Static mixer

A technology of static mixer and mixing unit, applied in the direction of fluid mixer, mixer, chemical instrument and method, etc., can solve the problems of general mixing ability and inability to meet the requirements of fluid mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

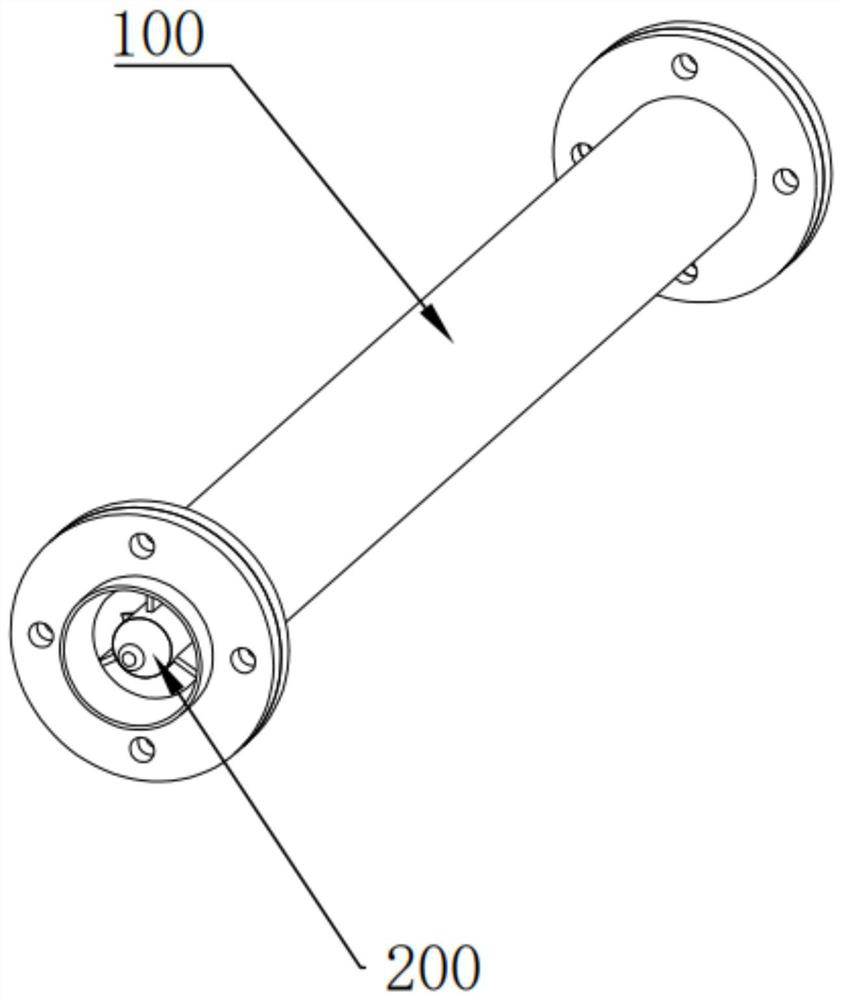

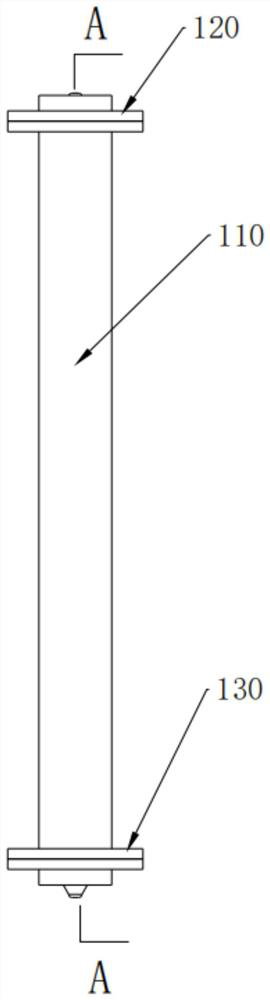

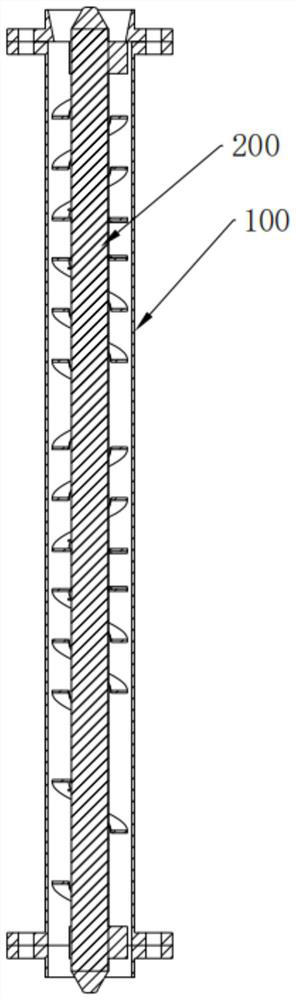

[0035] A static mixer such as Figure 1-7 As shown, it includes a housing 100, a mixing unit 200 arranged in the housing 100, the mixing unit 200 includes a guide column 210, at least one single helical twisted piece 220 arranged on the guide column 210 in sequence along the fluid flow direction and At least two sets of double helical strands 230 . The static mixer proposed in this embodiment can slow down the impact force of the entering fluid through the design of the single helical twisted piece 220, so that it can enter the double helical twisted piece 230 smoothly and stably for mixing. The design of the double-helical strand 230 increases the effect of fluid turbulence, and improves the mixing rate and uniformity of the fluid.

[0036] Specifically, the double helical twisted piece 230 is composed of two helical twisted pieces in the same direction. The starting positions of the two helical twisted pieces are different and the starting positions of the two helical twist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com