Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Continuous mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

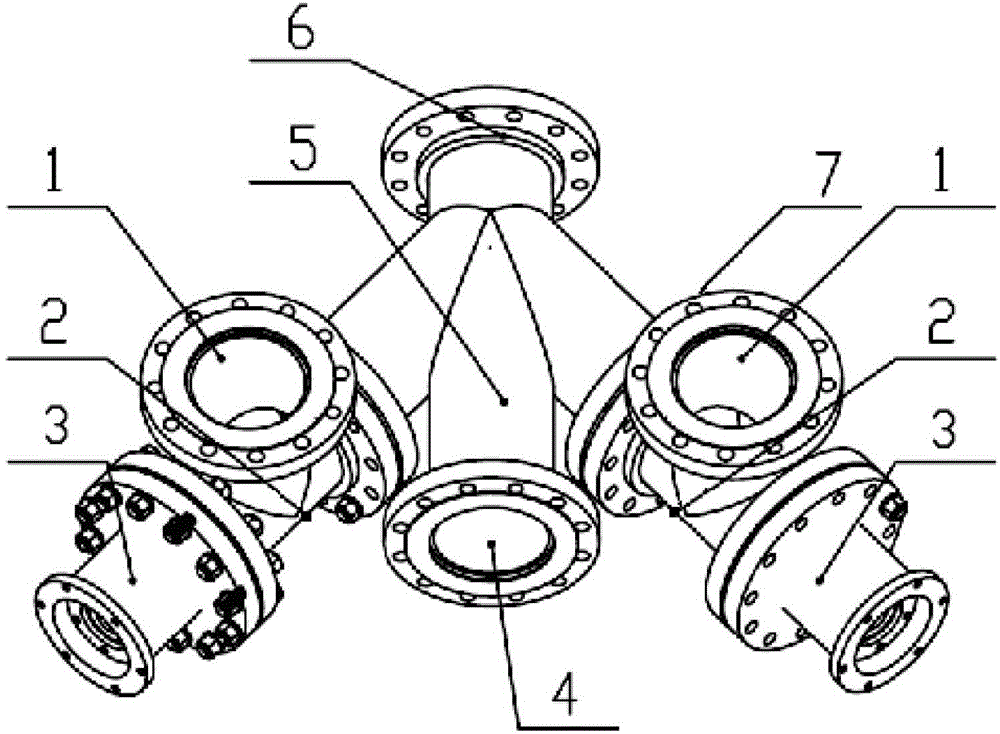

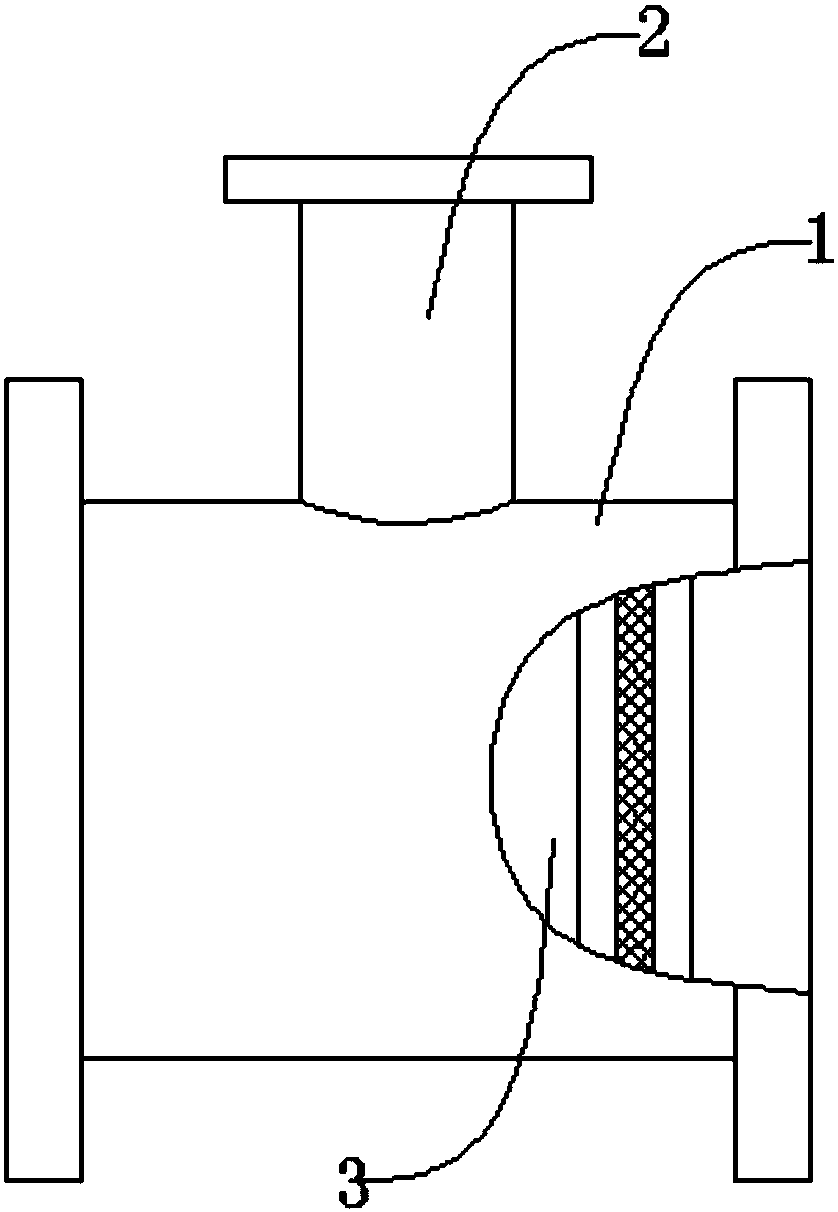

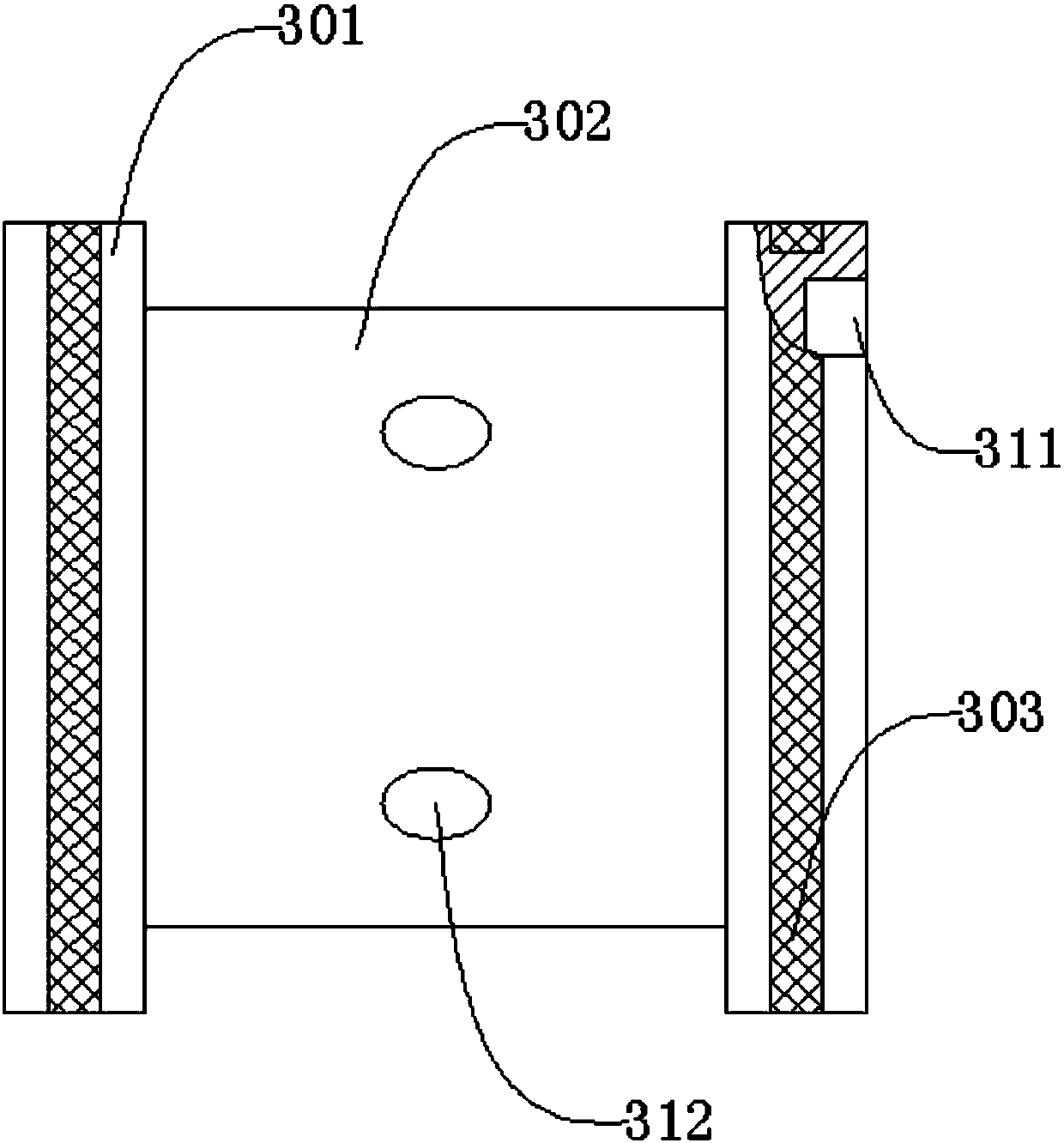

Solid-liquid mixing device

The invention provides a solid-liquid mixing device which is used for mixing a fracturing fluid. The solid-liquid mixing device contains a low-temperature and pressure resistant enclosed mixing container, a solid introducing port which is arranged on the mixing container and used for introducing solid particles of the fracturing fluid into an inner chamber of the mixing container, a liquid introducing port which is disposed on the mixing container and used for introducing a base solution of the fracturing fluid into the inner chamber, and a solid-liquid outlet which is arranged on the mixing container and used for exporting the fracturing fluid out of the inner chamber. According to the solid-liquid mixing device provided by the invention, by the adoption of the low-temperature and pressure resistant enclosed mixing container, the solid-liquid mixing device can meet mixing requirements for low temperature under pressure; and as the mixing container is respectively provided with the solid introducing port, the liquid introducing port and the solid-liquid outlet, the process of putting the solid particles and the base solution into the mixing container and the process of exporting the fracturing fluid out of the mixing container will not interfere with each other, and mixing of the fracturing fluid can be continuously carried out.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

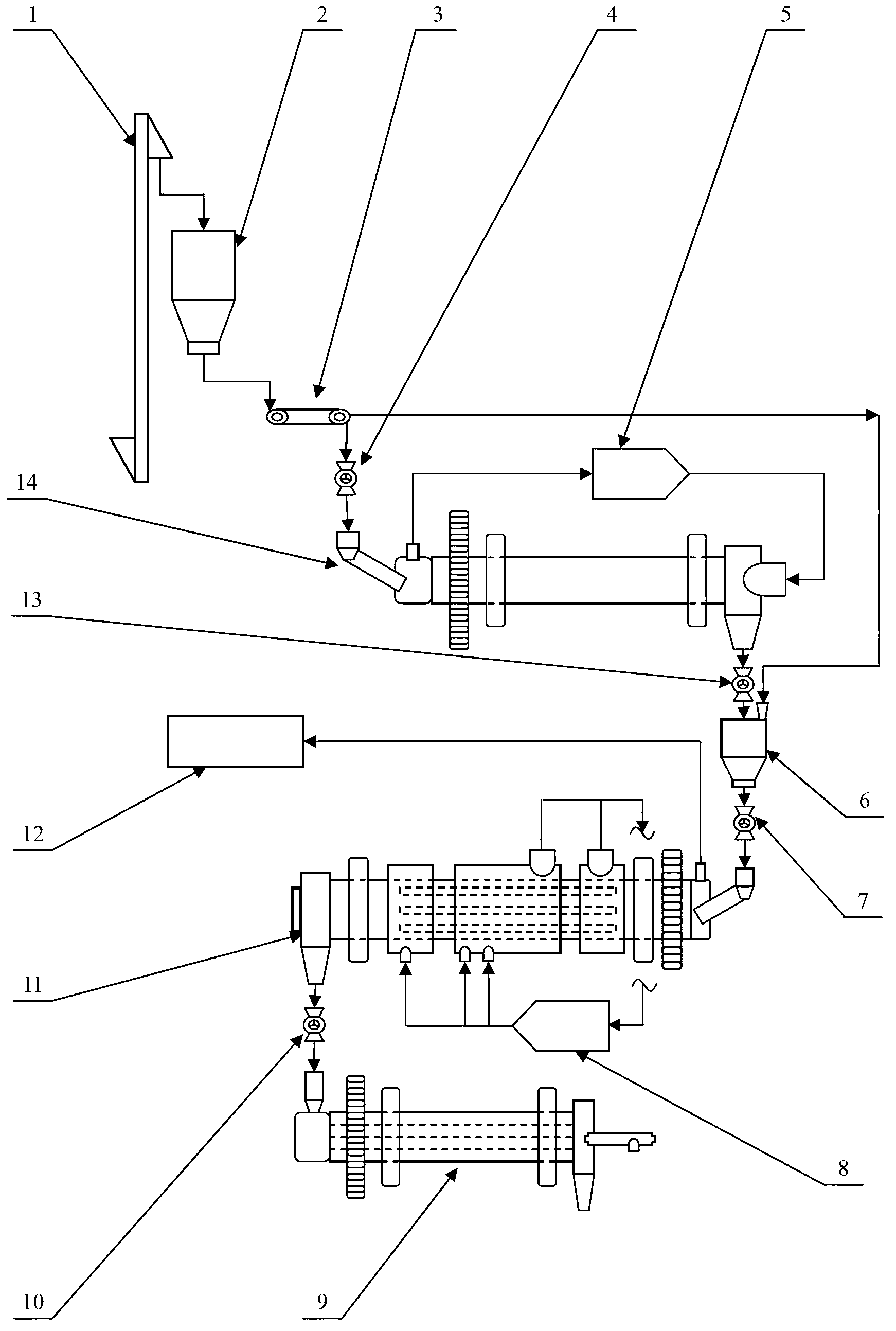

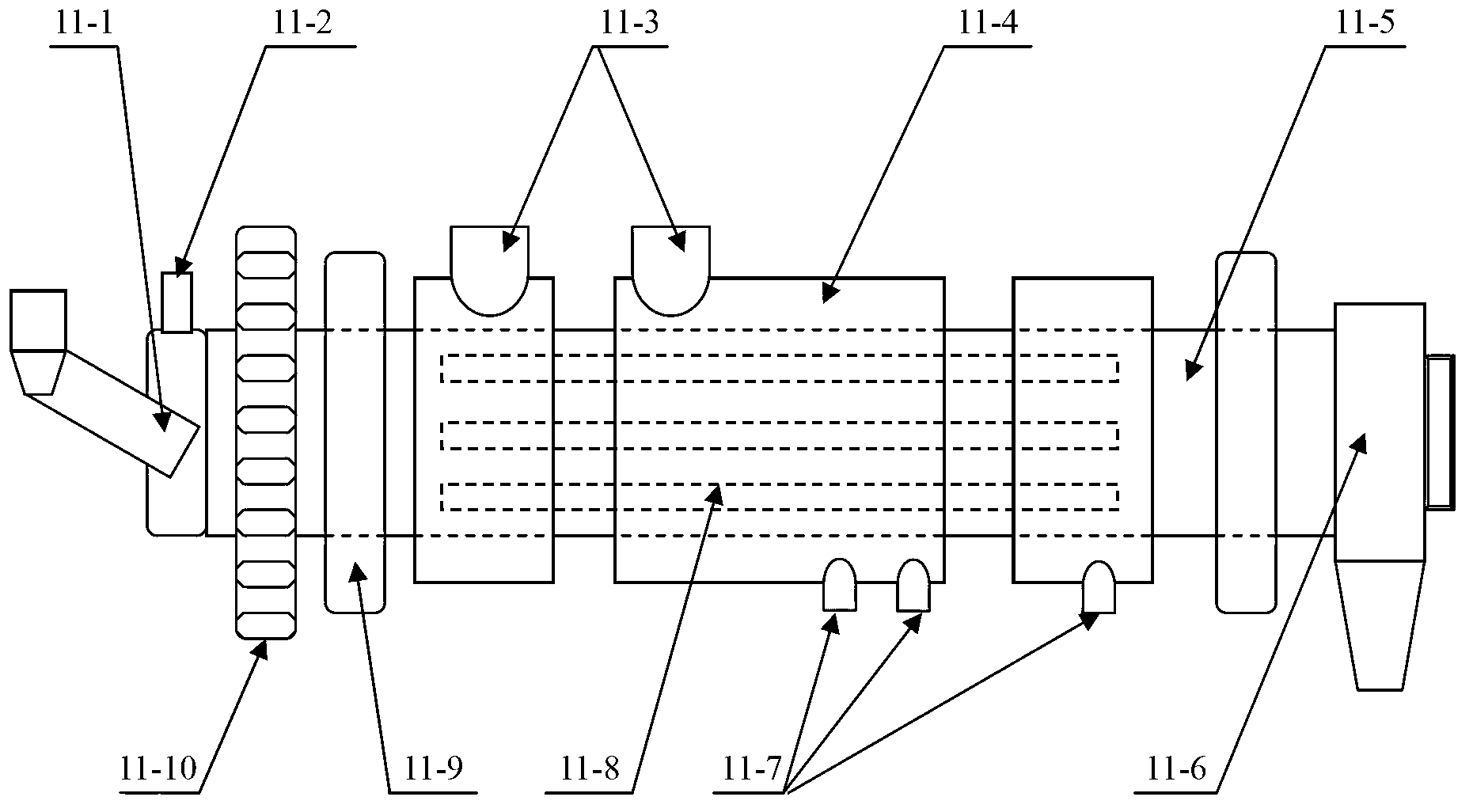

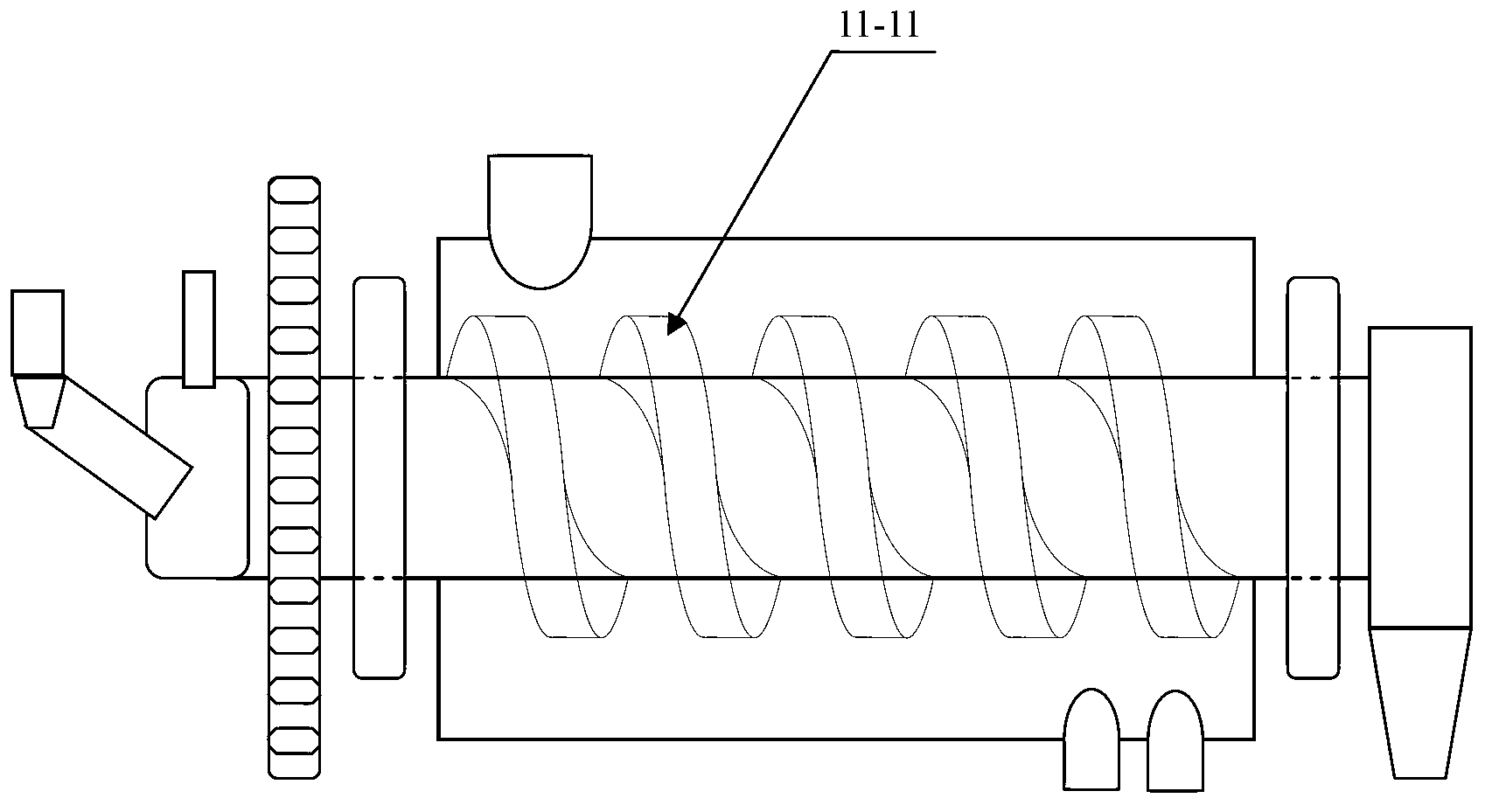

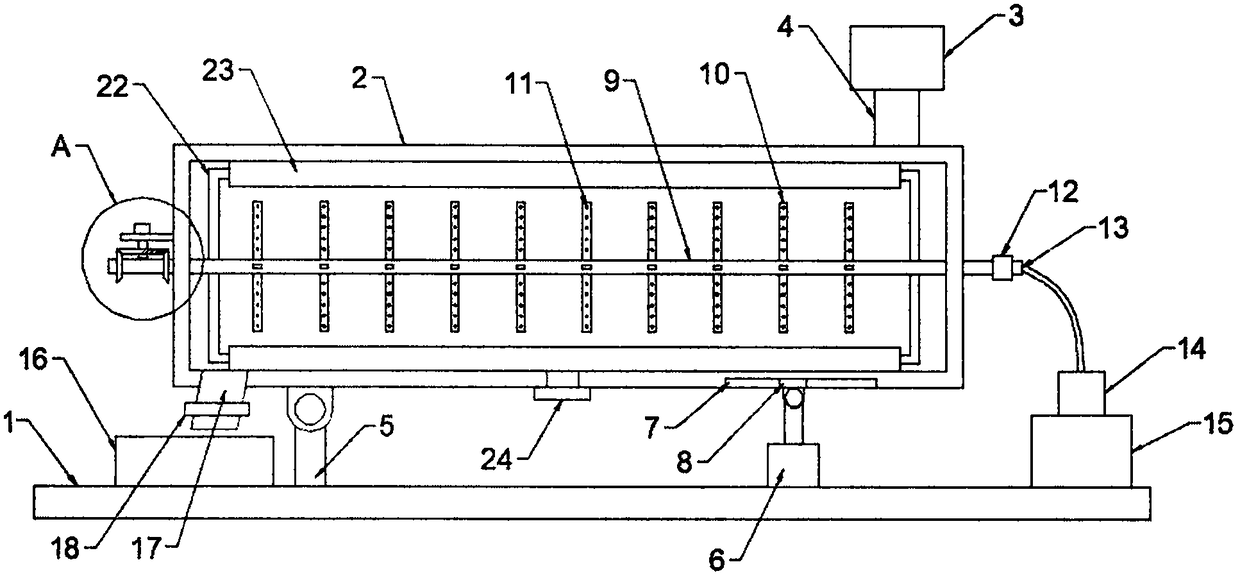

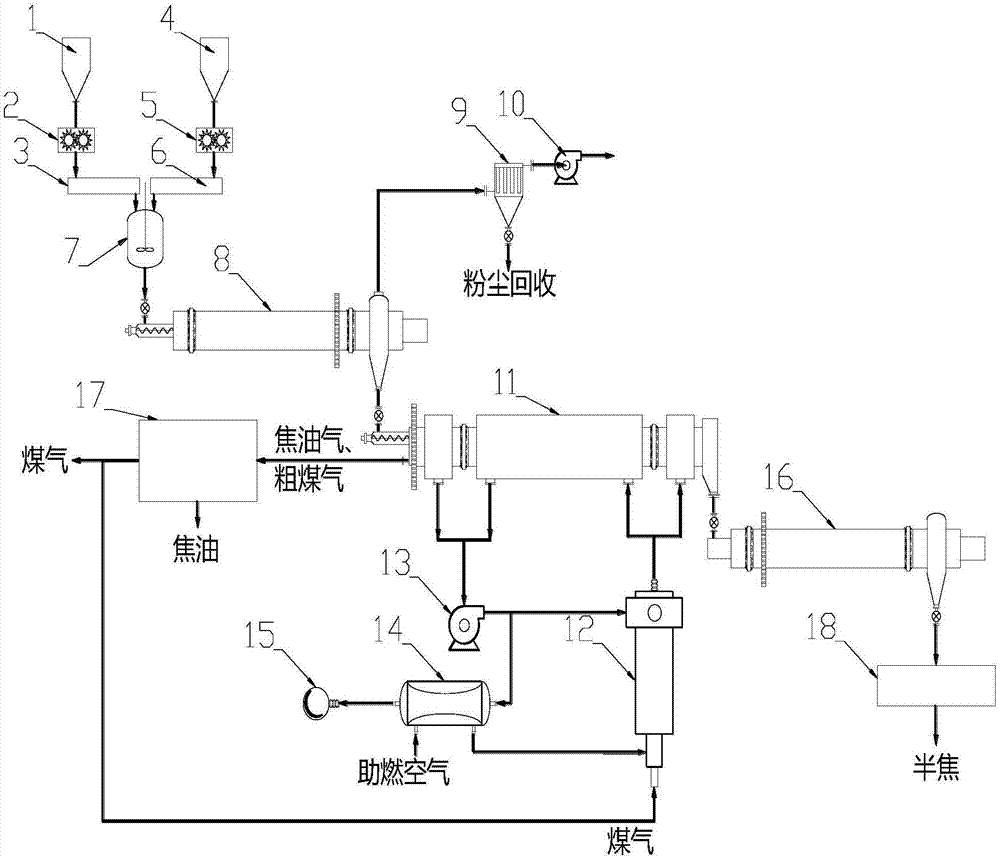

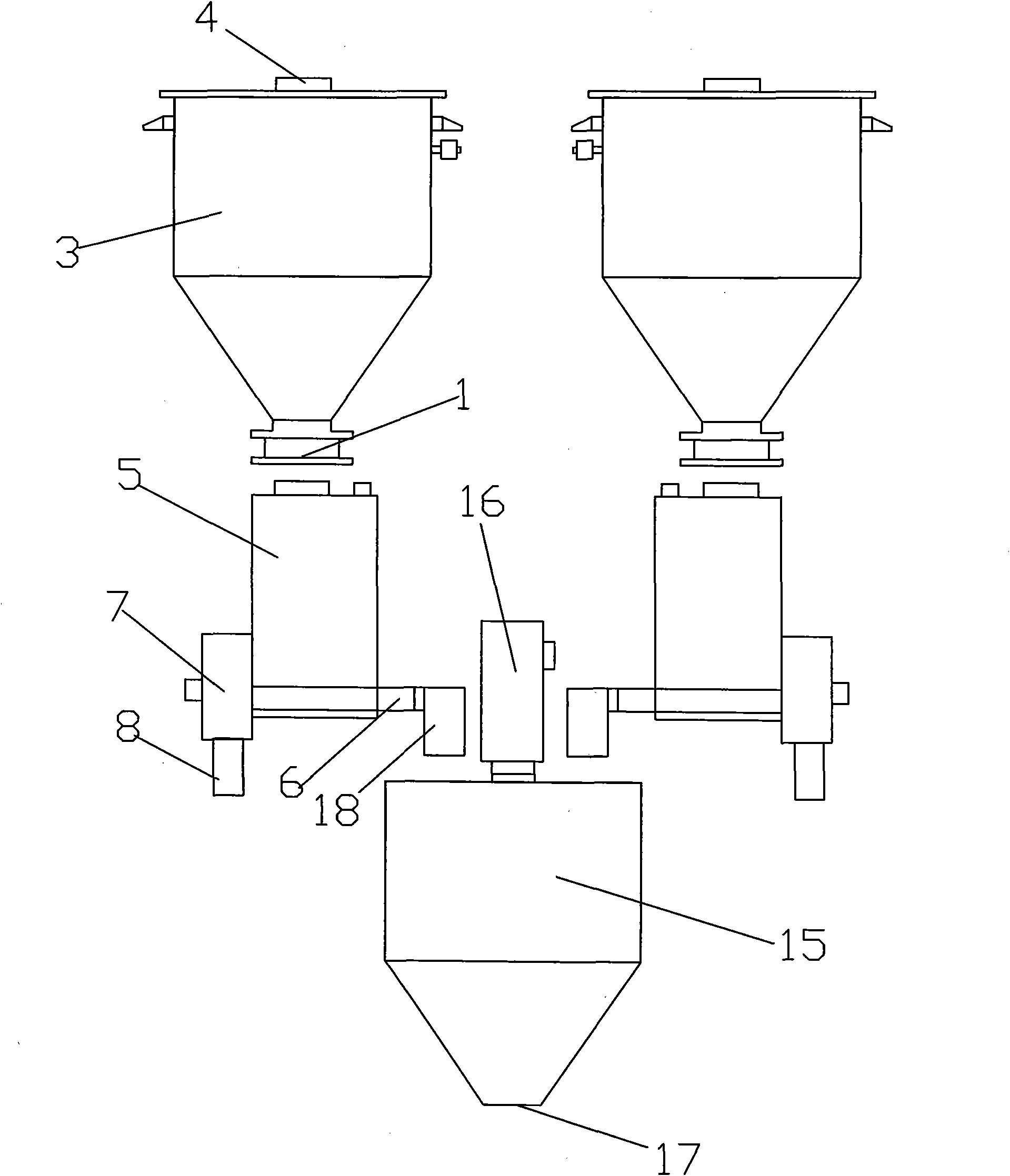

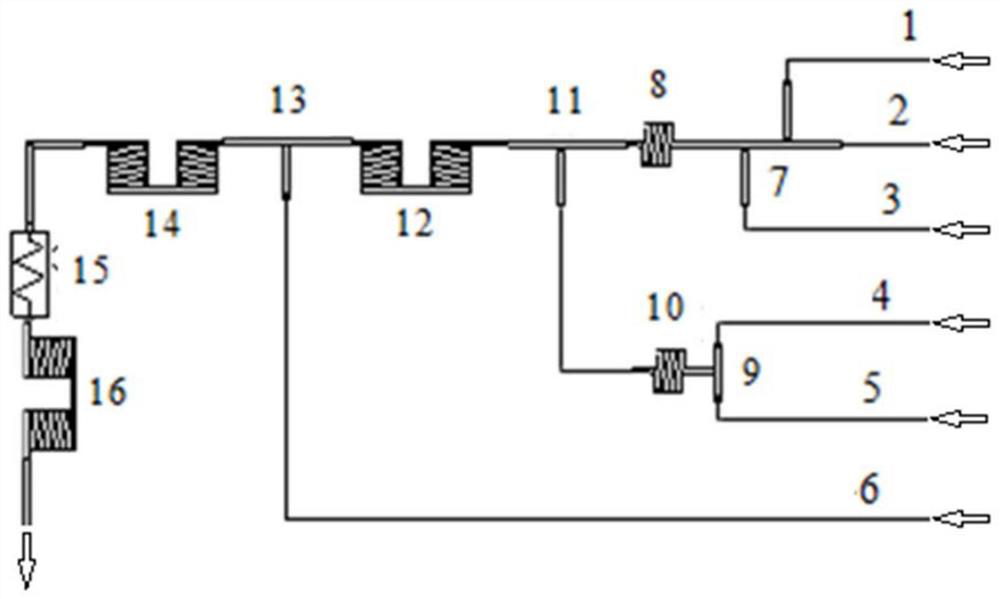

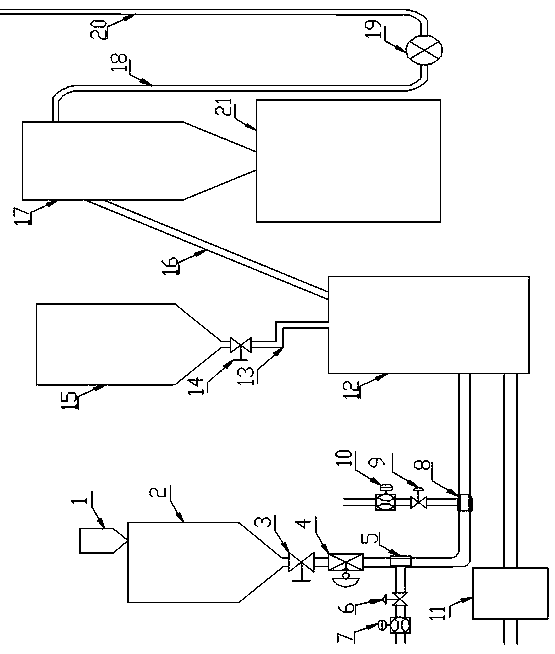

Low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass

ActiveCN103160301AIncrease profitReduce energy consumptionDirect heating destructive distillationBiofuelsCarbonizationOil shale gas

The invention discloses a low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass. The apparatus comprises a delivery apparatus, a storage bin, a metering apparatus, a drying furnace and a surge bin. The method comprises the following steps: drying, preheating, carbonizing, and cooling. The core of the invention is an external heating type rotary carbonization furnace which realizes the pyrolysis of oil sand, oil shale, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery) and biomass, and the product is high in purity and low in loss. The invention effectively solves the problems of solid materials such as adhesion, wall accretion and the like in the pyrolysis process by material returning. The technology provided by the invention is simple in process and reliable and stable in operation, and has obvious advantages in the treatment of small particle materials such as oil shale, oil sand, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery), biomass and the like.

Owner:何建祥

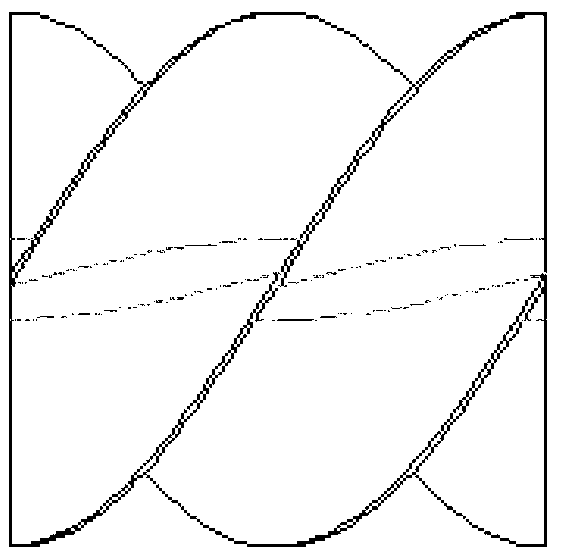

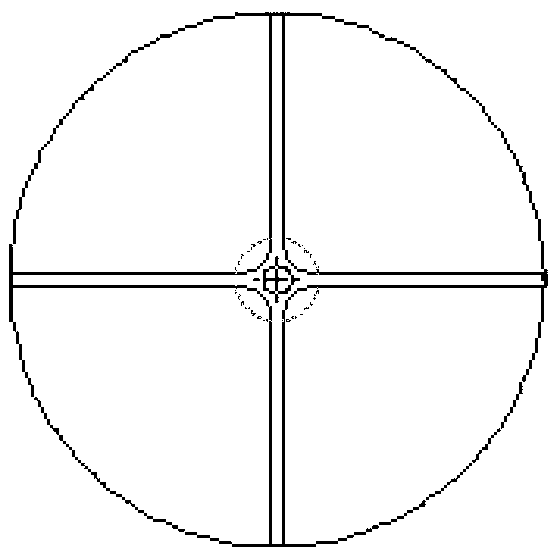

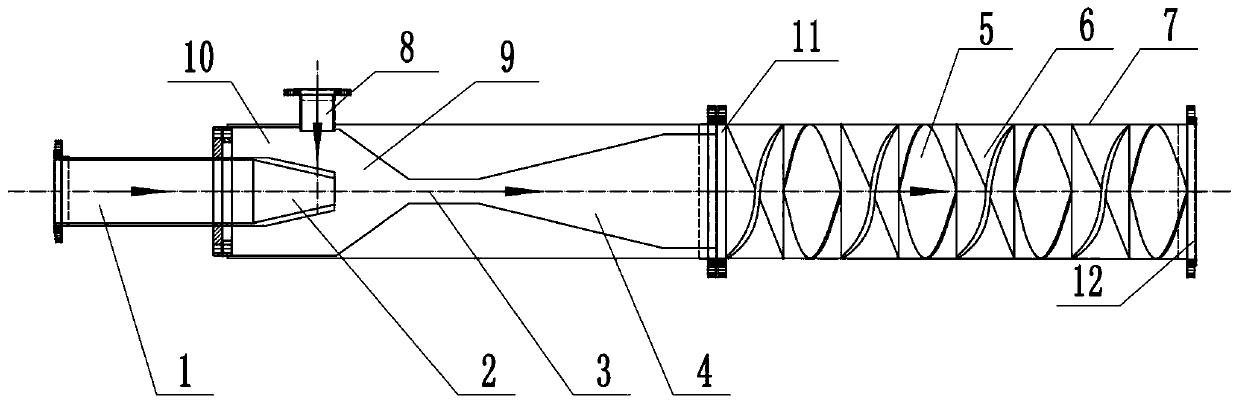

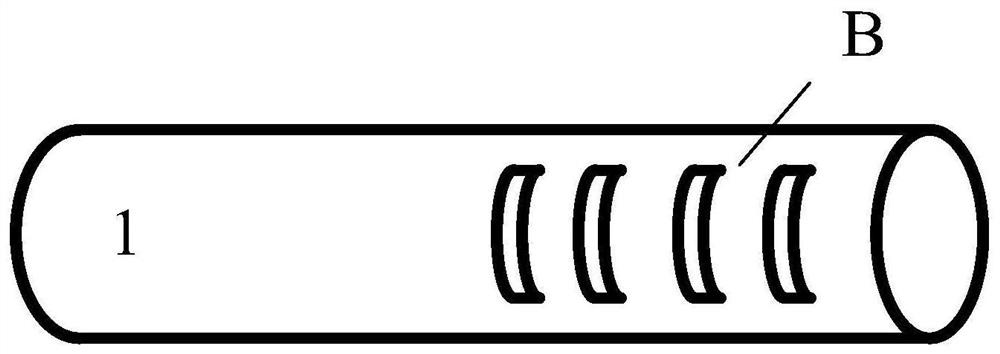

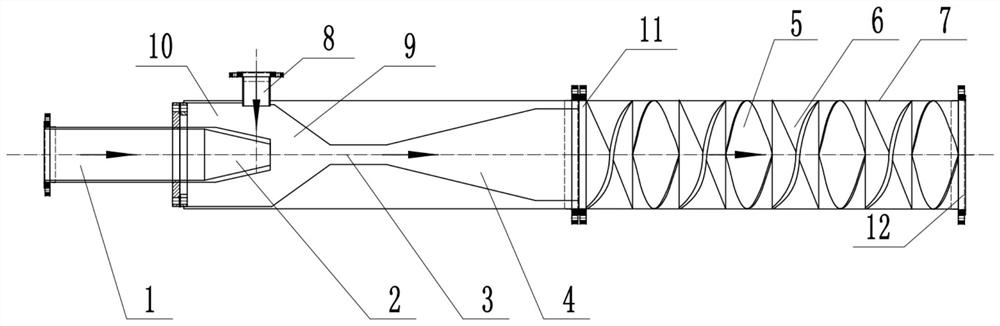

Spiral static mixer

The invention discloses a spiral static mixer which is applied to mixing of multiple materials and particularly mixing of high-viscosity materials. The spiral static mixer comprises a shell, mounting flanges, left rotating blades and right rotating blades and is characterized in that the mounting flanges are respectively arranged at the two ends of the shell, the left rotating blades and the right rotating blades are in multiple-spiral blade structures and sequentially and alternately arranged from an inlet of the shell to an outlet of the shell, the adjacent left rotating blades and right rotating blades are fixedly connected at the periphery in a staggering manner, and a washing lifting ring is connected at one end of a blade group formed by the left rotating blades and the right rotating blades. The spiral static mixer provided by the invention has the advantages of simple structure, high mixing efficiency, convenience and fastness in installation, low cost, convenience in washing and suitability for long-time working; a mixed blade unit can be replaced; and the spiral static mixer is more widely applied to mixing of the high-viscosity materials in the chemical engineering industry.

Owner:MECHANICS RES & DESIGN ACAD SICHUAN PROV

Apparatus used for uniformly mixing trace reagent and macro material in production of modified starch

ActiveCN108905739APrevent incomplete dischargeWell mixedTransportation and packagingRotary stirring mixersMixed materialsAirbag

The invention discloses an apparatus used for uniformly mixing a trace reagent and a macro material in the production of modified starch. The apparatus comprises a bottom base plate and a mixing cylinder, wherein one end, close to a hinge rod frame, of the bottom wall of the mixing cylinder is provided with a material discharge channel, a stirring round pipe coaxial with the mixing cylinder is arranged inside the mixing cylinder, the side wall, positioned inside the mixing cylinder, of the stirring round pipe is provided with a plurality of mixing pushing pipes, the side walls of the mixing pushing pipes are provided with a plurality of reagent dispersing holes, the outer side of the stirring round pipe is fixedly connected to a plurality of pushing rod frames, the pushing rod frames are provided with pressing rollers rotatably connected to the pushing rod frames, an airbag sleeve is arranged close to the inner wall of the mixing cylinder, the stirring round pipe bears against the inner side surface of the airbag sleeve, and the side wall of the mixing cylinder is provided with an inflation port. According to the present invention, the apparatus has characteristics of simple structure, convenient discharge of the mixed material, complete mixing, relatively low energy consumption, continuous mixing, continuous production, high production efficiency and strong practicability.

Owner:SHANDONG SHENZHOU XIANGYU TECH GRP

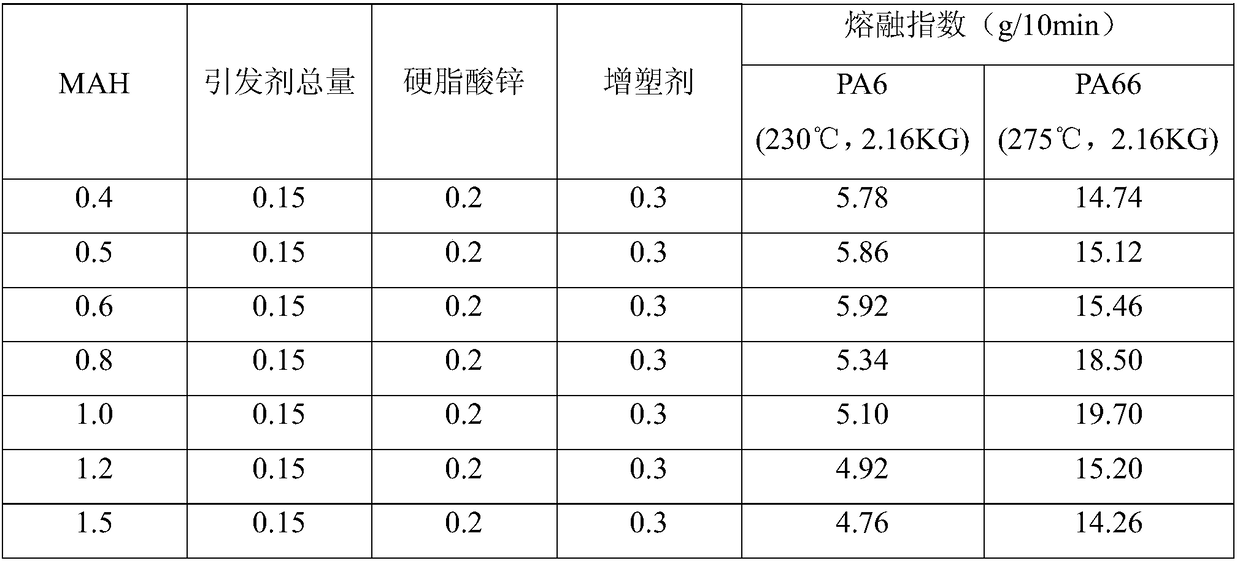

Low-temperature-resistant polyolefin grafted maleic anhydride flexibilizer used for nylon and preparation method of flexibilizer

ActiveCN108129833AImprove low temperature impact performanceGood compatibilityElastomerNylon material

The invention belongs to the field of polymer materials, and in particular relates to a low-temperature-resistant polyolefin grafted maleic anhydride flexibilizer used for nylon and a preparation method of the flexibilizer. The flexibilizer comprises the following raw materials in parts by weight: 100 parts of a polyolefin elastomer, 0.3-1.5 parts of maleic anhydride, 2-6 parts of an ionic polymer, 1.0-2.0 parts of polypropylene powder, 0.05-0.15 part of graft polypropylene, 0.05-0.25 part of a lubricant, 0.1-0.3 part of a plasticizer, 0.05-0.2 part of an initiator, and 0.1-0.3 part of an antioxidant. According to the flexibilizer provided by the invention, the maleic anhydride is grafted through the polyolefin elastomer, the polarity of the polyolefin elastomer is enhanced, and the grafted polyolefin elastomer can be used as a flexibilizer, an interfacial modifier and a compatibilizer of the nylon; and the flexibilizer can obviously improve the compatibility of the polyolefin elastomer and a strong-polarity nylon material, and can effectively improve the low-temperature impact performance.

Owner:SHENYANG KETONG PLASTIC

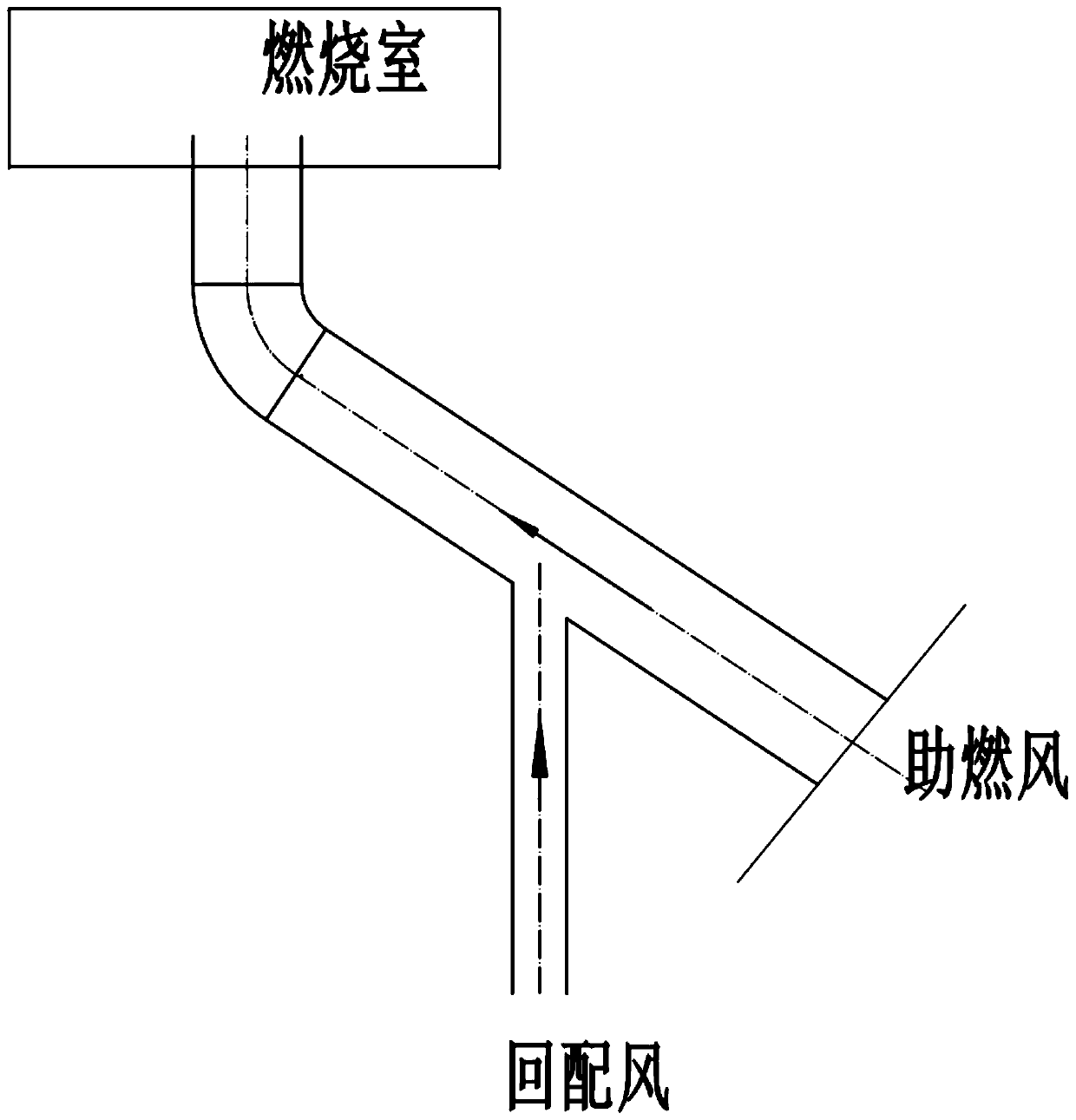

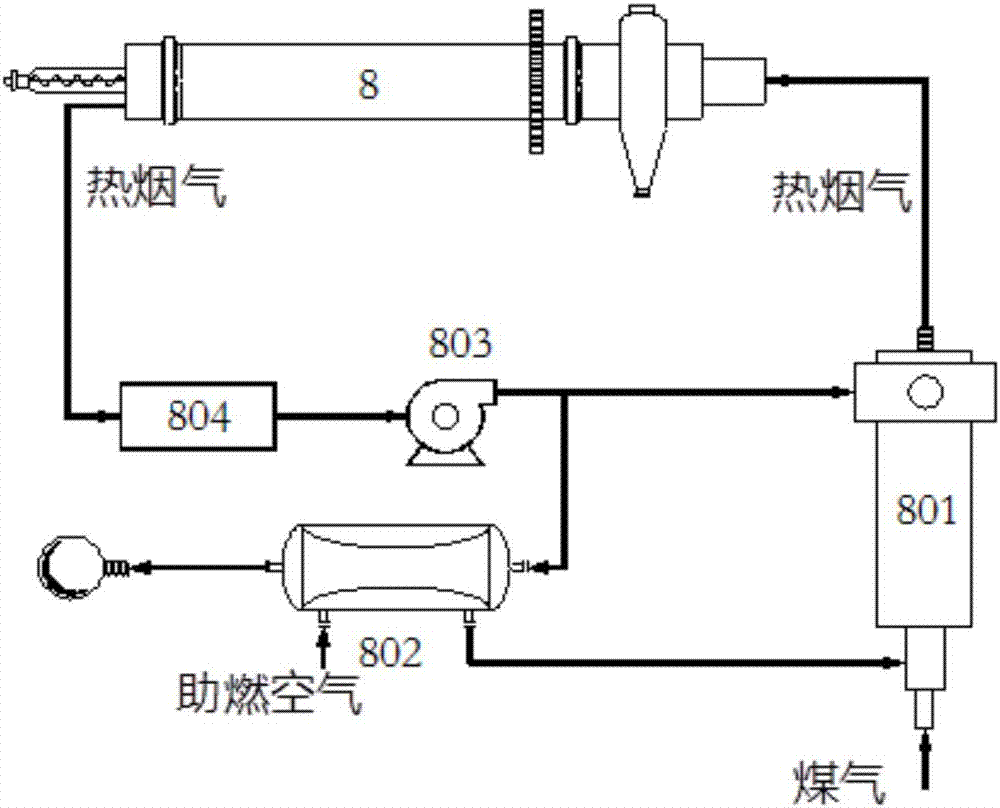

Static air mixer

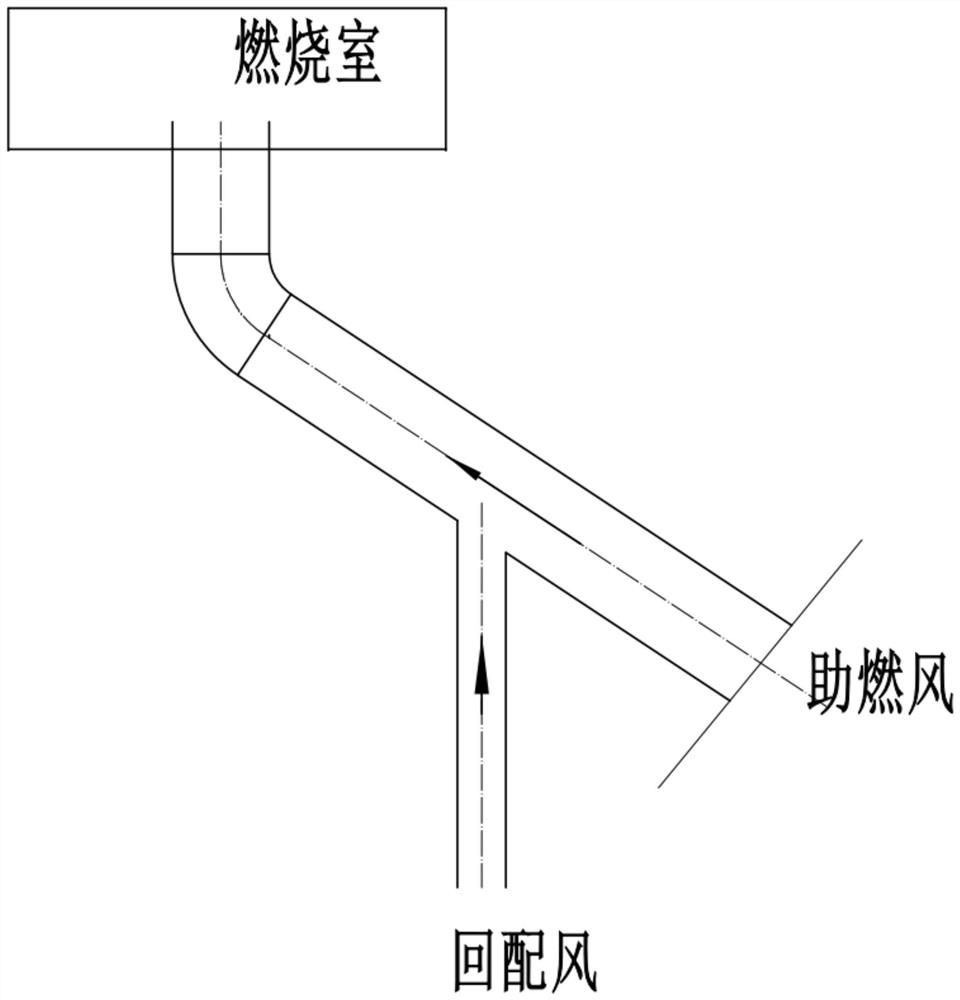

ActiveCN110822424AImprove mixing homogeneityContinuous mixingIncinerator apparatusGaseous fuel burnerThermodynamicsOxygen content

The invention discloses a static air mixer. Return distribution air and combustion-supporting air are introduced by utilizing a Venturi structure, are completely mixed under the action of a Venturi effect, keep at a complete importing state constantly, and are matched with a spiral air mixing channel, so that air flows are continuously blended and mixed uniformly, and the effects on uniformly mixing, reducing the oxygen content and outputting are achieved. According to the static air mixer, the return distribution air and the combustion-supporting air are introduced by utilizing the Venturi structure, are completely mixed under the action of the Venturi effect, keep at the complete importing state constantly, and are matched with the spiral air mixing channel, so that the air flows are continuously blended and mixed uniformly, and the effects on uniformly mixing, reducing the oxygen content and outputting are achieved.

Owner:青岛天正洁能环保科技有限公司

Improved method for producing colored and differential terylene fibre by melt direct spinning on-line adding technology

InactiveCN101348946AReduce lossesExtend the switching periodMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterFiltration

A method for manufacturing a colored and differential polyester fiber through an improved fused mass direct-spinning online additive technique belongs to the technical field of synthetic fiber manufacturing method, aiming to provide a method for manufacturing a colored and differential polyester fiber through the improved fused mass direct-spinning online additive technique which is convenient for manufacturing black and dark color polyester fibers. The method comprises the following technical points: before polyester fused mass enters a spinning box body, a dried and fused modified raw material is fed into the spinning box body, and is sufficiently and evenly mixed with the polyester fused mass through an efficient static mixer; and after filtration, the modified raw material and the polyester fused mass are fed into the spinning box body together so as to carry out spinning. The modified raw material is subjected to drying and melting, and is indirectly injected into the efficient static mixer, is sufficiently and evenly mixed with the polyester fused mass, and is subjected to filteration. The technical points ensure excellent fluidity and filtering performance, and prolong the switching cycle of a filter and the change cycle of a spinning component; moreover, the method reduces the loss of color master batch during filtration as well as the production cost for black and dark color fibers.

Owner:滁州安兴环保彩纤有限公司

Method for co-pyrolysis of solid waste and coal

ActiveCN107057730ASolve resource problemsNo need for additional investmentProductsReagentsTarCo pyrolysis

The invention discloses a method for co-pyrolysis of solid waste and coal. The method comprises the following steps: mixing solid waste with coal metered, drying, heating, carrying out destructive distillation pyrolysis, so as to obtain solid-state pyrolysis product semi-coke and gas-state pyrolysis product coal gas containing tar gas; cooling and sieving the semicoke, so as to obtain semi-coke with different particle sizes; and carrying out oil-gas separation on coal gas containing tar gas, so as to obtain tar and coal gas, wherein partial coal gas is taken as a heat source for pyrolysis of mixed materials, and rest coal gas is taken as a coal gas product. According to the method, the co-pyrolysis of solid waste and coal is realized by virtue of a horizontal rotary kiln, and the semi-coke, tar oil and coal gas are obtained after the pyrolysis of the mixed materials in the rotary kiln at a certain temperature. The method has the beneficial effects that a technical process is simple, the operation is reliable and stable, the problem that coal gas produced by pyrolysis of solid waste is less than heat required by the pyrolysis of solid waste is solved, and the method has obvious superiority on the treatment of solid waste with great composition change.

Owner:西安三瑞实业有限公司

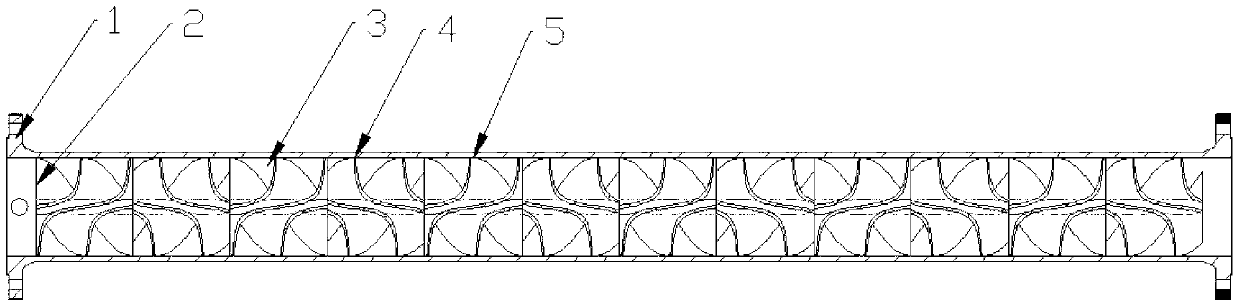

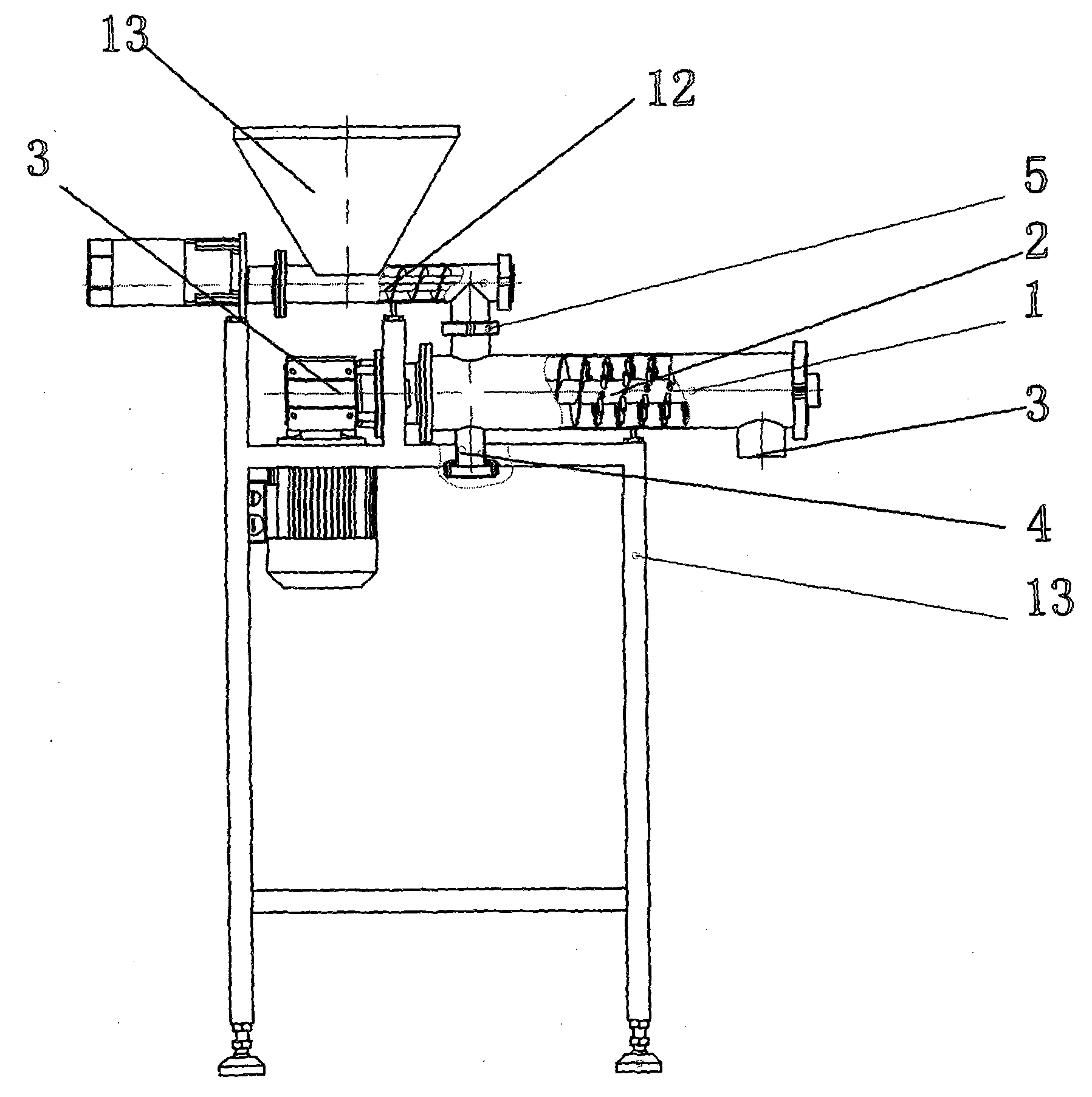

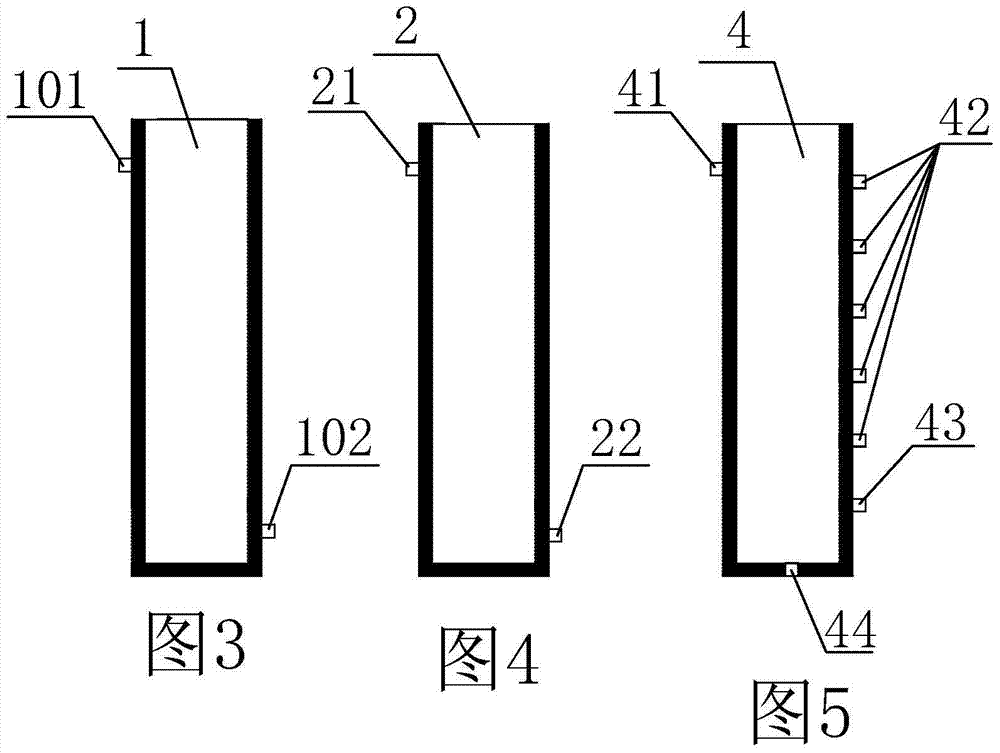

Liquid-solid mixer

InactiveCN102008914AReduce manufacturing costEasy to useMixing methodsTransportation and packagingMixed materialsEngineering

The invention relates to a liquid-solid mixer which is characterized by comprising a sleeve, mixer members arranged in the sleeve and a power device arranged at the front end of the sleeve, the mixer members are driven by the power device to rotate, a liquid material inlet and a solid material inlet are arranged on the side wall of the front end of the sleeve, a mixed material outlet is arranged on the side wall of the rear end of the sleeve, and the mixer members comprise a rotating shaft, conveying threads arranged at the front section of the rotating shaft and a mixing bar arranged on the circumferential surface of the rear section of the rotating shaft. Compared with the prior art, the invention has the advantages of low manufacture cost, convenience for use and capability of continuously mixing.

Owner:黎泽荣

Preparation method of alkali-soluble hydroxyethylcellulose fiber spinning solution with high solid content

InactiveCN101871129AShorten the time to dissolve celluloseHigh solid contentArtificial filaments from cellulose solutionsArtificial thread manufacturing machinesChemistryResidence time

The invention relates to a preparation method of a alkali-soluble hydroxyethylcellulose fiber spinning solution with high solid content, belonging to the technical field of novel environment-friendly fiber material preparation. The preparation method comprises the following steps of: (1) separately, continuously and quantificationally adding a dilute alkali solution with the concentration of 4-12 percent and alkali-soluble hydroxyethylcellulose powder with the etherification degree of 0.2-0.6 to a first counter-rotating twin screw extruder, wherein the weight percentage of the alkali-soluble hydroxyethylcellulose is 6-18 percent; and (2) sufficiently mixing and then continuously extruding into a second co-rotating twin screw extruder, regulating dissolution temperature to -30-5 DEG C and setting material residence time to 10-60 minutes, sufficiently dissolving, regulating the temperature, defoaming and then extruding to form the alkali-soluble hydroxyethylcellulose fiber spinning solution, and directly measuring and filtering and then carrying out wet spinning. The invention has continuous and efficient material mixing, dissolving and deforming process and is beneficial to realizing the continuous and stable spinning of the alkali-soluble hydroxyethylcellulose.

Owner:YANCHENG LANBANG TECHN FIBER

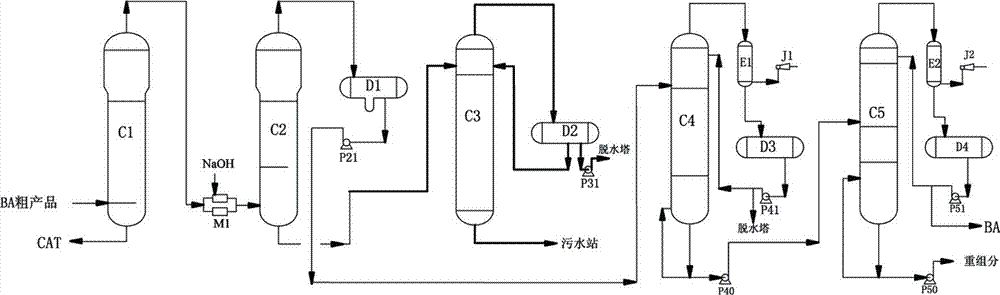

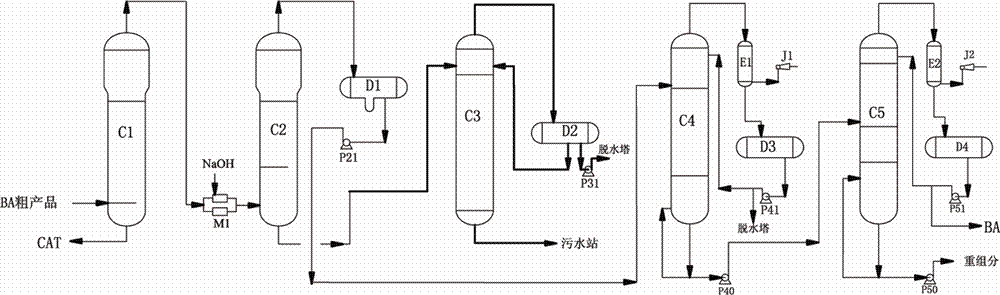

Purification method for butyl acrylate crude product

ActiveCN104761452ALow purityThe phenomenon of increased dosageCarboxylic acid esters separation/purificationOne passPurification methods

The invention discloses a purification method for a butyl acrylate crude product. The purification method comprises the following steps: with water as an extractant, carrying out continuous counter-current extraction on the butyl acrylate crude product, adequately mixing an extraction raffinate organic phase containing the butyl acrylate crude product with caustic soda liquid in a static mixer to have a neutralization reaction, discharging the separated salts, then removing impurities, light components and heavy components, and finally obtaining butyl acrylate with purity of 99.6% or above. The purification process disclosed by the invention is simple, the purity of butyl acrylate is high, and a one-pass yield can reach 98.5% or above; compared with the traditional process, the method disclosed by the invention has the advantages that 20% of the caustic soda liquid is saved averagely in the production of one ton of the butyl acrylate product, and the influence of neutralization and washing links on the purification system is reduced to the minimum. The purification method is remarkable in practicability and economic benefits and can be put into large-scale industrialized production easily.

Owner:PINGHU PETROCHEM

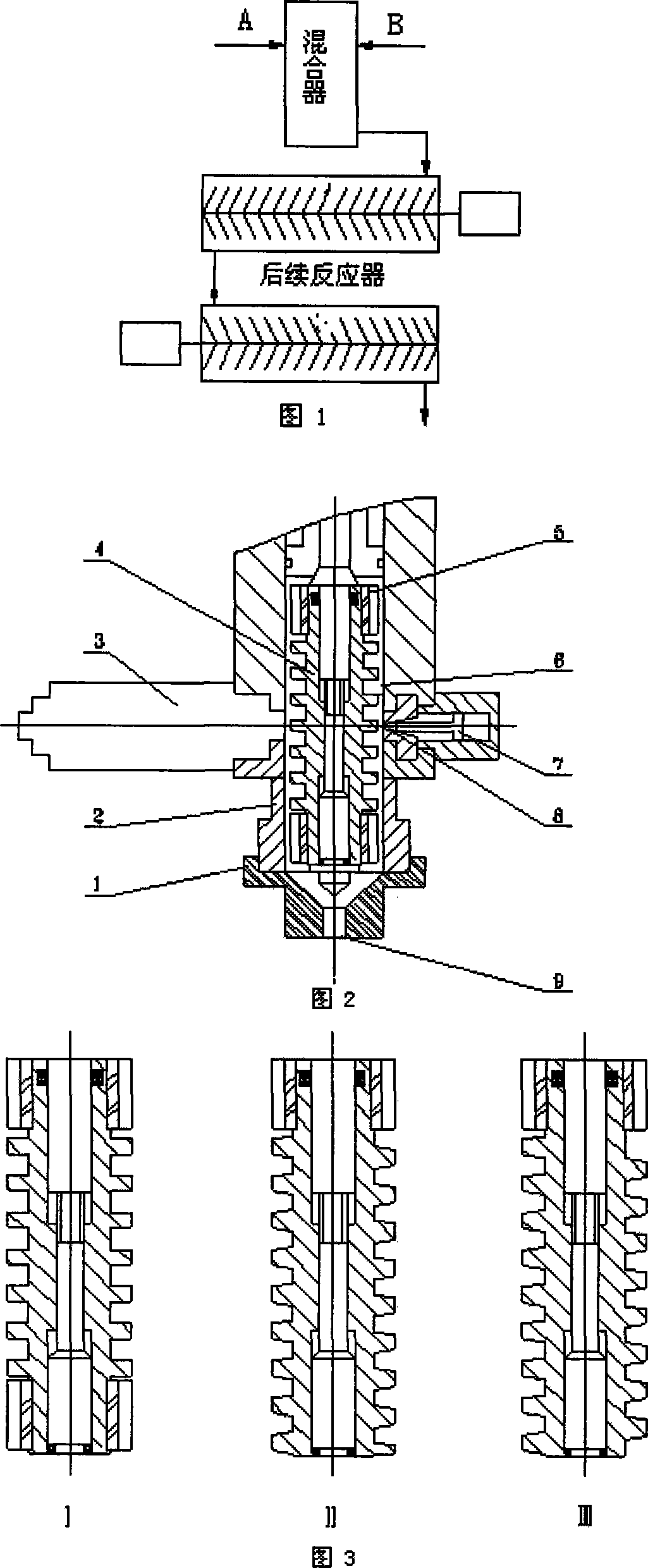

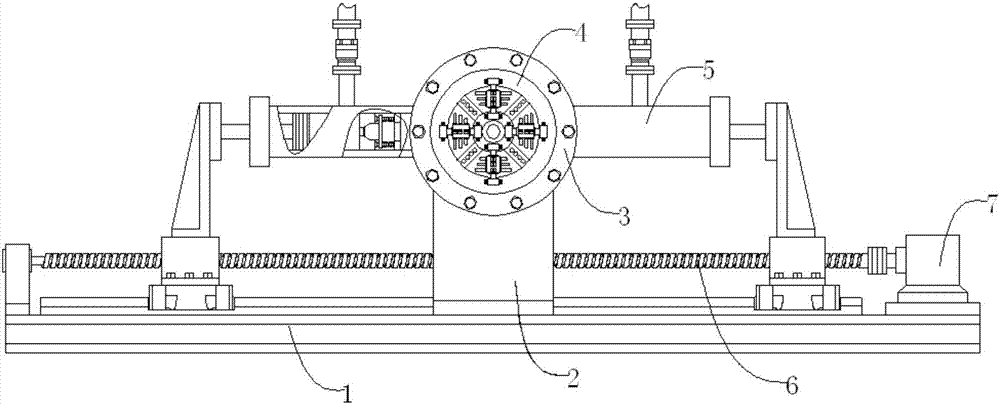

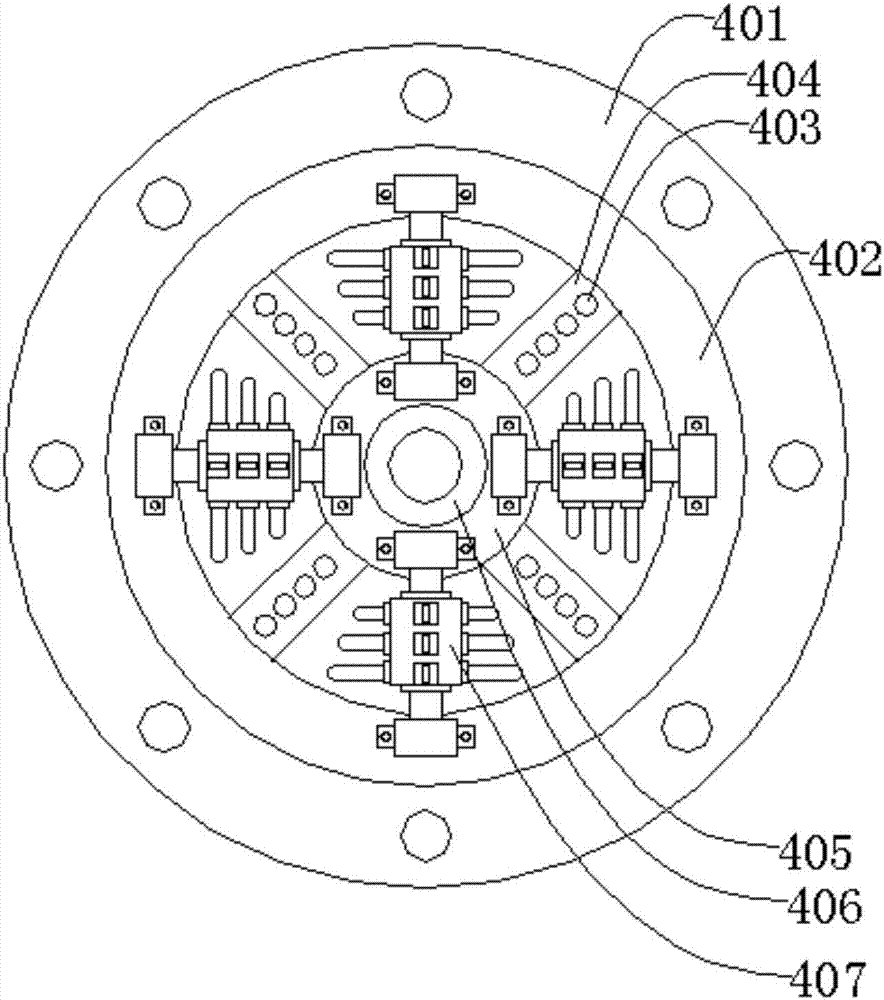

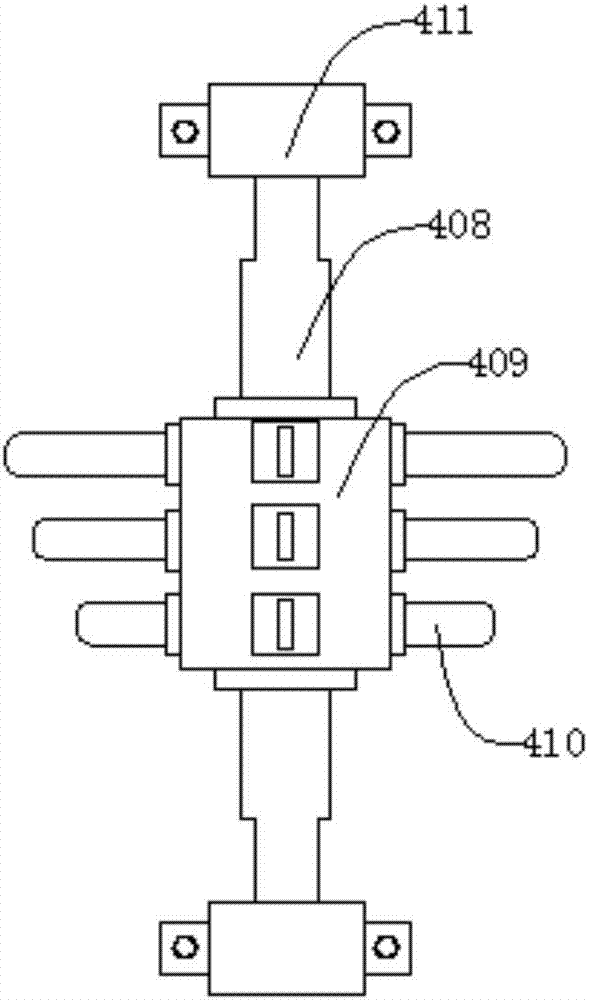

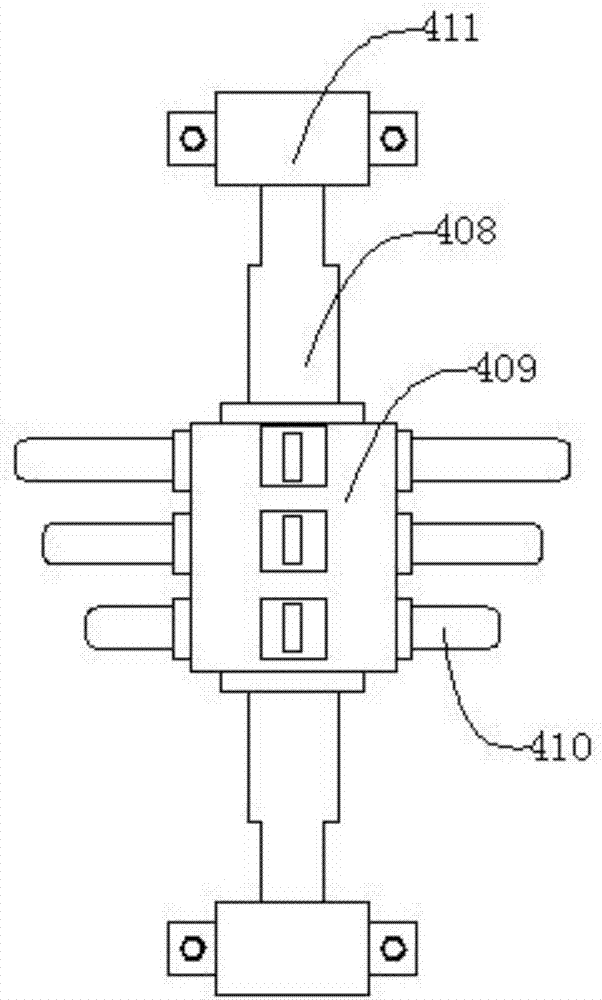

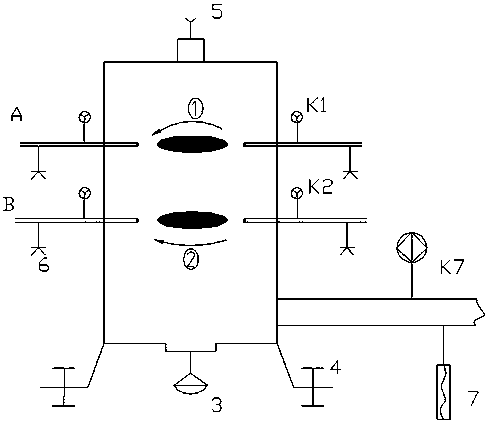

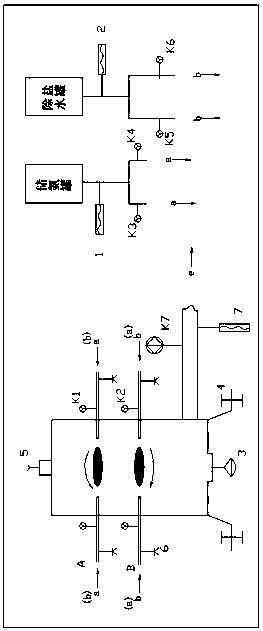

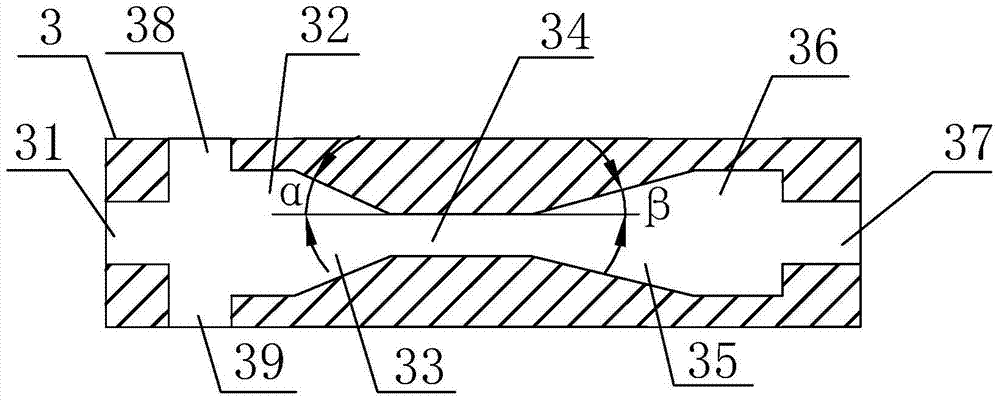

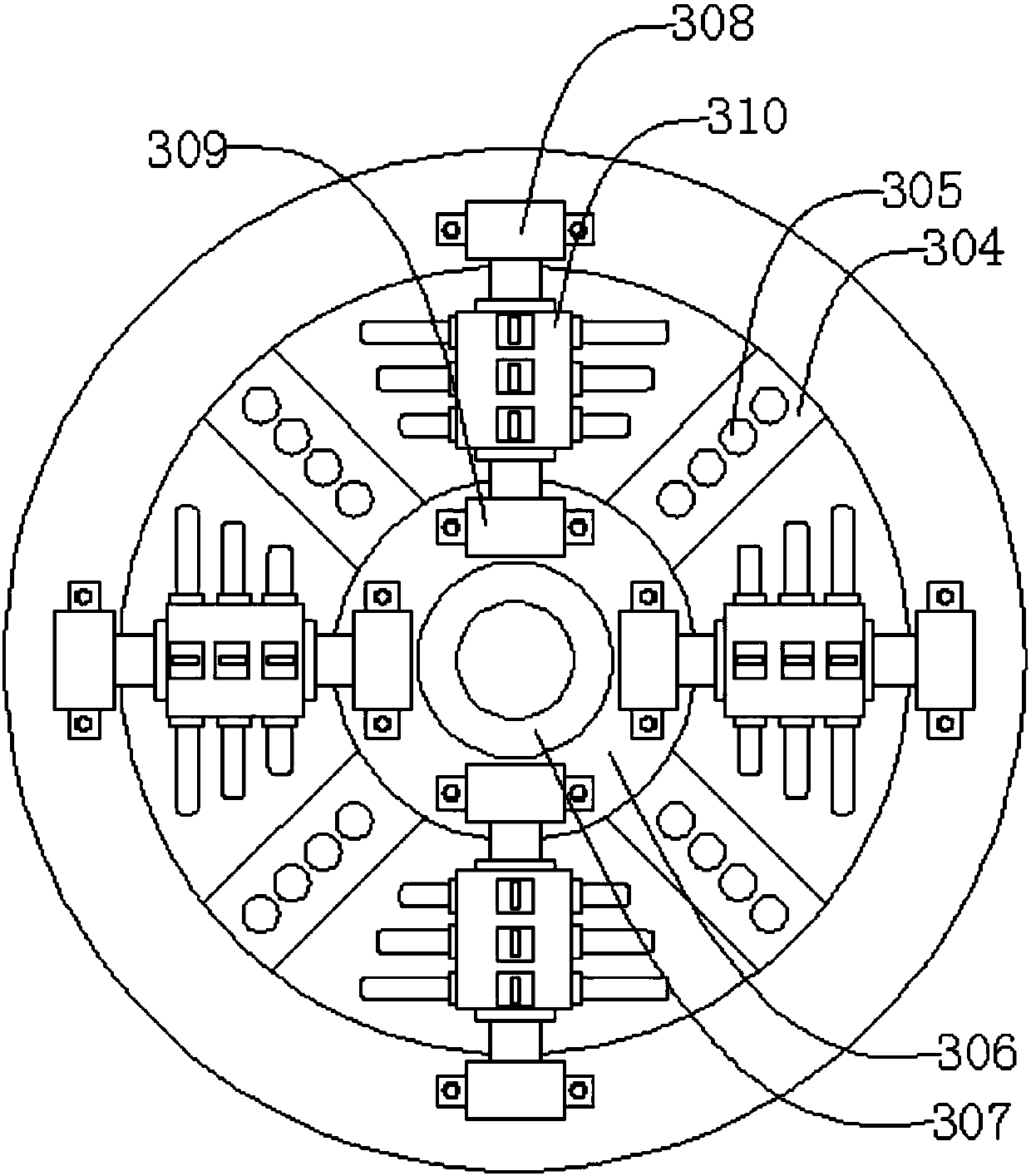

Mixer for aramid II polymerization

ActiveCN101195681AContinuous mixingMeet mixing requirementsMonocomponent polyamides artificial filamentTemperature differenceEngineering

The invention discloses a mixture for mixing materials with high temperature difference to polymerize aramid fiber II, which comprises a shell and a mixing chamber in the shell. The invention is characterized in that the mixing chamber is arranged with an internal mixing rod which top is connected with a mixing head, the shell is connected with two fluid channels communicated with the mixing chamber and an injection hole, and the lower end of the mixing shell is provided with an outlet. The invention can be used to continuously mix components at the ratio of stoichiometric coefficient, to meet different mixing demands of different materials. The invention can be used in the production of aramid fiber II, to continuously and stably produce poly-(p-phenyleneterephthalamide) resin.

Owner:中蓝晨光化工有限公司

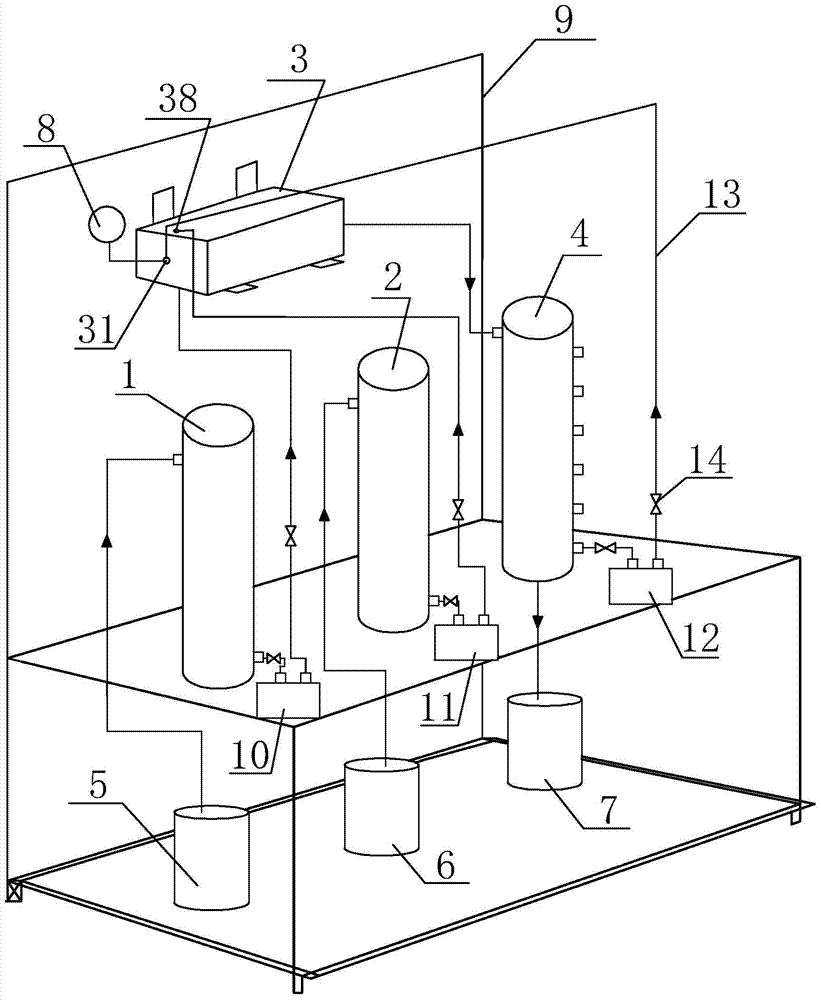

Automatic liquor distributing mechanism for smoke gas purifying medicine liquor

ActiveCN107570028AImprove purification efficiencyImprove purification effectFlow mixersDispersed particle separationHigh pressure waterHigh pressure

The invention discloses an automatic liquor distributing mechanism for smoke gas purifying medicine liquor. The automatic liquor distributing mechanism comprises a base, a bracket, a water inlet tube,a medicine distributing mechanism, two medicine pumping mechanisms which are symmetrically arranged along the medicine distributing mechanism, a lead screw and a servo motor, wherein the servo motordrives the lead screw to rotate, so that a slide base fixedly connected with a feeding nut is driven to move, and pistons in the medicine pumping mechanisms are driven to move, and therefore, medicineliquor proportioning and conveying is realized; and rotation speed and an angle of the servo motor are set, so that a movement distance and movement speed of the pistons can be set, and therefore, the medicine pumping amount is precisely controlled. The automatic liquor distributing mechanism is simple in structure; the reaction medicine liquor and high-pressure water are automatically proportioned, and the medicine is automatically pumped, and the medicine pumping amount is controllable and precise; and meanwhile, the medicine liquor and water are uniformly and continuously mixed, so that the smoke gas purifying efficiency and effect is improved.

Owner:池州市星聚信息技术服务有限公司

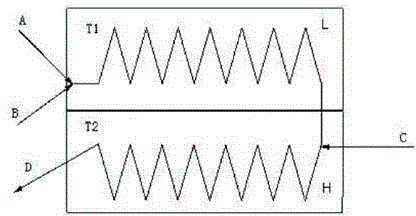

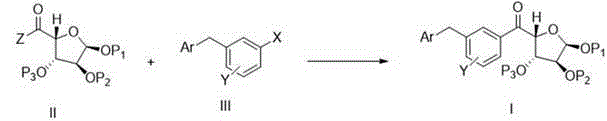

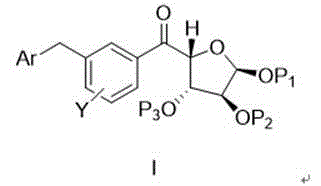

Method for preparing sodium-glucose co-transport enzyme inhibitor intermediate through utilization of micro-reactor

InactiveCN106279194AImprove securityReduce lossesSugar derivativesBulk chemical productionOrganic solventGlucose polymers

The invention discloses a method for preparing a sodium-glucose co-transport enzyme inhibitor intermediate through utilization of a micro-reactor. The method comprises: mixing a solution formed from a compound III and an organic solvent with a metal organic reagent in a micro-reactor unit (L) through material pipes, and allowing the mixed solution to flow to a micro-reactor unit (H) through (L); mixing a solution formed from a compound II and an organic solvent with the solution obtained in the first step in the micro-reactor unit (H) at a pre-set temperature (T2) through a material pipe, allowing the mixed solution to pass through the micro-reactor unit (H) and to flow out from an outlet after a reaction is over; post-treating the reaction liquid flowing out of the outlet to obtain a target product, which is sodium-glucose co-transport enzyme inhibitor intermediate I. The intermediate I is prepared through the micro-reactor, and the problem in heat release of such reaction is solved. The safety of the reaction is improved, the reaction yield is increased, the reaction time is shortened, and the reaction efficiency is improved. An amplification effect hardly exists in a micro-reactor, and therefore, compared with conventional batch-type technology, the method is more suitable for industrial production.

Owner:CHANGZHOU FANGNAN MEDICINE TECH CO LTD

Automatic smoke gas purifying device

ActiveCN107569993AImprove purification efficiencyImprove purification effectFlow mixersDispersed particle separationSewageEngineering

The invention discloses an automatic smoke gas purifying device. The automatic smoke gas purifying device comprises a base, a bracket, a water inlet tube, a medicine distributing mechanism, two medicine pumping mechanisms which are symmetrically arranged along the medicine distributing mechanism, a lead screw, a servo motor, a first bracket, a medicine tank, a medicine liquor inlet tube, a filterscreen, a distributing box, at least two distributing tubes which are symmetrically arranged along the distributing box, a second bracket, a speed-regulating motor, a transmission mechanism, a purifying tank, a first rotary shaft, a tapered head, not less than two throwing discs which are uniformly distributed along the tapered head from top to bottom, and are gradually increased in diameter, an air distributing plate, a guide head, an upper partition, an insertion tube, a gas collecting box, a lower partition, a sewage tube, a purified gas outlet tube, a smoke gas inlet tube, a liquid inlet tube, and a connecting hose. The device is simple in structure, performs primary reaction on the smoke gas and atomized medicine liquor, and performs secondary reaction on the smoke gas and the atomized medicine liquor, so that the smoke gas is automatically purified; and moreover, medicine pumping amount is precise and adjustable, reaction medicine liquor is automatically proportioned and pumped,the medicine liquor is uniformly and continuously mixed with water, the smoke gas purifying efficiency is high, and the smoke gas purifying effect is good.

Owner:池州市星聚信息技术服务有限公司

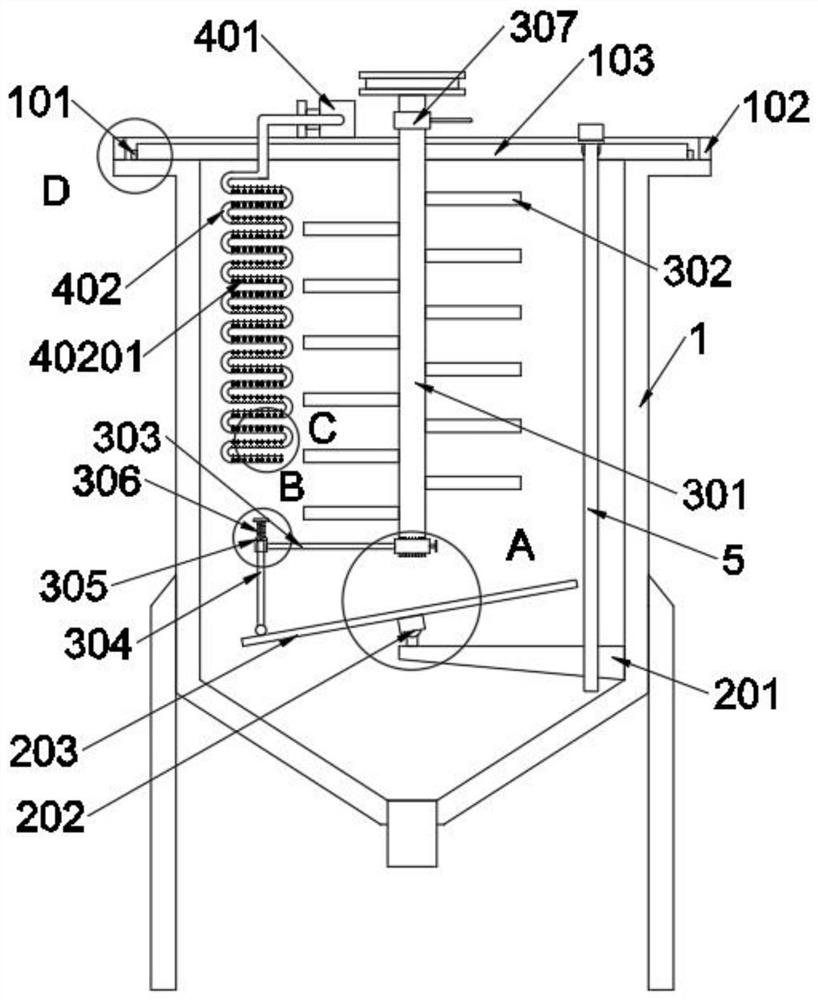

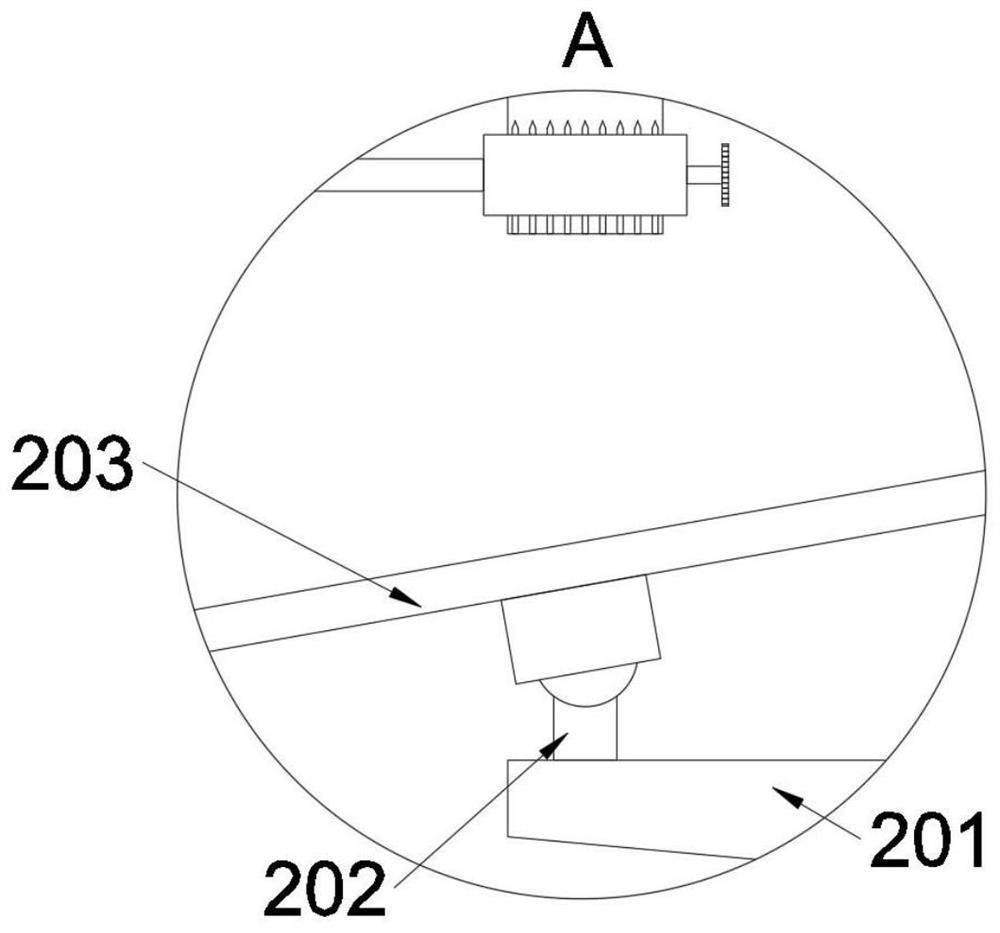

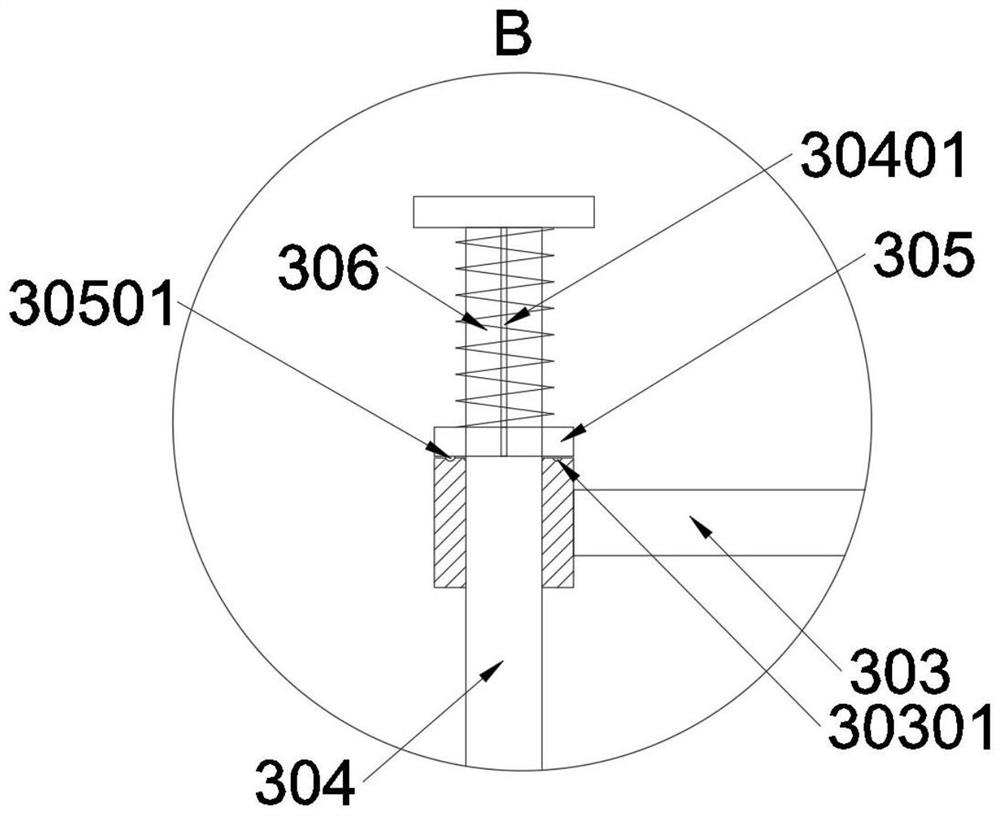

Chemical polymer material production equipment

InactiveCN111841471AImprove sealingAvoid pollutionChemical/physical/physico-chemical stationary reactorsFeed devicesEngineeringMechanical engineering

The invention provides chemical polymer material production equipment, relates to the technical field of chemical equipment, and solves the problems that other mixing structures cannot be synchronously mixed in a linkage manner during mixing to improve the mixing efficiency; multiple sealing cannot be achieved, and temporary collection cannot be achieved to provide buffer time for follow-up treatment when liquid leaks; and the sampling of different liquid levels cannot be realized during sampling. The chemical polymer material production equipment comprises a barrel body, and a first mixing structure is mounted in the barrel body, and a second mixing structure is further rotationally connected to the barrel body. Due to the fact that an annular groove is formed between a baffle ring and asealing ring, and the annular groove formed between the baffle ring and the sealing ring forms a liquid collecting structure, the liquid can be temporarily collected through the annular groove when overflowing, and the situation that the liquid directly flows to the outer wall of the barrel body to pollute the outer wall of the barrel body after overflowing can be prevented. And the buffer time ofthe maintenance treatment can be provided through temporary collection of the annular groove.

Owner:莱西市星脉先进材料技术中心

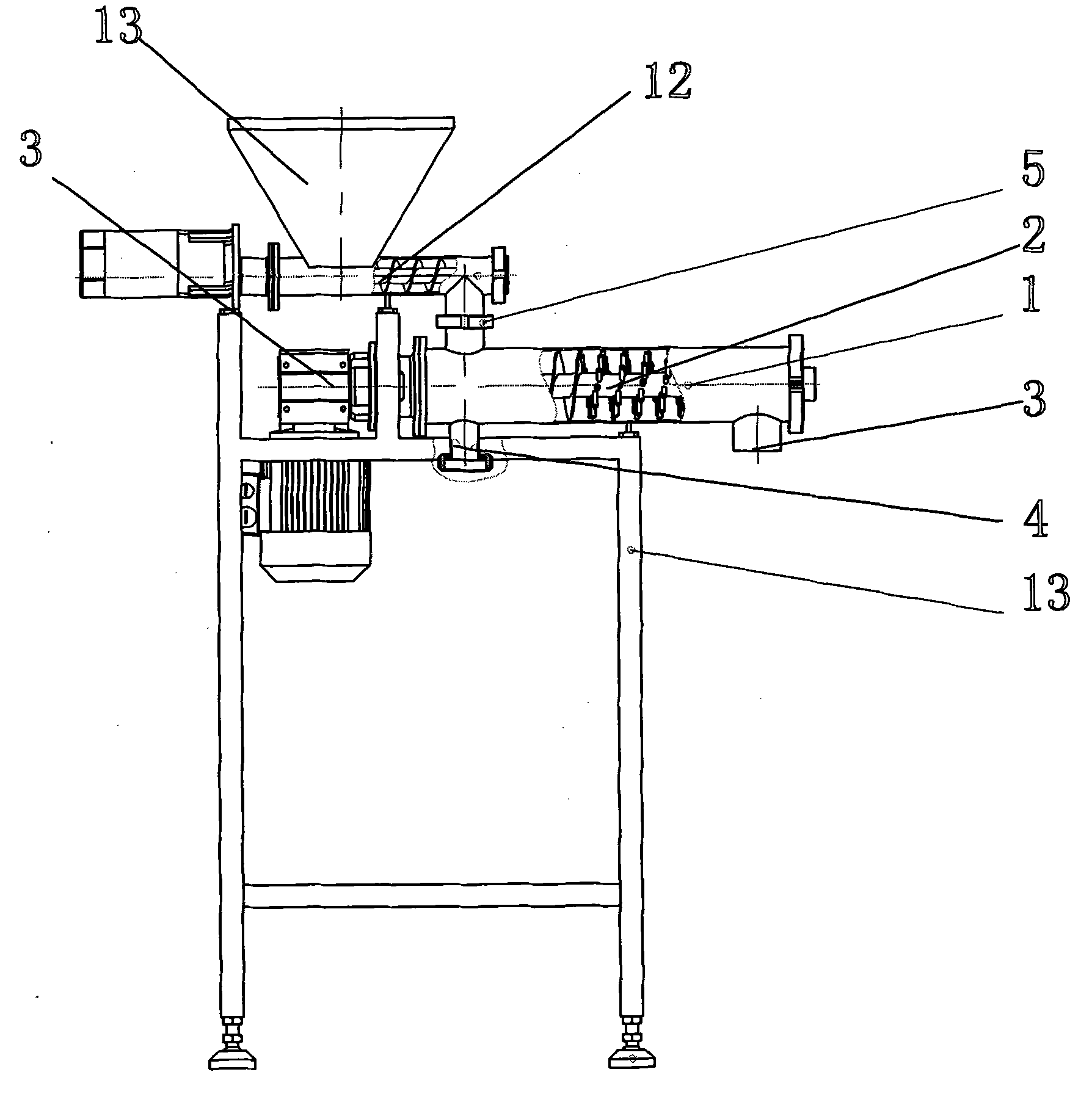

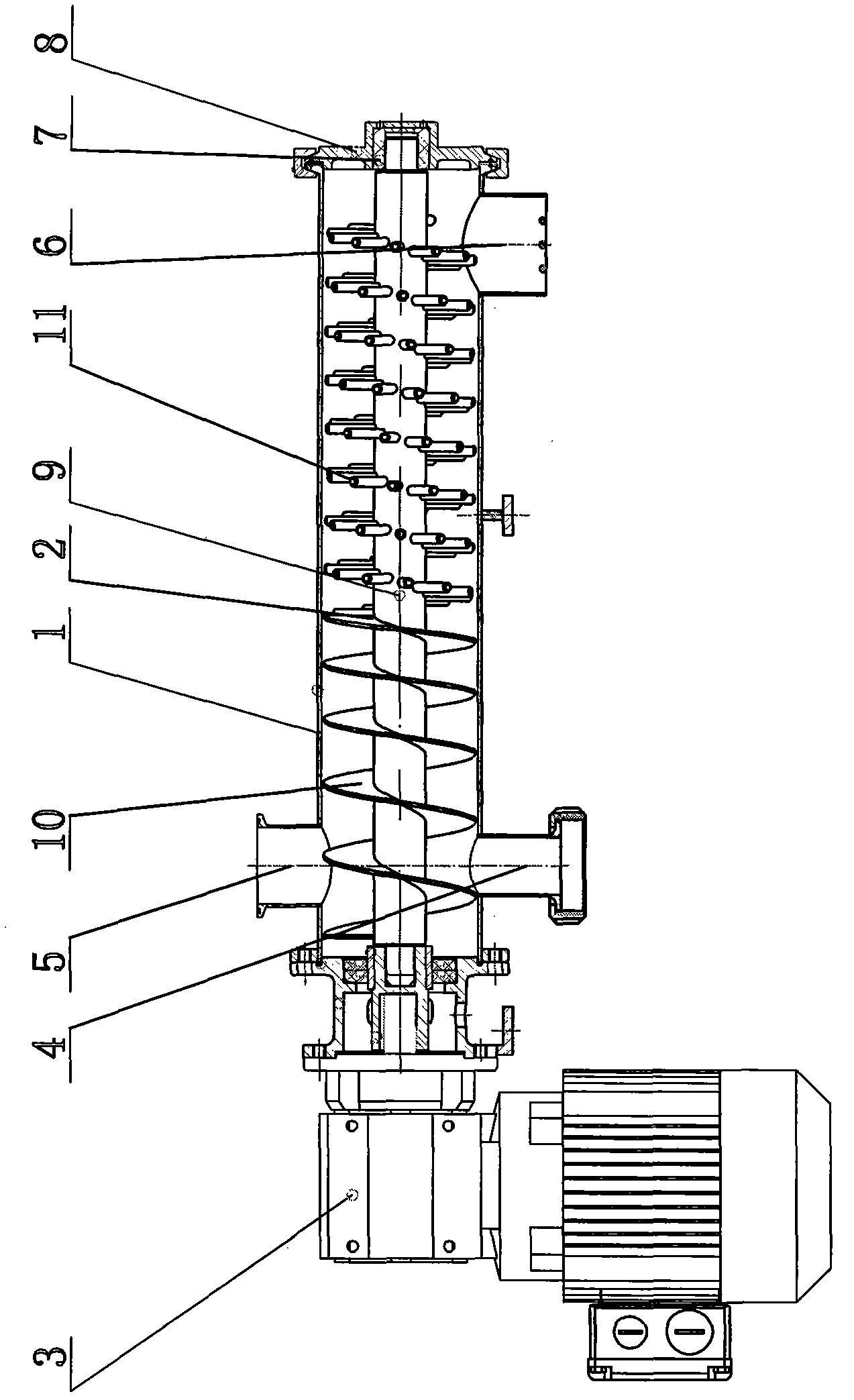

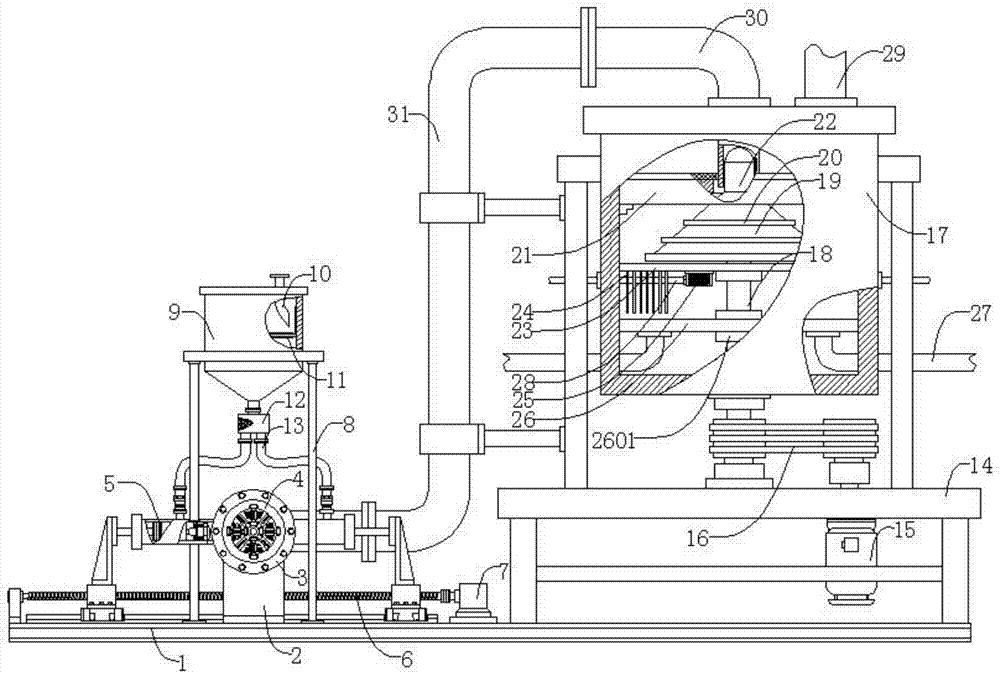

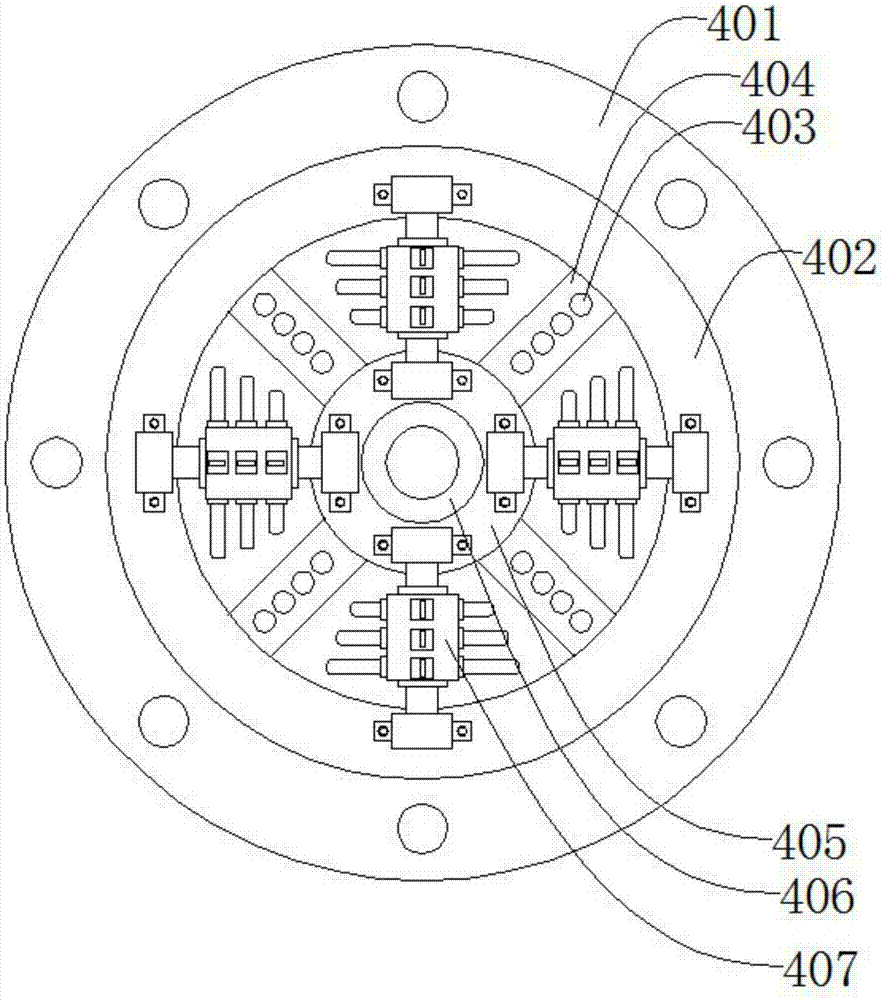

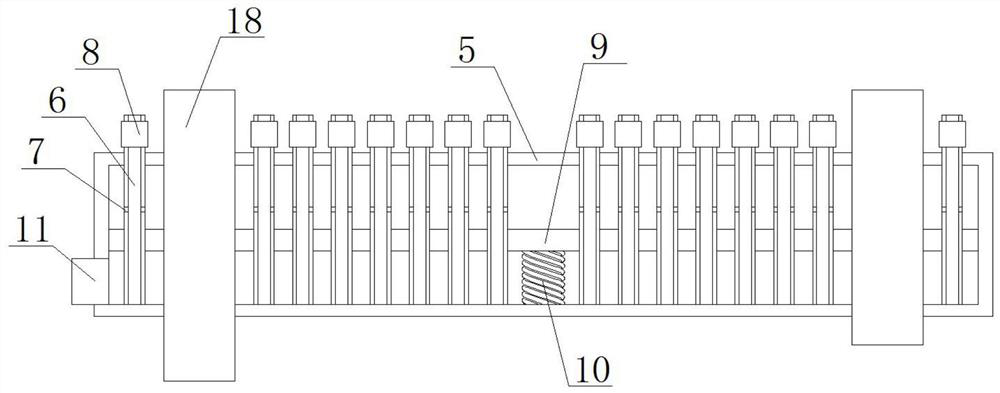

Device for multi-screw volume type continuous metering and material mixing

The invention relates to a device for multi-screw volume type continuous metering and material mixing, belonging to the field of chemical machinery. The device for multi-screw volume type continuous metering and material mixing comprises a screw metering device and a material mixing device, wherein the screw metering device comprises a feeding bin, a screw rod, a screw motor and a screw frequency converter, a feeding hole and a discharge hole are arranged on the feeding bin, the discharge hole is arranged above the screw rod, the screw rod is connected with the screw motor, the screw motor is connected with the screw frequency converter, the material mixing device consists of a material mixing tank and a material mixing motor, the material mixing tank is arranged opposite to the discharge end of the screw rod, the material mixing motor is arranged above the material mixing tank, and a blanking hole is arranged at the lower end of the material mixing tank. The invention has the advantage of reasonable structure design, realizes continuous metering and material mixing, improves the production technology and can regulate the material mixing proportion in real time.

Owner:ZHEJIANG HAILI ENVIRONMENTAL TECH CO LTD

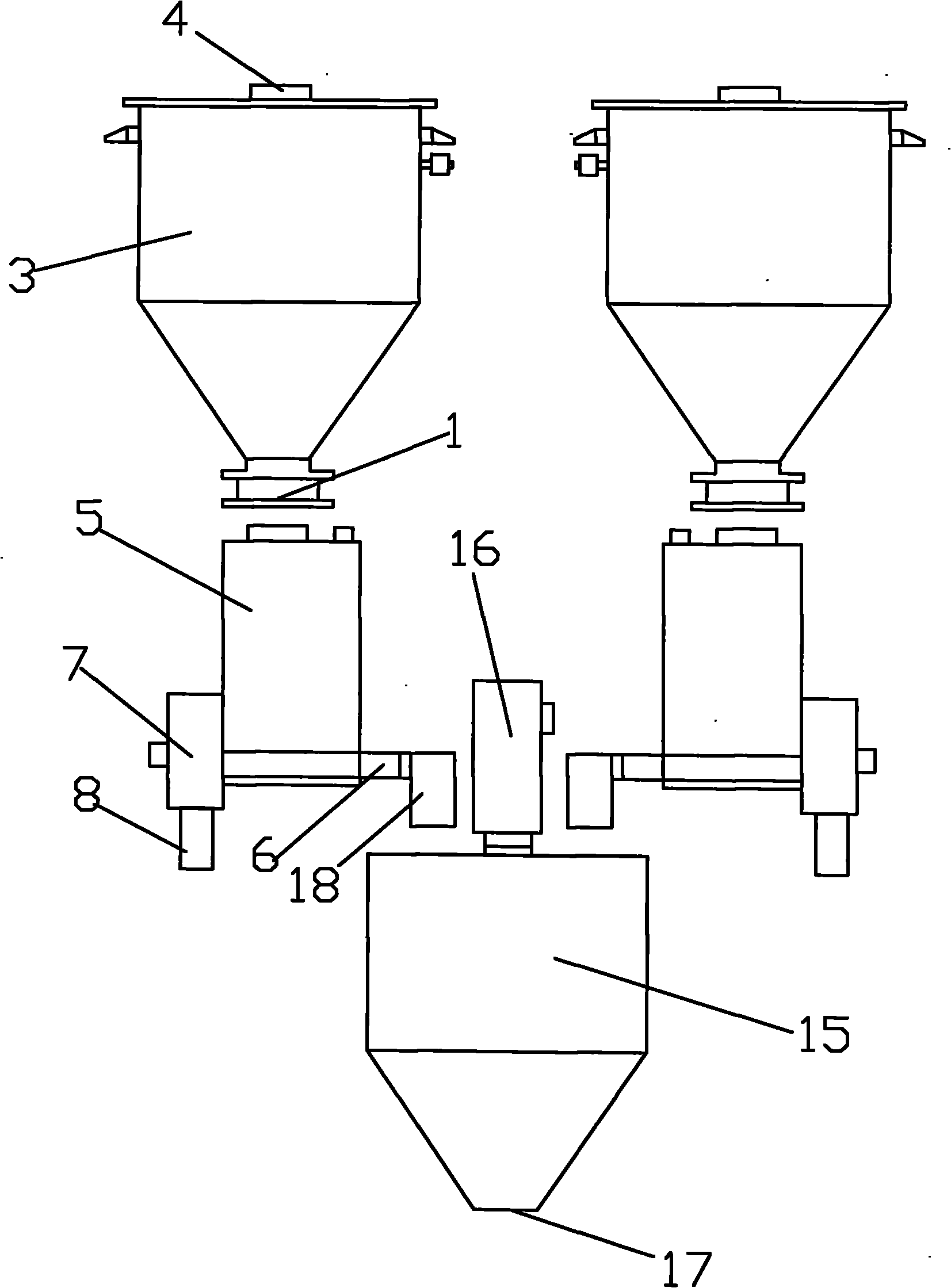

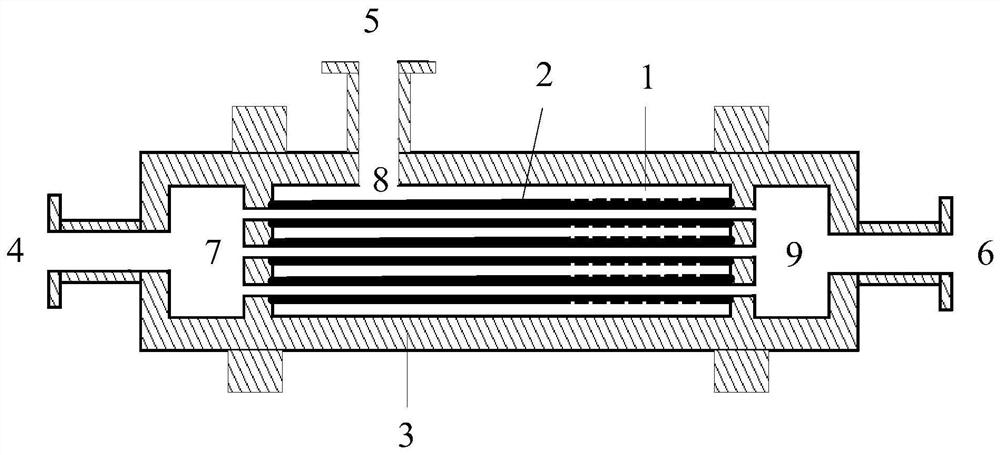

Tubular high-pressure micro-dispersion mixer

InactiveCN113041941AContinuous mixingMeet pressure requirementsFlow mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a tubular high-pressure micro-dispersion mixer and belongs to the technical field of chemistry and chemical engineering. The micro-dispersion mixer adopts a tube array layout, the shell of the mixer is used for bearing high pressure, micro sieve pores or micro grooves positioned at the downstream of a tube array are used as a dispersion structure, and a cavity between the tube array and the shell is used as a fluid distribution chamber. In the operation process, a specific dispersion structure can be selected according to the physical property of the system, the macromixing of a homogeneous system or the dispersion of liquid drops and bubbles of a heterogeneous system can be completed in the mixer only by respectively introducing the fluid to be dispersed and the main fluid, and the mixing process is continuous, efficient and stable.

Owner:TSINGHUA UNIV

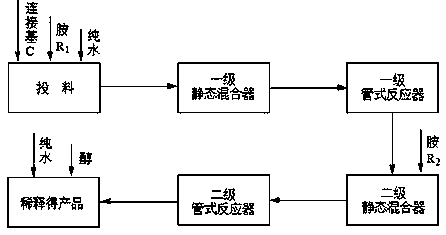

Continuous production method of biquaternary ammonium salt

ActiveCN110746308AImprove reaction speedChange reaction balanceOrganic compound preparationFlow mixersContinuous reactorOrganosolv

According to the invention, a production mode comprises: generating a monoquaternary ammonium salt intermediate, and then generating a target biquaternary ammonium salt product, wherein the whole production process achieves continuous production of continuous feeding, continuous mixing, continuous reaction and continuous discharging mainly through a static mixer and a continuous reactor; the production method is simple and easy to operate, a variety of biquaternary ammonium salts can be synthesized, and the equipment utilization rate is greatly increased through the continuous production modeso as to shorten the production period; and the use and the recovery treatment of organic solvents are avoided in the production process, no three wastes are generated in the whole process, and the method is environmentally friendly.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

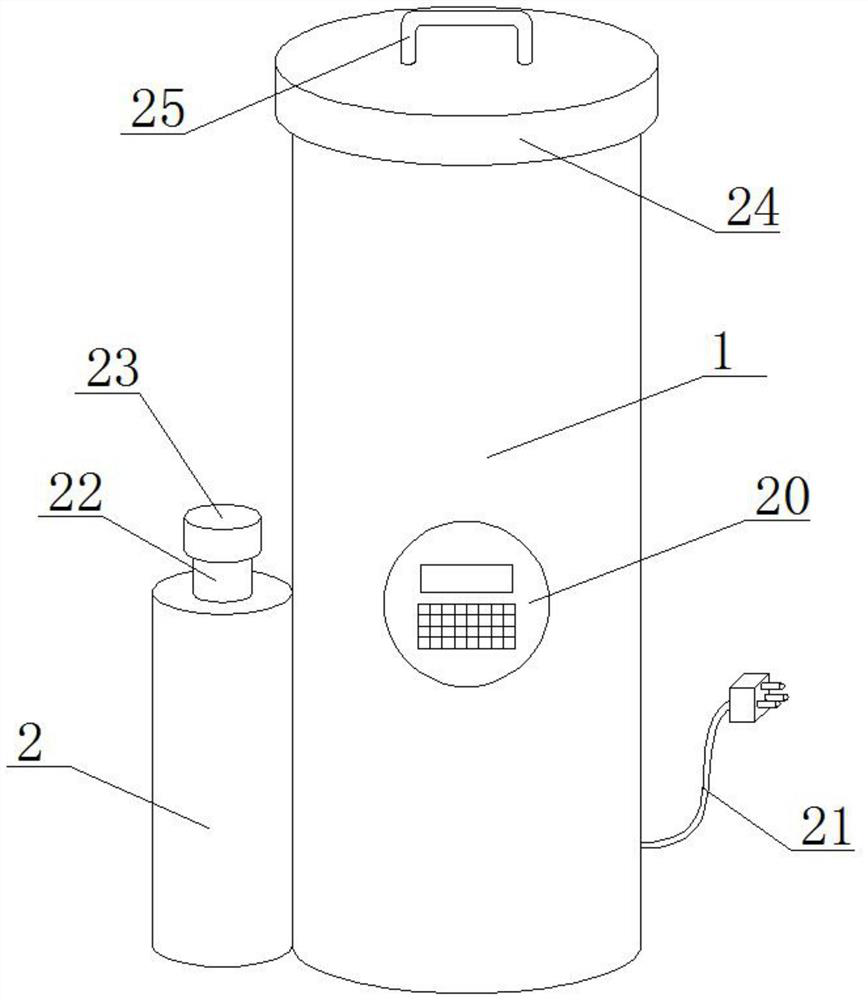

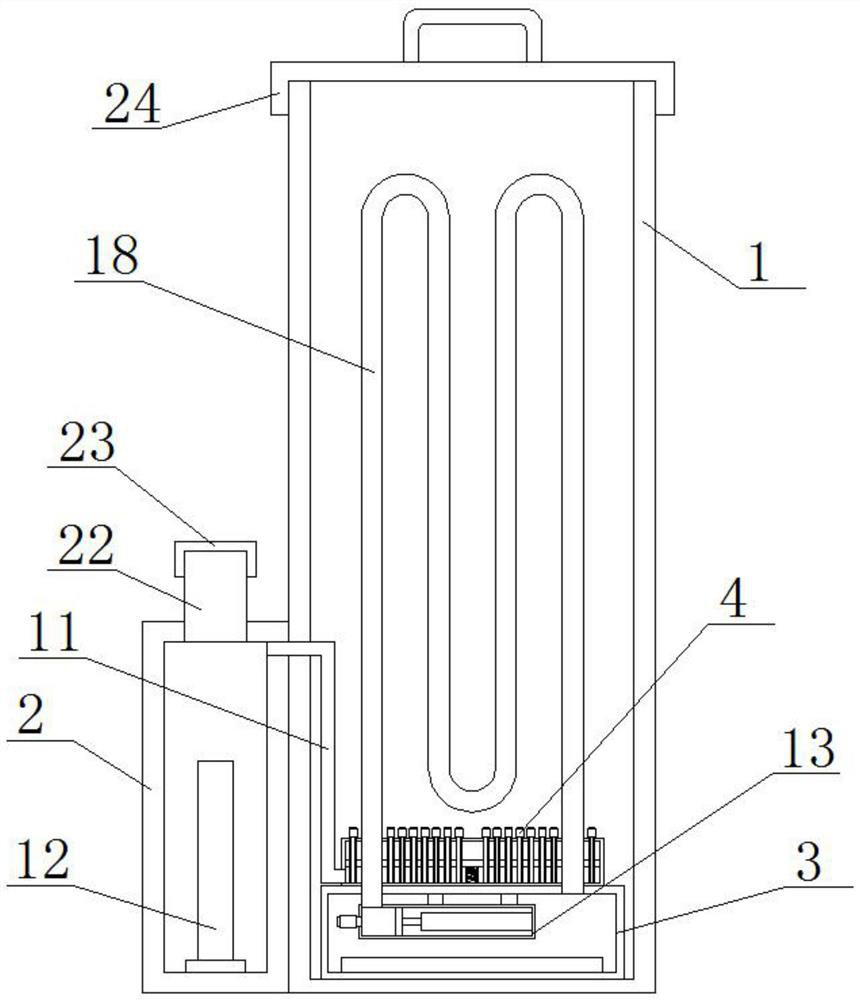

Formula and preparation device of amino acid nutritional beverage for physical recovery after exercise

InactiveCN113080352AContinuous mixingEffect of mixingTransportation and packagingMixer accessoriesNutritionProcess engineering

The invention provides an amino acid nutritional beverage formula for physical recovery after exercise and a preparation device. The amino acid nutritional beverage formula comprises a preparation disinfection tank and a steam generation tank; a disinfection box is fixedly mounted at the bottom of the preparation disinfection tank, a steam diffusion device is fixedly mounted at the top of the disinfection box, and the steam diffusion device comprises a steam box and a plurality of diffusion pipes. According to the amino acid nutritional beverage formula for physical recovery after exercise and the preparation device, the design is reasonable, the steam generation tank can continuously generate steam and convey the steam into the preparation disinfection tank, and part of beverage preparation water is added into various raw materials and water in a steam form, so on one hand, the mixing and stirring effects can be achieved, the raw materials can be continuously mixed without special stirring, and the preparation time is saved; on the other hand, steam can preheat the mixture, so the dissolution speed of the raw materials is increased.

Owner:WUHAN HONGBO BIOTECH CO LTD

A kind of purification method of butyl acrylate crude product

ActiveCN104761452BReduce usageReduce manufacturing costCarboxylic acid esters separation/purificationOne passPurification methods

Owner:PINGHU PETROCHEM

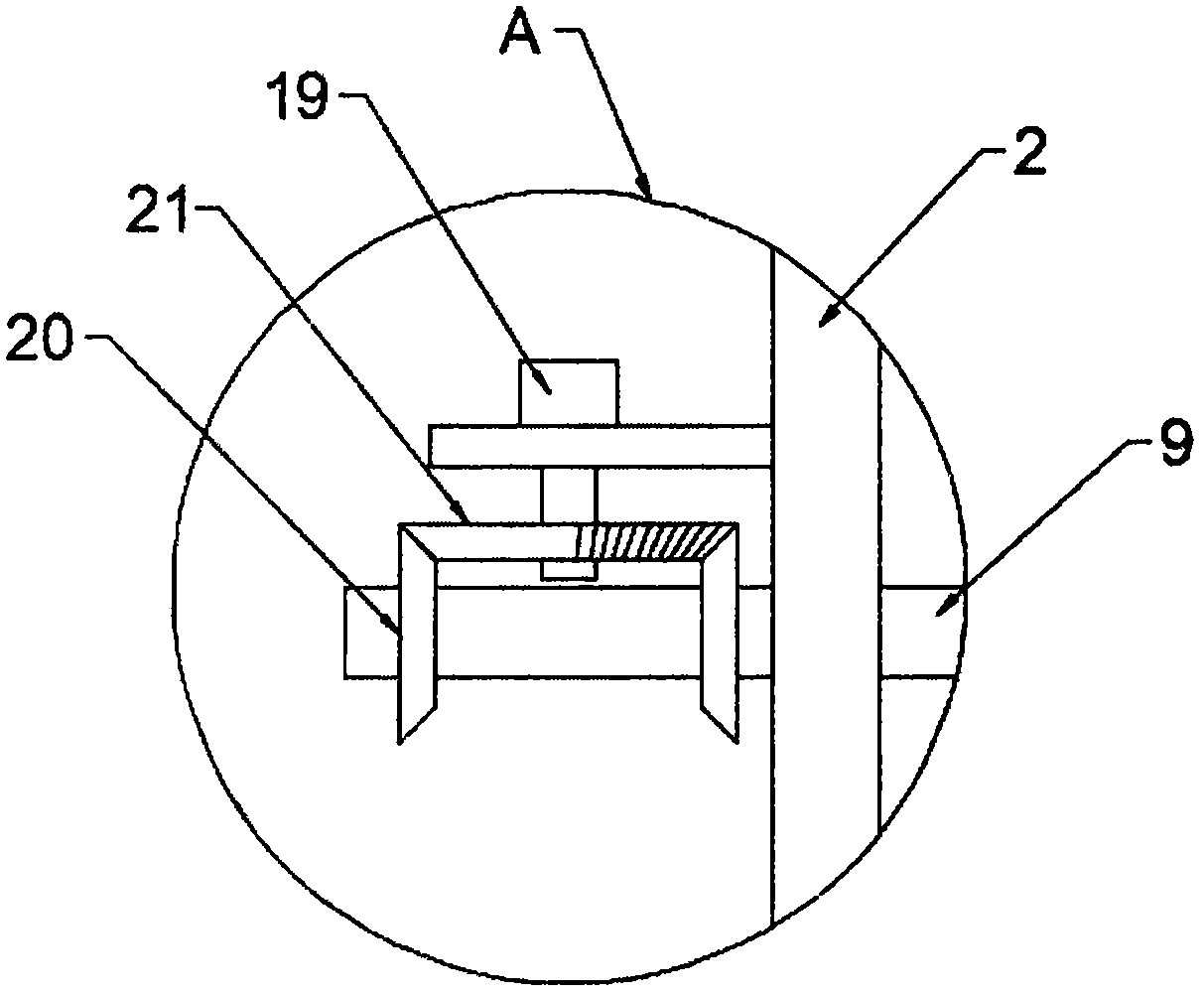

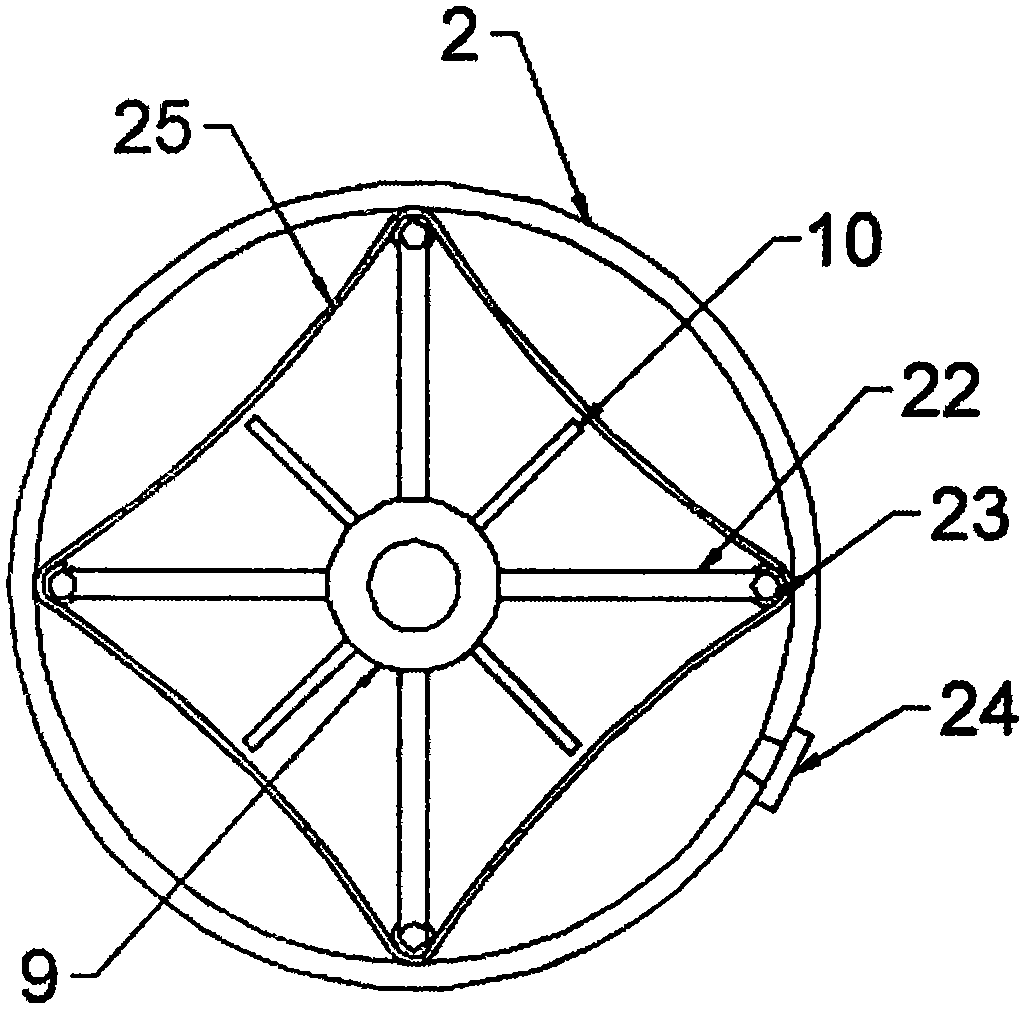

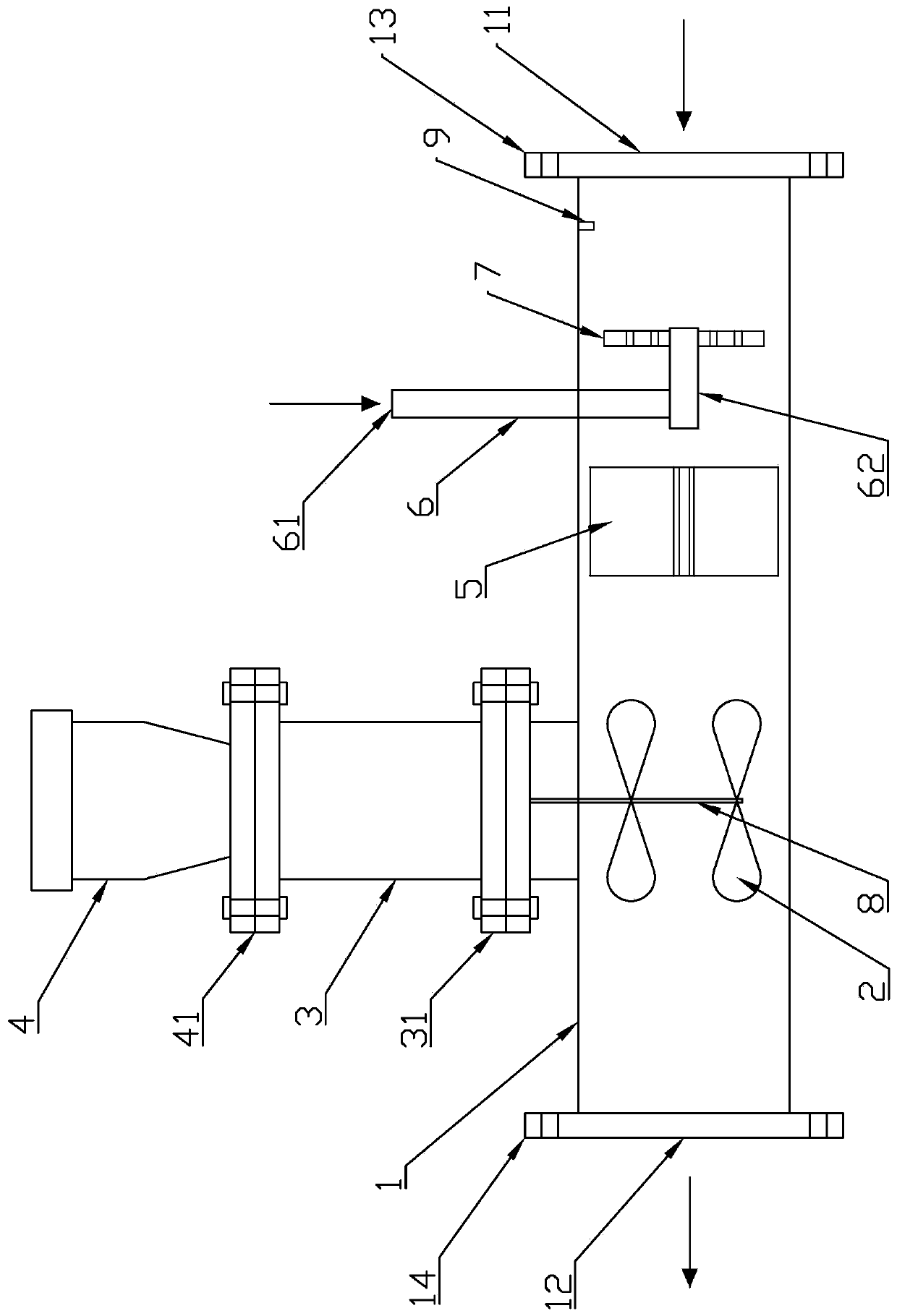

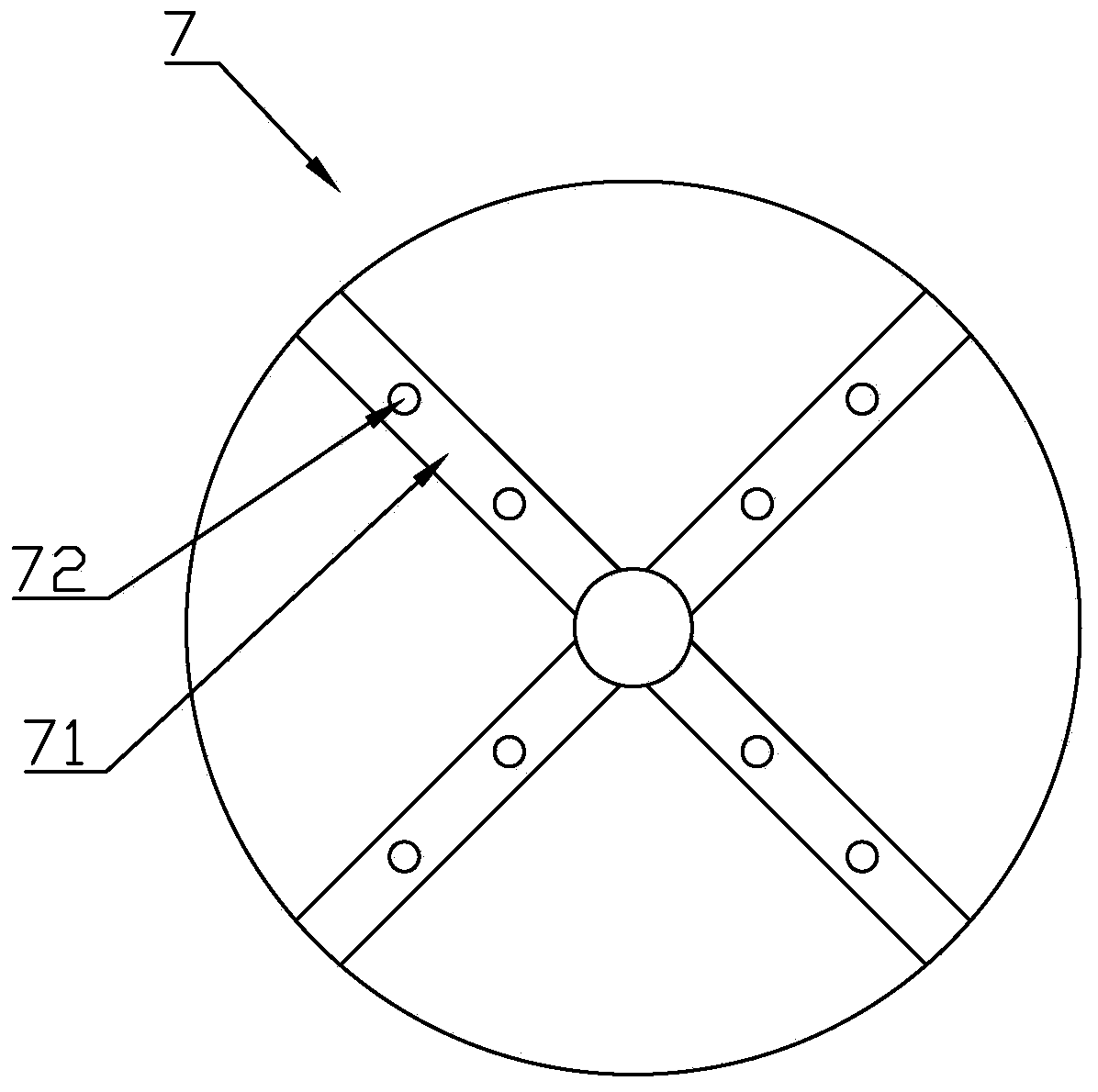

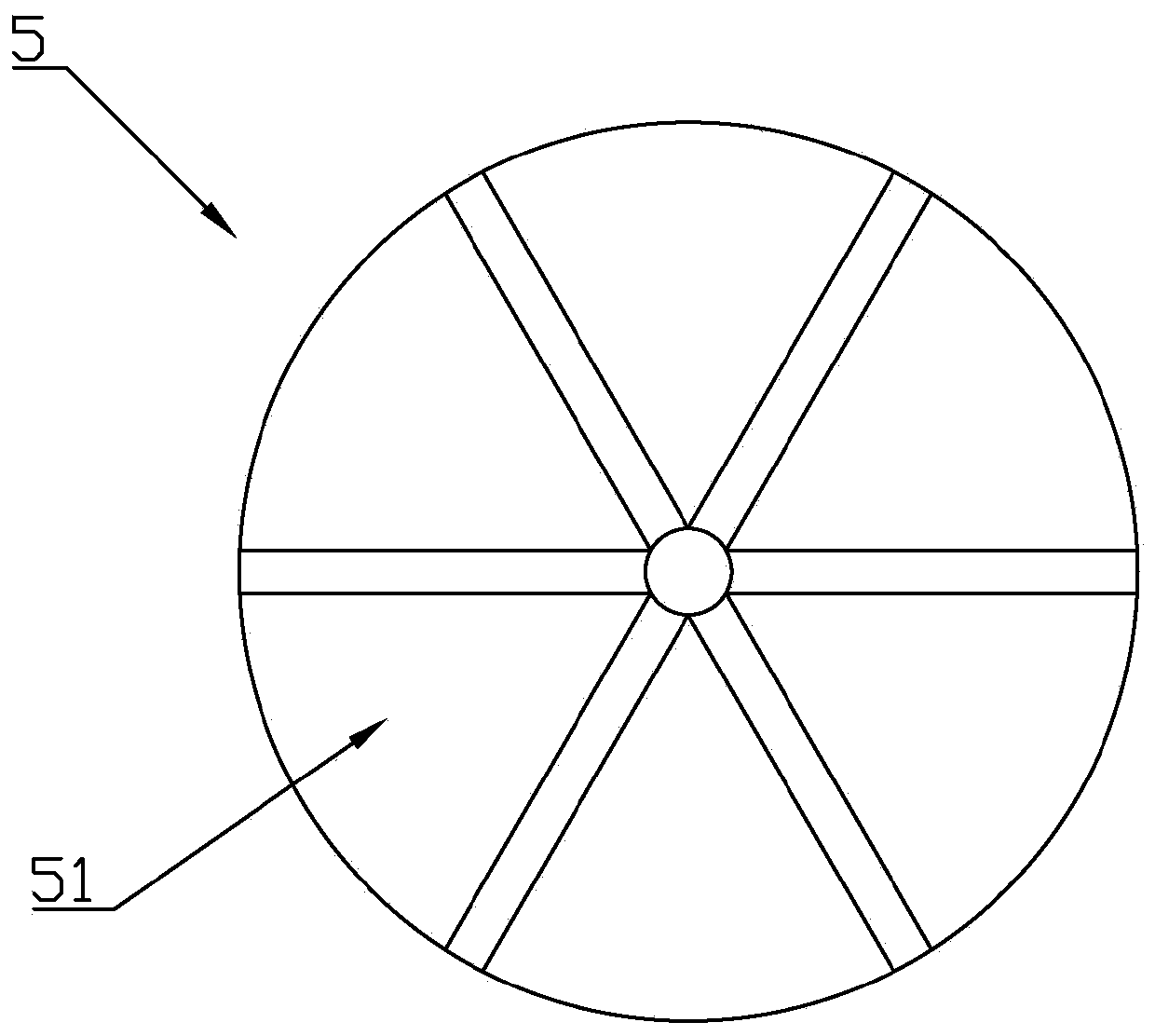

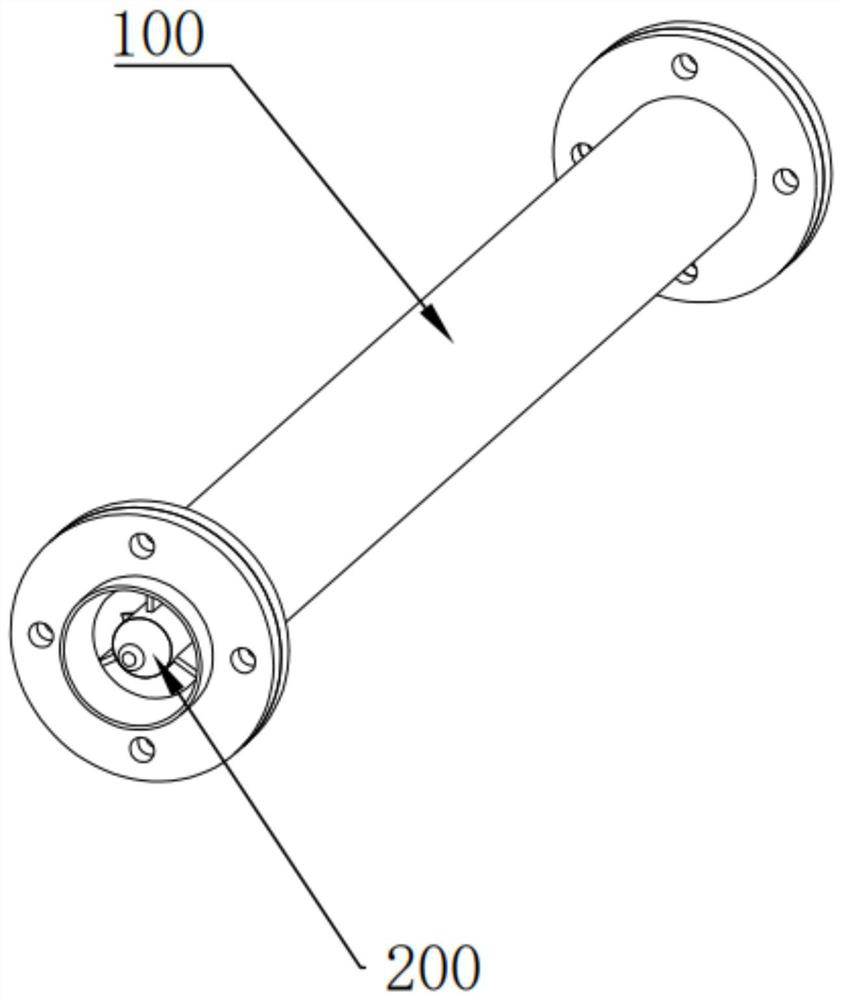

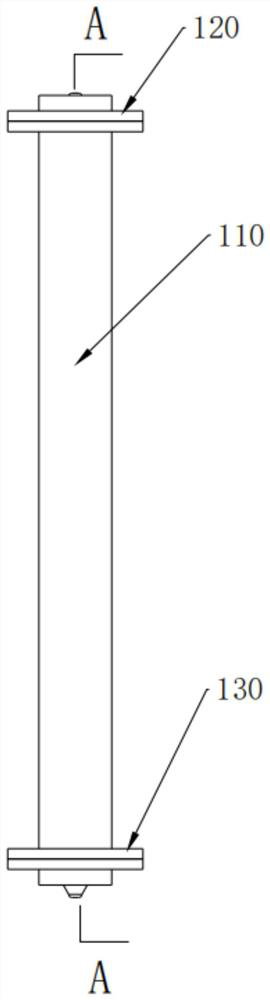

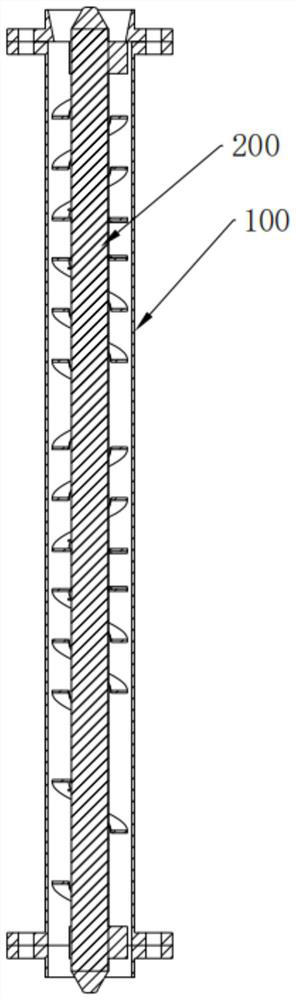

On-line dynamic and static mixer

PendingCN110732250AAdapt to a wide range of medium flow ratesGood media rectification effectFlow mixersTransportation and packagingRotational axisElectric machinery

The invention provides an on-line dynamic and static mixer which is provided with a barrel; a liquid inlet is formed in the front end of the barrel, and a mixing outlet is formed in the rear end of the barrel; an injection conduit is designed to extend into the barrel to be close to the front end from the radial side surface of the barrel, and the outer end of the injection conduit is provided with a medium inlet; a distributor is provided with a plurality of guide pipes arranged in a radial shape, the outer ends of the guide pipes are closed, the inner ends of the guide pipes are communicatedwith the injection conduit, and a plurality of spray holes are formed in the side wall of each guide pipe; a mixing internal part is arranged in the barrel at the downstream of the distributor; stirring blades are fixed in the barrel at the downstream of the mixing internal part, and a rotating shaft of the stirring blades is designed to extend out of the barrel along the radial direction and isconnected with a motor; the flow velocity detector is installed at the position, close to a liquid flow inlet, in the barrel and is in signal connection with the motor. The distributor, the mixing internal part and the stirring blades are adopted, so that a static mixer and a dynamic mixer are integrated, and the mixing efficiency is improved.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

Static mixer

PendingCN112808053AWell mixedSmall pressure lossFlow mixersTransportation and packagingEngineeringStatic mixer

The invention discloses a static mixer which comprises a shell and a mixing unit arranged in the shell, the mixing unit comprises a flow guide column, at least one single-spiral twisted part and at least two groups of double-spiral twisted pieces, the single-spiral twisted pieces and the double-spiral twisted pieces are sequentially arranged on the flow guide column in the flowing direction of fluid, and each double-spiral twisted part is composed of two spiral twisted pieces in the same direction. According to the static mixer provided by the invention, uniform mixing is completed by continuously changing the flowing mode of the fluid, so that the fluid is mixed more uniformly.

Owner:四川乐智机电工程有限公司

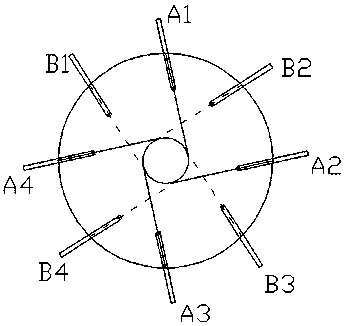

Ammonia water mixer for new boiler denitrification

ActiveCN105214532BEliminate stress stackingAvoid inadequate mixingFlow mixersHigh concentrationNitrogen oxide

The invention discloses a new type of ammonia water mixer for boiler denitrification, which is designed with the concept of "cut circle", that is, according to the size of the boiler, the original nitrogen oxide discharge, the local environmental protection requirements and other related indicators, in the mixer tank A certain number of spray guns are arranged on the body, and the spray guns are installed at a certain angle, and high-concentration ammonia water and desalinated water pass through the spray guns at intervals. Since the high-concentration ammonia water and desalted water have a certain pressure and speed under the action of their respective pumps, a specific tangential circle is formed in the mixer tank, and the tangential circle direction of the adjacent layer is opposite, so as to achieve a good mixing effect and eliminate The problem of mutual pressure. In addition, a switch is provided on the spray gun of the mixer, and the boiler variable load denitrification adjustment can be realized by closing some of the spray guns of the mixer symmetrically and at intervals. The device of the invention has good effect, low equipment cost, convenient installation and use, and solves the problem of mutual pressure between high-concentration ammonia water and demineralized water in the mixer and the problem of denitrification that cannot be adapted to boiler load changes.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD +1

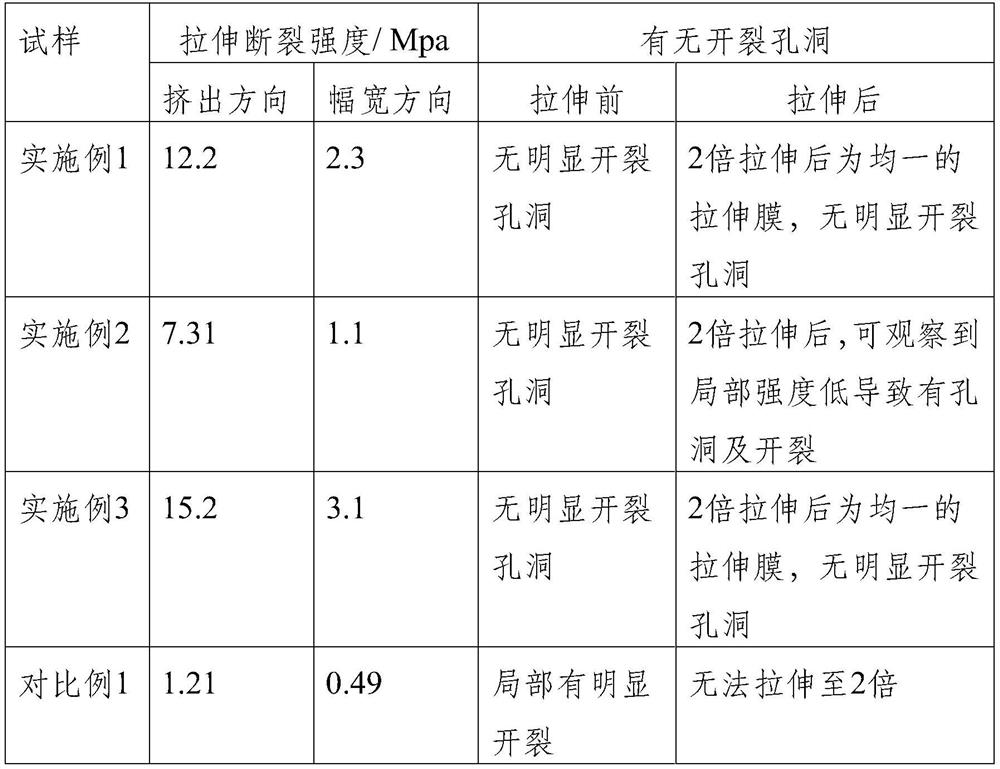

Method for mixing polytetrafluoroethylene dispersion resin with high-proportion filler

The invention discloses a method for mixing polytetrafluoroethylene dispersion resin with a high-proportion filler. The method comprises the following steps: S1, sucking a premixed polytetrafluoroethylene dispersion resin and filler mixture into supersonic jet milling equipment through a high-pressure gas negative pressure pipe, and sufficiently crushing and mixing; and S2, mixing the mixture obtained in the step S1 by adopting airflow of a fluidized bed mixer to obtain the polytetrafluoroethylene dispersion resin filler mixture blended with the extrusion aid. On the basis of existing supersonic speed crushing, a fluidized bed airflow mixing treatment step is added in the method for mixing the polytetrafluoroethylene dispersion resin with the high-proportion filler; compared with high-pressure, intermittent and short-time airflow mixing of pulse airflow mixing, the fluidized bed adopts high-pressure and low-flow airflow, and more uniform, continuous and efficient mixing can be realized. The invention further discloses a production method of the polytetrafluoroethylene product.

Owner:江苏中际信通讯材料有限公司

A static air mixer

ActiveCN110822424BImprove mixing homogeneityContinuous mixingIncinerator apparatusGaseous fuel burnerClassical mechanicsEngineering

This application discloses a static air mixer, which uses a Venturi structure to introduce return air and combustion-supporting air, and under the action of the Venturi effect, the two are completely mixed and kept in a state of complete confluence at all times, with the help of spiral air mixing Channel, so that the airflow is continuously kneaded and mixed to achieve the effect of uniform mixing, reducing the oxygen content and output, using the Venturi structure to introduce the return air and combustion air, and completely mix the two under the action of the Venturi effect , and keep completely confluent at all times, cooperate with the spiral air mixing channel, so that the airflow is continuously kneaded and mixed, so as to achieve the effect of uniform mixing to reduce the oxygen content and output.

Owner:青岛天正洁能环保科技有限公司

Method for measuring content of titanium dioxide in food and test pipeline

PendingCN113758888AContinuous generationGenerated in real timeMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsPhysical chemistrySaline solutions

The invention relates to a method for determining the content of titanium dioxide in food and a test pipeline for determining the content of titanium dioxide in food by a continuous flow analyzer and belongs to the technical field of food inspection. The method for measuring the content of titanium dioxide in food comprises the following steps of (1) mixing a digestion solution of a to-be-measured food sample with an ascorbic acid solution on line to obtain a to-be-measured solution; ascorbic acid being generated through online reaction of hydrochloric acid and an ascorbate solution; (2) uniformly mixing the to-be-detected solution with a diantipyrine methane solution on line to obtain a developing solution; and (3) carrying out ultraviolet spectrophotometric analysis on the color developing solution. The method is advantaged in that ascorbic acid used in the method for measuring the content of titanium dioxide in the food is generated through online reaction of hydrochloric acid and the ascorbate solution, the shelf life of ascorbate can reach 15 days or above, problems that ascorbic acid is prone to being oxidized and can be used after being prepared every day are solved, and a purpose of batch sample detection can be achieved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

A fast and efficient continuous mixer device

The invention relates to a fast and efficient continuous mixer device, which includes a material kettle I, a material kettle II, a Venturi tube and a material mixer. Constriction section, throat, diffusion section, outlet pipe and outlet. The inlet pipe is provided with two opposite feed inlet II and feed inlet III which are perpendicular to feed inlet I. The material mixer is provided with a material inlet, a material outlet, a circulation port and a sampling port. The material outlets on the material kettle I and the material kettle II are respectively connected to the material inlet II on the Venturi tube through the material pump and the pipeline. It is connected with the feed port III, the discharge port on the Venturi tube is connected to the feed port on the material mixer through a pipeline, and the circulation port on the material mixer is connected to the Venturi tube through a material pump and a pipeline. The feed port I on the top is connected. The invention not only enables the materials to be mixed quickly, uniformly and stably, but also allows the materials to be mixed in multiple cycles.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A device for uniformly adding powdery materials, an installation method and a use method

ActiveCN106319117BImprove liquidityAvoid the problem of poor feedingBlast furnace componentsBlast furnace detailsProcess engineeringCinder

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Continuous flue gas purification liquid mixing mechanism

ActiveCN107551842AImprove purification effectContinuous mixingFlow mixersAir quality improvementLiquid waterFlue gas

The invention discloses a continuous flue gas purification liquid mixing mechanism which comprises an outer pipe, a liquid inlet pipe and a dosing and mixing mechanism, wherein the liquid flows into acavity composed of a vertical ring and a cylinder through the liquid inlet pipe and flows into a liquid preparation pipe through a first shunt hole in the cylinder; one part of liquid is ejected viaa liquid ejection hole, and the other part of liquid is continuously ejected through a second liquid separation hole formed in a confluence block and a third liquid separation hole formed in a liquidpreparation ring; and when high-pressure water enters the cylinder, one part of high-pressure water pushes blades to rotate around a rotating shaft, so that the liquid ejected out of the liquid ejection hole is mixed with the high-pressure water, the other part of high-pressure water continuously flows through the liquid preparation ring, and therefore, the liquid ejected out of the third liquid separation hole is mixed with the high-pressure water. The device is simple in structure, and the liquid is dispersed and ejected out to be mixed with the high-pressure water. Meanwhile, due to the mixing mechanism, the liquid is uniformly and continuously mixed with the high-pressure water, and the flue gas purification effect is improved.

Owner:池州市星聚信息技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com