrylamide-acrylate copolymer toughened and modified polylactic acid material and a preparation method thereof. The hydroxymethyl acrylamide-acrylate copolymer serving as a toughening agent accounts for 5 to 15 percent of the weight of the material; and the material is a transparent material of which the tensile strength is 36 to 50Mpa, the breaking elongation is 40 to 350 percent, and the Izod impact strength is 5 to 17KJ / m<2>. The invention also discloses a method for preparing the polylactic acid material. Because the hydroxymethyl acrylamide-acrylate copolymer serving as the toughening agent can form a fine granular disperse phase in polylactic acid to play a role in toughening similar to rubber particles, the material has the advantages of small additive amount, high toughening efficiency, little influence on the strength, high machining flowability, transparency, rigidity and heat resistance, quick polymerization reaction, short productioncycle, simple process control, low cost and easy industrial popularization and application.

Owner:SICHUAN UNIV

Processing aid ACR for PVC sheet high-transparency product

InactiveCN112500535AStir wellFast polymerizationChemical/physical/physico-chemical moving reactorsManufacturing engineeringMethacrylate

The invention provides a processing aid ACR for PVC sheet high-transparency products, and relates to the technical field of production and manufacturing of processing aids ACR. The PVC sheet high-transparency product processing aid ACR is prepared from the following raw materials in parts by weight: 70-90 parts of methacrylate, 10-30 parts of acrylate and 2-5 parts of emulsifier, wherein the emulsifier is allyl polyether; the methacrylate, the acrylate and the emulsifier are put into a reaction tank for polymerization reaction, and processing aid ACR is obtained. According to the method, all materials participate in the polymerization reaction, no auxiliary substance is left in the product, the purity is high, subsequent refining treatment is not needed, the production process is simplified, and the production cost is reduced.

Owner:山东宏福化学有限公司

A continuous production system and production method of polysiloxane

ActiveCN111574714BOvercoming Difficult Stirring ProblemsFacilitate continuous productionPolymer scienceEngineering

The invention relates to the technical field of silicone rubber production, in particular to a continuous production system and production method of polysiloxane. The continuous production system of polysiloxane comprises: a pre-mixer; a polymeric twin-screw extruder connected to the discharge port of the pre-mixer; The first vacuum system that links to each other; the static mixer that links to each other with the discharge port of described polymerization type twin-screw extruder; The second vacuum system connected to the vacuum port of the strip-type devolatilizer; the devolatilization type twin-screw extruder connected to the outlet of the strip-type devolatilizer; the devolatilization type twin-screw extruder The third vacuum system connected to the vacuum port of the extruder. The final polysiloxane produced has higher viscosity and lower volatile content.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

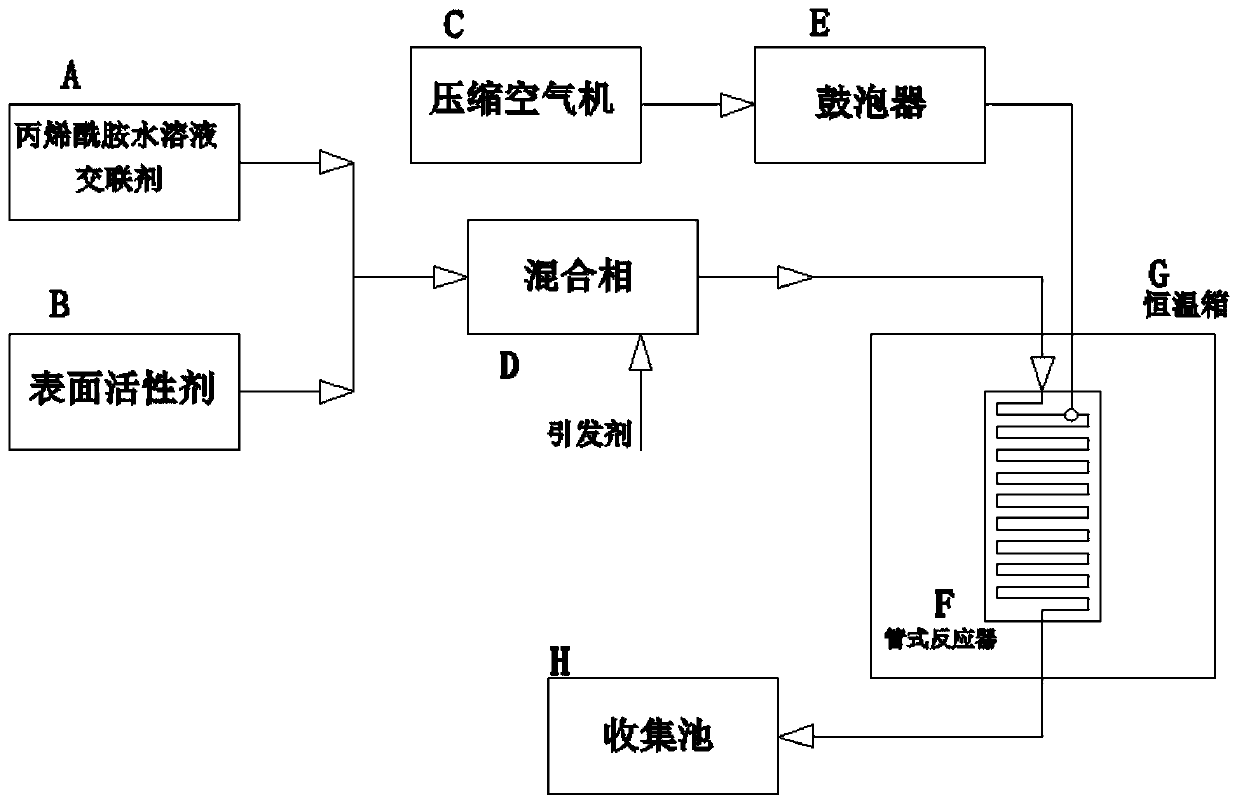

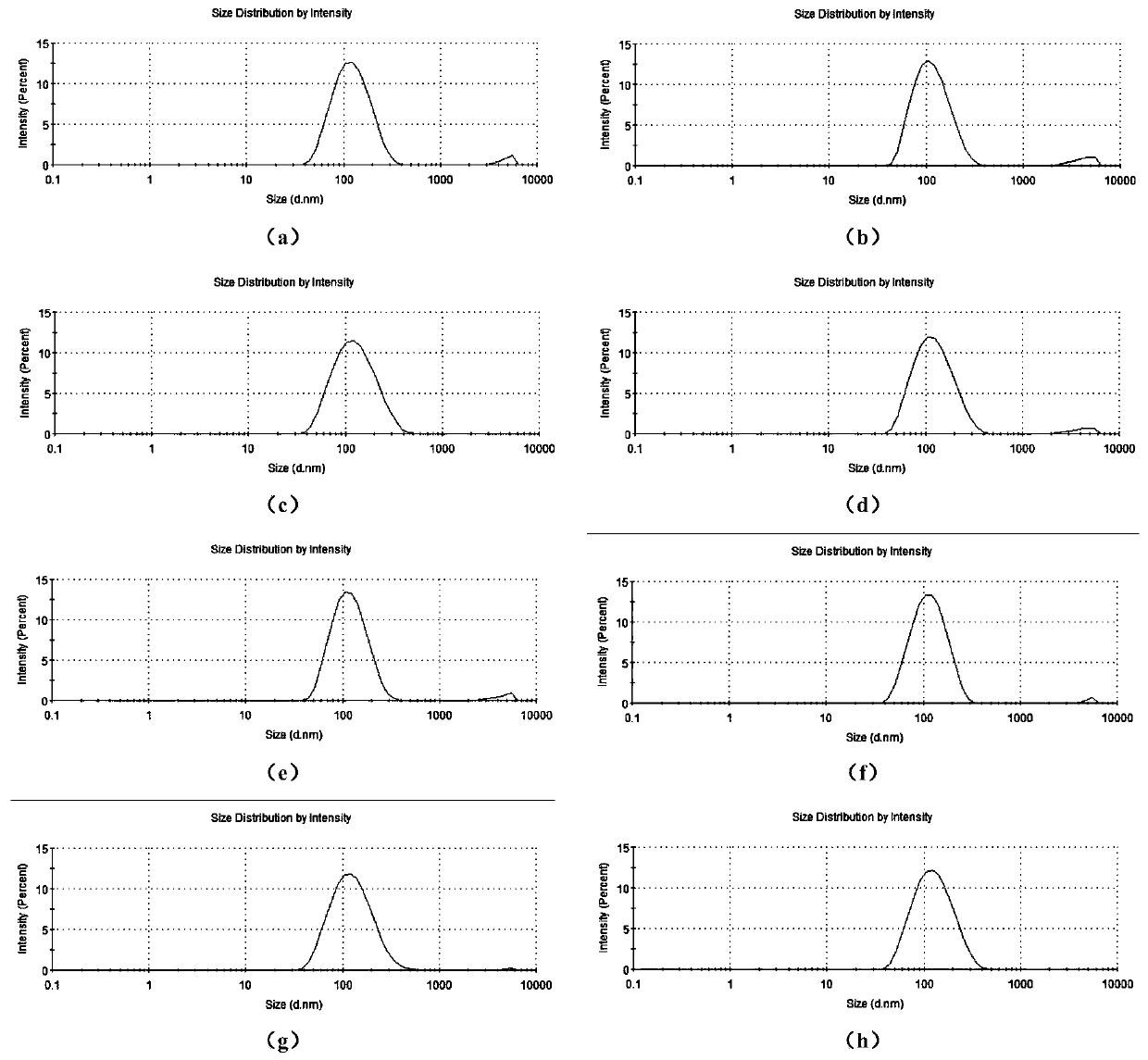

Preparation method and preparation device for polyacrylamide nanoparticles

ActiveCN110054727AFast polymerizationWith operational continuityMicroballoon preparationMicrocapsule preparationMicrosphereNanoparticle

The invention discloses a preparation method and a preparation device for polyacrylamide nanoparticles. The preparation method includes continuously introducing a liquid material, comprising acrylamide, crosslinking agents and initiators, and compressed air into a tubular reactor to decompose the initiators at a certain temperature to obtain free radicals, initiating polymerization of the acrylamide, guiding out a polyacrylamide-containing material from the tubular reactor, and collecting finished products of the polyacrylamide nanoparticles. The preparation method and the preparation device have the advantages that the process is simple, the high-safety tubular reactor is applied to continuous production, the prepared polyacrylamide nanoparticles have stable quality and uniform grain diameter, overflowing and colliding in a conventional kettle-type production process are avoided, and product quality and production efficiency are improved.

Owner:西安万德能源化学股份有限公司

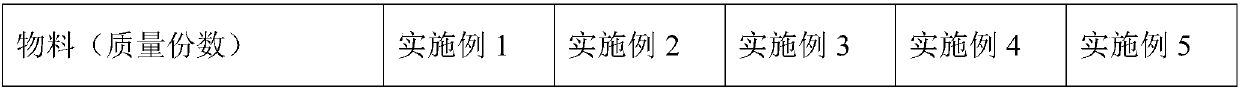

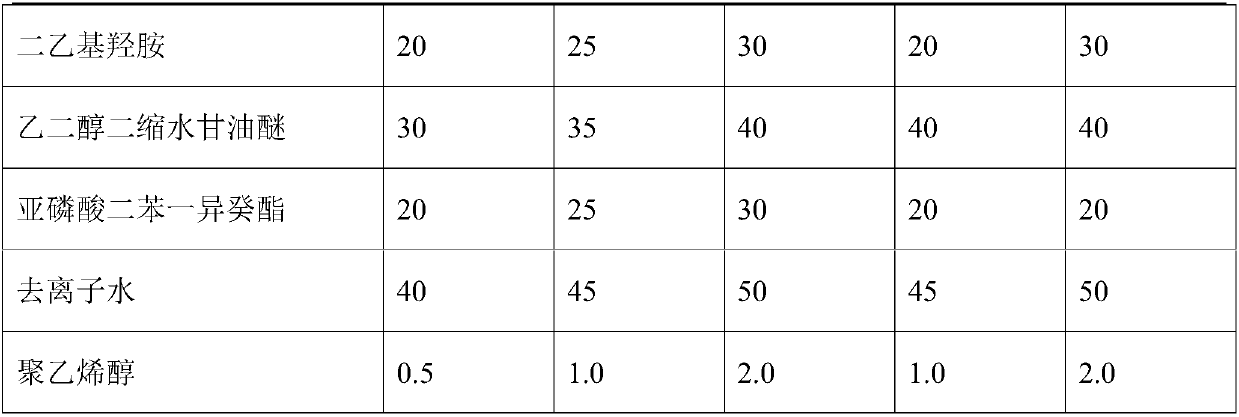

Vinyl chloride polymerization terminator with good low-temperature fluidity, and preparation method and application thereof

ActiveCN110760021AImprove low temperature fluidityThe composition is uniform and stablePhosphorous acidCold season

The invention belongs to the field of resin synthesis, and particularly relates to a vinyl chloride polymerization terminator with good low-temperature fluidity, and a preparation method and application thereof. The terminator comprises the following ingredients of, by weight, 20 parts to 30 parts of diethylhydroxylamine, 30 parts to 40 parts of ethylene glycol diglycidyl ether, 20 parts to 30 parts of diphenyl isodecyl phosphite, 40 parts to 50 parts of deionized water, and 0.5 part to 2 parts of a dispersing agent, wherein the dispersing agent is a polyvinyl alcohol aqueous solution with thedegree of polymerization ranging from 300 to 400, the alcoholysis degree ranging from 50% to 60%, and the concentration of 5%. The vinyl chloride polymerization terminator with good low-temperature fluidity is good in low-temperature fluidity, thereby being suitable for regions or seasons with the low temperature, and the composite terminator can stay uniform and stable without emulsifiers. The invention further provides the preparation method and the application of the terminator. The terminator not only has the good vinyl chloride polymerization termination effect while improving the thermal stability of resin, but also has the good low-temperature fluidity so that can be used at cold regions or cold seasons.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of green chemical preparation method of vinyl chloride/butyl acrylate copolymer

ActiveCN106496466BComposition is easy to controlOptimal Control StructurePotassium persulfatePotassium

The invention relates to a green preparation method of a vinyl chloride / butyl acrylate copolymer used as a thermoplastic elastomer. The preparation method is based on a synthesis technology of a copolymer formed by interfacial free-radical polymerization of water / oil two-phases. Based on a copolymer synthesis technology through water / oil two-phase interfacial free-radical polymerization, a polyhydroxy polyamine surface active initiator and potassium persulphate are subjected to an oxidation reduction reaction at normal temperature, free radicals are repeatedly generated on the interface and independent polymerization of vinyl chloride and butyl acrylate is initiated. Through molecules of the initiator, two chain segments are connected in series so as to form a poly-segment copolymer. It is proved through experiments that pH of an aqueous medium is within the range of 4-4.5, feed ratio of a monomer is very consistent with composition ratio of the copolymer and content of the butyl acrylate chain segments in the copolymer is adjustable within the range of 10-42wt%. According to the mode of polymerization reaction, conditions are mild and controllable, energy consumption is low, other organic solvents or emulsifiers are not used, and the product is pure. The method completely meets the requirement of green chemistry.

Owner:NINGBO UNIV

A kind of anionic surfactant initiator and preparation method thereof

InactiveCN105884937BComposition is easy to controlOptimal Control StructureSulfonic acids salts preparationPotassium persulfateSurface-active agents

The invention relates to an anionic surface active initiator and a preparation method thereof. The method comprises the steps that a tertiary amine compound containing sulfonate anion and dodecyl is synthesized, and the tertiary amine compound itself is surfactant; meanwhile, tertiary amine and potassium persulfate can be subjected to an oxidation-reduction reaction at room temperature, cationic free radicals are formed on nitrogen atoms and converted into carbon free radicals at adjacent positions, free radical generation can be repeated multiple times and controlled flexibly, multiphase concatenated polymerization of styrene and butyl acylate and styrene and acrylamide is initiated successively on a water or oil interface, and a segmented copolymer is obtained. It is provided through experiments that the feed ratio of a monomer and the component ratio of the copolymer are very consistent, it is illustrated that the initiation efficiency of the initiator is high, the polymerization reaction condition is mild and controllable, the energy consumption is low, other organic solvents and emulsifiers are not used, the product is pure, and the requirements of green chemistry are completely met.

Owner:牡丹江旭日新材料科技有限公司

Cationic polymerization method for vinyl monomer

The invention discloses a cationic polymerization method for vinyl monomer. In the method, a reaction medium, the vinyl monomer, an initiator, lewis acid and an additive are used, wherein the reaction medium is a mixed reaction medium comprising an organic solvent and water or completely water; the organic solvent is at least one selected from alkane, naphthenic hydrocarbon and halogenated hydrocarbon; the lewis acid is one or a mixture of substances which accord with a general formula of MXn or YRn-mXm; the additive is an oxygen atom and nitrogen atom-containing organic compound; the molar ratio of the lewis acid to the additive to the monomer is 1.0*10<-3> to 3.2*10<-2>:1.0*10<-3> to 3.0*10<-1>:1; and the materials are reacted at the temperature of between -100 and 50 DE C for 0.5 minute to 2 hours to form a polymerization product, namely polymer with molecular weight of 10<5>. The method can simplifies the process flow, saves the production cost, and has great significance and considerable market application value.

Owner:BEIJING UNIV OF CHEM TECH

A kind of polyhydroxy polyamine surfactant initiator and preparation method thereof

ActiveCN105884624BComposition is easy to controlOptimal Control StructureOrganic compound preparationTransportation and packagingPotassium persulfatePolyamine

The invention relates to a polyhydroxy polyamine surface active initiator and a preparation method thereof. Synthesize a tri-tertiary amine compound containing polyhydroxyl and hexadecyl, so that it exhibits the characteristics of a surfactant. At the same time, the tertiary amine can undergo a redox reaction with potassium persulfate at room temperature, and first form a cation on the nitrogen atom Free radicals are then converted into carbon free radicals at adjacent positions. The generation of free radicals can be repeated many times and flexibly controlled to achieve multi-phase series polymerization. Styrene and methyl acrylate and Styrene and acrylamide are polymerized to obtain corresponding multi-block copolymers. The experiment proves that the feed ratio of the monomer is very consistent with the composition ratio of the copolymer, indicating that the initiator has a high initiation efficiency, and the polymerization reaction conditions of this mode are mild. Controllable, low energy consumption, no other organic solvents and emulsifiers, pure product, fully meet the requirements of green chemistry.

Owner:NINGBO UNIV

A kind of bisbenzenesulfonate interfacial initiator and preparation method thereof

ActiveCN105884940BComposition is easy to controlOptimal Control StructureSulfonic acids salts preparationPotassium persulfateMode control

The invention relates to a bisbenzenesulfonate interface initiator and a preparation method thereof. Synthesize a tertiary amine compound containing bisbenzenesulfonate anion and didodecanyl, so that it exhibits the characteristics of a surfactant. At the same time, the tertiary amine can undergo a redox reaction with potassium persulfate at room temperature. Cationic free radicals are formed on the surface, and then converted into carbon free radicals at adjacent positions. The generation of free radicals can be repeated many times, flexibly controlled, and multi-phase series polymerization is realized. Styrene and acrylic acid are initiated sequentially on the water / oil interface. Polymerization of butyl ester and styrene and N,N-dimethylacrylamide to obtain a multi-block copolymer. Experiments have proved that the feed ratio of the monomer is very consistent with the composition ratio of the copolymer, indicating that the initiator has a higher initiation efficiency. , the polymerization reaction conditions of this mode are mild and controllable, the energy consumption is low, no other organic solvents and emulsifiers are used, and the product is pure, which fully meets the requirements of green chemistry.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com