Method for measuring content of titanium dioxide in food and test pipeline

A titanium dioxide and determination method technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, color/spectral characteristic measurement, and analysis by making materials undergo chemical reactions, can solve the problems of easy oxidation of ascorbic acid and other problems, and achieve The effects of avoiding ascorbic acid oxidation, improving efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The determination method of titanium dioxide content in the food of the present embodiment, take commercially available food (syrup, roasted peanut and strawberry jam) as the sample to be tested, utilize continuous flow analyzer to measure food by the continuous flow analyzer of embodiment 2 The test pipeline of the content of titanium dioxide in the medium is measured, which specifically includes the following steps:

[0040] (1) Sample digestion: put 0.25g of syrup in a microwave digestion tank, then add 2.5mL concentrated nitric acid and 2.5mL concentrated sulfuric acid into the microwave digestion tank, seal the digestion tank, and perform microwave digestion (see Table 1 for the digestion procedure) , to obtain a clear sample digestion solution.

[0041] Table 1 Microwave digestion program

[0042] step Initial temperature / °C Heating rate / ℃ / min End temperature / ℃ Hold time / min 1 room temperature(20) 20 120 3 2 120 12.5 220 5 3...

Embodiment 2

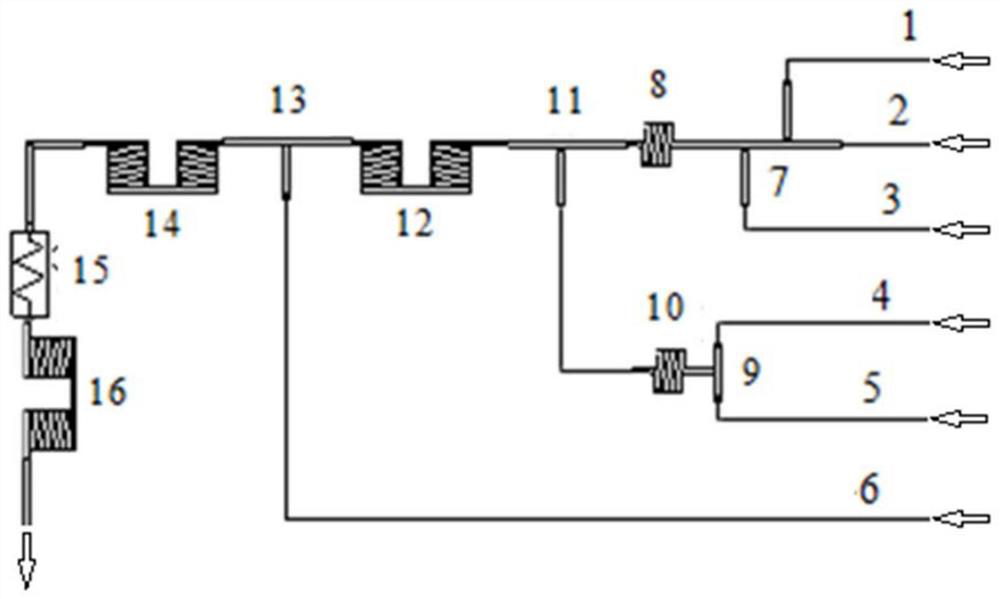

[0050] The test pipeline for the continuous flow analyzer of the present embodiment to measure the content of titanium dioxide in food, such as figure 1 As shown, including pipe 1, pipe 2, pipe 3, pipe 4, pipe 5, pipe 6, glass cross 7, mixing ring 8, T-shaped tee 9, mixing ring 10, T-shaped tee 11, mixing ring 12 , T-shaped tee 13, mixing ring 14, heating tank 15 and mixing ring 16;

[0051] The glass cross 7 has an air inlet, a dilution water inlet, a digestion solution inlet and an outlet, and one end of the pipeline 1, pipeline 2, and pipeline 3 is respectively connected with the air inlet, dilution water inlet, and digestion solution inlet of the glass cross 7 , the other end of pipeline 1 is used to connect to the air inlet pump tube, the other end of pipeline 2 is used to connect to the dilution water inlet pump tube, and the other end of pipeline 3 is used to connect to the digestion solution sampling pump tube;

[0052] The outlet of the glass cross 7 is connected to ...

experiment example

[0060] This experimental example has investigated the sensitivity of the assay method of titanium dioxide content in the food of the present invention, and the difference with embodiment 1 is, this experimental example changes the sample to be tested into standard solution, investigates the sensitivity of the titanium dioxide content in the food of the present invention with this The limit of detection and the limit of quantification of the determination method, and then examine the limit of detection and limit of quantification of the determination method of the comparative example. The results show that the detection limit of the assay method of titanium dioxide content in food of the present invention is 0.184mg / kg, the quantification limit is 0.613mg / kg, and the detection limit of the test method stipulated in GB / T5009.246-2016 is 1.5mg / kg. kg, the limit of quantification is 5.0mg / kg; the detection limit of the former is 1 / 8 of the latter, thus showing that the assay method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com