Acrylic resin film and manufacturing method thereof

An acrylic and resin film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as whitening, achieve the effects of less residue, excellent heat shrinkage resistance, and heat suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0150] A monomer mixture was prepared by charging 92 parts of refined MMA and 8 parts of MA into an autoclave with a stirrer and a collection tube. Add 0.006 parts of polymerization initiator (2,2'-azobis(2-methylpropionitrile), hydrogen abstraction ability: 1%, 1 hour half-life temperature: 83°C) and 0.15 parts of nOM to the monomer mixture, so that This is dissolved to obtain a raw material liquid. Oxygen is driven out of the manufacturing apparatus using nitrogen.

[0151] The above-mentioned raw material liquid was supplied from the autoclave at a constant flow rate to a continuous flow tank reactor whose temperature was controlled at 140°C so that the average residence time was 120 minutes, and bulk polymerization was carried out at a polymerization conversion rate of 57% to obtain acrylic acid Department of resin [B1].

[0152] The liquid discharged from the above-mentioned tank reactor was heated to 240°C, and supplied at a constant flow rate to a twin-screw extruder ...

manufacture example 2

[0154] A monomer mixture was prepared by charging 94 parts of refined MMA and 6 parts of MA into an autoclave with a stirrer and a collection tube. Add 0.006 parts of polymerization initiator (2,2'-azobis(2-methylpropionitrile), hydrogen abstraction ability: 1%, 1 hour half-life temperature: 83°C) and 0.35 parts of nOM to the monomer mixture, so that This is dissolved to obtain a raw material liquid. Oxygen is driven out of the manufacturing apparatus using nitrogen.

[0155] The above-mentioned raw material liquid was supplied from the autoclave at a constant flow rate to a continuous flow tank reactor whose temperature was controlled at 140°C so that the average residence time was 120 minutes, and bulk polymerization was carried out at a polymerization conversion rate of 57% to obtain acrylic acid Department of resin [B2].

[0156] The liquid discharged from the above-mentioned tank reactor was heated to 240°C, and supplied at a constant flow rate to a twin-screw extruder ...

Embodiment 1

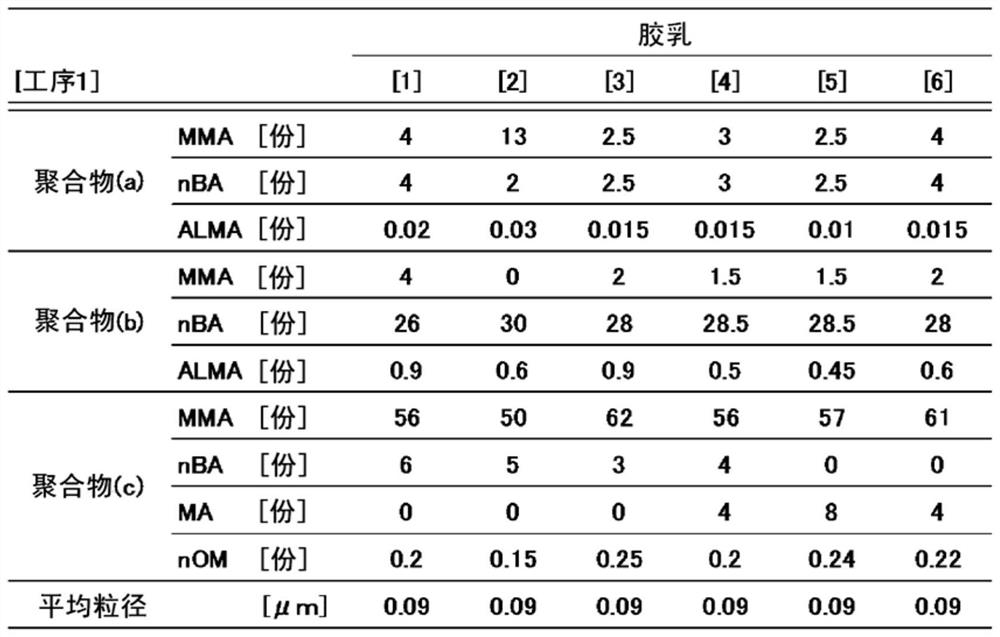

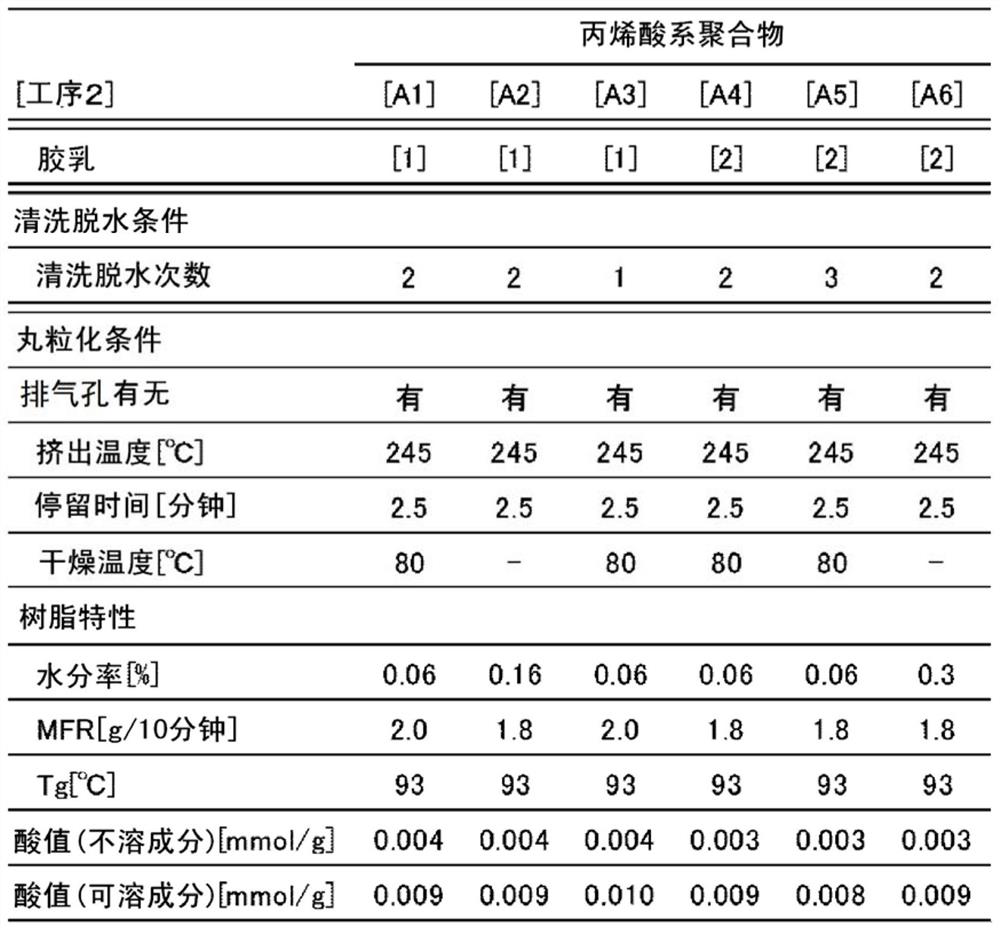

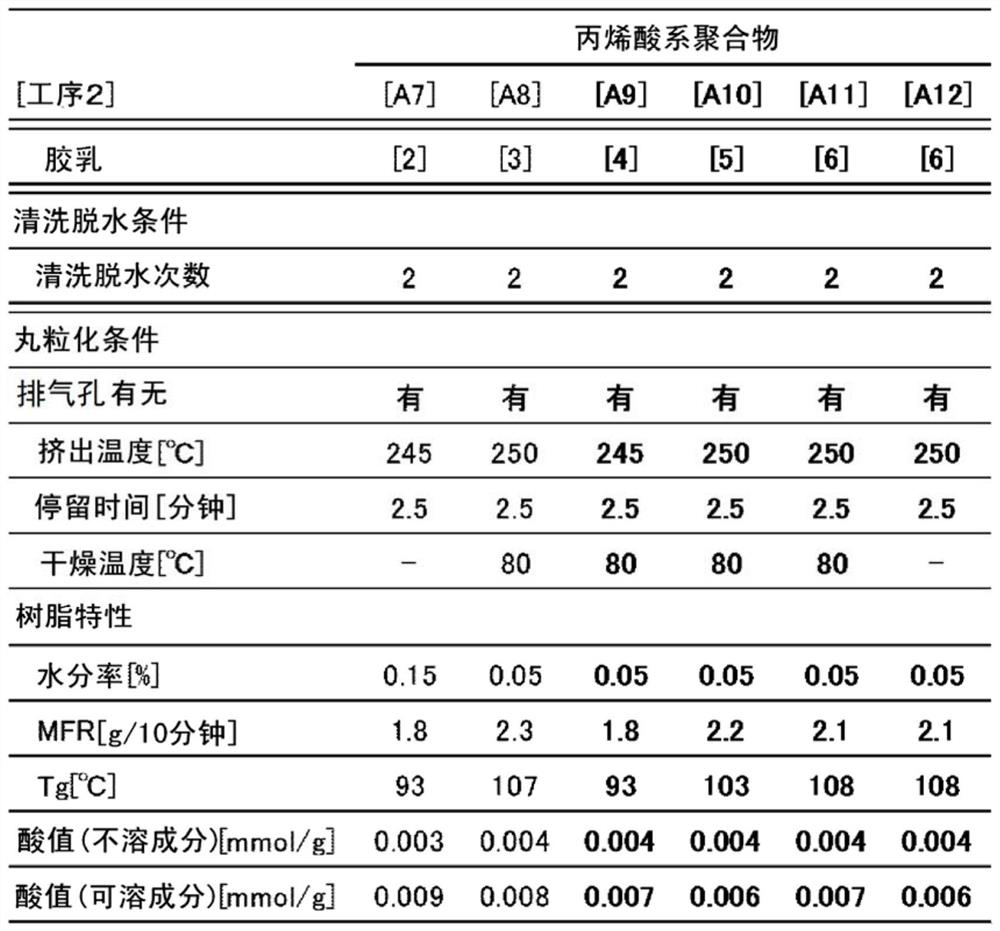

[0158] (Process 1)

[0159] Put 150 parts of ion-exchanged water, 1.3 parts of sodium dodecylbenzenesulfonate and 0.05 parts of sodium carbonate into a reaction vessel equipped with a stirrer, a thermometer, a nitrogen gas introduction part, a monomer introduction pipe, and a reflux condenser. Substitution is sufficient to form a state where there is substantially no influence of oxygen. Then, the temperature in the reaction container was set to 80°C. 0.015 parts of potassium persulfate was put into the reaction container, and stirred for 5 minutes. Next, a monomer mixture consisting of 4 parts of MMA, 4 parts of nBA and 0.02 part of ALMA was continuously added dropwise over 20 minutes to carry out emulsion polymerization. After completion of the dropwise addition, the mixture was further stirred for 30 minutes to carry out emulsion polymerization so that the conversion rate became 98% or more, and a latex containing the polymer (a) was obtained.

[0160] 0.030 parts of pot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com