Propylene random block copolymer, resin composition containing the copolymer and molded article made thereof

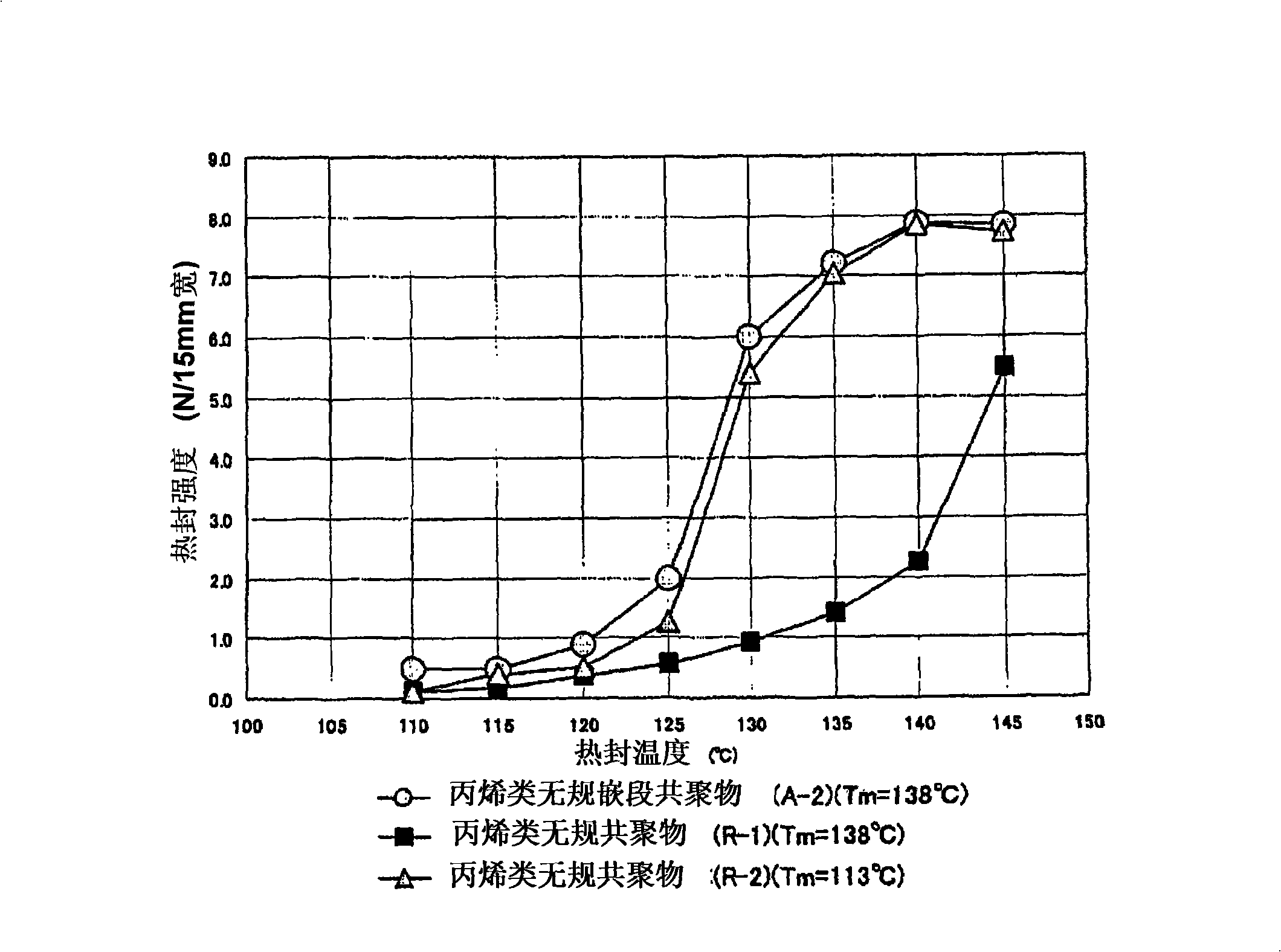

A technology of propylene-based resin and block copolymer, which is applied in the field of polypropylene resin composition and propylene-based random block copolymer, which can solve the problem of low molecular weight, high rigidity, difficulty in imparting impact resistance, tear strength, etc. Problems, to achieve the effect of excellent film forming, excellent heat shrinkability, excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

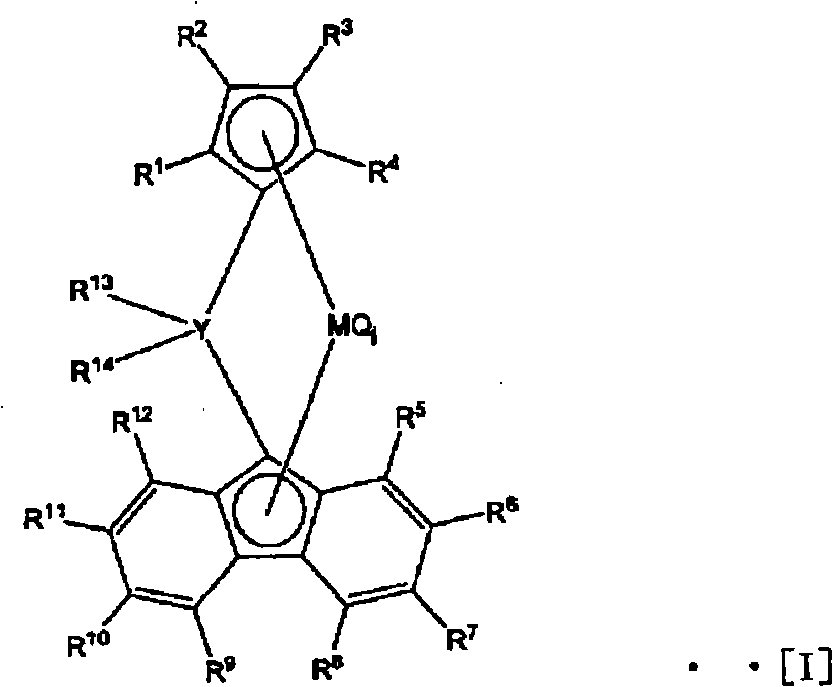

Method used

Image

Examples

Embodiment

[0133] Hereinafter, the present invention will be described in detail based on examples, but the present invention is not limited to these examples. However, the physical property measurement methods in Examples and Comparative Examples are as follows.

[0134] (m1) MFR (melt flow rate)

[0135] MFR is measured in accordance with ASTM D1238 (230° C., load 2.16 kg).

[0136] (m2) Melting point (Tm)

[0137] Measurement was performed using a differential scanning calorimeter (DSC, manufactured by PerkinElmer). The endothermic peak at the third stage measured here is defined as melting point (Tm).

[0138] (measurement conditions)

[0139] The first stage: heat up to 240°C at 10°C / min and keep for 10min.

[0140] Stage 2: Cool down to 60°C at 10°C / min.

[0141] The third stage: heating up to 240°C at 10°C / min.

[0142] (m3) The amount of n-decane soluble part at room temperature (D sol )

[0143] 200 ml of n-decane was added to a 5 g sample of the final product ...

manufacture example 1

[0201] (1) Manufacture of solid catalyst carrier

[0202] Sample 300 g of SiO in a 1 liter distillation flask 2 , Add 800ml of toluene to make slurry.

[0203] Next, the slurry was transferred to a 5-liter 4-necked flask, and 260 ml of toluene was added thereto.

[0204] 2830 ml of methylaluminoxane (hereinafter referred to as MAO)-toluene solution (manufactured by ALBEMARLE, 10% by weight solution) was introduced thereinto, and kept stirring at room temperature for 30 minutes. The temperature was raised to 110° C. over 1 hour, and the reaction was carried out for 4 hours. After the reaction, cool to room temperature. After cooling, the supernatant toluene was taken out and replaced with new toluene until the replacement rate was 95%.

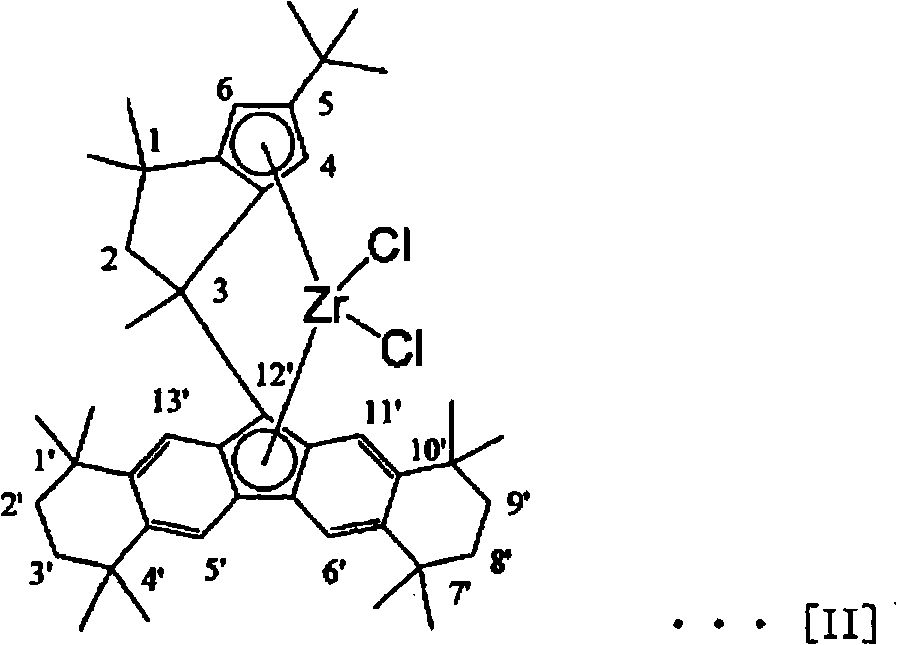

[0205] (2) Production of solid catalyst components (loading of metal catalyst components on carriers)

[0206] In the glove box, weigh 2.0 g of diphenylmethylene (3-tert-butyl-5-methylcyclopentadienyl) synthesized according to the record o...

manufacture example 2

[0219] It carried out by the method similar to manufacture example 1 except having changed the polymerization method as follows.

[0220] (1) Main aggregation

[0221] Continuously feed propylene at 40 kg / hour, hydrogen at 5 N liters / hour, and catalyst slurry produced in (3) of Production Example 1 as a solid catalyst component at a rate of 40 kg / hour to a tubular polymerizer having an internal volume of 58 liters. , 2.2 g / hour of triethylaluminum was supplied, and polymerization was carried out in a liquid-filled state in which no gas phase existed in the tubular polymerizer. The temperature of the tubular reactor was 30° C. and the pressure was 3.2 MPa / G. The catalyst in this reaction is a M1 type catalyst.

[0222] The resulting slurry was sent to a vessel polymerizer with an inner volume of 1,000 liters with a stirrer, and further polymerized. To the polymerizer, propylene was supplied at 45 kg / hour, ethylene was supplied so that the ethylene concentration in the gas ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com