A fast and efficient continuous mixer device

A mixer and high-efficiency technology, used in mixers, chemical instruments and methods, dissolution and other directions, can solve the problems of affecting the fluid mixing effect, low mixing efficiency, time-consuming and energy consumption, etc. , Improve the effect of mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

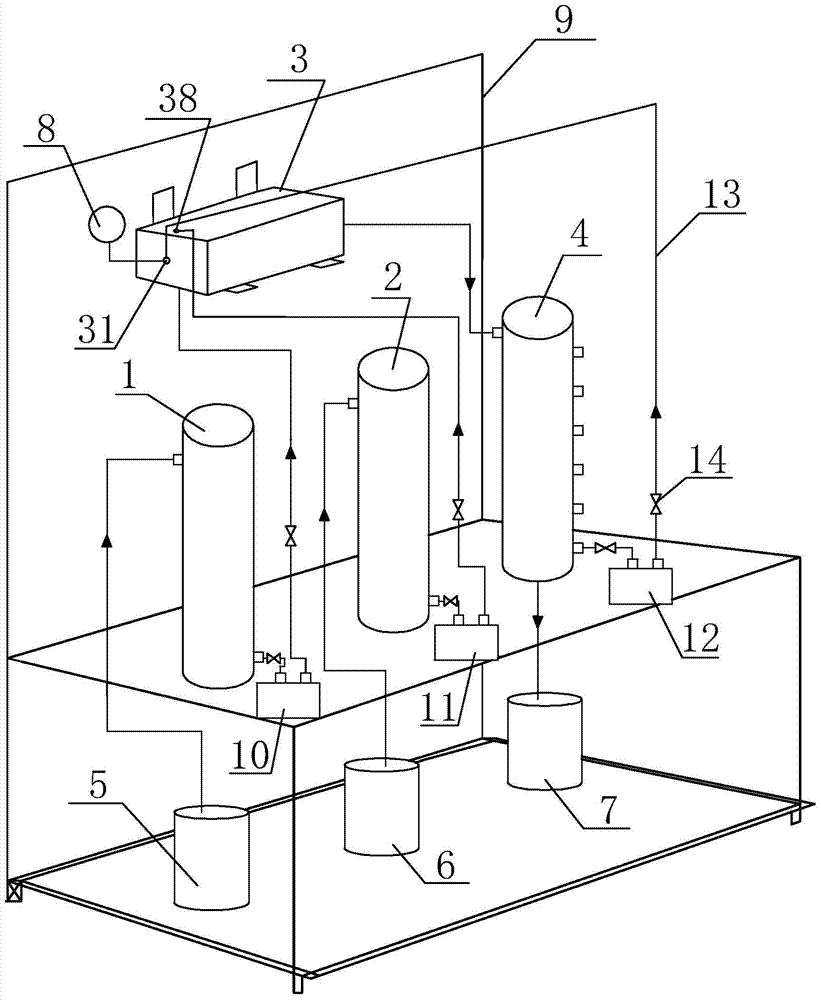

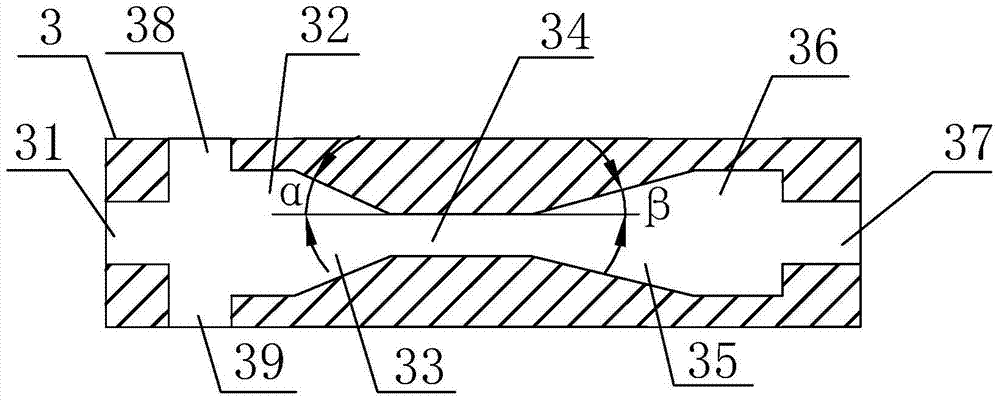

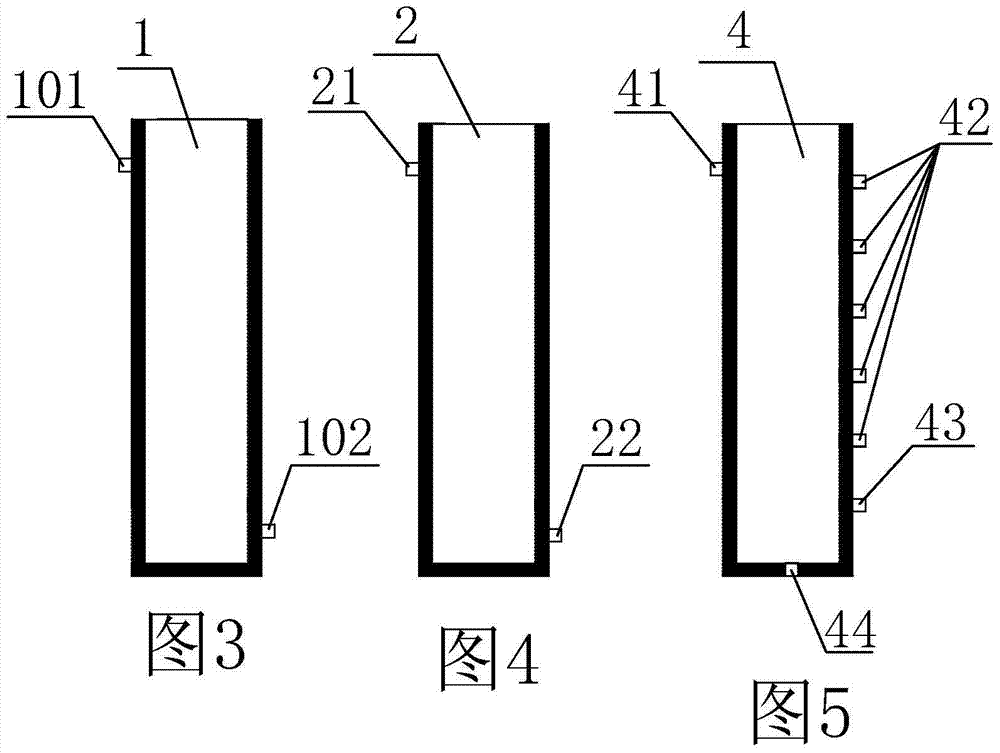

[0025] A fast and efficient continuous mixer device, including material kettle I1, material kettle II2, Venturi tube 3, material mixer 4, material pool I5, material pool II6, discharge pool 7, pressure gauge 8, fixed frame 9, Material pump I10, material pump II11 and material pump III12, the material kettle I1 and material kettle II2 are cylinders with an interlayer in the middle, and the upper ends of the material kettle I1 and material kettle II2 are provided with feed ports , the lower ends are all provided with discharge ports, and the venturi tube 3 is a cuboid with a length of 40-50 cm and a width of 10-20 cm. Shrinking section 33, throat 34, diffuser section 35, outlet pipe 36 and outlet 37, said inlet pipe 32 is provided with two opposite feed inlets II 38 and feed inlets perpendicular to feed inlet I31. Port III39, the inclination angle α of the hypotenuse of the tapered section 33 of the Venturi tube 3 is 20°, and the inclination angle β of the hypotenuse of the diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com