Active materials, non-aqueous electrolyte batteries, assembled batteries, battery packs, automobiles and vehicles

A non-aqueous electrolyte and active material technology, applied in the direction of non-aqueous electrolyte storage batteries, battery electrodes, battery components, etc., can solve the problems of battery characteristic decline, battery resistance increase, battery deformation, etc., and achieve excellent life characteristics, excellent Effects of high voltage and excellent input and output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0025] According to the first embodiment, an active material for a battery is provided. The active substance contains the general formula Li (2+w) Na (2-x) M1 (x / 2) Ti (6-y) M2 z o 14 Indicated titanium-containing oxides. In the general formula, the subscripts w, x, y and z are respectively in the ranges of 0≤w≤6, 0<x<2, 0≤y≤3, 0≤z≤3. M1 is at least one metal element selected from Sr, Ba, and Pb. M2 is at least one element selected from metal elements M (excluding Ti and M1) and P. M1 may be one metal element selected from Sr, Ba, and Pb, or may be two or more metal elements selected from Sr, Ba, and Pb. M2 may be one element selected from the metal element M (excluding Ti and M1) and P, or may be two or more elements selected from the metal element M (excluding Ti and M1) and P.

[0026] The active material for a battery according to the first embodiment can perform intercalation and deintercalation reactions of lithium at a potential lower than that of lithium titan...

no. 2 Embodiment approach

[0097] According to the second embodiment, a nonaqueous electrolyte battery can be provided. The nonaqueous electrolyte battery includes a positive electrode, a negative electrode, and a nonaqueous electrolyte. The negative electrode contains the battery active material according to the first embodiment.

[0098] The non-aqueous electrolyte battery according to the second embodiment may further include a separator arranged between the positive electrode and the negative electrode. The positive electrode, the negative electrode and the separator can constitute an electrode group. A non-aqueous electrolyte is held in the electrode group.

[0099] The electrode group may have a laminated structure, for example. In the stacked electrode group, a plurality of positive electrodes and a plurality of negative electrodes are alternately stacked with a separator interposed therebetween.

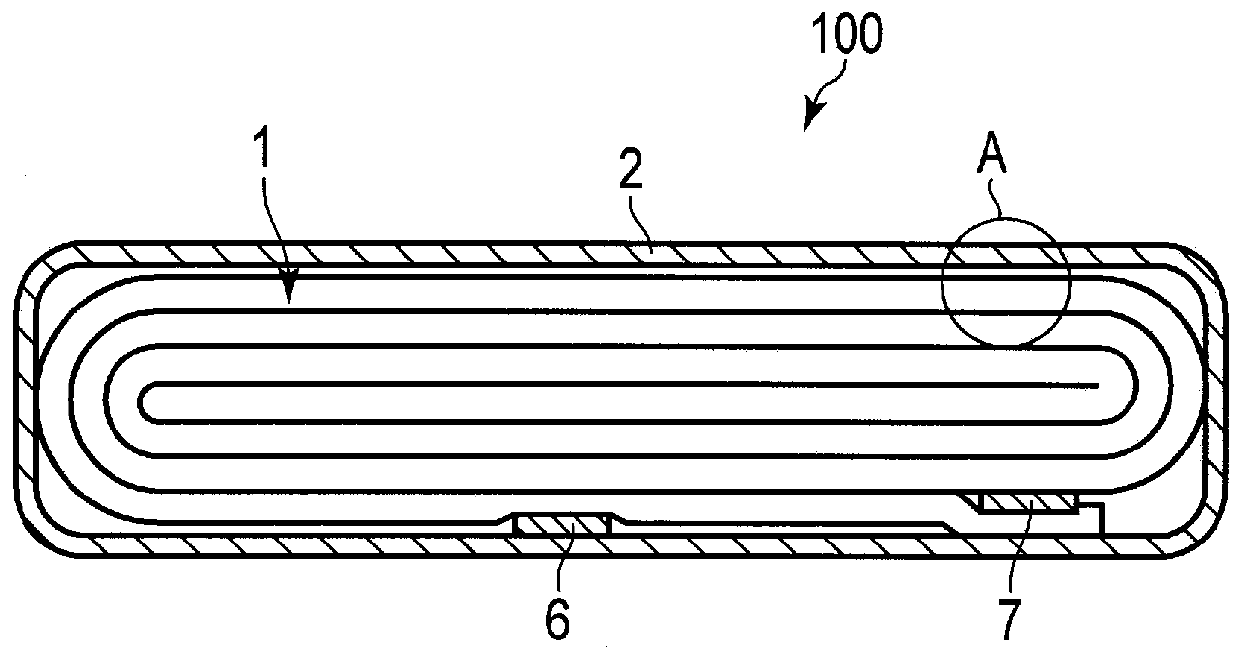

[0100] Alternatively, the electrode group may also have a wound-type structure. A wound-type e...

no. 3 Embodiment approach

[0158] According to a third embodiment, an assembled battery is provided. The assembled battery according to the third embodiment includes the plurality of non-aqueous electrolyte batteries according to the second embodiment.

[0159] In the assembled battery according to the third embodiment, the individual cells can be arranged electrically connected in series or in parallel, or can be arranged in a combination of series connection and parallel connection.

[0160] For example, the assembled battery according to the third embodiment may include 6m nonaqueous electrolyte batteries including a negative electrode containing the battery active material according to the first embodiment and an iron-containing phosphoric acid having an olivine crystal structure. Compound positive electrode and non-aqueous electrolyte. Here, m is an integer of 1 or more. 6m non-aqueous electrolyte batteries can be connected in series to form a battery pack. As described in the second embodiment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com