Automatic backfire recovery device

A backfire and automatic technology, applied in the direction of gas flame welding equipment, metal processing equipment, welding equipment, etc., can solve the problem that the Brown gas cannot be continuously supplied to the Brown gas delivery pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

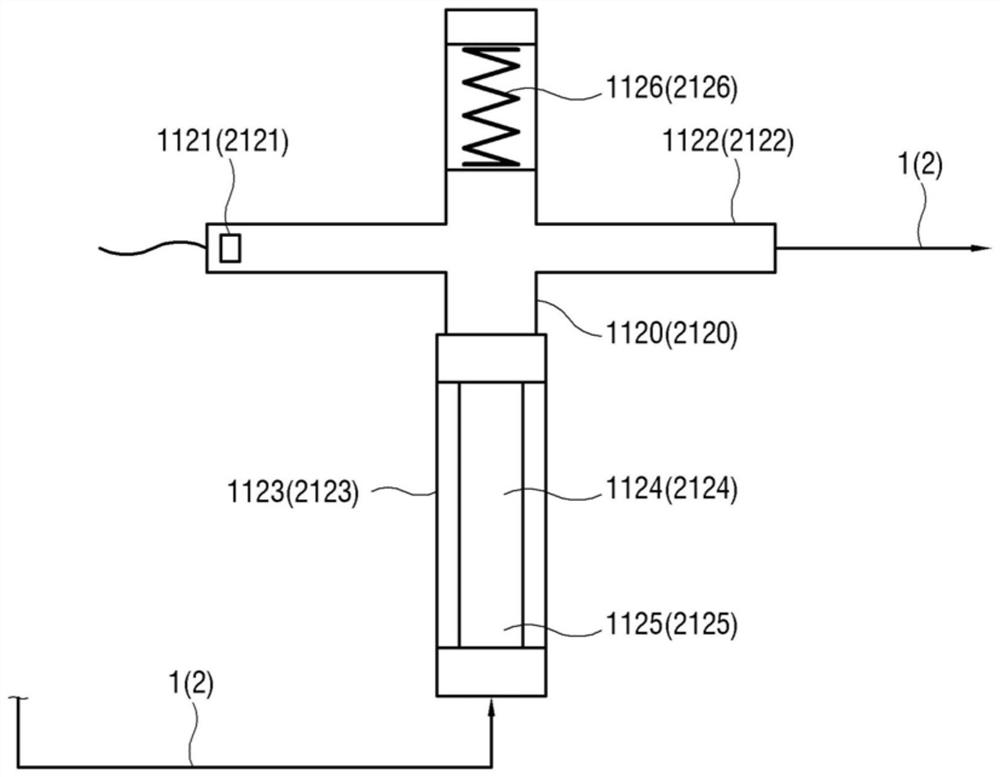

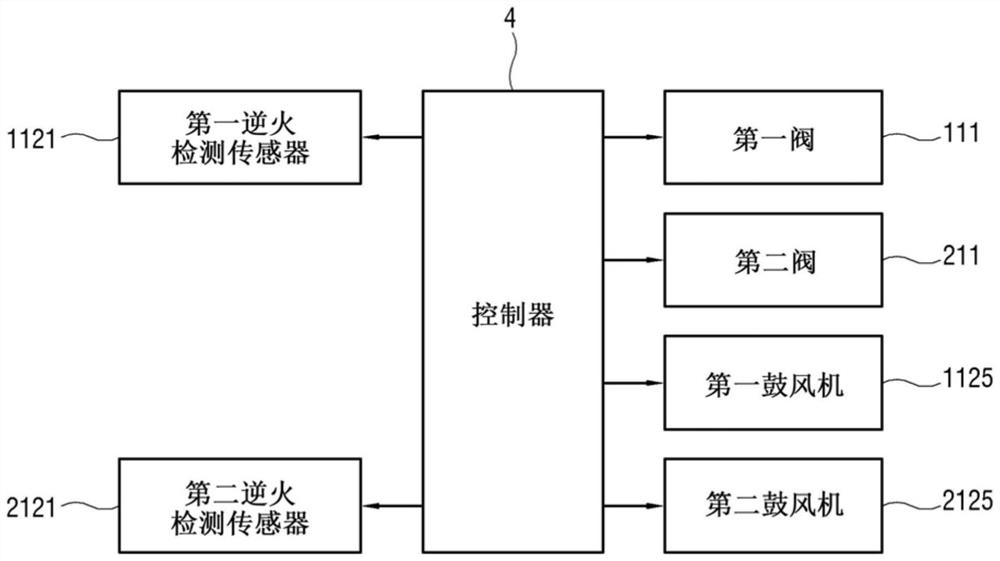

[0018] Hereinafter, the disclosure of the present invention will be described in more detail with reference to the accompanying drawings.

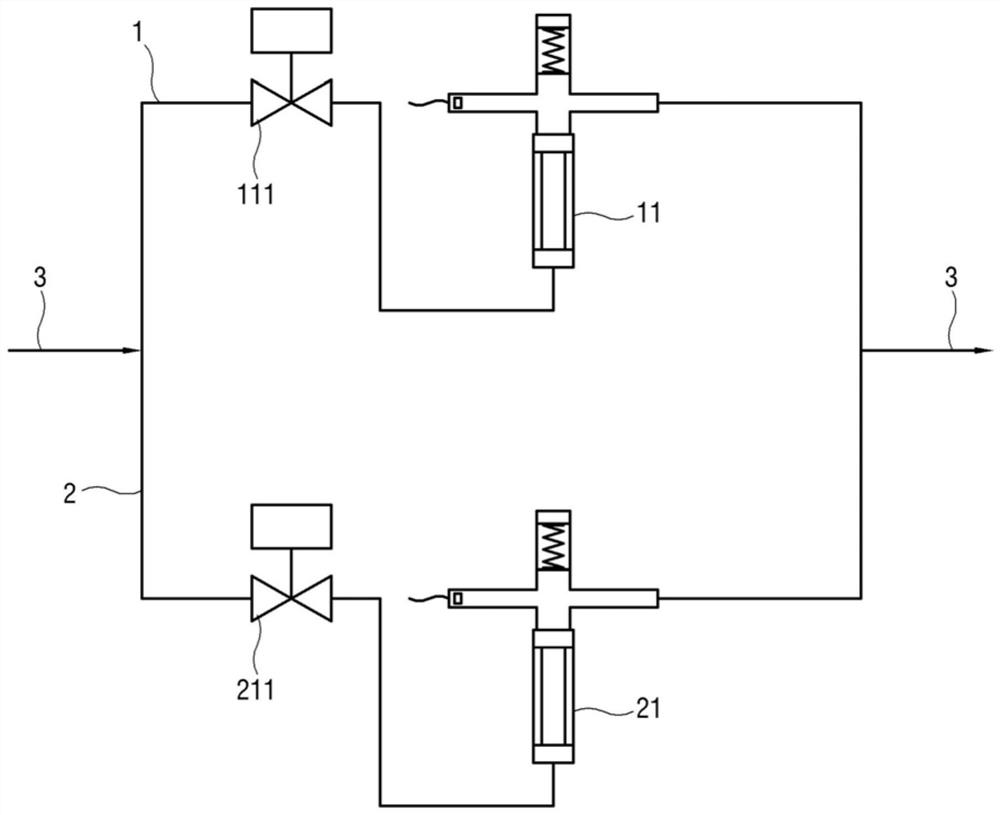

[0019] figure 1 It is a figure which shows the whole structure of the automatic backfire recovery apparatus based on this invention.

[0020] The two branch pipes 1 and 2 branch off from the delivery pipe 3 which delivers and supplies the Brownian gas. Brown gas passes through the duct 3 in figure 1 It is delivered from left to right in the middle, and the delivered Brown gas is supplied to the two branch pipes 1 and 2, respectively. The right ends of the two branch pipes 1 and 2 are again joined and connected to the delivery pipe 3 . Due to this structure, the two branch pipes 1 and 2 have a structure in which they are rejoined after branching from the middle of the conveying pipe 3 . and figure 1 Unlike the configuration shown, the delivery pipe 3 may be constructed without the delivery pipe 3 present at the downstream ends of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com