A static air mixer

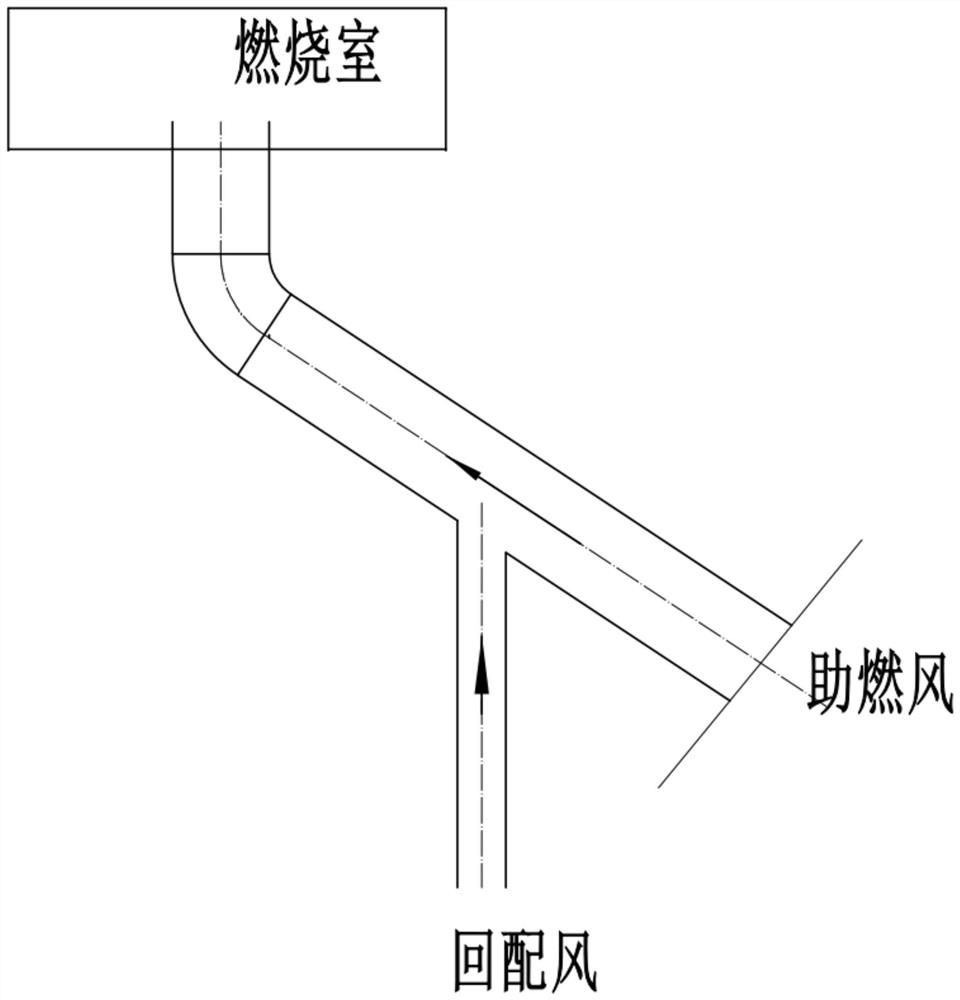

An air mixer, static technology, applied in the burner, gas fuel burner, combustion type and other directions, can solve the problems of reducing the effect of low nitrogen combustion, difficulty in effectively reducing NOx, and unevenness of the flow field of the return air flow, etc. Achieve the effect of improving the degree of mixing and homogeneity, maintaining complete and continuous mixing, and increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

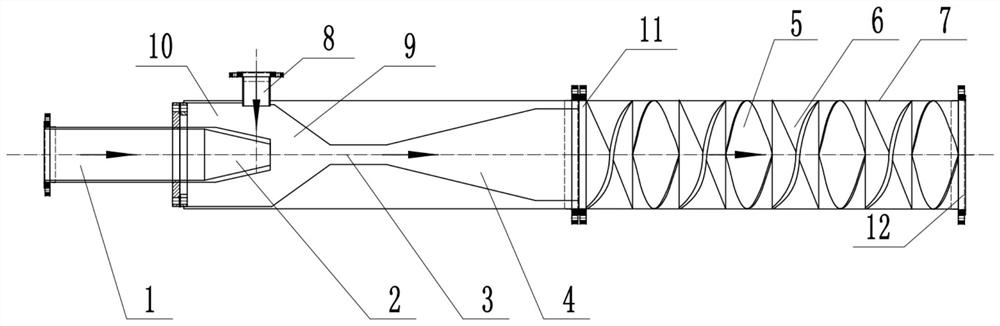

[0030] In a typical implementation of the present application, such as figure 2 As shown, a static air mixer is proposed.

[0031] It includes two parts, the main pipeline and the static air mixing structure 7. The main pipeline receives the combustion-supporting air and the return distribution air and performs preliminary mixing on the two. The gas is fully mixed and discharged; the main pipe and the static air mixing structure are connected through the butt joint flange 11 at the end, and the end of the static air mixing structure away from the main pipe is connected to the follow-up equipment through the flange 12 , input the mixed gas to the subsequent equipment.

[0032] Specifically, such as figure 2 , along the direction of air flow, the left end of the main pipeline is closed by flange connection, the flange cover cooperates with the main pipeline to form a receiving chamber, the receiving chamber communicates with the mixing chamber, and then forms a Venturi struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com