Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Excellent low temperature impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

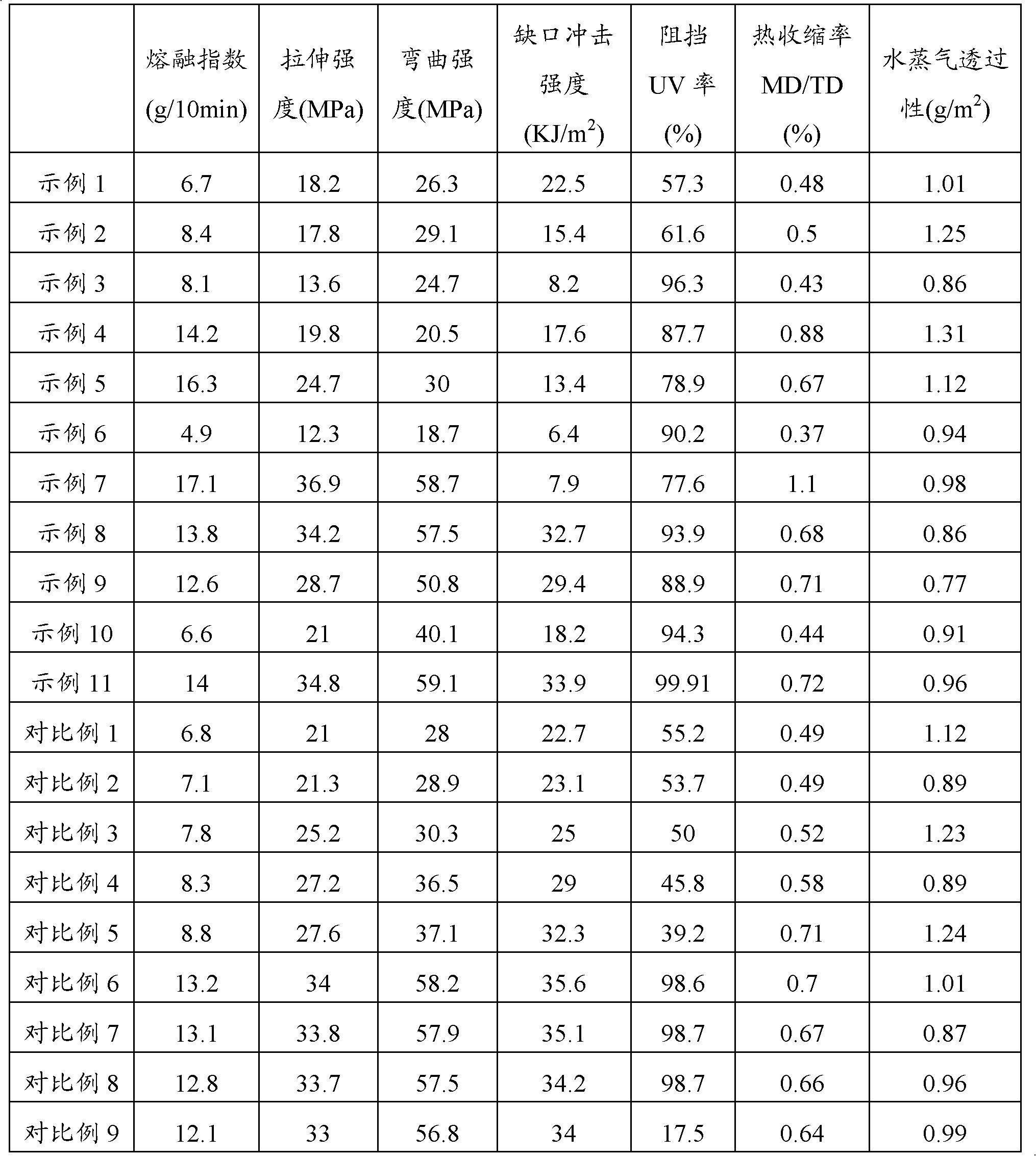

Polypropylene composition for solar battery and preparation method thereof

ActiveCN102504407AGood weather resistanceExcellent low temperature impact resistancePhotovoltaic energy generationSemiconductor devicesAntioxidantUltraviolet

The invention provides a polypropylene composition for a solar battery and a preparation method thereof, wherein the polypropylene composition for the solar battery comprises 50-100 parts by weight of at least one of homo-polymerized polypropylene and co-polymerized polypropylene, 0-50 parts by weight of inorganic filler, 15-25 parts by weight of anti-ultraviolet assistant, 0.2-30 parts of antioxidant, 0.5-20 parts by weight of plasticizer and 0.1-10 parts by weight of modified polymer. According to the invention, the polypropylene composition for the solar battery has good weather resistance, ultraviolet resistance and low-temperature impact resistance.

Owner:北京太阳能电力研究院有限公司

Polyester elastomer composition and method of making the same

InactiveCN101230184AExcellent low temperature impact resistanceImprove wear resistanceChemical industryPolyester

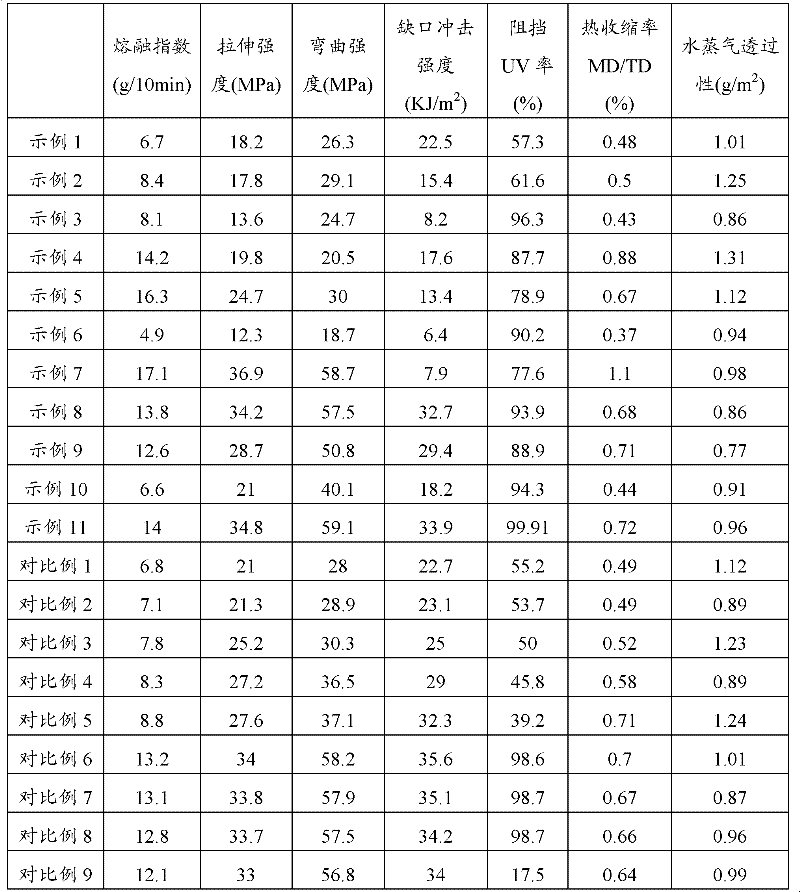

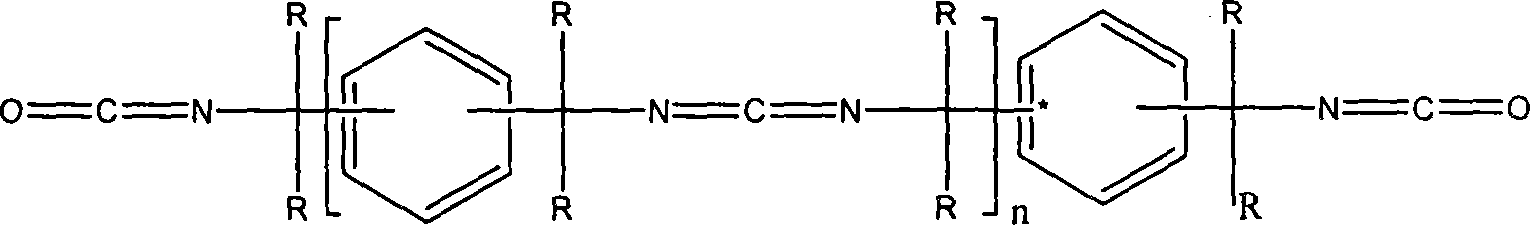

The invention relates to polyester elastomer composition and a preparation method thereof, which belongs to the chemical industry technology field. The composition comprises components with following proportion by weight: 60-100 parts of polyester elastomer, 0.01-10 parts of epoxy compound, 0-10 parts of poly carbodiimide compound, 0-5 parts of acid anhydride grafting body, 0-40 parts of toughened high polymer compound, 0-3 parts of nucleating agent, 0-5 parts of compatiblizing agent, and 0.1-1 part of antioxidant. The components are evenly mixed by adopting a high speed mixer, then the extrusion granulation is performed through a double screw, the combined properties of the prepared polyester elastomer composition are fine, and the high and low temperature impact properties under the high modulus are outstanding.

Owner:BEIJING CHEM IND RES INST

Polypropylene-based resin composition for powder slush molding

ActiveUS6906144B2Improve the heating effectExcellent low-temperature impact resistanceOrganic dyesWaxPolypropylene

A polyproplylene-based resin composition for powder slush molding which is a mixture of a polypropylene homopolymer, copolymer, or terpolymer; an olefin rubber; a styrene rubber; a process oil; and a polypropylene wax, wherein the composition is excellent in low-temperature impact resistance and heat resistance and has no offensive odor. The composition can be formed by a cryofreeze pulverization method in the presence of liquid nitrogen into a powder having an average particle size of 200 to 300 μm suitable for powder slush molding. The powder can be adhered to a polyurethane foamed layer and a surface treating agent without a primer coating. The powder is particularly suitable for forming the interior surface for manufacture of an automobile surface such as an instrument panel.

Owner:HYUNDAI MOTOR CO LTD

Polypropylene composition and preparation method thereof

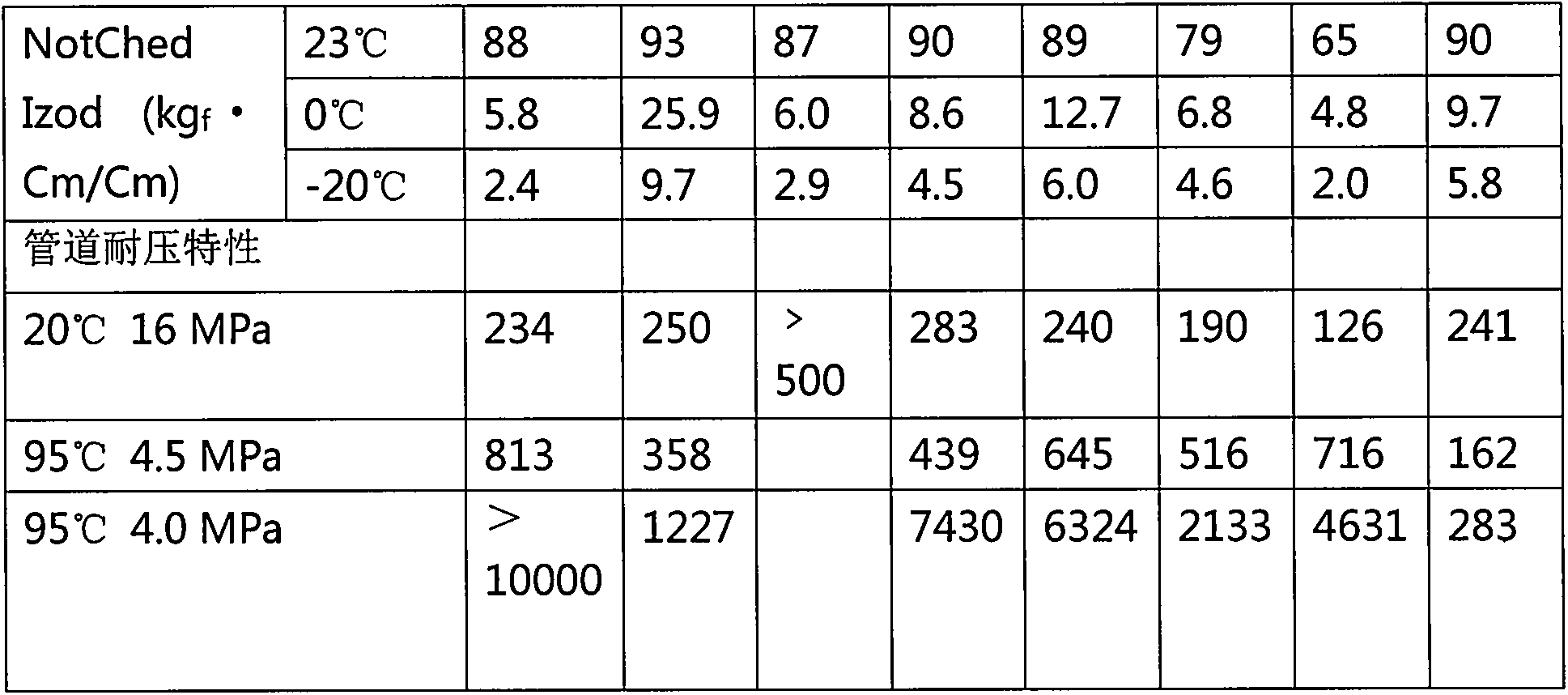

InactiveCN103524903AImprove heat resistanceImprove pressure resistancePolymer scienceMelt flow index

The invention discloses a polypropylene composition. The polypropylene composition includes an ethylene-propylene random elastic copolymer composition composed of an ethylene-propylene random copolymer with a melt index of 0.5 to 5 g / 10 min and 0.5 to 10 wt% of ethylene and an ethylene-propylene elastic polymer with 25 to 75 wt% of ethylene and further includes a beta-crystal generating agent. The polypropylene composition has the characteristics of excellent impact resistance and overpressure resistance and is applicable to preparation of pipelines with the characteristics of improved flexibility, impact resistance at low temperature and overpressure resistance at high temperature.

Owner:大韩道恩高分子材料(上海)有限公司

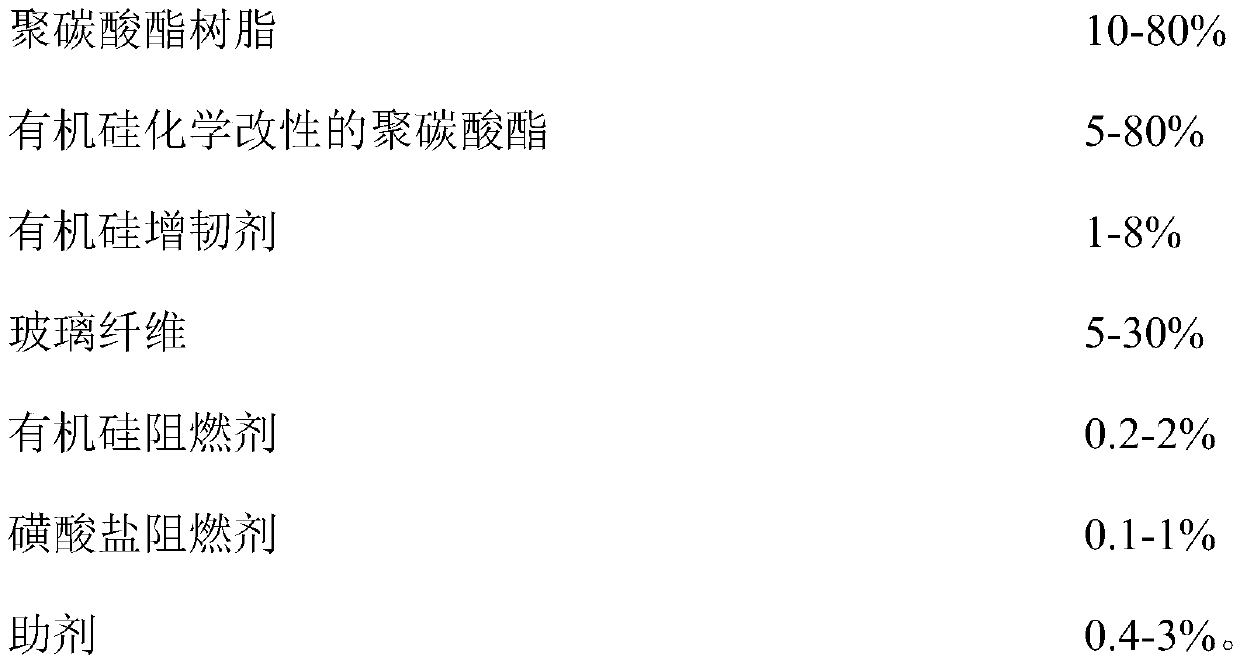

Glass-fiber-reinforced flame-retardant polycarbonate composite material, and preparation method and applications thereof

The invention relates to a glass-fiber-reinforced flame-retardant polycarbonate composite material, and a preparation method and applications thereof. The glass-fiber-reinforced flame-retardant polycarbonate composite material comprises, by mass, polycarbonate resin of 10 to 80%, silicone chemically modified polycarbonate of 5 to 80%, silicone toughening agent of 1 to 8%, glass fiber of 5 to 30%,silicone flame retardant of 0.2 to 2%, sulfonate flame retardant of 0.1 to 1%, and an auxiliary agent of 0.4 to 3%. The glass-fiber-reinforced flame-retardant polycarbonate composite material possesses excellent low temperature impact resistance, flame resistance, rigidity, heat resistance, and hydrolysis resistance, contains no halogen, and is friendly to the environment.

Owner:SHENZHEN HALCYON NEW MATERIALS

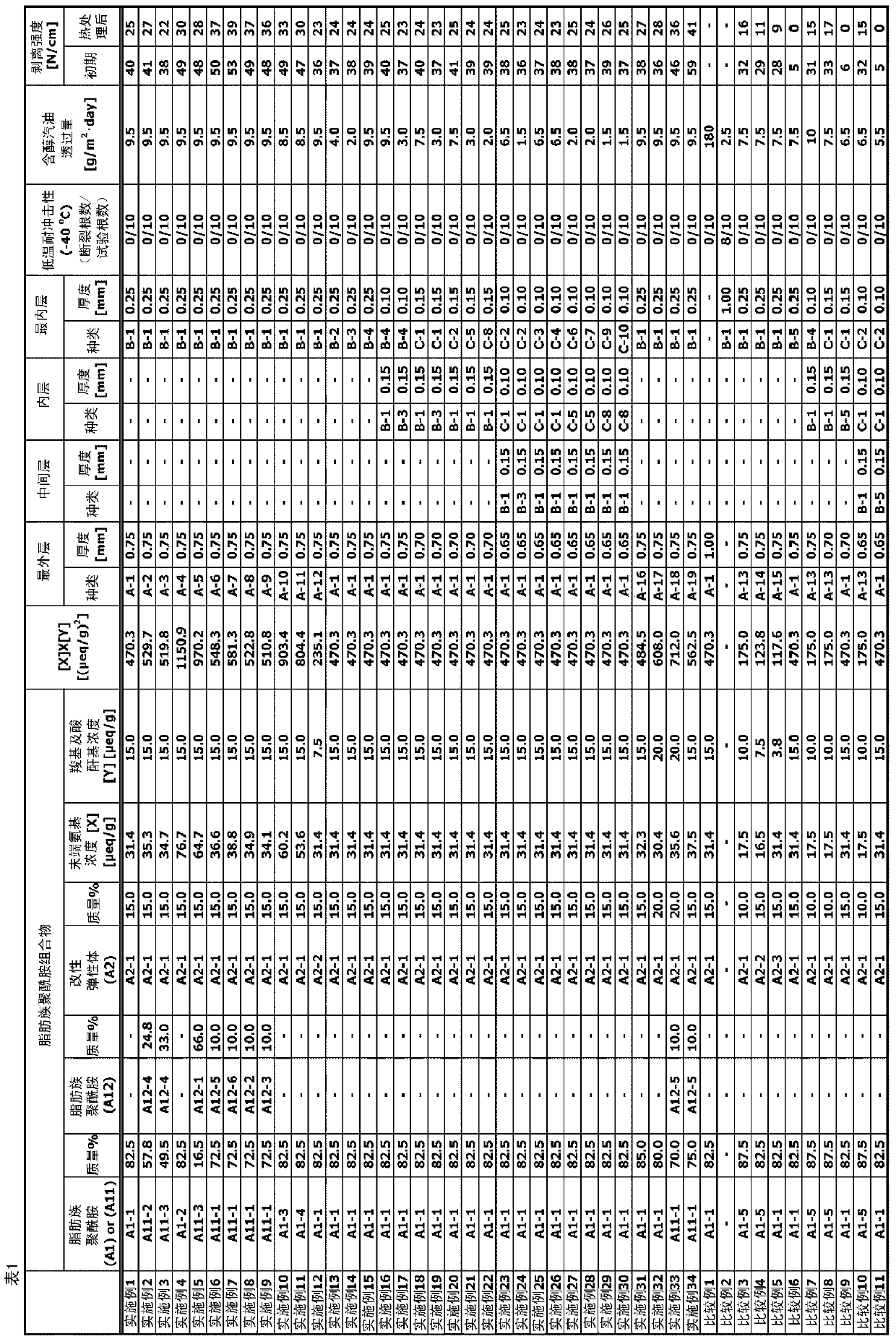

Laminated tube

ActiveCN105517789AGood durabilityImproved durabilitySynthetic resin layered productsVehicle componentsPolyamideCarboxyl radical

A laminated tube comprising at least two layers and having an (a) layer including an aliphatic polyamide composition (A), and a (b) layer including a semi-aromatic polyamide composition (B) including a specific semi-aromatic polyamide (B1), wherein the aliphatic polyamide composition (A) includes a specific amount of an aliphatic polyamide (A1) and a specific amount of an elastomer polymer (A2) containing an unsaturated compound having a carboxyl group and / or an acid anhydride group, and the product, per 1g of the aliphatic polyamide composition (A), of the concentration [X] of the terminal amino group of the aliphatic polyamide (A1) and the total concentration [Y] of the carboxyl group and acid anhydride group of the elastomer polymer (A2) is a specific amount.

Owner:UBE IND LTD

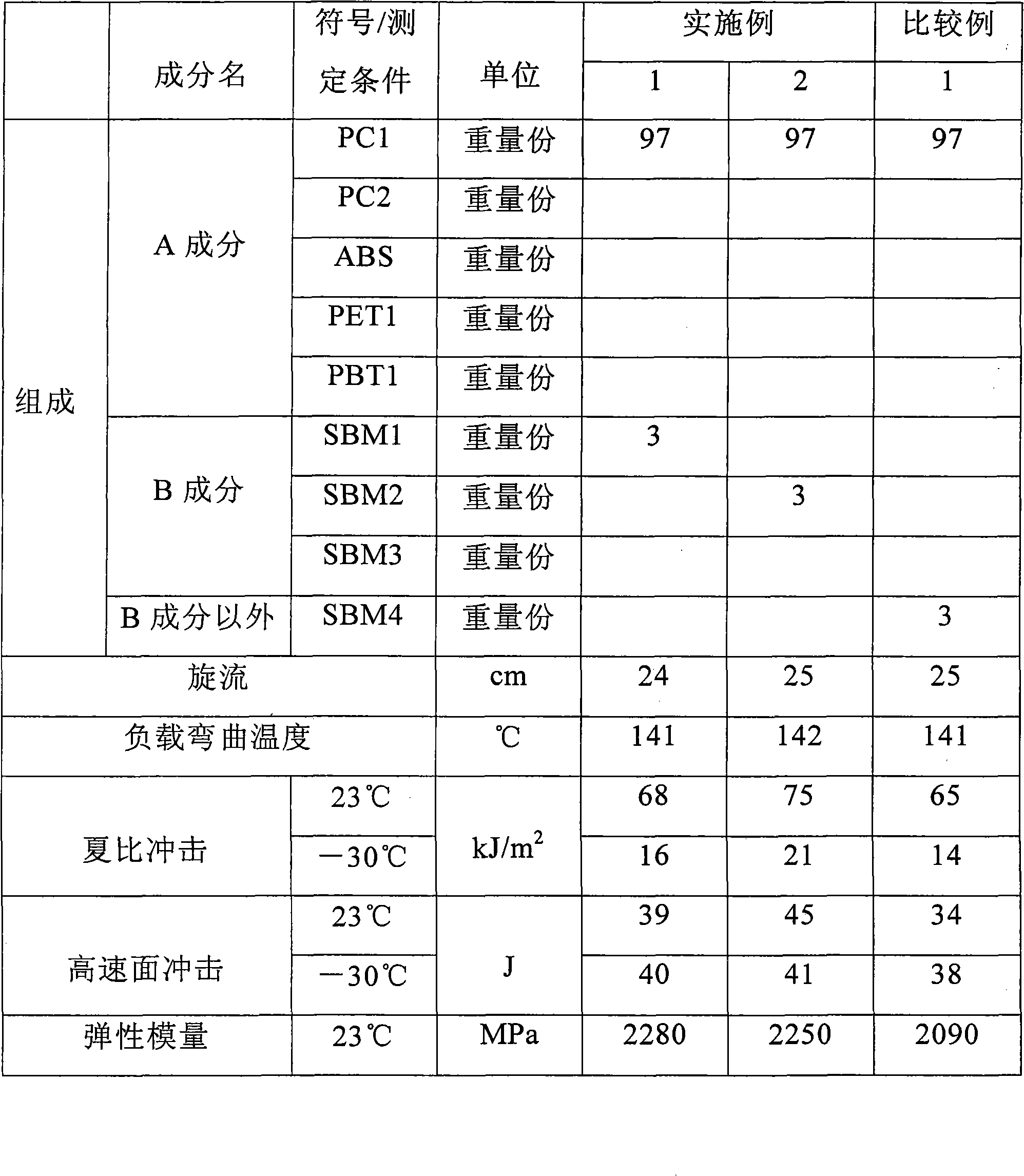

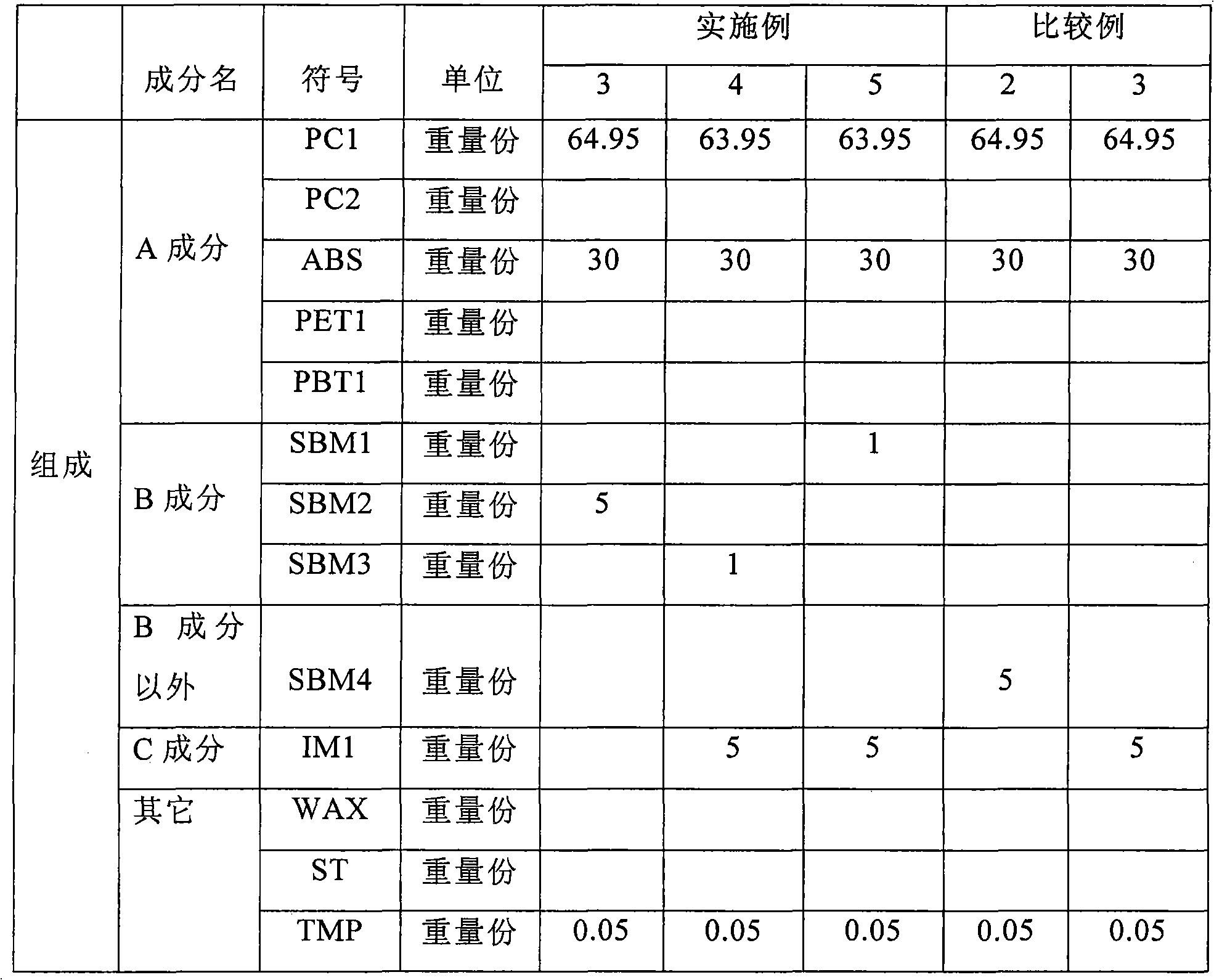

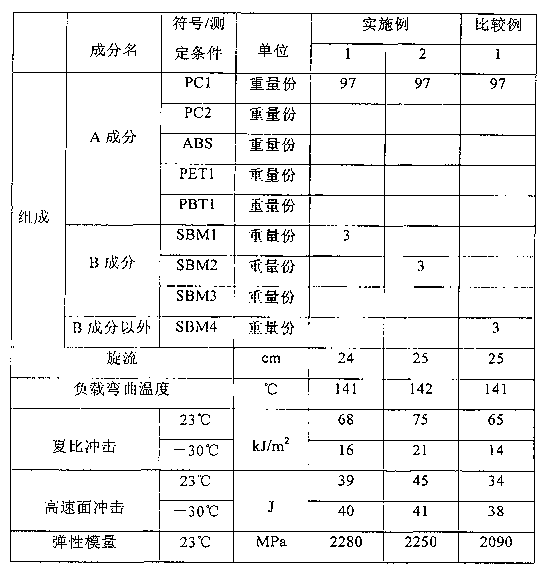

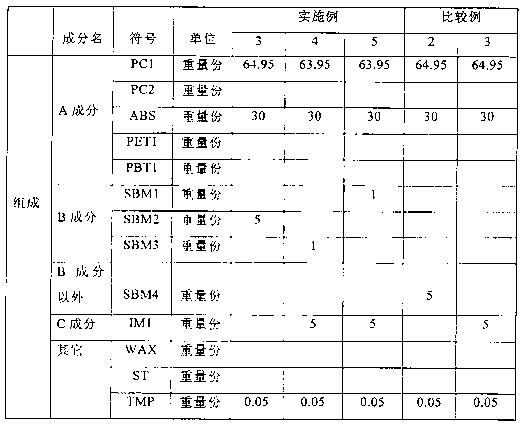

Thermoplastic resin composition

InactiveCN101255272AGood physical and mechanical propertiesExcellent low temperature impact resistanceComposition BPolystyrene

The invention aims to provide a thermoplastic resin composition having excellent mechanical physical property, especially excellent surface impact strength at low temperature, characterized in that the thermoplastic resin composition having excellent impact resistance at low temperature comprises 99% to 50% by weight of thermoplastic resin (composition A) and 1% to 50% by weight of block copolymer (composition B) composed of S block with polystyrene as the main composition, B block with poly (1,4-butadiene) as the main composition and M block with polymethylmethacrylate as the main composition, and the block copolymer includes at least one binding unit selected from a group consisting of S-B-M, M-S-B-S-M and M-B-S-B-M.

Owner:TEIJIN KASEK KK

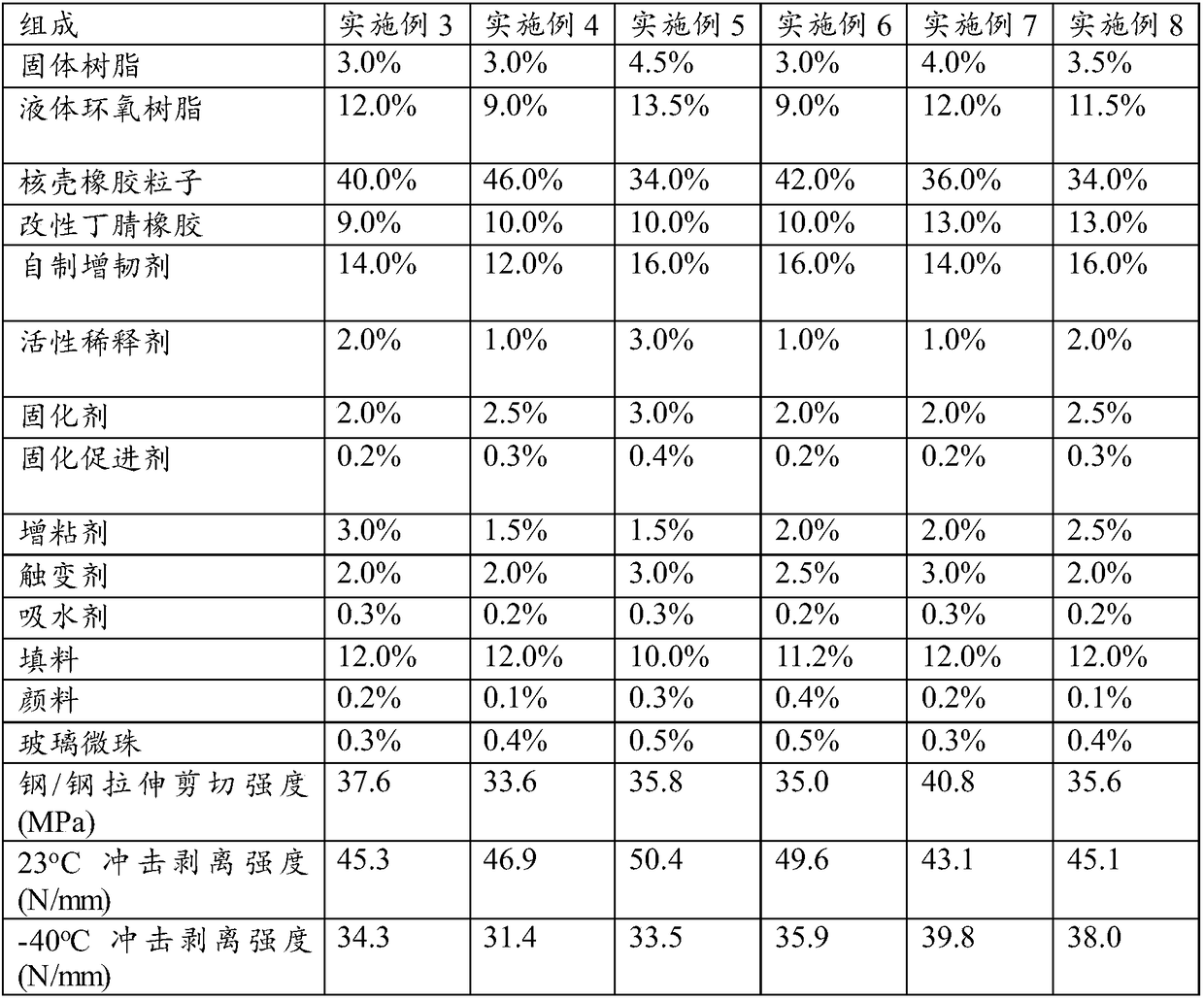

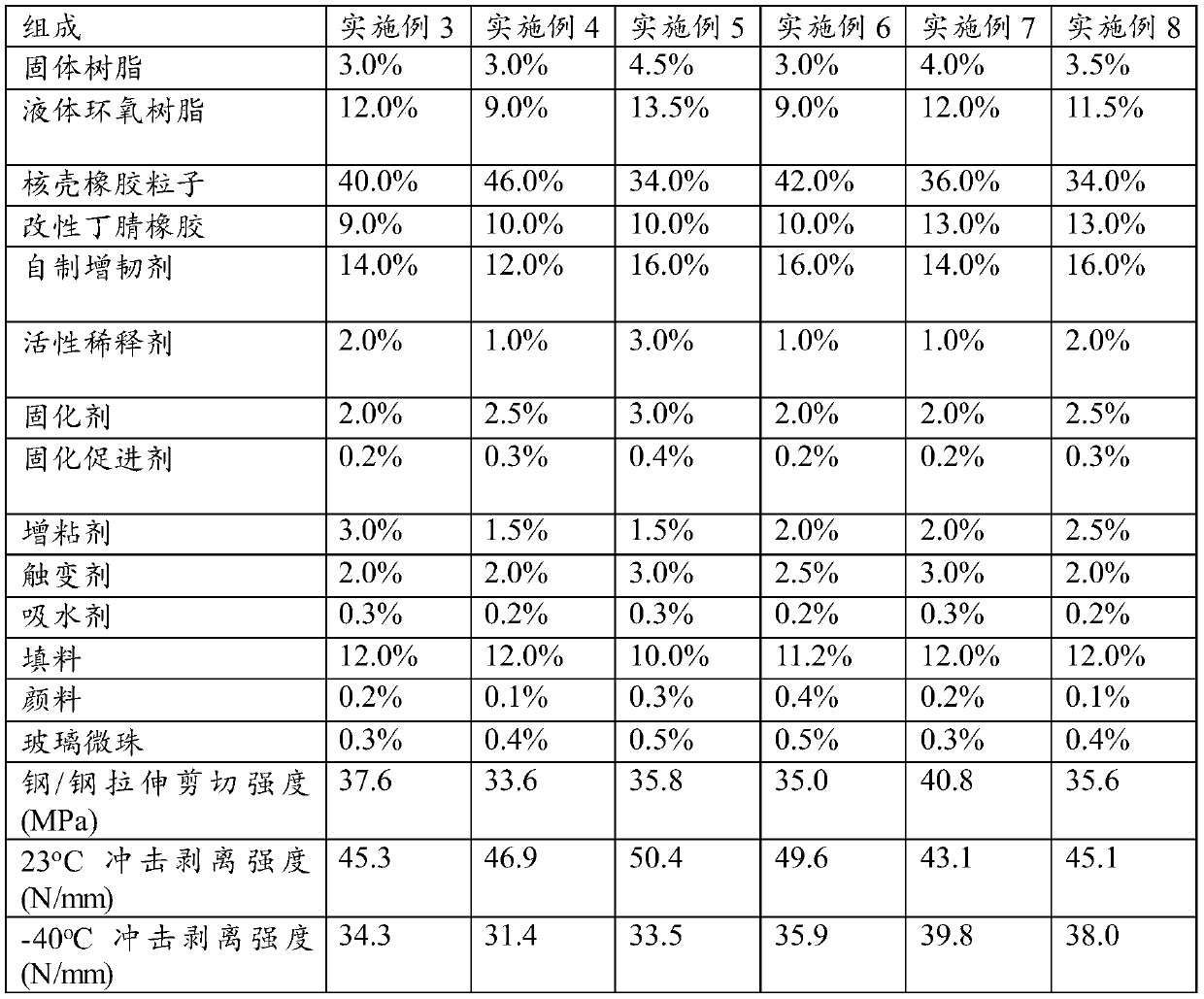

Low-temperature-impact-resistant epoxy adhesive composition and preparation method thereof

ActiveCN108570302AExcellent low temperature impact resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPrepolymerPolymer chemistry

The present invention provides a low-temperature-impact-resistant epoxy adhesive composition, which comprises: at least two epoxy resins; at least a bifunctional epoxy diluent; at least three toughening agents, wherein the toughening agents at least comprise a liquid rubber toughening agent having a core-shell structure, an epoxy resin modified nitrile butadiene rubber, and a ketoxime-terminated reactive polyurethane elastic prepolymer; at least an inorganic filler; at least a water removing agent; at least a thixotropic agent; at least a thermally-activated latent curing agent; and at least acuring accelerator. According to the present invention, the two different epoxy resins are used as the raw materials, and the composite toughening agent at least comprising the liquid rubber toughening agent having the core-shell structure, the epoxy resin modified nitrile butadiene rubber and the ketoxime-terminated reactive polyurethane elastic prepolymer is added, such that the obtained epoxyadhesive composition has good low-temperature-impact resistance.

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

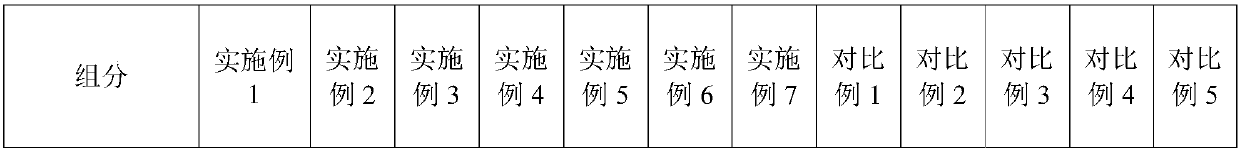

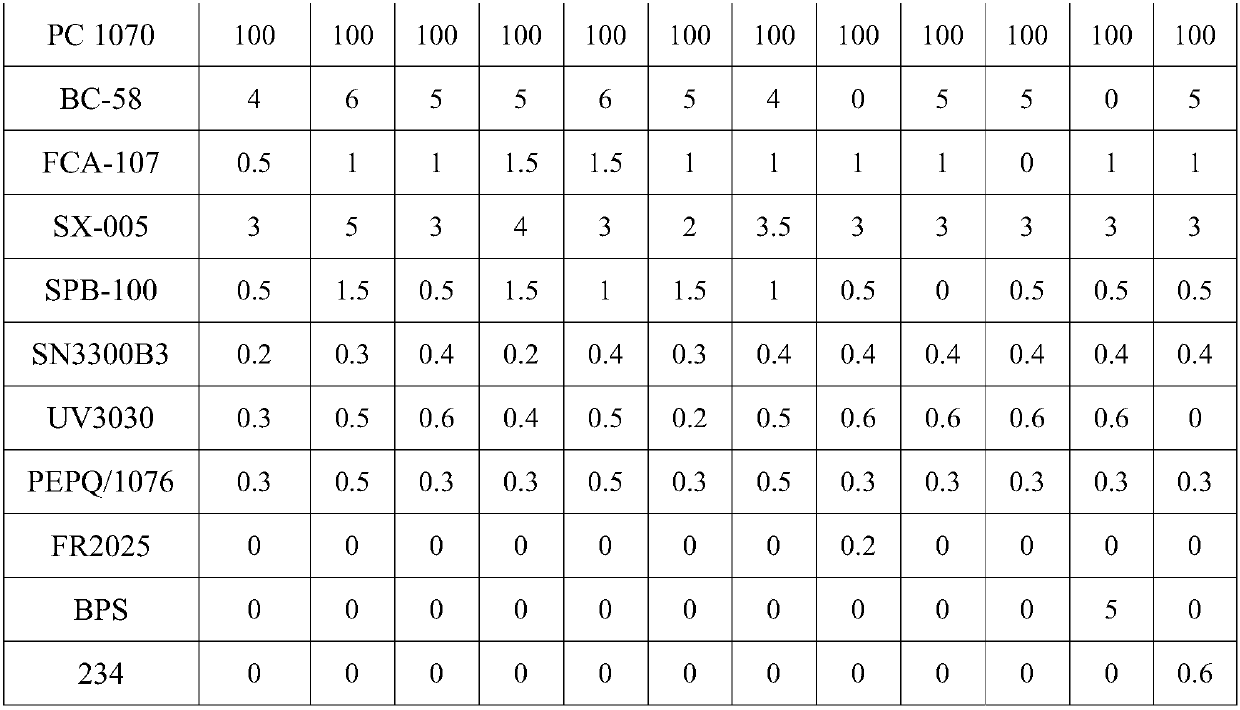

Low-temperature-resistant, damp-heat-resistant and flame-retardant PC (polycarbonate) material for charging gun casing and preparation method of PC material

ActiveCN108047679AGood moisture and heat aging resistanceAffect heat and humidity resistanceAging resistanceHeat resistance

The invention relates to a low-temperature-resistant, damp-heat-resistant and flame-retardant PC (polycarbonate) material for a charging gun casing and a preparation method of the PC material. The PCmaterial is prepared from components of raw materials in parts by weight as follows: 100 parts of PC, 4-6 parts of a flame retardant, 0.5-1 part of a flame retardant synergist, 3-4 parts of a low-temperature-resistant flexibilizer, 0.5-1.5 parts of poly[nitrilo(diphenoxyphosphoranylidyne)], 0.2-0.4 parts of an anti-drip agent, 0.3-0.6 parts of an ultraviolet light absorber and 0.3-0.5 parts of anantioxidant. The raw materials are put in a high-speed mixer to be mixed, then the mixture is extruded by a double-screw extruder and granulated by a granulator, and the PC material can be obtained. The flame-retardant PC material has excellent low-temperature impact resistance, excellent damp and heat ageing resistance and excellent heat resistance, is particularly applicable to the field of thecharging gun casings used in changeable, harsh and complicated environments and has excellent safety protection capability.

Owner:上海日之升科技有限公司

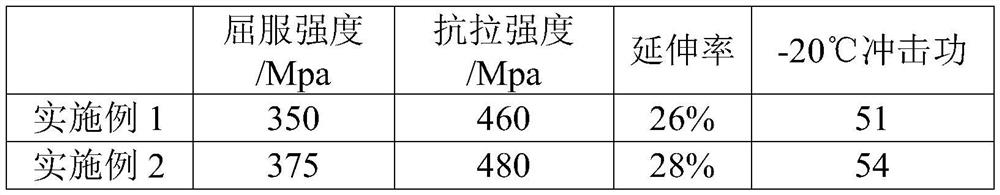

A kind of high-strength corrosion-resistant and cold-resistant hot-rolled steel coil and its production method and application

Owner:HEBEI IRON AND STEEL

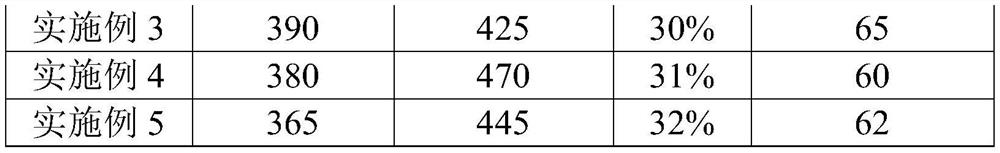

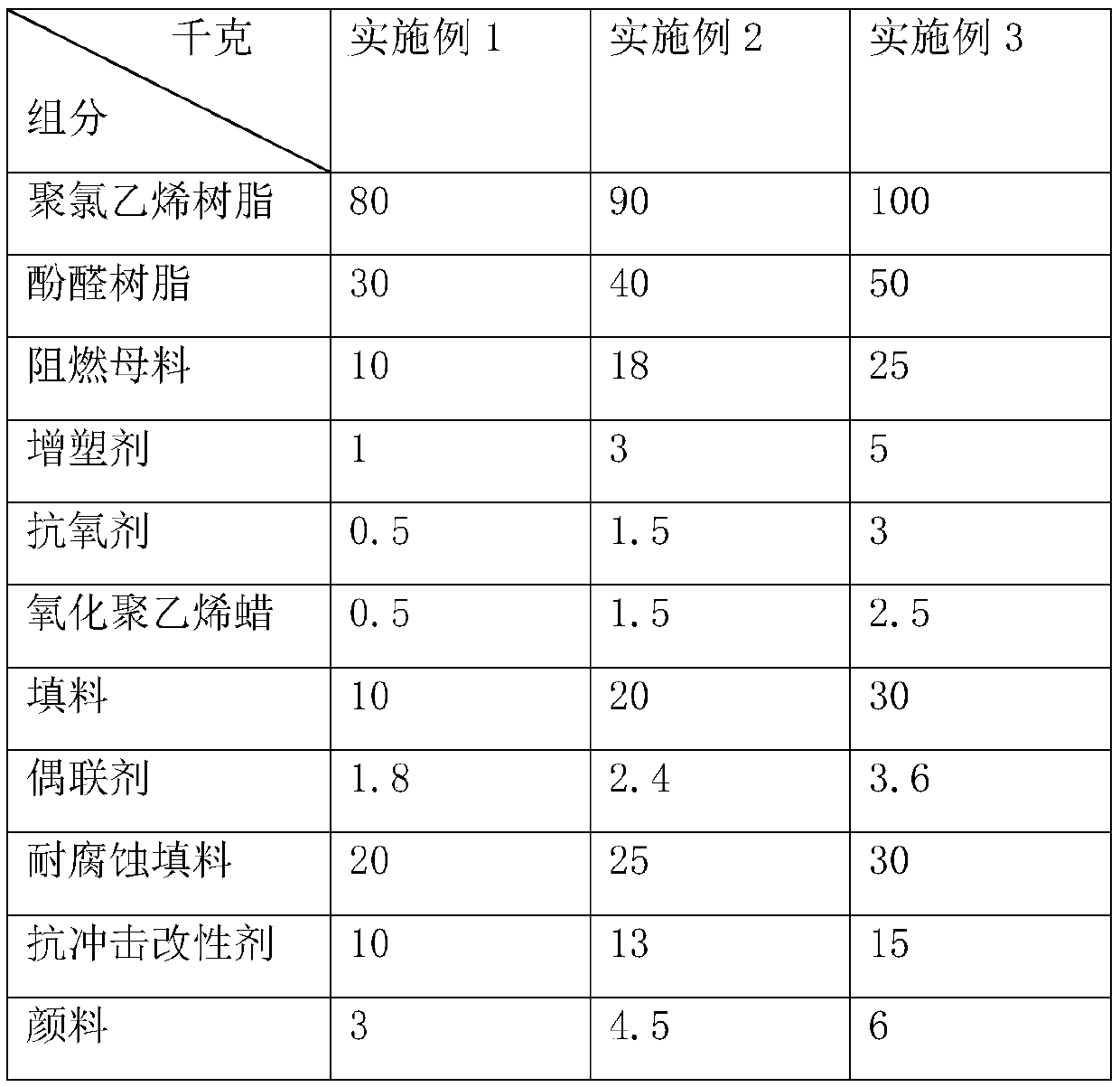

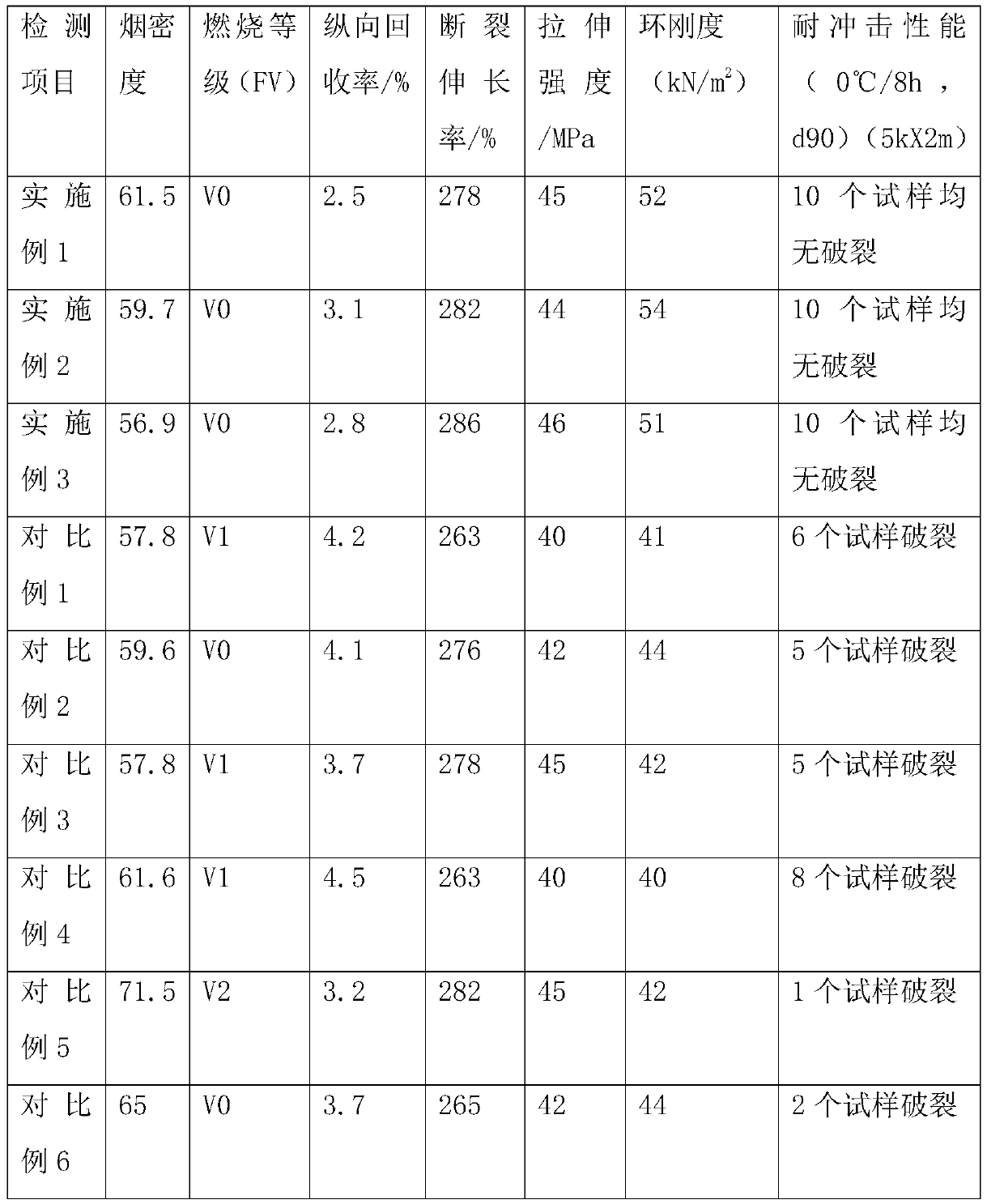

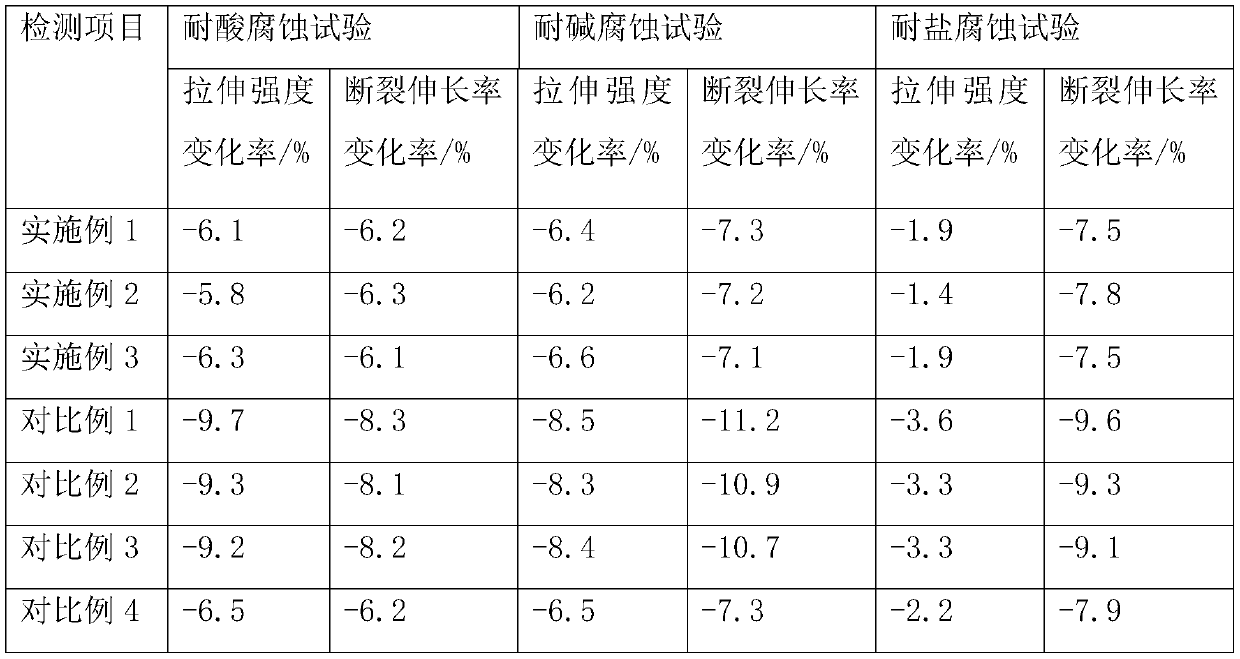

Flame-retardant PVC cable tube and preparation method thereof

The invention discloses a flame-retardant PVC cable tube and a preparation method thereof. The flame retardant PVC cable tube comprises the following components: polyvinyl chloride resin, phenolic resin, flame retardant masterbatch, a plasticizer, an antioxidant, oxidized polyethylene wax, a filler, a coupling agent, a corrosion resistant filler, a shock resistance modifier and pigment. The corrosion resistant filler includes, by weight, 5-12 parts of modified aramid fibers, 16-20 parts of ceramsite, 3-8 parts of graphene, 15-30 parts of epoxy resin emulsion, 5-10 parts bentonite and 3-6 partsof a ceramic adhesive. The shock resistance modifier includes, by weight, 11-16 parts of polylactic acid, 7-13 parts lignin fiber, 4-8 parts beet pulp, 3-7 parts of soybean meal, 8-14 parts of polyolefin elastomer, 5-10 parts of piperazine pyrophosphate and 20-30 parts of polystyrene resin. The flame-retardant PVC cable tube has the advantages of good flame retardancy, high corrosion resistance and strong impact resistance.

Owner:深圳市深捷通管业发展有限公司

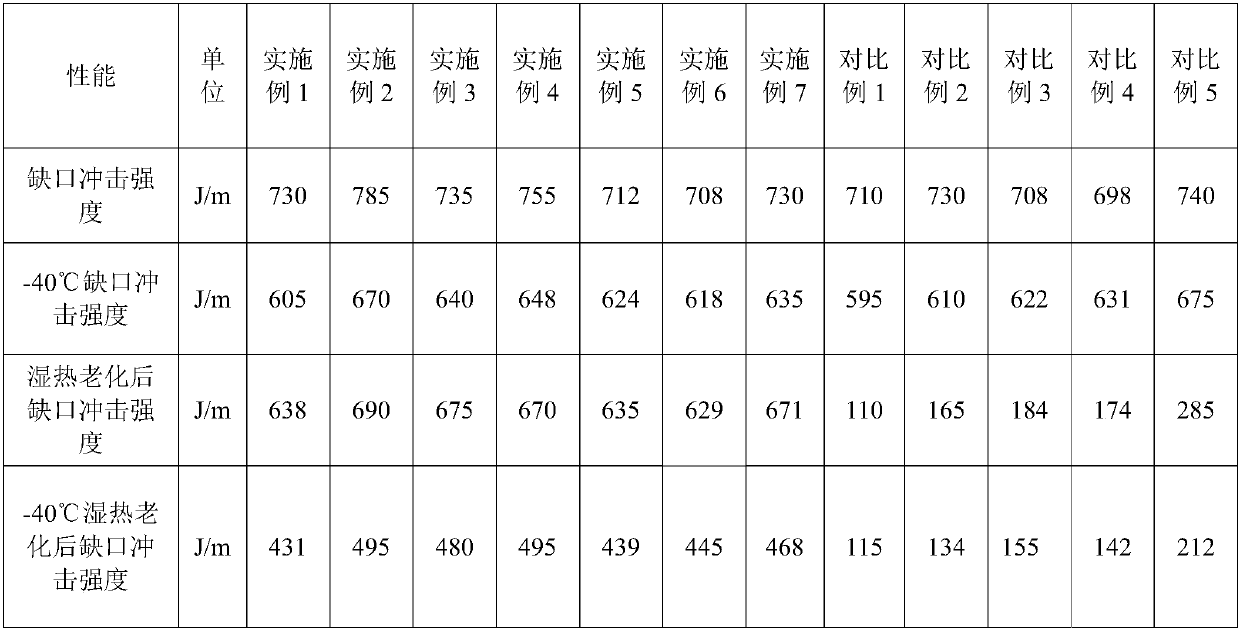

High-strength corrosion-resistant cold-resistant hot rolled steel coil as well as production method and application thereof

The invention relates to the technical field of hot rolled steel coils, and particularly discloses a high-strength corrosion-resistant cold-resistant hot rolled steel coil as well as a production method and application thereof. The high-strength corrosion-resistant cold-resistant hot rolled steel coil comprises the following components in percentage by weight: 0.15% to 0.20% of C, less than or equal to 0.1% of Si, 0.025% to 0.055% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.02% to 0.06% of ALs, 0.025% to 0.050% of Ti, 0.10% to 0.20% of Cu, 0.30% to 0.60% of Cr, 0.01% to 0.03% of V and the balance of iron and inevitable impurities. According to the high-strength corrosion-resistant cold-resistant hot rolled steel coil as well as the production method and application thereof, titanium, copper, vanadium, chromium, manganese and other elements are added into steel, so that the hot rolled steel coil has excellent deformation performance and also has high-strength, corrosion-resistant and cold-resistant effects.

Owner:HEBEI IRON AND STEEL

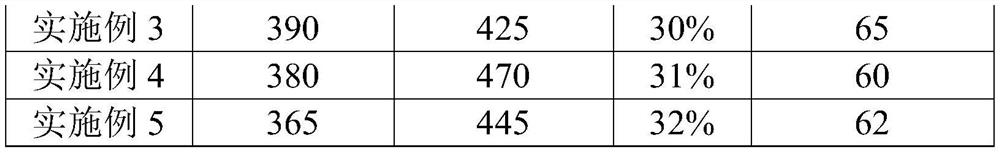

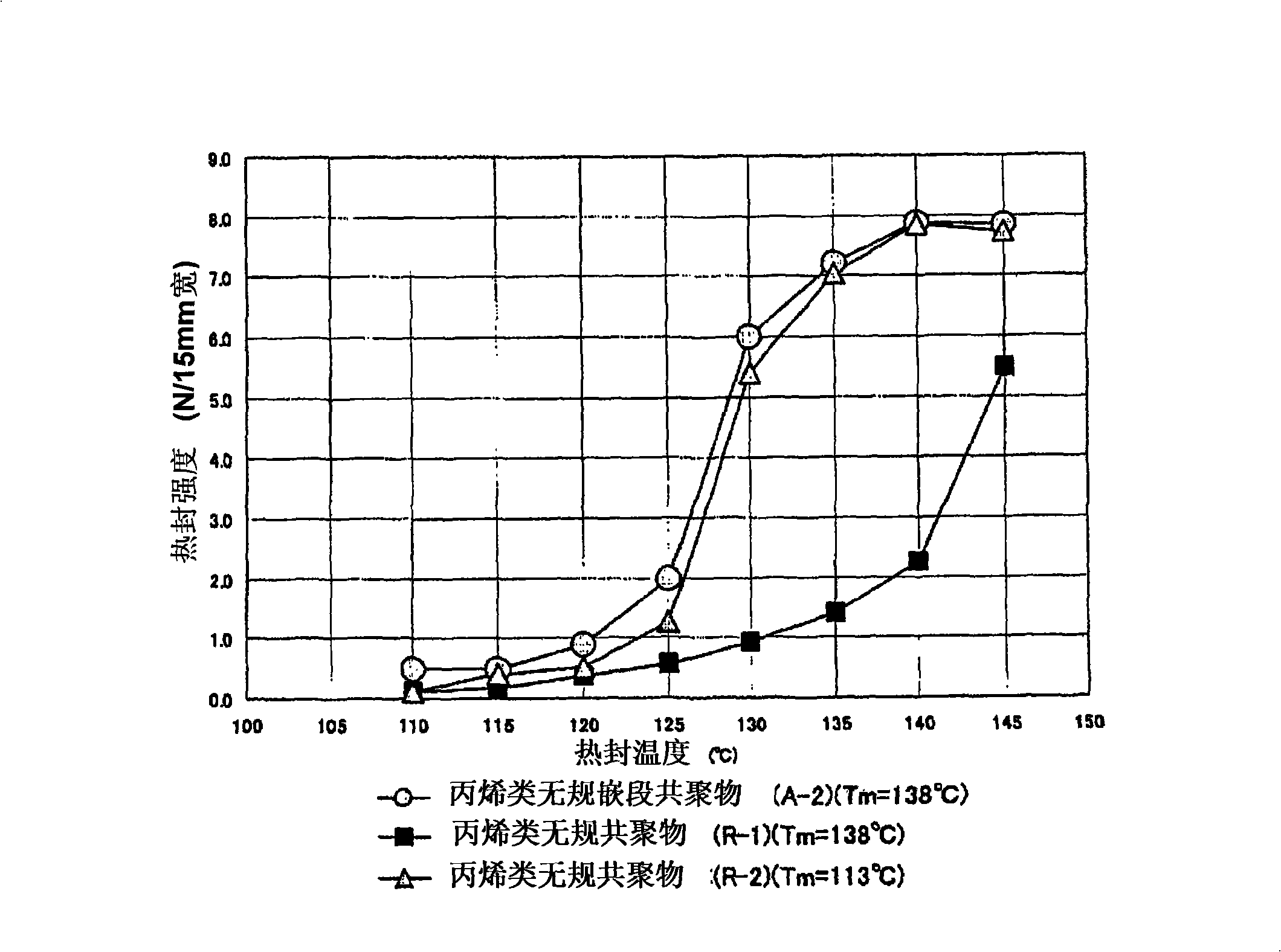

Propylene random block copolymer, resin composition containing the copolymer and molded article made thereof

ActiveCN101410426AExcellent film forming propertyExcellent low temperature impact resistanceFiberPolymer science

The invention provides a propylene random block copolymer (A) that has a melt flow rate from 0.1 to 100 g / 10 min and a melting point from 100 to 155 DEG C and includes 90 to 60% by weight of a portion insoluble (D insol ) in n-decane at room temperature and 10 to 40% by weight of a portion soluble (D sol ) in n-decane at room temperature, wherein the D insol satisfies the following requirements (1) through (3) and the D sol satisfies the following requirements (4) through (6). The invention further provides molded articles such as sheets, films, injection molded articles, hollow molded articles, injection blow molded articles and fibers, which are formed of the propylene random block copolymer (A) or a propylene resin composition containing the propylene random block copolymer (A). (1) The molecular weight distribution (Mw / Mn) obtained by GPC of the D insol is from 1.0 to 3.5, (2) the content of skeletons derived from ethylene in the D insol is from 0.5 to 13% by mole, (3) the total amount of 2,1- and 1,3-propylene units in the D insol is 0.2% by mole or less, (4) the molecular weight distribution (Mw / Mn) obtained by GPC of the D sol is from 1.0 to 3.5, (5) the intrinsic viscosity [] in decalin at 135 DEG C of the D sol is from 1.5 to 4 dl / g and (6) the content of skeletons derived from ethylene in the D sol is from 15 to 35% by mole.

Owner:MITSUI CHEM INC +1

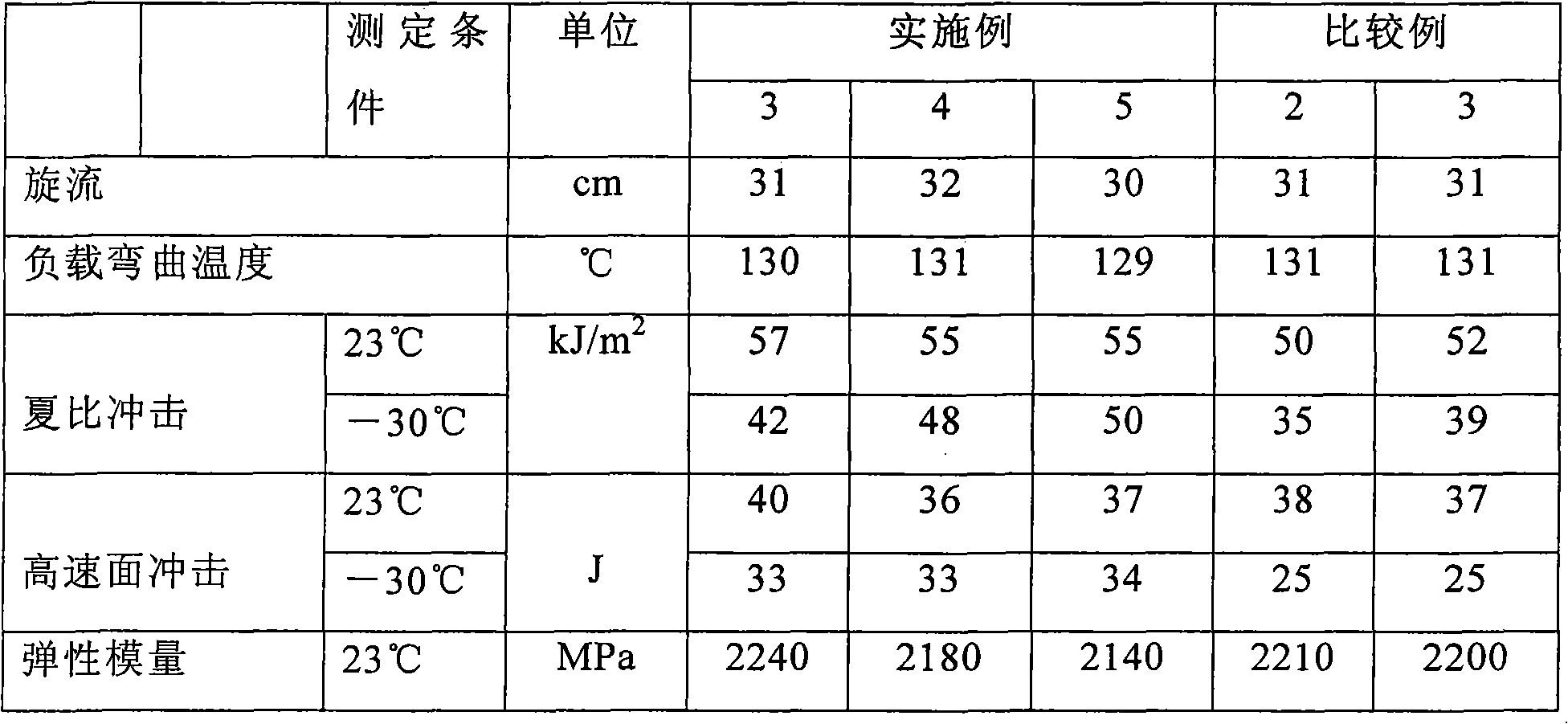

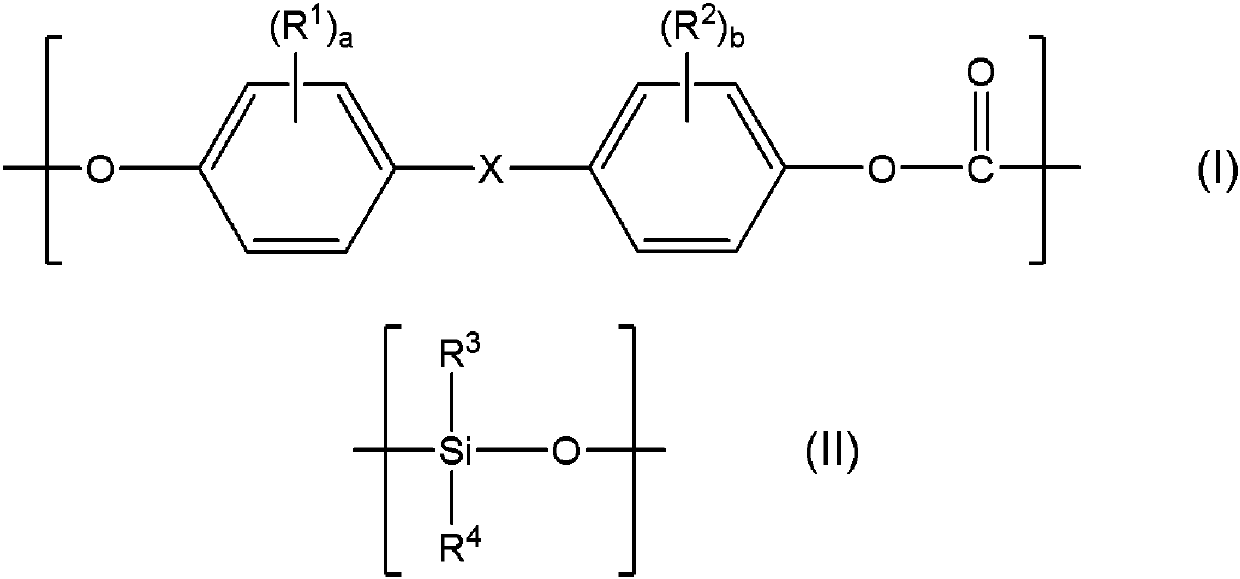

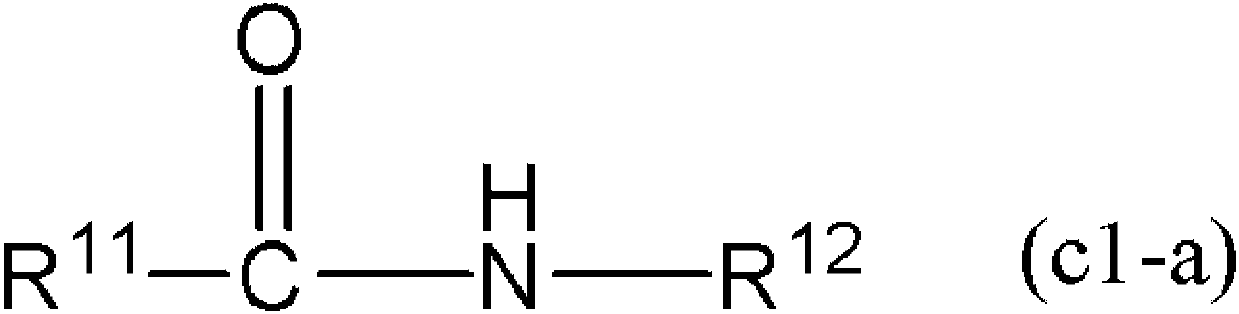

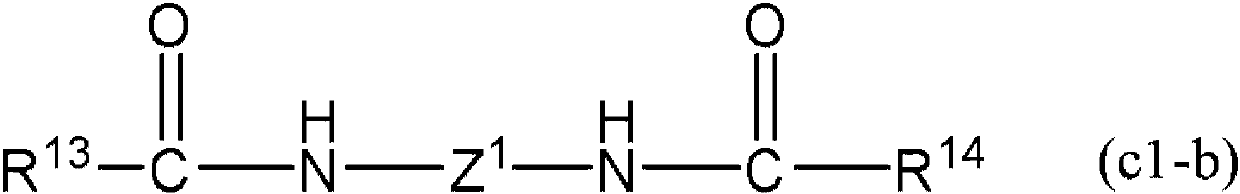

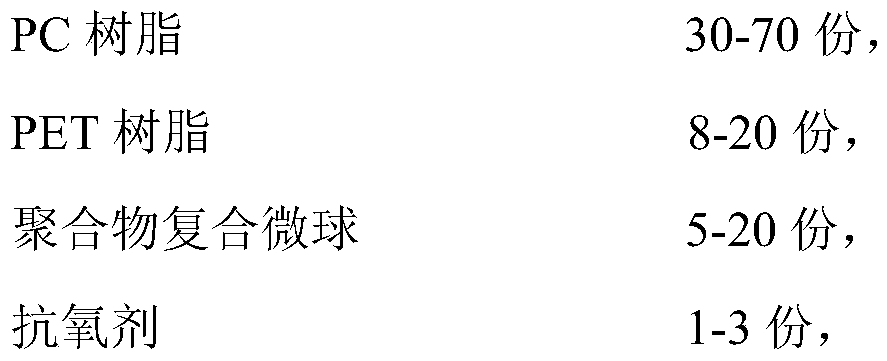

Polycarbonate resin composition and molded article thereof

ActiveUS20170335100A1Excellent flowabilityExcellent low-temperature impact resistancePolyolefinShell molding

A polycarbonate resin composition which has excellent low-temperature impact resistance and flowability high enough to enable thin molding and provides a coated molded article having a good appearance and high impact resistance. The resin composition comprises 100 parts by weight of a resin component including a polycarbonate resin (component A) and a polycarbonate-polydiorganosiloxane copolymer resin (component B) and 0.5 to 2.5 parts by weight of a polyolefin resin (component C).

Owner:TEIJIN LTD

Polycarbonate-based resin composition and molded article thereof

A polycarbonate-based resin composition that combines 0.5-40 parts by mass of a white pigment (B) and 0.02-5.0 parts by mass of a hydrolysis resistance agent (C) per 100 parts by mass of a polycarbonate-based resin (A) containing a predetermined polycarbonate-polyorganosiloxane copolymer (A1).

Owner:IDEMITSU KOSAN CO LTD

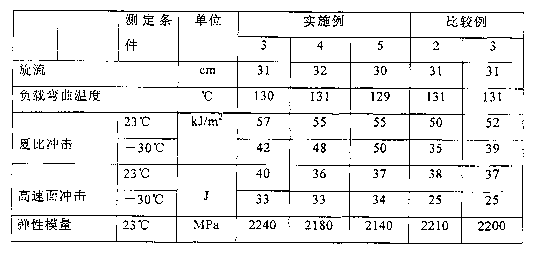

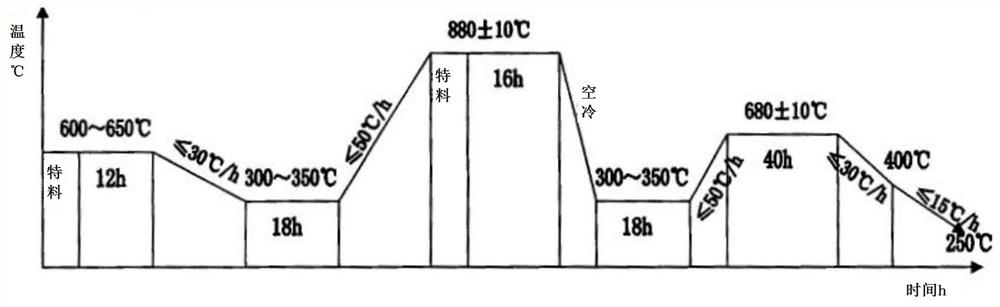

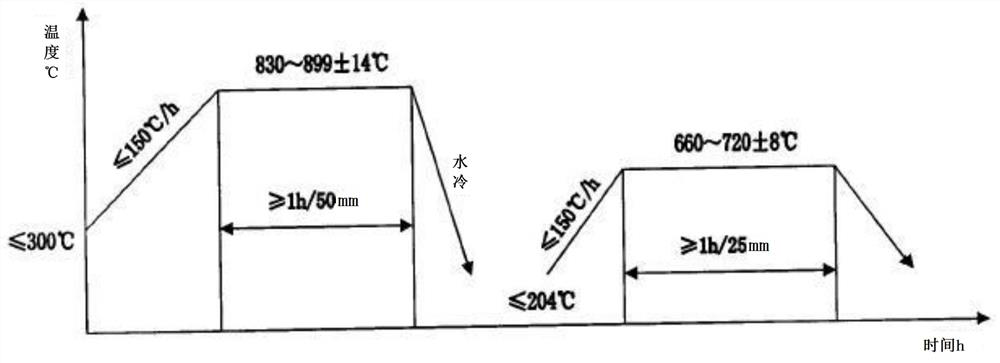

Treatment method of 630 steel

ActiveCN104357634AExcellent low temperature impact resistanceMeet the requirements of impact energy ≥ 45 joulesSolution treatmentThermal insulation

The invention discloses a treatment method of 630 steel, which comprises the following steps: carrying out hot rolling, and forging to form a 630 steel bar; carrying out solution treatment on the 630 steel bar at 1000-1100 DEG C, and cooling the bar to room temperature in air; carrying out overaging treatment on the 630 steel bar at 680-740 DEG C, wherein the number of minutes for treatment is determined according to the number of millimeters of the bar diameter; cooling the bar to room temperature in air; carrying out thermal-insulation heating treatment on the 630 steel bar at 1000-1080 DEG C, and cooling the bar to room temperature in air; and carrying out aging treatment on the 630 steel bar at 580-640 DEG C, and cooling the bar to room temperature in air. When the method is used for treating the 630 steel, the ballistic work of the 630 steel at -40 DEG C can be greater than or equal to 45J, thereby enhancing the low-temperature impact resistance of the 630 steel.

Owner:SUZHOU DOUBLE GOLD IND

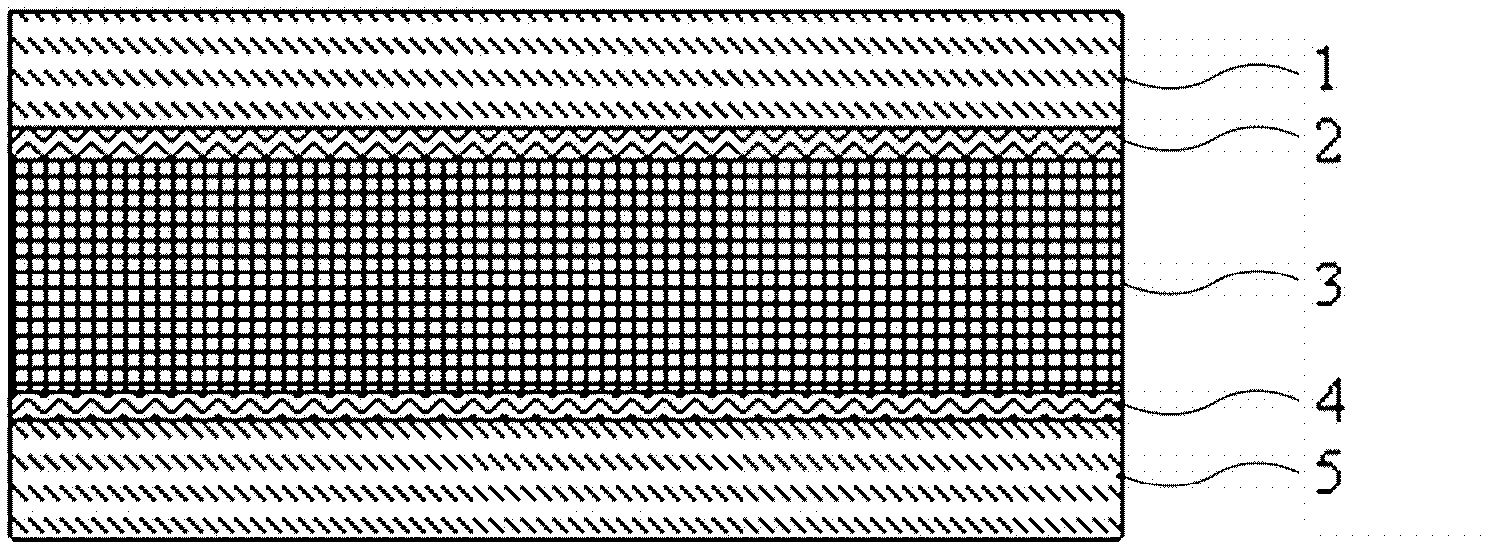

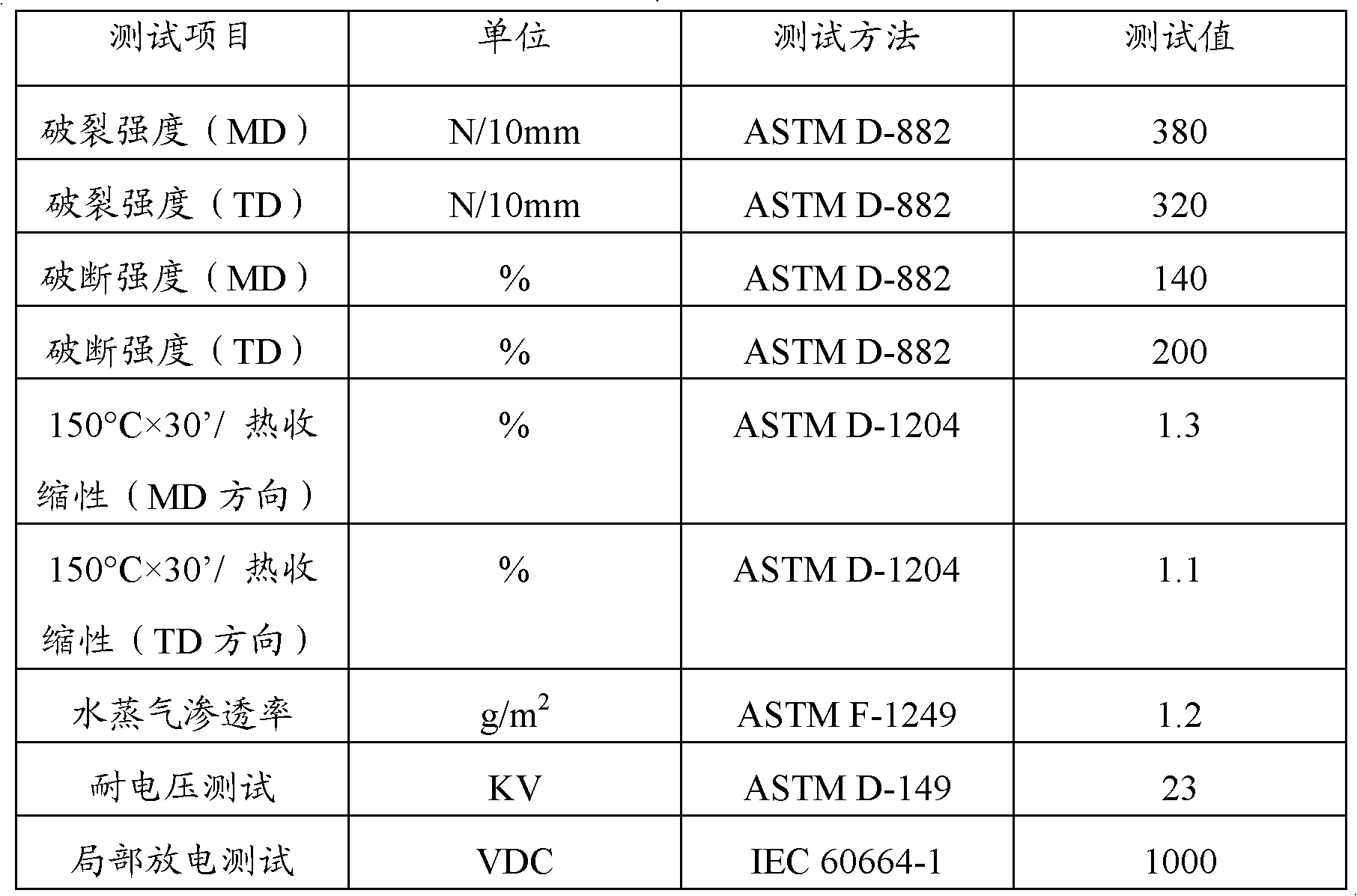

High-temperature steaming and boiling casting polypropylene film

InactiveCN109466147AExcellent low temperature impact resistanceGuaranteed retort resistanceFlexible coversWrappersElastomerPolyolefin

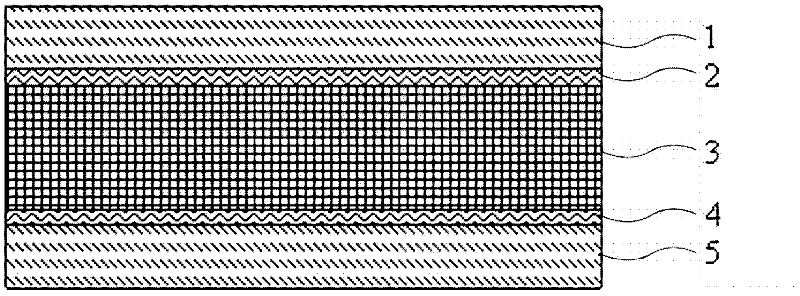

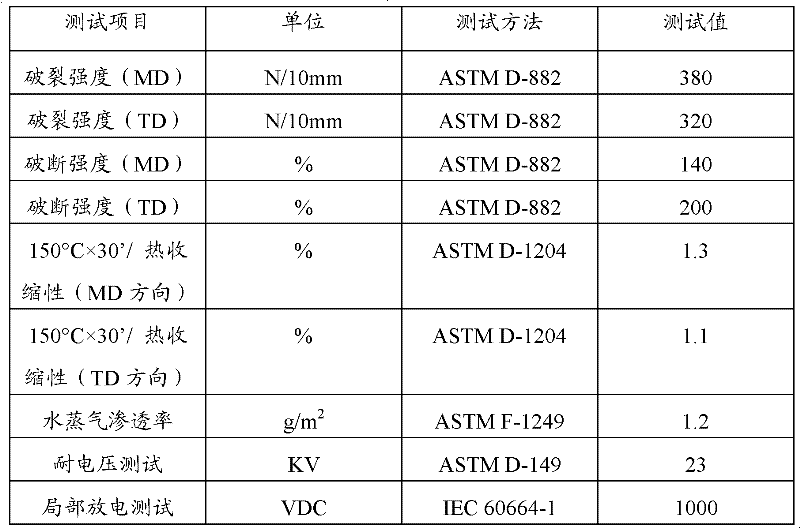

The invention discloses a high-temperature steaming and boiling casting polypropylene film, the high-temperature steaming and boiling casting polypropylene film is characterized in that the film is ofa three-layer structure, the three-layer structure sequentially comprises a corona layer (1), a middle layer (2) and a heat sealing layer (3) from top to bottom, wherein the corona layer (1) comprises 85-98% of block copolymerization polypropylene and 2-15% of polyolefin elastomer, the middle layer (2) comprises 85-98% of block copolymerization polypropylene and 2-15% of polyolefin elastomer, theheat sealing layer (3) comprises 78-96% of block copolymerization polypropylene, 2-15% of polyolefin elastomer and 2-7% of silicone smooth master batch, and the proportion is mass percent; in addition, the thickness ratio of the corona layer (1) to the middle layer (2) to the heat sealing layer (3) is 1:(2-4):(1-2).

Owner:大连盛林薄膜新材料有限公司

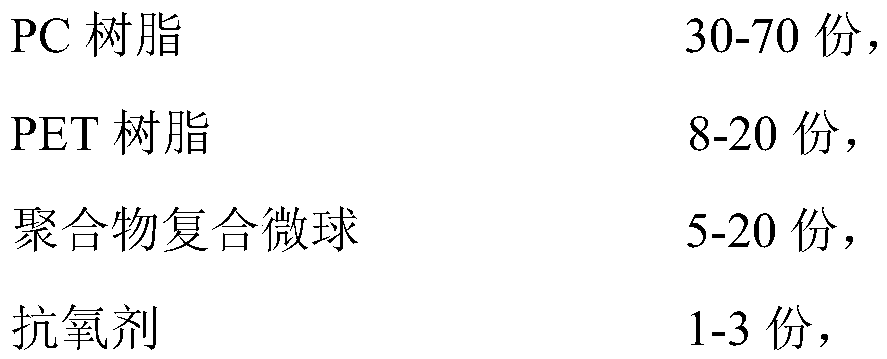

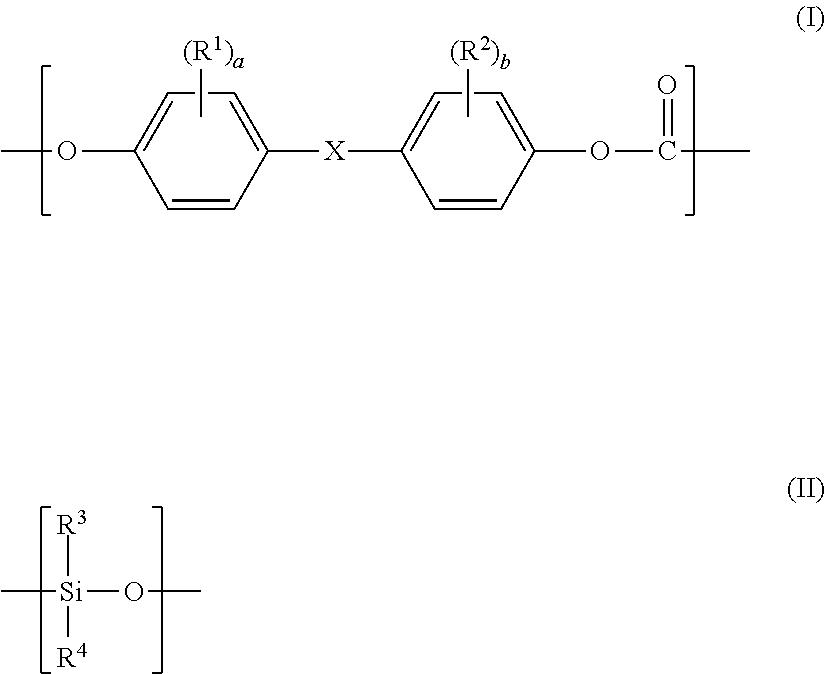

Solvent-resistant and low temperature impact-resistant polycarbonate alloy material and preparation method thereof

The invention discloses a solvent-resistant and low temperature impact-resistant polycarbonate alloy material and a preparation method thereof. The alloy material concretely comprises, by weight, 30-70 parts of PC resin, 8-20 parts of PET resin, 5-20 parts of polymer composite microspheres, 1-3 parts of an antioxidant and 0.5-2 parts of a lubricant, and the polymer composite microspheres are prepared from, by weight, 3-10 parts of a fluorine-containing acrylate / maleic anhydride block copolymer, 1-7 parts of functionalized fullerene powder and 1-3 parts of a surfactant. Functionalized polymer composite microsphere master batches are prepared by using an efficient emulsion polymerization process, the organic-inorganic hybrid polymer composite microspheres take fullerene C60 as a core and thefluorine-containing acrylate / maleic anhydride copolymer as a long-chain branch, the unique core-shell structure can improve the stability of the PC / PBT alloy material in various chemicals, and an acrylate elastomer layer has good interfacial compatibilizing and toughening effects as a microsphere shell.

Owner:上海华合复合材料有限公司

Low-temperature-impact-resistant PP (polypropylene) plastic and preparation method thereof

The invention discloses a low-temperature-impact-resistant PP (polypropylene) plastic and a preparation method thereof. The impact-resistant low-temperature PP plastic comprises PP, low-density polyethylene, ethylene-propylene copolymers, propylene-Farnesene copolymers, pitch-based carbon fibers, silochrom, chopped nylon fibers, antioxidants and lubricating agents. Low-temperature-impact resistance and mechanical properties of the low-temperature-impact-resistant PP plastic are enhanced.

Owner:徐菡

Polycarbonate-based resin composition and molded article thereof

InactiveUS20180355113A1Satisfactory low temperature impact resistanceExcellent low-temperature impact resistancePolycarbonateChemistry

Provided is a polycarbonate-based resin composition, including a polycarbonate-based resin (A) containing a predetermined polycarbonate-polyorganosiloxane copolymer (A1), and 0.5 part by mass to 40 parts by mass of a white pigment (B) and 0.02 part by mass to 5.0 parts by mass of a hydrolysis resistant agent (C) with respect to 100 parts by mass of the polycarbonate-based resin (A).

Owner:IDEMITSU KOSAN CO LTD

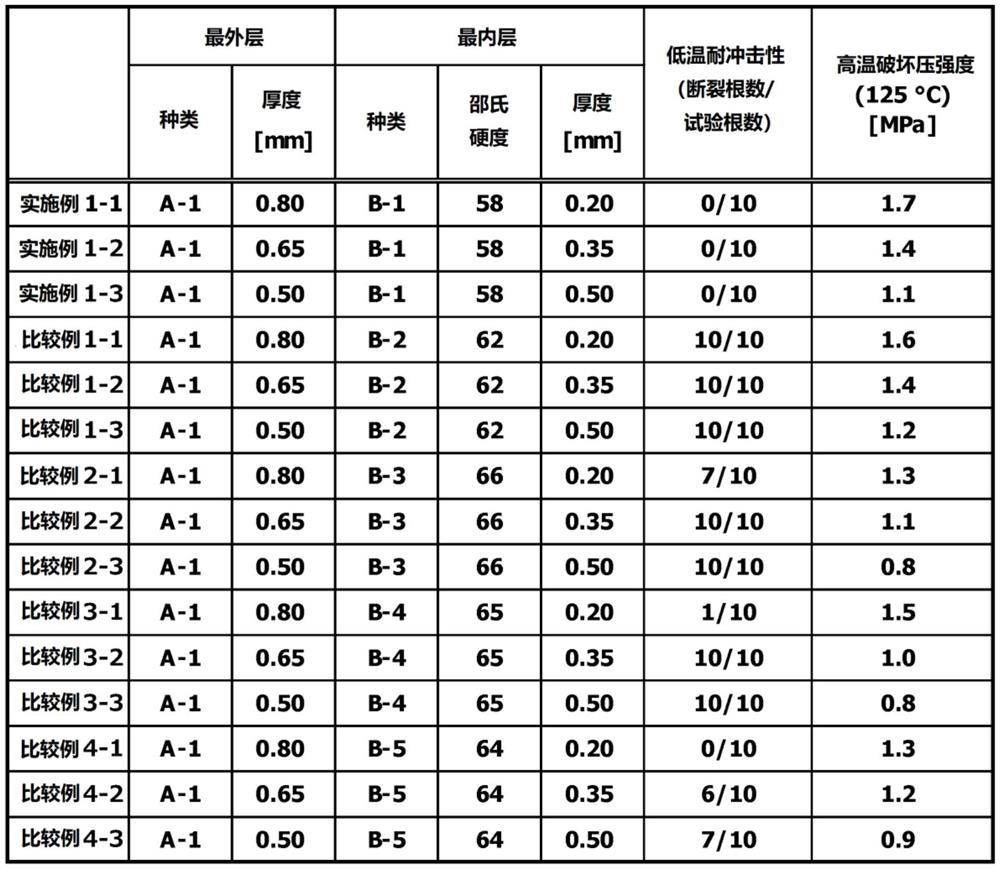

Laminate

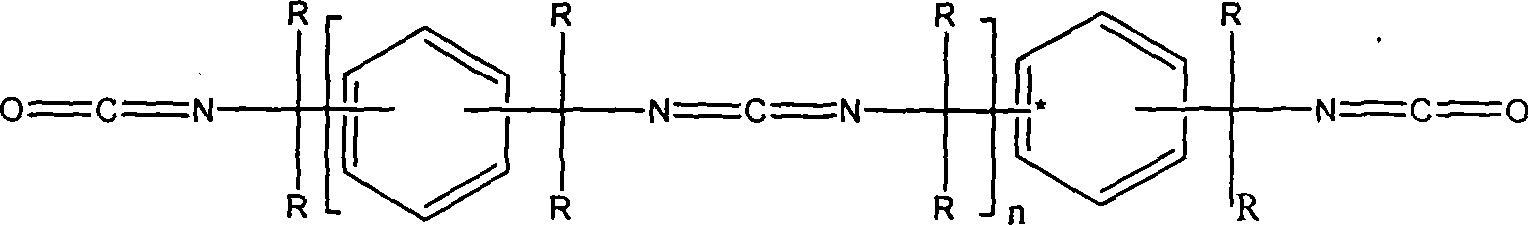

PendingCN113646172AExcellent low temperature impact resistanceExcellent breaking pressureSynthetic resin layered productsMedical devicesPolymer sciencePolyolefin

Provided is a laminate that has excellent low-temperature impact resistance and bursting pressure strength at high temperatures despite having a thick modified polyolefin layer.The laminate has two or more layers including an (a) layer and a (b) layer, the (a) layer includes an aliphatic polyamide composition (A), and the (b) layer includes a modified polyolefin (B). The modified polyolefin (B) includes a unit derived from a monomer based on an alfa-olefin having 2-10 carbon atoms, and a unit derived from an unsaturated compound having at least one functional group selected from the group consisting of: unsaturated compounds having at least one group selected from the group consisting of a carboxyl group, a hydroxyl group, an epoxy group, an amino group, an amide group, an imide group, a nitrile group, a thiol group, and an isocyanate group; and derivatives of unsaturated compounds having a carboxyl group. The Shore hardness (D scale) of the modified polyolefin (B) as measured according to ASTM D2240 is 30-61.

Owner:UBE IND LTD

A kind of processing method of 630 steel

ActiveCN104357634BExcellent low temperature impact resistanceMeet the requirements of impact energy ≥ 45 joulesSolution treatmentThermal insulation

The invention discloses a treatment method of 630 steel, which comprises the following steps: carrying out hot rolling, and forging to form a 630 steel bar; carrying out solution treatment on the 630 steel bar at 1000-1100 DEG C, and cooling the bar to room temperature in air; carrying out overaging treatment on the 630 steel bar at 680-740 DEG C, wherein the number of minutes for treatment is determined according to the number of millimeters of the bar diameter; cooling the bar to room temperature in air; carrying out thermal-insulation heating treatment on the 630 steel bar at 1000-1080 DEG C, and cooling the bar to room temperature in air; and carrying out aging treatment on the 630 steel bar at 580-640 DEG C, and cooling the bar to room temperature in air. When the method is used for treating the 630 steel, the ballistic work of the 630 steel at -40 DEG C can be greater than or equal to 45J, thereby enhancing the low-temperature impact resistance of the 630 steel.

Owner:SUZHOU DOUBLE GOLD IND

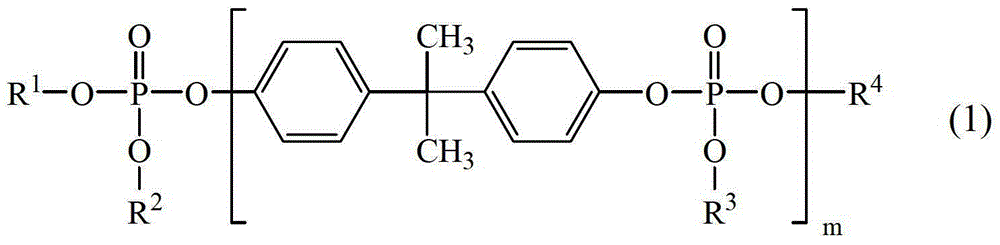

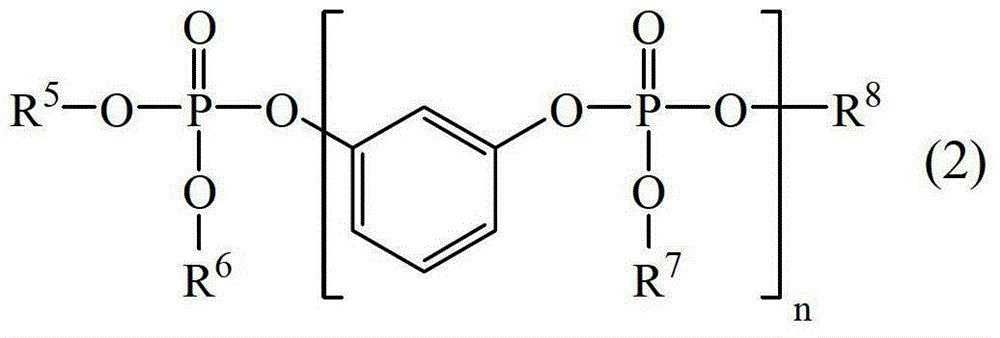

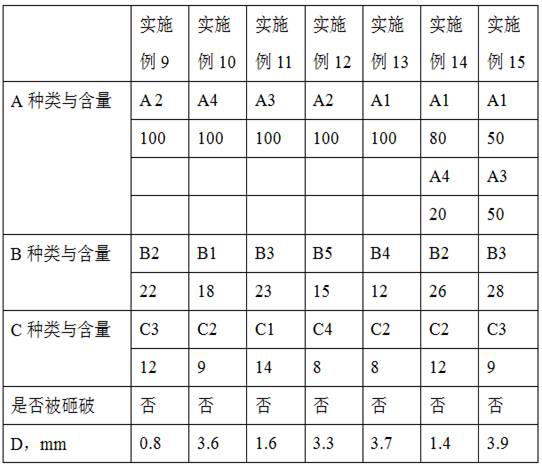

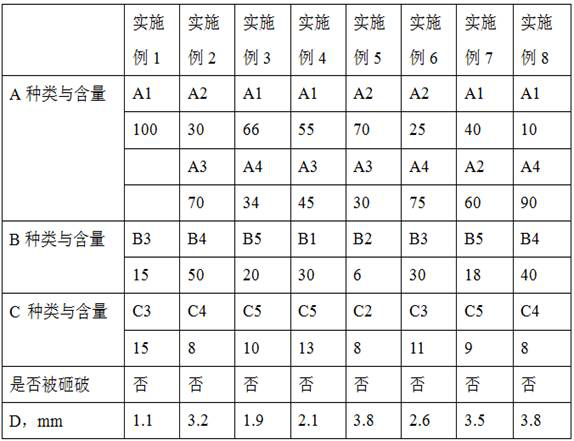

Polycarbonate composition and its application

InactiveCN103881347BImprove impact resistanceImprove flame retardant performancePhosphateFire resistance

The present invention relates to a polycarbonate composition and the application thereof. The polycarbonate composition includes a polycarbonate (A), a first phosphate compound (B1), a second phosphate compound (B2), a polyvinyl fluoride resin (C) and a small size of core-shell polymer (D); the diameter thereof is less then 0.2[mu]m. The polycarbonate composition has better low temperature impact resistance and fire resistance via appropriate dosage of the first phosphate compound (B1), the second phosphate compound (B2), and the small size of core-shell polymer (D), molding products made by the polycarbonate composition's subsequent application are suitable for using in cold regions.

Owner:CHI MEI CORP

Thermoplastic resin composition

InactiveCN101255272BGood physical and mechanical propertiesExcellent low temperature impact resistanceComposition BPolystyrene

The invention aims to provide a thermoplastic resin composition having excellent mechanical physical property, especially excellent surface impact strength at low temperature, characterized in that the thermoplastic resin composition having excellent impact resistance at low temperature comprises 99% to 50% by weight of thermoplastic resin (composition A) and 1% to 50% by weight of block copolymer (composition B) composed of S block with polystyrene as the main composition, B block with poly (1,4-butadiene) as the main composition and M block with polymethylmethacrylate as the main composition, and the block copolymer includes at least one binding unit selected from a group consisting of S-B-M, M-S-B-S-M and M-B-S-B-M.

Owner:TEIJIN KASEK KK

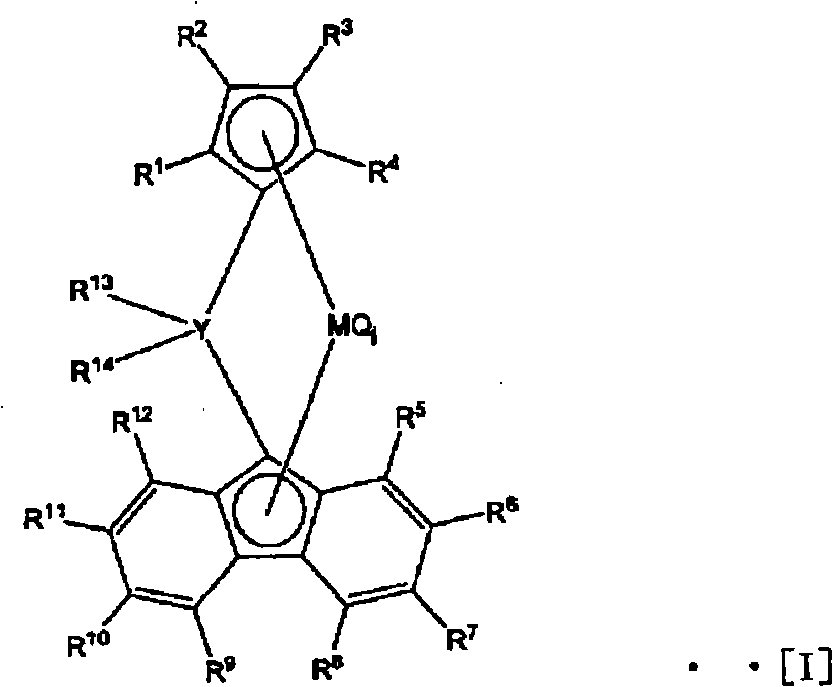

A pipe joint and its preparation method

ActiveCN111471926BHigh strengthImprove plasticityMetal-working apparatusFurnace typesNiobiumManganese

The invention discloses a pipe joint, whose chemical composition and weight percentage are: carbon 0.27-0.34%, manganese 0.66-1.09%, phosphorus ≤ 0.020%, sulfur ≤ 0.015%, silicon 0.13-0.37%, nickel 0.72-0.93% , chromium 0.81-1.09%, molybdenum 0.33-0.47%, aluminum 0.01-0.031%, niobium 0.015-0.035%, vanadium 0.03-0.06%, copper ≤ 0.15%, and the balance is iron and unavoidable impurities. In the present invention, by rationally controlling the dosage of each component, each component synergizes and promotes each other, improves the strength and plasticity of the material, and improves the low-temperature impact resistance of the forging; adopts the post-forging heat treatment process and the heat treatment of quenching and tempering of the present invention process, refining the precipitation strengthening phase, improving the corrosion resistance of steel, and further improving the low temperature impact resistance of forgings.

Owner:YANTAI UNIV

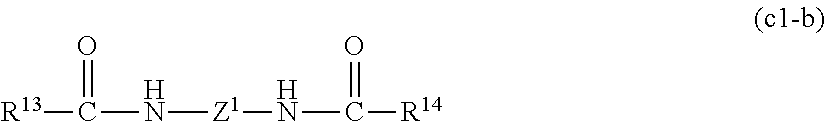

Thermoplastic copolyester composite material and preparation method and application thereof

The invention discloses a thermoplastic copolyester composite material which comprises the following components in parts by weight: 100 parts of thermoplastic polyether ester; 6-50 parts of a styrene-acrylonitrile-glycidyl methacrylate copolymer; 8-20 parts of an ethylene-glycidyl methacrylate copolymer; the thermoplastic polyether ester is a polycondensate of terephthalic acid / isophthalic acid / 1, 4-butanediol / polytetrahydrofuran ether glycol. The thermoplastic copolyester composite material has the advantage of good low-temperature impact resistance.

Owner:KINGFA SCI & TECH CO LTD

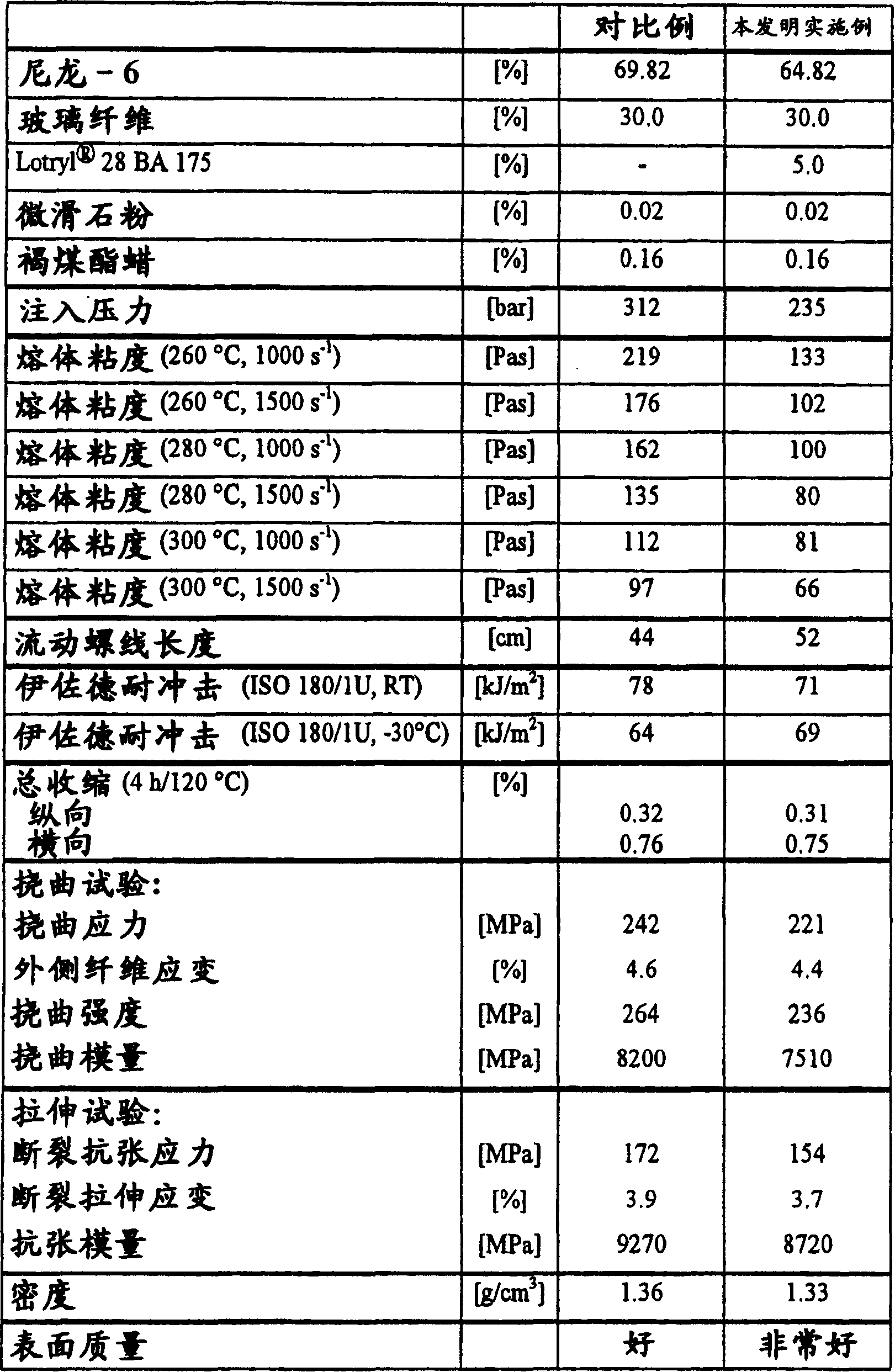

Polyamide moulding compositions with improved flowability

The present invention relates to a thermoplastic polyester and olefin-alkyl (meth)acrylate copolymer with high melt flow index, in which the thermoplastic polyeste contains a alpha-alkene and at least one of (meth)acrylate(s) with 1-4C aliphatic alcohols showing a melt flow index(MFI) of not less than 50 g / 10 min. The present invention also relates to a method of preparing the thermoplastic polyester and to the use of the thermoplastic moulding material in electric, electrical, telecom, motor or computer industries, and model piece application in gym, domestic appliance, medicine or entertainment industries.

Owner:LANXESS DEUTDCHLAND GMBH

A kind of low temperature impact resistant epoxy adhesive composition and preparation method thereof

ActiveCN108570302BExcellent low temperature impact resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceNitrile rubber

The present invention provides a low-temperature-impact-resistant epoxy adhesive composition, which comprises: at least two epoxy resins; at least a bifunctional epoxy diluent; at least three toughening agents, wherein the toughening agents at least comprise a liquid rubber toughening agent having a core-shell structure, an epoxy resin modified nitrile butadiene rubber, and a ketoxime-terminated reactive polyurethane elastic prepolymer; at least an inorganic filler; at least a water removing agent; at least a thixotropic agent; at least a thermally-activated latent curing agent; and at least acuring accelerator. According to the present invention, the two different epoxy resins are used as the raw materials, and the composite toughening agent at least comprising the liquid rubber toughening agent having the core-shell structure, the epoxy resin modified nitrile butadiene rubber and the ketoxime-terminated reactive polyurethane elastic prepolymer is added, such that the obtained epoxyadhesive composition has good low-temperature-impact resistance.

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

Polypropylene composition for solar battery and preparation method thereof

ActiveCN102504407BGood weather resistanceExcellent low temperature impact resistancePhotovoltaic energy generationSemiconductor devicesAntioxidantUltraviolet

The invention provides a polypropylene composition for a solar battery and a preparation method thereof, wherein the polypropylene composition for the solar battery comprises 50-100 parts by weight of at least one of homo-polymerized polypropylene and co-polymerized polypropylene, 0-50 parts by weight of inorganic filler, 15-25 parts by weight of anti-ultraviolet assistant, 0.2-30 parts of antioxidant, 0.5-20 parts by weight of plasticizer and 0.1-10 parts by weight of modified polymer. According to the invention, the polypropylene composition for the solar battery has good weather resistance, ultraviolet resistance and low-temperature impact resistance.

Owner:北京太阳能电力研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com