Novel oval twisted pipe heat exchanger with vortex generators

A technology of vortex generators and heat exchangers, which is applied in the field of heat exchange, can solve the problems of rare, destroy the fluid boundary layer, increase the degree of fluid turbulence, etc., and achieve the advantages of reducing flow resistance, flexible and diverse layout methods, and strengthening the heat transfer process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

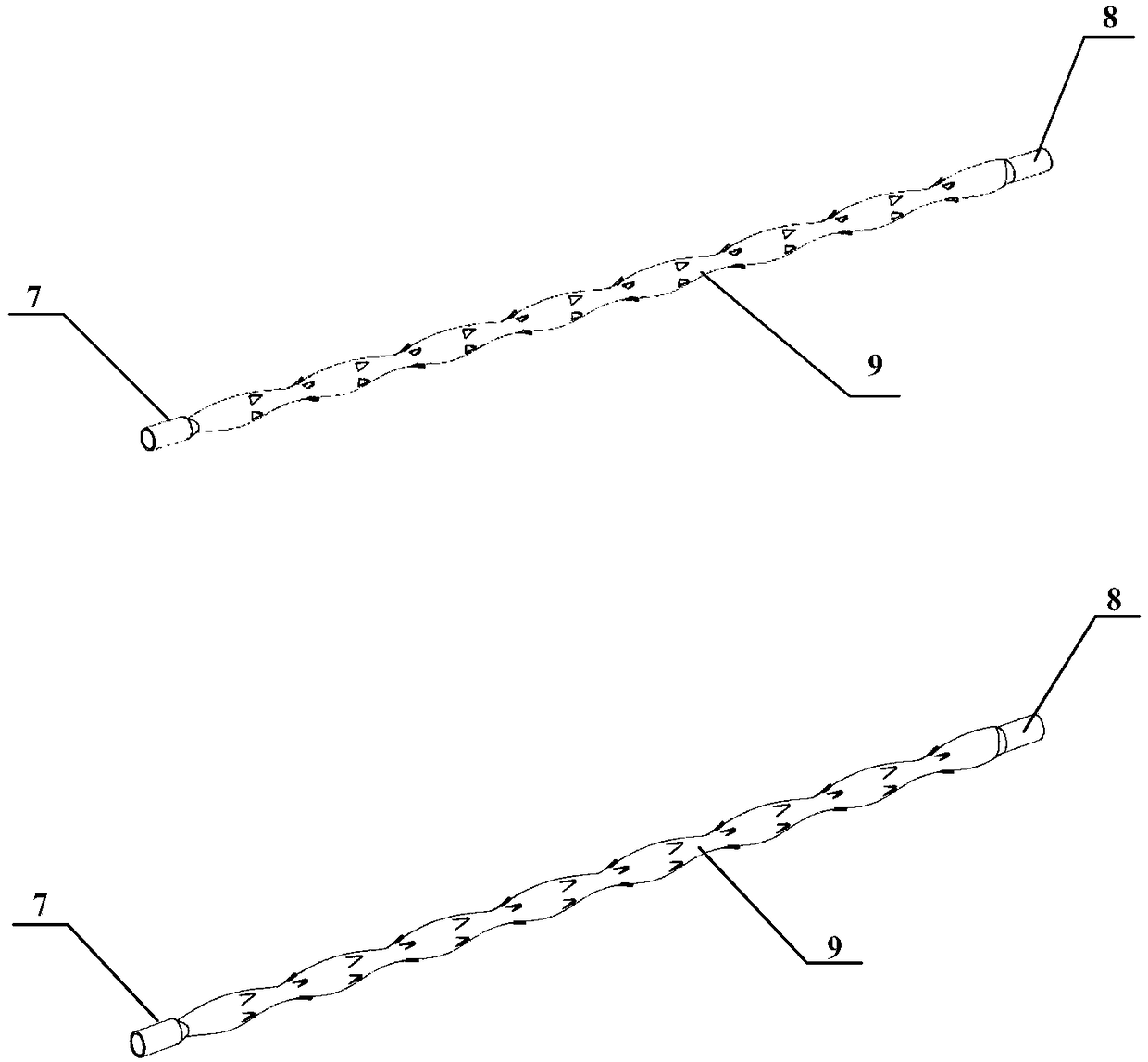

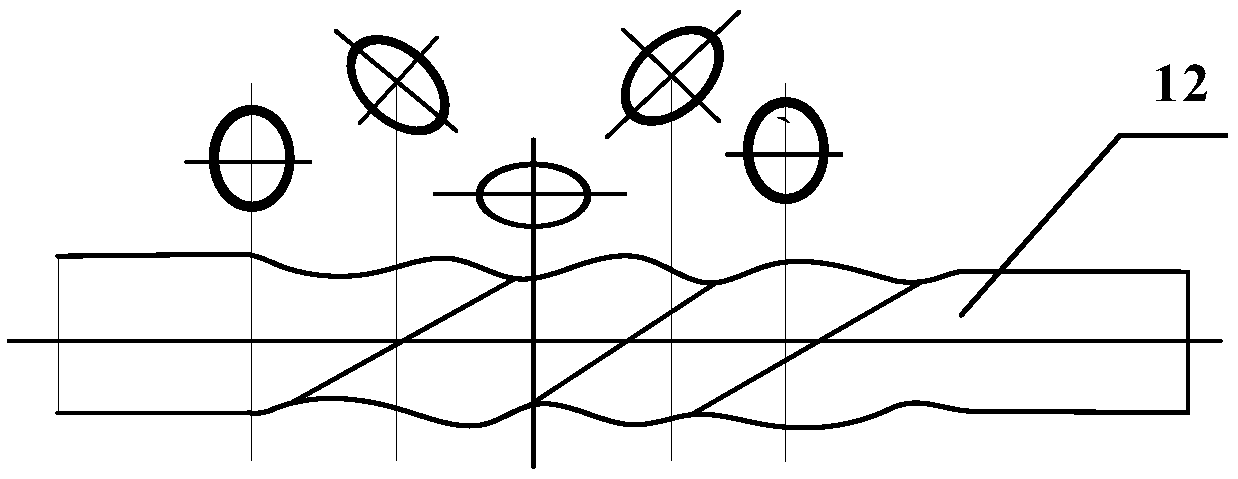

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. These drawings are all simplified schematic diagrams, and are only used to schematically illustrate the basic structure of the present invention.

[0037] The elliptical twisted tube heat exchanger with vortex generator provided by the present invention has simple structure, various forms, and wide application range, especially involving condensation. In addition, the point contact at the long axis of adjacent tubes between tube bundles can save folding Flow plate, play the role of self-support. The enhanced heat transfer tube achieves the purpose of enhancing heat transfer by increasing the heat transfer area and forming a vortex structure, thereby thinning the boundary layer. When the fluid flows in the tube, the elliptical spiral twisted channel structure in the tube easily ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com