a gasifier

A technology of gasification furnace and furnace body, which is applied in the field of gasification furnace, and can solve the problems of less gas, insufficient gas concentration, falling and compacting of fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

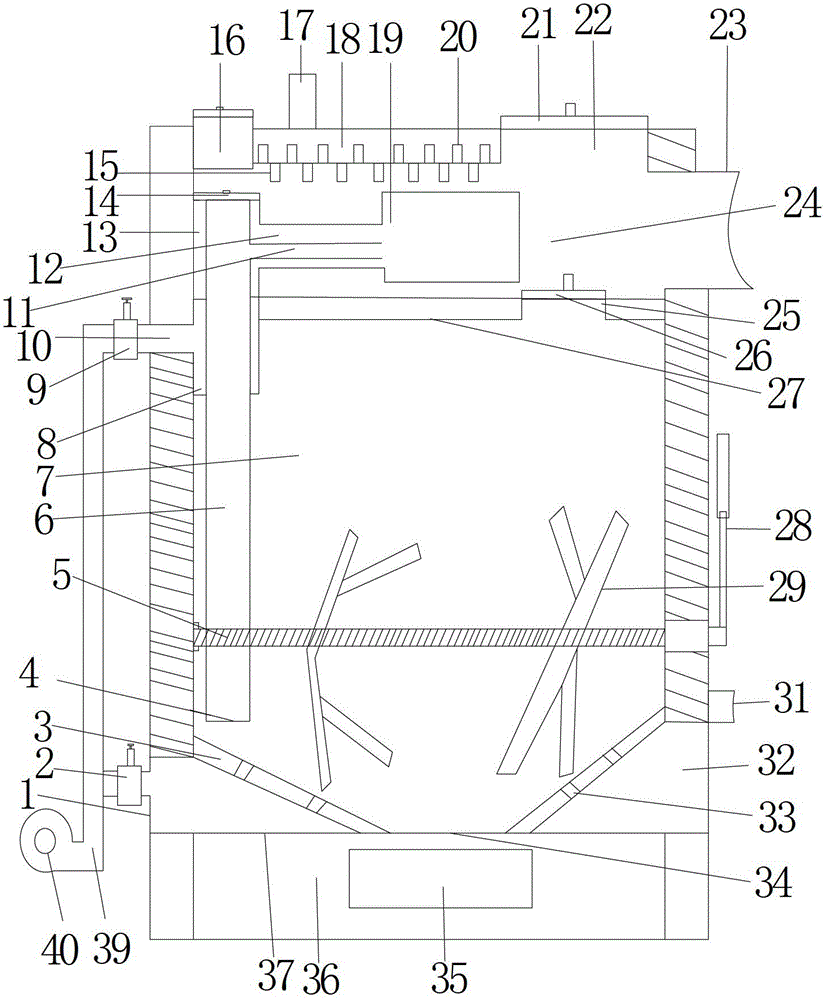

[0013] Example 1, such as figure 1 Shown, a kind of gasification furnace comprises furnace body 1, is provided with pressing shaft 4 in furnace body 1, is provided with pressing claw 29 on the pressing shaft 4, and one end of pressing shaft 4 passes through furnace body 1 and is connected with The furnace body 1 is rotatably connected, and one end of the pressing shaft 4 passing through the furnace body 1 is connected with a pressing handle 28 .

[0014] In the gasification furnace of the above embodiment, after the fuel in the furnace body 1 is burned out, the flame becomes weaker, and the pressing handle 28 is pressed back and forth to drive the pressing shaft 4, and the pressing claw 29 on the pressing shaft 4 is stirred The fuel drives the fuel to fall, and the fuel at the bottom is compacted, which can continuously generate gas and avoid the occurrence of flameout.

Embodiment 2

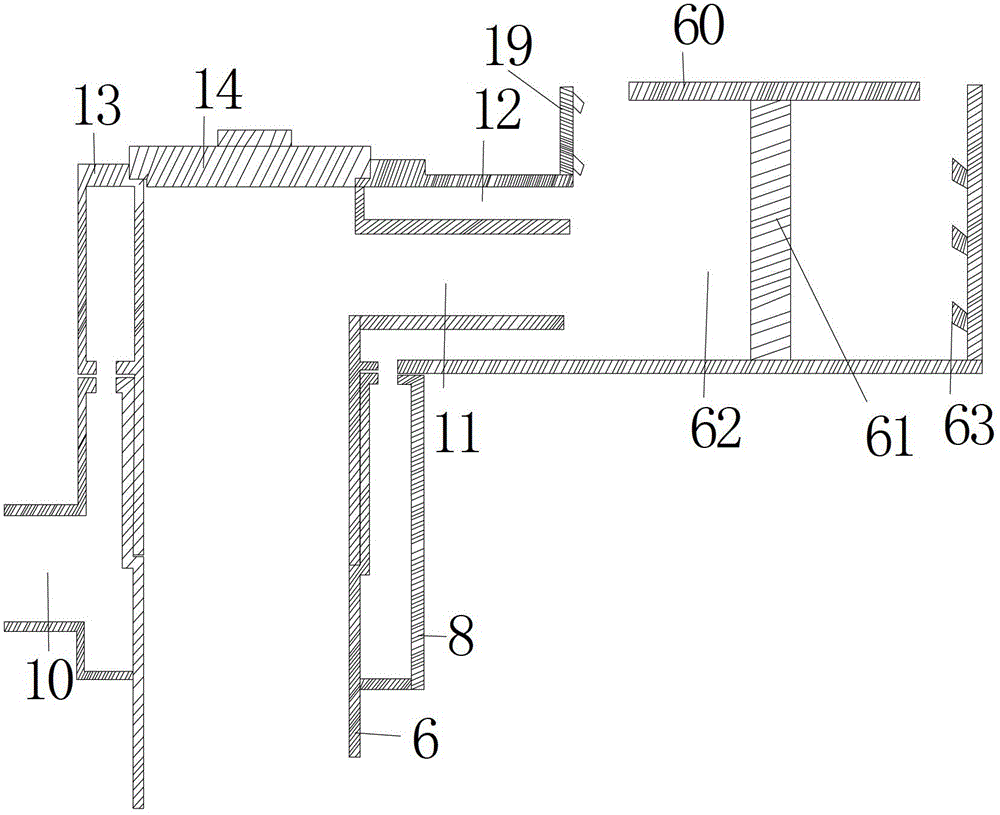

[0015] Example 2, such as figure 1 and figure 2 Shown, a kind of gasification furnace comprises furnace body 1, is provided with pressing shaft 4 in furnace body 1, is provided with pressing claw 29 on the pressing shaft 4, and one end of pressing shaft 4 passes through furnace body 1 and is connected with The furnace body 1 is rotatably connected, and one end of the pressing shaft 4 passing through the furnace body 1 is connected with a pressing handle 28 .

[0016] The body of heater 1 is divided into an upper combustion chamber 24 and a lower combustion chamber 7 by a partition 27, the binder shaft 4 is positioned in the lower combustion chamber 7, and one side of the upper combustion chamber 24 top is provided with a stove mouth 22, and the stove mouth 22 is provided with a A stove mouth cover 21 is arranged, and the dividing plate 27 is provided with a feed port 25, and the feed port 25 is provided with a feed port cover 26. One side of the top of the upper combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com