Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94 results about "Carbonaceous film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A carbonaceous film or carbon film is an organism outline of a fossil. It is a type of fossil found in any rock when organic material is compressed, leaving only a carbon residue or film. When an organism is buried under many layers of sediment, pressure and heat increase during diagenesis and if the organism lacks a hard skeleton only leaving this thin film of carbon residue on rock surfaces.

Electrolytic anode and method for electrolytically synthesizing fluorine containing substance using the electrolytic anode

ActiveUS20060219570A1Synthetic strongSuppress generationMachining electrodesElectrical-based machining electrodesSubstance useFluoride

The present invention provides an electrolytic anode for use in electrolytically synthesizing a fluorine-containing substance by using an electrolytic bath containing a fluoride ion including: an electroconductive substrate having a sure including an electroconductive carbonaceous material; and an electroconductive carbonaceous film having a diamond structure, the electroconductive carbonaceous film coating a part of the electroconductive carbonaceous substrate, and a method for electrolytically synthesizing a fluorine-containing substance using the electrolytic anode.

Owner:TOYO TANSO KK +1

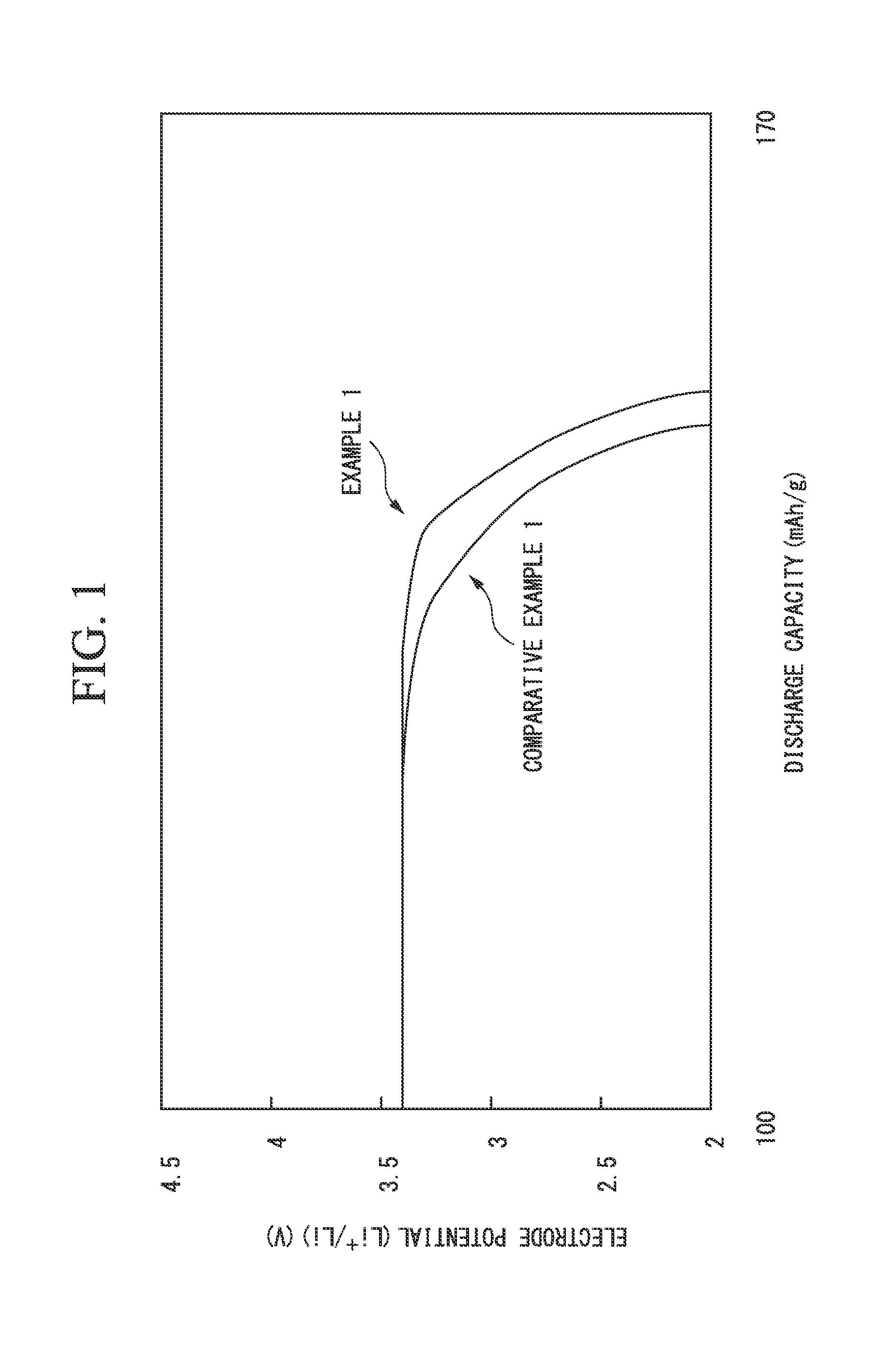

Cathode active material, secondary battery comprising the same, and method of manufacturing the positive active material

ActiveUS20160141607A1Improve initial efficiencyIncrease capacityElectrode thermal treatmentChemical electrode manufacturingOxygenCarbonaceous film

A positive active material including: a core comprising a metal oxide, a non-metal oxide, or a combination thereof capable of intercalation and deintercalation of lithium ions or sodium ions; and a non-conductive carbonaceous film including oxygen on at least one portion of a surface of the core; a lithium battery including the positive active material; and a method of manufacturing the positive active material.

Owner:SAMSUNG ELECTRONICS CO LTD

Electronic device and its manufacturing method

InactiveUS6756670B1Improve reliabilityImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesWater resistantCarbonaceous film

An electronic device comprising a substrate having a frame, a metal lead and an electronic parts in a bonding structure, and a molding of an organic resin formed on the substrate, wherein the surface of the organic resin is provided with a hardened water-resistant or carbonaceous film or wherein pores at the surface of the organic resin are filled within an inactive gas such as argon because of a plasma treatment of the resin surface with the inactive gas whereby impurities are prevented from entering into the organic resin through the pores.

Owner:SEMICON ENERGY LAB CO LTD

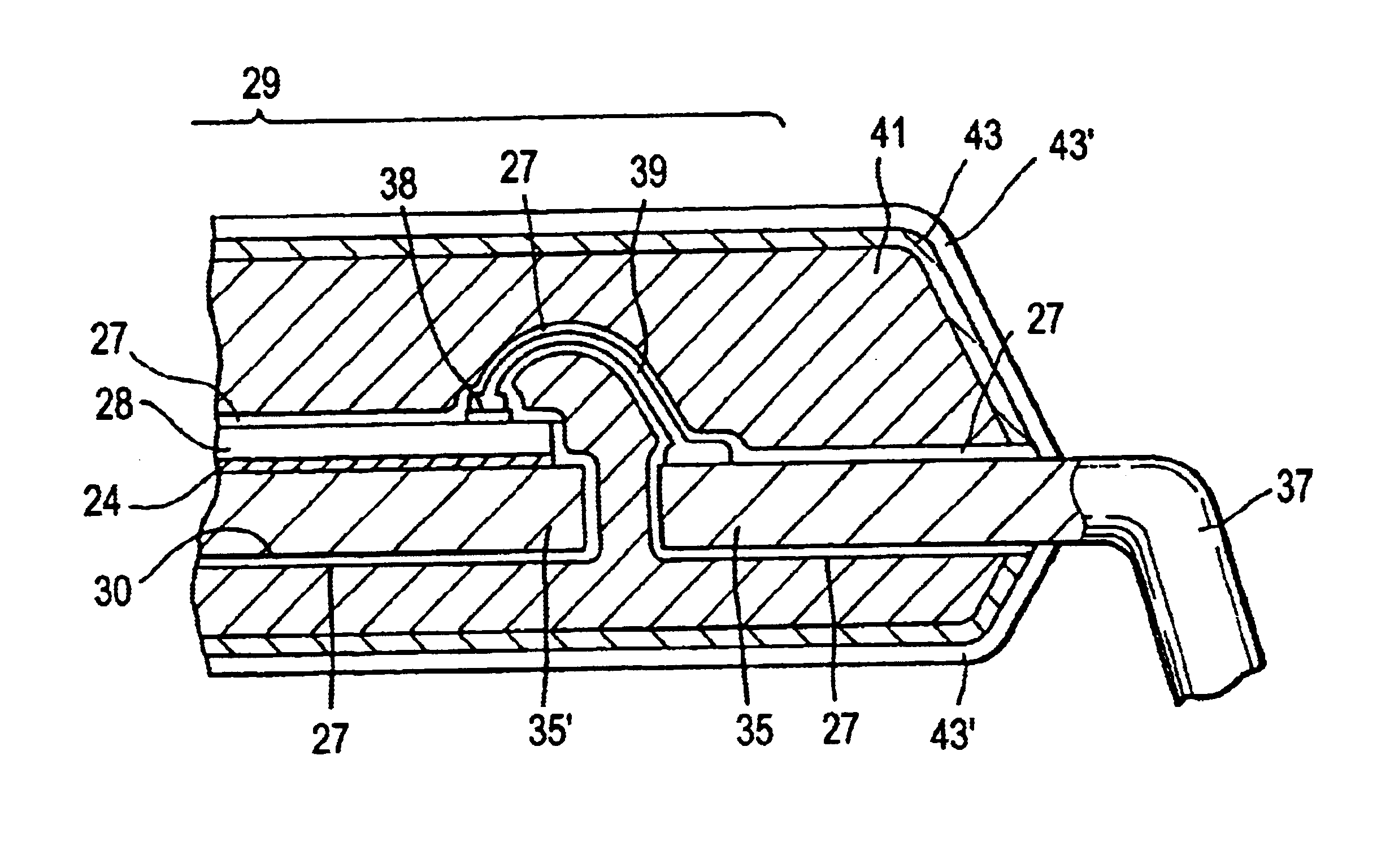

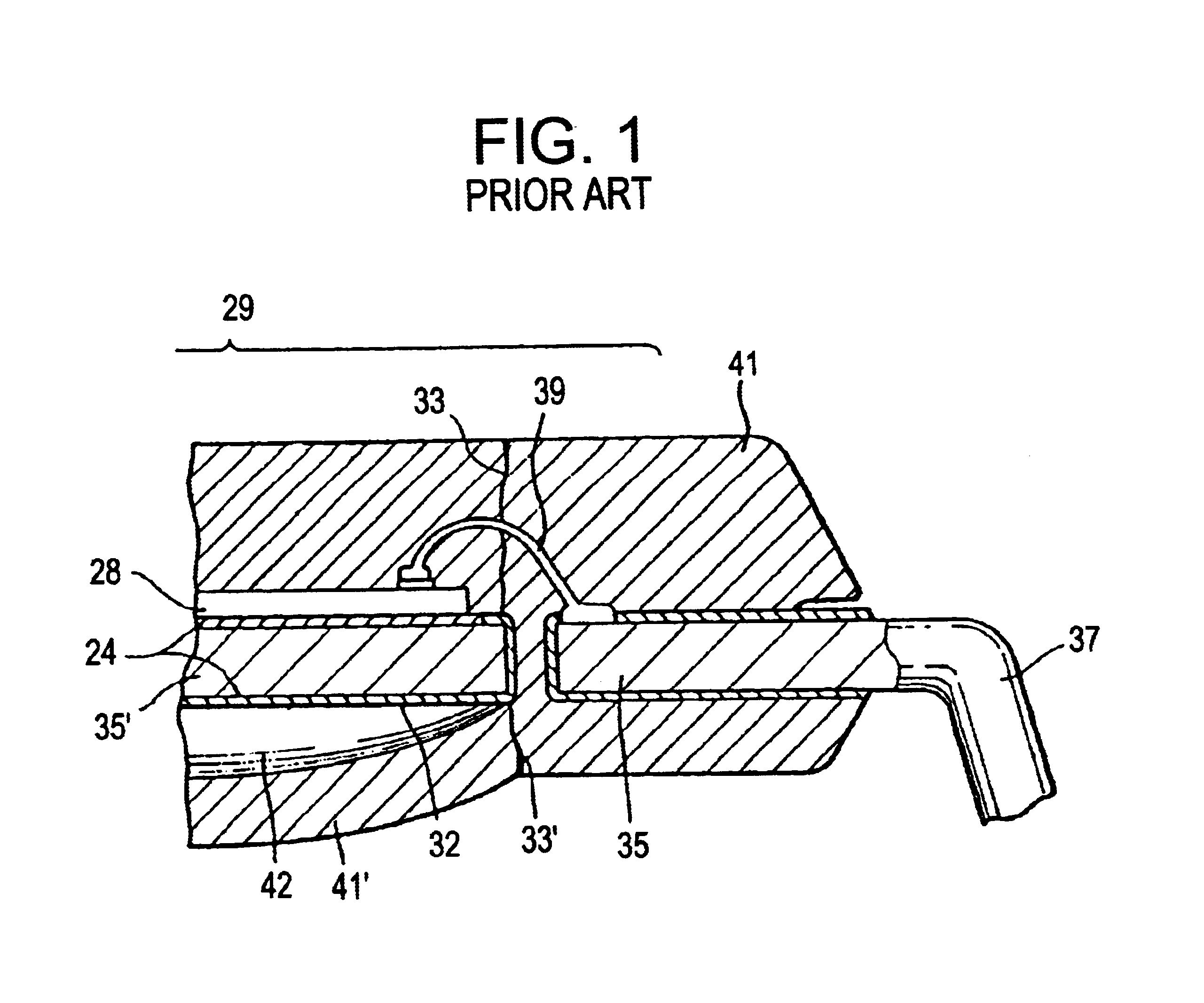

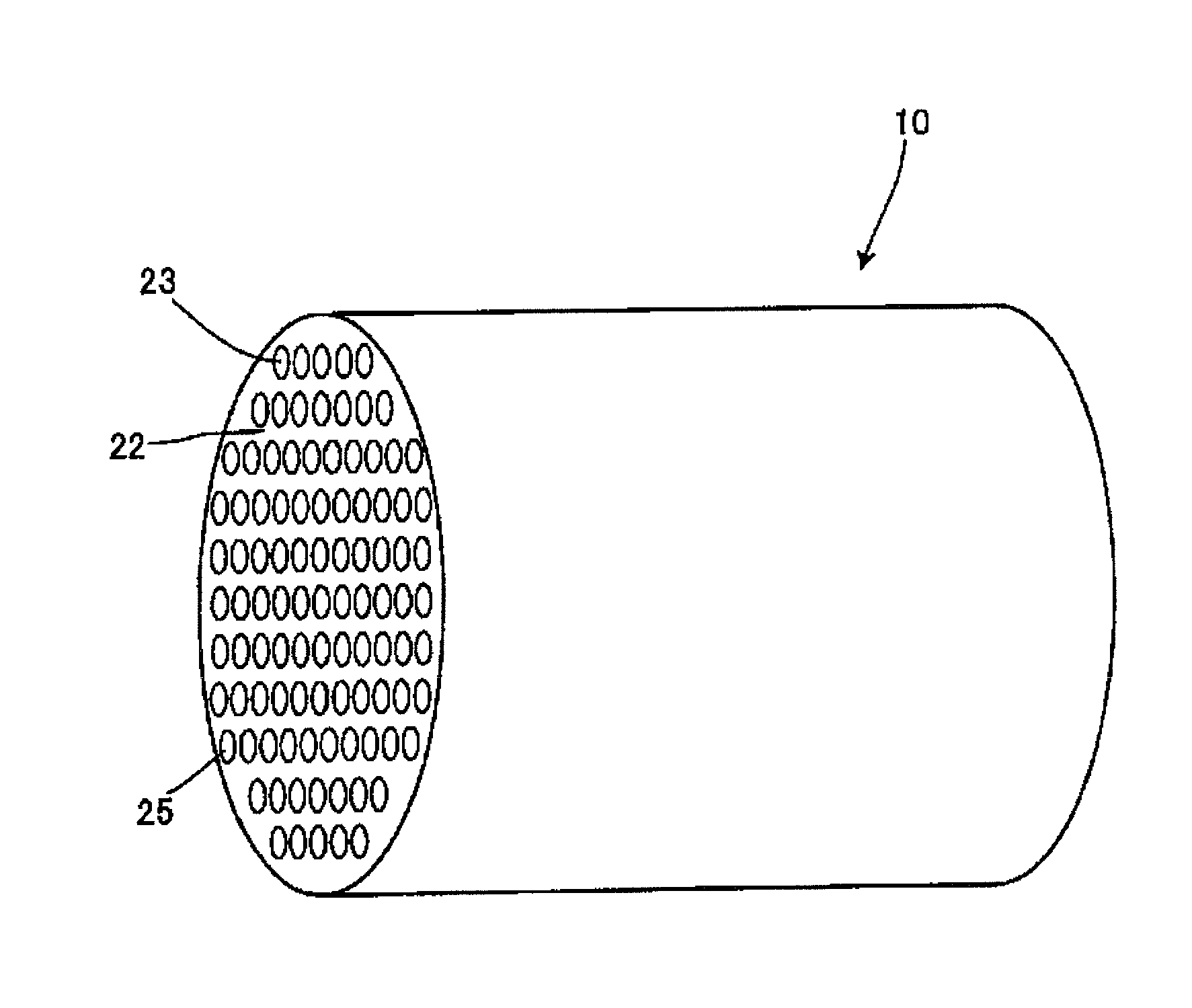

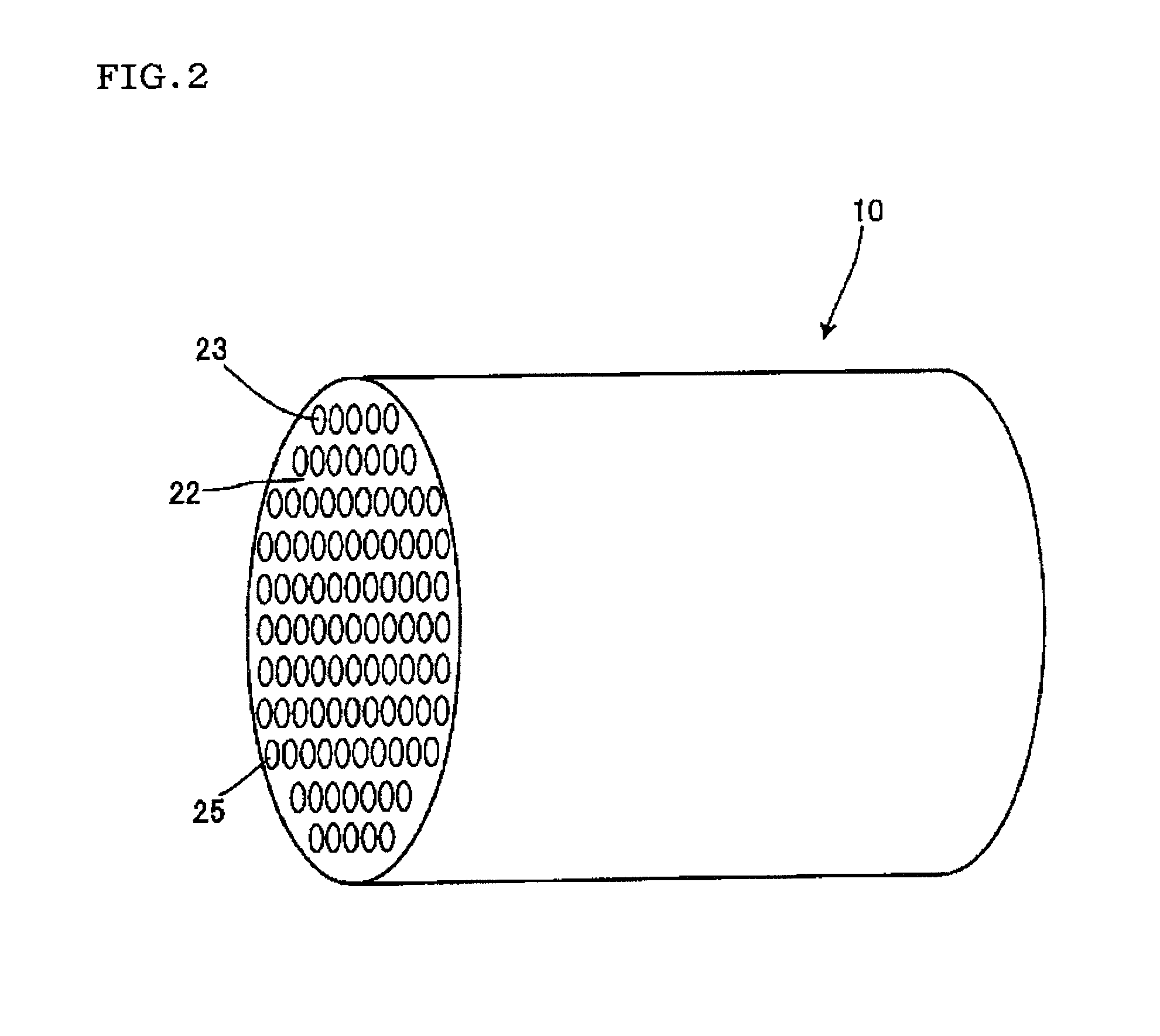

Ceramic filter and regenerating method thereof

InactiveUS20080105627A1Improve performanceEasy to disassembleMembranesSemi-permeable membranesCarbonaceous filmMaterials science

A ceramic filter includes a porous base member formed of a ceramic porous body, a carbonaceous membrane formed on the porous base member, and an inorganic separation membrane (e.g., a silica membrane) formed on the carbonaceous membrane. As the inorganic separation membrane, instead of the silica membrane, a titania membrane, a zirconia membrane, a zeolite membrane or the like may be used. In a regenerating method of the ceramic filter, the deteriorated ceramic filter is thermally treated to remove the carbonaceous membrane and the silica membrane from the porous base member, then the carbonaceous membrane is formed on the porous base member, and the silica membrane is formed on the carbonaceous membrane.

Owner:NGK INSULATORS LTD

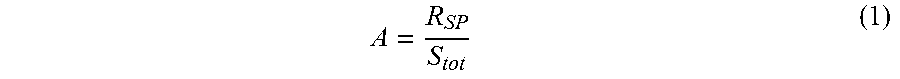

Electrode material and method for producing the same

InactiveUS20130260245A1Conductivity is unevenLower internal resistanceFinal product manufactureSecondary cellsPore diameterCarbonaceous film

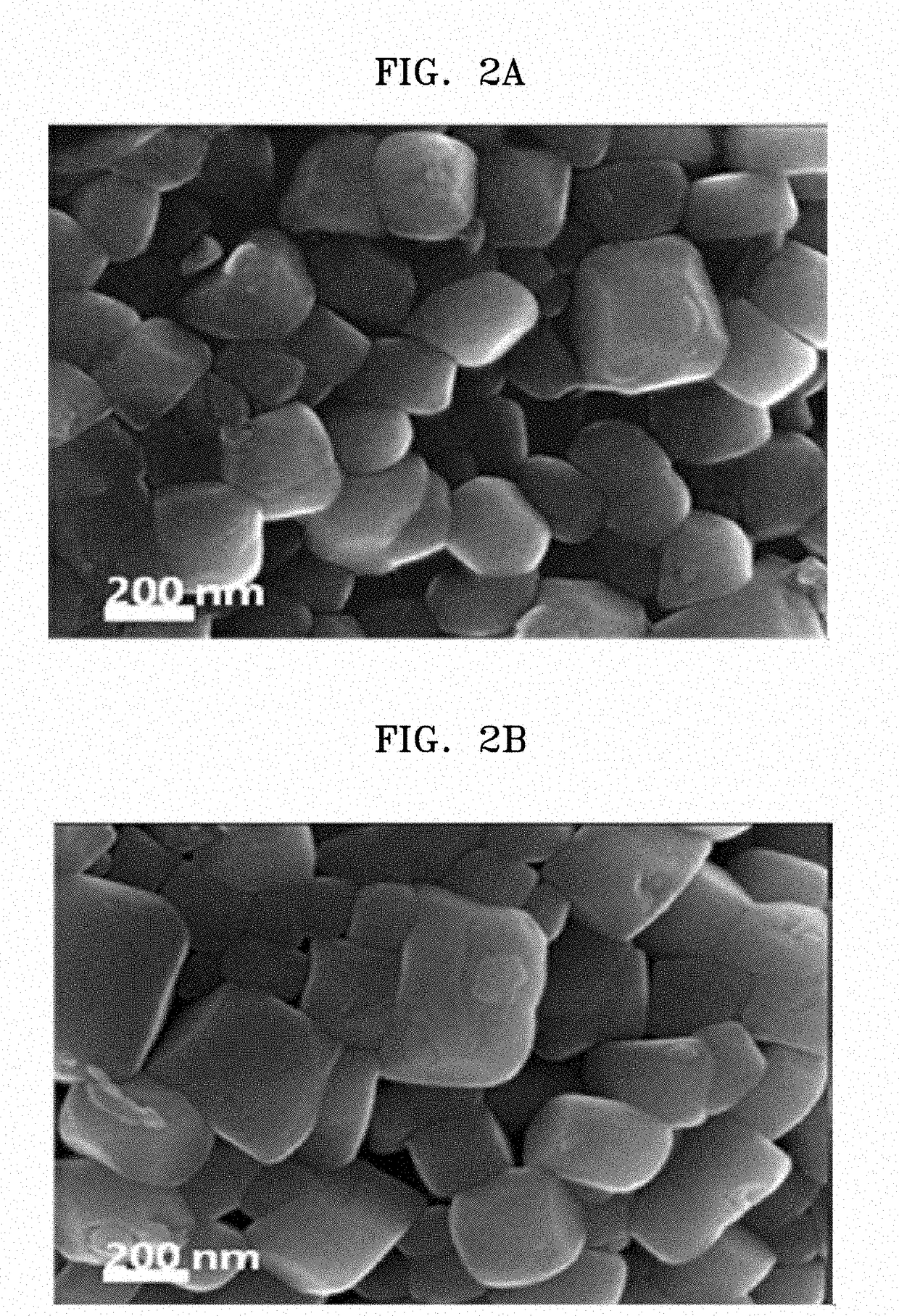

The present invention provides an electrode material in which unevenness in a supporting amount of a carbonaceous film is less when using an electrode-active material having a carbonaceous film on a surface thereof as the electrode material, and which is capable of improving conductivity, and a method for producing the electrode material. The electrode material includes an aggregate formed by aggregating an electrode-active material in which a carbonaceous film is formed on a surface. In the electrode material, an average particle size of the aggregate is 0.5 to 100 μm, a volume density of the aggregate is 50 to 80 vol % of a volume density in a case in which the aggregate is a solid, and 80% or more of the surface of the electrode-active material is covered with the carbonaceous film. Alternatively, the electrode material includes an aggregate formed by aggregating electrode-active material particles in which a carbonaceous film is formed on a surface. In the electrode material, an average particle size of the aggregate is 0.5 to 100 μm, a pore size (D50) when an accumulated volume percentage of a pore size distribution of the aggregate is 50% is 0.1 to 0.2 μm, and porosity of the aggregate is 15 to 50 vol % with respect to a volume in a case in which the aggregate is a solid.

Owner:SUMITOMO OSAKA CEMENT CO LTD

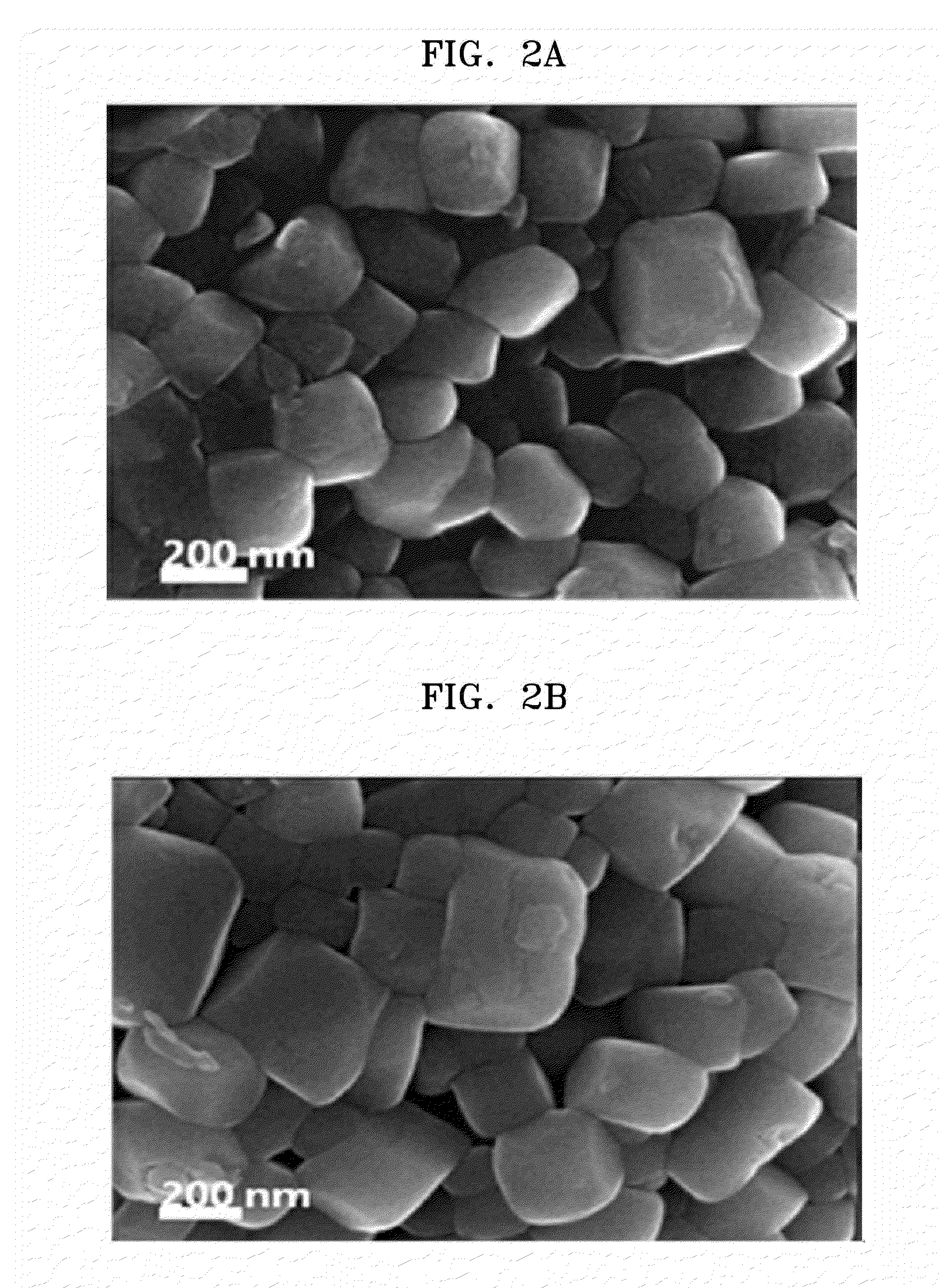

Electrode material, method for manufacturing electrode material, electrode, and lithium ion battery

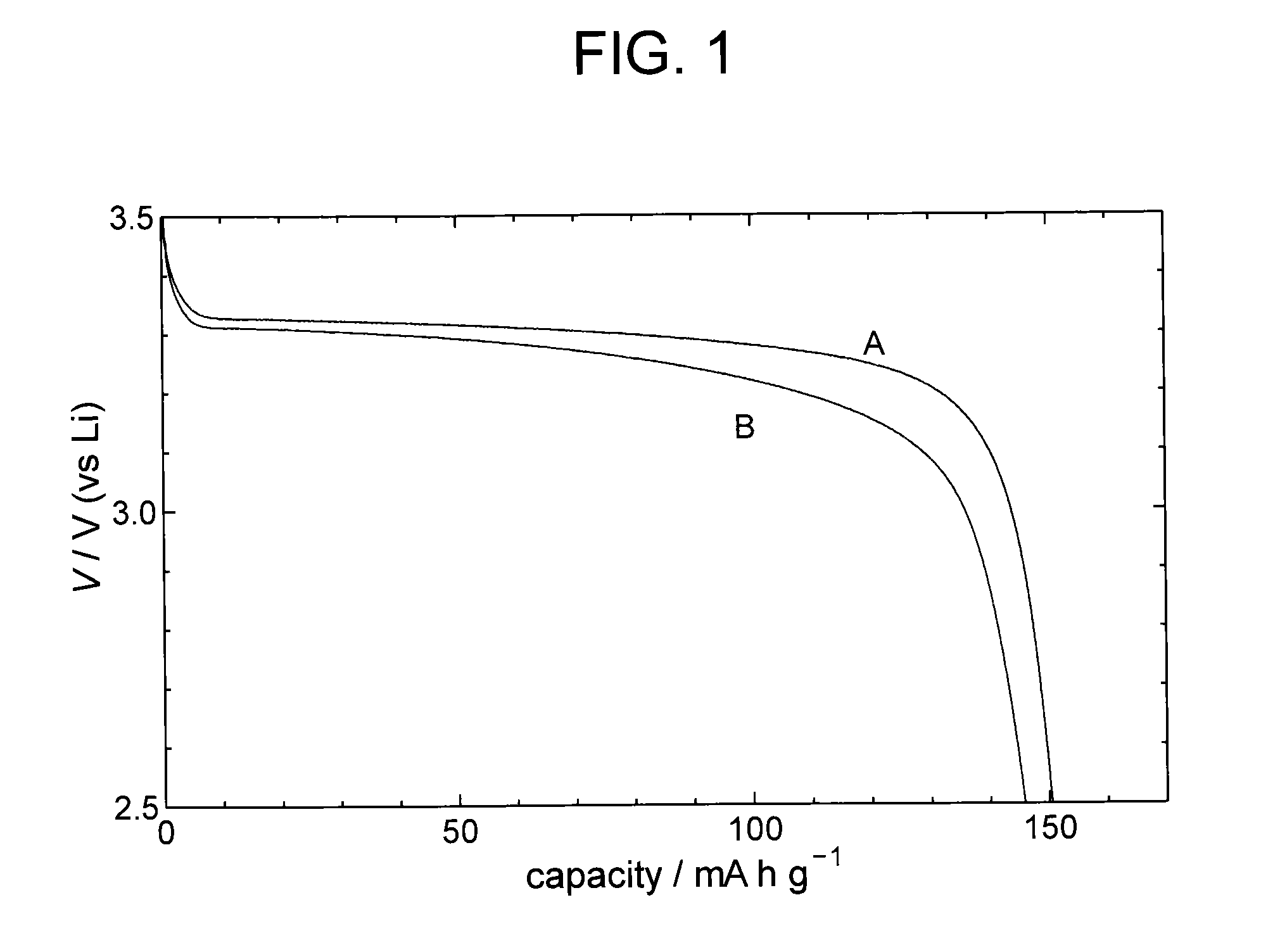

InactiveUS20180062165A1Reduce DC resistanceImprove discharge performanceElectrode thermal treatmentPositive electrodesFull width at half maximumX-ray

An electrode material made of a carbonaceous-coated electrode active material having primary particles of an electrode active material and aggregates of the primary particles and a carbonaceous film that coats the primary particles of the electrode active material and the aggregates of the primary particles, in which an average particle diameter of the carbonaceous-coated electrode active material is 30 nm or more and 200 nm or less, a crystallite diameter obtained from a full width at half maximum of a (020) plane in an X-ray diffraction measurement is 30 nm or more and 100 nm or less, a specific surface area obtained using a BET method is 10 m2 / g or more and 25 m2 / g or less, and a carbon content is 0.5% by mass or more and 2.5% by mass or less.

Owner:SUMITOMO OSAKA CEMENT CO LTD

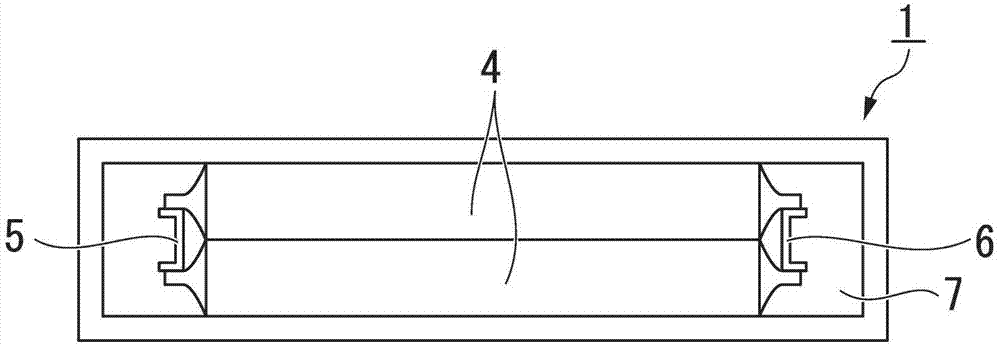

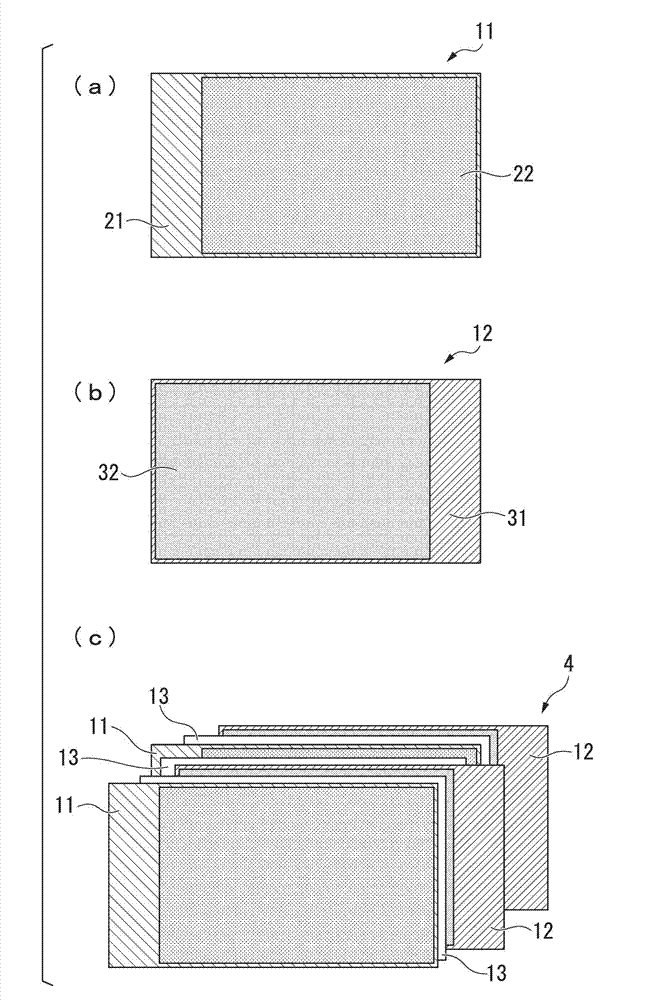

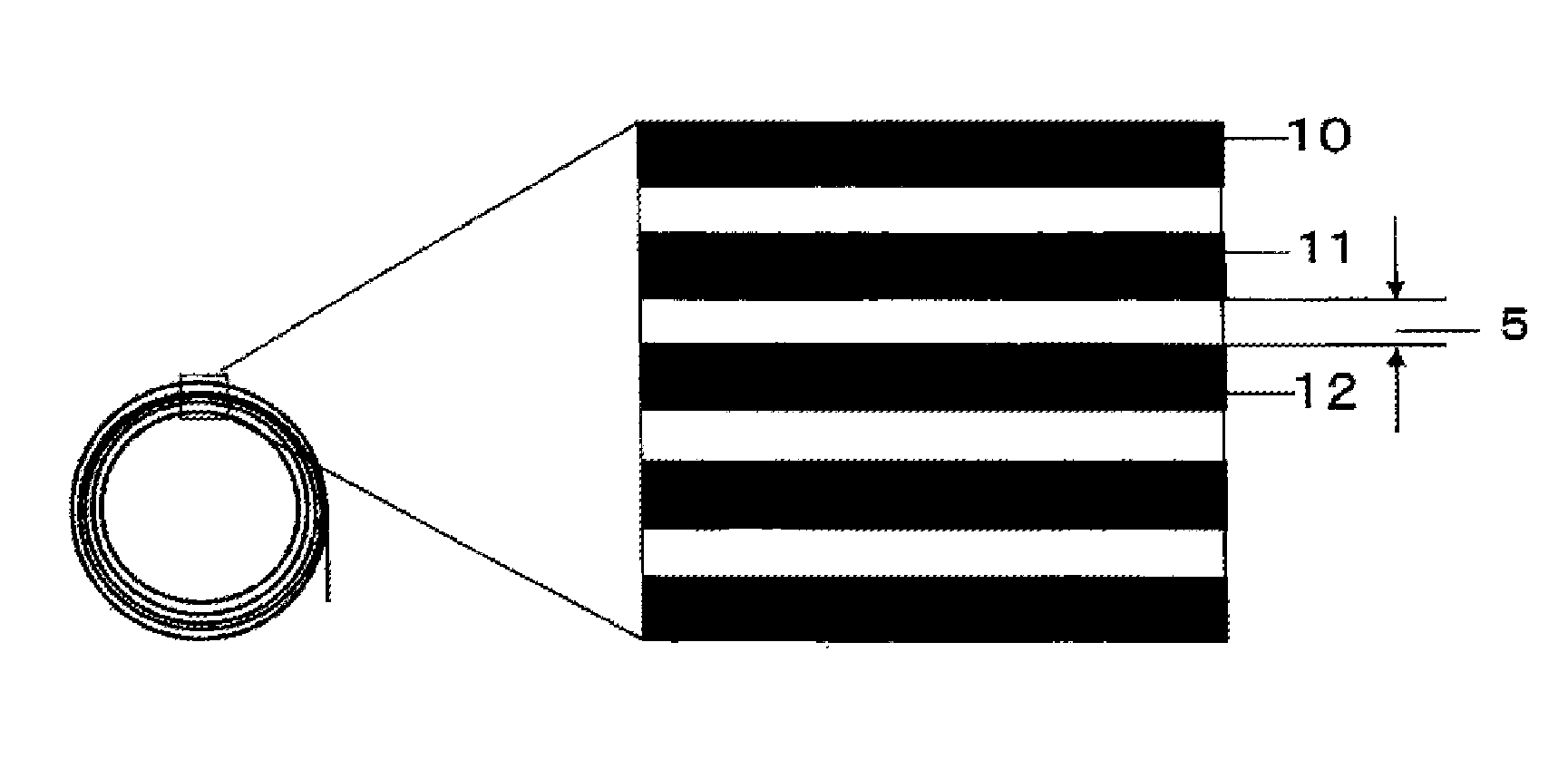

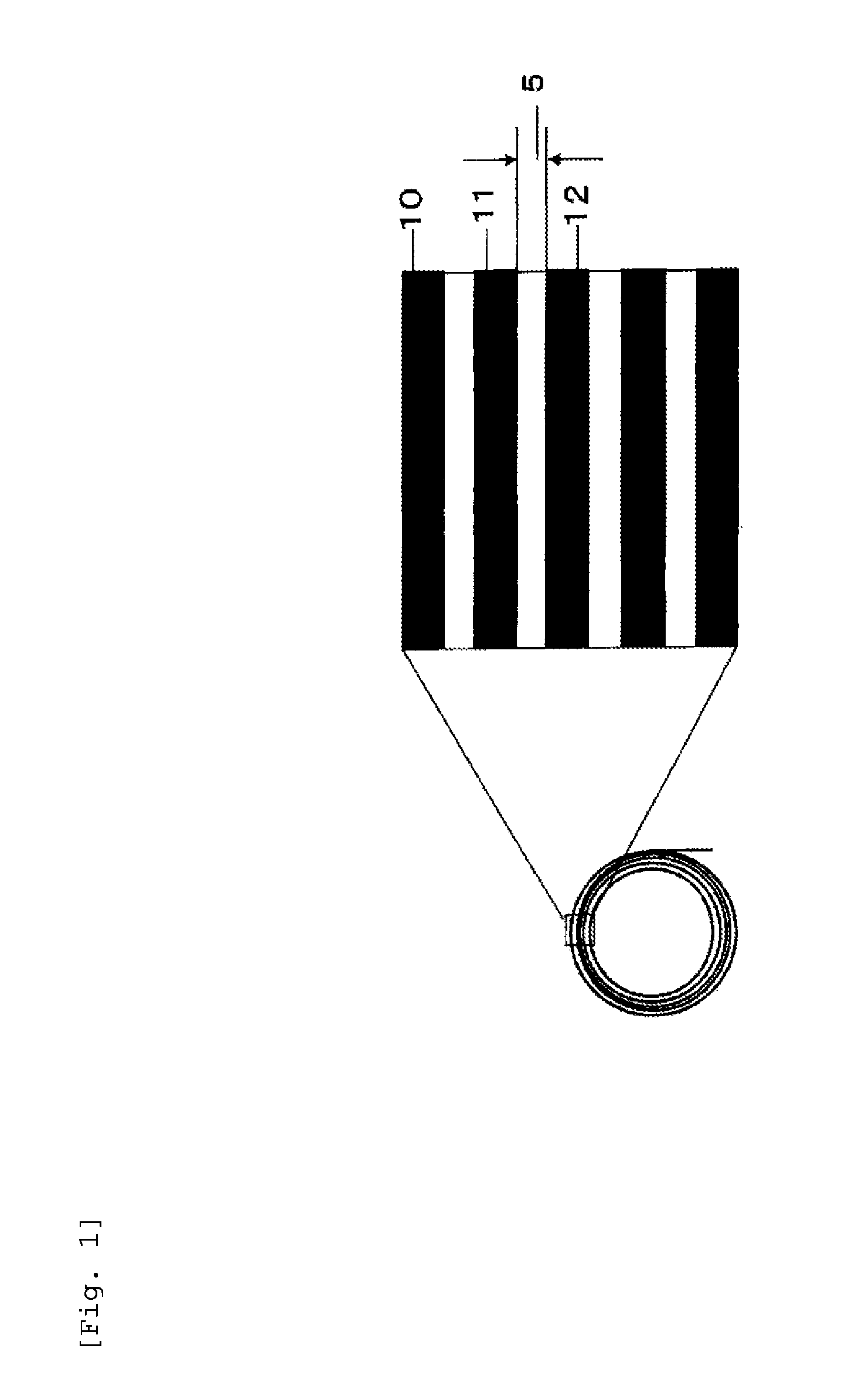

Method for manufacturing carbonaceous film, and graphite film obtained thereby

ActiveUS20110169180A1Increase production capacityEasy to produceCarbon preparation/purificationCarbonizationPolymer thin films

In a method for producing a carbonaceous film in which a polymer film is wrapped around a core and is subjected to a heat treatment, material film surfaces during the carbonization step are prevented from fusion, whereby a long carbonaceous having a large area film is obtained.Fusion can be prevented by subjecting a polymer film to a heat treatment under a reduced pressure, and under a reduced pressure while allowing an inert gas to flow. The range of the pressure reduction is preferably −0.08 MPa to −0.01 kPa. It is preferred to carry out carbonization with the pressure reduced in the range of from −0.08 MPa to −0.01 kPa while allowing an inert gas to flow. In addition, the polymer film wrapped around the core is placed in an outer casing, and provided that a value derived by dividing (internal diameter of the outer casing−diameter of the core) by 2 is designated as “a” (mm), and a thickness of wrapping of the polymer film is designated as “b” (mm), a value (b / a) derived by dividing the “b” by the “a” is set to fall within the range of from 0.2 to 0.9.

Owner:KANEKA CORP

Electrode material

InactiveUS20150325846A1Unevenness of amountImprove electronic conductivityPositive electrodesNon-aqueous electrolyte accumulator electrodesCoverage ratioCarbonaceous film

An electrode material includes an aggregate which is formed by aggregating electrode active material particles having a carbonaceous film forced on the surface thereof, in which a volume density of the aggregate is 50% by volume or more and 80% by volume or less of the volume density of a solid body which has the same external appearance as the aggregate, a coverage ratio of the carbonaceous film with respect to the surface of the electrode active material particles is 80% or more, and an average thickness of the carbonaceous film is 1.0 nm or more and 7.0 nm or less.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Positive electrode material for lithium ion secondary batteries, positive electrode for lithium ion secondary batteries, and lithium ion secondary battery

InactiveUS20160322630A1Reduce amountIncreased durabilitySecondary cellsPositive electrodesLithiumRare-earth element

A positive electrode material for lithium ion secondary batteries includes central particles composed of LiFexMn1-x-yMyPO4 (0.05≦x≦1.0, 0≦y≦0.14, wherein M represents at least one element selected from Mg, Ca, Co, Sr, Ba, Ti, Zn, B, Al, Ga, In, Si, Ge, and rare earth elements), and a carbonaceous film that covers surfaces of the central particles, in which a specific magnetization is 0.70 emu / g or less, and an amount of water detected by a Karl Fischer titration method (coulometric titration method) in a temperature range of 100° C. or higher and 250° C. or lower is 8,000 ppm or less.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Electrode material for lithium-ion rechargeable battery, method for manufacturing electrode material for lithium-ion rechargeable battery, electrode for lithium-ion rechargeable battery, and lithium-ion rechargeable battery

ActiveCN106558699AImprove output characteristicsIncreased durabilityElectrode thermal treatmentPositive electrodesBattery chargeElectrical battery

Owner:SUMITOMO METAL MINING CO LTD

Lithium-ion secondary battery

ActiveUS20170288226A1Excellent long-term cycle characteristicSecondary cellsPositive electrodesInorganic phosphateRare-earth element

A lithium-ion secondary battery including a cathode, an anode, and an electrolyte, in which the lithium-ion secondary battery includes inorganic phosphate particles, and the cathode includes cathode active material particles which include central particles made of LixAyMzPO4 (0≦x≦1.1, 0.8≦y≦1.1, and 0≦z≦0.2; here, A represents at least one element selected from the group consisting of Fe, Mn, Co, and Ni, and M represents at least one element selected from the group consisting of Mg, Ca, Co, Sr, Ba, Ti, Zn, B, Al, Ga, In, Si, Ge, and rare earth elements) and a carbonaceous film that coats surfaces of the central particles.

Owner:SUMITOMO METAL MINING CO LTD

Electrode material for lithium-ion secondary battery and lithium-ion secondary battery

ActiveCN108630910ALower volume resistanceReduce the interface resistance valueSecondary cellsPositive electrodesLITHIUM PHOSPHATEEngineering

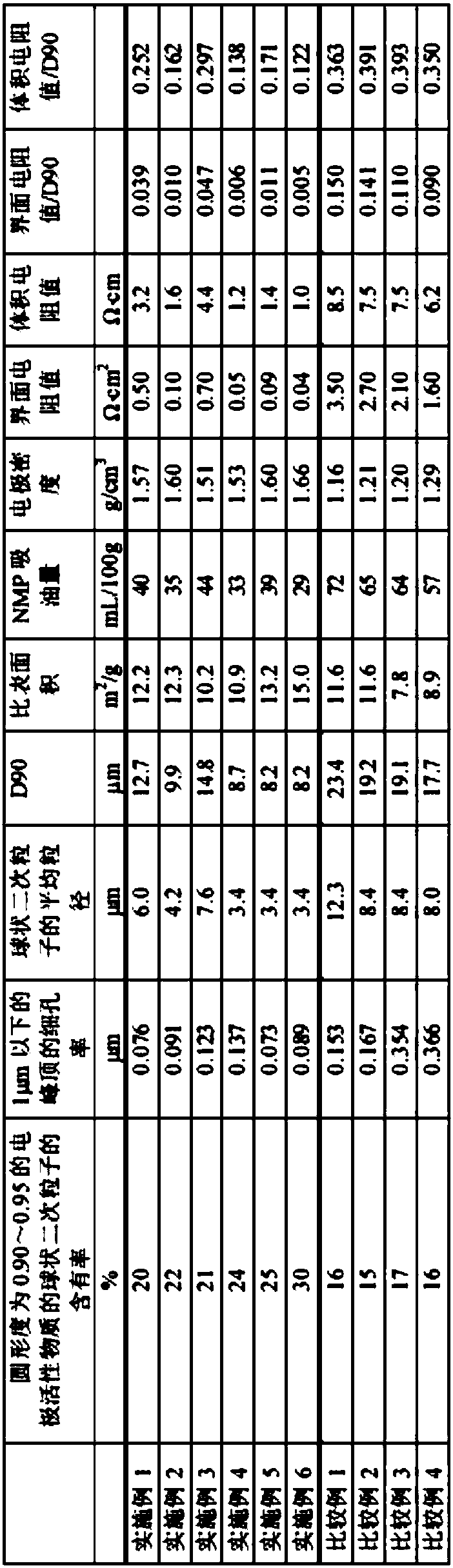

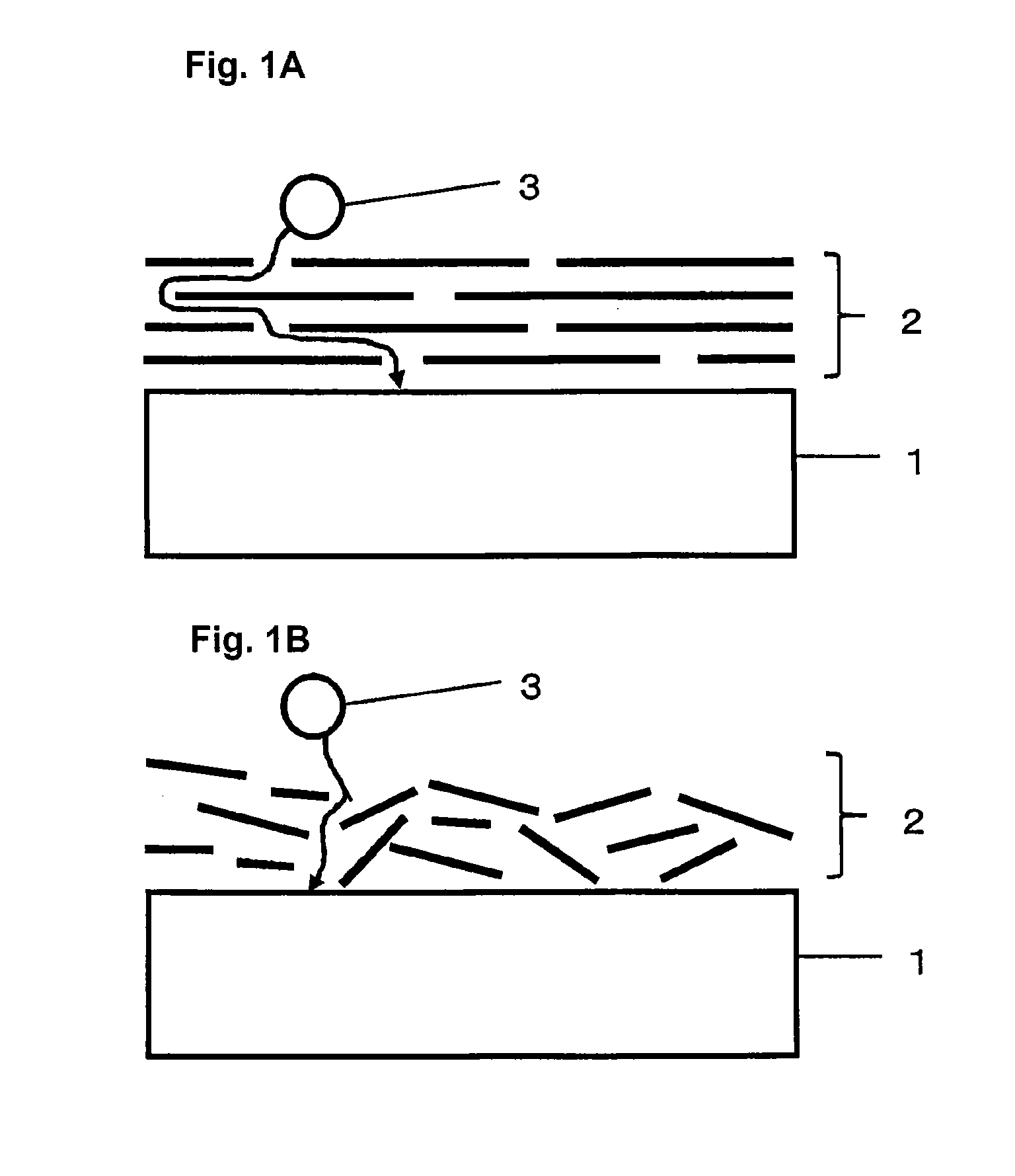

The present invention provides an electrode material for a lithium-ion secondary battery, being able to reduce the volume resistance value of an electrode mixture layer and the interface resistance value of the electrode mixture layer and an aluminum current collector, provides a lithium-ion secondary battery having improved charge / discharge characteristics. The electrode material for a lithium-ion secondary battery includes an electrode active material made of a transition metal lithium phosphate compound having an olivine structure and a carbonaceous film coating the electrode active material, the specific surface area of the electrode active material is 10 m<2> / g to 25 m<2> / g, the average particle diameter of spherical secondary particles formed by granulating the primary particles of the electrode active material is 0.5 mu m to 15 mu m, and, regarding the content of spherical secondary particles having a circularity of, measured using a flow-type particle image analyzer, of 0.90 to0.95, the proportion of the number of the spherical secondary particles in the total number of all of single particles and spherical secondary particles present during the measurement of the degree of circularity is 18% or more. In a lithium-ion secondary battery, a cathode includes a cathode mixture layer formed using the electrode material.

Owner:SUMITOMO METAL MINING CO LTD

Electrode material, paste for electrodes, and lithium ion battery

InactiveUS20150380725A1Suppression pressure dropElectrode thermal treatmentElectrode carriers/collectorsVoltage dropGraphite

An electrode material in which an electrode active material having a carbonaceous film formed on the surface is used and which is capable of suppressing a voltage drop when high-speed charge and discharge is carried out in a low-temperature environment is provided.A electrode material, wherein the electrode material have a particulate shape, the electrode material is formed a carbonaceous film on surfaces of electrode active material particles, and the carbonaceous film is constituted randomly stacking graphene layers. Preferably, an inflection ratio of a lithium ion migration path in the carbonaceous film in the electrode material is in a range of 1.1 to 100.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Positive electrode for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery and battery module

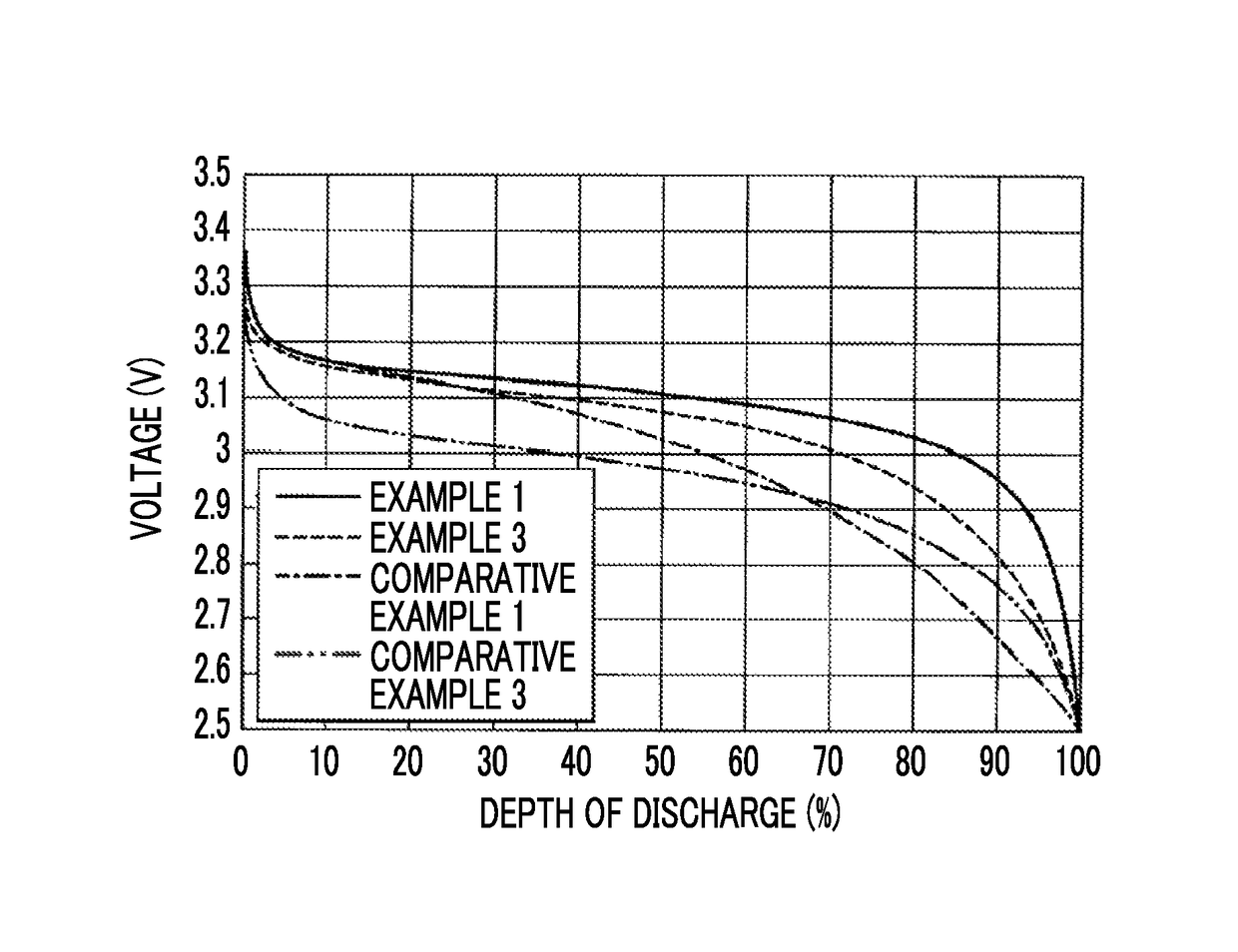

InactiveCN103250280AFast charging and dischargingIncrease insertion/release speedLi-accumulatorsNon-aqueous electrolyte accumulator electrodesElectrical batteryEngineering

The present invention provides a positive electrode for a non-aqueous electrolyte secondary battery in which the charge / discharge rate of a secondary battery is increased by increasing the discharge / discharge rate of the positive electrode as a result of increasing the rate of incorporation and release of lithium ions in olivine-type phosphorous complex compound particles, a non-aqueous electrolyte secondary battery provided with this positive electrode for a non-aqueous electrolyte secondary battery, and a battery module provided with this non-aqueous electrolyte secondary battery. The positive electrode for a non-aqueous electrolyte secondary battery of the present invention is a positive electrode for a non-aqueous electrolyte secondary battery containing olivine-type lithium complex compound particles having a carbonaceous film formed on the surface thereof as a positive electrode active material, in which the coverage factor of the carbonaceous film relative to the surface area of the olivine-type lithium complex compound particles is preferably 95% or more, and the packed density of the olivine-type lithium complex compound particles in this positive electrode for a non-aqueous electrolyte secondary battery is preferably 0.90 g / cm3 to 1.09 g / cm3.

Owner:ELIIY POWER +1

Positive electrode material for lithium ion secondary batteries, positive electrode for lithium ion secondary batteries, lithium ion secondary battery, and method of producing positive electrode material for lithium ion secondary batteries

ActiveUS20160293942A1Excellent battery characteristicsReduce in quantitySecondary cellsPositive electrodesLithiumRare-earth element

To provide a positive electrode material for lithium ion secondary batteries capable of reducing waste loss, a method of producing the same, a positive electrode for lithium ion secondary batteries and a lithium ion secondary battery which contain the above-described positive electrode material for lithium ion secondary batteries. A positive electrode material for lithium ion secondary batteries, wherein the positive electrode material includes inorganic particles whose surfaces are coated with a carbonaceous film, the inorganic particles being represented by a formula LiFexMn1-x-yMyPO4 (0.05≦x≦1.0, 0≦y≦0.14, where M represents at least one selected from the group consisting of Mg, Ca, Co, Sr, Ba, Ti, Zn, B, Al, Ga, In, Si, Ge, and rare earth elements), a specific surface area is 6 m2 / g to 20 m2 / g, a lightness L* is 0 to 40, and a chroma C* is 0 to 3.5.

Owner:SUMITOMO METAL MINING CO LTD

Electrode material, electrode, and lithium ion battery

ActiveUS20160093878A1Improve discharge characteristicsCoatability can be guaranteedPositive electrodesLi-accumulators2-PyrrolidoneSodium-ion battery

An electrode material including electrode active material particles having a carbonaceous film formed on the surfaces thereof in which the coatability of the carbonaceous film can be guaranteed even when a crushing process is carried out, and the rate characteristics and the like are not degraded during charge and discharge, an electrode and a lithium ion battery having excellent charge and discharge characteristics for which the electrode material is used are provided. The electrode material includes electrode active material particles having a carbonaceous film formed on surfaces thereof, and an affinity value to N-methyl-2-pyrrolidone measured through pulse NMR is in a range of 5000 to 20000.

Owner:SUMITOMO METAL MINING CO LTD

Electrode material for lithium-ion secondary battery, electrode for lithium-ion secondary battery, and lithium-ion secondary battery

ActiveUS20170279112A1High rate characteristicsElectrode thermal treatmentSecondary cellsSlurryNon oxidative

An electrode material includes inorganic particles of LiFexMn1-x-yMyPO4 and a carbonaceous film coating surfaces of the inorganic particles, and volume of micropores having micropore diameter of 2 to 10 nm is 3 to 11 cm3 / g. A method for manufacturing an electrode material includes immersing the inorganic particles in an aqueous solution having pH of 7.0 to 10.0; producing a slurry including the inorganic particles, a carbonaceous film precursor, and water; producing a dried substance of the slurry by drying the slurry; and calcinating the dried substance in a non-oxidative atmosphere of 500° C. to 1,000° C., and an amount of the carbonaceous film precursor blended into 100 parts by mass of the inorganic particles when converted to a carbon element is 1.0 to 5.0 parts by mass. An electrode includes the electrode material. A lithium-ion secondary battery includes a cathode; an anode; and a non-aqueous electrolyte, the cathode being the electrode.

Owner:SUMITOMO METAL MINING CO LTD

Electrode material and method for manufacturing same

ActiveUS20160190589A1Not impair improvement of electron conductivityImprove wettabilityNon-metal conductorsElectric discharge heatingSimple Organic CompoundsNon oxidative

An electrode material including electrode active material particles and a carbonaceous film layer coating surfaces of the electrode active material particles and including a metal oxide, a content ratio of the metal oxide in the carbonaceous film layer being 5% by mass to 70% by mass. A method for manufacturing an electrode material, in which electrode active material particles, a metal salt or metal alkoxide containing any one or more metal atoms selected from a group consisting of Al, Zr, Si, and Ti, and an organic compound which is a precursor of carbon are mixed so that a total blending amount of the metal salt or metal alkoxide satisfies that an amount of a metal oxide in the carbonaceous film layer when the metal salt or metal alkoxide is all changed to the metal oxide is 5% by mass to 70% by mass, and are heated in a non-oxidative atmosphere.

Owner:SUMITOMO METAL MINING CO LTD

Electrode material for lithium-ion secondary battery and lithium-ion secondary battery

InactiveUS20180277887A1Decreasing volume resistance valueImprove discharge characteristicsSecondary cellsPositive electrodesLITHIUM PHOSPHATEOlivine

An electrode material for a lithium-ion secondary battery includes an electrode active material made of a transition metal lithium phosphate compound having an olivine structure and a carbonaceous film coating the electrode active material, the specific surface area of the electrode active material is 10 m2 / g to 25 m2 / g, the average particle diameter of spherical secondary particles formed by granulating the primary particles of the electrode active material is 0.5 μm to 15 μm, and, regarding the content of spherical secondary particles having a circularity of, measured using a flow-type particle image analyzer, of 0.90 to 0.95, the proportion of the number of the spherical secondary particles in the total number of all of single particles and spherical secondary particles present during the measurement of the degree of circularity is 18% or more. In a lithium-ion secondary battery, a cathode includes a cathode mixture layer formed using the electrode material.

Owner:SUMITOMO OSAKA CEMENT CO LTD

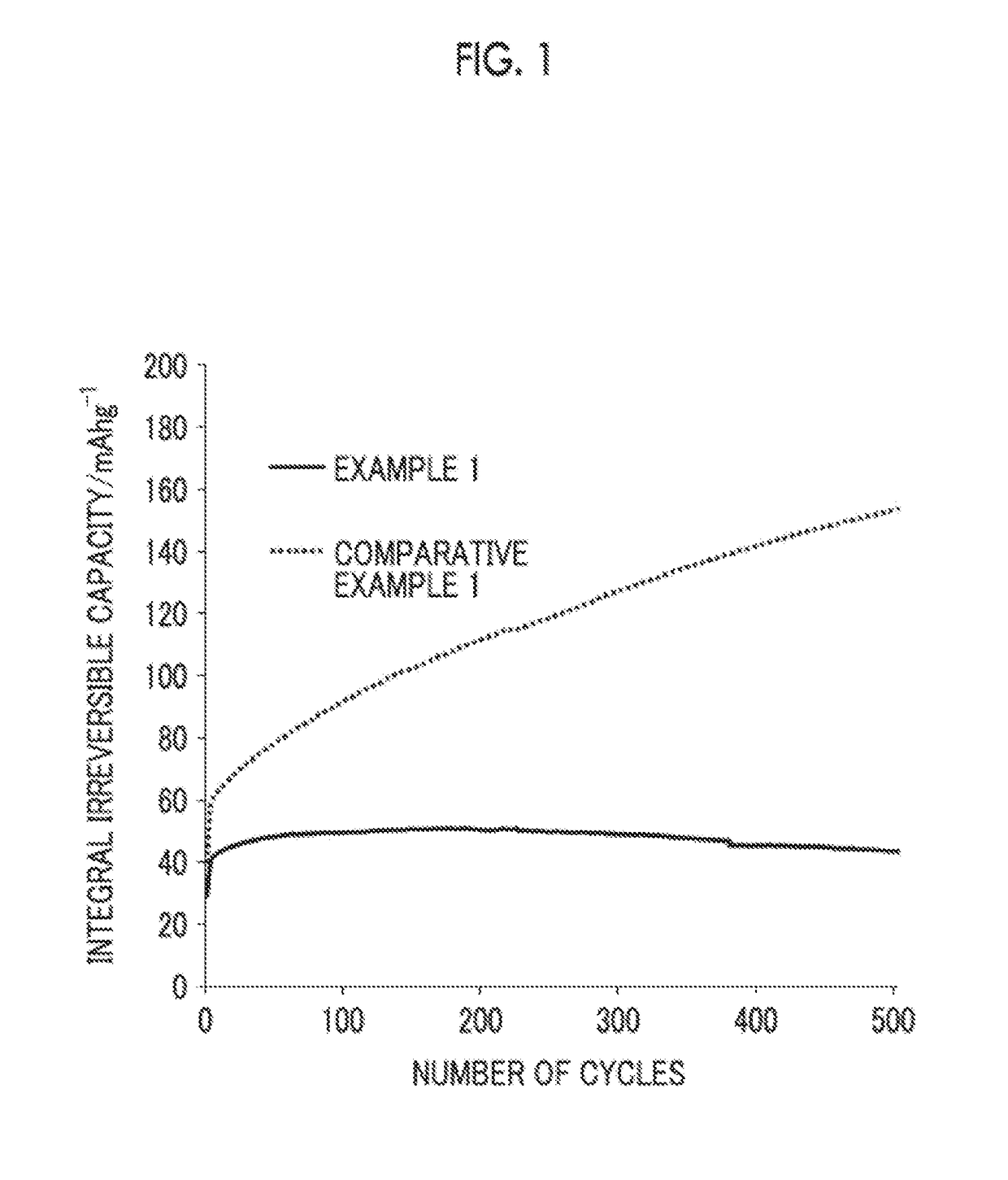

Electrode material for lithium-ion rechargeable battery, method for manufacturing electrode material for lithium-ion rechargeable battery, electrode for lithium-ion rechargeable battery, and lithium-ion rechargeable battery

InactiveUS20170092937A1Improve output characteristicsIncreased durabilityElectrode thermal treatmentPositive electrodesBattery chargeLithium metal

Provided are an electrode material for a lithium-ion rechargeable battery including core particles of an active material and a carbonaceous film, in which a powder resistance is 150 Ω·cm or less, and a lithium-ion rechargeable battery produced using the electrode material and a lithium metal exhibits a difference between a sum of a charge capacity with an upper limit voltage of 4.2 V and the lithium-ion rechargeable battery charged at a constant current and a charge capacity with the lithium-ion rechargeable battery charged at a constant voltage for seven days at 4.2 V after the constant current charging and a discharge capacity with the lithium-ion rechargeable battery discharged at a constant current to 2 V after the constant voltage charging reaches 25 mAh / g or less, a method for manufacturing the electrode material, an electrode including the electrode material, and a lithium-ion rechargeable battery including the electrode as a cathode.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Cathode material for lithium-ion secondary battery, cathode for lithium-ion secondary battery, and lithium-ion secondary battery

ActiveUS10109861B2Reduce reduction reactionExcellent input and output characteristicsPositive electrodesLi-accumulatorsPeak intensityCarbonaceous film

A cathode material for a lithium-ion secondary battery of the present invention includes central particles represented by LixAyMzPO4 and a carbonaceous film that coats surfaces of the central particles, an average value of R values (I1580 / I1360), which are ratios of a peak intensity (I1580) of a spectrum at a frequency band of 1,580±50 cm−1 to a peak intensity (I1360) of the spectrum at a frequency band of 1,360±50 cm−1 in a Raman spectrum analysis, measured at five points is 0.80 or more and 1.10 or less, and a standard deviation of the R values measured at five points is 0.010 or less.

Owner:SUMITOMO METAL MINING CO LTD

Electrode material for lithium-ion secondary battery, method for manufacturing same, electrode for lithium-ion secondary battery, and lithium-ion secondary battery

InactiveUS20170237064A1Improve output characteristicsIncreased durabilityElectrode thermal treatmentElectrode carriers/collectorsElectrical resistance and conductanceLithium metal

An electrode material for a lithium-ion secondary battery includes an electrode active material and a carbonaceous film with which a surface of the electrode active material is coated, in which a powder resistance under compression at a pressure of 45 MPa is 130 Ω·cm or lower and a lithium-ion secondary battery including a cathode including the electrode material for a lithium-ion secondary battery and an anode made of lithium metal exhibits battery characteristics that a difference between a sum of a charge capacity thereof obtained when constant current charged with an upper limit voltage with respect to the anode set to 4.20 V and a charge capacity thereof obtained when constant voltage charged at 4.20 V for ten days after the constant current charge and a discharge capacity thereof obtained when constant current discharged to 2 V after the constant voltage charge is set to 20 mAh / g or lower.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Electrode material for lithium-ion rechargeable battery and method for manufacturing same

ActiveUS20170092933A1Adhesiveness of highGood dispersibilityElectrode thermal treatmentSecondary cellsLithiumRare-earth element

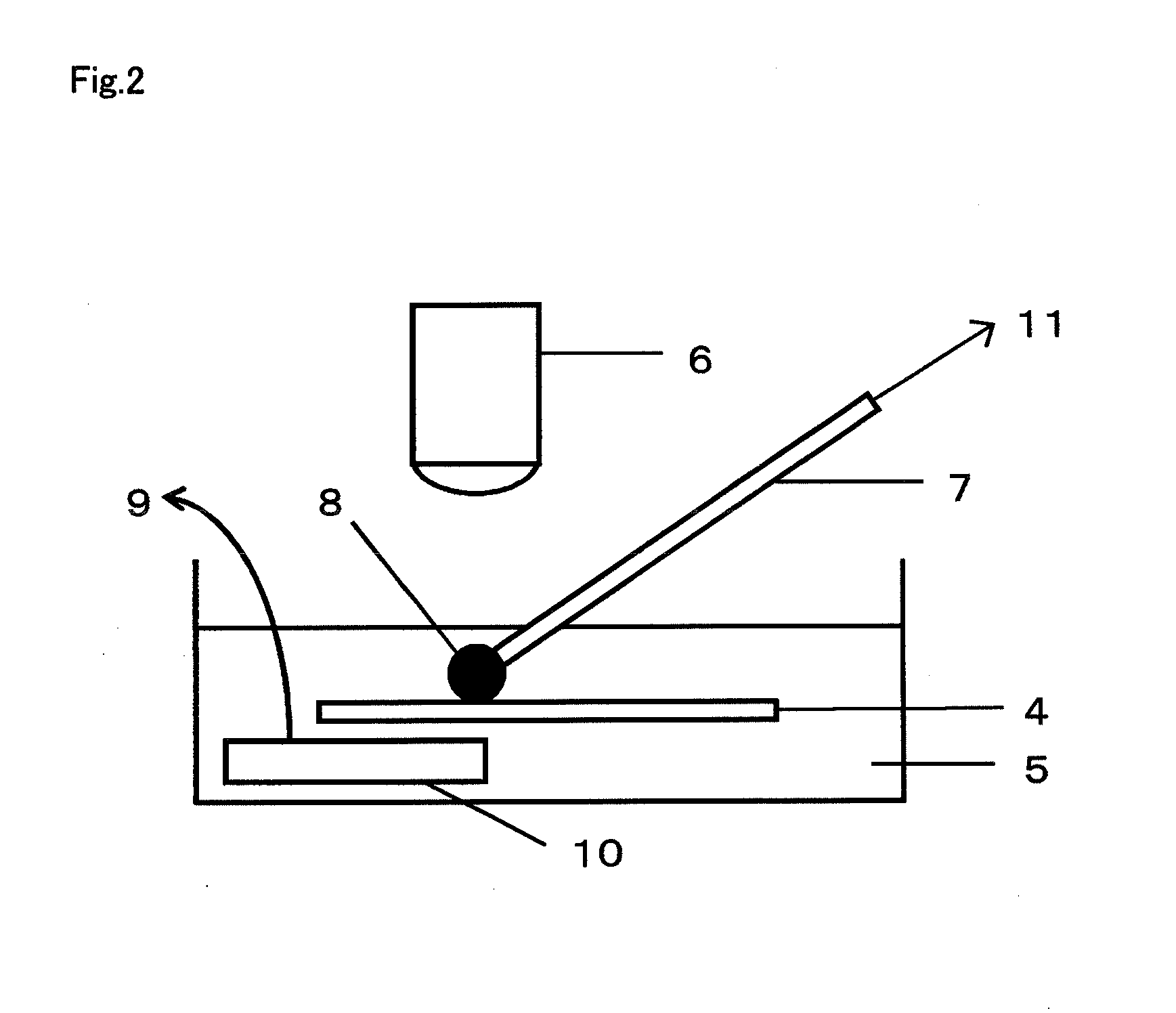

An electrode material for a lithium-ion rechargeable battery of the present invention is an electrode material for a lithium-ion rechargeable battery formed by coating a surface of an electrode active material represented by General Formula LiFexMn1-x-yMyPO4 (here, M represents at least one element selected from Mg, Ca, Co, Sr, Ba, Ti, Zn, B, Al, Ga, In, Si, Ge, and rare earth elements, 0.05≦x≦1.0, 0≦y≦0.14) with a carbonaceous film, in which an angle of repose is in a range of 35° or more and 50° or less.

Owner:SUMITOMO METAL MINING CO LTD

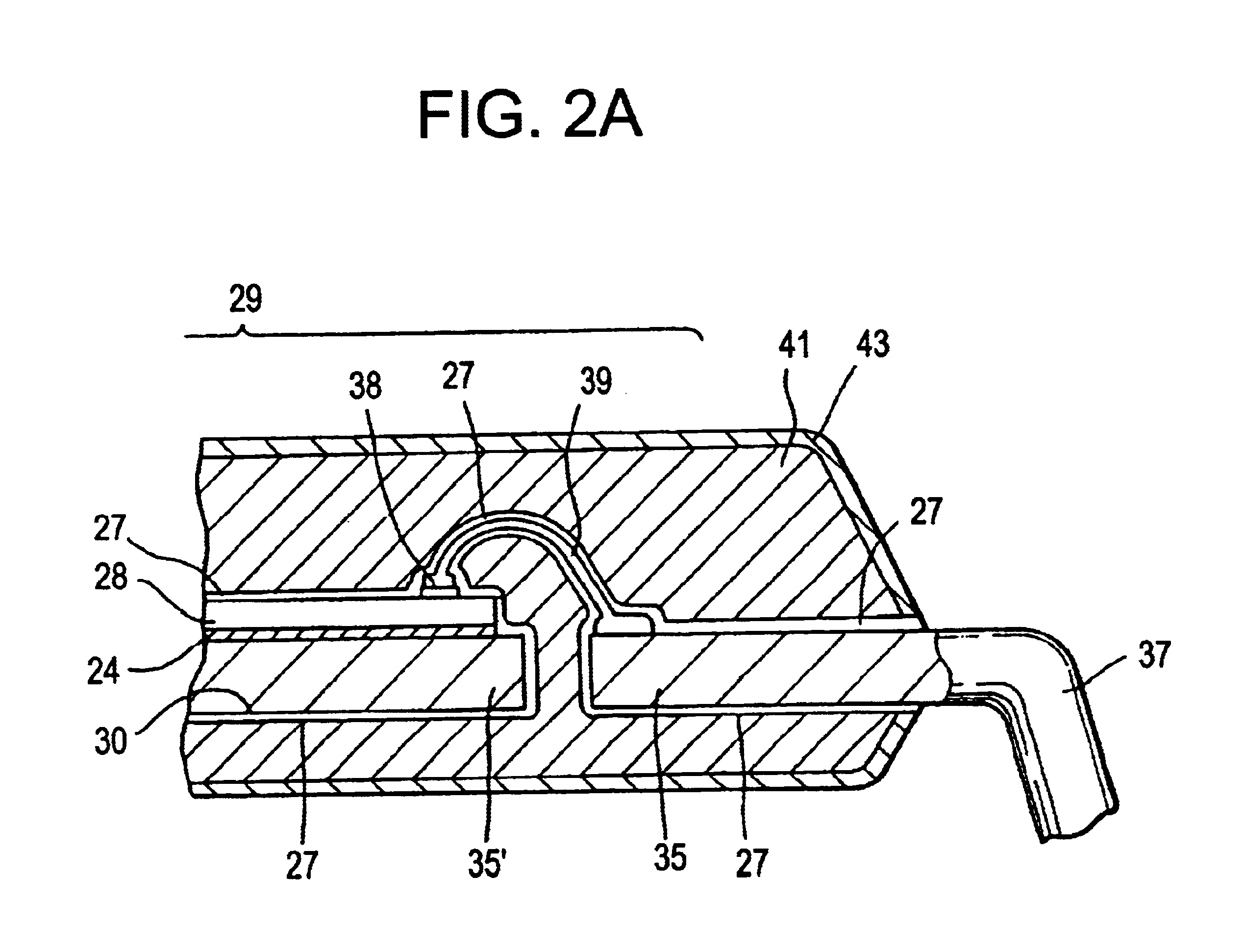

Separation membrane-porous material composite and method for manufacturing the same

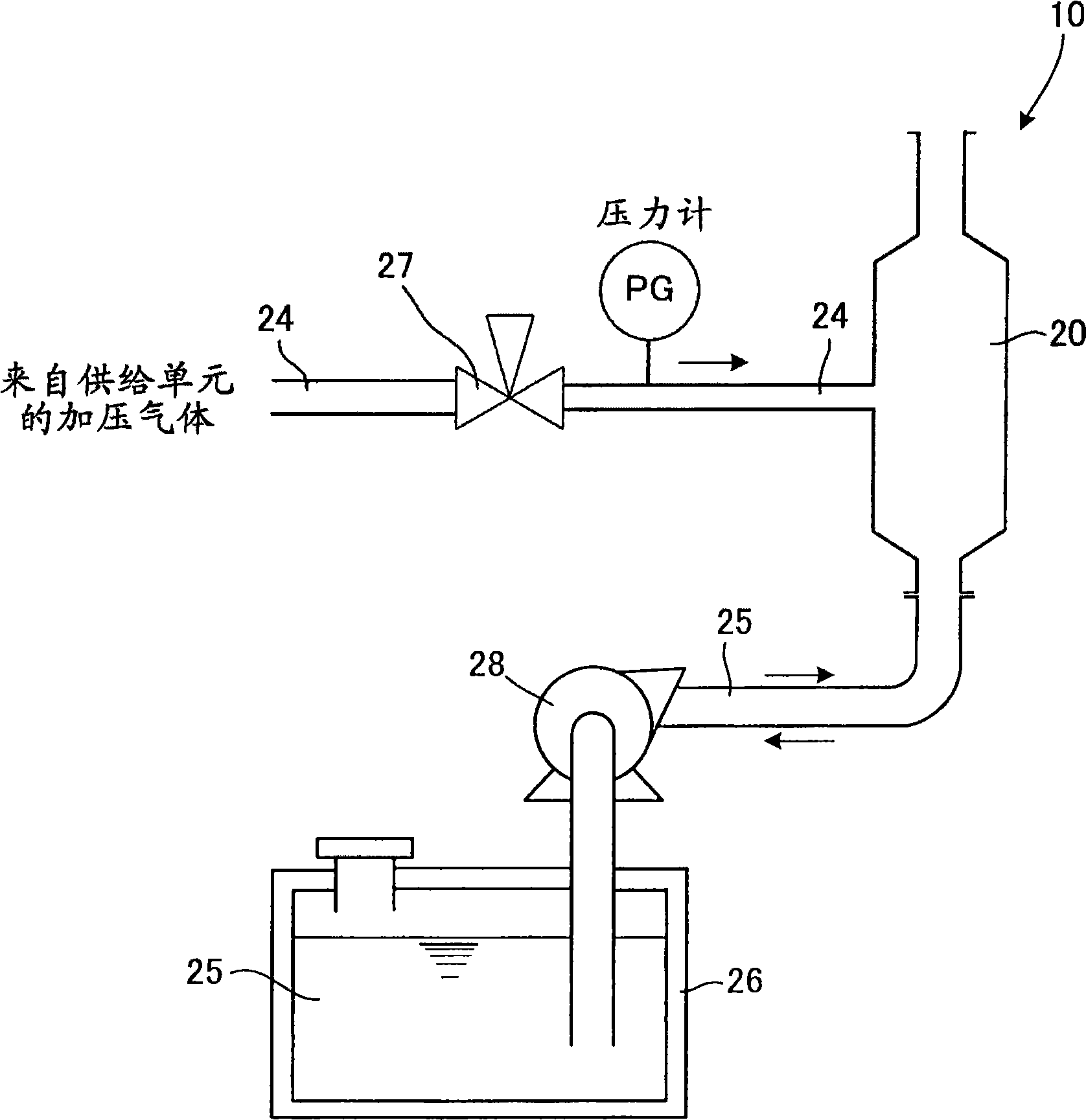

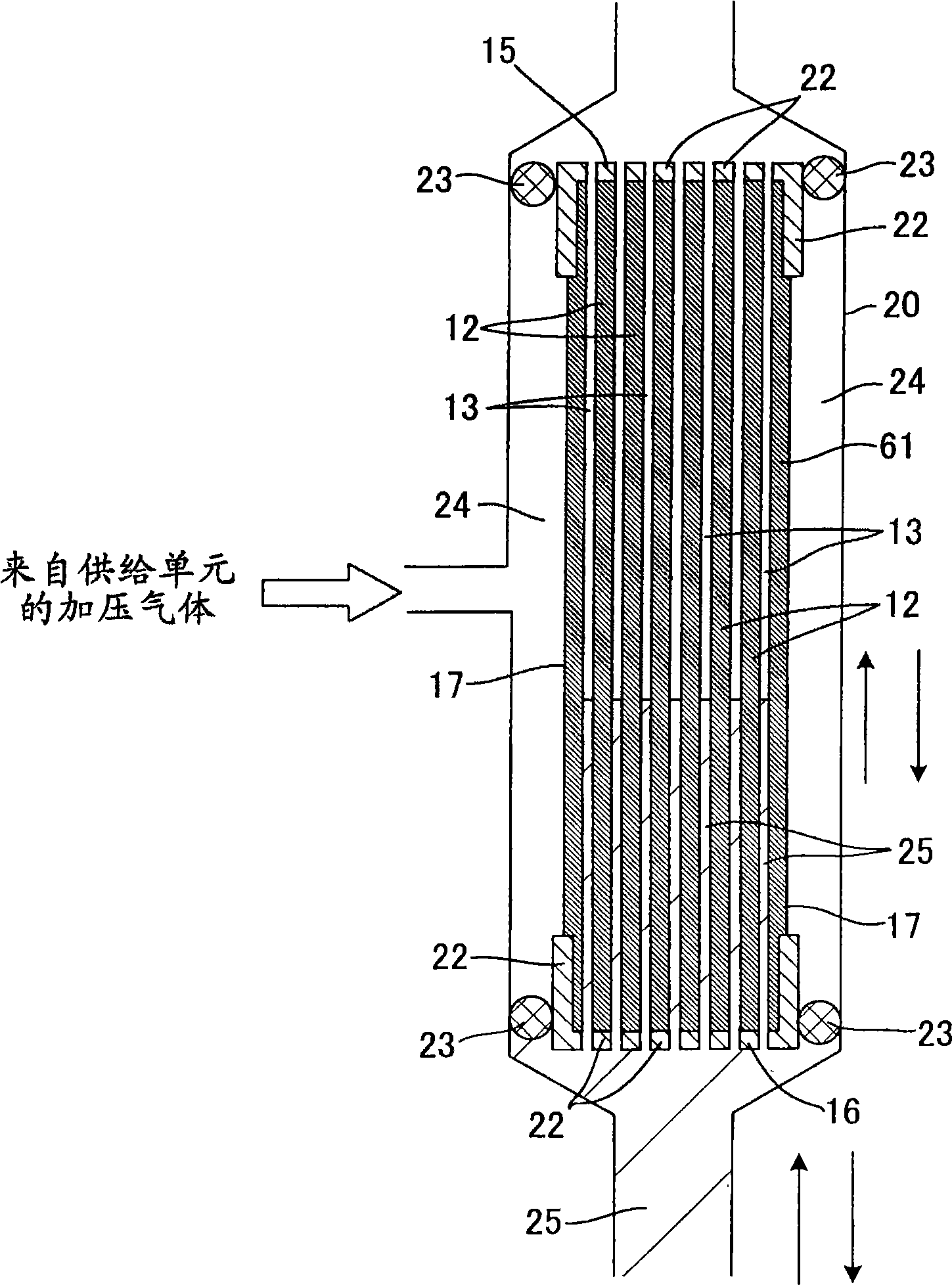

ActiveCN101534929AGood effectHigh trafficSemi-permeable membranesMembranesCarbon layerCarbonaceous film

A separation membrane-porous material composite (1) being improved in flux and selectivity, which comprises a porous ceramic material and a separation membrane formed on the porous material, wherein a composite layer (65) having a thickness of 1 mm or less is provided at the interface between the porous material (61) as a dense layer (64) and the separation membrane (66) being formed as a carbonaceous film while maintaining an increased pressure inside the porous material to avoid penetration of the carbon layer precursor into the pores.

Owner:NGK INSULATORS LTD

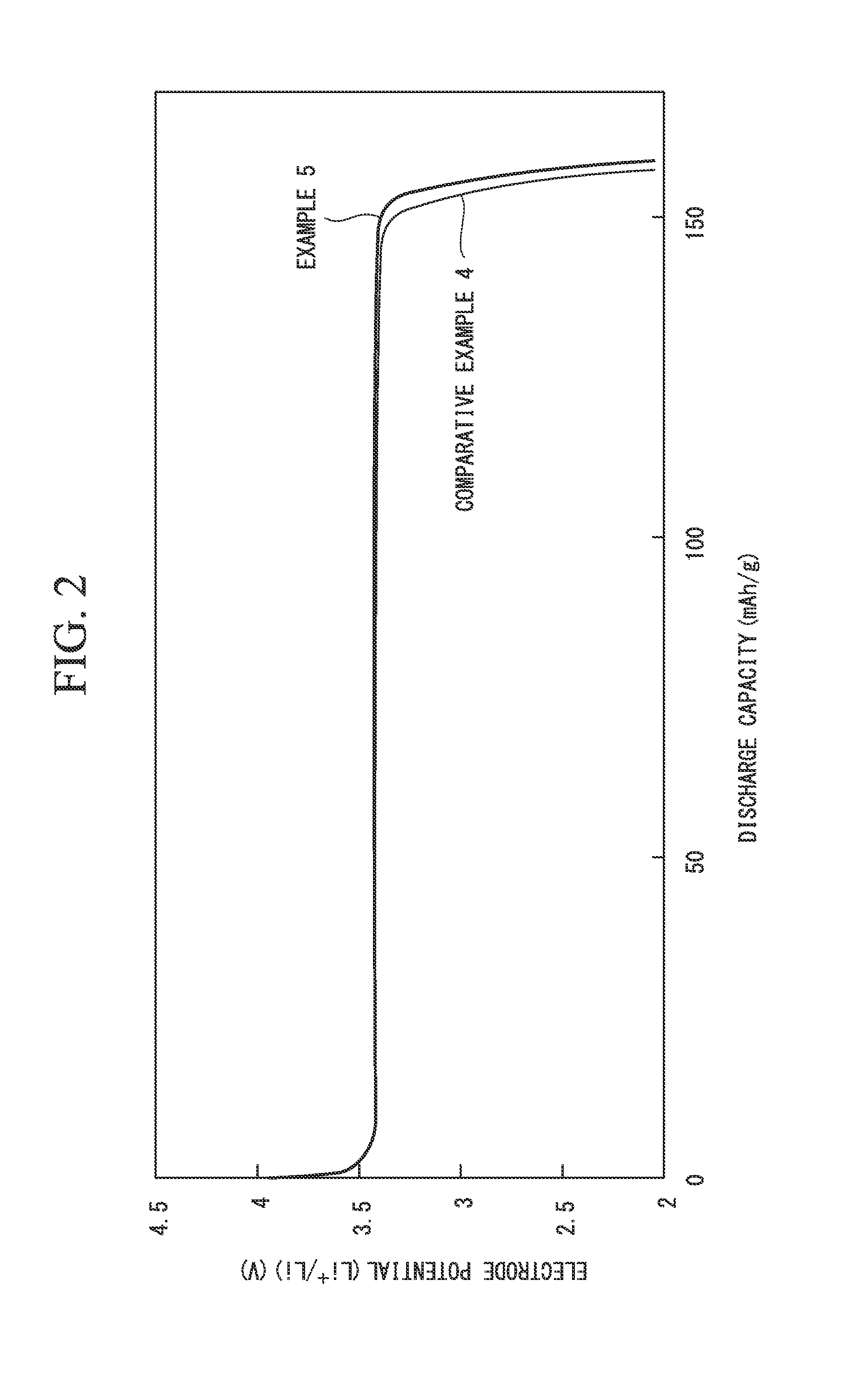

Cathode active material, secondary battery comprising the same, and method of manufacturing the positive active material

ActiveUS20180205077A1Increase capacityImprove efficiencyPositive electrodesIron compoundsOxygenCarbonaceous film

A positive active material including: a core comprising a metal oxide, a non-metal oxide, or a combination thereof capable of intercalation and deintercalation of lithium ions or sodium ions; and a non-conductive carbonaceous film including oxygen on at least one portion of a surface of the core; a lithium battery including the positive active material; and a method of manufacturing the positive active material.

Owner:SAMSUNG ELECTRONICS CO LTD

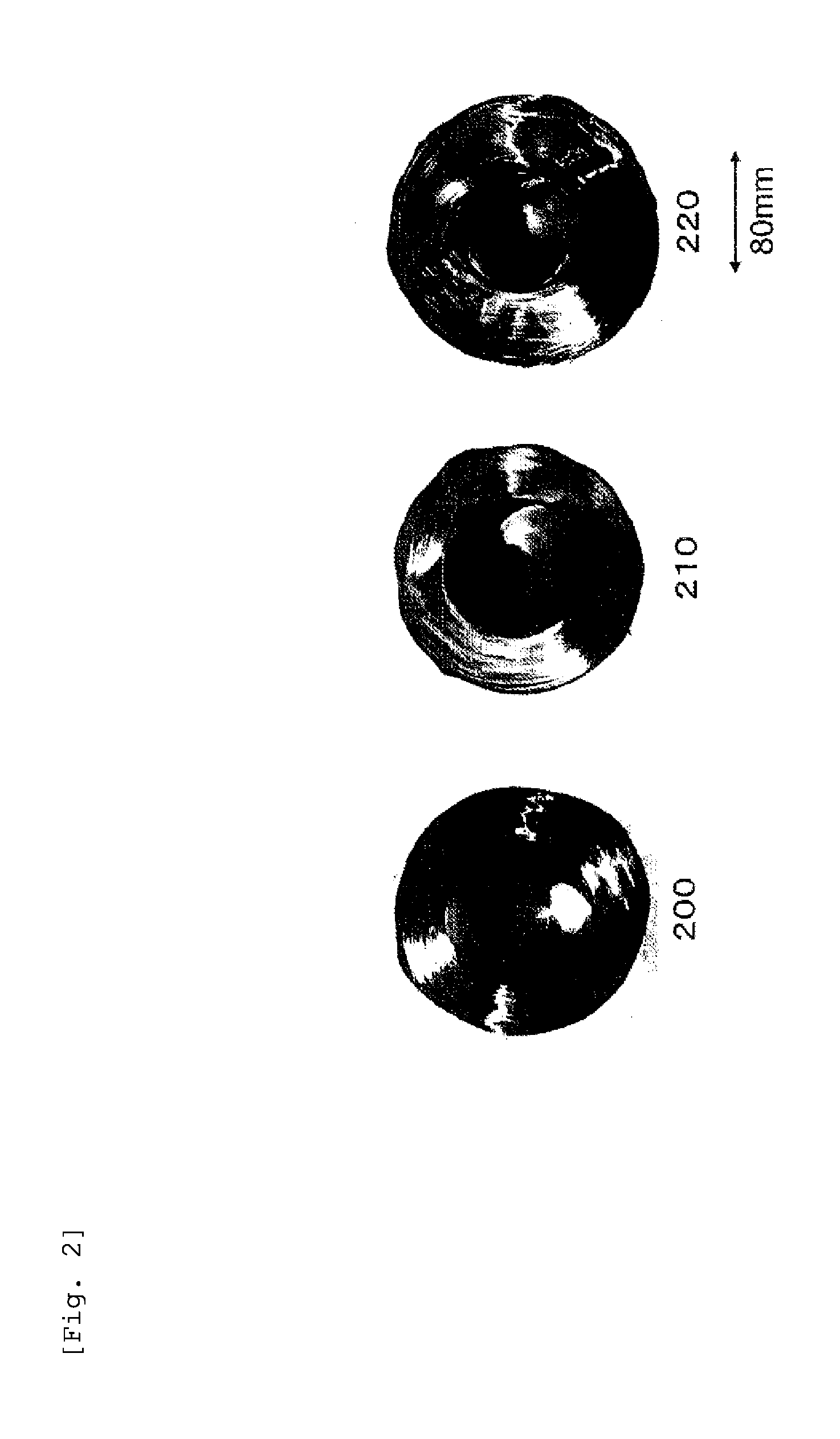

Method for producing carbonaceous film, method for producing graphite film, roll of polymer film, and roll of carbonaceous film

Disclosed herein is a method for producing an elongated (rolled) carbonaceous film by polymer pyrolysis while suppressing the fusion bonding of the carbonaceous film. The method for producing a carbonaceous film includes the step of heat-treating a polymer film wound into a roll, wherein the heat treatment is performed after the polymer film is wound into a roll to have a gap between adjacent layers of the polymer film at a temperature lower than a pyrolysis onset temperature of the polymer film so that the roll of polymer film as a whole satisfies a relationship that a value obtained by dividing a thickness of a gap between adjacent layers of the polymer film (Ts) by a thickness of the polymer film (Tf) (Ts / Tf) is 0.16 or higher but 1.50 or lower. As a method for forming gaps between the layers of the polymer film, a method in which the polymer film is wound into a roll together with a slip sheet and then the slip sheet is removed can be used, which is effective at suppressing the fusion bonding of a carbonaceous film.

Owner:KANEKA CORP

Electrolytic anode and method for electrolytically synthesizing fluorine containing substance using the electrolytic anode

ActiveUS7335285B2Synthetic strongSuppress generationMachining electrodesElectrical-based machining electrodesSubstance useFluoride

The present invention provides an electrolytic anode for use in electrolytically synthesizing a fluorine-containing substance by using an electrolytic bath containing a fluoride ion including: an electroconductive substrate having a sure including an electroconductive carbonaceous material; and an electroconductive carbonaceous film having a diamond structure, the electroconductive carbonaceous film coating a part of the electroconductive carbonaceous substrate, and a method for electrolytically synthesizing a fluorine-containing substance using the electrolytic anode.

Owner:TOYO TANSO KK +1

Electrode material, paste for electrodes, and lithium ion battery

ActiveUS20160156026A1Reduce conductivitySuppression resistanceElectrode thermal treatmentPositive electrodesParticulatesAluminium-ion battery

Owner:SUMITOMO METAL MINING CO LTD

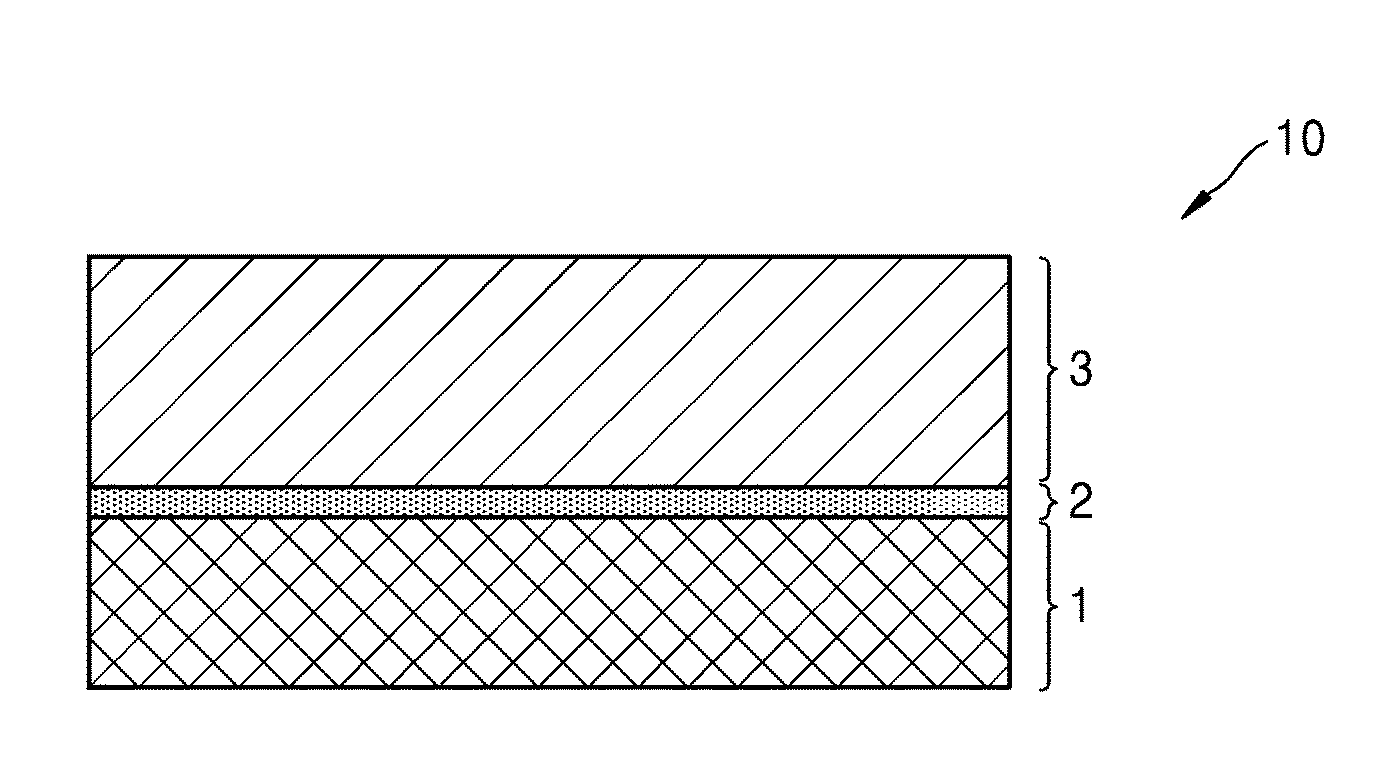

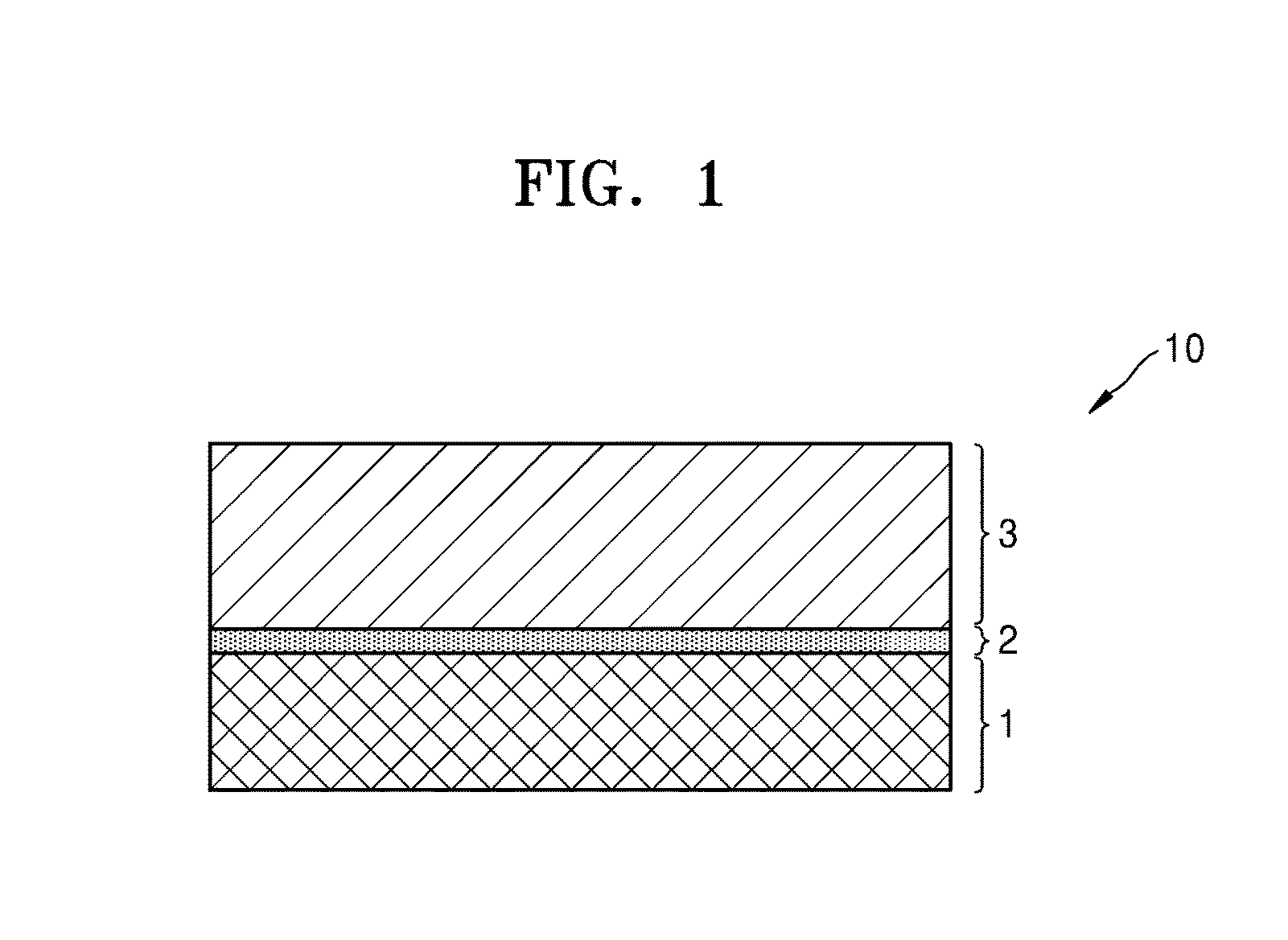

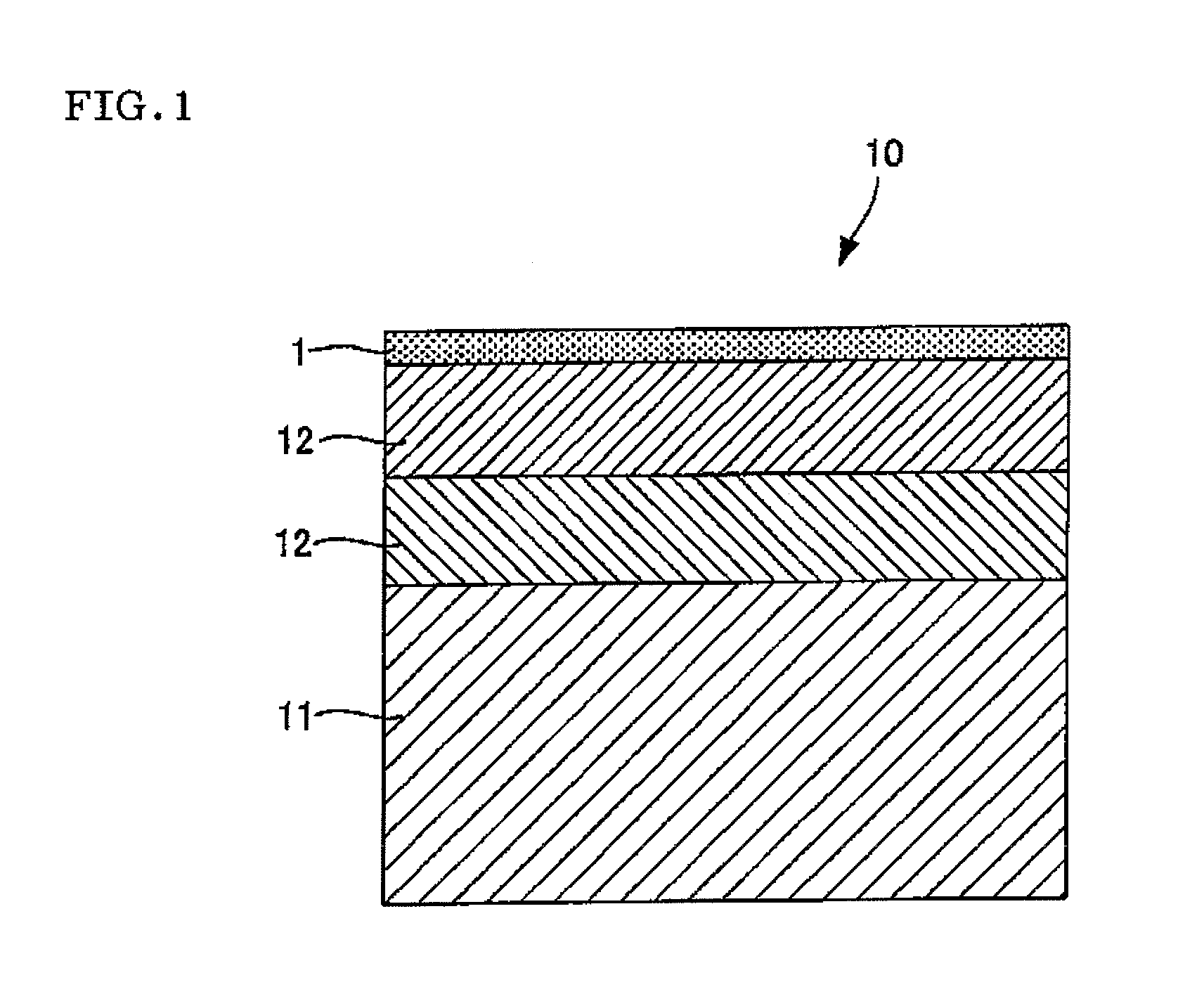

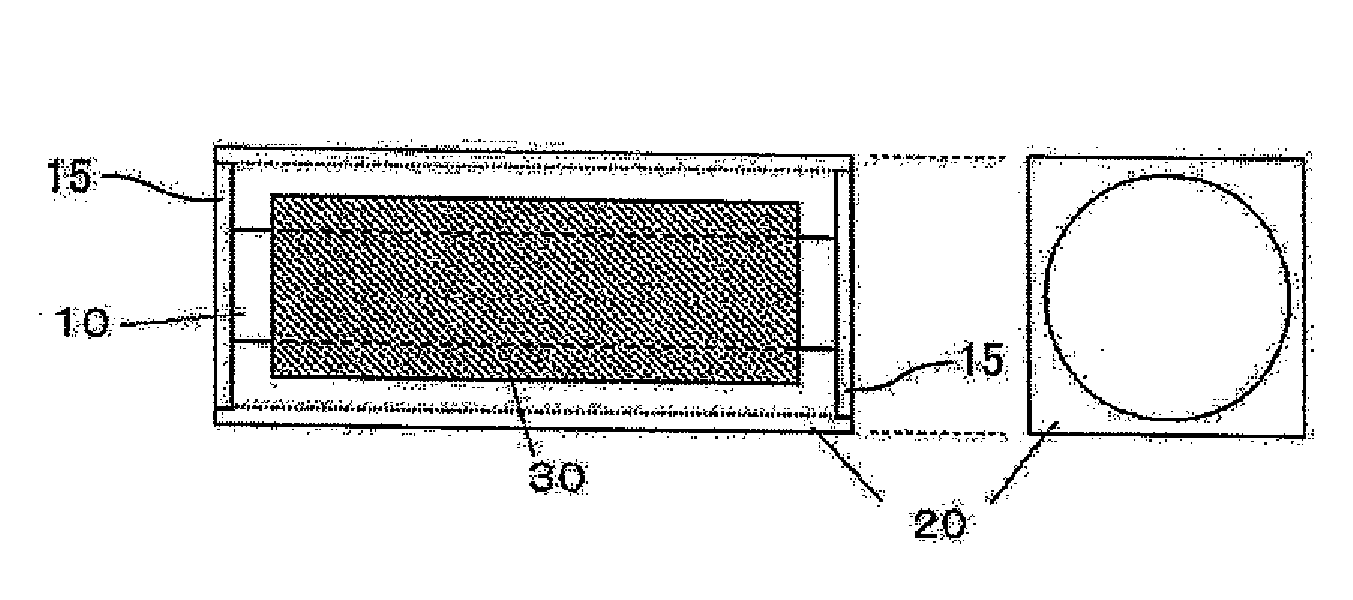

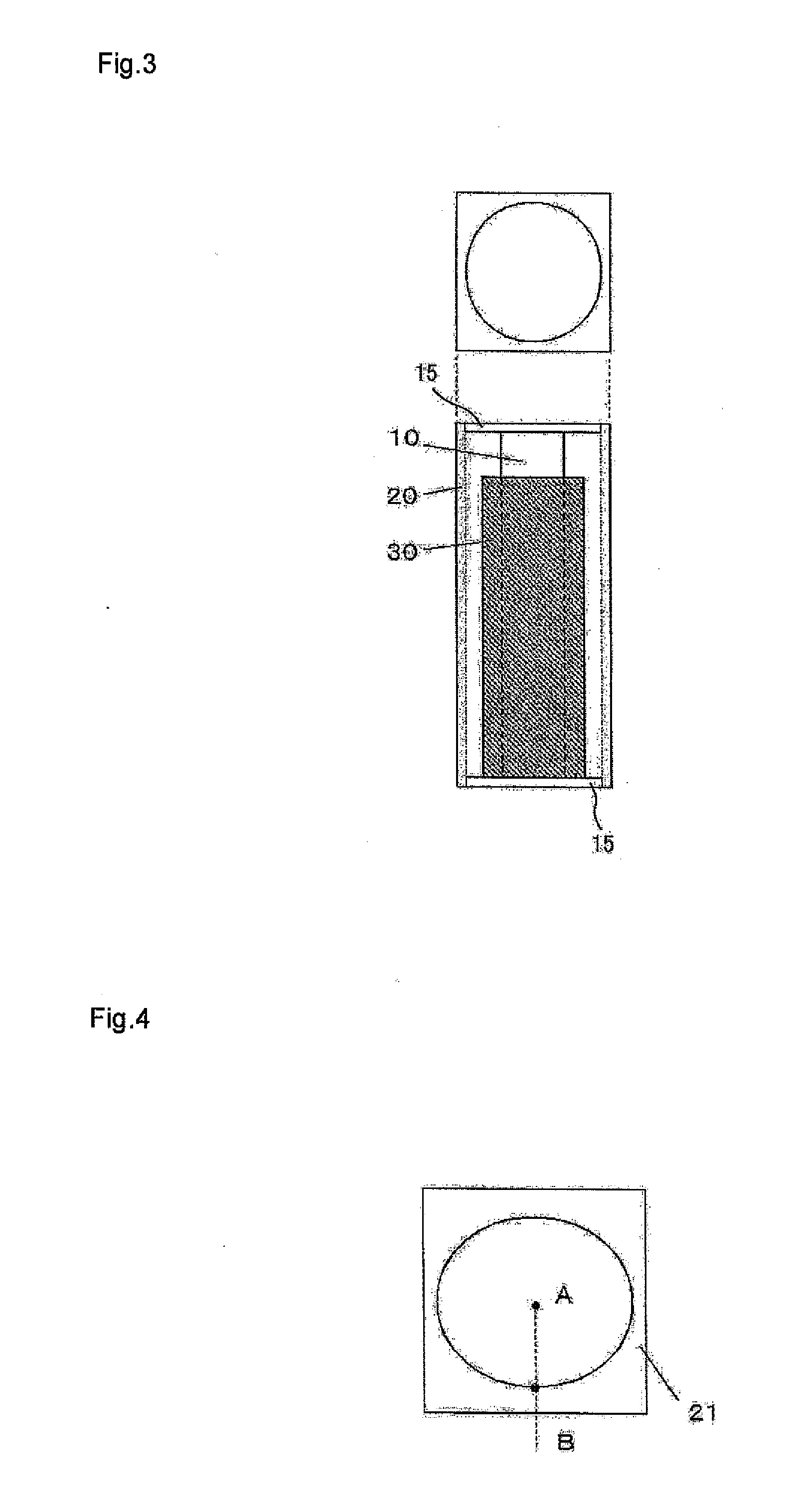

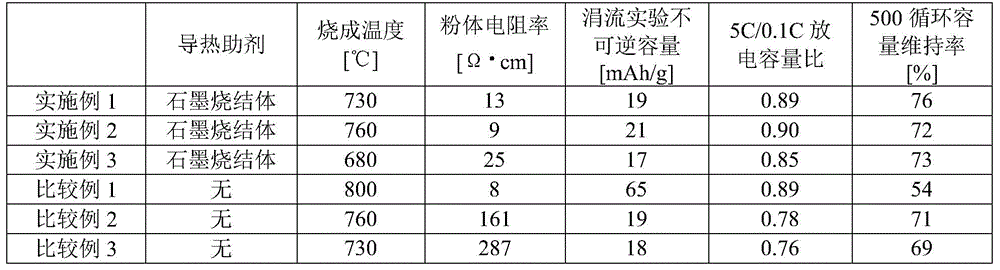

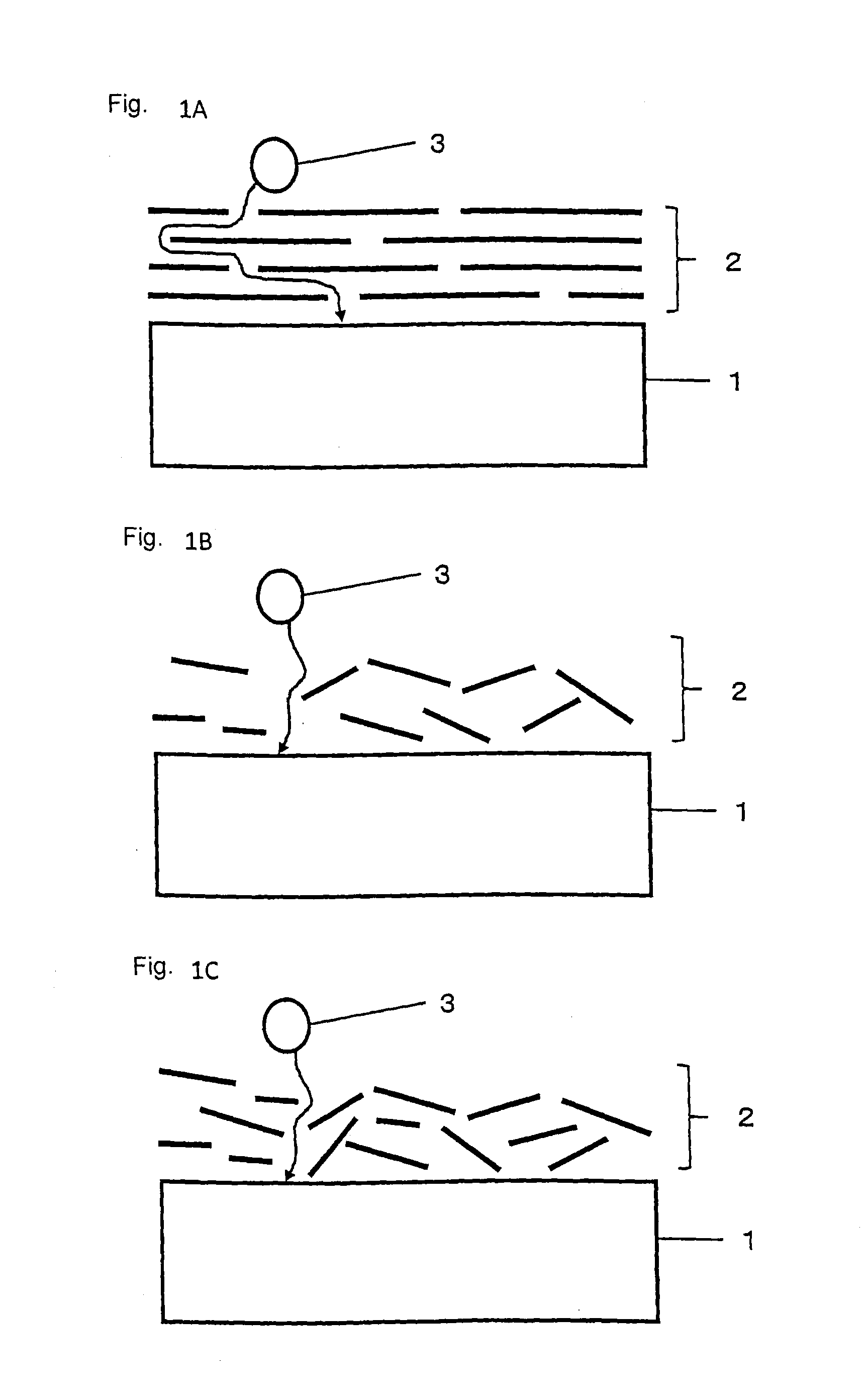

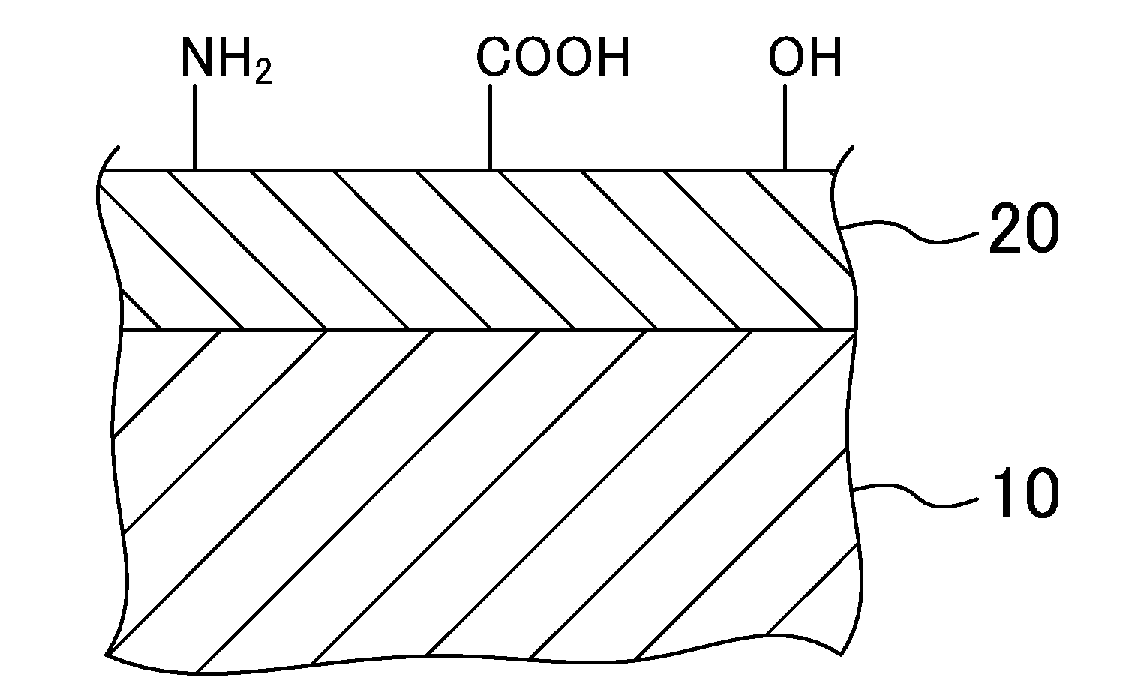

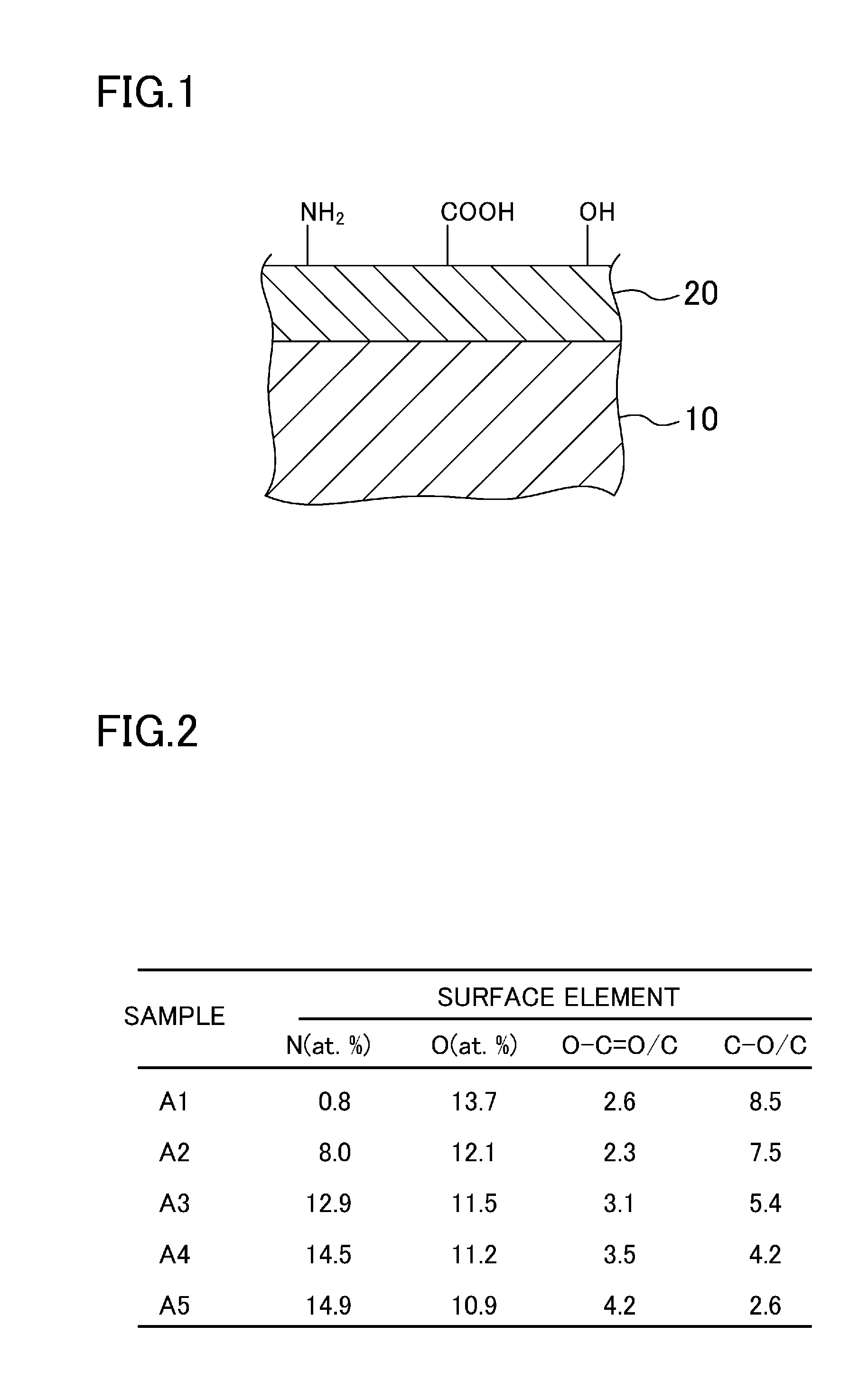

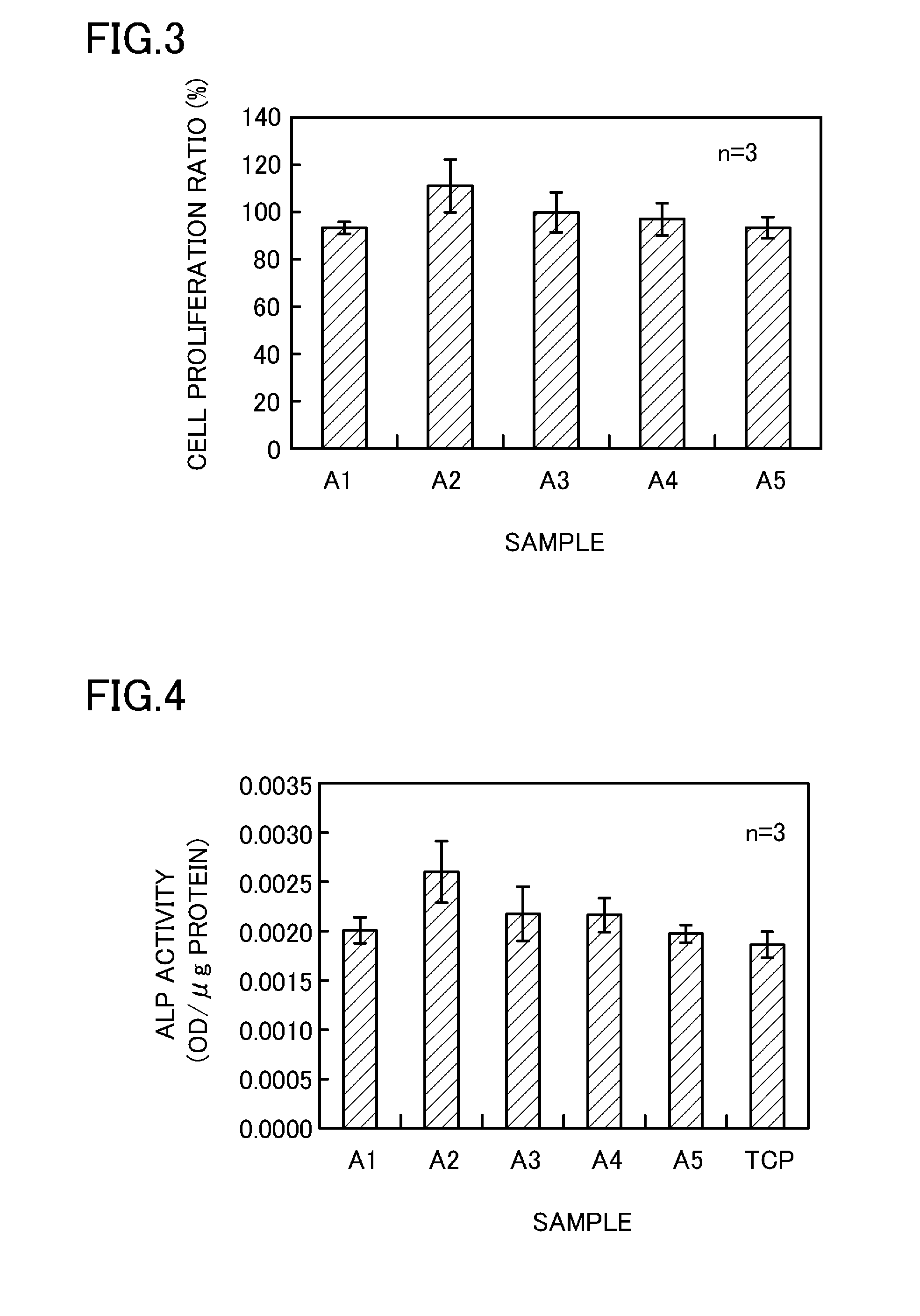

Implant material

ActiveUS20130108879A1Improve stabilityIncreased durabilityDental implantsImpression capsNitrogenOxygen

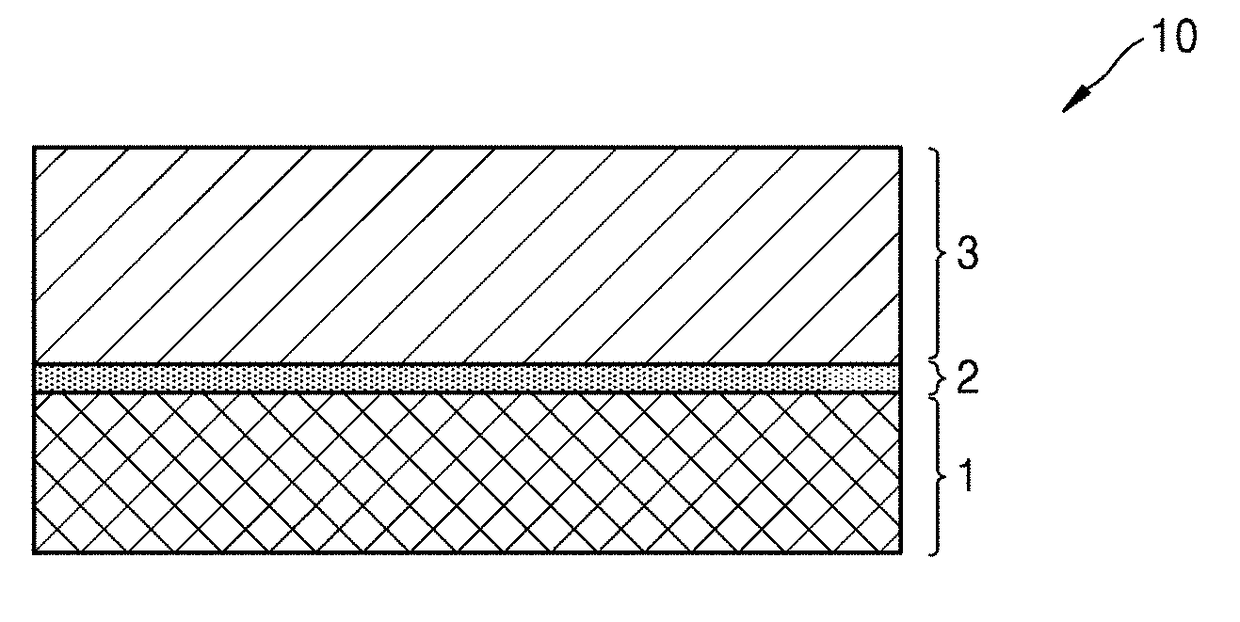

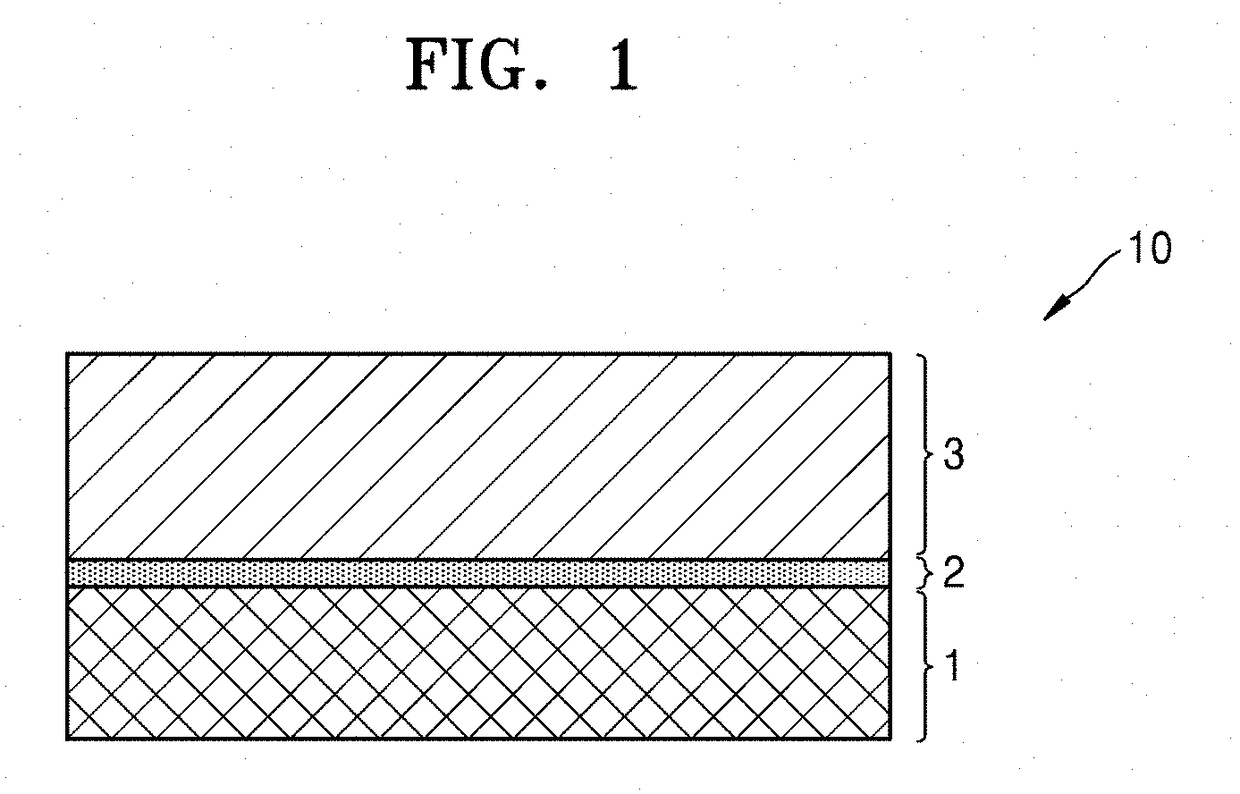

An implant material includes: a base material 10; and a carbonaceous film 20 provided on a surface of the base material 10. The carbonaceous film 20 includes carbon atoms, oxygen atoms, and nitrogen atoms in a surface thereof, and the carbon atoms are bonded to the oxygen atoms to form carboxyl carbon and carbon having a single bond with oxygen. In the surface of the carbonaceous film 20, a content of nitrogen atoms is greater than or equal to 8.0 at. %, a content of carbon having a single bond with oxygen is greater than or equal to 5.4%, and a content of carboxyl carbon is less than or equal to 3.1%.

Owner:TOYO ADVANCED TECH CO LTD

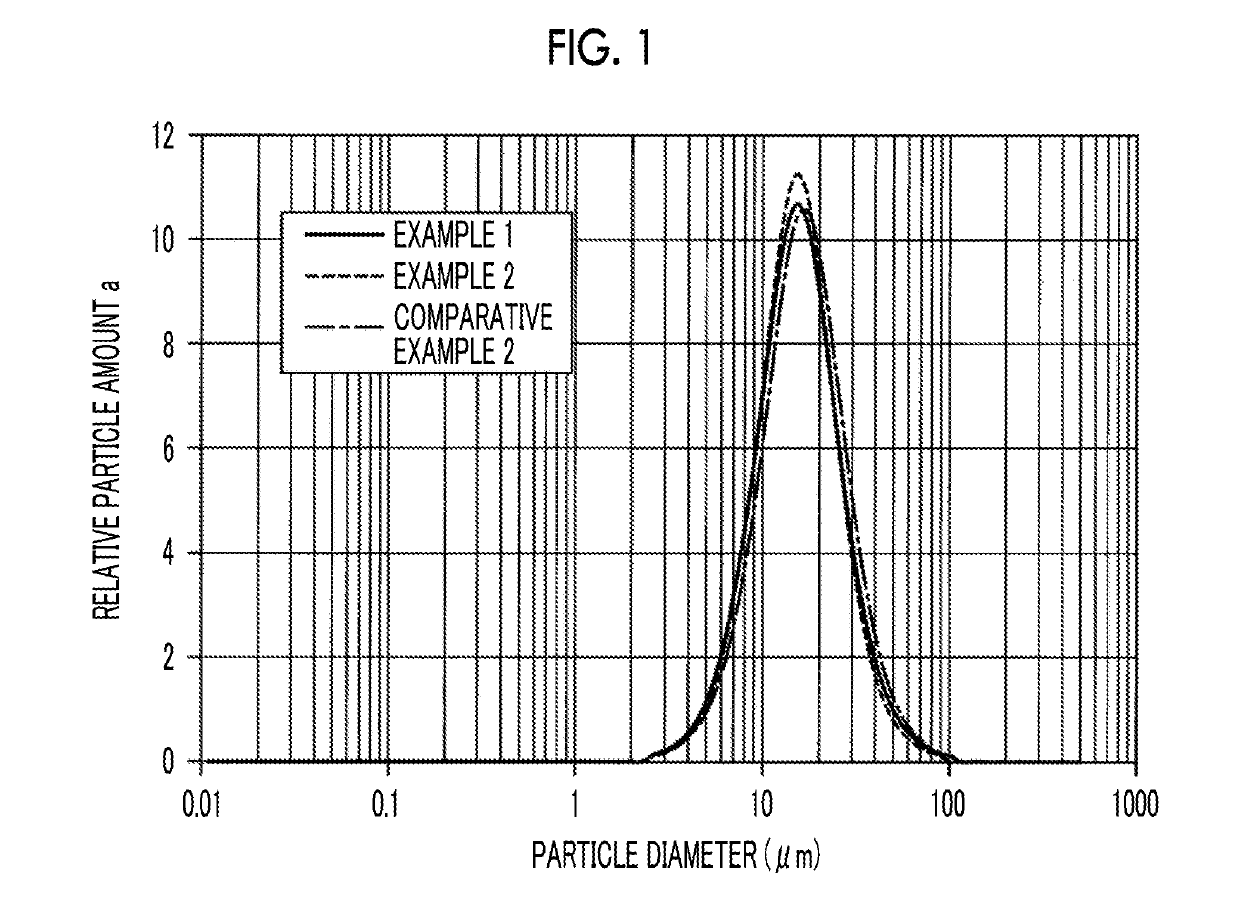

Cathode material for lithium-ion secondary battery and method for manufacturing the same, cathode for lithium-ion secondary battery, and lithium-ion secondary battery

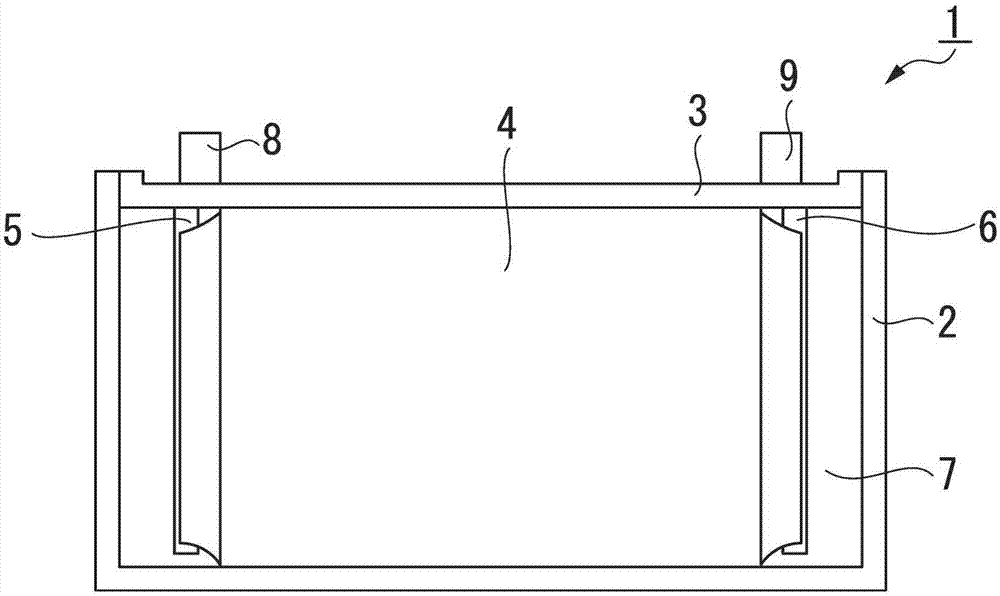

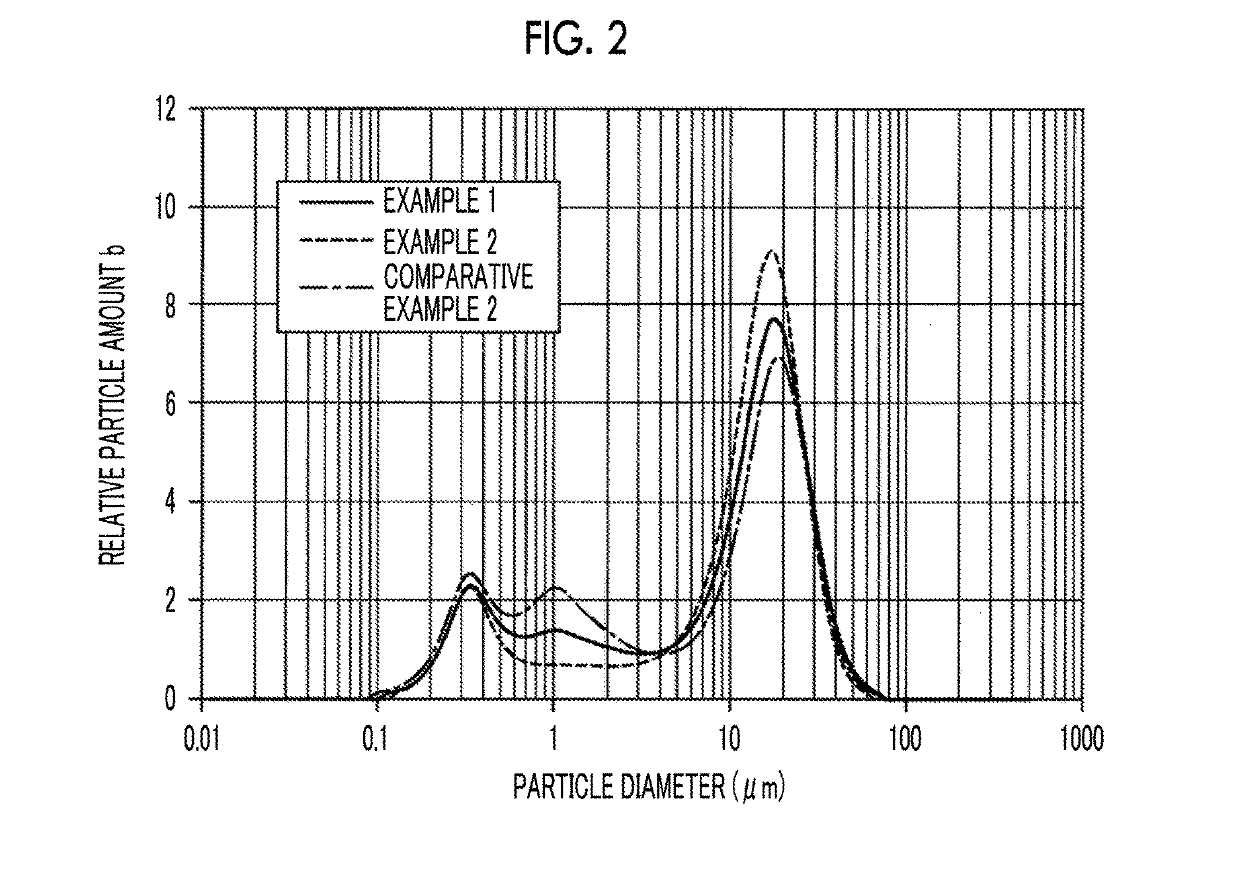

ActiveUS20190097230A1Improve electronic conductivityUniform structureSecondary cellsPositive electrodesCarbonaceous filmParticle-size distribution

A cathode material for a lithium-ion secondary battery, the cathode material including: secondary particles which are granulated active material particles including central particles and a carbonaceous film that coats surfaces of the central particles, wherein a granulated body breakage degree ((a−b) / a) of the secondary particles is 0.03 or more and 0.30 or less, and the granulated body breakage degree is calculated based on a relative particle amount a, at which a maximum peak is shown in a particle size distribution of the secondary particles, and a relative particle amount b, at which a maximum peak in a particle size distribution of the secondary particles is shown after a dispersion treatment of the secondary particles is performed using a homogenizer.

Owner:SUMITOMO METAL MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com