Mixer for aramid II polymerization

A technology of mixer and aramid fiber, applied in the direction of single-component polyamide artificial filament, etc., can solve the problem of inability to continuously and stably produce high molecular weight resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

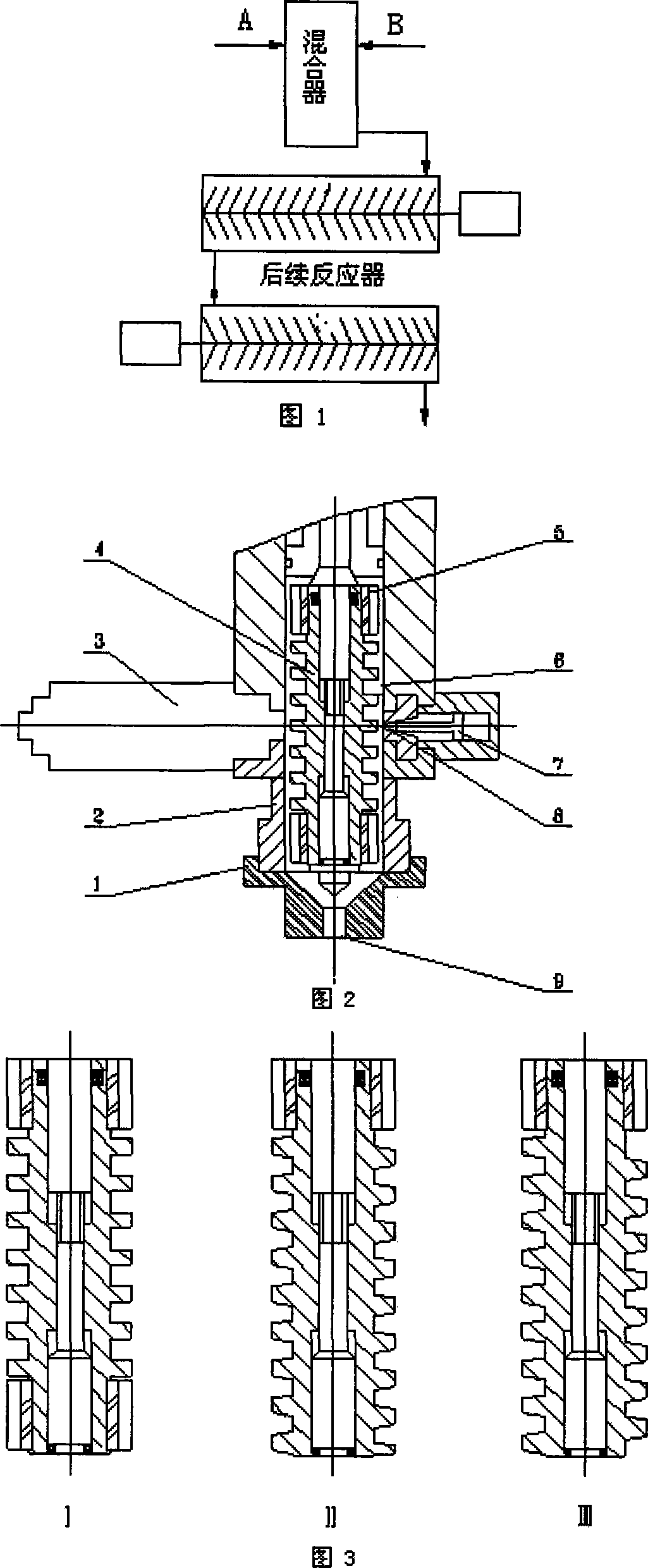

[0025] This example refers to the solvent NMP-CaCl 2 The process of producing poly-p-phenylene terephthalamide resin.

[0026] dissolved in NMP-CaCl 2 The solution containing 4.5% to 8% p-phenylenediamine in the solution is cooled to the required temperature, and part of the terephthaloyl chloride in the molten state (accounting for 20% to 50% of the total demand) is sprayed into the above mixer (stirring The rod structure is type II), and the uniformly mixed mixture enters the prepolymer reactor in a short time (not higher than 1 second), and the prepolymer A solution generated after reacting for a certain period of time, cools the prepolymer After reaching a certain temperature, spray into the above-mentioned mixer with the terephthaloyl chloride (80%~50%) in the molten state of the remaining part (stirring rod structure is type III), stir and mix violently at the middle position of the mixer, The resulting mixture enters the first polymerization reactor after staying in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com