Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Excellent input and output characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

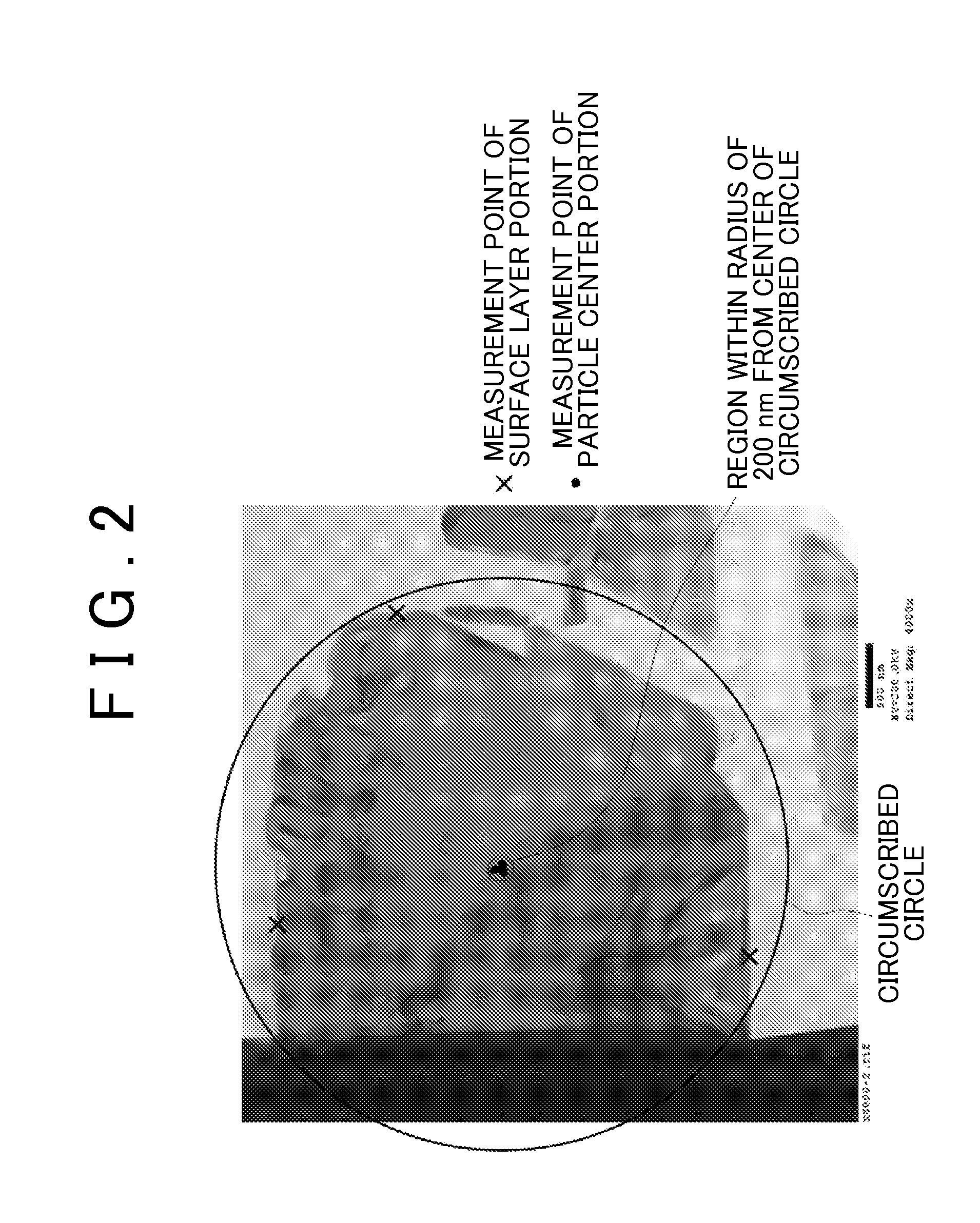

Positive active material for lithium-ion secondary battery, positive electrode for lithium-ion secondary battery, and lithium-ion secondary battery

ActiveUS20160028080A1Excellent initial characteristicIncreased durabilityPositive electrodesNon-aqueous electrolyte accumulator electrodesSurface layerX ray spectra

A positive active material for a lithium-ion secondary battery includes a lithium composite oxide particle containing nickel atoms, manganese atoms, and fluorine atoms. The lithium composite oxide particle includes a particle center portion and a surface layer portion that is closer to a surface of the lithium composite oxide particle than the particle center portion is. A fluorine atom concentration Fc (at %) of the particle center portion measured by energy dispersive X-ray spectroscopy is lower than a fluorine atom concentration Fs (at %) of the surface layer portion.

Owner:TOYOTA JIDOSHA KK

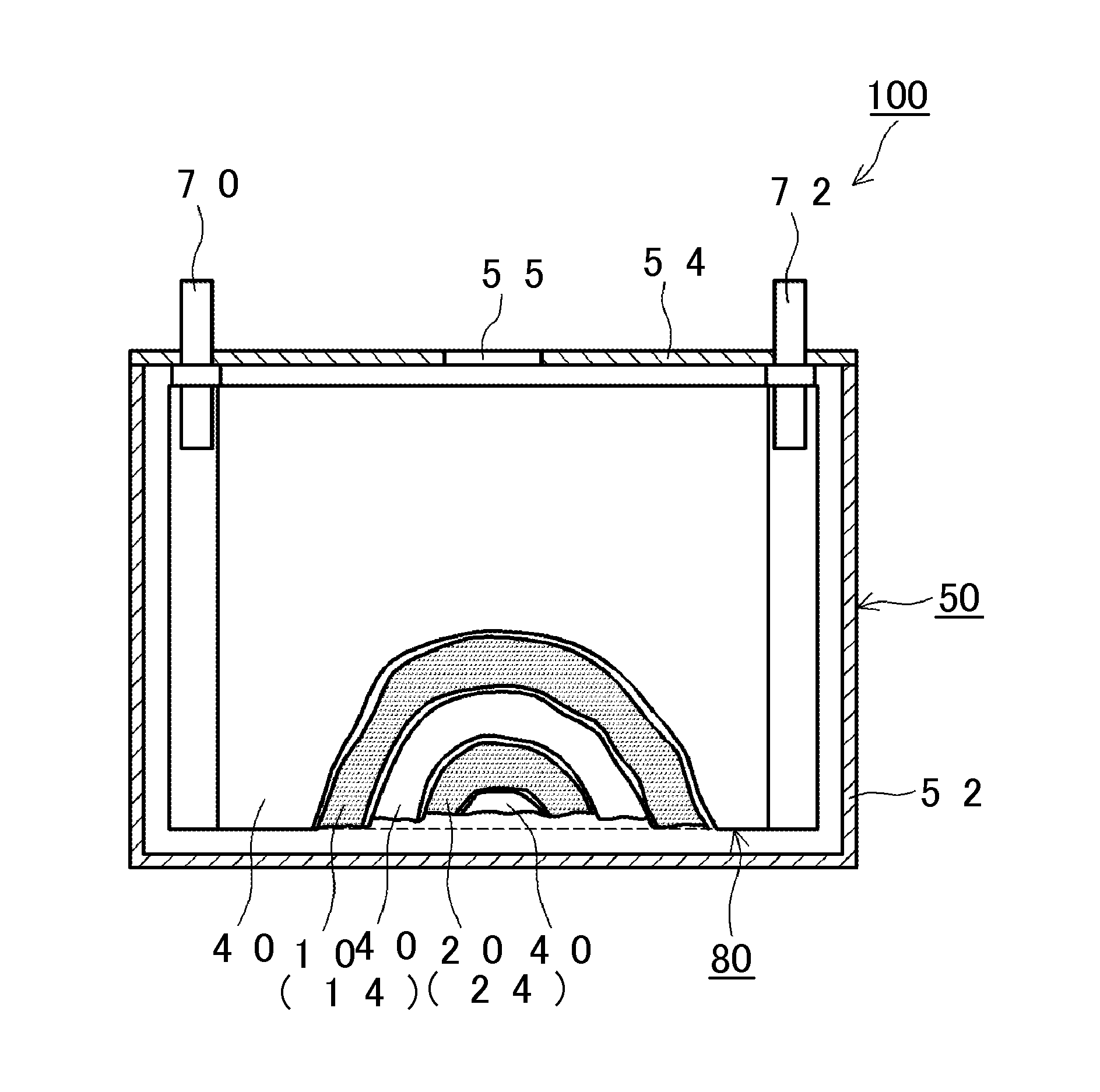

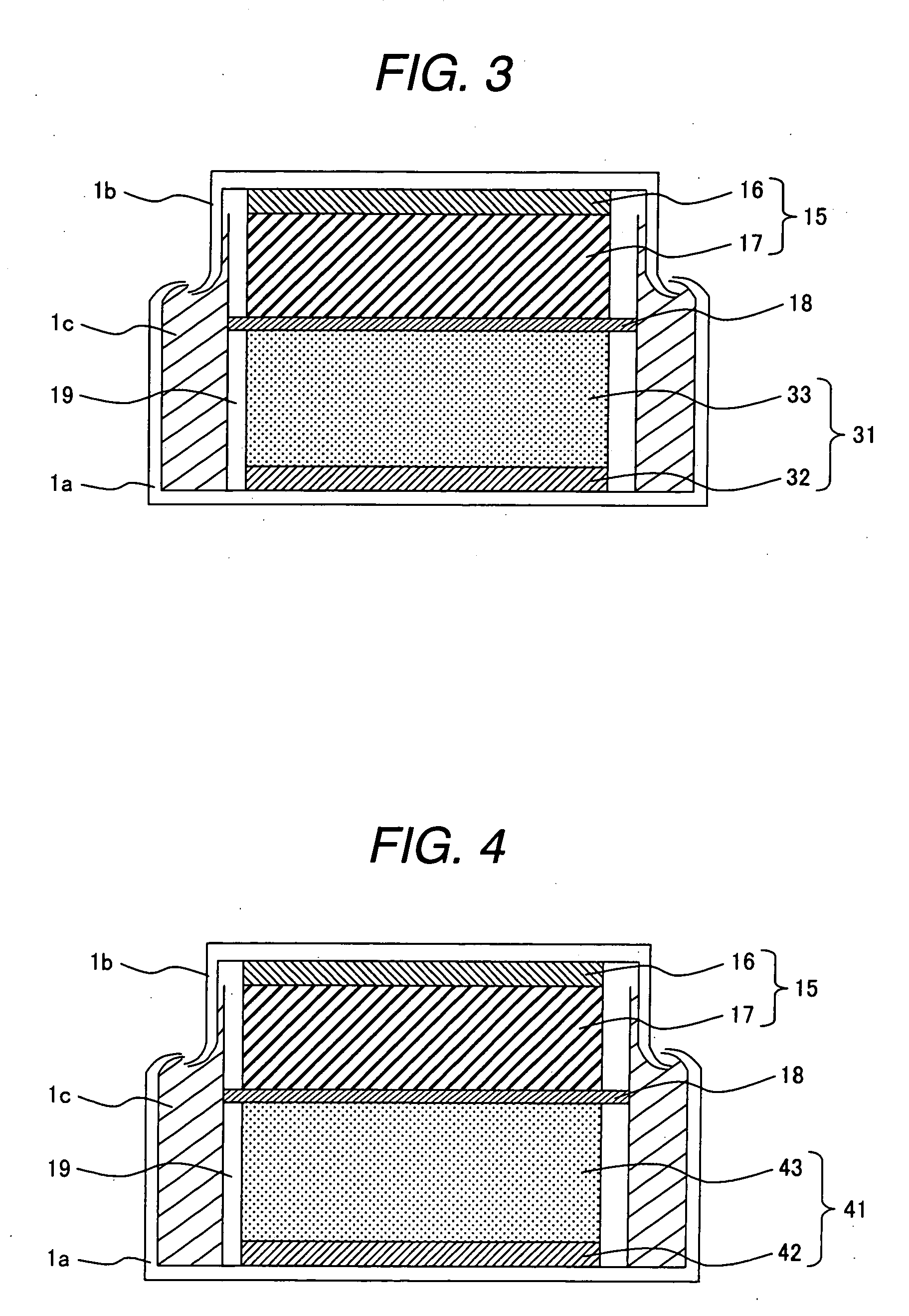

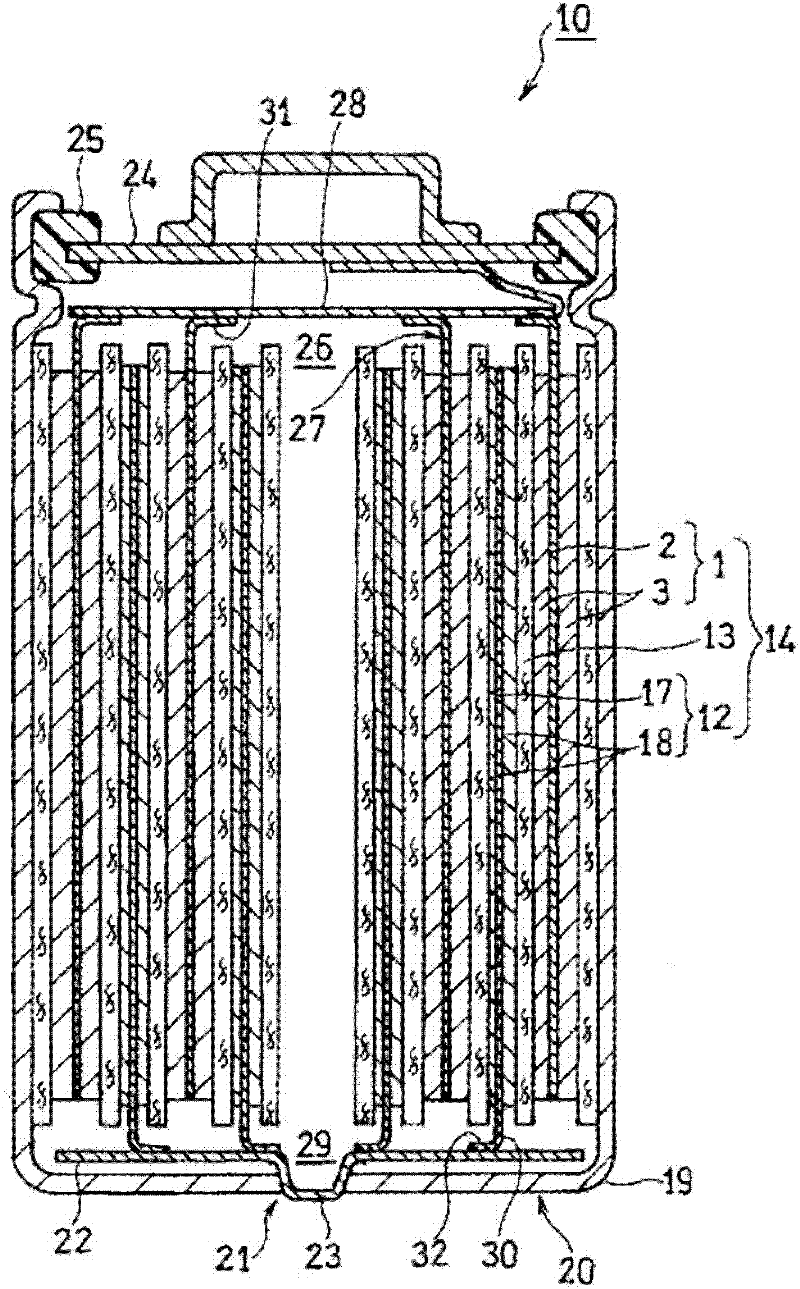

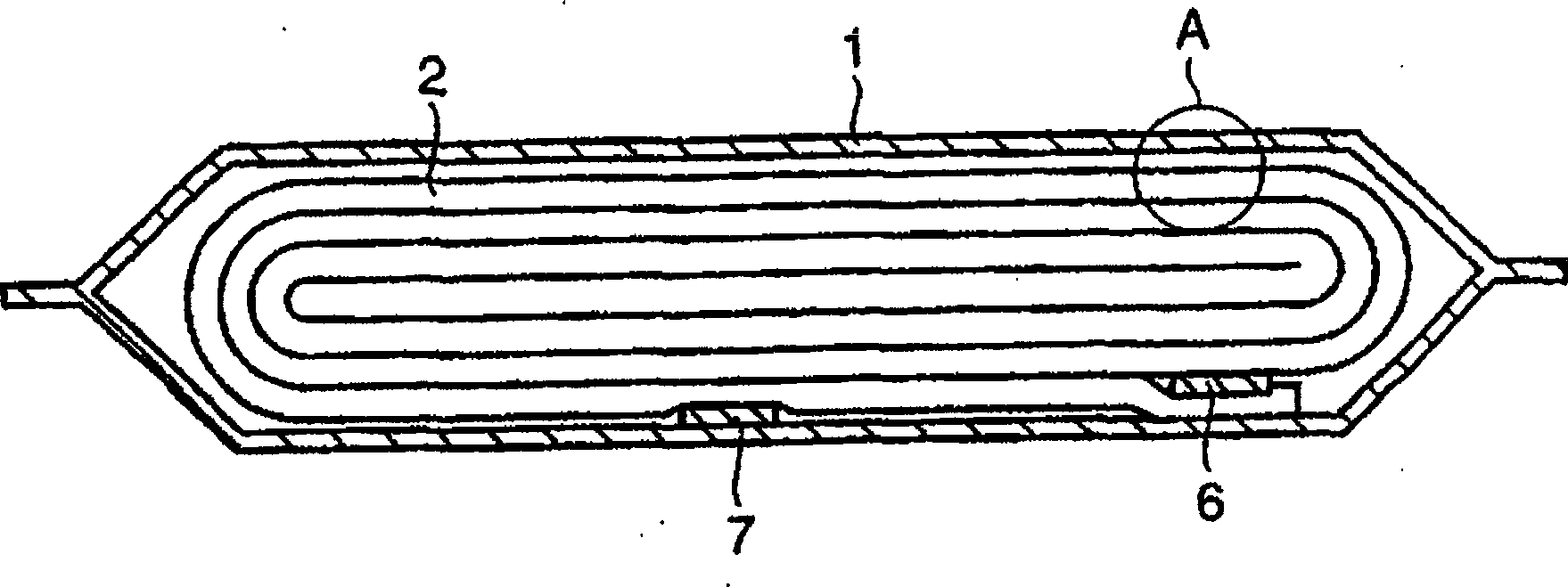

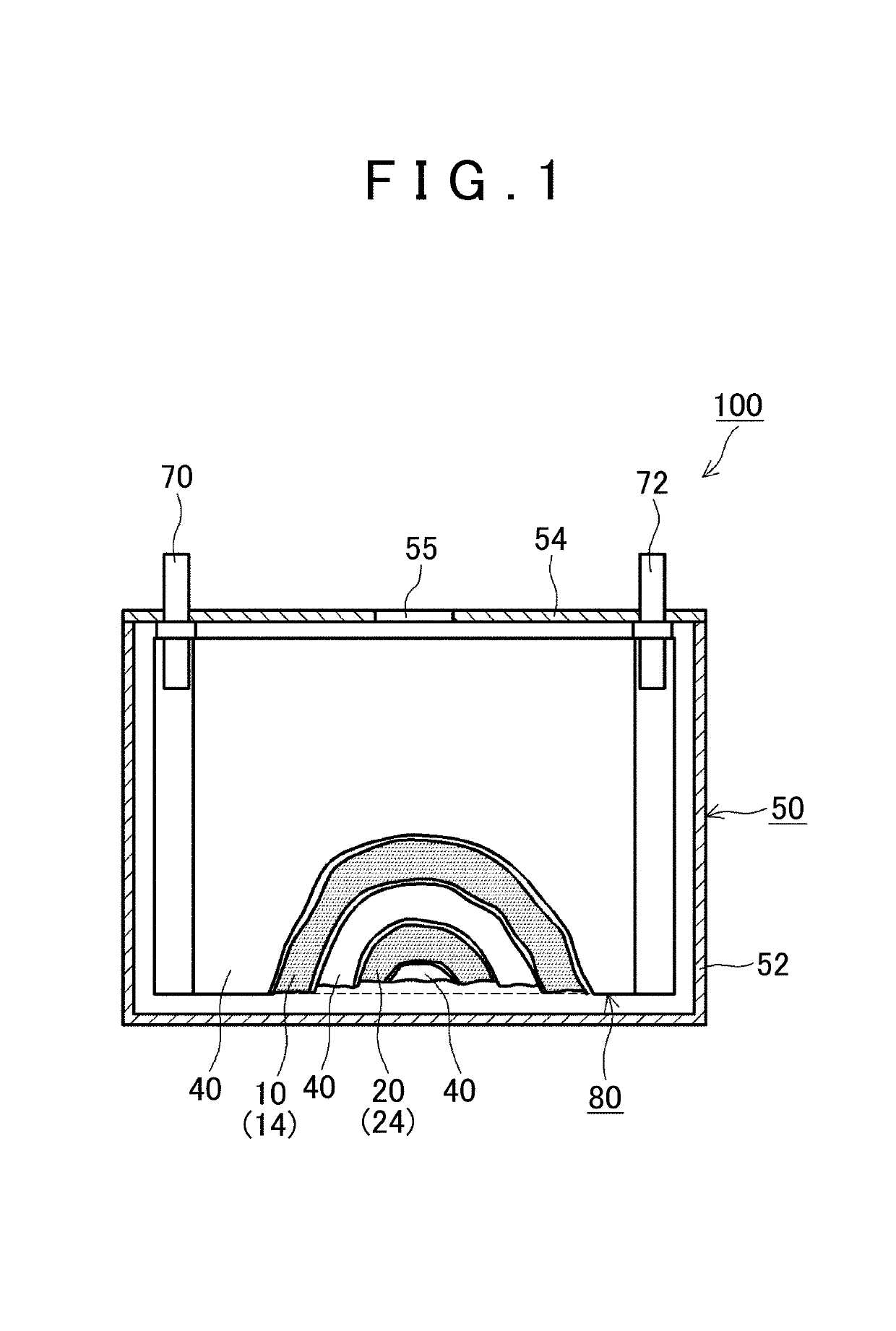

Energy storage device, energy storage device module, and electric car using the same

InactiveUS20050260497A1Excellent input and output characteristicsImprove featuresHybrid vehiclesAuxillary drivesLithiumReaction layer

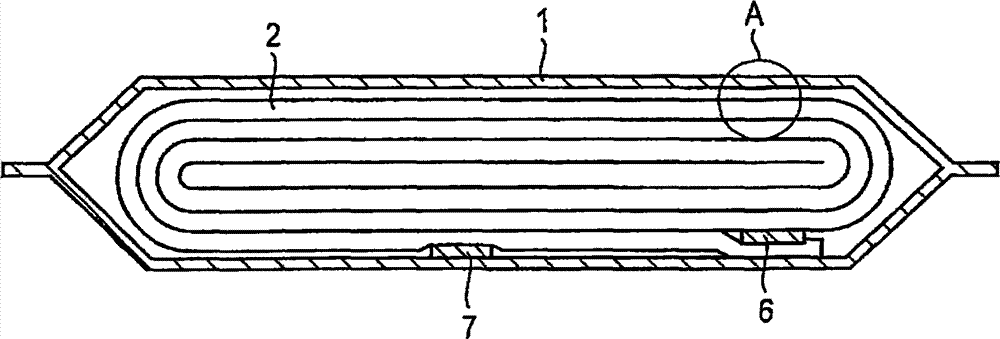

An energy storage device comprising a negative electrode plate having a negative electrode active material layer of a carbonaceous composite material formed on a negative electrode collector, a positive electrode plate having a positive electrode active material layer capable of inserting and releasing lithium ions and a non-faradic reaction layer capable of accumulating and releasing electric charges upon physical adsorption-desorption of ions on the surface layer of the positive electrode active material layer and an insulator layer for electrically insulating the positive electrode plate from the negative electrode plate, the insulator layer being capable of permeating only mobile ions. The carbonaceous composite material comprises particles of graphite and / or amorphous carbon and activated charcoal, and the particles of the graphite and / or amorphous carbon and particles of the activated charcoal are united.

Owner:HITACHI LTD

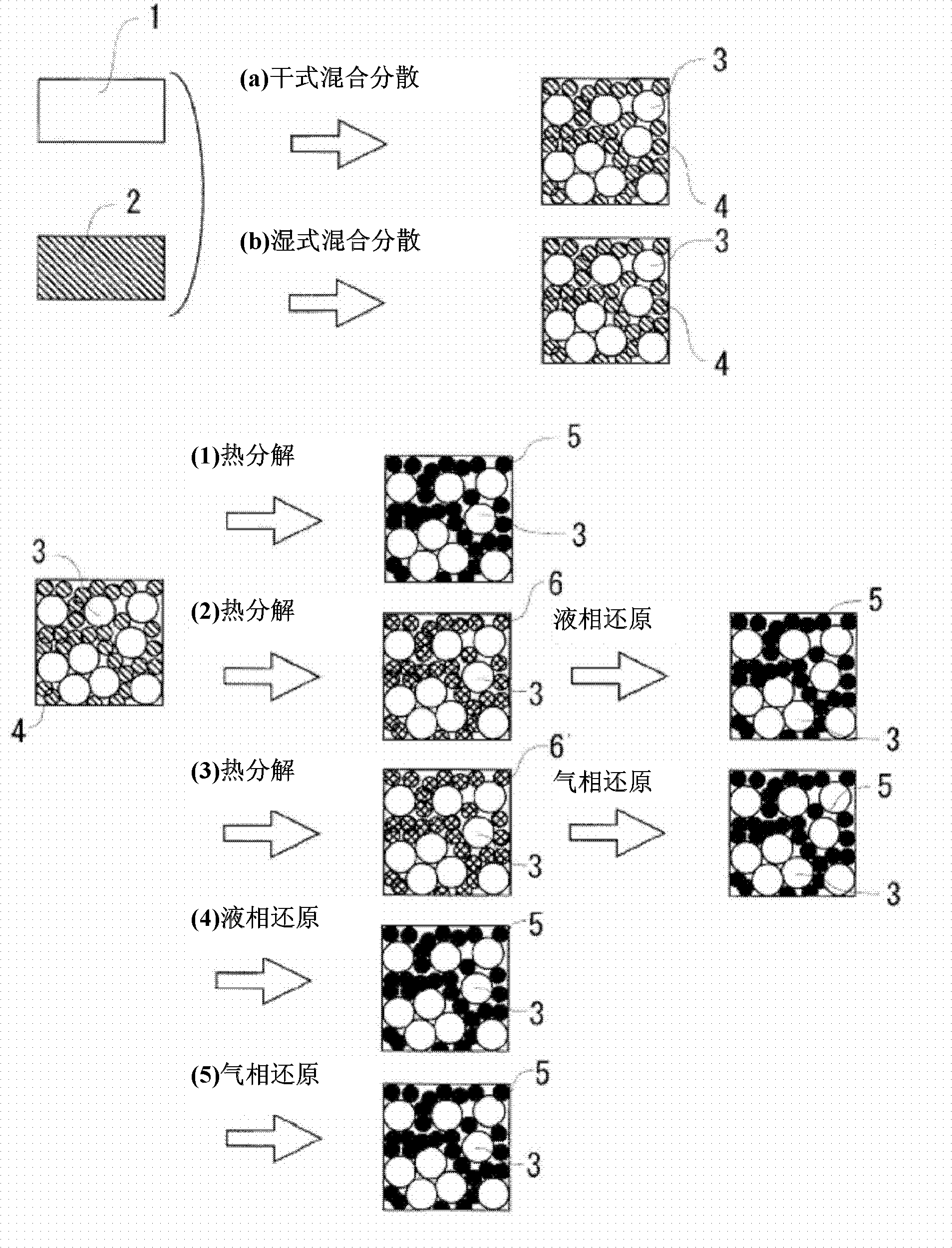

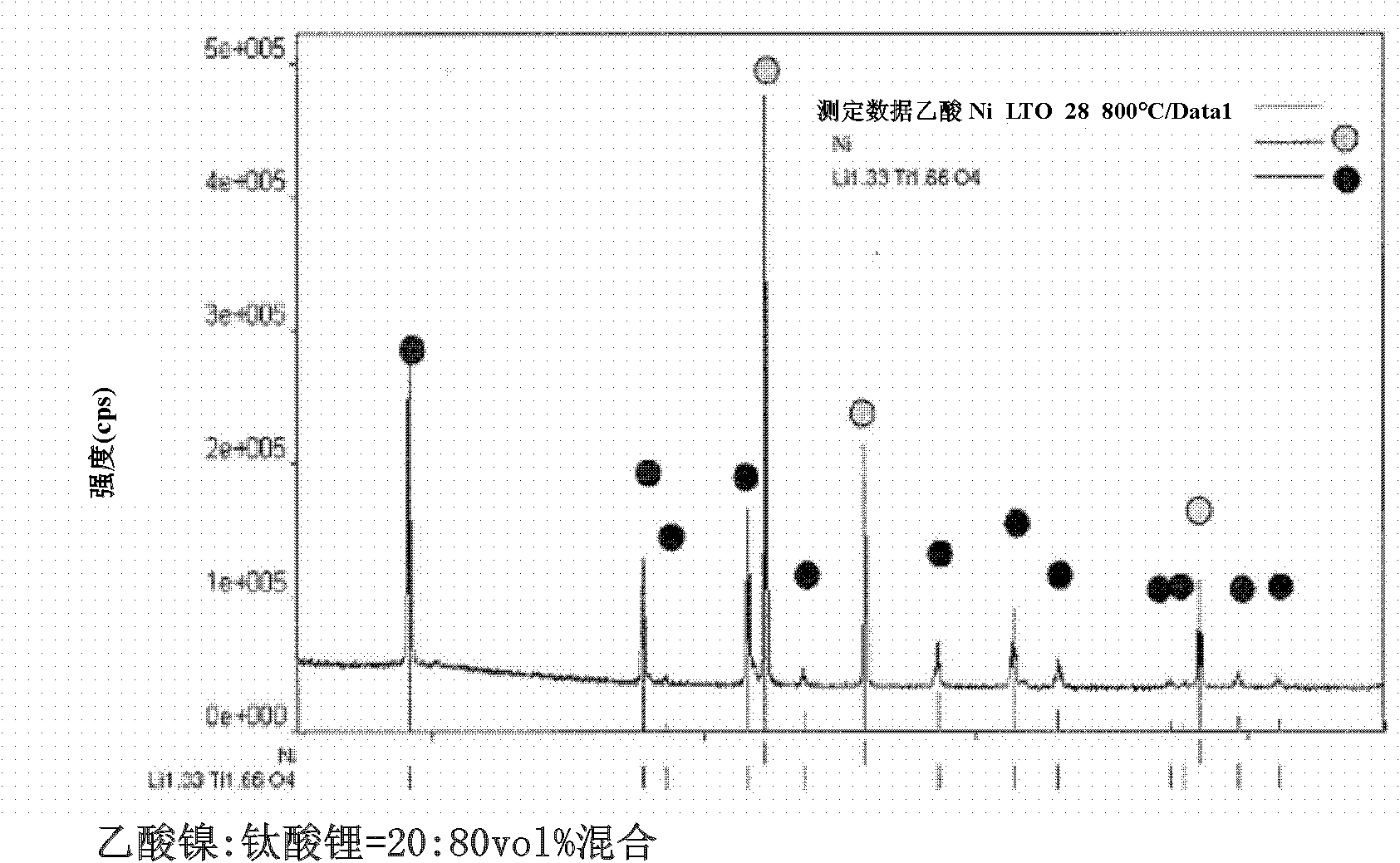

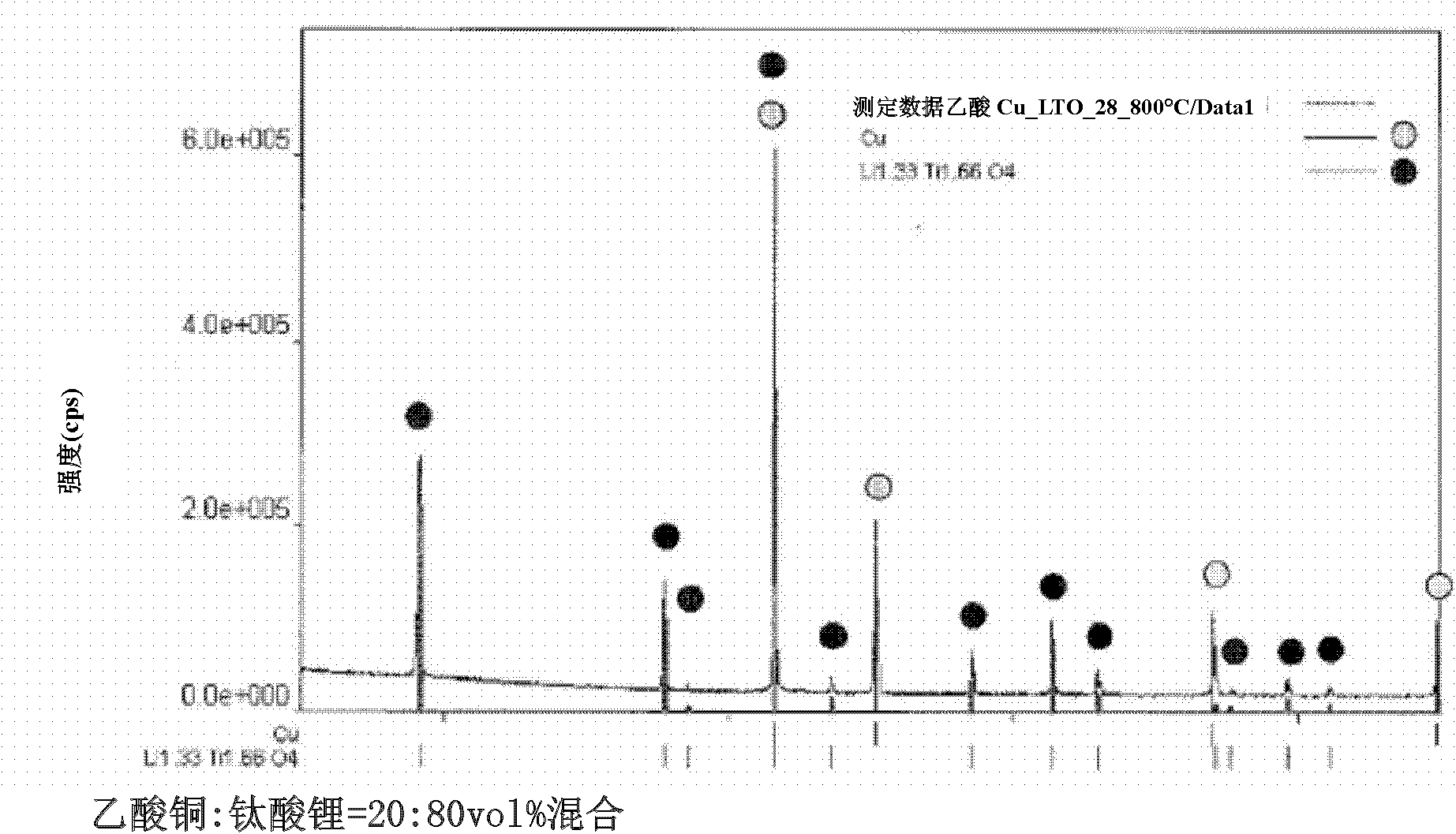

Electrode material, method for producing same, and lithium ion secondary battery

ActiveCN102388486AImprove conductivityLower internal resistanceElectrode thermal treatmentNon-aqueous electrolyte accumulator electrodesChemical reactionInternal resistance

Secondary batteries for automobiles require good input / output characteristics and low internal resistance. Although there is a conventional technique wherein the surface of an active material is coated with metal particles for the purpose of reducing the internal resistance of a battery, the technique cannot achieve remarkable effects on improvement in the conductivity of the active material or decrease in the internal resistance of the battery since an oxide film is formed on the metal particle surfaces. Disclosed is an electrode material which is produced by mixing and dispersing an active material and a metal source compound, and then depositing metal particles on the surface of the active material by thermal decomposition, vapor phase reduction, liquid phase reduction or a chemical reaction combining any of the thermal decomposition, vapor phase reduction and liquid phase reduction. Since an oxide film is not formed on the metal particles, an electrode material having high conductivity can be obtained. The electrode material can have significant effects on decrease in the internal resistance of a battery and improvement in the input / output characteristics of a battery.

Owner:NAMICS CORPORATION

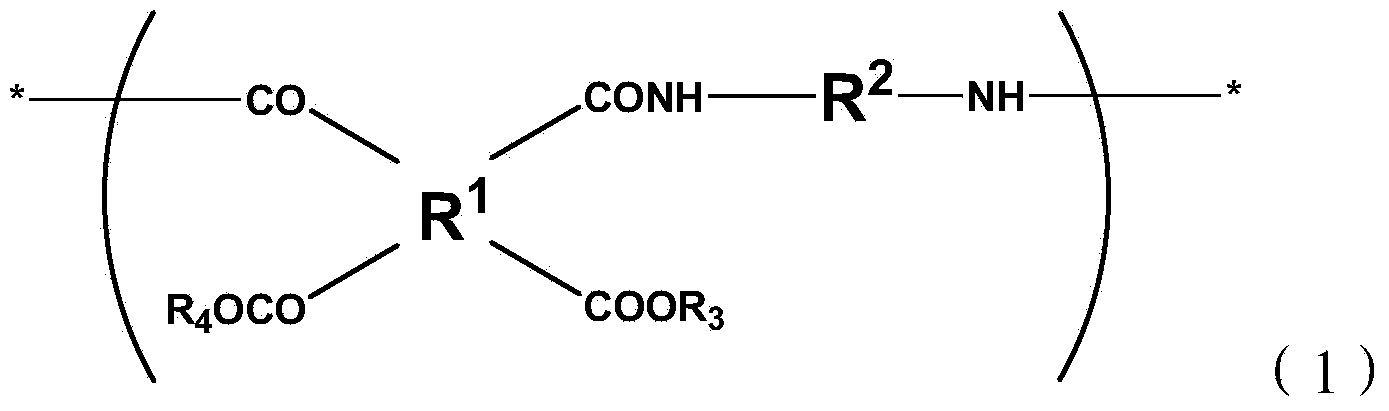

Resin composition for lithium ion cell positive electrode

ActiveCN104054200AExcellent charge and discharge characteristicsExcellent input and output characteristicsCell electrodesLi-accumulatorsLithiumCharge discharge

Disclosed is a resin composition for a lithium ion cell positive electrode that imparts strong adhesiveness and electrolyte injectability and shows good charge-discharge properties and input-output properties. The resin composition for a lithium ion cell positive electrode is a resin composition for a lithium ion cell positive electrode comprising a polyimide precursor having an average thermal linear expansion coefficient under from 20 to 200 DEG C after imidation of 3 to 50 ppm and / or a polyimide having an average thermal linear expansion coefficient under from 20 to 200 DEG C of 3 to 50 ppm, as well as a positive electrode active substance, wherein the electrode active substance is one where the surface of a compound oxide comprising lithium is coated by a lithium ion conductor material.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Active material, nonaqueous electrolyte battery, battery pack and vehicle

ActiveCN107017386AExcellent input and output characteristicsMolybdeum compoundsTantalum compoundsTitanium nitrideTitanium carbide

According to one embodiment, there is provided an active material. The active material includes secondary particles. The secondary particles include first primary particles and second primary particles. The first primary particles include an orthorhombic Na-containing niobium-titanium composite oxide. The second primary particles include at least one selected from the group consisting of a carbon black, a graphite, a titanium nitride, a titanium carbide, a lithium titanate having a spinel structure, a titanium dioxide having an anatase structure, and a titanium dioxide having a rutile structure.

Owner:KK TOSHIBA

Non-aqueous electrolyte secondary battery and assembly thereof

ActiveUS20150311563A1Improve battery performanceExcellent high rate characteristicsOrganic electrolyte cellsSecondary cellsInorganic phosphateLithium metal

Provided is a non-aqueous electrolyte secondary battery combining excellent input / output performance with great durability (cycle characteristics) and an assembly thereof. The present invention provides a non-aqueous electrolyte secondary battery assembly. The positive electrode has a maximum operating voltage of 4.3 V or higher relative to lithium metal, comprising a positive electrode active material and an ion-conductive inorganic phosphate compound. The non-aqueous electrolyte solution comprises a supporting salt, an oxalatoborate-type compound, and a non-aqueous solvent. The non-aqueous solvent is formed of a non-fluorinated solvent. This invention also provides a non-aqueous electrolyte secondary battery obtained by charging the non-aqueous electrolyte secondary battery assembly.

Owner:TOYOTA JIDOSHA KK

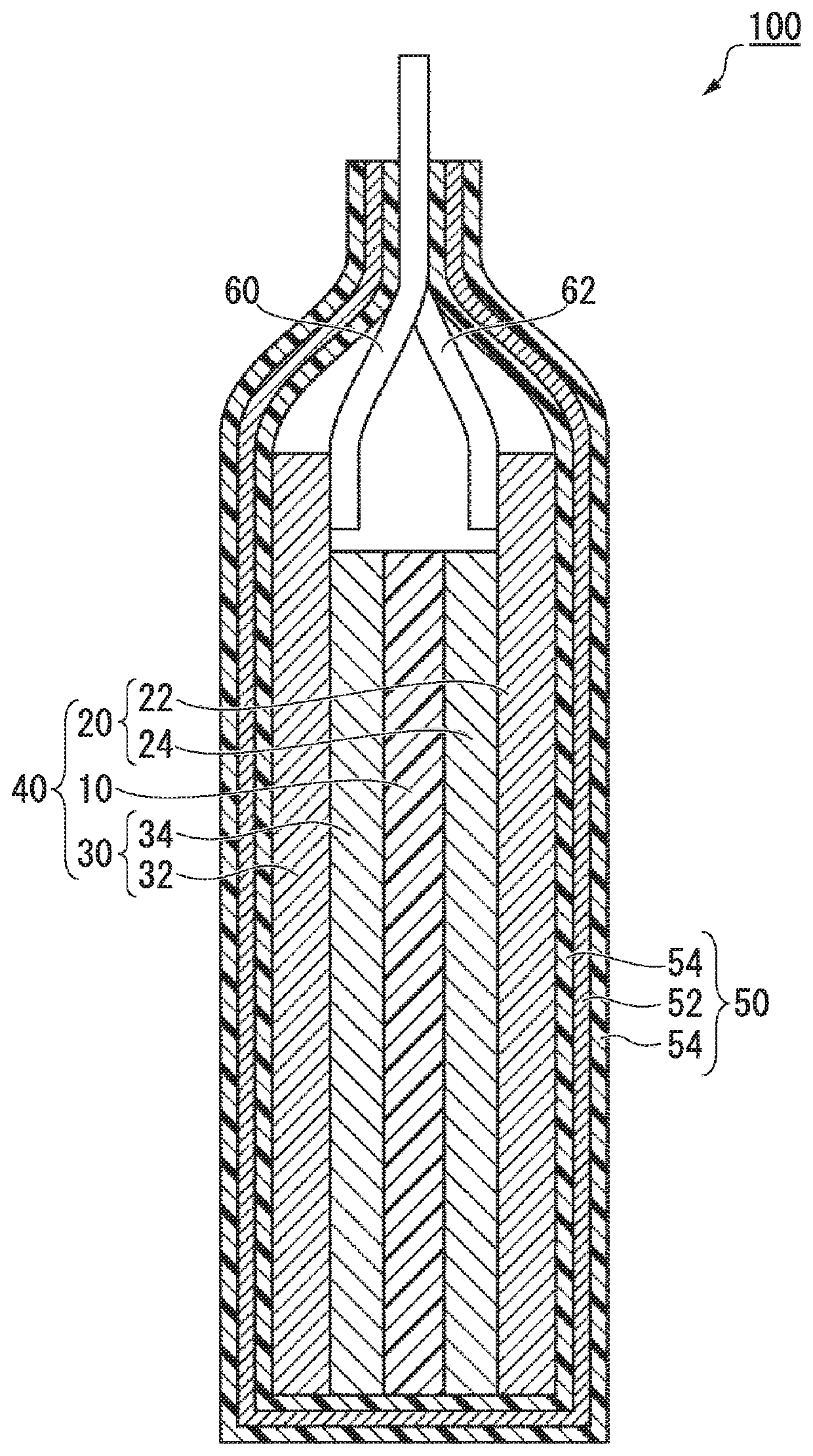

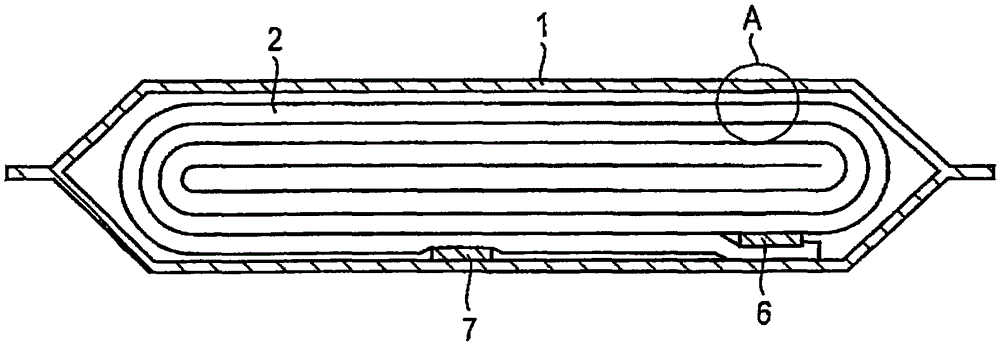

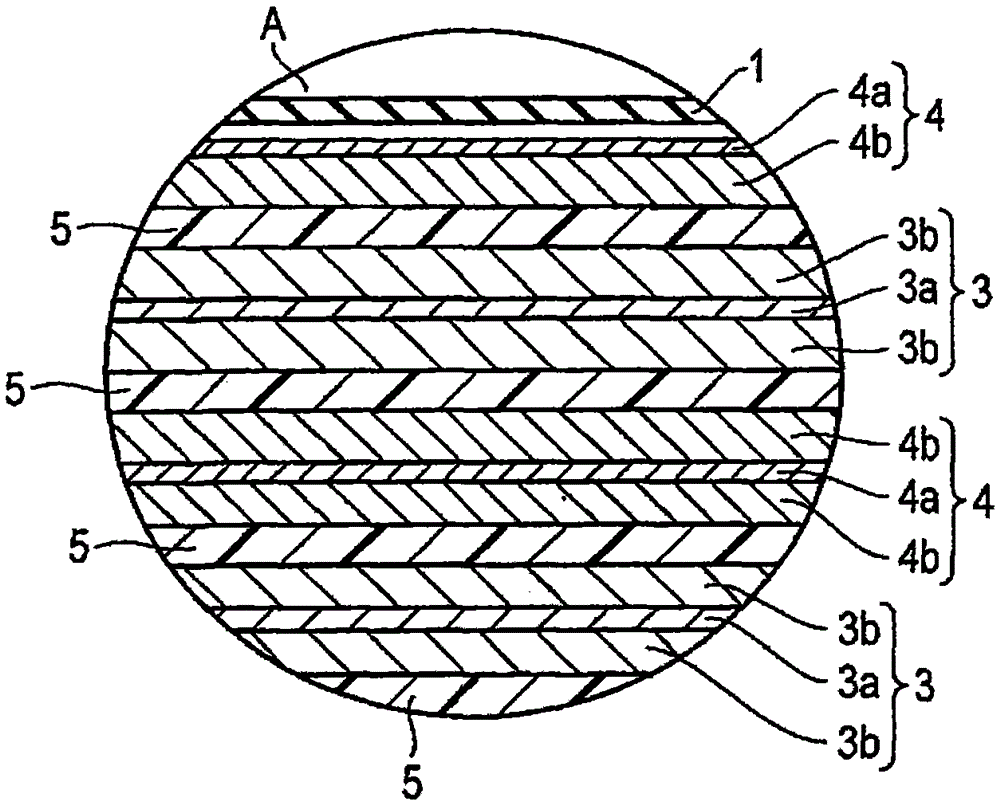

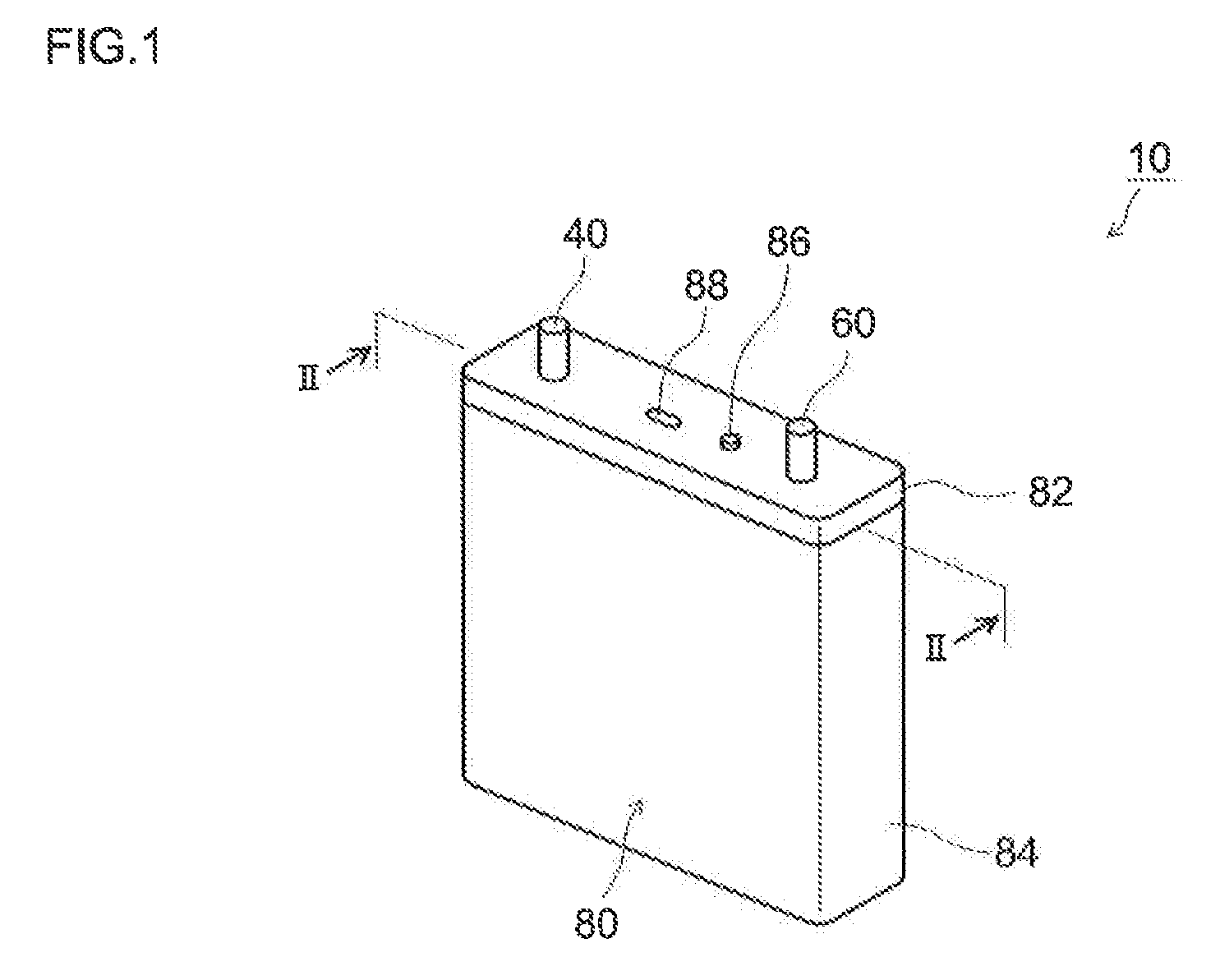

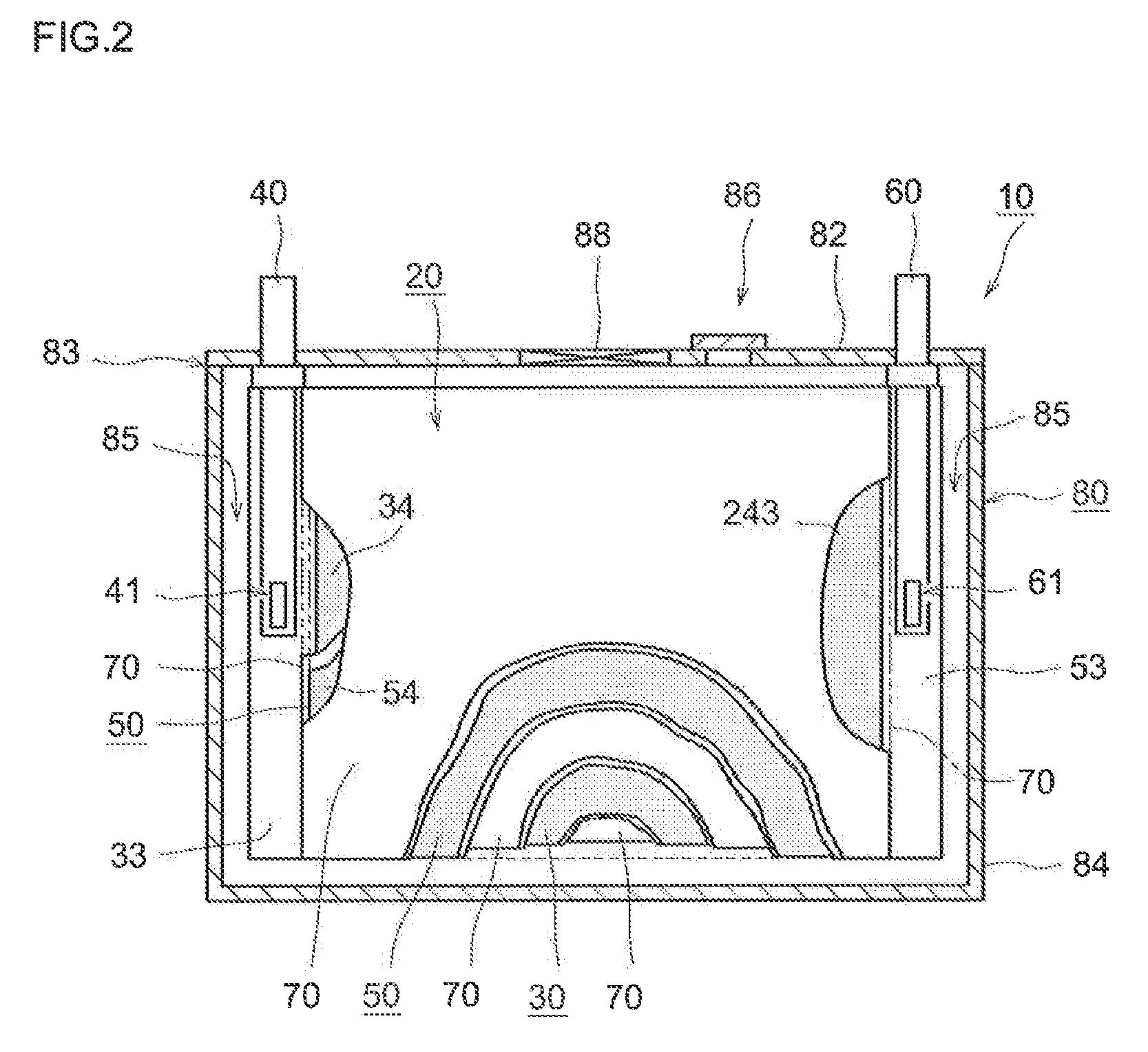

Lithium secondary battery

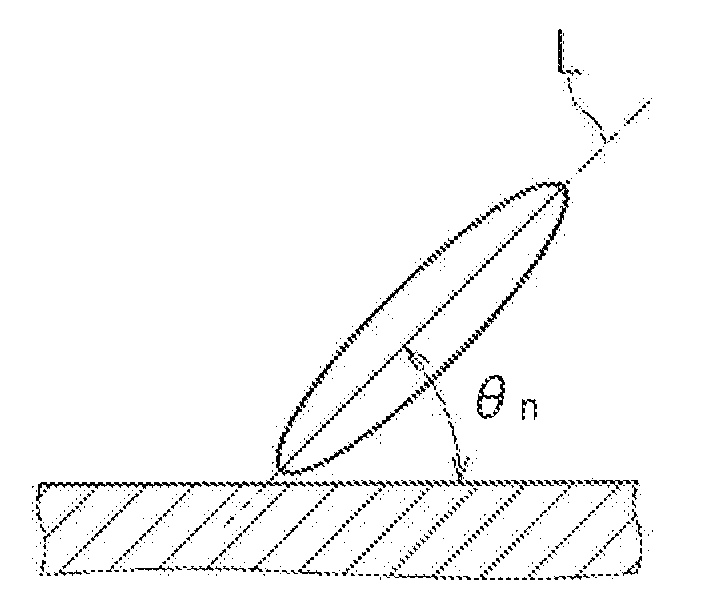

ActiveUS20140349189A1Reduce resistanceHigh rate characteristicsFinal product manufactureSecondary cellsGraphiteEngineering

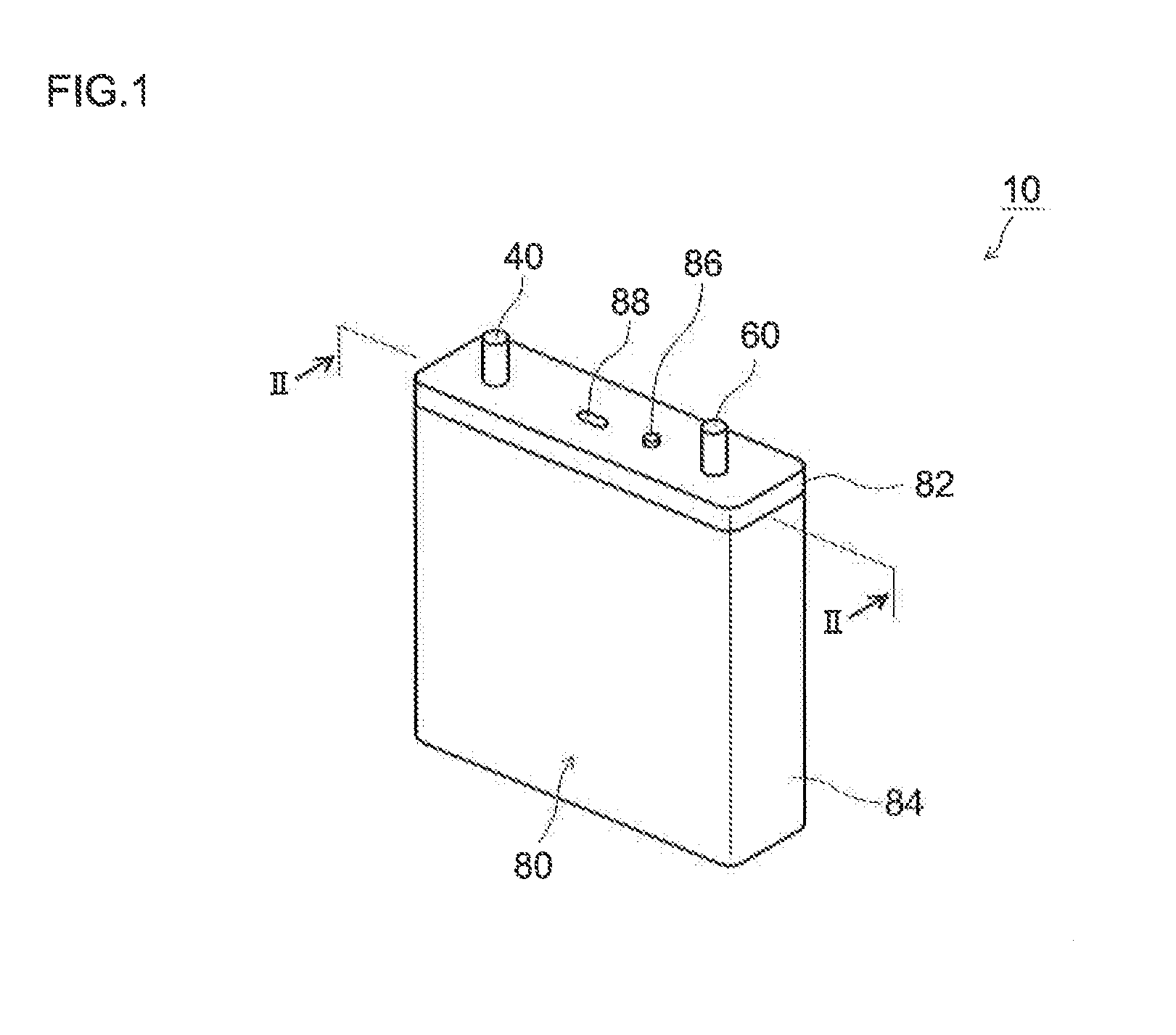

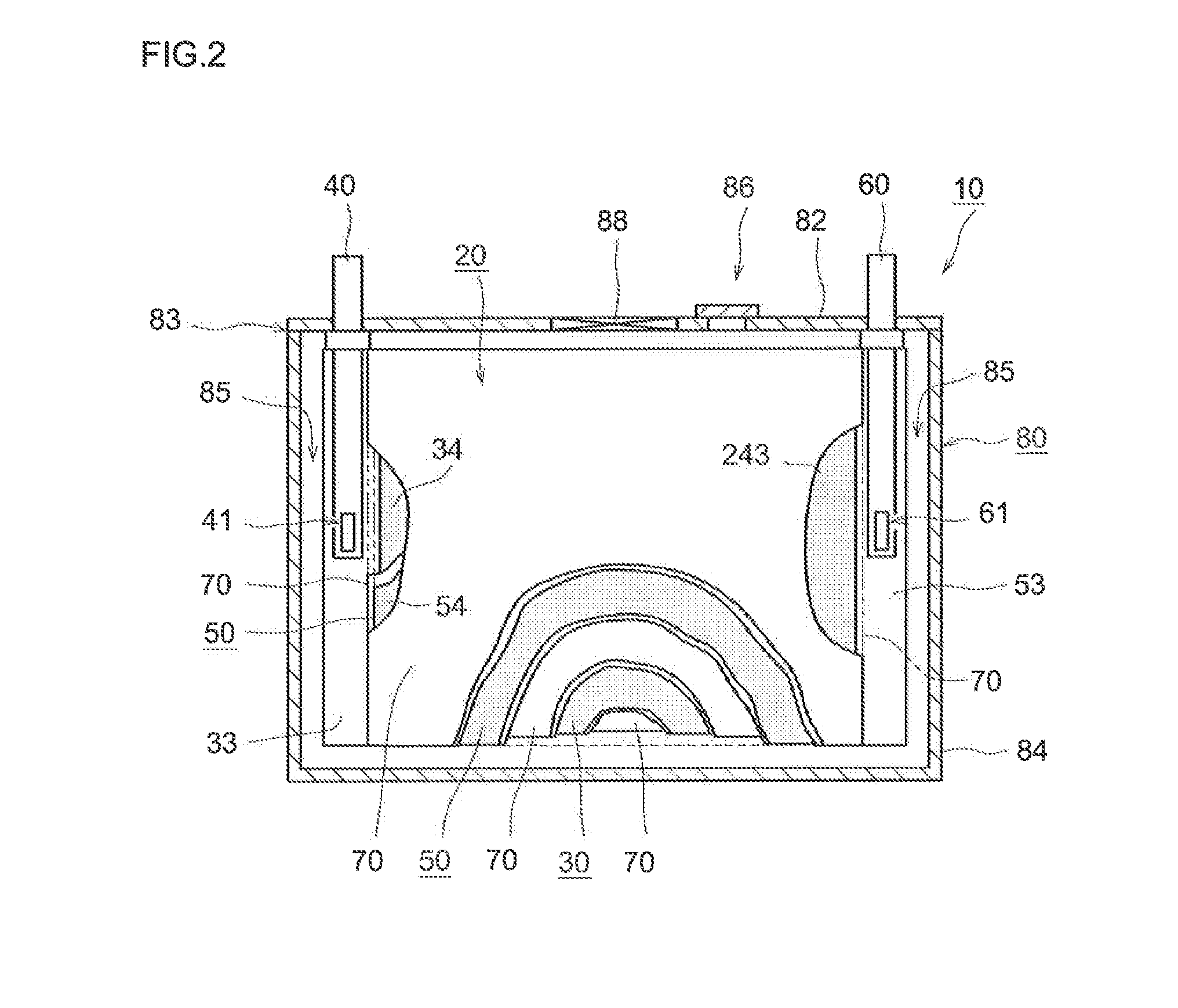

A lithium secondary battery 10 of the present invention is a secondary battery provided with a positive electrode 30 having a positive electrode active material layer 34 on a positive electrode collector 32, and a negative electrode 50 having a negative electrode active material layer 54 on a negative electrode collector 52. The positive electrode active material layer 34 contains a positive electrode active material capable of reversibly storing and releasing lithium ions. The negative electrode active material layer 54 contains a negative electrode active material made up of lamellar graphite that is bent so as to have an average number of bends f per particle of 0<f≦3, and an average aspect ratio of 1.8 or higher. In a cross-section perpendicular to the surface of the negative electrode collector 52, the negative electrode active material is oriented in such a manner that the perpendicularity defined as n2 / n1, is 1 or greater, n1 being the number of negative electrode active material units such that 0°≦θn≦30°, and n2 being the number of negative electrode active material units such that 60°≦θn≦90°, where θn is the angle formed by a major axis of the negative electrode active material units with respect to the surface of the negative electrode collector 52.

Owner:TOYOTA JIDOSHA KK

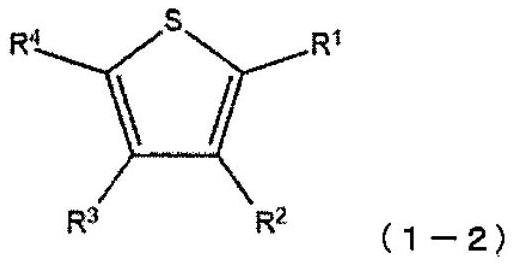

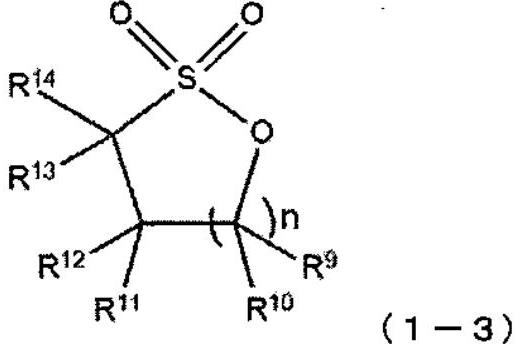

Nonaqueous secondary battery

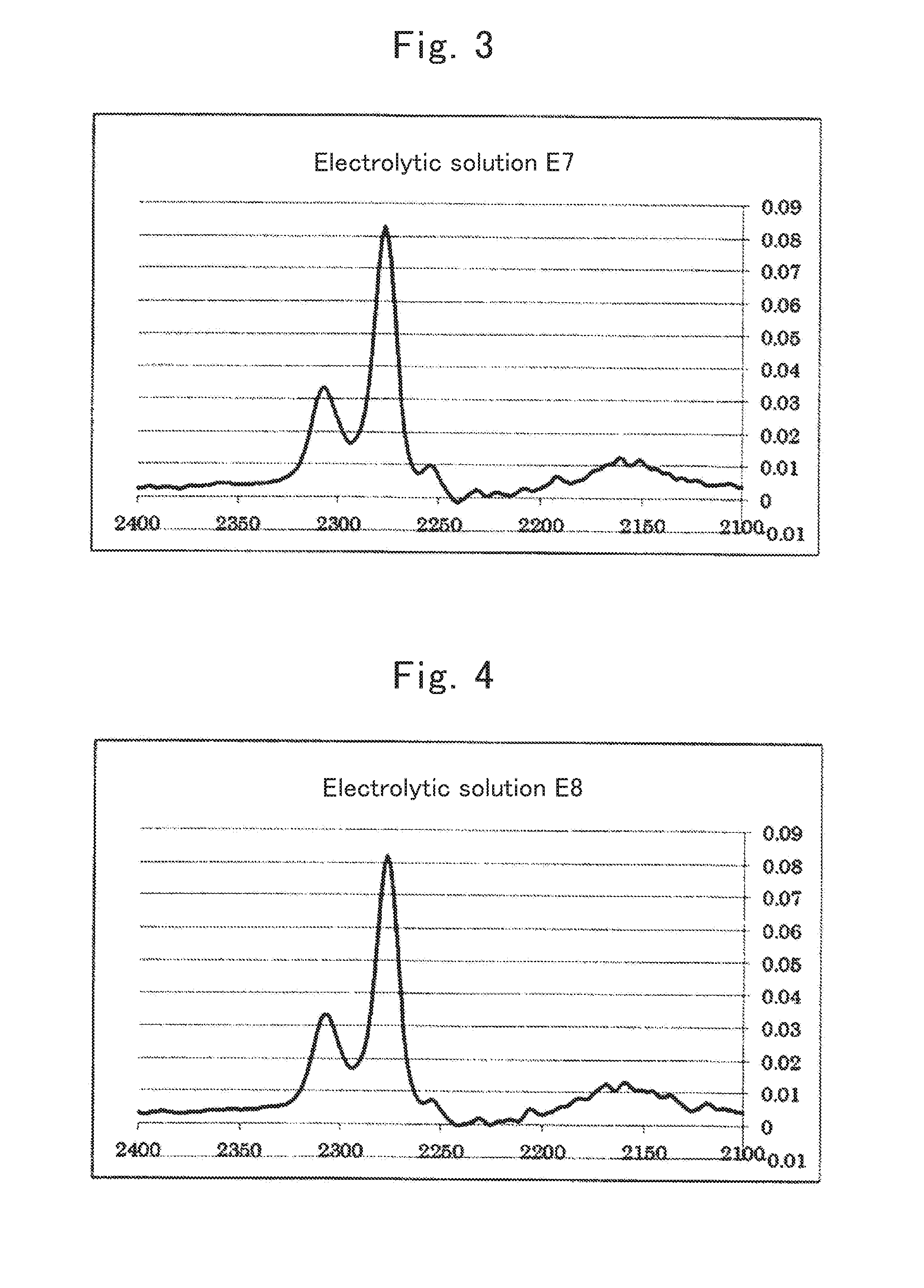

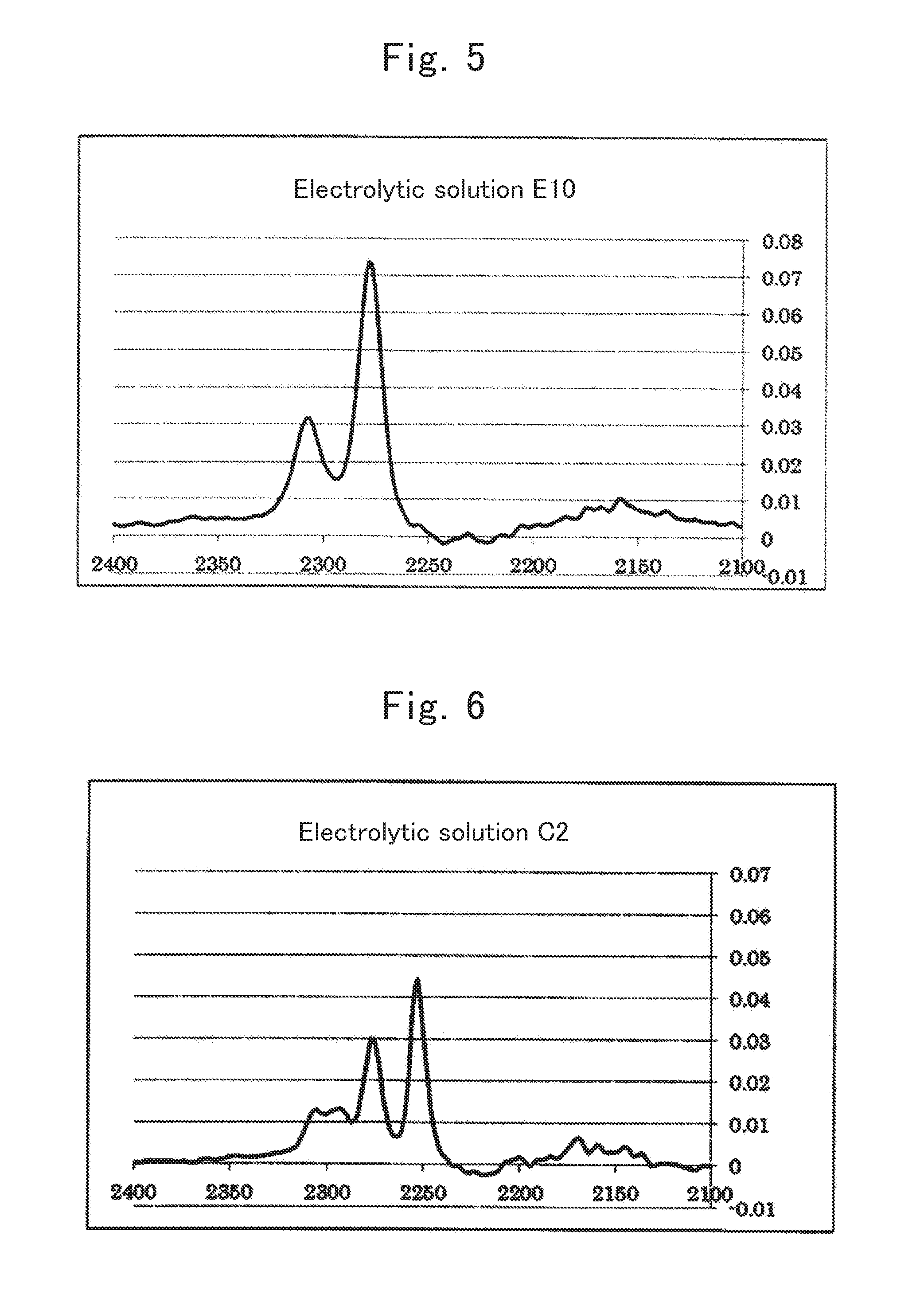

InactiveUS20160218390A1Excellent input and output characteristicsImprove securityPositive electrodesLi-accumulatorsElectrolytic agentAlkaline earth metal

A positive electrode of a nonaqueous secondary battery has a positive electrode active material including at least one selected from lithium metal complex oxides having a layered rock salt structure, lithium metal complex oxides having a spinel structure, and polyanion based materials. The electrolytic solution contains a metal salt whose cation is an alkali metal, an alkaline earth metal, or aluminum, and an organic solvent having a heteroelement. Regarding an intensity of a peak derived from the organic solvent in a vibrational spectroscopy spectrum of the electrolytic solution, when an intensity of an original peak of the organic solvent is represented as Io and an intensity of a peak resulting from shifting of the original peak is represented as Is; Is>Io is satisfied. The nonaqueous secondary battery may have a usage maximum potential of the positive electrode of not lower than 4.5 V when Li / Li+ is used for reference potential.

Owner:THE UNIV OF TOKYO

Electrode, nonaqueous electrolyte battery, and battery pack

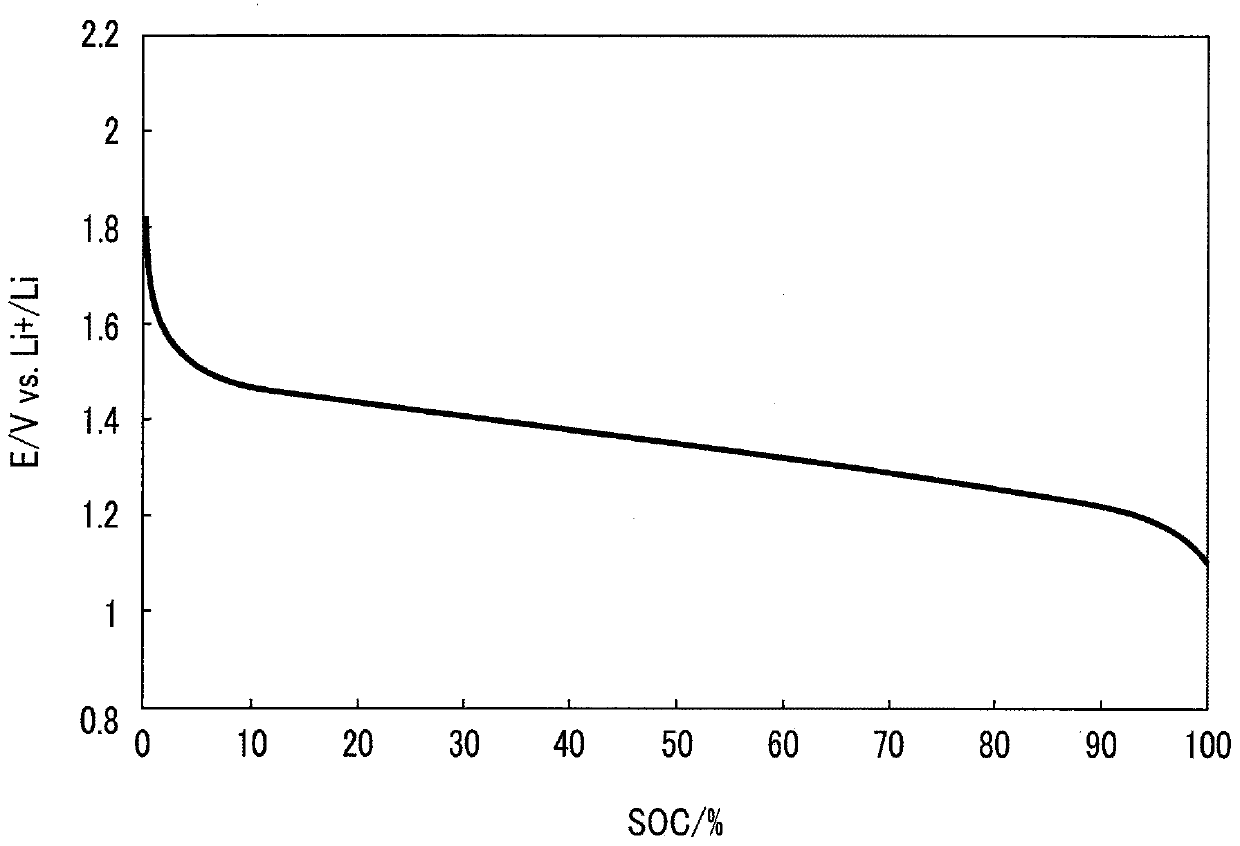

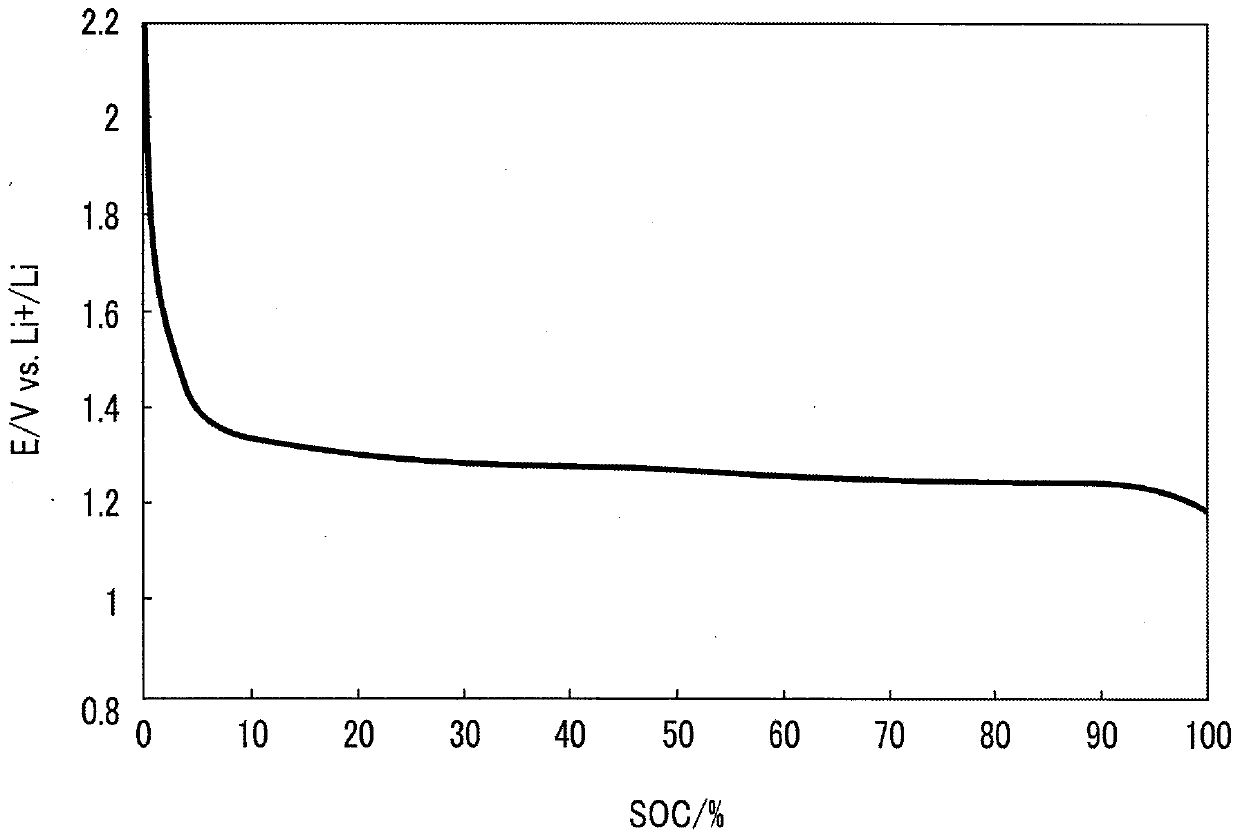

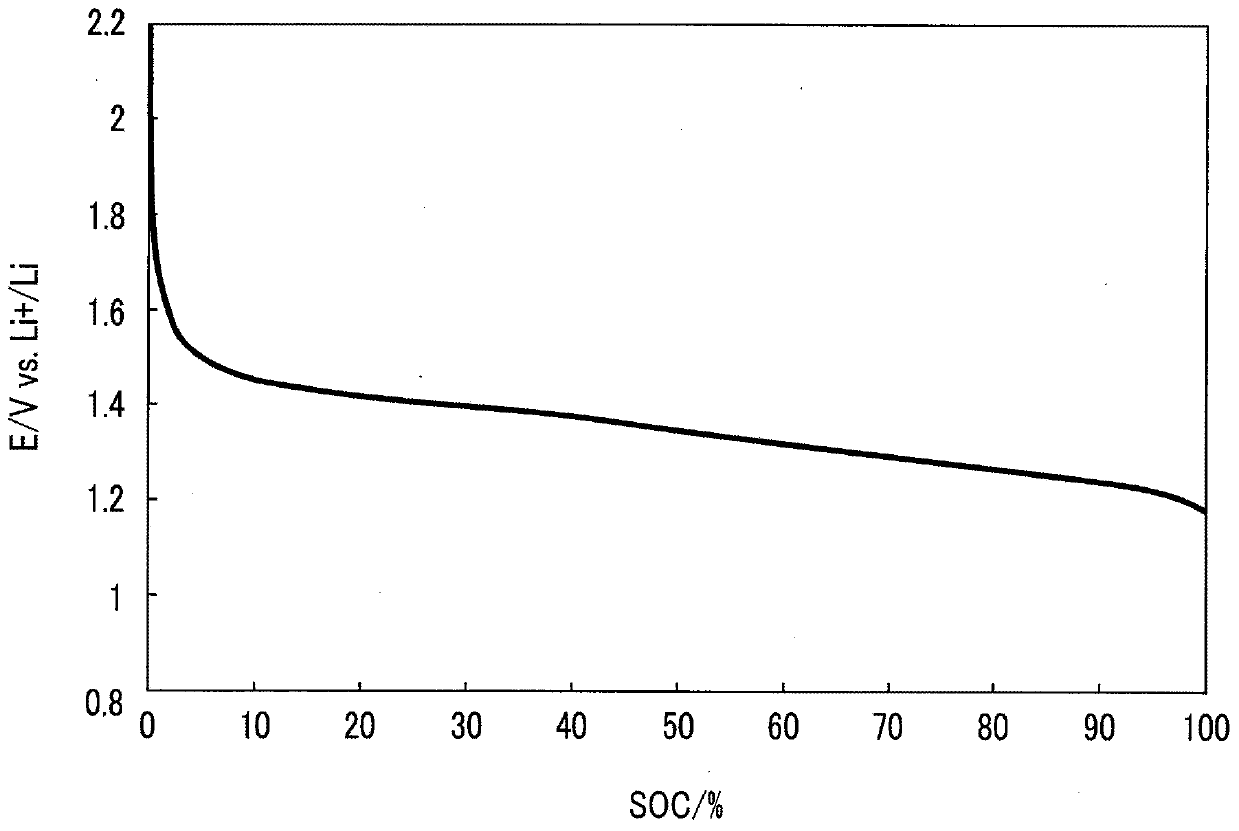

ActiveCN103117376AExcellent input and output characteristicsCell electrodesSmall-sized cells cases/jacketsLithiumGram

According to one embodiment, an electrode includes a current collector, an active material-containing layer, a first peak, a second peak and a pore volume. The active material-containing layer contains an active material having a lithium absorption potential of 0.4 V (vs. Li / Li+) or more. The first peak has a mode diameter of 0.01 to 0.1 mum in a diameter distribution of pores detected by mercury porosimetry. The second peak has a mode diameter of 0.2 mum (exclusive) to 1 mum (inclusive) in the diameter distribution of pores. The pore volume detected by the mercury porosimetry is within a range of 0.1 to 0.3 mL per gram of a weight of the electrode excluding a weight of the current collector.

Owner:KK TOSHIBA

Positive electrode for lithium ion battery, method for producing same, and lithium ion battery using the positive electrode

ActiveCN102449818AGood reliability and durabilityExcellent input and output characteristicsPositive electrodesElectrode collector coatingTotal thicknessLithium carbonate

Disclosed are: a positive electrode which contains lithium-containing nickel oxide as a positive electrode active material and has excellent input / output characteristics, excellent durability and excellent reliability; and a lithium ion battery which uses the positive electrode. The positive electrode comprises a positive electrode collector and a positive electrode active material layer that is formed on the surface of the positive electrode collector. The positive electrode active material layer contains a lithium-containing nickel oxide represented by general formula (1): LixNi1-(p+q+r)CopAlqMrO2+y (wherein M represents a transition element (excluding Ni and Co) or the like; and 0.8 = x = 1.4 and 0 < (p + q + r) = 0.7) and lithium carbonate, and has a high lithium carbonate concentration region and a low lithium carbonate concentration region. The high concentration region occupies 2-80% of the total thickness of the positive electrode active material layer from the surface thereof, while the low concentration region occupies the rest on the positive electrode collector side.

Owner:PANASONIC CORP

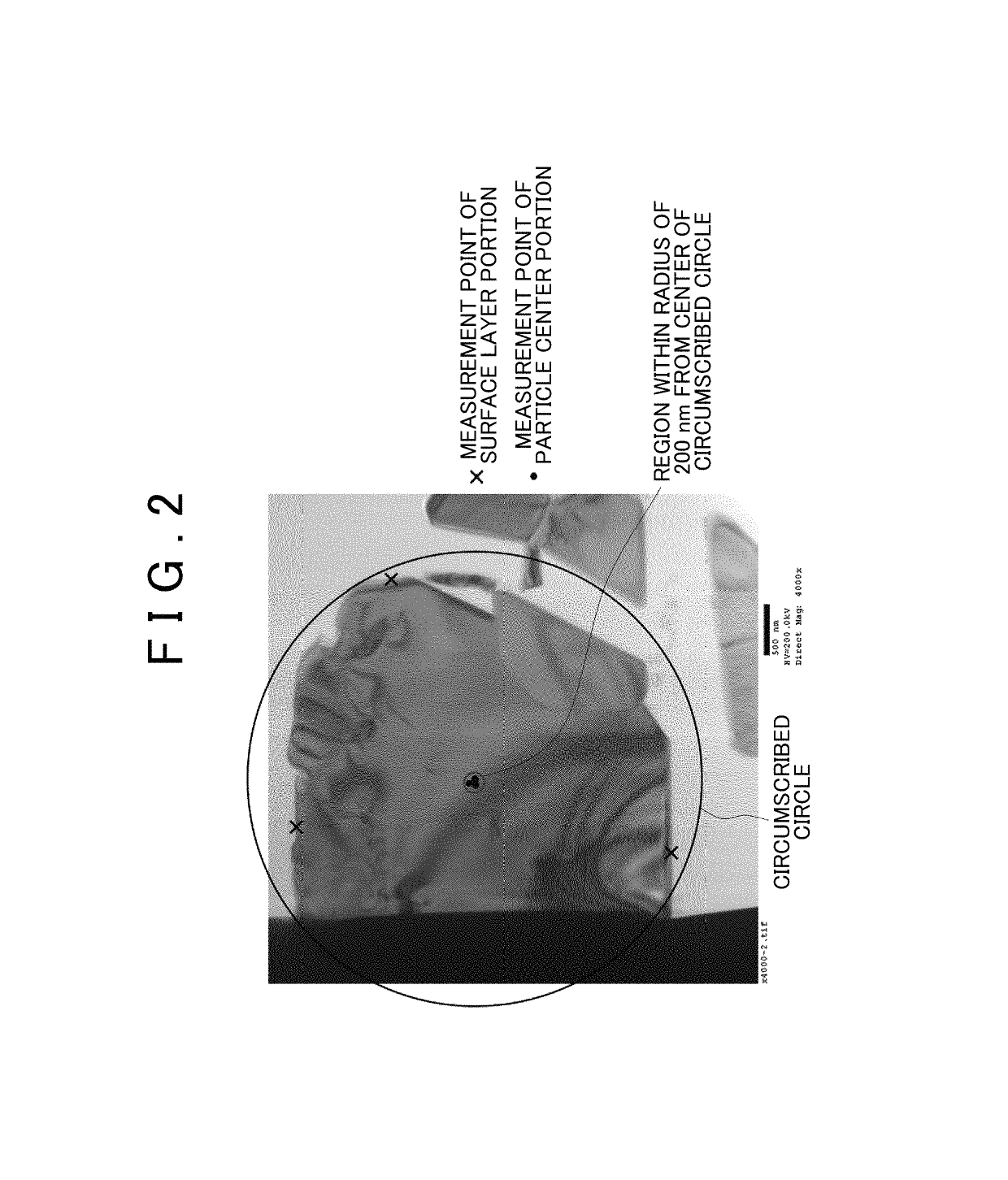

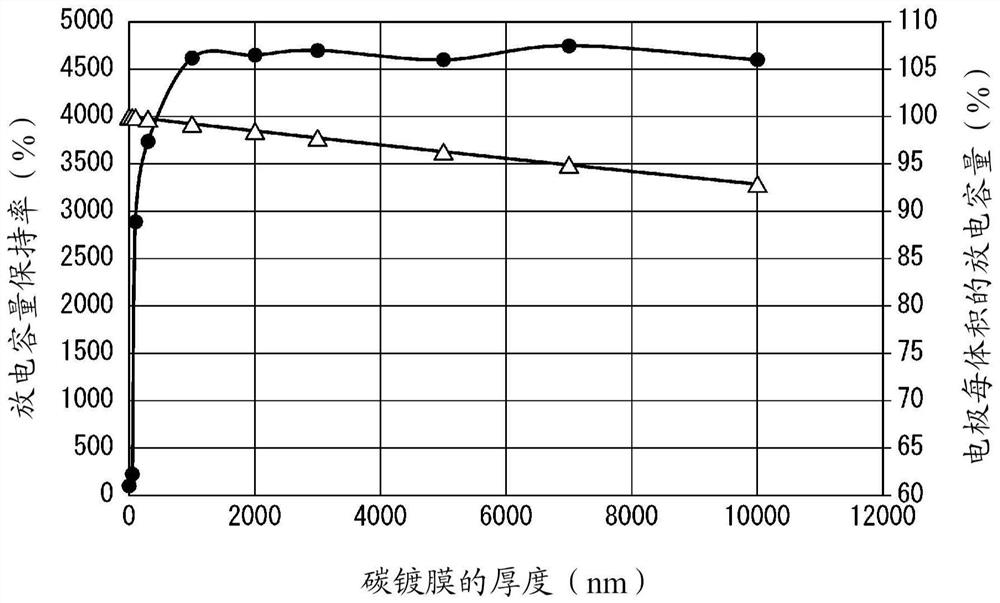

Cathode material for lithium-ion secondary battery, cathode for lithium-ion secondary battery, and lithium-ion secondary battery

ActiveUS10109861B2Reduce reduction reactionExcellent input and output characteristicsPositive electrodesLi-accumulatorsPeak intensityCarbonaceous film

A cathode material for a lithium-ion secondary battery of the present invention includes central particles represented by LixAyMzPO4 and a carbonaceous film that coats surfaces of the central particles, an average value of R values (I1580 / I1360), which are ratios of a peak intensity (I1580) of a spectrum at a frequency band of 1,580±50 cm−1 to a peak intensity (I1360) of the spectrum at a frequency band of 1,360±50 cm−1 in a Raman spectrum analysis, measured at five points is 0.80 or more and 1.10 or less, and a standard deviation of the R values measured at five points is 0.010 or less.

Owner:SUMITOMO METAL MINING CO LTD

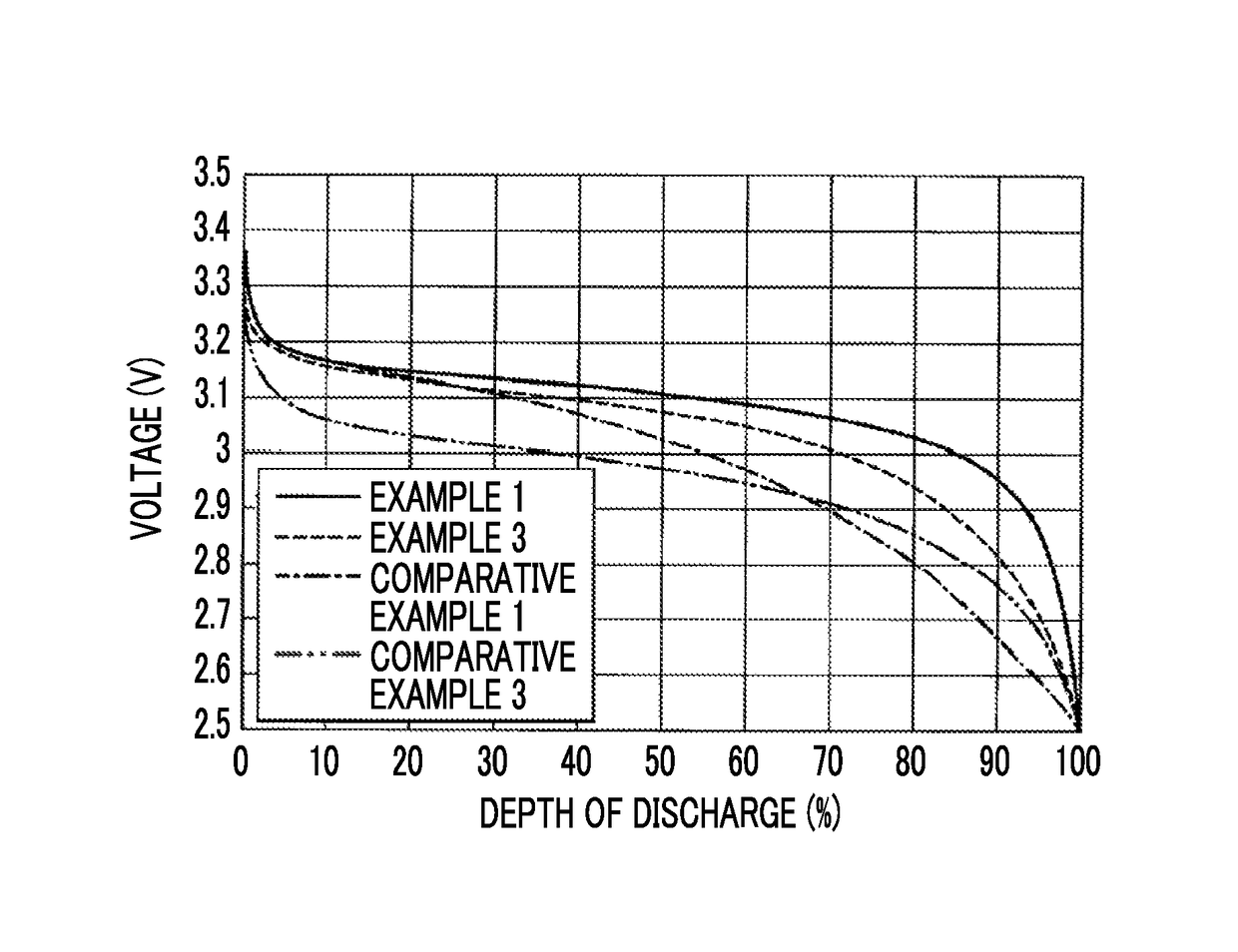

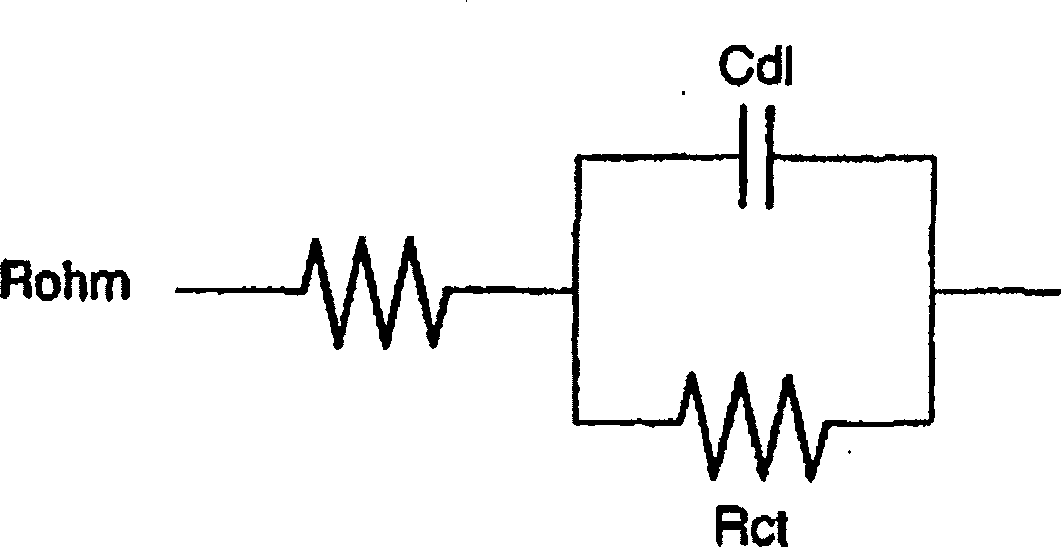

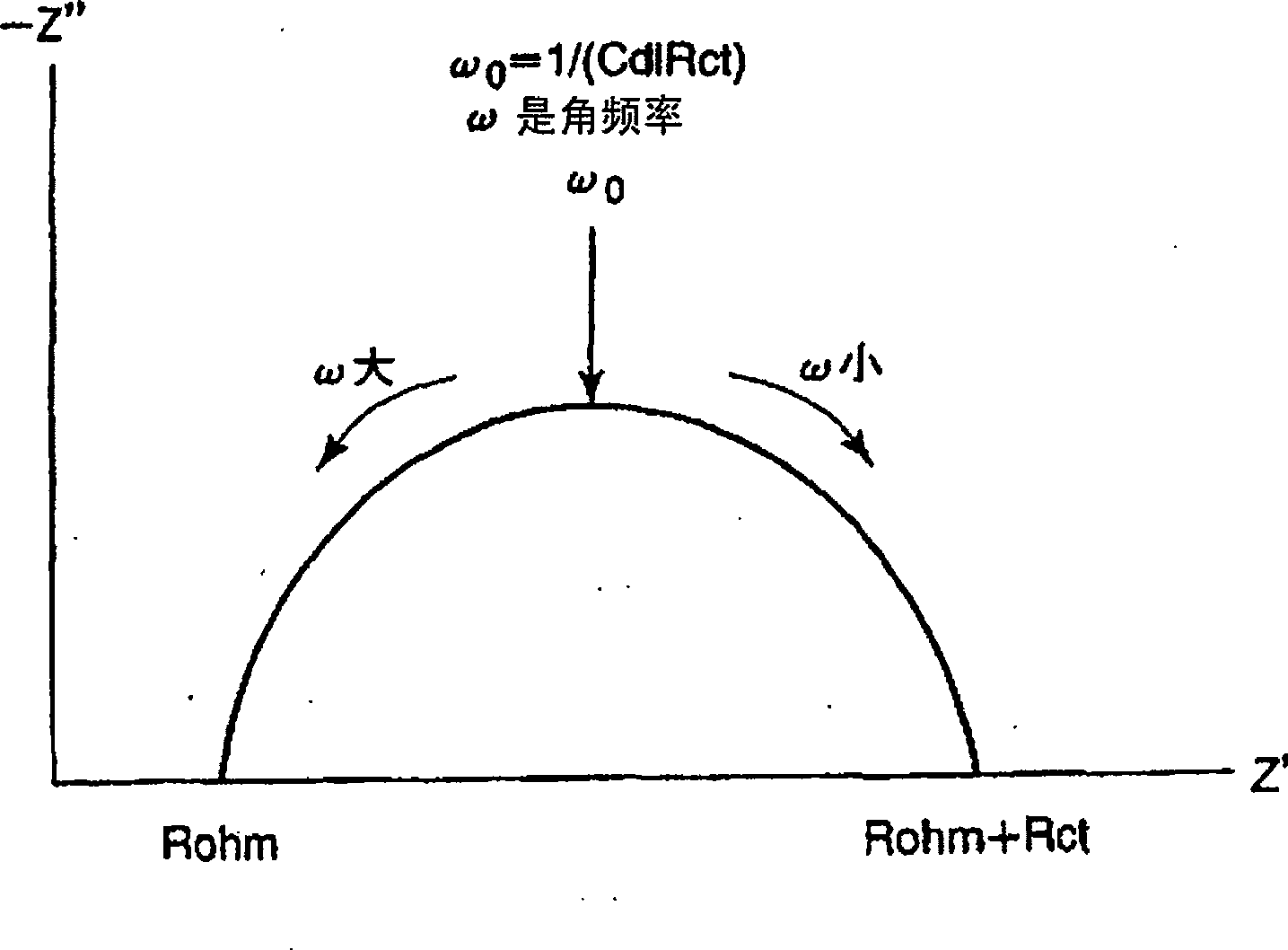

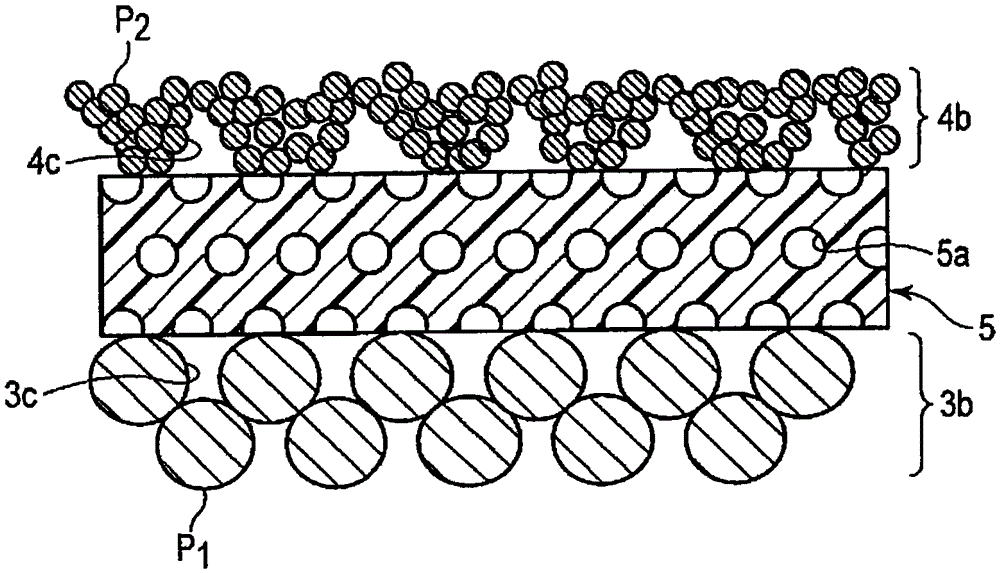

Non-aqueous electrolyte battery, battery pack and vehicle

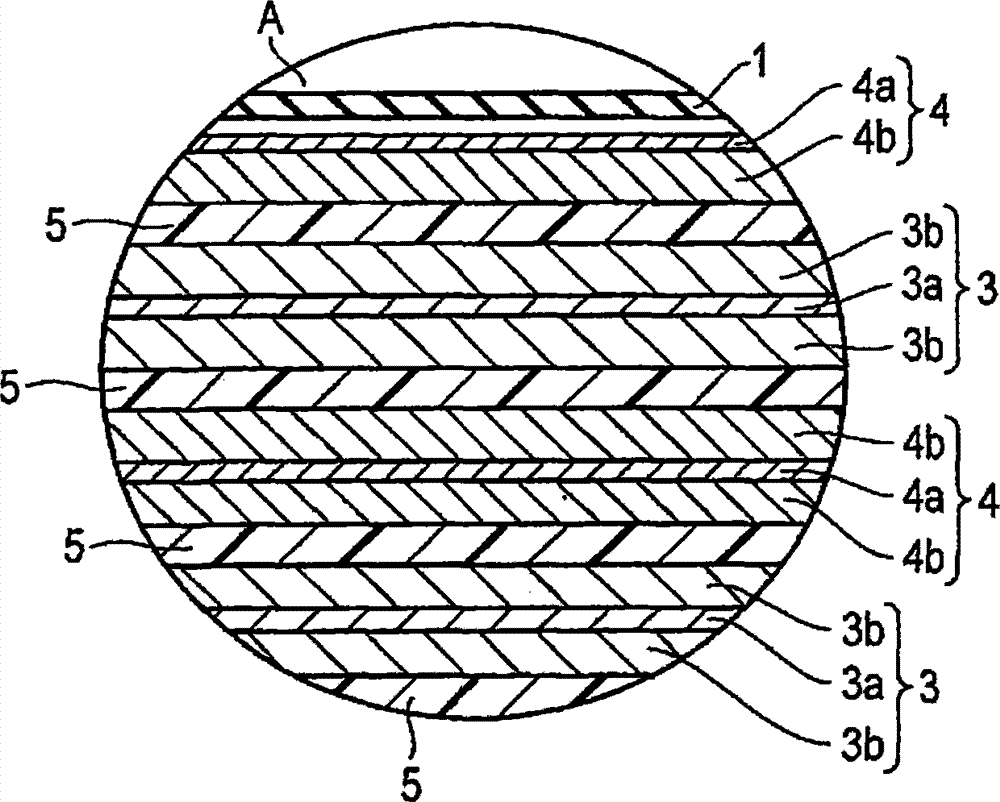

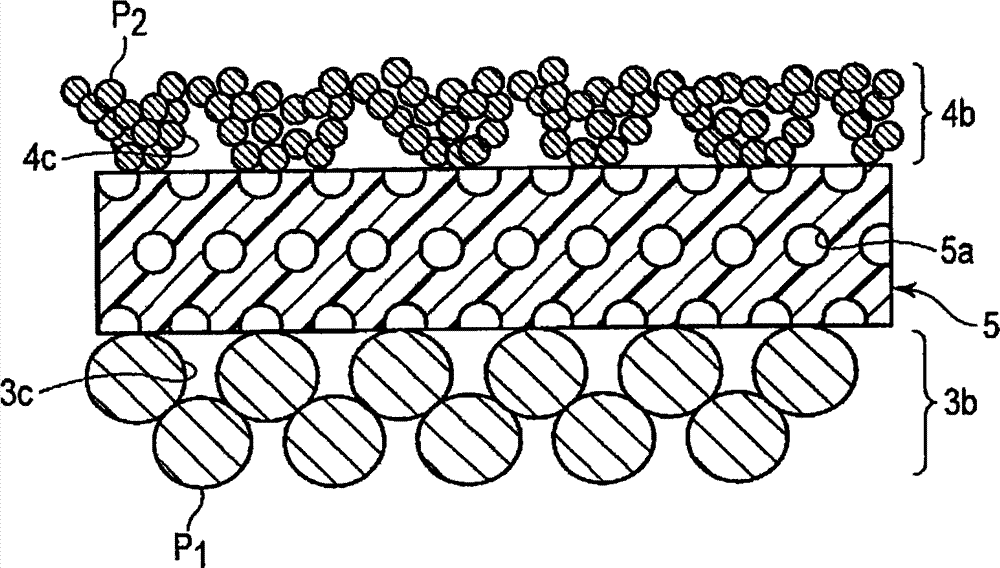

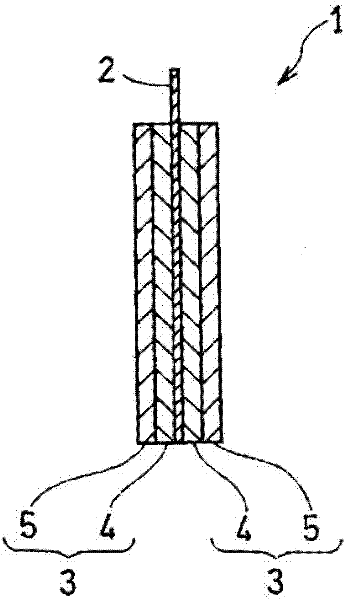

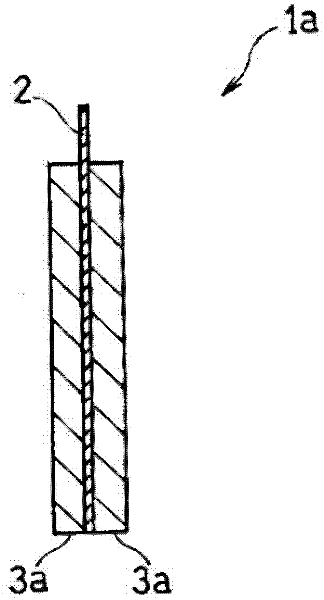

ActiveCN100524937CExcellent input and output characteristicsFinal product manufactureElectrode carriers/collectorsElectrical batteryEngineering

The present invention provides a non-aqueous electrolyte battery having excellent input-output characteristics at a large current, a battery pack including the non-aqueous electrolyte battery, and an automobile. The non-aqueous electrolyte battery comprises: a positive electrode (3); a negative electrode (4), the negative electrode comprising a negative electrode active material with a Li insertion potential greater than or equal to 0.4V (vs. Li / Li+); configured on the positive electrode (3) and the negative electrode The diaphragm (5) between (4) has a porosity greater than or equal to 50% as measured by the mercury intrusion method, and the median diameter of the voids measured by the mercury intrusion method is larger than the mode diameter, and the above-mentioned a surface roughness of the negative electrode larger than the above-mentioned mode diameter; and a nonaqueous electrolyte.

Owner:KK TOSHIBA

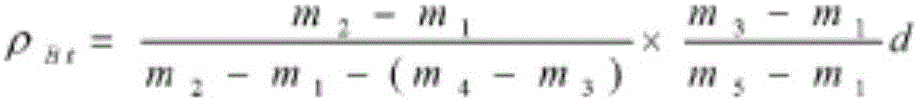

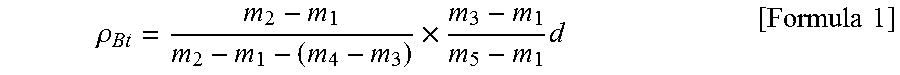

Carbonaceous material for negative electrode of nonaqueous-electrolyte secondary battery, negative electrode for nonaqueous-electrolyte secondary battery, nonaqueous-electrolyte secondary battery, and vehicle

InactiveCN106133964AExcellent input and output characteristicsImprove featuresHybrid capacitor electrodesSecondary cellsLithiumHydrogen

The purpose of this invention is to provide, among other things, a carbonaceous material for a negative electrode of a nonaqueous-electrolyte secondary battery, said carbonaceous material having a high volumetric energy density and excellent cycle characteristics. This negative-electrode material for a nonaqueous-electrolyte secondary battery comprises, as an active material, a carbon-material mixture that contains a plurality of non-graphitic carbon materials. The true density (rouBt) of said carbon-material mixture, as determined using a butanol method, is between 1.60 and 2.05 g / cm<3>, inclusive; the atomic ratio of hydrogen to carbon (H / C) in the carbon-material mixture, as per elemental analysis, is no more than 0.10; and the discharge capacity of the carbon-material mixture at 0 to 0.1 V relative to a lithium reference electrode is between 80 and 230 mAh / g, inclusive.

Owner:KUREHA KAGAKU KOGYO KK

Cathode material for lithium-ion secondary battery, cathode for lithium-ion secondary battery, and lithium-ion secondary battery

ActiveUS20180097230A1Reduce reduction reactionExcellent input and output characteristicsPositive electrodesLi-accumulatorsLithiumPeak intensity

A cathode material for a lithium-ion secondary battery of the present invention includes central particles represented by LixAyMzPO4 and a carbonaceous film that coats surfaces of the central particles, an average value of R values (I1580 / I1360), which are ratios of a peak intensity (I1580) of a spectrum at a frequency band of 1,580±50 cm−1 to a peak intensity (I1360) of the spectrum at a frequency band of 1,360±50 cm−1 in a Raman spectrum analysis, measured at five points is 0.80 or more and 1.10 or less, and a standard deviation of the R values measured at five points is 0.010 or less.

Owner:SUMITOMO METAL MINING CO LTD

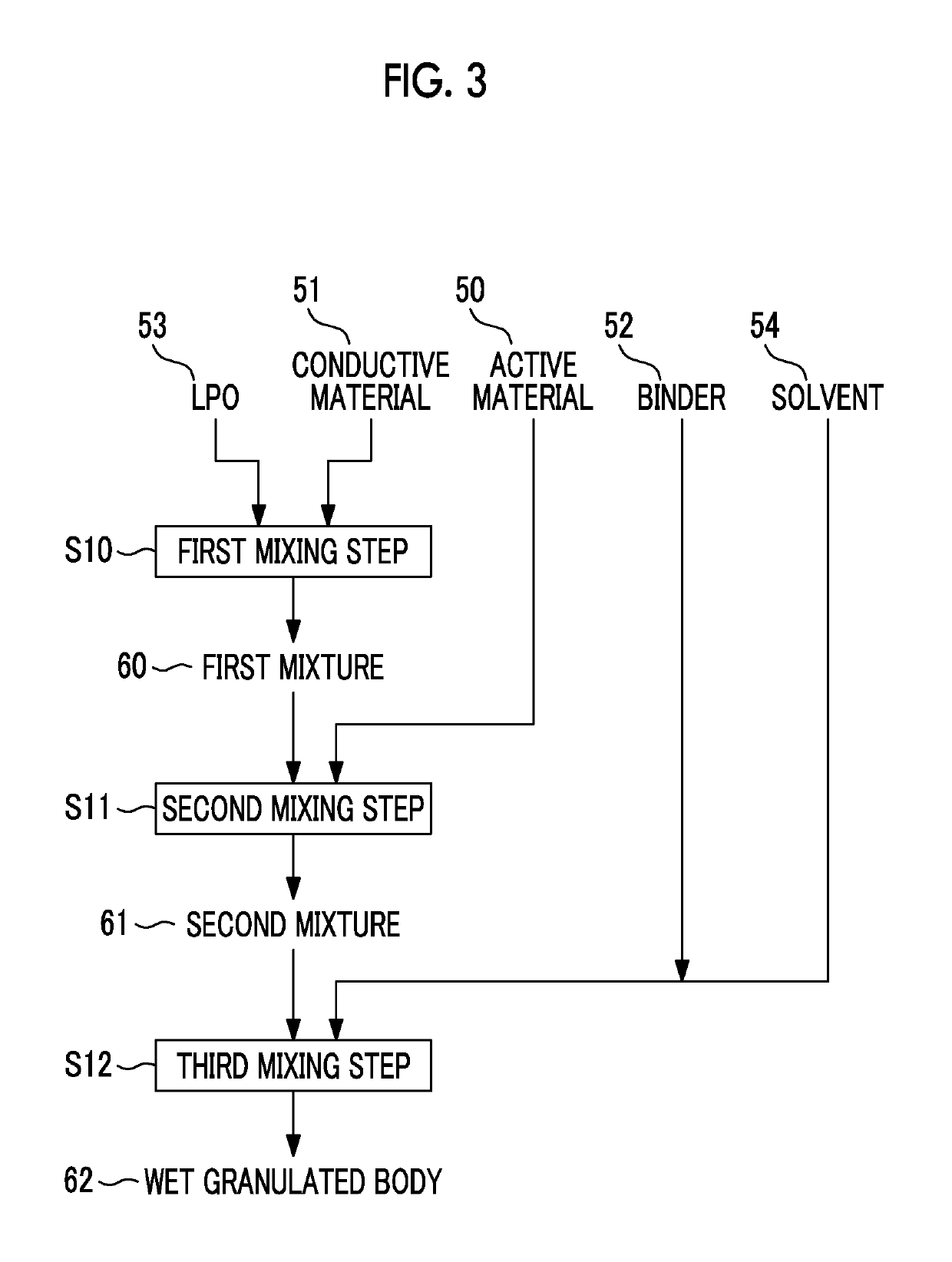

Method of manufacturing lithium ion secondary battery

ActiveUS20170263918A1Easy inputImprove output characteristicsFinal product manufactureElectrode collector coatingLithiumPhosphate

A manufacturing method of a lithium ion secondary battery includes: forming a first mixture by mixing powder of a first electrode material, which is one of the active material and the conductive material, with powder of trilithium phosphate; forming a second mixture by mixing the first mixture with powder of a second electrode material which is the other one of the active material and the conductive material; forming a wet granulated body by mixing the second mixture with the binder and a solvent; and forming the active material layer by attaching the wet granulated body to the surface of the current collector foil.

Owner:TOYOTA JIDOSHA KK

Cathode material for lithium-ion secondary battery, cathode for lithium-ion secondary battery, and lithium-ion secondary battery

ActiveUS20190103611A1Reduce interface resistanceImprove conductivityElectrode carriers/collectorsSecondary cellsMaximum diameterElectrical battery

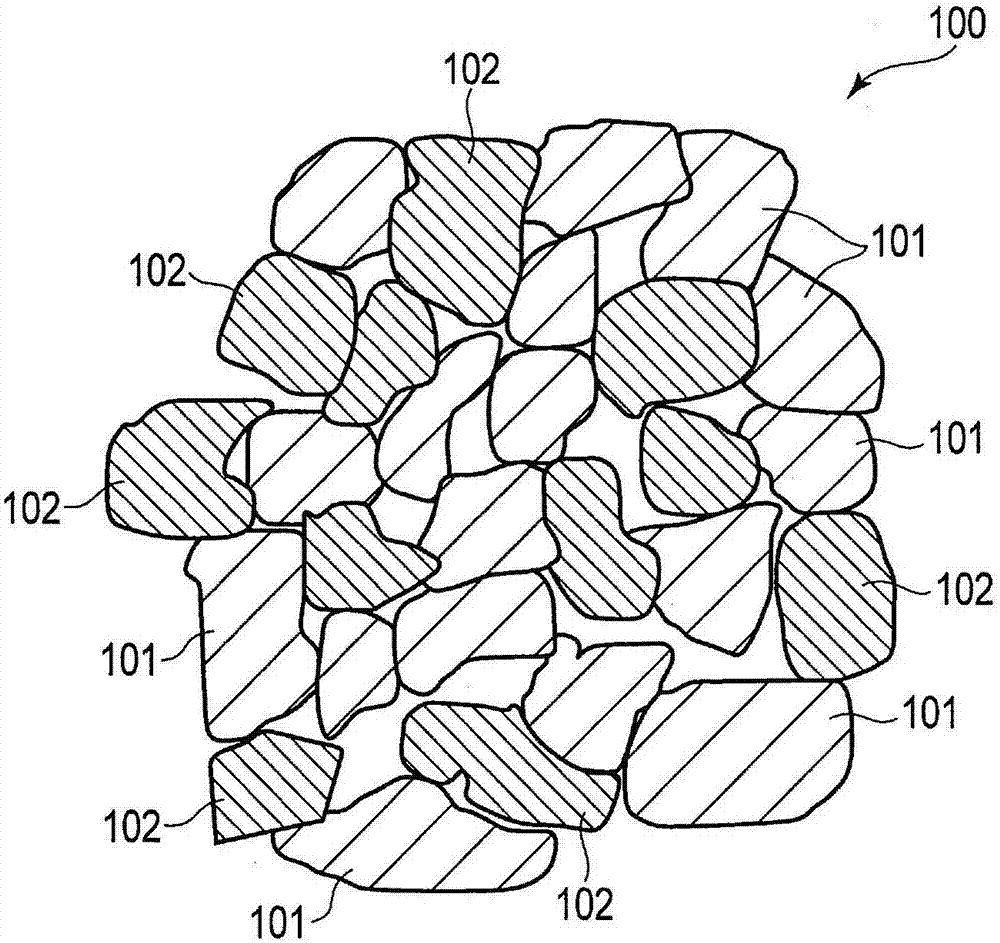

A cathode material for a lithium-ion secondary battery including: granulated bodies in which primary particles are aggregated, wherein an average particle diameter of the granulated bodies is 0.90 μm or more and 2.00 μm or less, particle diameters of 90% or more of the granulated bodies are 0.25 μm or more and 3.50 μm or less, wherein particle diameters of the granulated bodies are evaluated such that 300 granulated bodies are randomly selected from a view of the granulated bodies using a scanning electron microscope, a plurality of diameters of each of the 300 granulated bodies that pass through a central point thereof are evaluated, and a maximum diameter selected from said plurality of diameters is considered as a particle diameter of each of the granulated bodies.

Owner:SUMITOMO METAL MINING CO LTD

Positive active material for lithium-ion secondary battery, positive electrode for lithium-ion secondary battery, and lithium-ion secondary battery

ActiveUS10340513B2Increase in resistance can be suppressedSuppresses of decompositionPositive electrodesLi-accumulatorsSurface layerX ray spectra

A positive active material for a lithium-ion secondary battery includes a lithium composite oxide particle containing nickel atoms, manganese atoms, and fluorine atoms. The lithium composite oxide particle includes a particle center portion and a surface layer portion that is closer to a surface of the lithium composite oxide particle than the particle center portion is. A fluorine atom concentration Fc (at %) of the particle center portion measured by energy dispersive X-ray spectroscopy is lower than a fluorine atom concentration Fs (at %) of the surface layer portion.

Owner:TOYOTA JIDOSHA KK

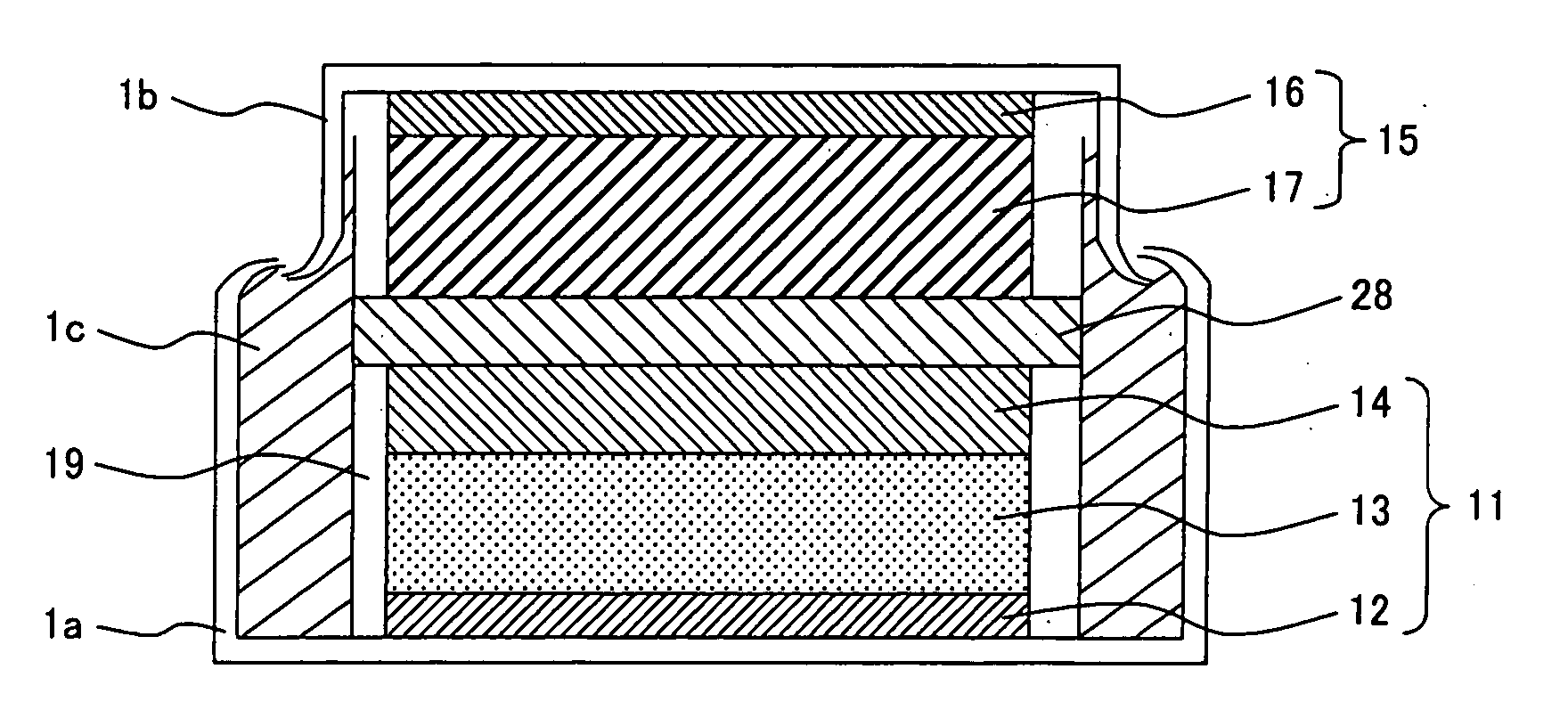

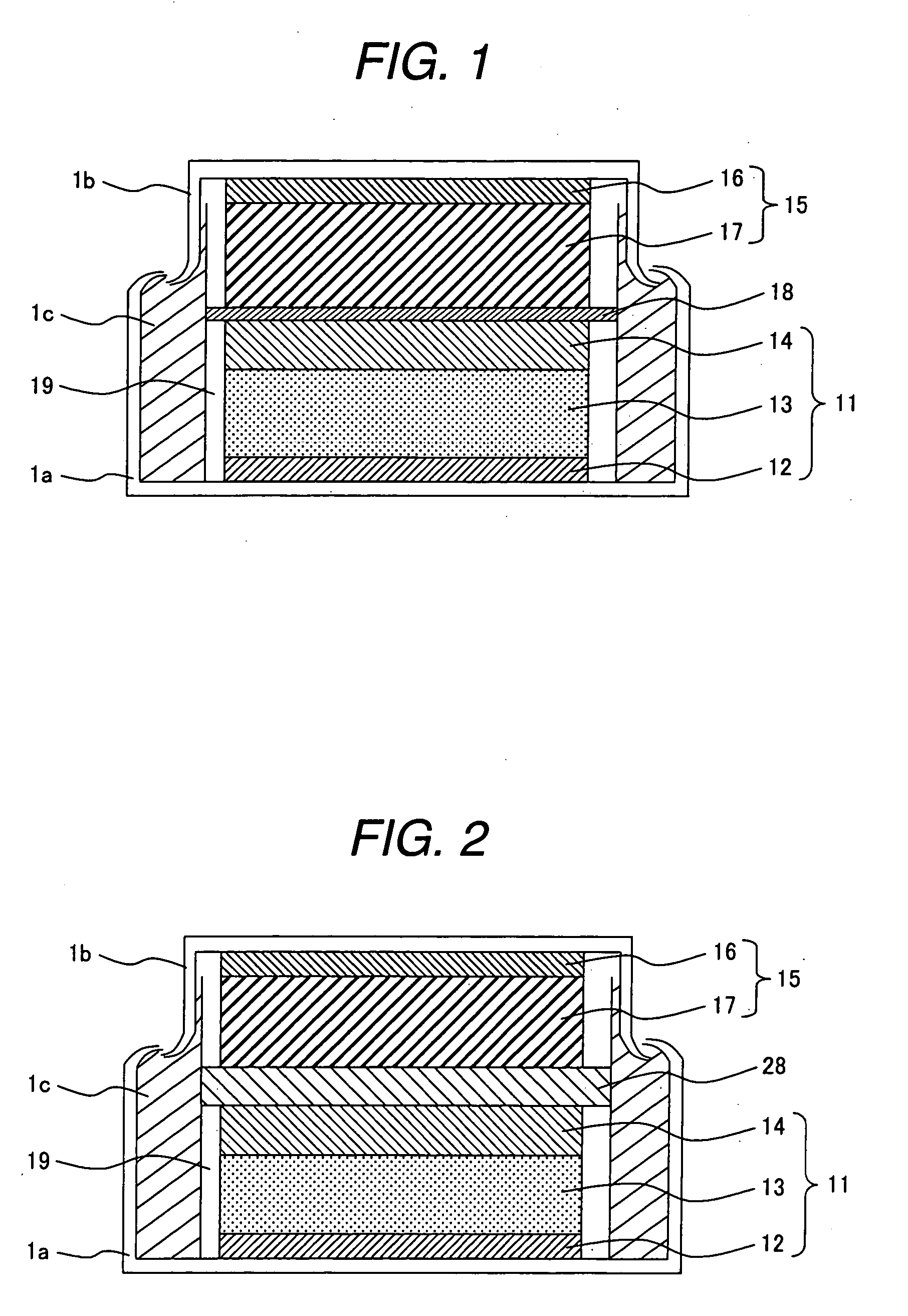

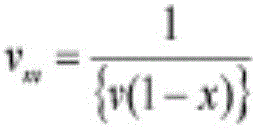

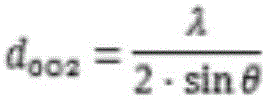

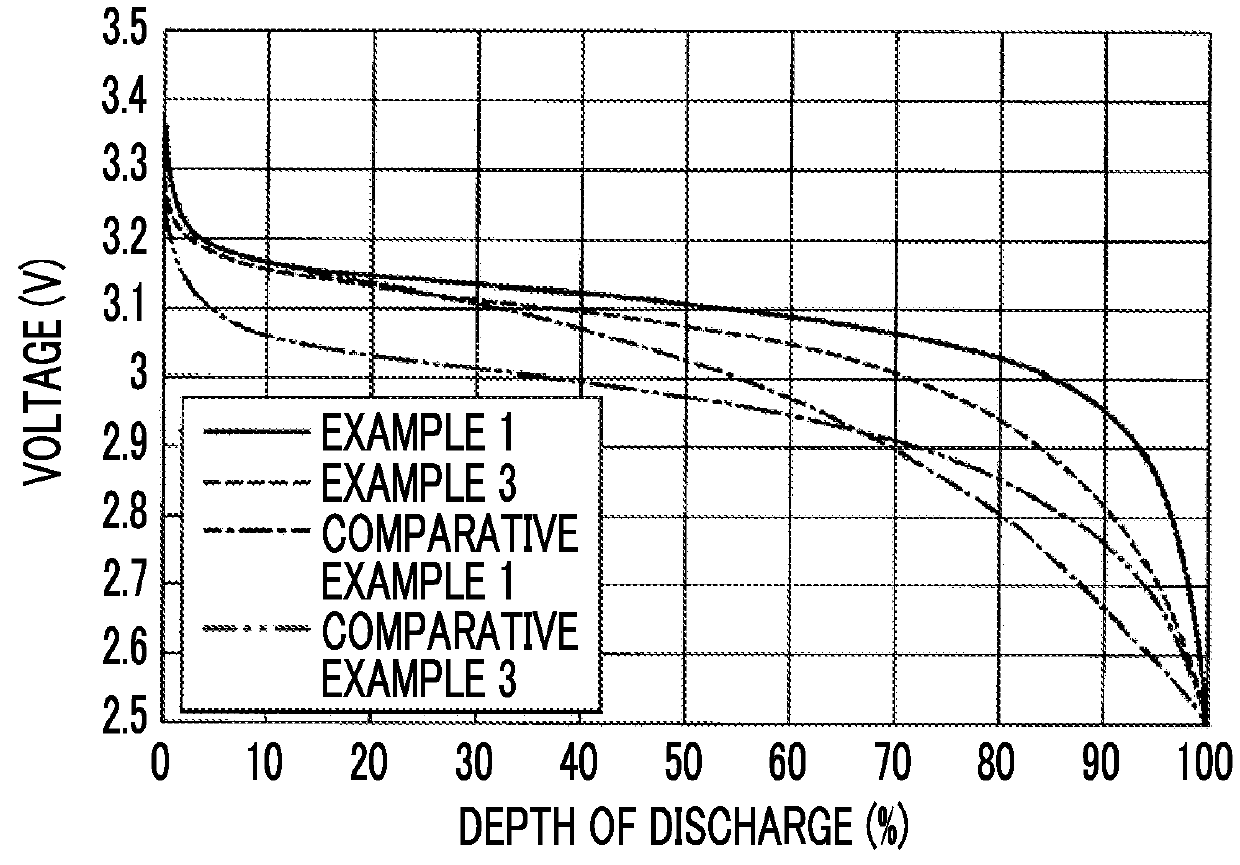

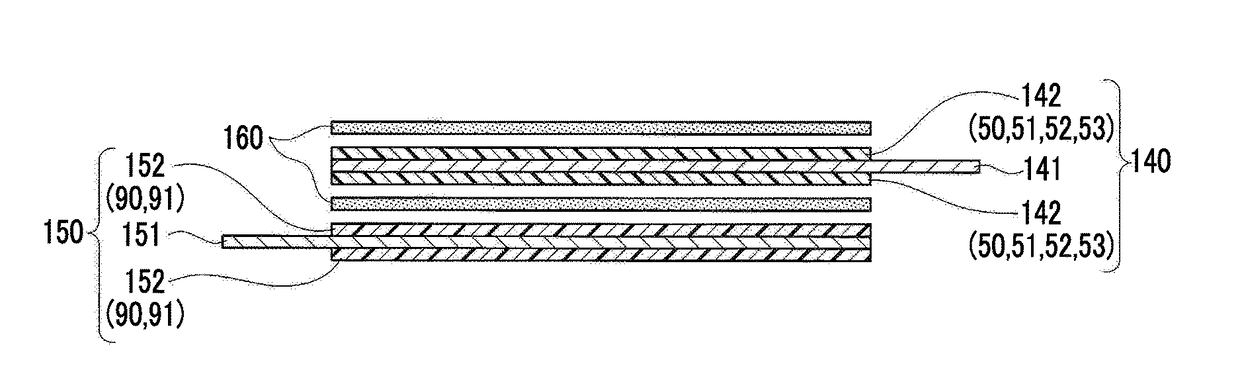

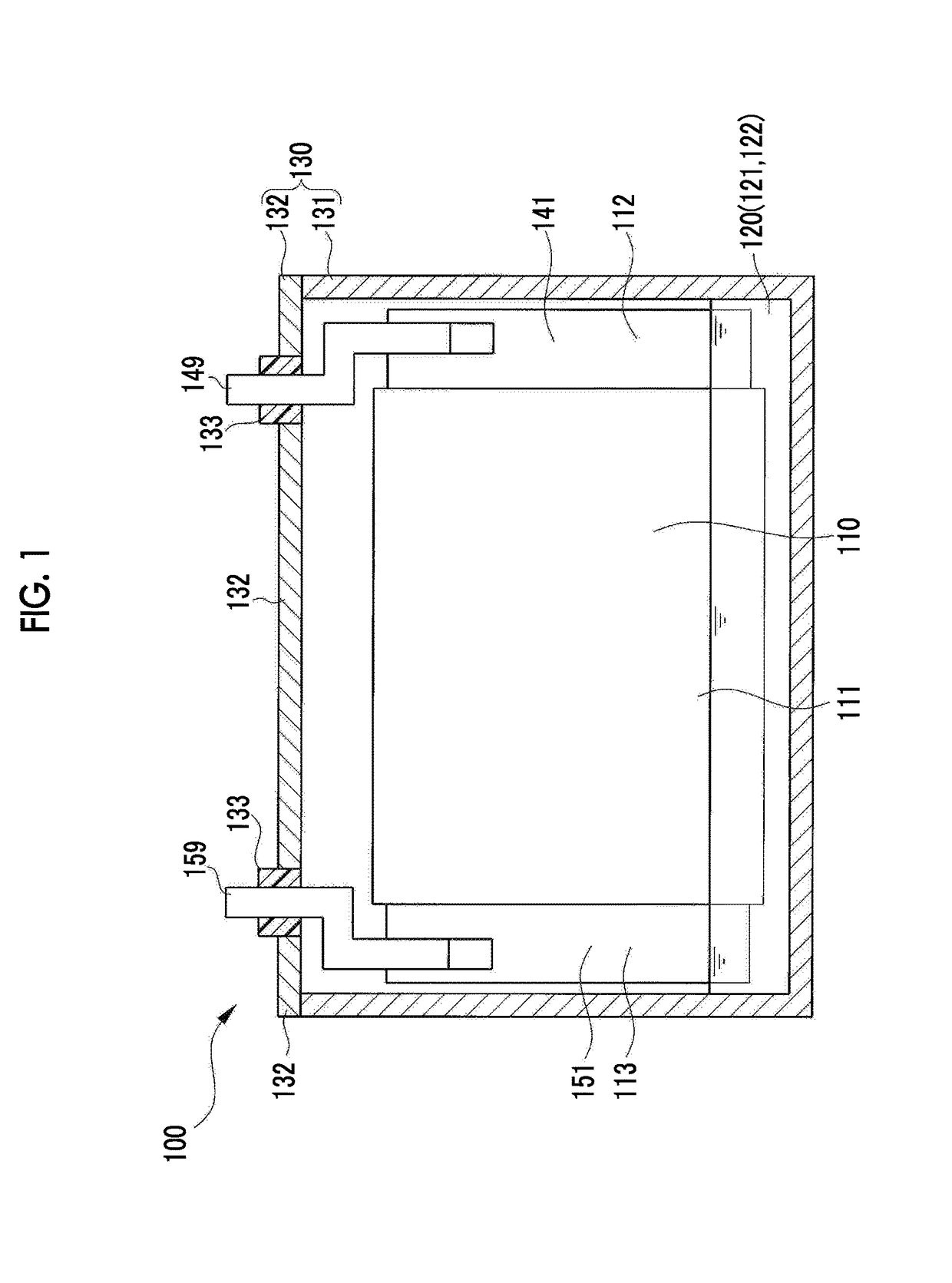

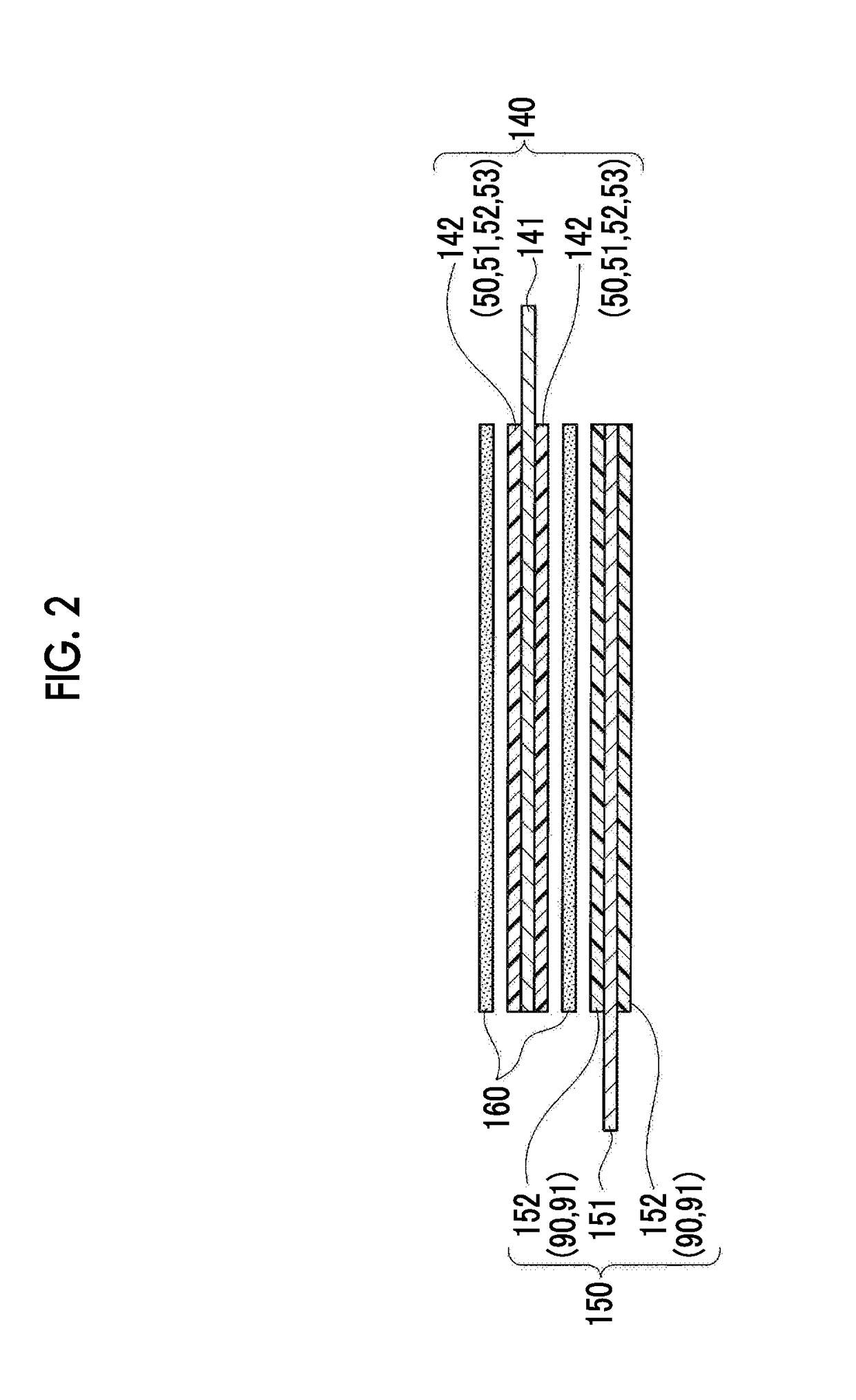

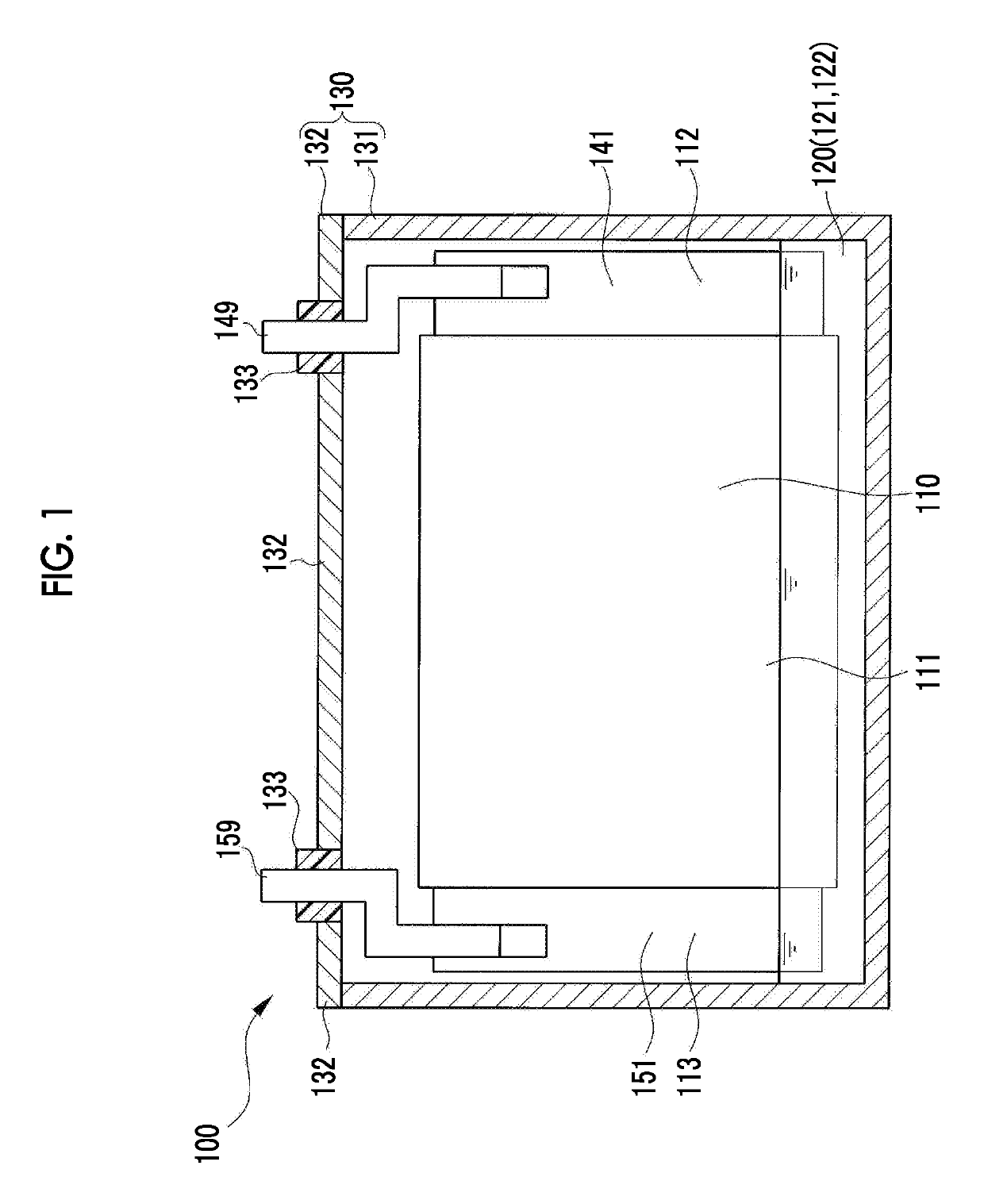

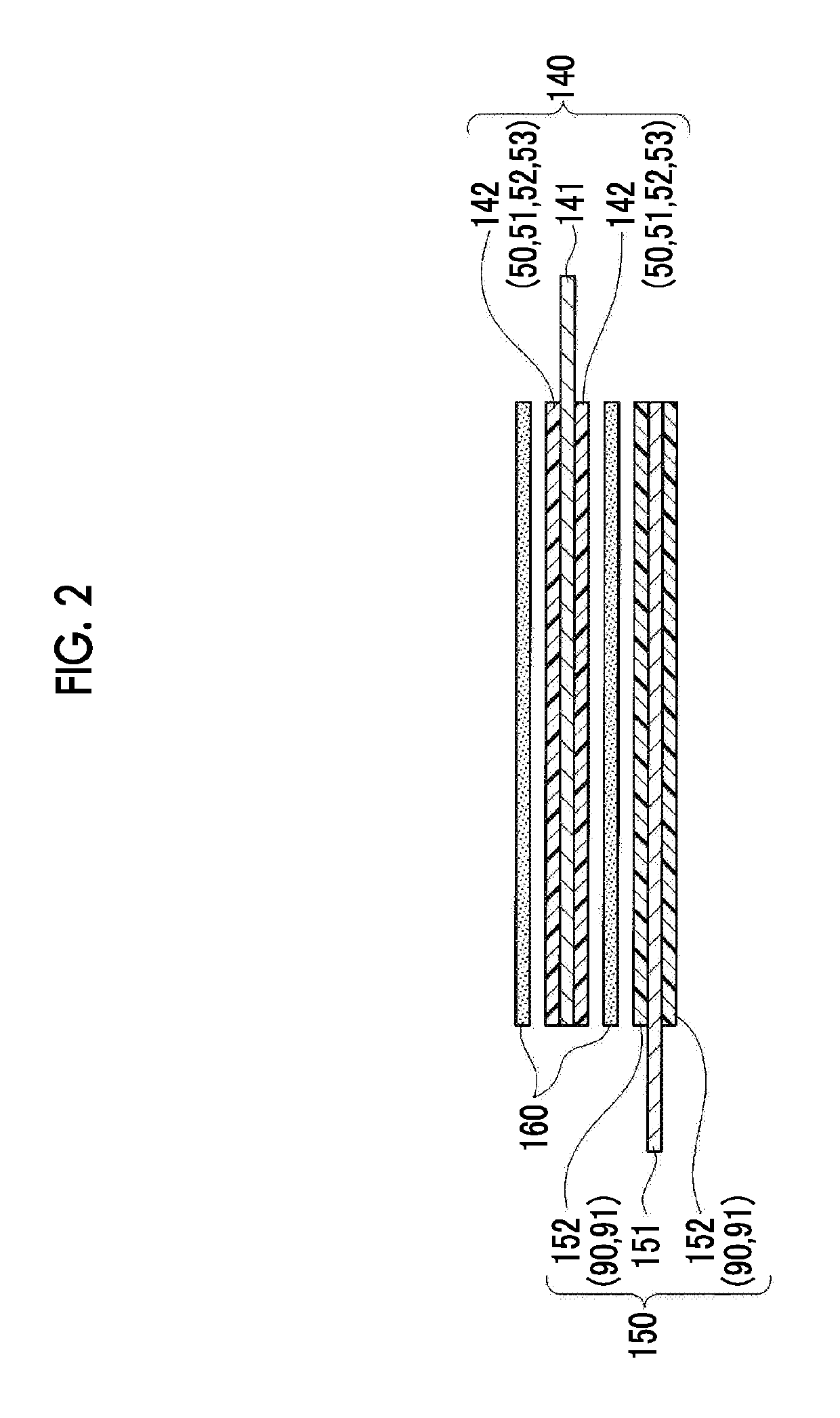

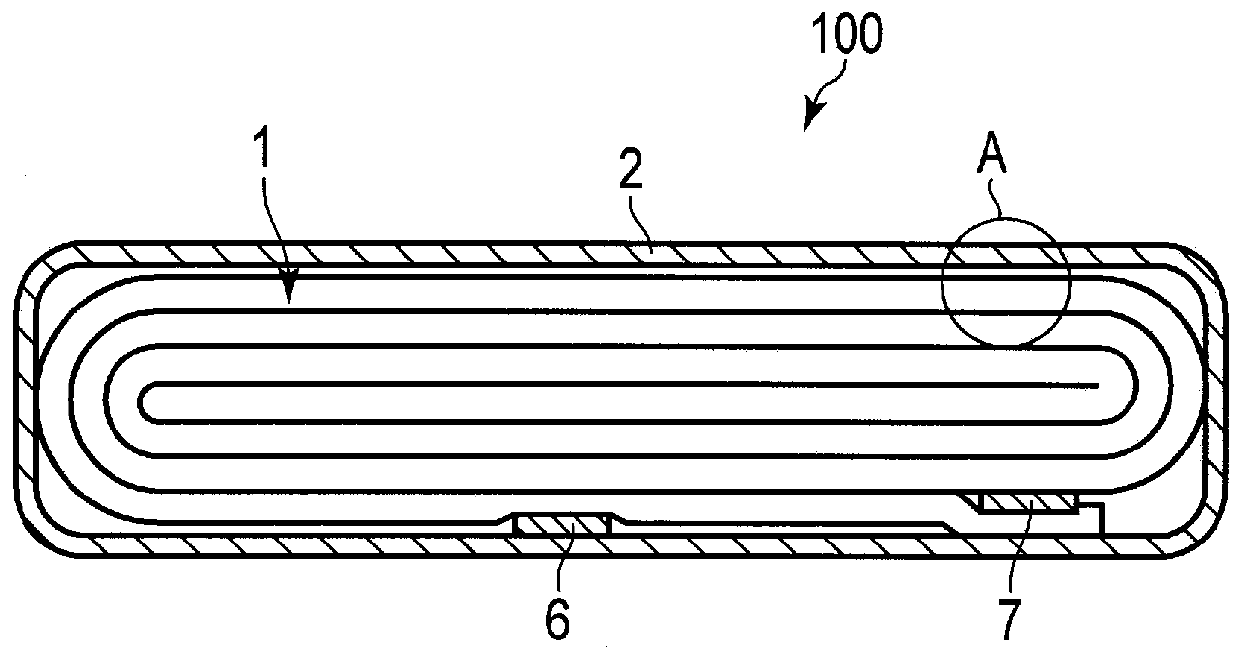

Negative electrode for lithium ion secondary battery and lithium ion secondary battery

ActiveUS10615406B2Excellent input and output characteristicsPrevent precipitationFinal product manufactureSecondary cellsElectrical batteryGraphite

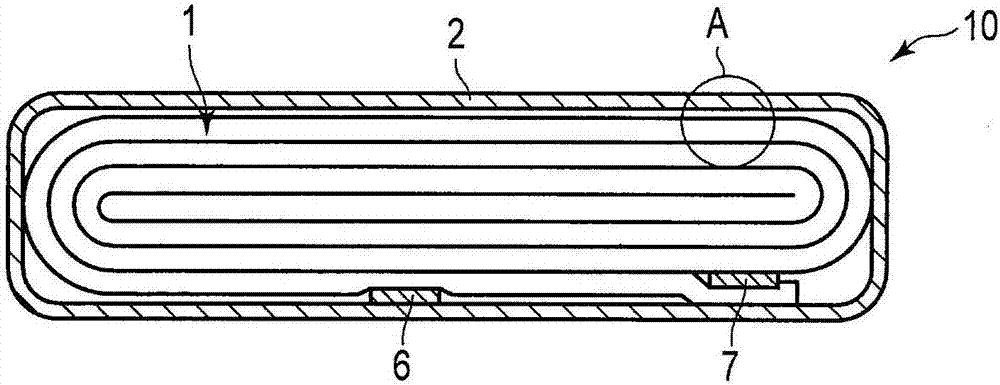

A negative electrode of a lithium ion secondary battery of the present invention includes a current collector (32) and a negative electrode active material layer (34) provided on the current collector (32). In the negative electrode of a lithium ion secondary battery, the negative electrode active material layer (34) includes carbon particles, a degree of graphitization of the carbon particles is 1.0 or more and 1.5 or less and a degree of orientation of the carbon particles is 50 or more and 150 or less; where, the degree of graphitization is a ratio (P101 / P100) between a peak intensity P101 of the (101) plane and a peak intensity P100 of the (100) plane in an X-ray diffraction pattern and the degree of orientation is a ratio (P002 / P110) between a peak intensity P002 of the (002) plane and a peak intensity P110 of the (110) plane in an X-ray diffraction pattern.

Owner:TDK CORPARATION

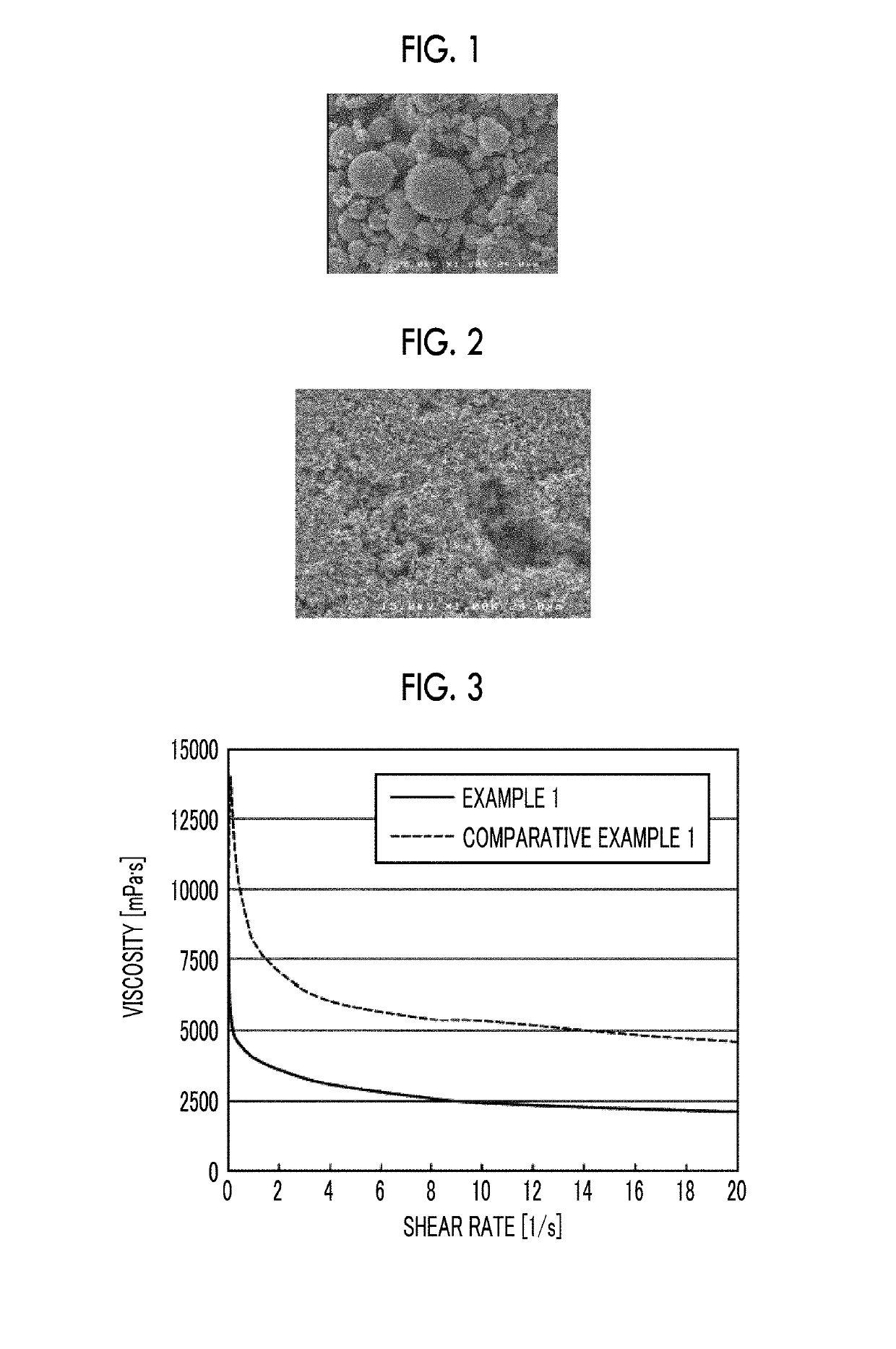

Cathode material for lithium-ion secondary battery, cathode for lithium-ion secondary battery, and lithium-ion secondary battery

ActiveUS20190097214A1Increase energy densityEasy inputSecondary cellsPositive electrodesSolid componentTotal solid content

A cathode material for a lithium-ion secondary battery including: active material particles including central particles represented by general formula LixAyDzPO4 (here, A represents at least one element selected from the group consisting of Co, Mn, Ni, Fe, Cu, and Cr, D represents at least one element selected from the group consisting of Mg, Ca, Sr, Ba, Ti, Zn, B, Al, Ga, In, Si, Ge, Sc, and Y, 0.9<x<1.1, 0<y≤1, 0≤z<1, and 0.9<y+z<1.1) and a carbonaceous film that coats surfaces of the central particles, wherein, when a mixture of the active material particles, a conductive auxiliary agent and a binder in which a mixing ratio thereof is 94:1:5 in terms of a mass ratio is dissolved in a solvent to form paste having a total solid content amount of 45% by mass, a viscosity of the past is 5,000 mPa·s or less at a shear rate of 4.0 [l / s].

Owner:SUMITOMO METAL MINING CO LTD

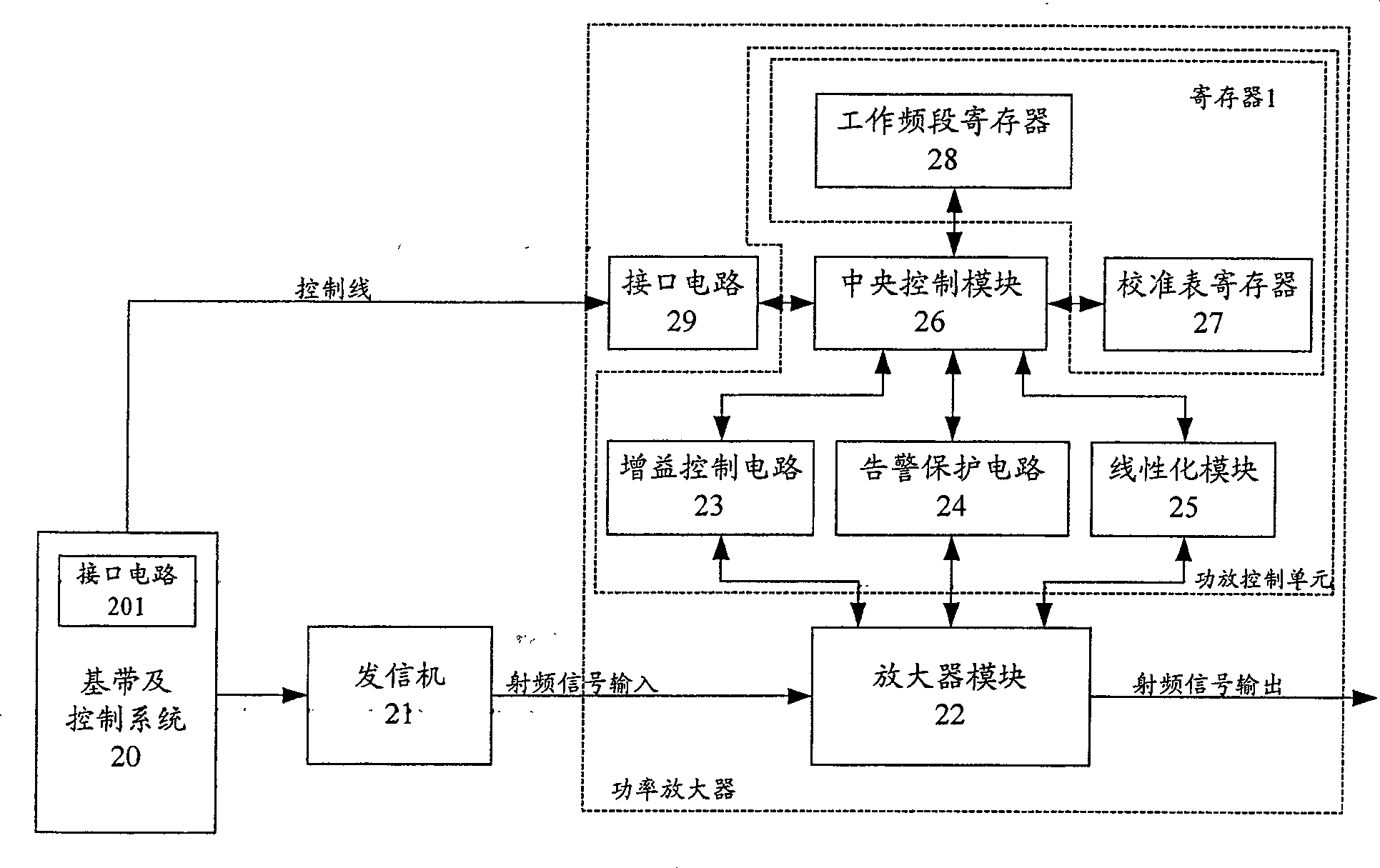

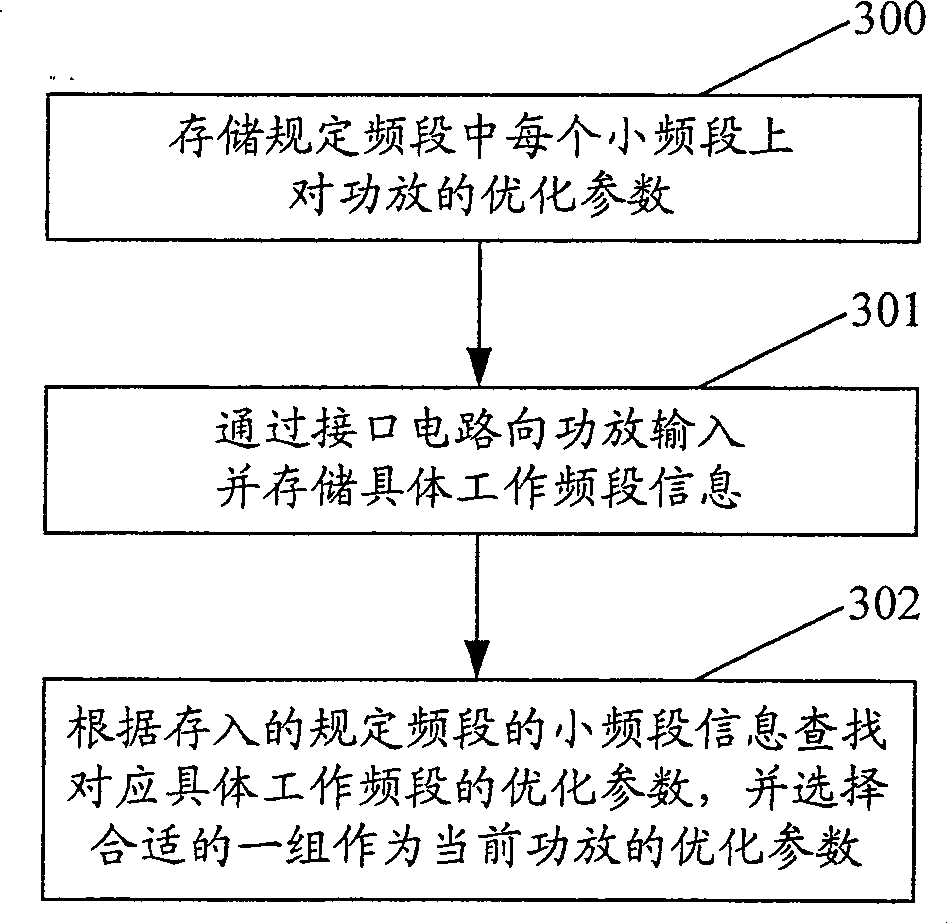

Method for optimizing radio-frequency power amplifier and radio-frequency power amplifier system

ActiveCN100461624CExcellent input and output characteristicsRealize dynamic optimizationAmplifier modifications to reduce non-linear distortionGain controlAudio power amplifierEngineering

This invention discloses a method for optimizing RF power amplifier including: a power amplifier receives an actual working frequency point to adjust the performance parameters of the power amplifier. This invention discloses a RF power amplifier system, which gets information of actual working frequency points by a baseband then to be transmitted to a power amplifying control unit of the power amplifier via an interface circuit, in which, the power amplifying control unit determines the most suitable working performance parameter based on the point information to optimize the input and output property of the power amplifier.

Owner:HUAWEI TECH CO LTD

Method of manufacturing lithium ion secondary battery

ActiveUS10497931B2Inhibit deteriorationDurability is deterioratedFinal product manufactureElectrode collector coatingLithiumPhosphate

Owner:TOYOTA JIDOSHA KK

Electrode, non-aqueous electrolyte battery and battery pack

ActiveCN103117376BExcellent input and output characteristicsCell electrodesSecondary cellsEngineeringBattery pack

The present invention relates to an electrode, a nonaqueous electrolyte battery and a battery pack. To provide electrodes, non-aqueous electrolyte batteries and battery packs with improved input and output characteristics. According to an embodiment, an electrode including a current collector and an active material-containing layer formed on the current collector is provided. The Li insertion potential of the active material is 0.4 V (vs. Li / Li+) or more. In the pore size distribution measured by mercury porosimetry, there are a first peak having a mode diameter of 0.01 μm to 0.1 μm and a second peak having a mode diameter of more than 0.2 μm and 1 μm or less. The volume of the pores measured by the mercury intrusion porosimetry is 0.1 mL to 0.3 mL per 1 g of the electrode weight (the weight excluding the current collector).

Owner:KK TOSHIBA

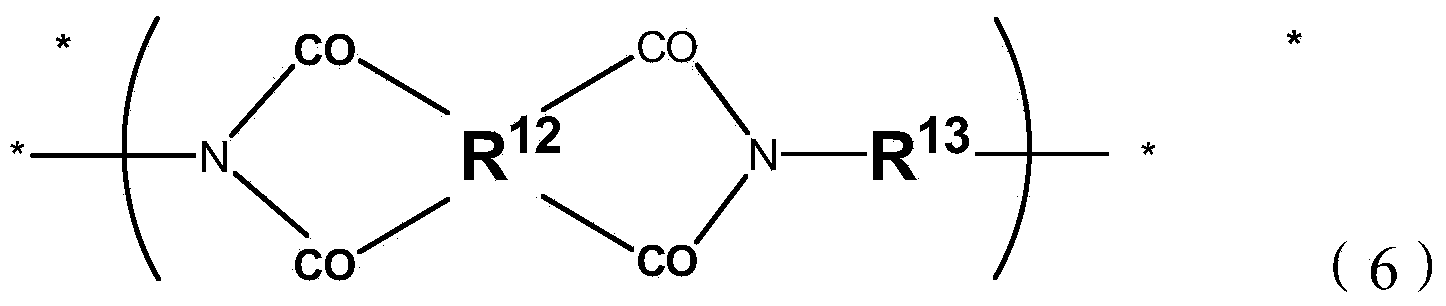

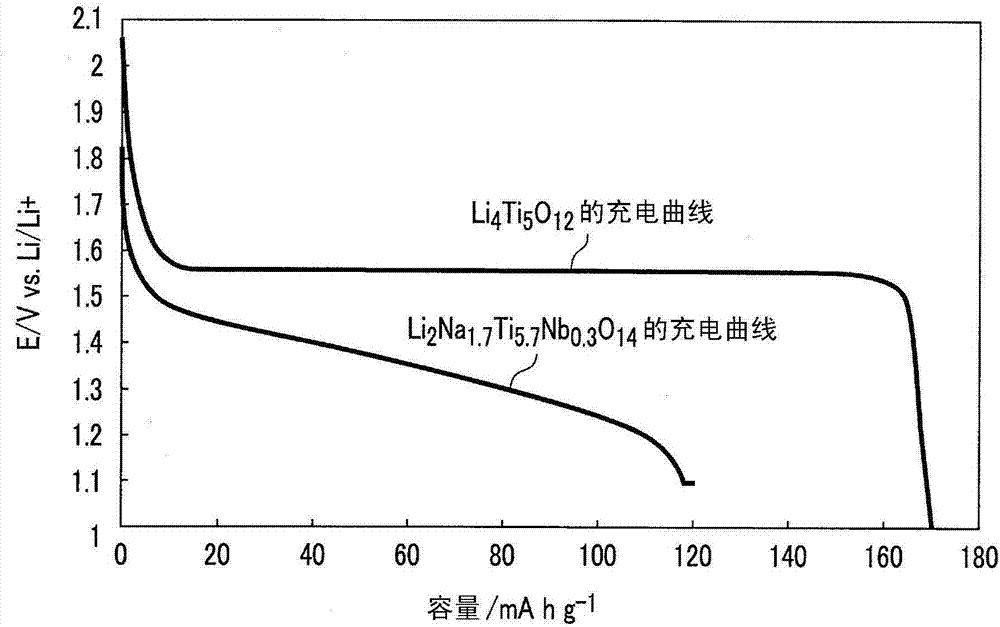

Electrodes, non-aqueous electrolyte batteries, battery packs and vehicles

ActiveCN107039632BExcellent input and output characteristicsSecondary cellsNegative electrodesAqueous electrolyteBattery cell

The present invention provides an electrode of a non-aqueous electrolyte battery capable of exhibiting excellent input-output characteristics in a highly charged state. According to one embodiment, an electrode is provided. The electrode contains the first composite oxide of orthorhombic crystal-type Na-niobium-titanium composite oxide and the general formula Li 2+a Na 2+b Ti 6 o 14 The second composite oxide represented by (-0.2≤a≤2, -0.2≤b≤0.2).

Owner:KK TOSHIBA

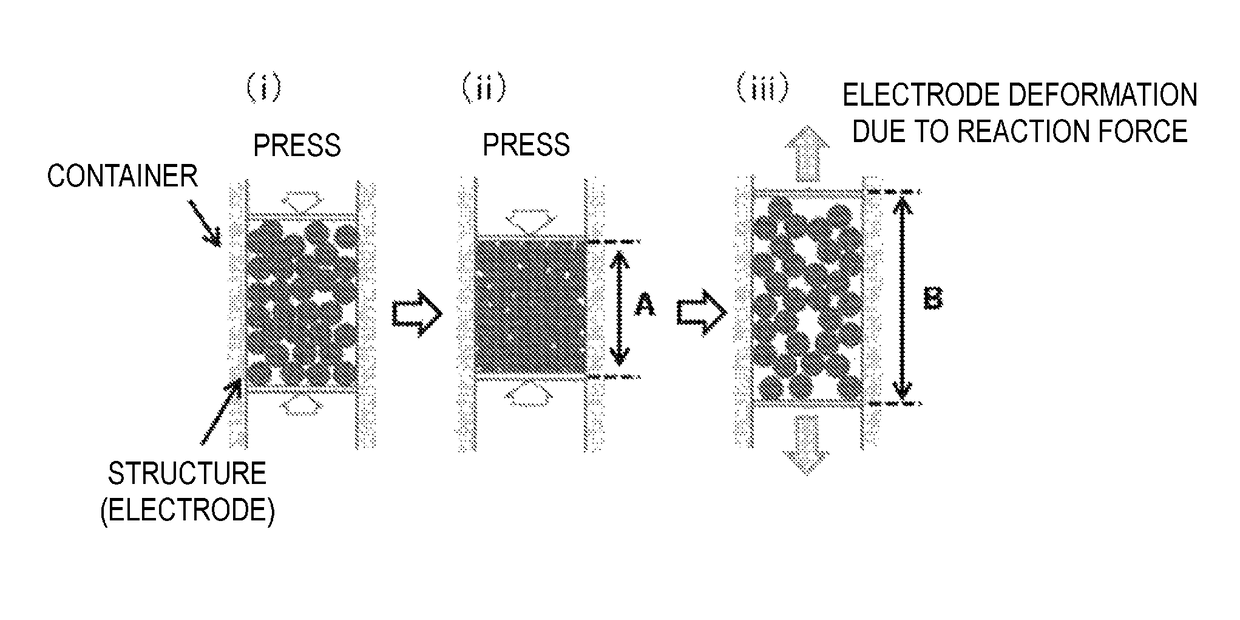

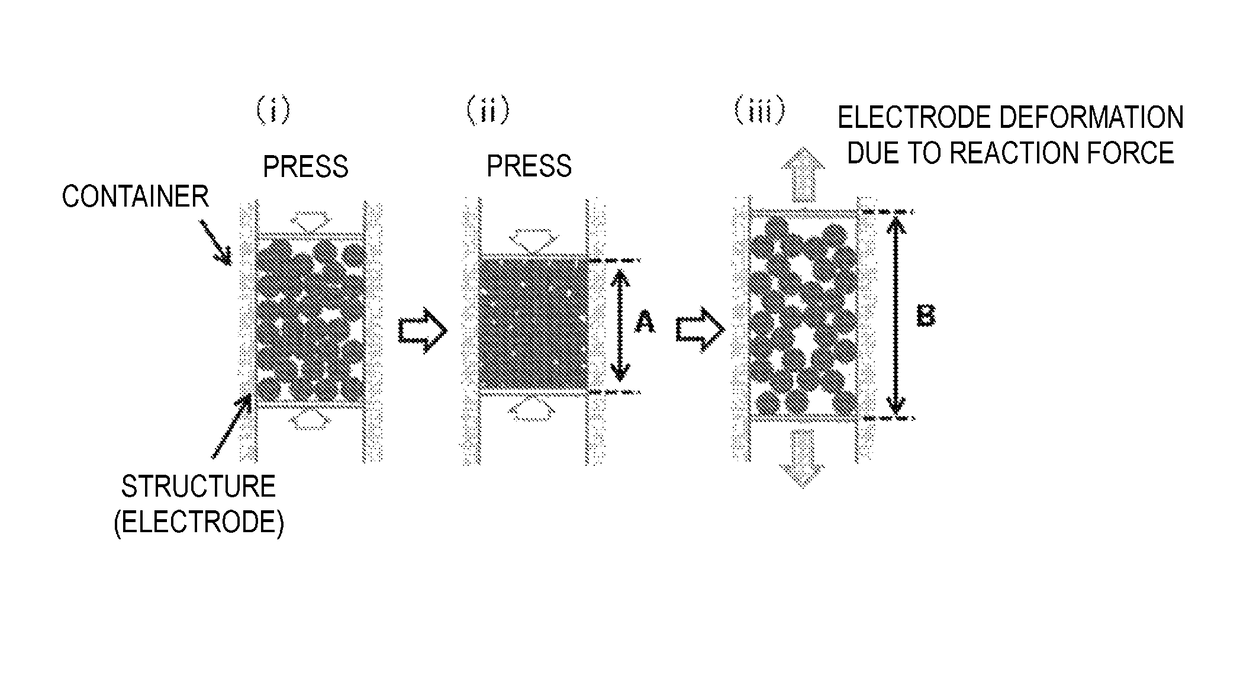

Production method for negative electrode for all-solid-state battery, and negative electrode for all-solid-state battery

ActiveUS9947927B2Excellent input and output characteristicsSmall overall deformationSolid electrolytesElectrode manufacturing processesAll solid stateMaterials science

An object of the present invention is to provide a production method for suppressing the deformation of a negative electrode in the production of a negative electrode for an all-solid-state battery using turbostratic carbon and a solid electrolyte.The problem described above can be solved by a production method for a negative electrode for an all-solid-state battery comprising the steps of:(1) coating a carbonaceous material having a true density of from 1.30 g / cm3 to 2.10 g / cm3 determined by a butanol method with a solid electrolyte; and(2) pressure-molding the solid electrolyte-coated carbonaceous material.

Owner:KUREHA KAGAKU KOGYO KK

Method for producing nonaqueous alkali metal electricity storage element

PendingCN113597690AExcellent input and output characteristicsSuppress micro short circuitElectrode manufacturing processesHybrid capacitor electrodesElectrolytic agentElectric capacity

The present invention provides a method for producing a nonaqueous alkali metal electricity storage element, which comprises a voltage application step wherein a voltage is applied to a nonaqueous alkali metal electricity storage element precursor in which a positive electrode precursor, a negative electrode, a separator and a nonaqueous electrolyte solution are contained in an outer case. With respect to this method for producing a nonaqueous alkali metal electricity storage element, a positive electrode active material layer of the positive electrode precursor contains a positive electrode active material and an alkali metal compound other than the positive electrode active material; and (1) a pressure is applied to the precursor from the outside before or during the voltage application step; (2) the precursor is heated before or during the voltage application step; (3) in the voltage application step, constant-current charging of the precursor is performed, and constant-voltage charging of the precursor is subsequently performed; (4) the C-rate of the constant-current charging is 1.0 to 100.0 times the discharge capacity (Ah) of the thus-obtained nonaqueous alkali metal electricity storage element; and (5) the voltage value of the constant-voltage charging is 4.20 V or more.

Owner:ASAHI KASEI KK

Nonaqueous electrolyte secondary battery

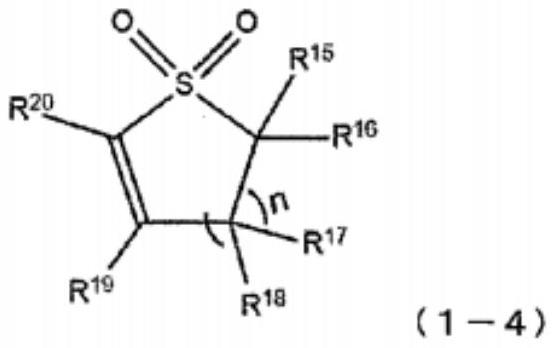

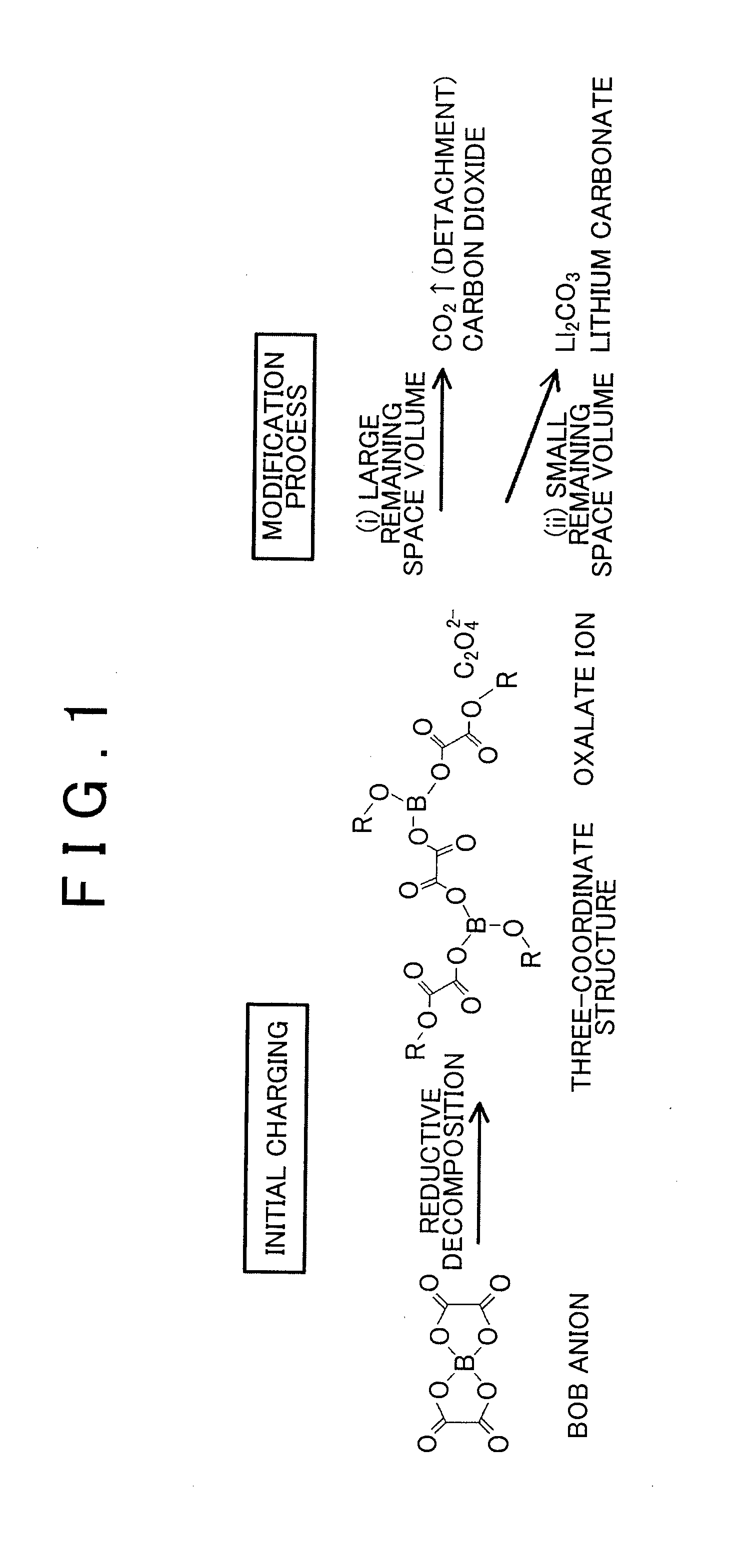

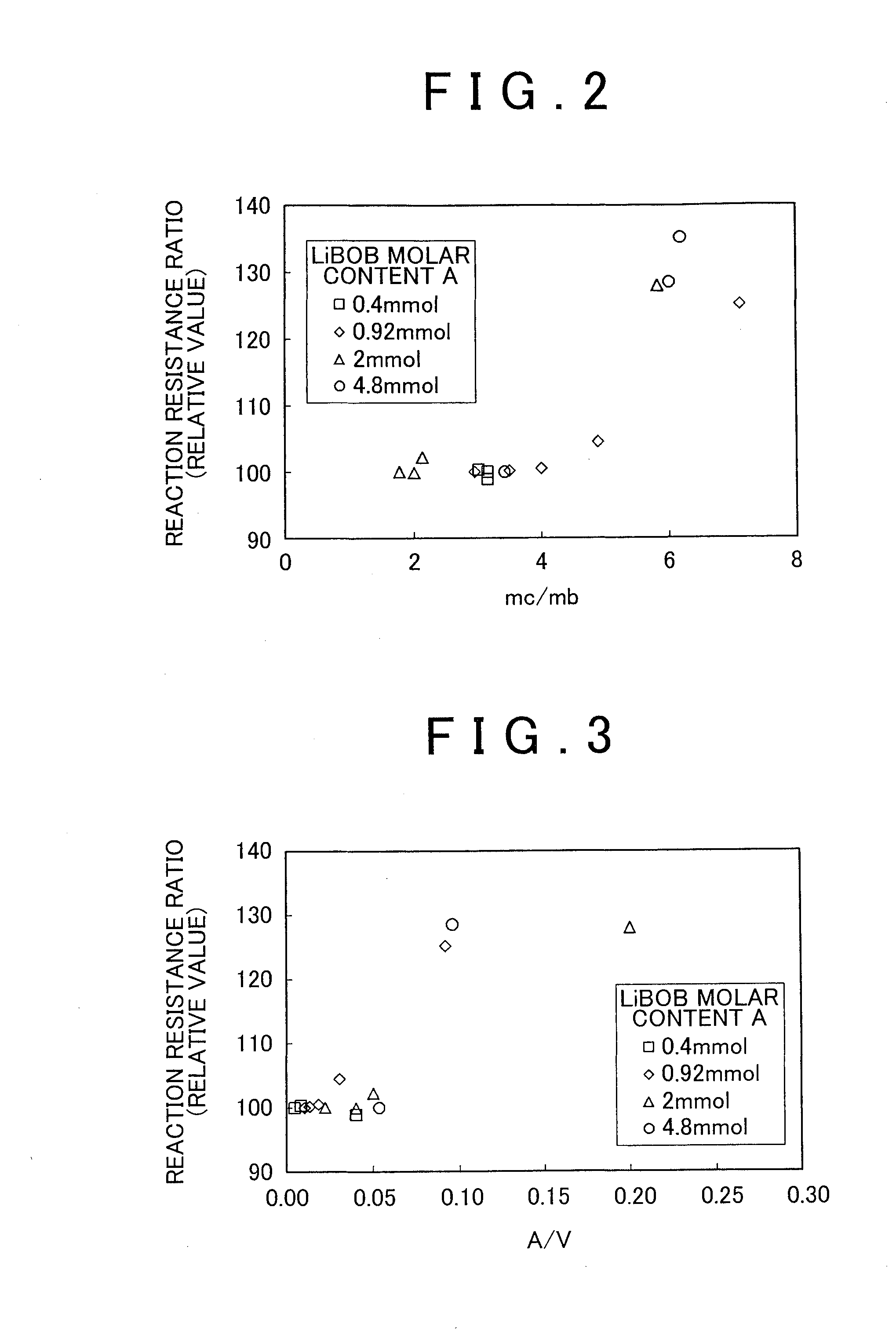

ActiveUS20170054179A1Increase resistanceExcellent input and output characteristicsFinal product manufactureElectrode carriers/collectorsBoron atomChemistry

The present invention provides a nonaqueous electrolyte secondary battery configured such that a positive electrode, a negative electrode, and a nonaqueous electrolyte are accommodated in a battery case. The battery includes lithium bis(oxalato)borate (LiBOB) at least at the time of assembly of the battery. The negative electrode includes a film derived from the LiBOB and containing a boron atom (B) and a carbonate ion (CO32−). A ratio (mc / mb) of a molar content mc of the carbonate ion to a molar content mb of the boron atom is 4.89 or less. In a preferred aspect, when a molar content A of the LiBOB is A (mmol) and a remaining space volume in the battery case is V (cm3) at the time of the assembly, a ratio A / V is 0.053 or less.

Owner:TOYOTA JIDOSHA KK

Lithium secondary battery

ActiveUS9312568B2Excellent characteristicsLower internal resistanceFinal product manufactureSecondary cellsLithiumGraphite

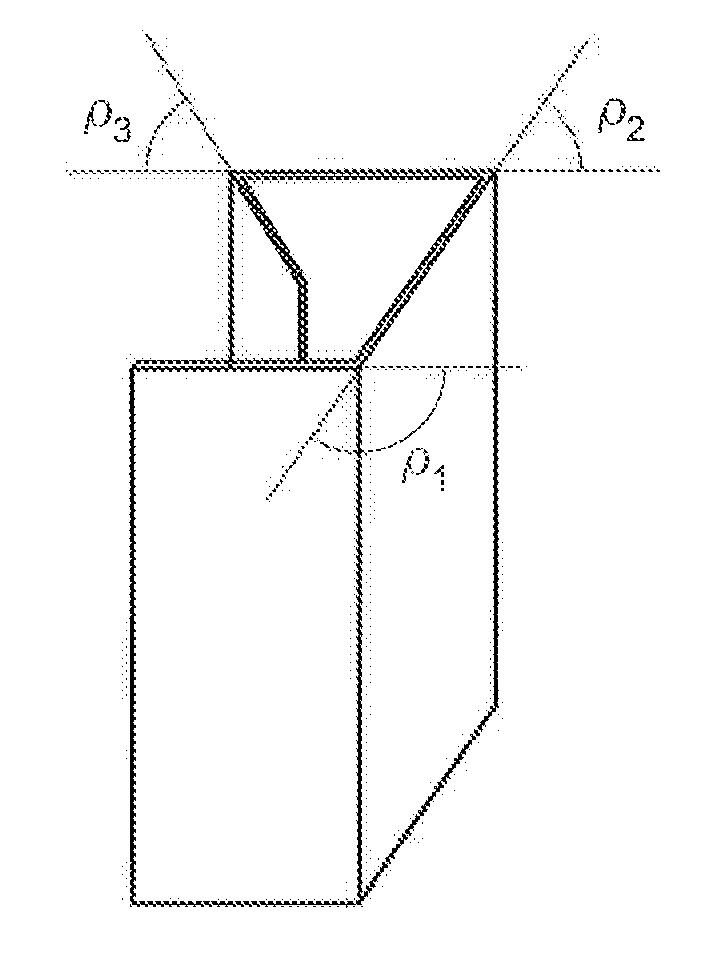

A lithium secondary battery 10 of the present invention is a secondary battery provided with a positive electrode 30 having a positive electrode active material layer 34 on a positive electrode collector 32, and a negative electrode 50 having a negative electrode active material layer 54 on a negative electrode collector 52. The positive electrode active material layer 34 contains a positive electrode active material capable of reversibly storing and releasing lithium ions. The negative electrode active material layer 54 contains a negative electrode active material made up of lamellar graphite that is bent so as to have an average number of bends f per particle of 0<f≦3, and an average aspect ratio of 1.8 or higher. In a cross-section perpendicular to the surface of the negative electrode collector 52, the negative electrode active material is oriented in such a manner that the perpendicularity defined as n2 / n1, is 1 or greater, n1 being the number of negative electrode active material units such that 0°≦θn≦30°, and n2 being the number of negative electrode active material units such that 60°≦θn≦90°, where θn is the angle formed by a major axis of the negative electrode active material units with respect to the surface of the negative electrode collector 52.

Owner:TOYOTA JIDOSHA KK

Active materials, non-aqueous electrolyte batteries, assembled batteries, battery packs, automobiles and vehicles

ActiveCN106486655BExcellent input and output characteristicsImprove life characteristicsCell electrodesLi-accumulatorsPhysical chemistryAqueous electrolyte

The present invention provides an active material for a battery capable of realizing a nonaqueous electrolyte battery exhibiting excellent input / output characteristics, excellent life characteristics, and high voltage. The battery active material according to one embodiment of the present invention contains the general formula Li (2+w) Na (2‑x) M1 (x / 2) Ti (6‑y) M2 z o 14 Indicated titanium-containing oxides. M1 is at least one metal element selected from Sr, Ba, and Pb. M2 is at least one element selected from metal elements M (excluding Ti and M1) and P.

Owner:KK TOSHIBA

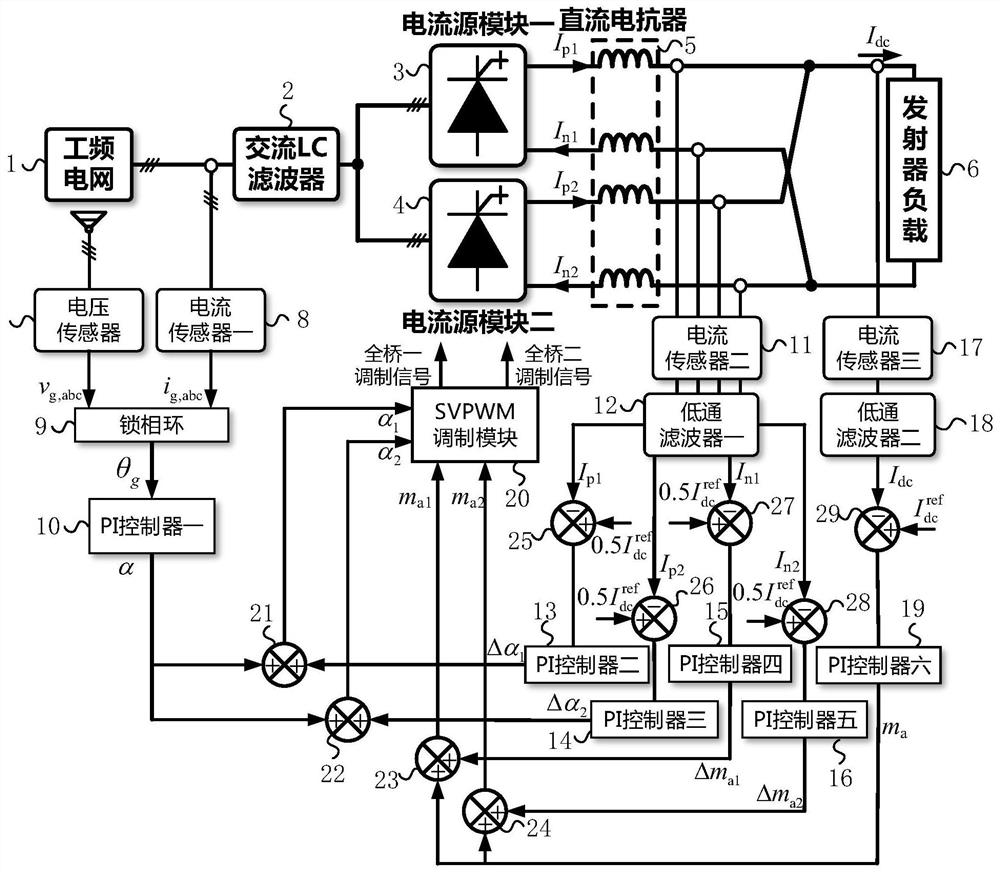

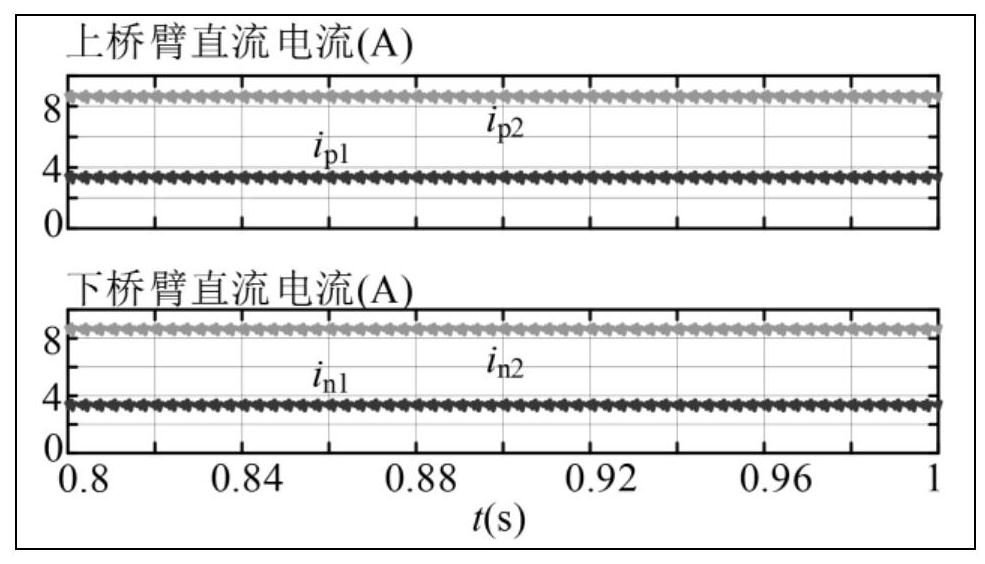

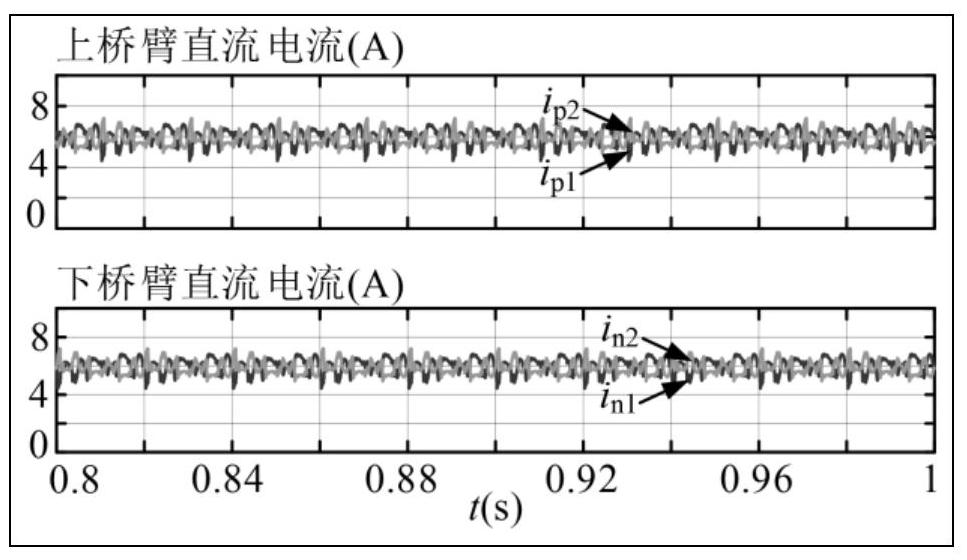

Wireless transmitter power supply current sharing controller and method based on current source

ActiveCN113078831ANatural short-circuit resistanceExcellent input and output characteristicsAc-dc conversion without reversalDc source parallel operationCurrent transducerLow-pass filter

The invention discloses a wireless transmitter power supply current sharing controller and method based on a current source, and the controller comprises a power frequency power grid, an AC LC filter, a first current source module, a second current source module, a DC reactor, a transmitter load, a voltage sensor, a first current sensor, a phase-locked loop, a first PI controller, a second current sensor, a first low-pass filter, a second PI controller, a third PI controller, a fourth PI controller, a fifth PI controller, a third current sensor, a second low-pass filter, a sixth PI controller, an SVPWM modulation module, an adder and a subtracter. Current sharing control of the two current source modules can be realized. According to the method, enumeration and selection of space vectors are avoided, so that the method can be conveniently applied to current sharing of any current source modules connected in parallel, and the method has good expandability.

Owner:张昌浩

Hybrid capacitor

ActiveCN114207756AExcellent input and output characteristicsIncreased durabilityHybrid capacitor electrodesHybrid capacitor current collectorsGraphiteCapacitor

In a hybrid capacitor according to the present invention, a positive electrode contains graphite as a positive electrode active material, a current collector on the positive electrode side is an aluminum material, and the aluminum material is covered with a carbon plating film in which the content ratio of an sp2 structure, sp2 / (sp2 + sp3), is 80% or more.

Owner:TEIKOKU PISTON RING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com