Purification method for butyl acrylate crude product

The technology of a butyl acrylate and a purification method is applied in the field of purification of crude butyl acrylate products, and can solve the problems of high price, difficulty in large-scale industrial production, complicated processes, etc., and achieves the reduction of dosage, shortening of washing link time, and saving. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

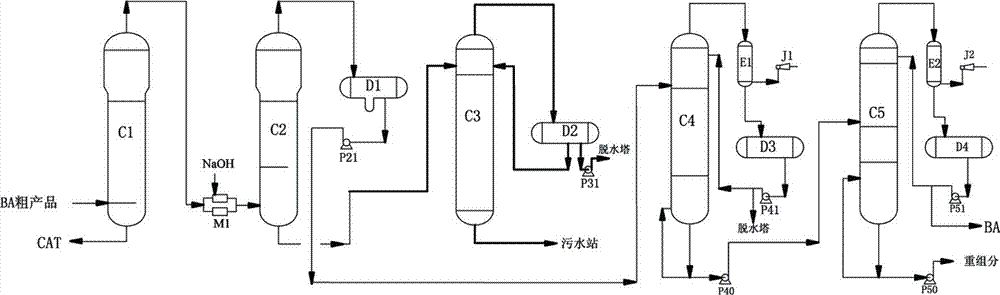

[0026] Embodiment 1 A kind of purification method of butyl acrylate crude product, its process flow diagram is as figure 1 As shown, it specifically includes the following steps:

[0027] 1) extraction

[0028] With desalinated water as extraction agent, the crude product of butyl acrylate enters the extraction tower C1 with an average flow rate of 10000kg / h and carries out continuous countercurrent extraction in the extraction tower C1; the organic acid catalyst in the crude product of butyl acrylate enters the water phase, and The desalinated water is countercurrently contacted to recover the organic acid catalyst in the water phase, and the recovered organic acid catalyst is sent back to the reactor from the bottom of the extraction tower C1; butyl acrylate and by-products enter the raffinate organic phase, and are collected from the top of the extraction tower C1 Outflow, continuously enter the static mixer M1;

[0029] The by-products in the described butyl acrylate cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com