Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Enhanced heat transfer properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Constant-pressure multiple-effect evaporation condensation sea water desalination device with air medium

InactiveCN101921036AReduce consumptionImprove performanceSeawater treatmentMultistage water/sewage treatmentWater desalinationEnergy recovery

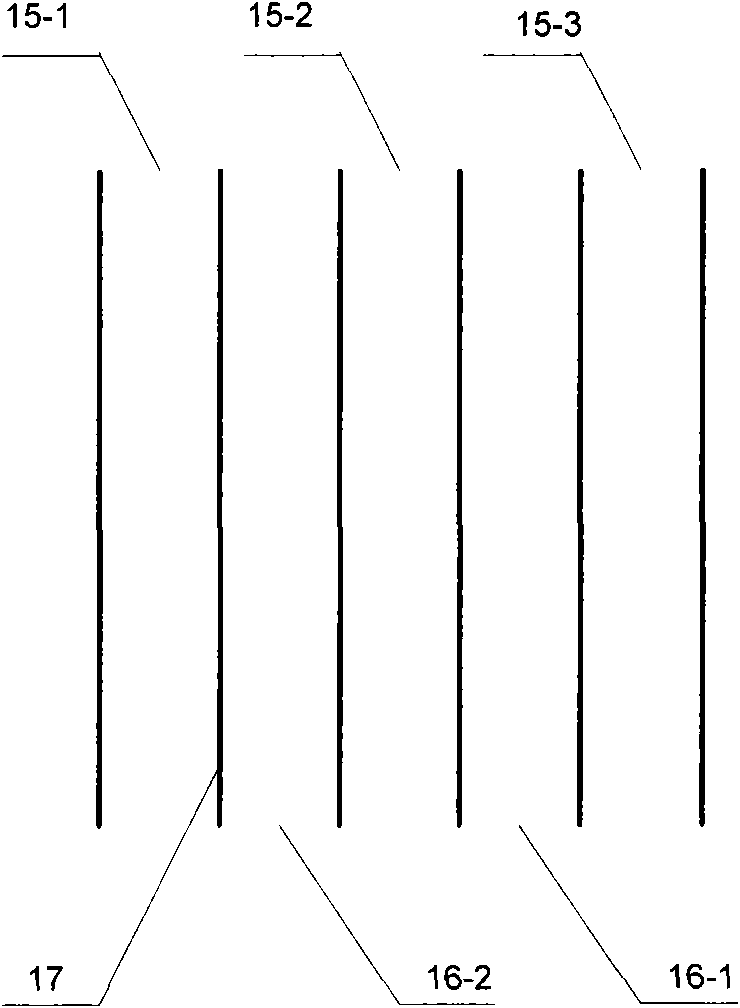

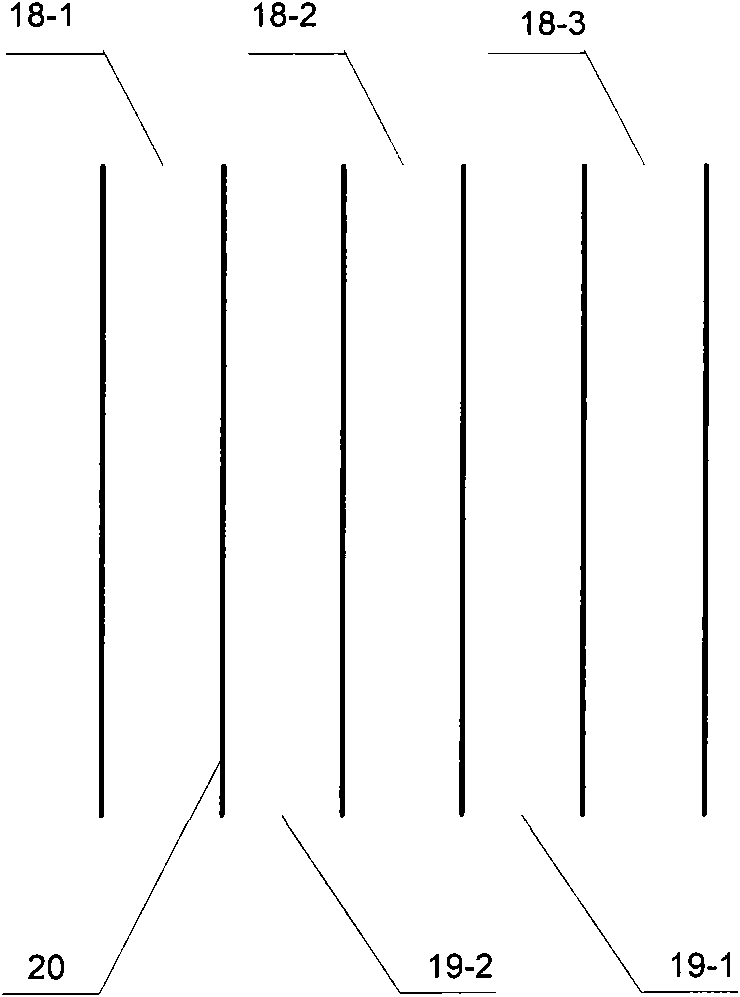

The invention discloses a constant-pressure multiple-effect evaporation condensation sea water desalination device with an air medium, which mainly comprises a low-and-medium temperature heat source (13), a first-stage heating evaporator (14), an evaporation condenser (4) and a last-stage condenser (8). The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser (8) are installed in sequence closely, and the low-and-medium heat source (13) and the first-stage heating evaporator (14) are connected together. The first-stage heating evaporator (14), the evaporation condenser (4) and the last-stage condenser are all formed by combining a plurality of heat exchange plates which are arranged from left to right in sequence, and a gap is reserved between every two adjacent heat exchanging plates to form a flow channel for heat exchange fluid. By adopting the plate-type heat exchange principle, the sea water desalination device realizes multiple-effect air humidification and dehumidification evaporation and condensation for sea water desalination under constant pressure. Heat and moisture transfer is performed between sprayed sea water and overflowing air, and the condensation latent heat of fore effect heat and moisture air can be absorbed at the same time, and therefore, energy recovery is realized and the fore effect heat and moisture air can be condensed to obtain fresh water.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

Environmental protection type self-radiation nano ecological paint and preparation method thereof

InactiveCN101781480AReduce pollution factorImprove self-cooling effectCoatingsFar infraredNano carbon

The invention provides an environmental protection type self-radiation nano ecological paint and a preparation method thereof, belonging to the field of functional paints. The nano ecological paint comprises the components: 15% to 80% of aluminum sol, 15% to 80% of silicon sol, 4% to 10% of nano heat conductive filler, 3% to 27% of pigment and 5% to 25% of anti-settling agent, wherein the nano heat conductive filler is a compound body of 2% to 5% of nano carbon tube and 2% to 10% of nano cobalt oxide or 2% to 10% of nano zirconia. The preparation method comprises the steps of: weighing corresponding aluminum sol, nano heat conductive filler, pigment, anti-settling agent and the like, mixing and rapidly dispersing the components as component a; weighing corresponding silicon sol as component b; and mixing, slowly dispersing, standing and curing components a and b for obtaining the nano ecological paint. The invention has the advantages that the powdery bodies of the nano cobalt oxide and the zirconia have self-radiation and far-infrared release functions; the nano powder is attached to the tube wall of the carbon tube to form a netty one-dimensional heat transmitting channel; and the heat transmitting characteristic of the paint is enhanced.

Owner:SHANGHAI EXCILON NEW MATERIALS

Nano fluid-enhanced heat transfer characteristic test system with low surface energy evaporator

InactiveCN105738410ALow Surface Energy PropertiesImprove heat transfer performanceMaterial heat developmentSignal onEnhanced heat transfer

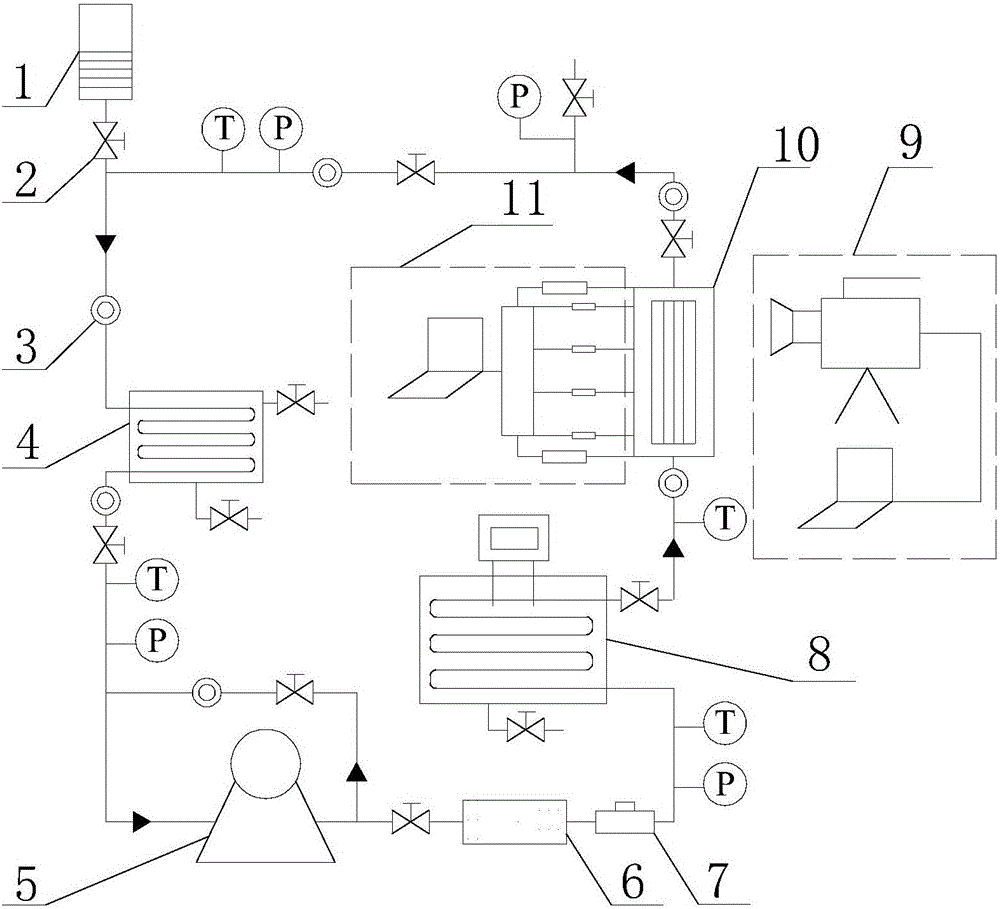

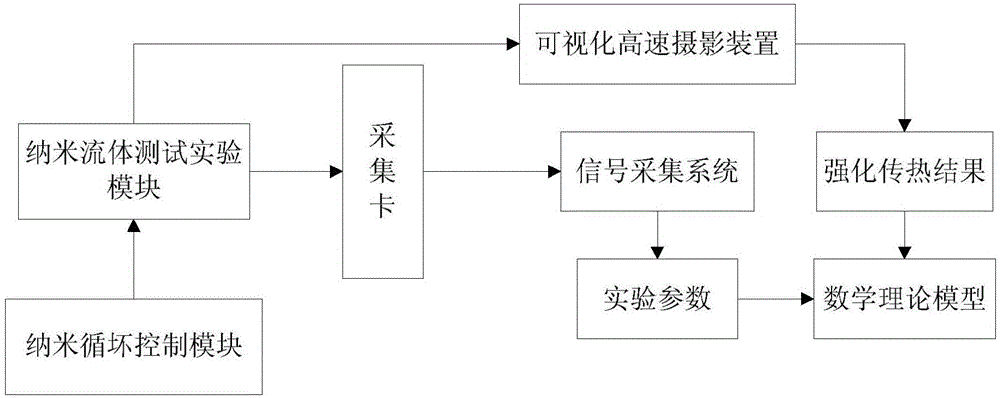

The invention discloses a nano fluid-enhanced heat transfer characteristic test system with a low surface energy evaporator. The nano fluid-enhanced heat transfer characteristic test system comprises a nano fluid circulation control module, a low surface energy micro-channel evaporator test section module, an enhanced heat transfer data acquisition and analysis module and a nano fluid phase-change visual acquisition module, wherein the nano fluid circulation control module is used for controlling the flow velocity, the flow rate, the temperature and the pressure of a nano fluid in a control pipeline; the low surface energy micro-channel evaporator test section module is used for performing low surface energy micro channel evaporator enhanced heat transfer test on the nano fluid; the enhanced heat transfer data acquisition and analysis module is used for acquiring and analyzing a temperature and pressure sensor signal on the low surface energy micro channel evaporator test section module, so as to obtain required test parameters; the nano fluid phase-change visual acquisition module is used for observing the enhanced heat transfer and the phase change process of the nano fluid in the low surface energy micro channel evaporator test section module. The nano fluid-enhanced heat transfer characteristic test system disclosed by the invention can be used for testing the gas-liquid phase-change evolution process of the nano fluid containing Al2O3, Fe3O4 and the like in a low surface energy micro channel and the nano fluid-enhanced heat transfer characteristics.

Owner:SOUTH CHINA UNIV OF TECH

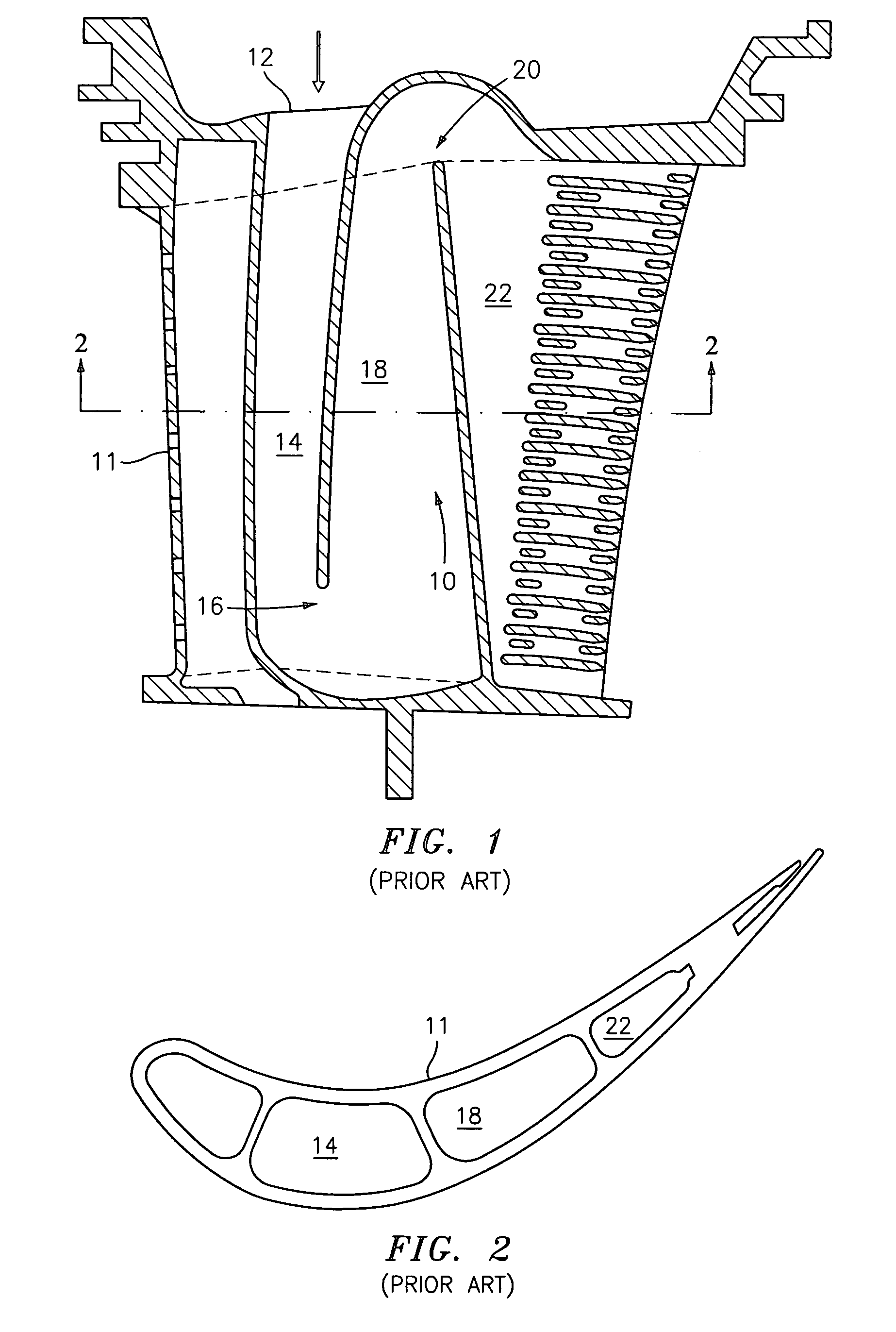

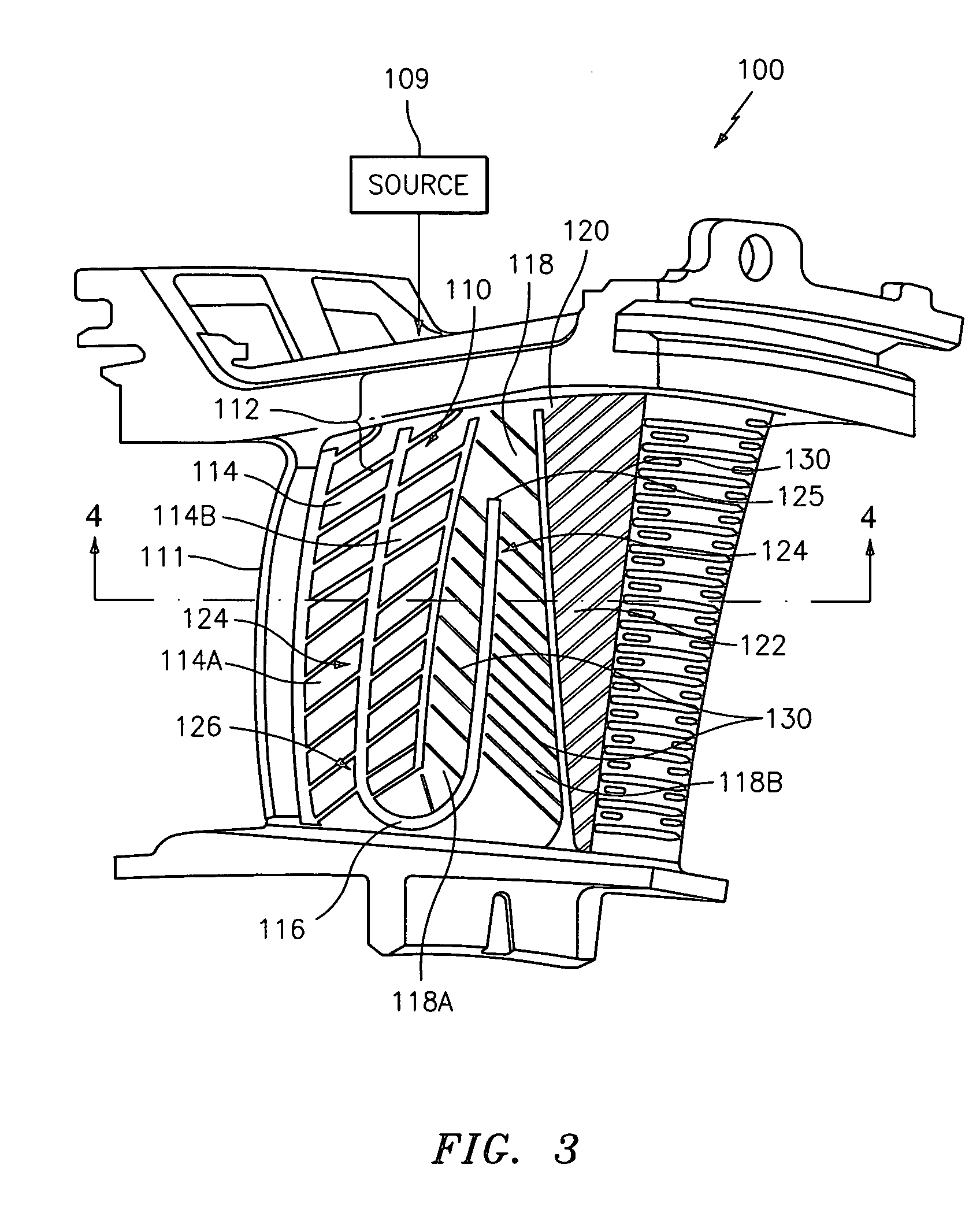

Enhanced serpentine cooling with U-shaped divider rib

ActiveUS20070231138A1Improved structureEnhanced heat transfer propertiesEngine manufacturePump componentsCooling channelEngineering

Owner:RAYTHEON TECH CORP

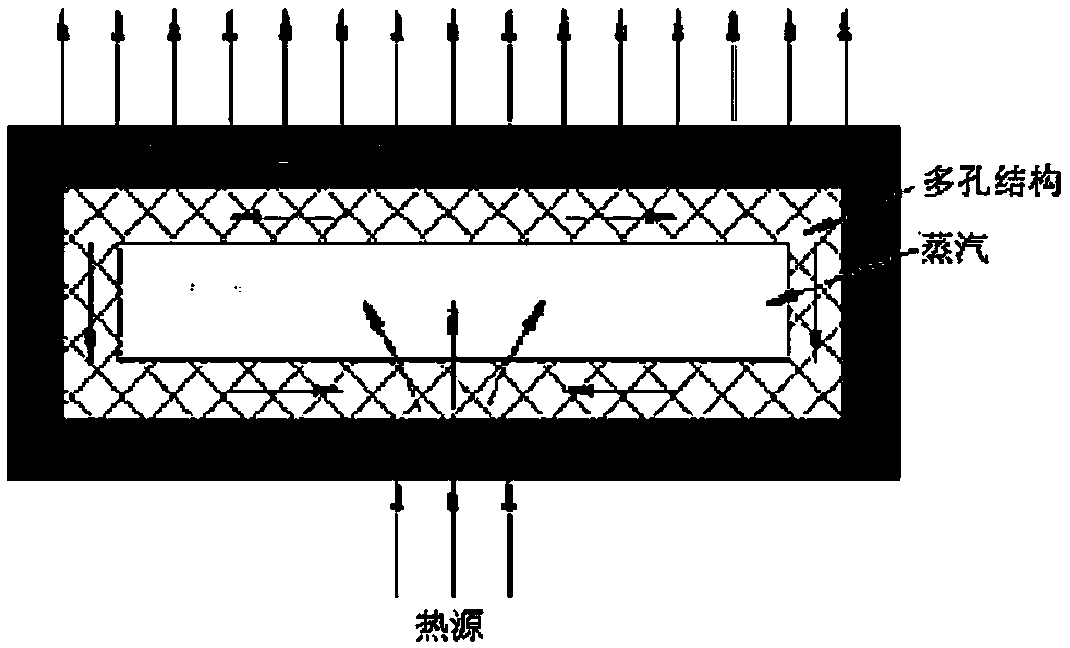

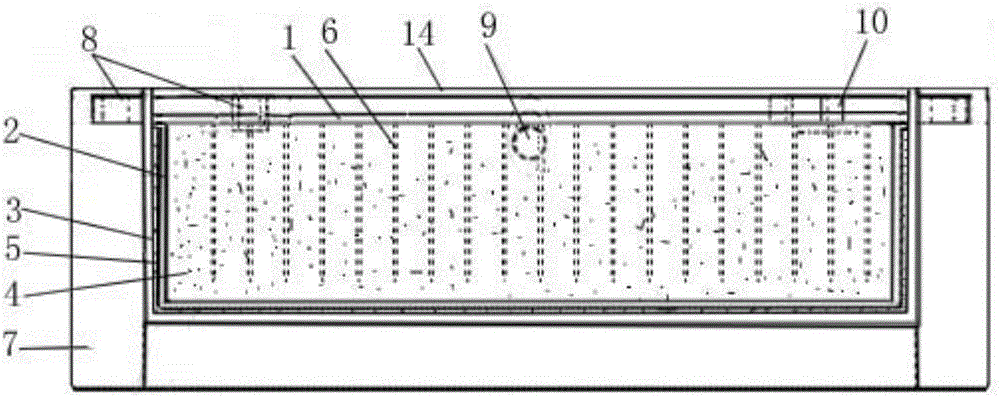

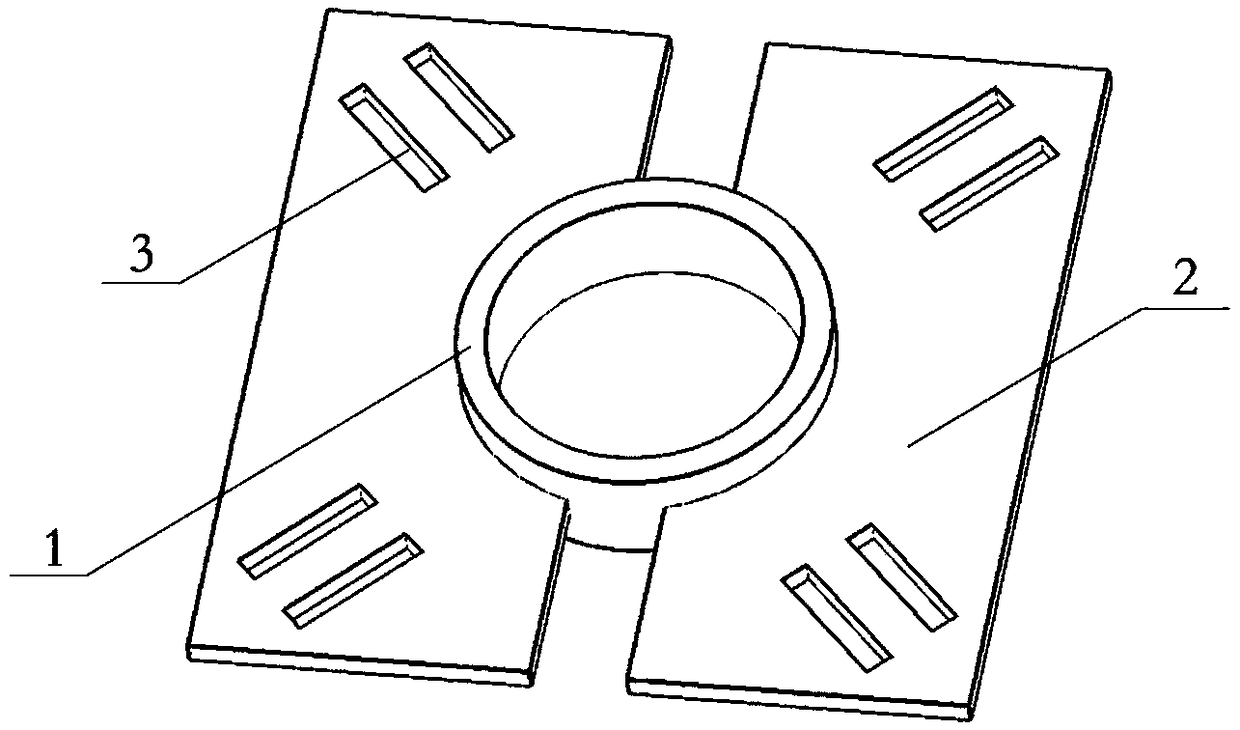

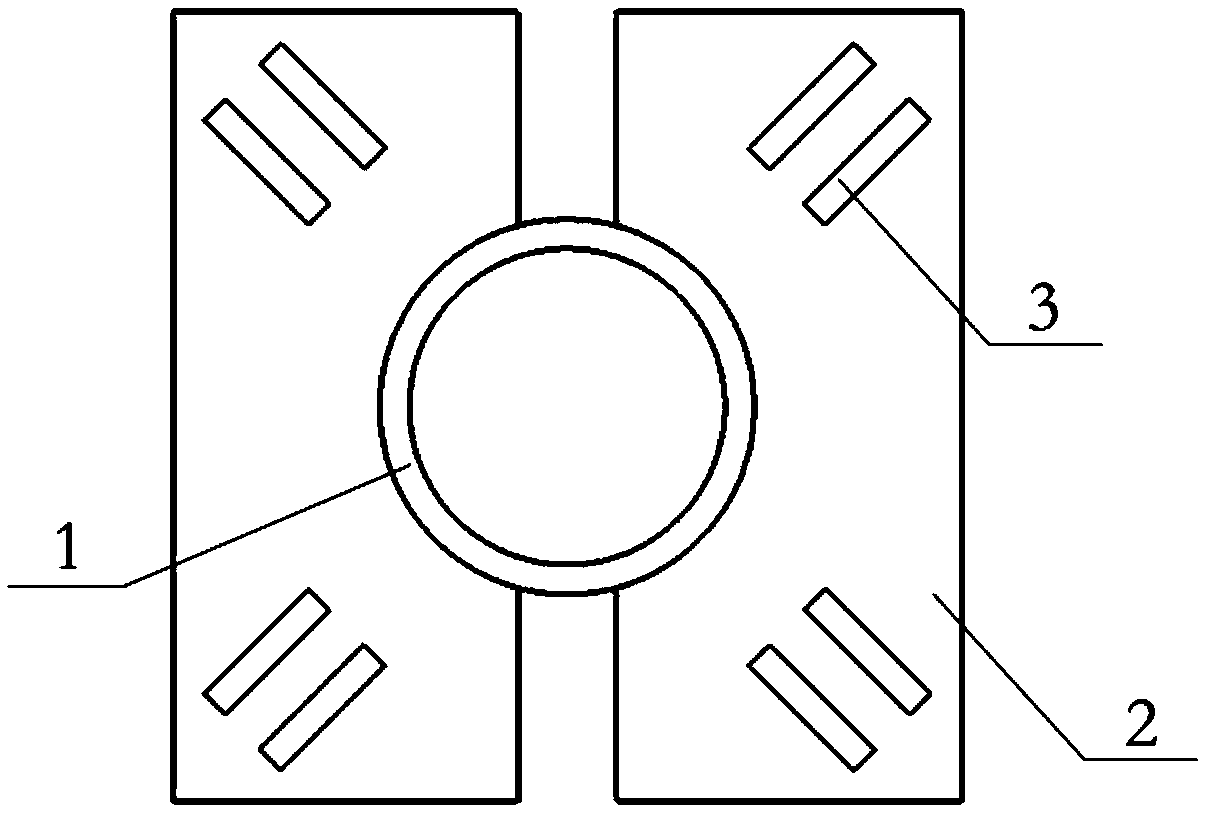

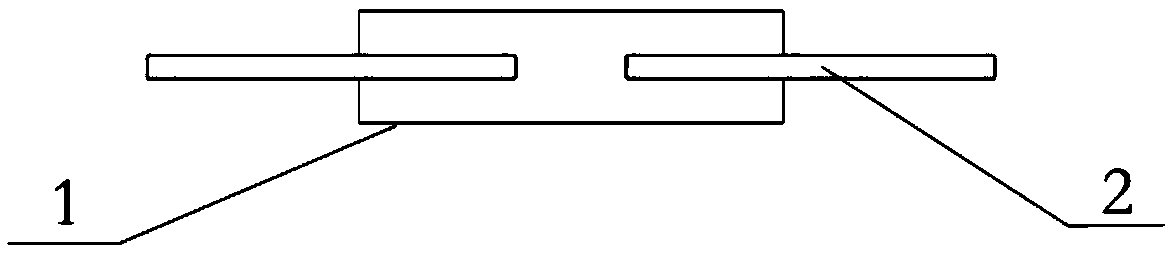

Thin wall temperature equalization plate and manufacturing method thereof

InactiveCN109612316ASimple structureImprove performanceIndirect heat exchangersHeat exchange apparatusComputer moduleEngineering

The invention provides a temperature equalization plate. The temperature equalization plate comprises a pressure resistant shell and a heat transfer working medium, and the shell is composed of an upper base plate (1) and a lower base plate (2); the base plates are provide with working medium tanks (3), capillary cores (4) and reinforcing column modules (5); the upper base plate (1) and the lowerbase plate (2) are welded to form a closed working medium cavity; and the working medium cavity is filled with the heat transfer working medium. A temperature equalization plate manufacturing method includes the steps of reinforcing column distribution calculation, base plate preparation, capillary core preparation, base plate welding, heat transfer working medium filling, filling port clamping sealing and finish machining. According to the temperature equalization plate and the temperature equalization plate manufacturing method, the manufacture of the thin high-heat transfer performance temperature equalization plate is can realized, and great advantages are achieved in the application of the high-power component heat dissipation field with narrow installation space.

Owner:SHANGHAI INST OF SATELLITE EQUIP

Magnetic nano-fluid concentrating photovoltaic combined heat and power generation device

ActiveCN104601103ATake advantage ofEffective absorptionSolar heating energySolar heat devicesEngineeringRidge

The invention relates to a magnetic nano-fluid concentrating photovoltaic combined heat and power generation device. The device comprises a photovoltaic battery pack module, and also a photovoltaic battery pack module cooling assembly, a photo-thermal assembly and a magnetic field adjustment assembly; the photovoltaic battery pack module cooling assembly comprises a first header, a second header and an S-shaped cooling pipe; the photo-thermal assembly comprises a circulating pump, a heat exchanger, a plurality of transparent collector pipes, a plurality of light homogenizing bodies, a Fresnel lens and a frame; the light homogenizing bodies are multi-ridge lenses, and the area of the upper surface of each multi-ridge lens is greater than the bottom area of the multi-ridge lens; the magnetic field adjustment assembly comprises an S-shaped magnet and a coil wound around S-shaped magnet arms; one collector pipe is arranged between every two adjacent magnet arms; the S-shaped magnet and the plurality of collector pipes are located in the same plane; the nano-fluid is put into all the first header, the cooling pipe, the second header, the collector pipes, the heat exchanger and the circulating pump. The magnetic nano-fluid concentrating photovoltaic combined heat and power generation device has the advantages of simple structure, increase of solar energy utilization rate and the like.

Owner:HOHAI UNIV CHANGZHOU

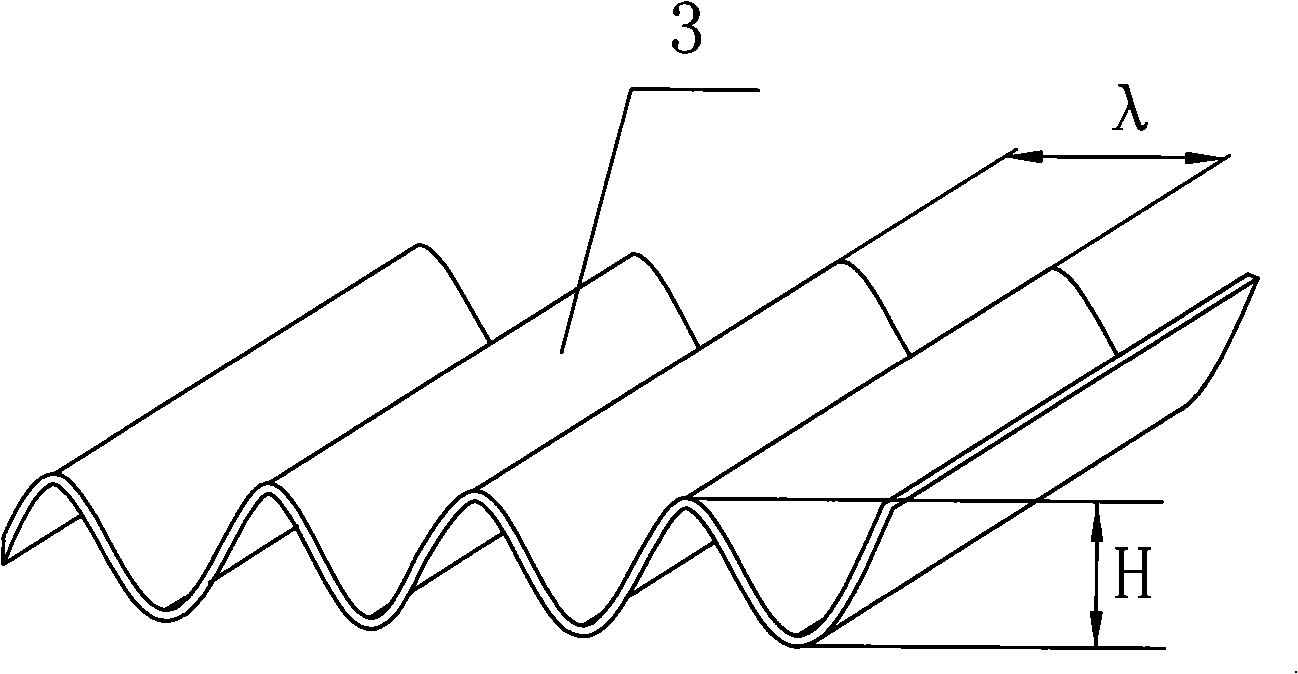

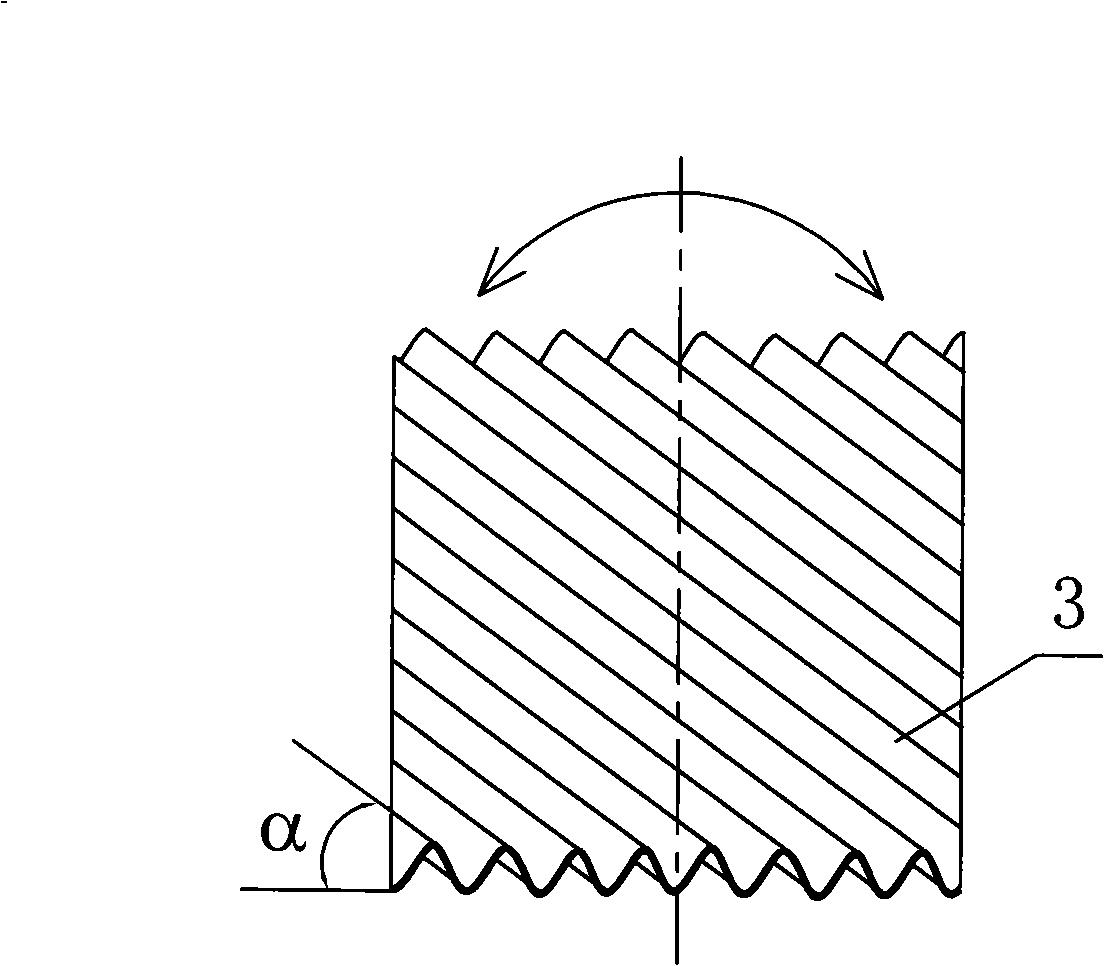

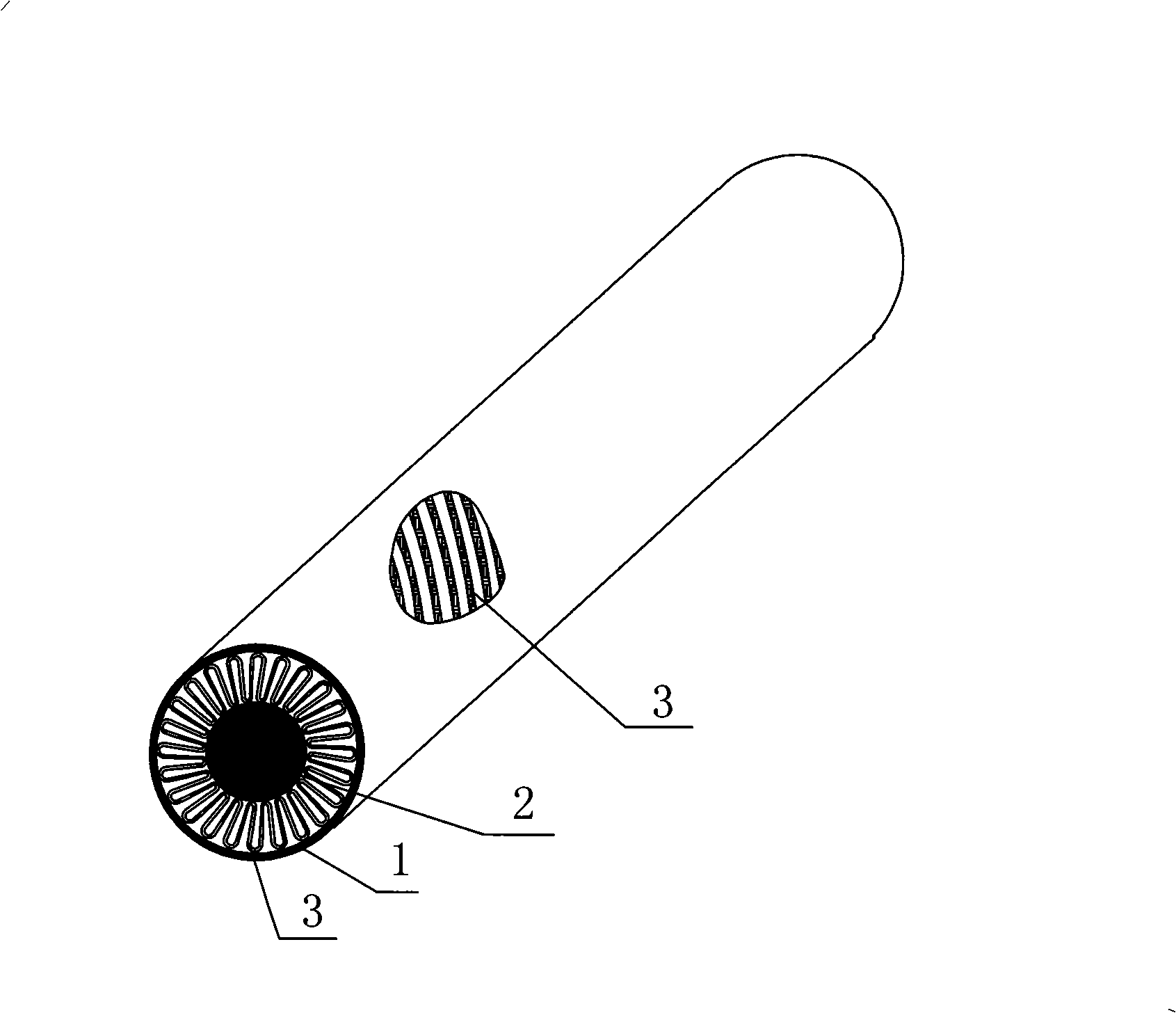

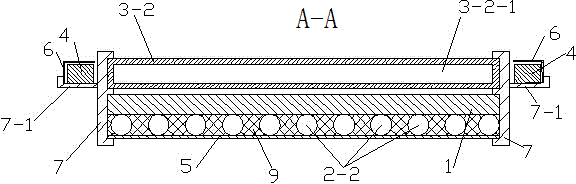

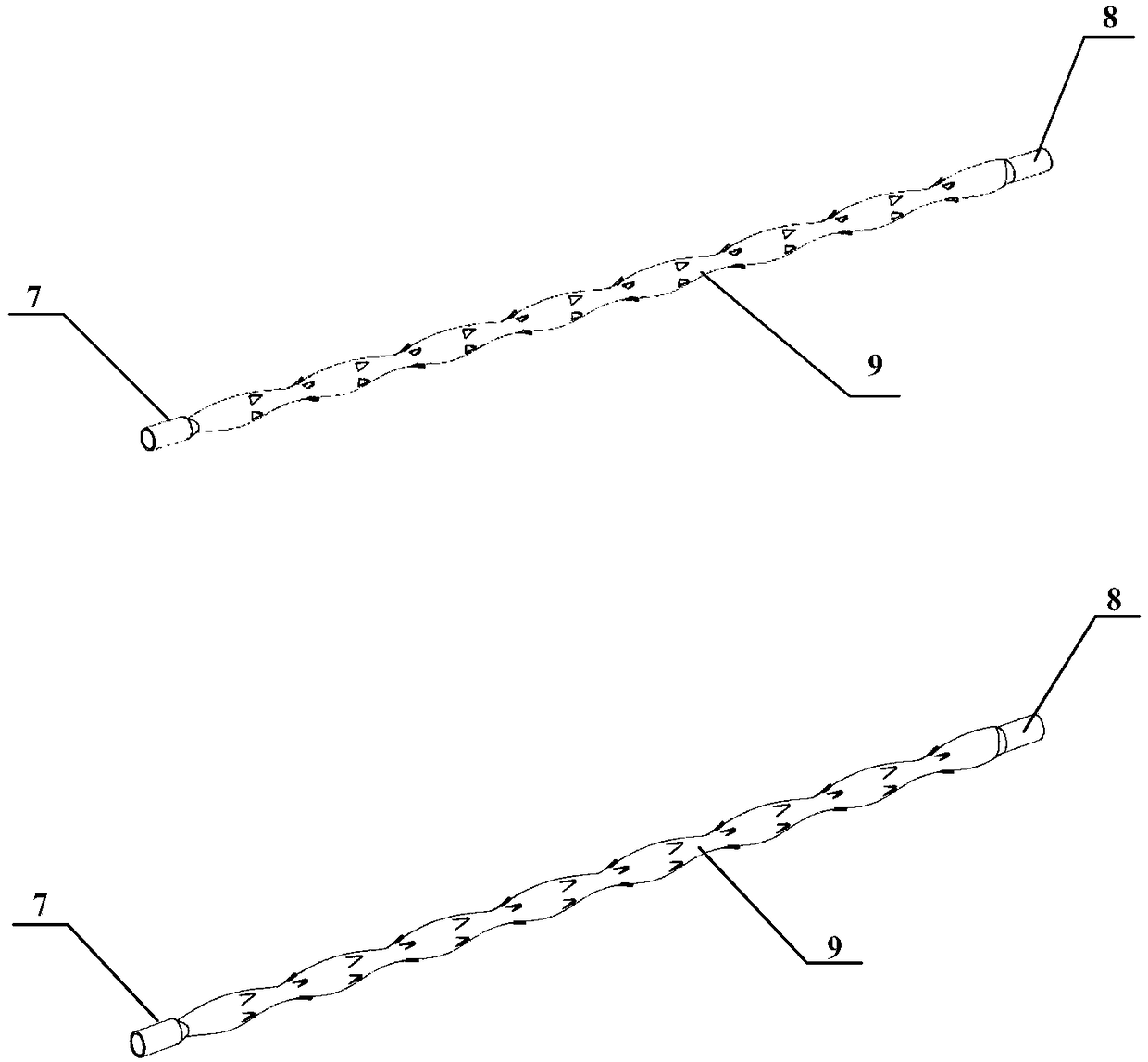

Longitudinal spiral inner fin tube

InactiveCN101334248AEffective destructionIncrease the heat exchange areaStationary tubular conduit assembliesTubular elementsEngineeringLength wave

The invention discloses a longitudinal spiral inner fin tube, which comprises an outer tube and a core tube sleeved concentrically and an inner fin nested and wound around the tube core in a circumambient way between the outer tube and the core tube, wherein the inner fin is connected with the outer tube and the core tube by adopting a braze welding way, the inner fin is formed by bending a corrugated inner fin plate and a cylindrical shape longitudinal spiral inner fin tube is formed between the outer tube and the core tube, and a plurality of longitudinal spiral type circulating passages are distributed on the longitudinal spiral type inner fin tube; the included angle between the corrugation texture of the corrugated inner fin plate and the horizontal direction is Alpha, wherein Alpha is larger than or equal to 15 degrees and lower than or equal to 85 degrees; the corrugation shape of the corrugation adopts continuous periodic functions, and the longitudinal amplitude height H is equal to the spacing between the outer tube and the core tube; the greater viscosity of the medium circulated in the inner fin is, the sparser the corrugation, the longer the corrugation wavelength Lambada, the less amount of the longitudinal spiral type circulating passages, and the greater the degree of Alpha; the reverse is also true. The structure of the longitudinal spiral inner fin tube is simple and the machining and fabrication is simple and convenient, the heat transfer area in the tube can be effectively increased, and simultaneously the flow resistance in the tube can also be effectively reduced.

Owner:XI'AN PETROLEUM UNIVERSITY

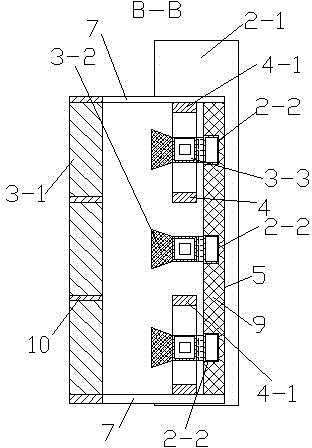

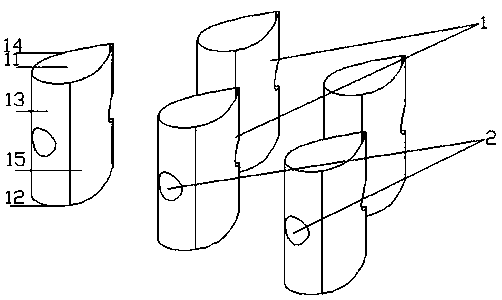

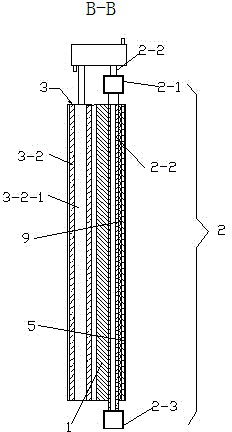

Turbulent flow column structure used for reinforced heat exchange of turbine blade

PendingCN109944645ASmall pressure lossIncreased turbulenceBlade accessoriesMachines/enginesTurbine bladeEngineering

The invention discloses a turbulent flow column structure used for reinforced heat exchange of a turbine blade. The turbulent flow column structure comprises a turbulent flow column body. The turbulent flow column body is a column body with the cross section being of a water drop shape. One end of the water drop shape is an arc end. The other end of the water drop shape is a vertex end. The turbulent flow column body is provided with a penetrating hole transversely penetrating through the arc end and the vertex end of the water drop shape. The penetrating hole is located in the longitudinal center height of the turbulent flow column body. Compared with a traditional turbulent flow column, on one hand, a part of gas directly penetrates through the turbulent flow column through the penetrating hole, and can pass through the turbulent flow column more smoothly, and thus the pressure loss of the gas is reduced; on the other hand, the gas flows through the penetrating hole and flows out ofthe penetrating hole and then is mixed with wake gas flow of the turbulent flow column of the water drop shape, the turbulence degree of the gas is improved, thus the heat transfer performance is improved, and the heat transfer characteristic of the turbine blade is reinforced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Solar cell panel temperature adjusting and controlling device

InactiveCN106788221APrevent overheatingWeaken the impactPhotovoltaicsPhotovoltaic energy generationCells panelPhase-change material

The invention discloses a solar cell panel temperature adjusting and controlling device, belonging to the field of photovoltaic cell panel temperature control. The solar cell panel temperature adjusting and controlling device is characterized in that a phase change material box body is welded and connected with a device shell, and a tempered glass plate is placed at the upper port of the device shell; two long side faces of the device shell are welded with outside radiating ribs; and a solar cell panel base plate is welded with the phase change material box body, an inside needle rib is welded on the solar cell panel base plate, and a phase change material and a thermal diode material are respectively injected into the temperature adjusting and controlling device by forming a heat storage material injection hole and a thermal diode material injection hole. The solar cell panel temperature adjusting and controlling device disclosed by the invention has the advantages that the heat transfer characteristic of a phase change heat storage material is strengthened, and the overall heat conducting property of the device is enhanced, so that the heat dissipation effect of a solar cell panel working under a high temperature condition is achieved, the normal working temperature of the solar cell panel is maintained, the service life of the solar cell panel is prevented from being shortened due to over temperature and heat, the generating efficiency can not be lowered, the influence of a low-temperature environment on the solar cell panel and the tempered glass plate is weakened, and the frost crack is prevented.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Magnetic nano-fluid light condensation type photovoltaic combined heat and power generation device

InactiveCN104539238ATake advantage ofEffective absorptionPhotovoltaicsPhotovoltaic energy generationComputer modulePrism

The invention relates to a magnetic nano-fluid light condensation type photovoltaic combined heat and power generation device. The magnetic nano-fluid light condensation type photovoltaic combined heat and power generation device comprises a photovoltaic cell assembly module, a heat storage assembly, a photo-thermal assembly and a magnetic field adjusting assembly; the heat storage assembly comprises a heat reservoir and a heat exchange pipe; the heat reservoir is internally provided with phase change media; an inlet and an outlet of the heat exchange pipe are exposed out of the heat reservoir; the photo-thermal assembly comprises a circulating pump, a first header, a second header, multiple transparent heat gathering pipes, multiple uniform light bodies, Fresnel lenses and a framework; the uniform light bodies are polygon prisms; the area of the upper surface of the polygon prisms is greater than that of the bottom of the polygon prisms; the magnetic field adjusting assembly comprises S-shaped magnets and coils wound around the arms of the S-shaped magnets, one heat gathering pipe is arranged between the arms of every two adjacent magnets, and the S-shaped magnets and the heat gathering pipes are located on the same plane; the heat exchange pipe, the heat gathering pipes, the circulating pump, the first header and the second header are all internally provided with nano-fluid which can circulate and flow. The magnetic nano-fluid light condensation type photovoltaic combined heat and power generation device has the advantages of being simple in structure, capable of improving the solar energy utilization ratio, and the like.

Owner:HOHAI UNIV CHANGZHOU

Magnetic nanofluid plate type solar cogeneration unit

InactiveCN104485886ATake advantage ofEffective absorptionSolar heating energySolar heat devicesCells panelCogeneration

The invention relates to a magnetic nanofluid plate type solar cogeneration unit which comprises a photovoltaic cell panel as well as a photovoltaic cell cooling assembly, a photo-thermal assembly and a magnetic field adjusting assembly, wherein the photovoltaic cell cooling assembly comprises a first header, a second header and a cooling tube, the cooling tube is mounted on the back surface of the photovoltaic cell panel, and the first header and the second header are communicated by the cooling tube; an insulation layer is further arranged on the back surface of the photovoltaic cell panel; the photo-thermal assembly comprises a heat exchanger, a circulating pump and a transparent hollow plate which is arranged on the front surface of the photovoltaic cell panel; the magnetic field adjusting assembly comprises a U-shaped magnet and a coil, the U-shaped magnet is wound with the coil, the hollow plate is covered with the magnetic field adjusting assembly, and the coil is located on two sides of the hollow plate; the first header, the second header, the cooling tube, the heat exchanger, the hollow plate and the circulating pump are filled with nanofluids and form a circulating loop by the aid of the circulation pump. The magnetic nanofluid plate type solar cogeneration unit has the advantages that the structure is simple, the solar energy utilization ratio can be improved and the like.

Owner:HOHAI UNIV CHANGZHOU

Copper metal fiber with regular flaky finned structure and manufacturing method for same

The invention discloses a copper metal fiber with a regular flaky finned structure and a manufacturing method for the same. Copper alloy round bars with 35-60mm diameters are used as raw materials, and a continuous microfine metal fiber is cut by a multi-tooth cutting tool on a lathe. The manufacturing method is simple in process and high in cutting efficiency, requirements on equipment conditions are low, the equivalent diameter of the manufactured copper metal fiber ranges from 50 micrometers to 100 micrometers, the regular flaky finned structure is arranged along the length direction of the fiber, the fiber has rich rough surface appearance, and the specific surface area of the metal fiber can be remarkably increased. Therefore, the sintering property of the metal fiber can be improved, and functional characteristics of the metal fiber as a porous metal raw material in numerous application fields can be enhanced.

Owner:SOUTH CHINA UNIV OF TECH

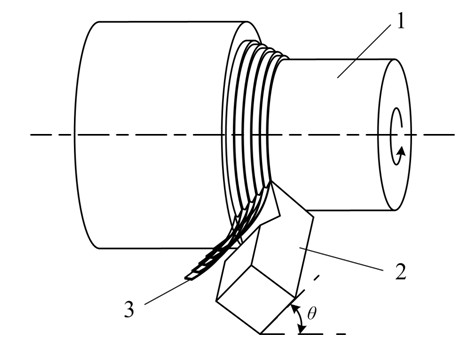

Novel oval twisted pipe heat exchanger with vortex generators

ActiveCN108917436AReduce thermal resistanceImprove heat transfer performanceStationary tubular conduit assembliesHeat transfer modificationHigh energyHeat resistance

The invention discloses an oval twisted pipe heat exchanger with vortex generators. The oval twisted pipe heat exchanger is mainly composed of parts of a pipe box, pipe plates, a shell, heat exchangepipes, ends and the like. Each heat exchange pipe comprises an inlet straight pipe segment, an outer finned pipe with an oval twisted pipe structure and an outlet straight pipe segment, and the interior of each heat exchange pipe is of an oval spiral twisted channel structure. Each outer finned pipe comprises an oval twisted pipe and finned plates which are provided with the corresponding vortex generators and can be closely attached to the oval twisted pipe. The finned plates of each outer finned pipe are divided into the upper finned plate and the lower finned plate, and the two finned plates of each outer finned pipe are brazed to the corresponding oval twisted pipe through the brazing process. The structures of the vortex generators on the finned plates can be triangular forms, dual blade forms and other forms. The vortex generators can generate vortex structures, high-energy fluid of main flow is entrained into a boundary layer through the vortex entrainment function, low-energy fluid in the boundary layer can be reversely pushed out of the boundary layer to enter the main flow, and energy exchange of inner fluid and outer fluid is completed; and the boundary layer is thinned,and therefore heat resistance is reduced.

Owner:NANJING UNIV OF TECH

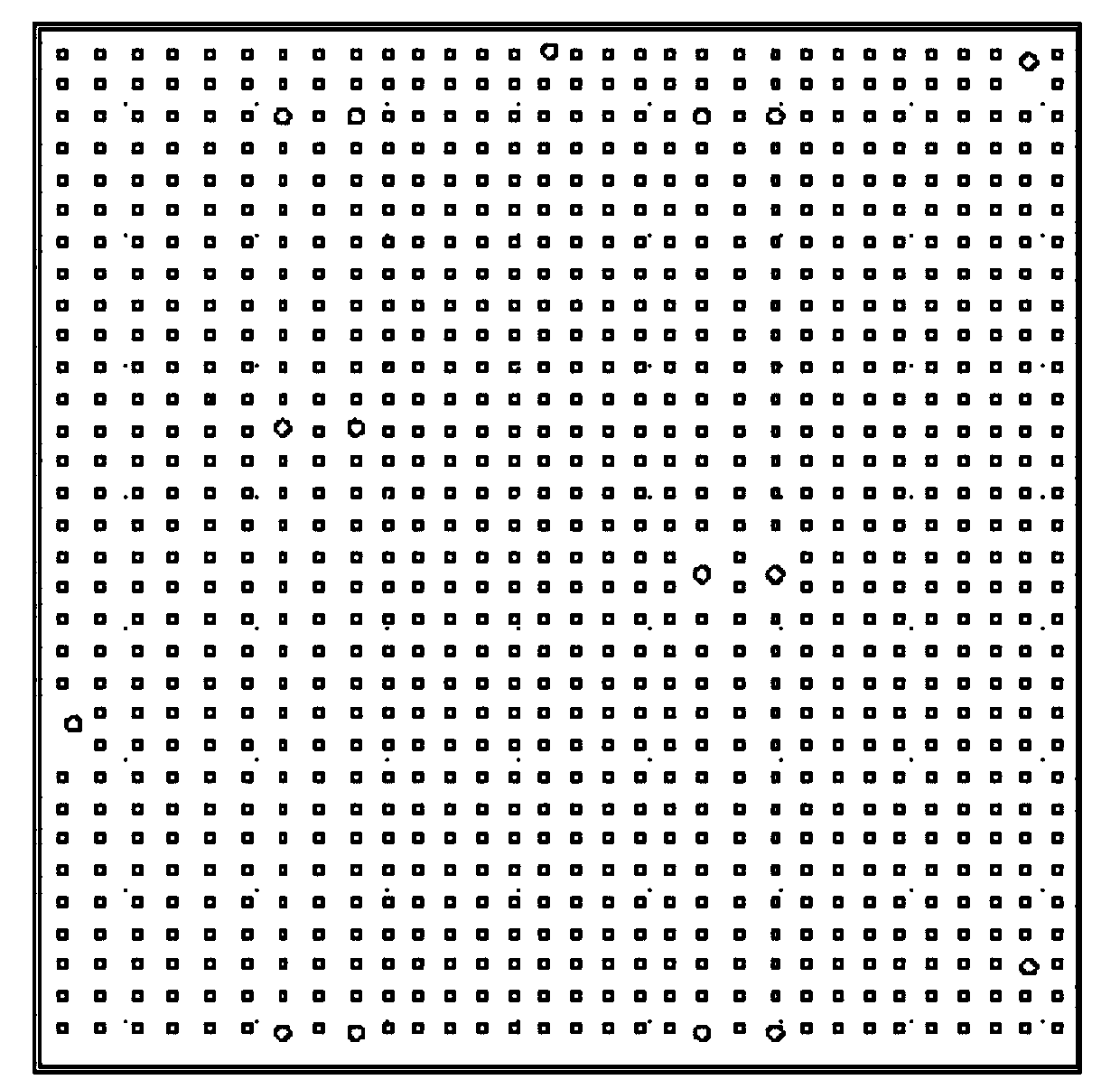

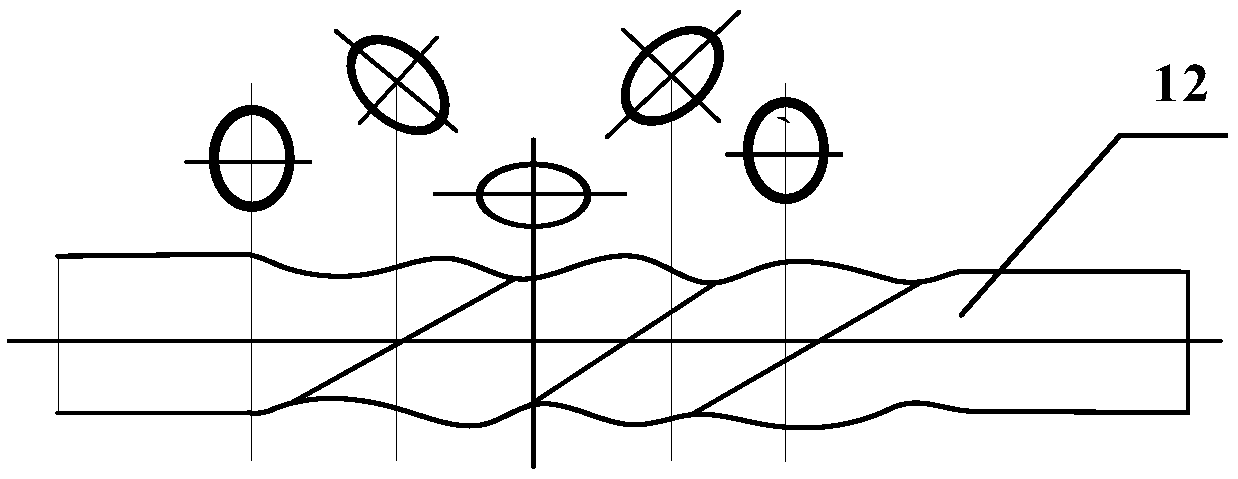

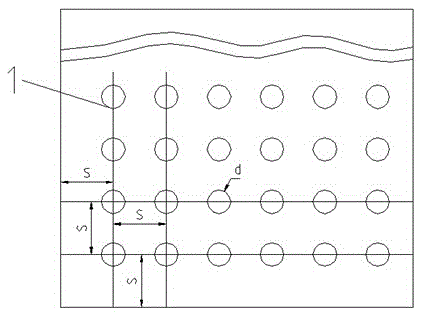

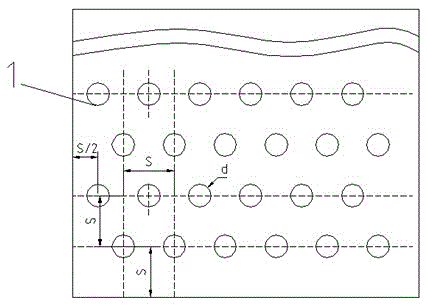

Rotary air preheater heat transfer corrugated plate with interrupted holes and processing method for rotary air preheater heat transfer corrugated plate

ActiveCN104329977AEnhanced heat transfer propertiesReduce consumptionCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention discloses a rotary air preheater heat transfer corrugated plate with interrupted holes and a processing method for the rotary air preheater heat transfer corrugated plate. The interrupted holes are formed in the rotary air preheater heat transfer corrugated plate; the rotary air preheater heat transfer corrugated plate is formed by alternately overlapping a first locating plate and a second locating plate; the second locating plate is 0.4-0.8mm thick; the first locating plate is formed by connecting an incision and a ripple with each other; the first locating plate is 0.4-0.8mm thick; the interrupted holes are round and rectangular in shape, and the size, the spacing and the arrangement mode of the interrupted holes are comprehensively obtained after being verified by the strict technical design and experimental results; by forming the round interrupted holes in the carbon steel flat plate, and then, rolling is performed through a corrugated roller to form the rotary air preheater heat transfer corrugated plate with the interrupted holes. According to the novel rotary air preheater heat transfer corrugated plate with the interrupted holes, the heat-transfer characteristic of the existing rotary air preheater heat transfer corrugated plate can be effectively improved, and the flow resistance in the channel of the existing rotary air preheater heat transfer corrugated plate is reduced, and meanwhile, steel consumption required for processing the rotary air preheater heat transfer corrugated plate is reduced.

Owner:ZHEJIANG KAIER NEW MATERIALS +1

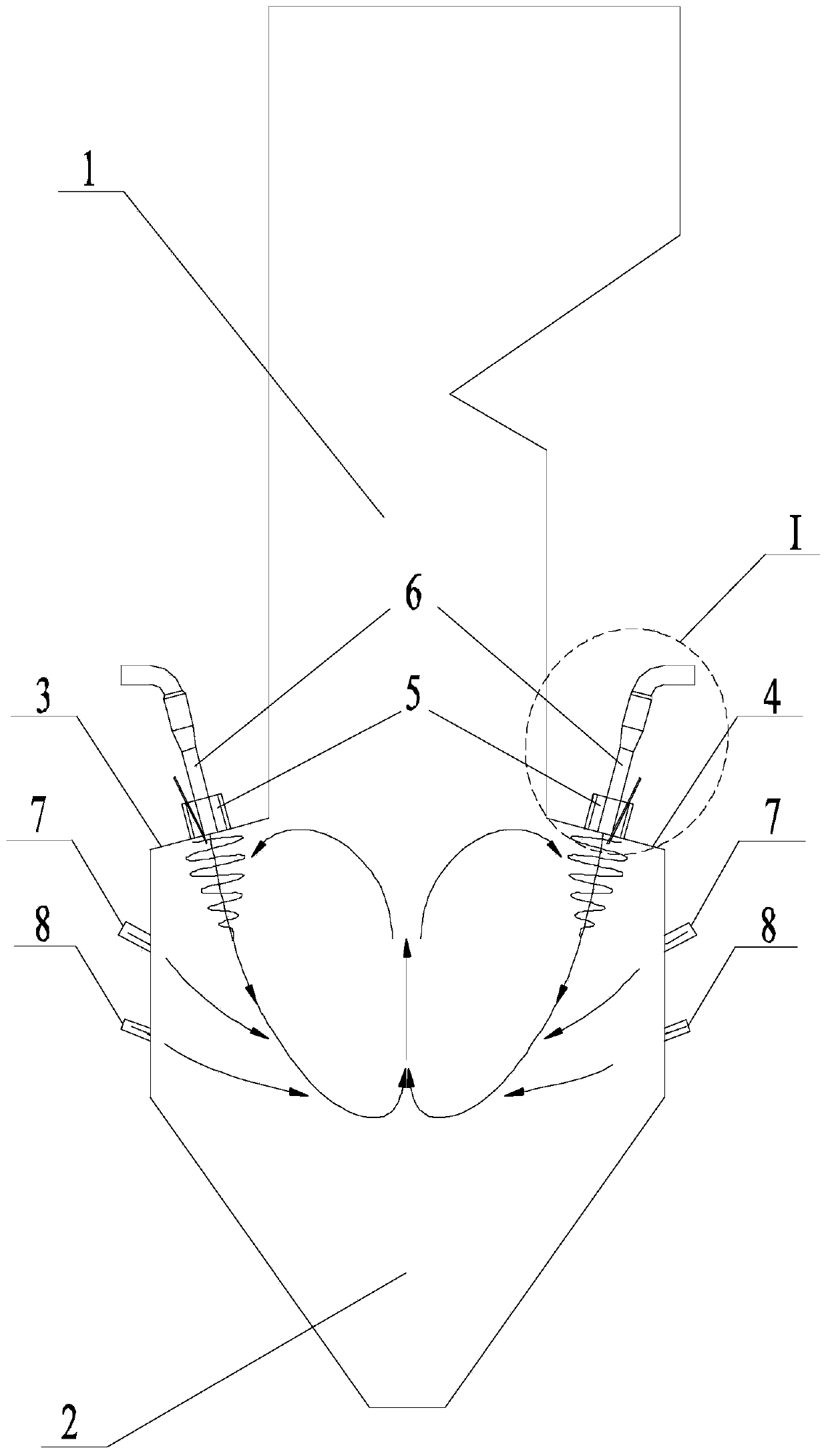

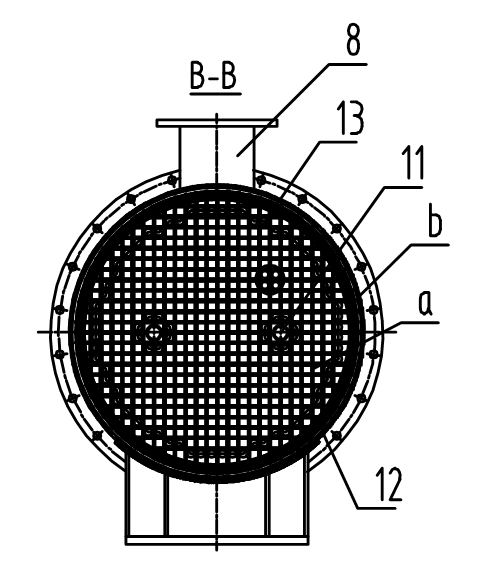

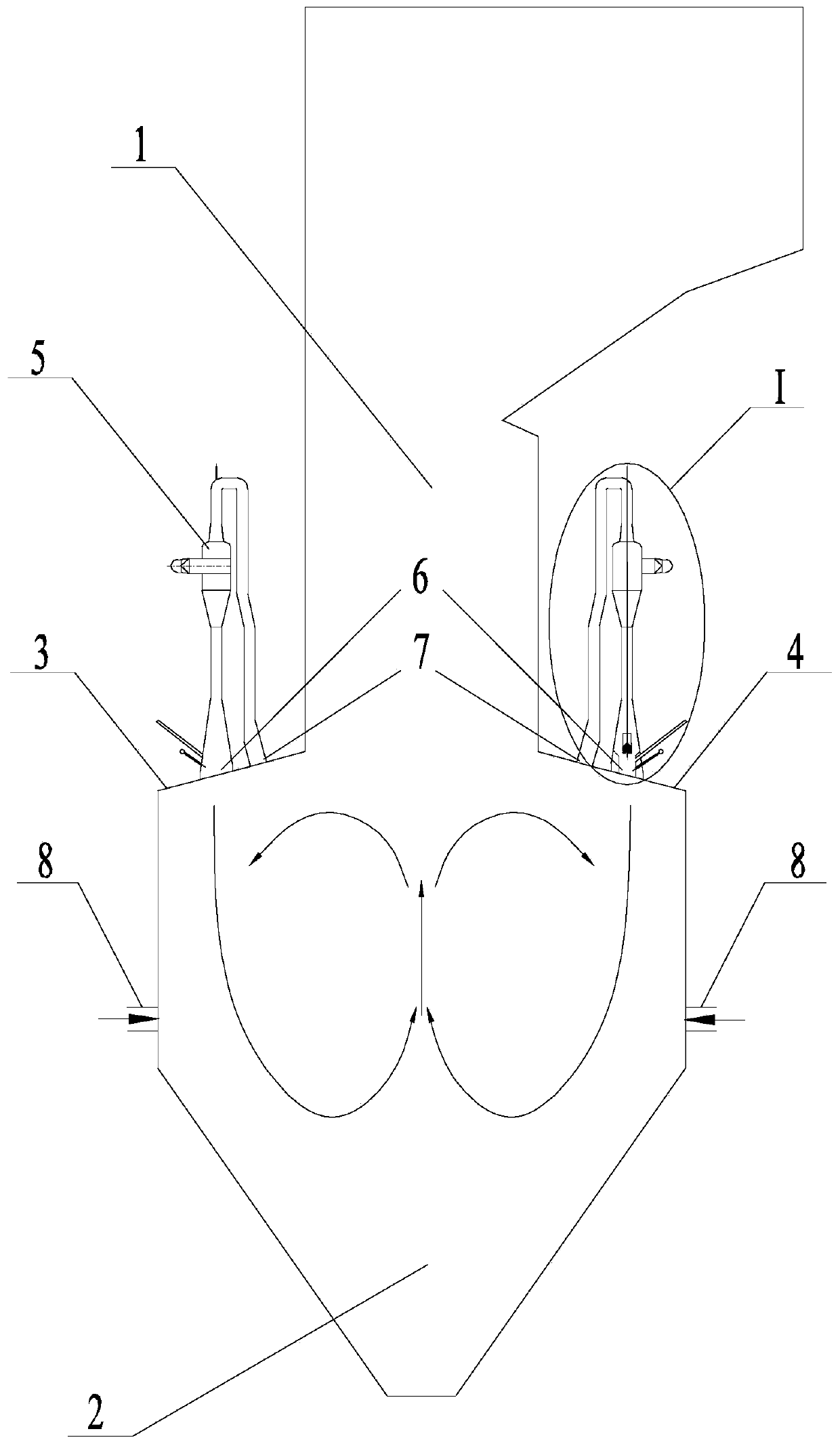

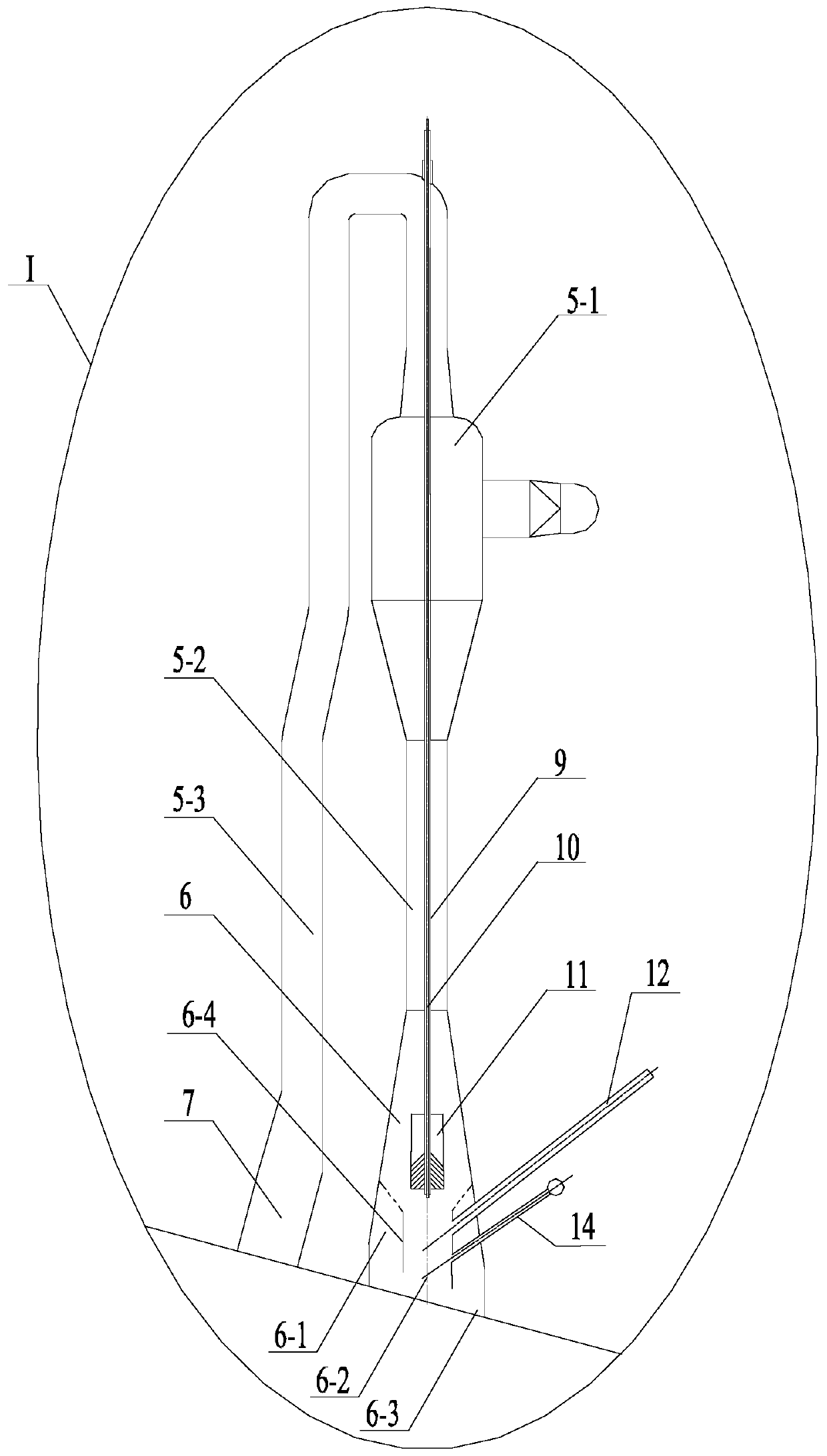

W flame boiler with double-cyclone-barrel thick and thin pulverized coal separation type combustors

InactiveCN111023084APromote fireImprove featuresPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCombustorPower station

The invention provides a W flame boiler with double-cyclone-barrel thick and thin pulverized coal separation type combustors, and relates to a power station boiler which adopts the flexible peak regulation technology. The W flame boiler with the double-cyclone-barrel thick and thin pulverized coal separation type combustors is used for solving the problems that a W flame boiler is poor in ultralowload stable combustion and operation capacity, and the flexible peak regulation load cannot be 20%. The W flame boiler comprises an upper combustion chamber, a lower combustion chamber, a front boiler arch, a rear boiler arch, a front wall, a rear wall, the multiple double-cyclone-barrel thick and thin pulverized coal separation type combustors and multi-layer arch bottom secondary air nozzles. Each double-cyclone-barrel thick and thin pulverized coal separation type combustor comprises two thick pulverized coal airflow nozzles and two exhaust air nozzles. The upper combustion chamber, the front boiler arch, the front wall, the lower combustion chamber, the rear wall and the rear boiler arch are combined to form a boiler body. The multi-layer arch bottom secondary air nozzles are arrangedon the front wall and the rear wall in sequence from top to bottom. The double-cyclone-barrel thick and thin pulverized coal separation type combustors are installed on the front boiler arch and therear boiler arch in a linear mode, and the corresponding thick pulverized coal airflow nozzles and the corresponding exhaust air nozzles of each double-cyclone-barrel thick and thin pulverized coal separation type combustor communicate with the boiler body. The invention belongs to the field of boilers.

Owner:HARBIN INST OF TECH

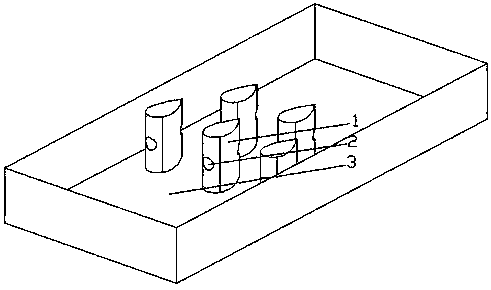

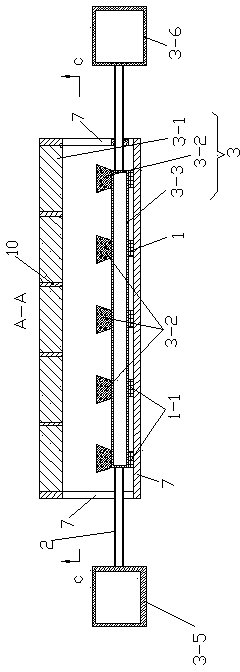

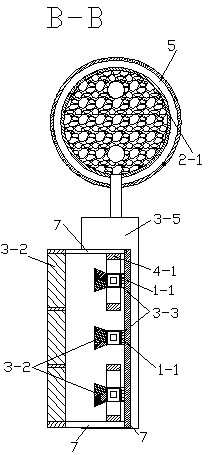

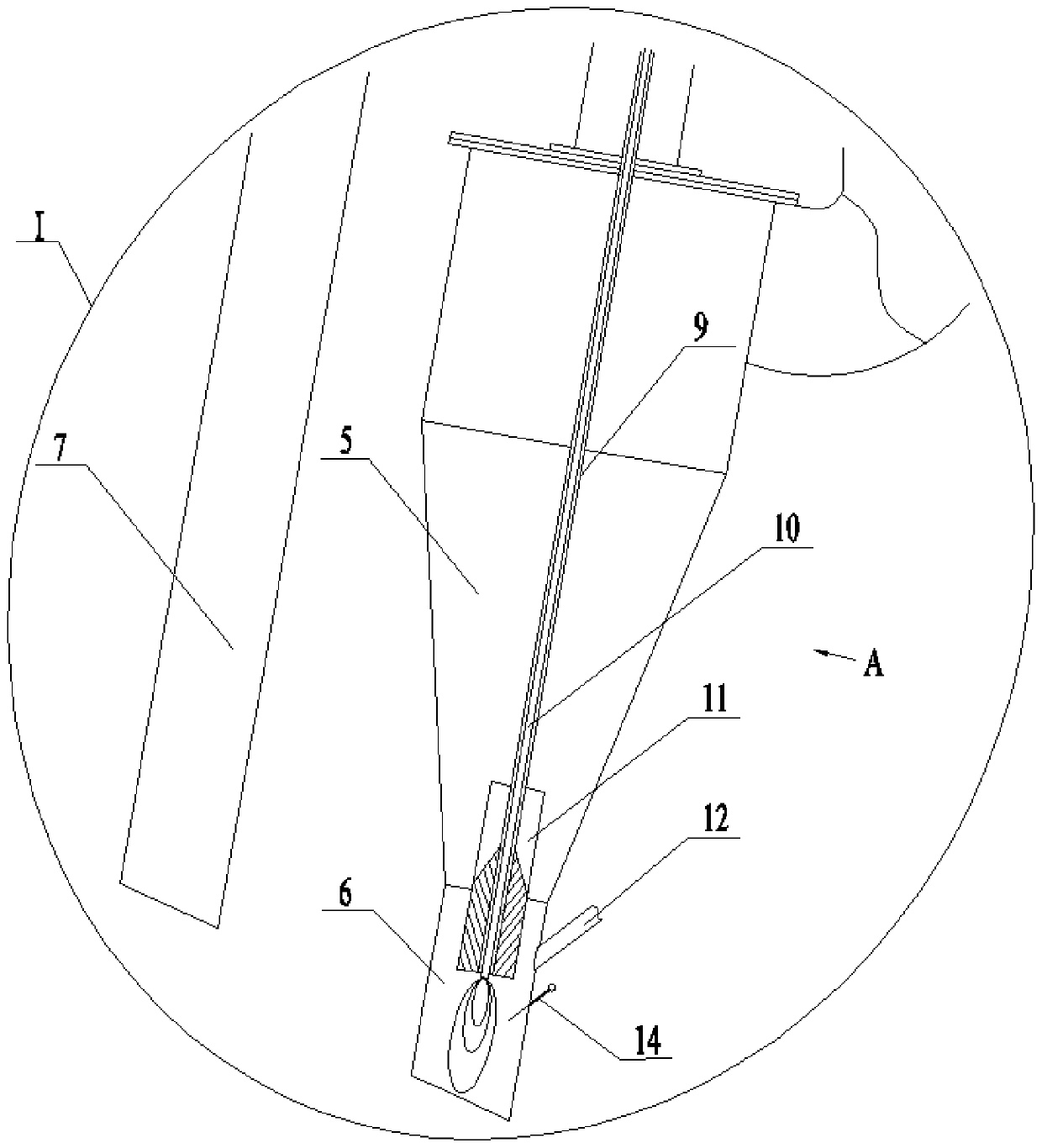

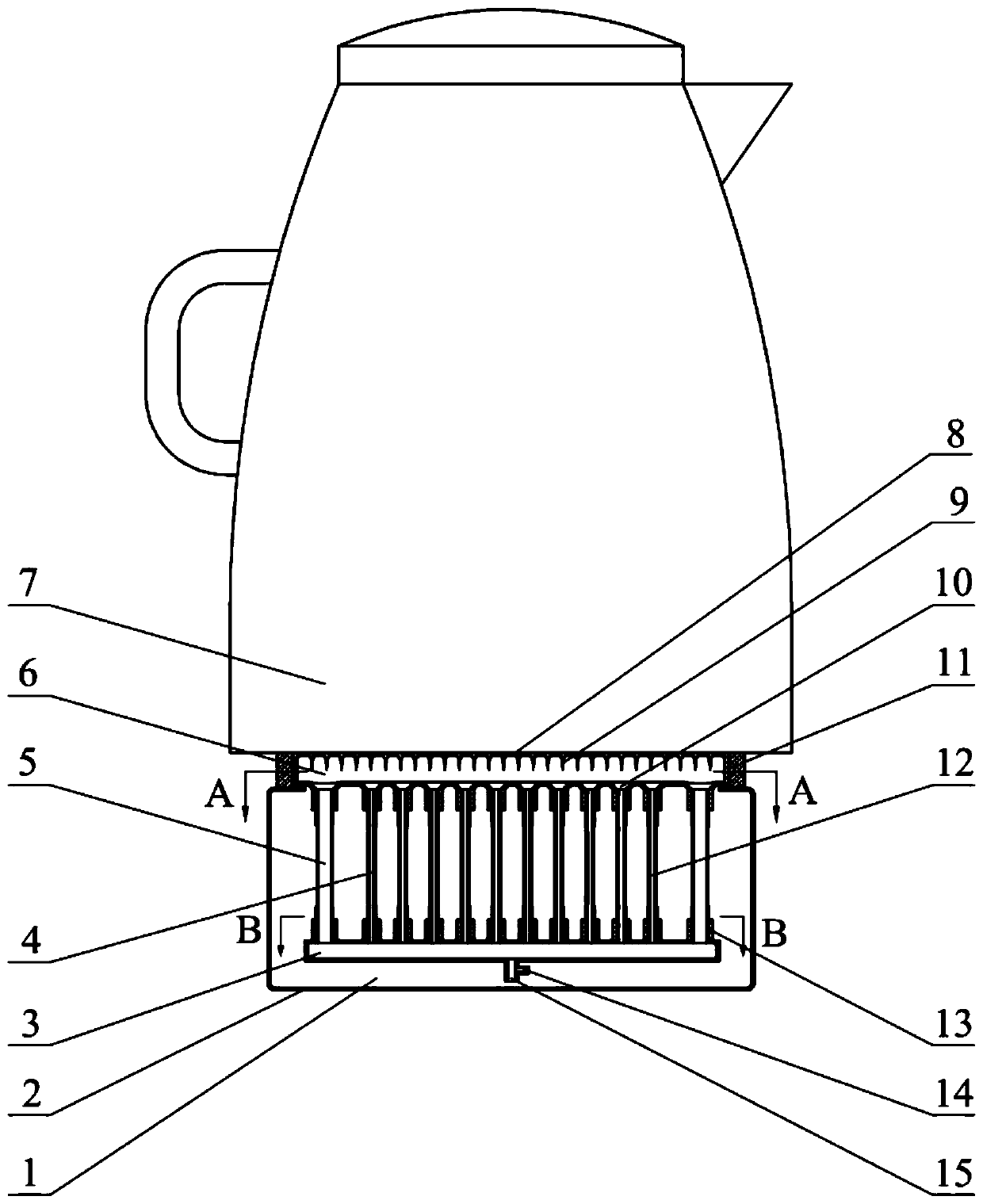

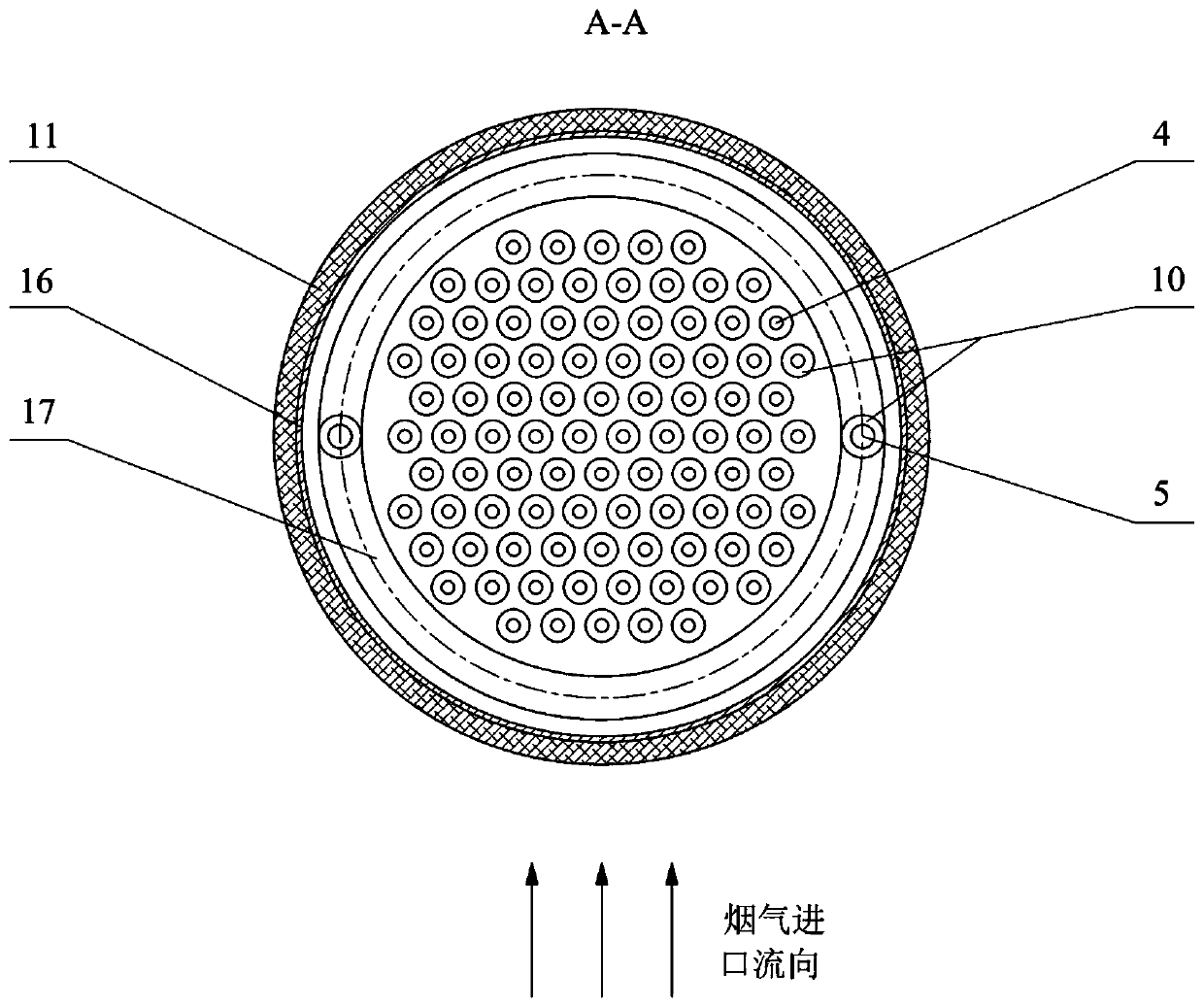

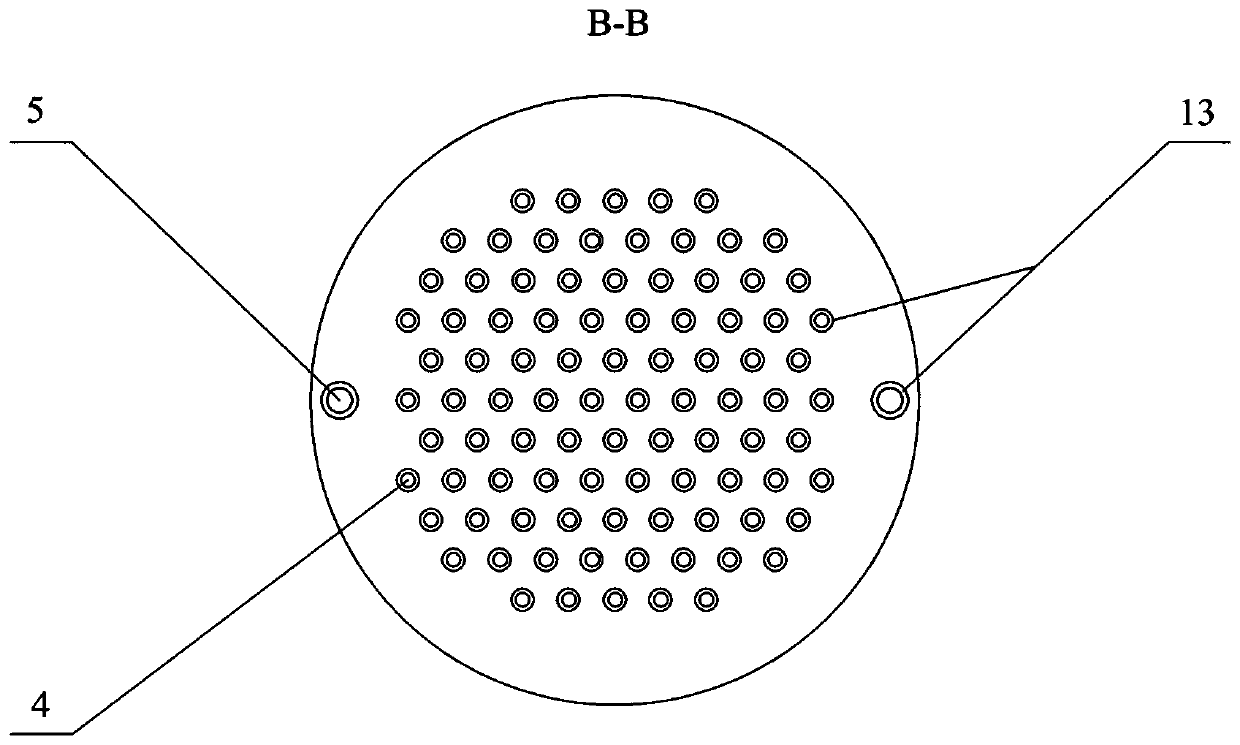

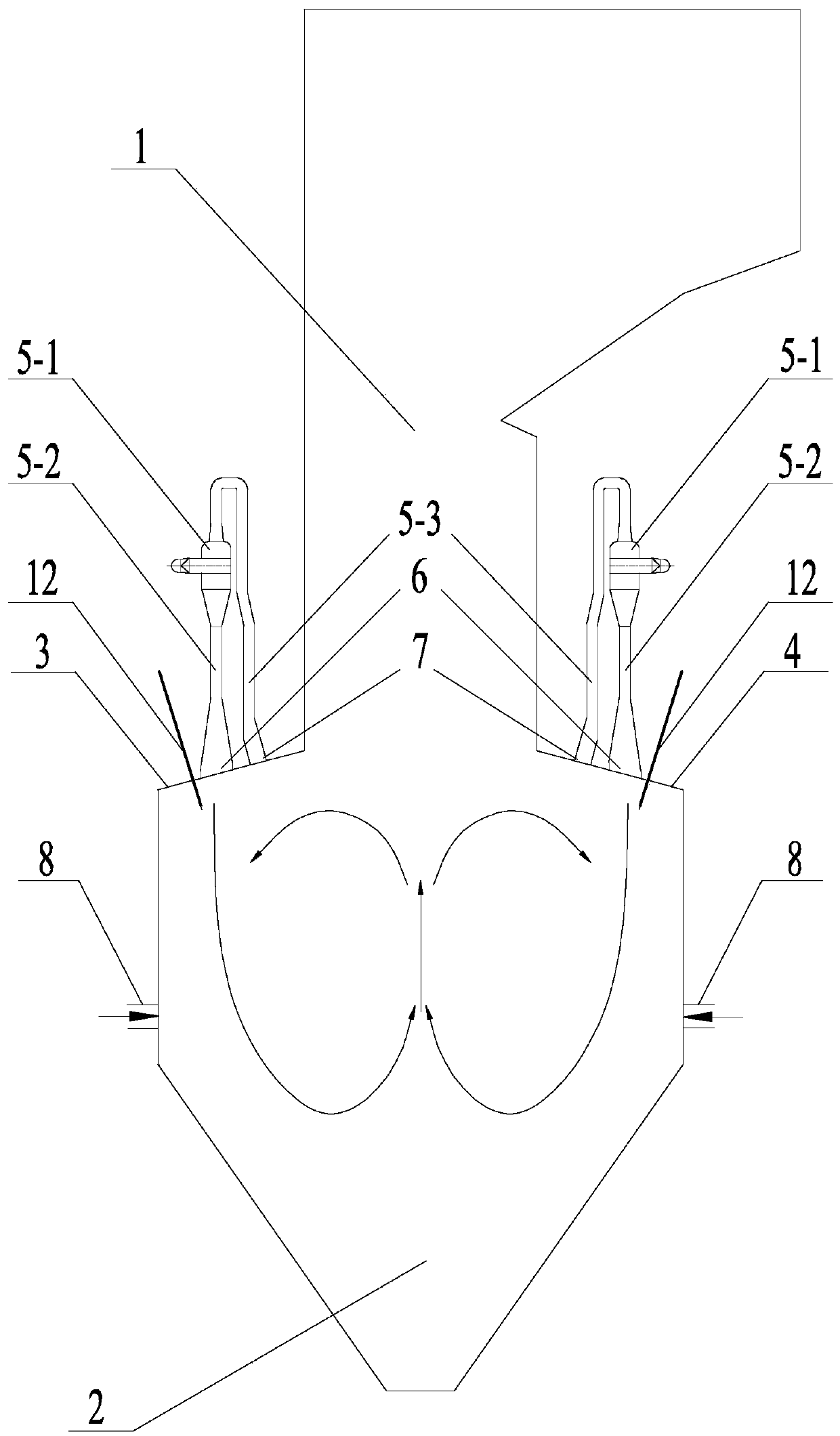

Parallel small diameter heat pipe enhanced heat exchange device for recovering medium and low temperature flue gas waste heat and preparation method thereof

ActiveCN110425510AImprove Primary UtilizationReduce heat pollutionIndirect heat exchangersCombustion technology mitigationExhaust gasProcess engineering

The invention relates to a parallel small diameter heat pipe enhanced heat exchange device for recovering medium and low temperature flue gas waste heat, aims to solve the problem of waste of medium and low temperature flue gas waste heat generated in small combustion equipment primarily, recovers the flue gas waste heat by means of parallel small diameter heat pipes to produce hot water or heat other substances, and is suitable for recovering waste heat of small flow flue gas or a discontinuous small flow heat source. The parallel small diameter heat pipe enhanced heat exchange device is primarily characterized in that the parallel small diameter heat pipe enhanced heat exchange device is good in heat transfer property, compact in structure, small in size, easy to process and low in cost,and can achieve self transfer of heat and efficient recovery of waste heat, so that the exhaust gas temperature is reduced greatly and the integral efficiency of the system is improved. The device isquite suitable for heat recovery of small capacity medium and low temperature flue gas waste heat and discontinuous waste heat resources, and a heating container is taken conveniently.

Owner:NANJING UNIV OF TECH +1

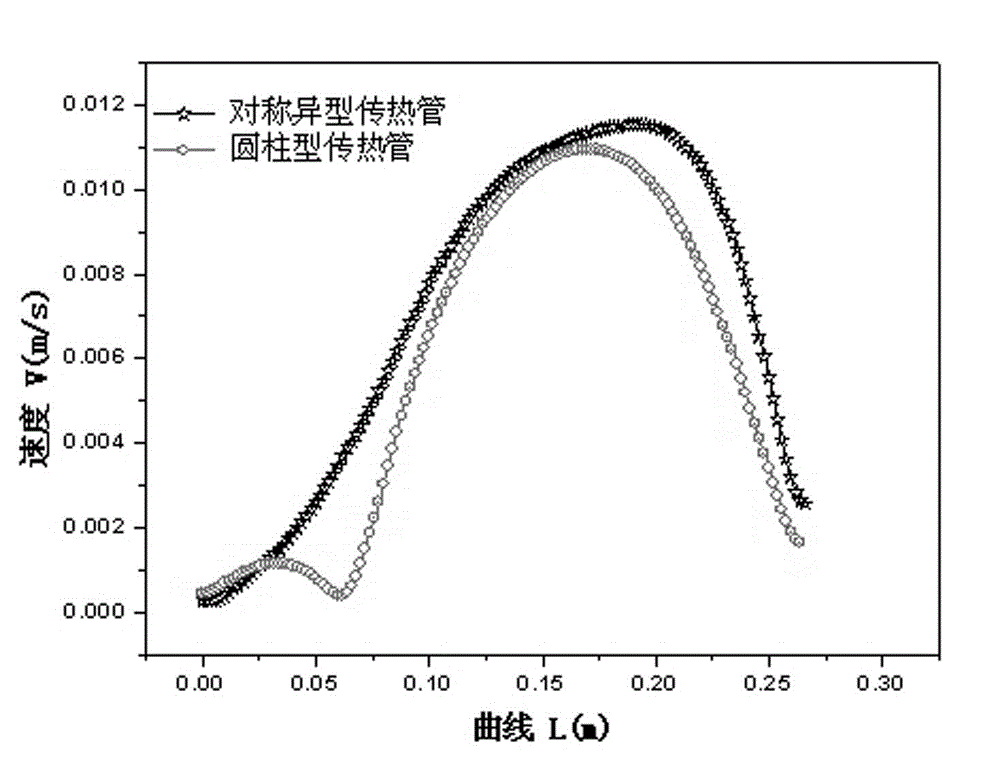

Novel initiative jet cooling device

InactiveCN102878842AEnhanced heat transfer propertiesSmall flow resistanceStationary conduit assembliesWork periodHeat transmission

The invention relates to a novel initiative jet cooling device and belongs to the field of long-term damage-free storage and transportation of low-temperature liquid. The novel initiative jet cooling device comprises a casing, a heat transmission pipe, a fin and a forced jet pump, wherein the fin is additionally mounted on the outer side of a cold end of the heat transmission pipe which is a special-shaped symmetrical water-drop pipe, and the cross-sectional shape of the fin is identical to that of the special-shaped symmetrical water-drop pipe of the transmission pipe. The novel initiative jet cooling device solves the problem that a conventional initiative storage and transportation system for low-temperature liquid is low in efficiency, is practically significant to long-term damage-free storage and transportation of cryogenic low-temperature liquid (liquid hydrogen, liquid oxygen, liquid nitrogen and liquid helium), is especially applicable to storage space for the low-temperature liquid, effectively solves the problem about deficient space energy, improves system performance of the storage space, and prolongs the effective work period of the low-temperature storage system.

Owner:中国航天科技集团公司第五研究院第五一0研究所

H-shaped finned tube with radially-formed slits on surface

InactiveCN108731534AAvoid heat exchange area reductionShort slit widthCorrosion preventionHeat exhanger finsEngineeringHeat transfer

The invention discloses an H-shaped finned tube with radially-formed slits on the surface. The H-shaped finned tube comprises a base tube and a plurality of fin sets which sleeve the two sides of theouter wall of the base tube correspondingly and are arranged in the axial direction of the base tube; each fin set is composed of two fins, the fins for each fin set are rectangular and are connectedwith the outer wall of the base tube in a symmetrical mode through side grooves of the fins arranged on the sides, next to the base tube, of the fins, the two fins for each fin set are located on thesame horizontal plane perpendicular to the axial direction of the base tube, a certain gap is formed between the two fins for each fin set, and the plurality of slits are formed in the surfaces of thefins; and the included angles between the slits and the incoming flow direction range from 40 degrees to 50 degrees, and the slits are symmetrically arranged on the two sides of the connecting linesbetween the center of the base tube and the four corners of the fins. According to the H-shaped finned tube, disturbance can be well carried out through the slits on the surfaces on the exterior fluidso as to damage the boundary layer to strengthen the heat transfer; then, the directions of the slits hardly affect the heat conduction inside the finned tube, and therefore, the fin efficiency cannot be reduced; and again, the directions of the slits and the flowing direction can reduce the flowing resistance which is increased due to the damage of the boundary layer as much as possible while the disturbance is formed and the damage boundary layer is damaged, moreover, the flowing friction area is reduced, and due to the two factors, the flowing resistance of the fined tube is integrally reduced.

Owner:XI AN JIAOTONG UNIV

W flame boiler adopting turbulent burners

ActiveCN111023083APromote fireImprove featuresPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationPower stationCombustor

The invention discloses a W flame boiler adopting turbulent burners, relates to a power station boiler adopting a flexible peak shaving technology, and belongs to the field of boilers. The invention aims to solve the problem that the W flame boiler adopts the turbulent pulverized coal burners in the prior art, the maximum peak shaving capacity of a boiler with a common micro-oil ignition mode is about 50%, the requirement of the government on the flexible peak shaving capacity of the power station boiler cannot be met; the W flame boiler adopting the turbulent burners comprises an upper hearth, a lower hearth, a front furnace arch, a rear furnace arch, a front wall, a rear wall and a plurality of turbulent pulverized coal burners, each turbulent pulverized coal burner comprises an adjustable cone pulling rod, a micro oil ignition gun and a flow guide cone, wherein the micro oil ignition guns are installed in the adjustable cone pulling rods, the bottom ends of the adjustable cone pulling rods are fixedly installed in the flow guide cones, the adjustable cone pulling rods, the micro oil ignition guns and the flow guide cones are installed in shells of the turbulent pulverized coal burners, and the turbulent pulverized coal burners are installed on a front furnace arch water wall and a rear furnace arch water wall correspondingly.

Owner:HARBIN INST OF TECH

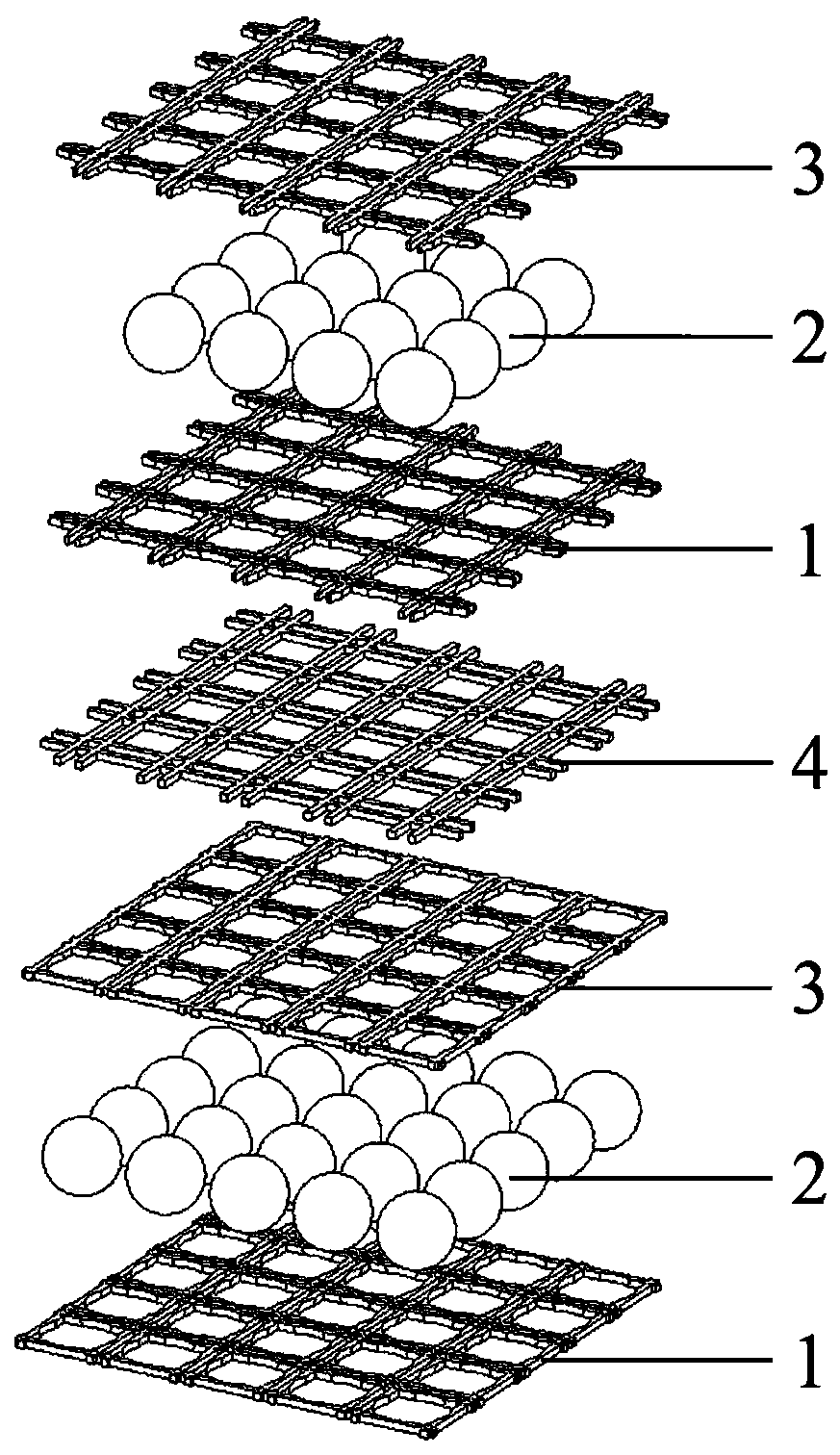

Accumulation method for grillwork particle composite bed

ActiveCN110395488AStructure is controllable and easy to implementImprove heat transfer performanceRigid containersContainers with multiple articlesMaterials scienceHeat transfer

The invention relates to an accumulation method for a grillwork particle composite bed. The upper and lower layers of positioning grillworks and spherical particles are pre-assembled to form a spherical-layer entirety, a container is filled with the spherical-layer entirety layer by layer at the top of the container, when the grillworks and particles descend, the relative positions of the grillworks and particles are invariant, and an orderly accumulation structure can be automatically formed. According to the accumulation method for the grillwork particle composite bed, multiple different orderly accumulation modes and multi-gradient orderly accumulation structures can be achieved, and compared with a grilling particle composite accumulation bed, under the condition of maintaining the heat transfer characteristic at the same level, by reasonably designing an accumulation structure, the heat transfer performance is possibly further improved.

Owner:XI AN JIAOTONG UNIV

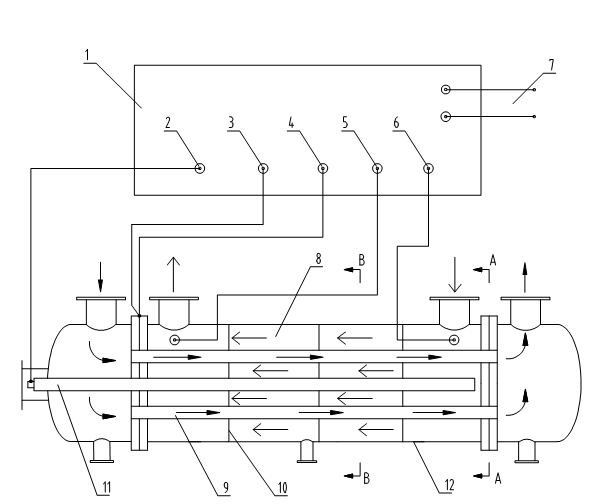

Anodic protection baffle rod type acid cooler

InactiveCN101949016AReduce side pressure dropEnhanced heat transfer propertiesCorrosion preventionStationary conduit assembliesThermodynamicsEngineering

The invention relates to an anodic protection baffle rod type acid cooler which comprises an acid cooler shell (12) and is characterized in that a heat exchange tube box is arranged in the acid cooler shell (12); the heat exchange tube box comprises a plurality of baffle plates (10); the baffle plates (10) comprise baffle rods (a) and baffle rings (b); a plurality of baffle rods (a) are arranged on the baffle rings (b), and the baffle rods (a) on adjacent baffle rings (b) are arranged in a staggered mode to form a spatial staggered grid structure; and a heat exchange tube (13) is arranged in the spatial grid structure. The anodic protection baffle rod type acid cooler of the invention has reasonable design, reduces the vibration of the heat exchange tube, improves the heat transfer coefficient, reduces the consumption of the kinetic energy, has good anodic protection effect, low corrosion rate, safety and reliability, and absolutely can be used under the technological conditions of high acid content; and compared with an anodic protection baffle plate type acid cooler, the comprehensive economic benefit is greatly improved.

Owner:NANJING GAOYUAN ENVIRONMENTAL PROTECTION ENG

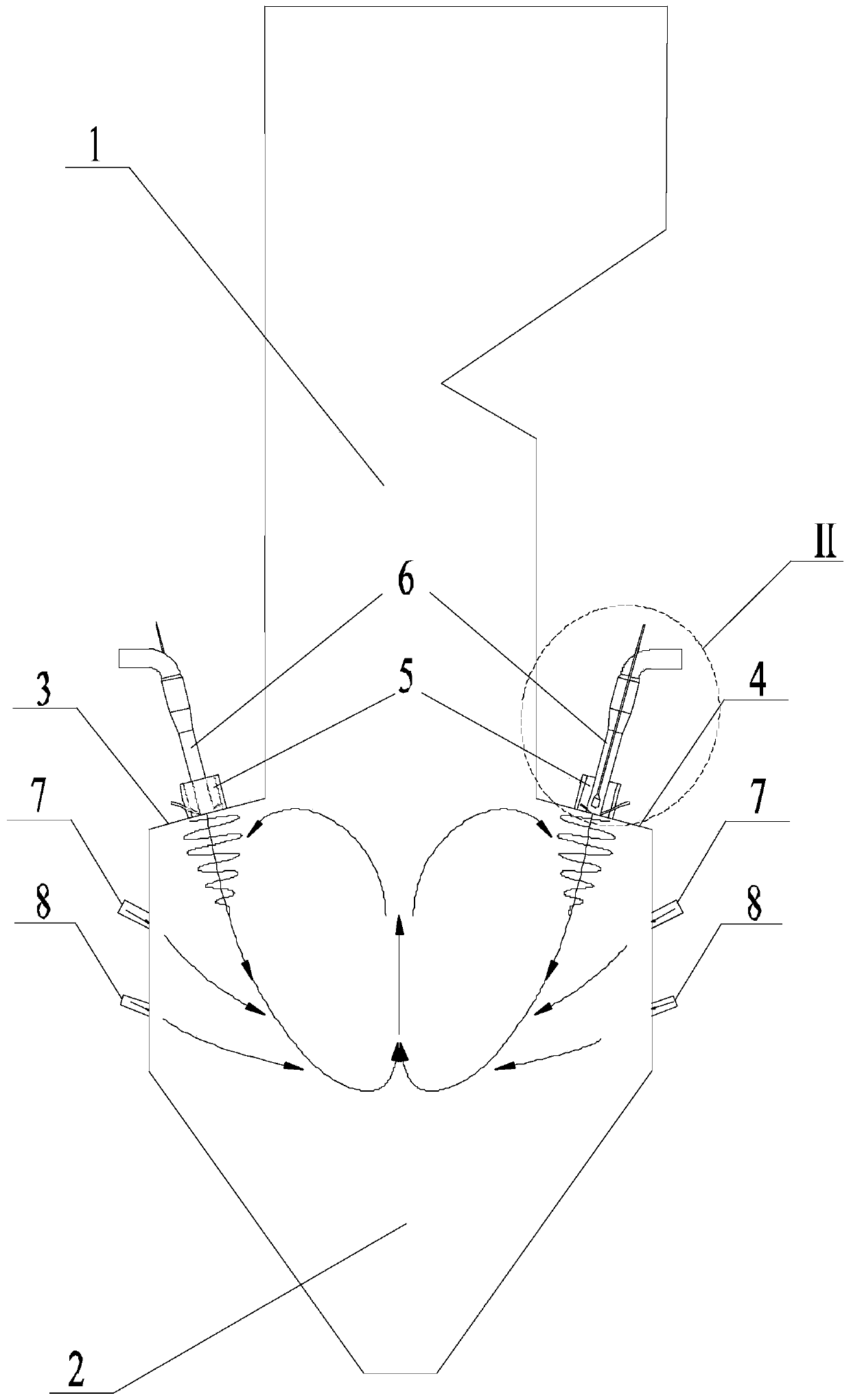

W-flame boiler adopting slit type combustor

ActiveCN111023081AImprove ignition characteristicsImprove low-load combustion stabilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsCombustor

The invention discloses a W-flame boiler adopting a slit type combustor, and relates to a W-flame boiler adopting a flexible peak regulation technology. The W-flame boiler adopting the slit type combustor aims to solve the problems that when the load of the conventional W-flame boiler is lower than 50 percent by adopting an oil gun ignition mode, the combustion is unstable and even the fire is extinguished; and the flexible peak regulation capacity of the boiler needs to reach 20% of full load, but a boiler meeting the condition does not exist in the prior art. The W-flame boiler comprises anupper hearth, a lower hearth, a front boiler arch, a rear boiler arch, a front wall, a rear wall, a plurality of straight flow gap type combustors and a plurality of grading air nozzles; and each straight flow gap type combustor comprises a hollow rotational flow adjusting pull rod, a tiny-oil burning torch and a pulverized coal flow guiding body, wherein the tiny-oil burning torch is installed inthe hollow rotational flow adjusting pull rod, the bottom end of the hollow rotational flow adjusting pull rod is fixedly connected with the pulverized coal flow guiding body, and the hollow rotational flow adjusting pull rod, the tiny-oil burning torch and the pulverized coal flow guiding body are installed in the straight flow gap type combustor shell. The invention belongs to the field of boilers.

Owner:HARBIN INST OF TECH

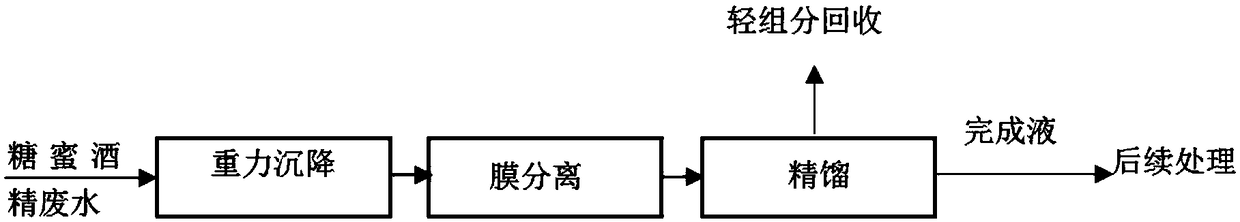

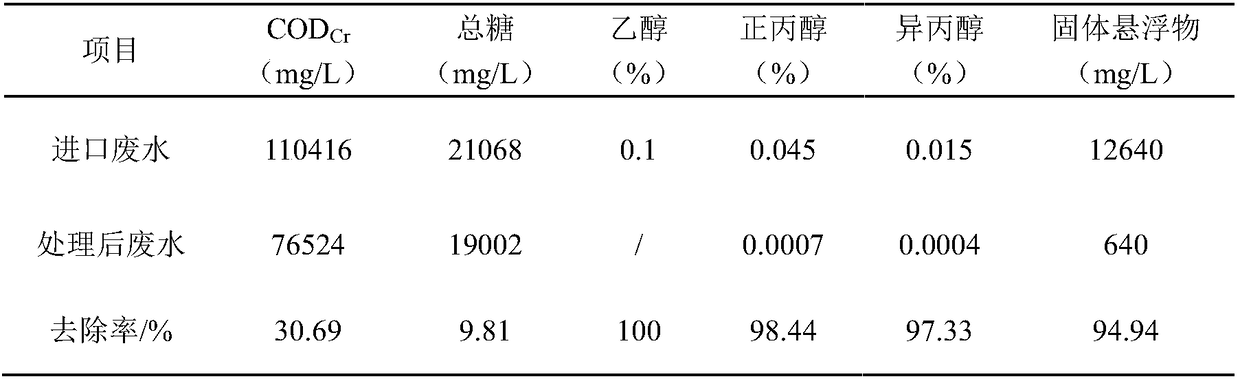

Pretreatment method of molasses alcohol wastewater

ActiveCN108383307AImprove separation efficiencyImprove stabilitySpecific water treatment objectivesTreatment involving filtrationPretreatment methodFiltration

The invention belongs to the technical field of industrial sewage treatment, and discloses a pretreatment method of molasses alcohol wastewater. The pretreatment method comprises the steps of performing sedimentation, filtration and rectification pretreatment on the molasses alcohol wastewater; and specifically comprises the following steps: (1) sedimentation: the molasses alcohol wastewater is added into a gravity sedimentation pool, and a flocculating agent is put into the pool through a concentric circle distributor, the wastewater after the flocculation and gravity sedimentation treatmentis filtered through a filter and then subjected to microfiltration treatment through a membrane separation device; and (2) rectification: after the microfiltration treatment, the wastewater enters a rectification tower for rectification to obtain a tower top product and a tower bottom product which are subjected to subsequent processing separately. According to the pretreatment method, the separation efficiency is high, the stability is good, the pertinence is high, colloids, flocculates and other solid particles in the wastewater can be effectively removed, light components in the wastewatercan be well separated and recovered, and load of the subsequent treatment process can be effectively reduced, thereby ensuring that the wastewater is finally discharged up to standards, therefore, thepretreatment method is suitable for mass production.

Owner:SOUTH CHINA UNIV OF TECH

Mzi-type optical waveguide hybrid integrated thermo-optic switch with graphene-doped trapezoidal cladding and its preparation method

ActiveCN110441861BEnhanced heat transfer propertiesImprove heat dissipation characteristicsOptical waveguide light guideNon-linear opticsPhotosensitive polymerSingle layer graphene

The invention relates to an MZI type optical waveguide hybrid integrated thermo-optical switch with a graphene doped trapezoidal cladding, and a preparation method of the switch, and belongs to the technical field of optical waveguide type thermo-optical switch preparation. The method comprises the following steps: spin-coating a silicon dioxide substrate with a photosensitive polymer core layer material; performing photoetching on the photosensitive polymer core layer material by adopting a mask to obtain an optical waveguide core layer; then performing spin-coating of a graphene-doped polymer cladding material, evaporating of a metal film, spin-coating of a photoresist, registering and photoetching, and developing to prepare an electrode pattern; and finally performing cleavage so as toprepare the MZI type optical waveguide hybrid integrated thermo-optical switch with the graphene-doped trapezoidal cladding on the substrate. According to the method, the trapezoidal cladding structure is used for replacing a flat cladding structure, so that the heating efficiency of an electrode is improved; and the polymer material doped with single-layer graphene dispersion liquid is adopted toreplace a traditional polymer material, so that the problems of high power consumption and long switch time caused by low heat conductivity of polymer are solved. The method has the excellent effectsof simple process flow, high preparation precision and the like.

Owner:JILIN UNIV

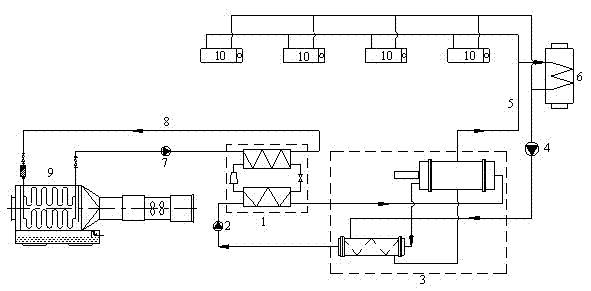

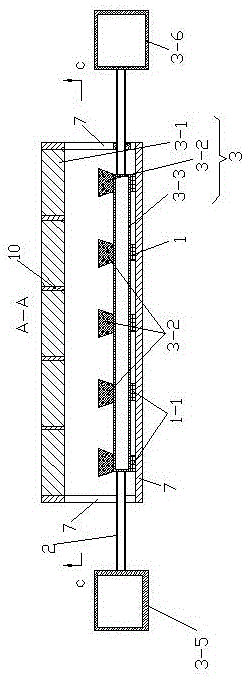

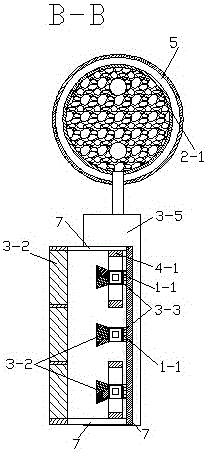

Mine cooling system using ice slurry cold storage technology on secondary side fluid

ActiveCN102808643AImprove cooling effectImprove performanceDomestic cooling apparatusLighting and heating apparatusEngineeringSlurry

The invention discloses a mine cooling system using an ice slurry cold storage technology on a secondary side fluid, and relates to a mine cooling system. A primary refrigerating medium is cooled to 10 DEG C below zero by a low-temperature screw ethylene glycol unit 1 of the system; 35% of the ethylene glycol is conveyed to an ice slurry preparation device 3 by a primary refrigerating medium pump; soft and fluffy ice crystals particles are generated on the tube wall through heat exchange of the primary refrigerating medium in the ice slurry preparation device and secondary refrigerating medium containing an additive blocking the growth and antifreeze properties of the ice crystal; the ice crystal particles are scraped off through a reciprocating polyurethane scraping device to form IPF (ice packing factor) 2%-30% ice slurry; the IPF 2%-30% ice slurry is conveyed to a gate way air cooling unit 6 and a mining air cooler 10 by a cold insulation pipeline 5, so as to exchange heat with air flow in the air cooler, thereby the temperature of the air flow is reduced. Through the heat exchange of the cooling water and air flow inside a re-cooling device 9, the temperature of the cooling water is reduced to 32 DEG C, and then the cooling water is returned to the low-temperature screw ethylene glycol unit 1 to complete underground heat removal circulation. The system can be widely applied to controlling high-temperature heat damage to underground mining work surfaces of coal mines and non-coal mines.

Owner:CCTEG SHENYANG RES INST

A magnetic nanofluid concentrating photovoltaic heat and power cogeneration device

InactiveCN104539238BTake advantage ofEffective absorptionPhotovoltaicsPhotovoltaic energy generationCogenerationEngineering

The invention relates to a magnetic nano-fluid light condensation type photovoltaic combined heat and power generation device. The magnetic nano-fluid light condensation type photovoltaic combined heat and power generation device comprises a photovoltaic cell assembly module, a heat storage assembly, a photo-thermal assembly and a magnetic field adjusting assembly; the heat storage assembly comprises a heat reservoir and a heat exchange pipe; the heat reservoir is internally provided with phase change media; an inlet and an outlet of the heat exchange pipe are exposed out of the heat reservoir; the photo-thermal assembly comprises a circulating pump, a first header, a second header, multiple transparent heat gathering pipes, multiple uniform light bodies, Fresnel lenses and a framework; the uniform light bodies are polygon prisms; the area of the upper surface of the polygon prisms is greater than that of the bottom of the polygon prisms; the magnetic field adjusting assembly comprises S-shaped magnets and coils wound around the arms of the S-shaped magnets, one heat gathering pipe is arranged between the arms of every two adjacent magnets, and the S-shaped magnets and the heat gathering pipes are located on the same plane; the heat exchange pipe, the heat gathering pipes, the circulating pump, the first header and the second header are all internally provided with nano-fluid which can circulate and flow. The magnetic nano-fluid light condensation type photovoltaic combined heat and power generation device has the advantages of being simple in structure, capable of improving the solar energy utilization ratio, and the like.

Owner:HOHAI UNIV CHANGZHOU

Polyimide glue poured motor winding insulation structure and preparation method thereof

PendingCN113922608AImprove stabilityImprove high temperature resistanceApplying solid insulationImidePolymer science

The invention discloses a polyimide glue poured motor winding insulation structure and a preparation method thereof. The method comprises the steps of wrapping the surface of a metal wire with a high temperature resistant polyimide / adhesive resin composite film, sintering at 320-370 DEG C to melt the adhesive resin, and bonding the high temperature resistant polyimide film into a whole to form a first wrapping insulation layer; performing oxidation etching treatment on the surface of the first wrapping insulating layer; after the metal wire is made into a motor stator electromagnetic wire winding, pouring the high-temperature-resistant thermosetting polyimide resin adhesive, and heating and curing to form a resin pouring insulating layer. Compared with the prior art, the manufacturing method of the polyimide glue poured motor winding insulation structure has important influences on the improvement of the heat resistance grade, the operation reliability / durability and the service life of a special motor, and has bright application prospects in the field of heavy oil reservoir exploitation.

Owner:沈阳方舟石油科技发展有限公司 +1

Rotary air preheater heat transfer corrugated plate with spoiler holes and its processing method

ActiveCN104329977BEnhanced heat transfer propertiesReduce consumptionCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

Owner:ZHEJIANG KAIER NEW MATERIALS +1

Tubular falling film spraying device

ActiveCN106823427AGood flowEnhanced heat transfer propertiesEvaporator accessoriesEngineeringDrainage tubes

The invention discloses a tubular falling film spraying device which comprises an inner tube, a sleeve and a drainage tube. The tube outer diameter of the sleeve and the drainage tube is the same as the tube outer diameter of a working tube; the outer diameter of the inner tube is smaller than that of the sleeve; an opening is formed in the top of the inner tube; a line of outflow holes is formed in the bottom of the sleeve along a straight line; the inner tube is centered inside the sleeve; a semicircular surface spacer is embedded into the top of an inner wall of the sleeve, and a lower edge of the sleeve is just in contact with the outer wall of the inner tube; a midline of the opening of the inner tube, an axis of the inner tube and a midline of the outflow holes in the bottom of the sleeve are positioned on the same vertical plane; the front and rear ends of the opening of the inner tube need to be flush with the outer edge of the outflow hole on the outermost side of the sleeve; more than one sealing tube clamp is respectively used at gaps between the inner tube and the left and right ends of the sleeve; the drainage tube is arranged just under the sleeve, and a spacing between the drainage tube and the sleeve is 2mm; the drainage tube and the sleeve are fixedly welded by welding or a tube plate. According to the device disclosed by the invention, spraying media can be uniformly distributed, and excellent flow pattern and high heat-transfer characteristics are obtained, so that the efficiency of the device is improved.

Owner:DALIAN UNIV OF TECH

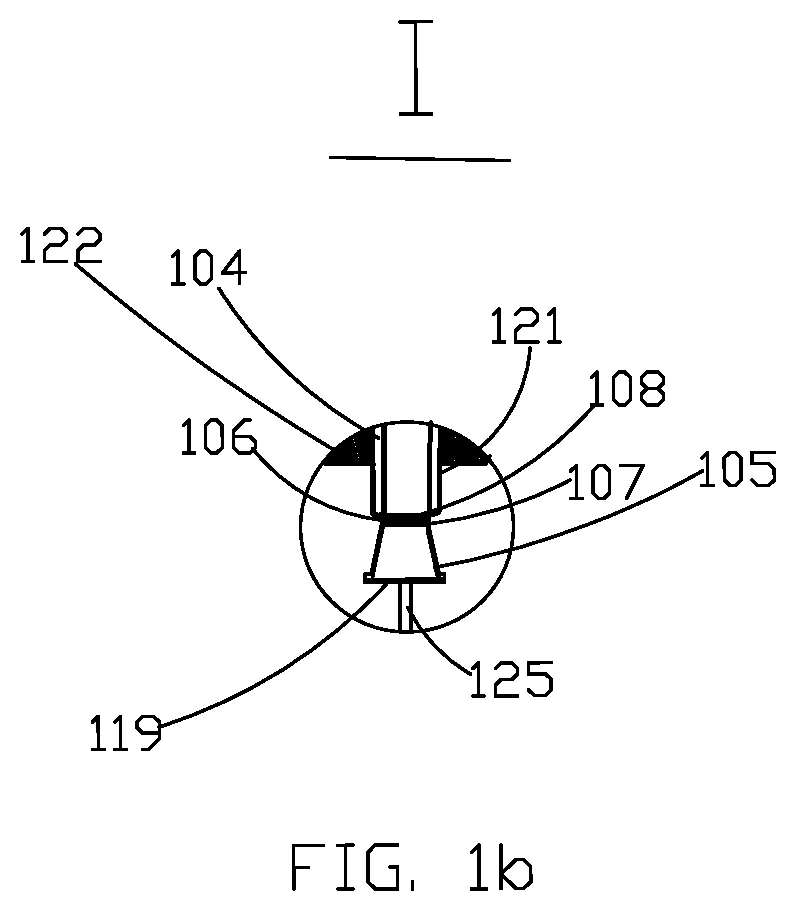

Concentrating solar power module

InactiveUS20210088255A1Enhanced heat transfer propertiesReduce heat lossSolar heating energySolar heat collector controllersEngineeringSolar power

This invention relates to concentrating solar power systems with application of parabolic dish-shaped reflectors.A proposed CSP module applies a two-phase thermosiphon intended to transport heat generated by concentrated sunlight on a sunlight receiver onto the external surface of a heat exchanging pipe. The outer end butt of a distal plug, which seals the lower section of the two-phase thermosiphon, is provided with a sunlight absorbing coating.A tracking manipulator is installed below a dish-shaped mirror and joined with its supporting structure; it provides orientation of the axis of the dish-shaped mirror towards the sun.The walls of the two-phase thermosiphon are provided with a metal vacuum insulated jacket, which has a flexible middle sub-section of its lower section.Design of the middle and distal sub-sections of the lower section of the two-phase thermosiphon allows accompanied orientation of the distal sub-section axis of the two-phase thermosiphon towards the sun.

Owner:LEVIN ALEXANDER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com