Liquid-solid mixer

A technology for mixers and solid materials, which is applied to mixers, mixing methods, mixers with rotating stirring devices, etc., can solve the problems of inconvenient use and high manufacturing costs, and achieve continuous mixing, low manufacturing costs, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

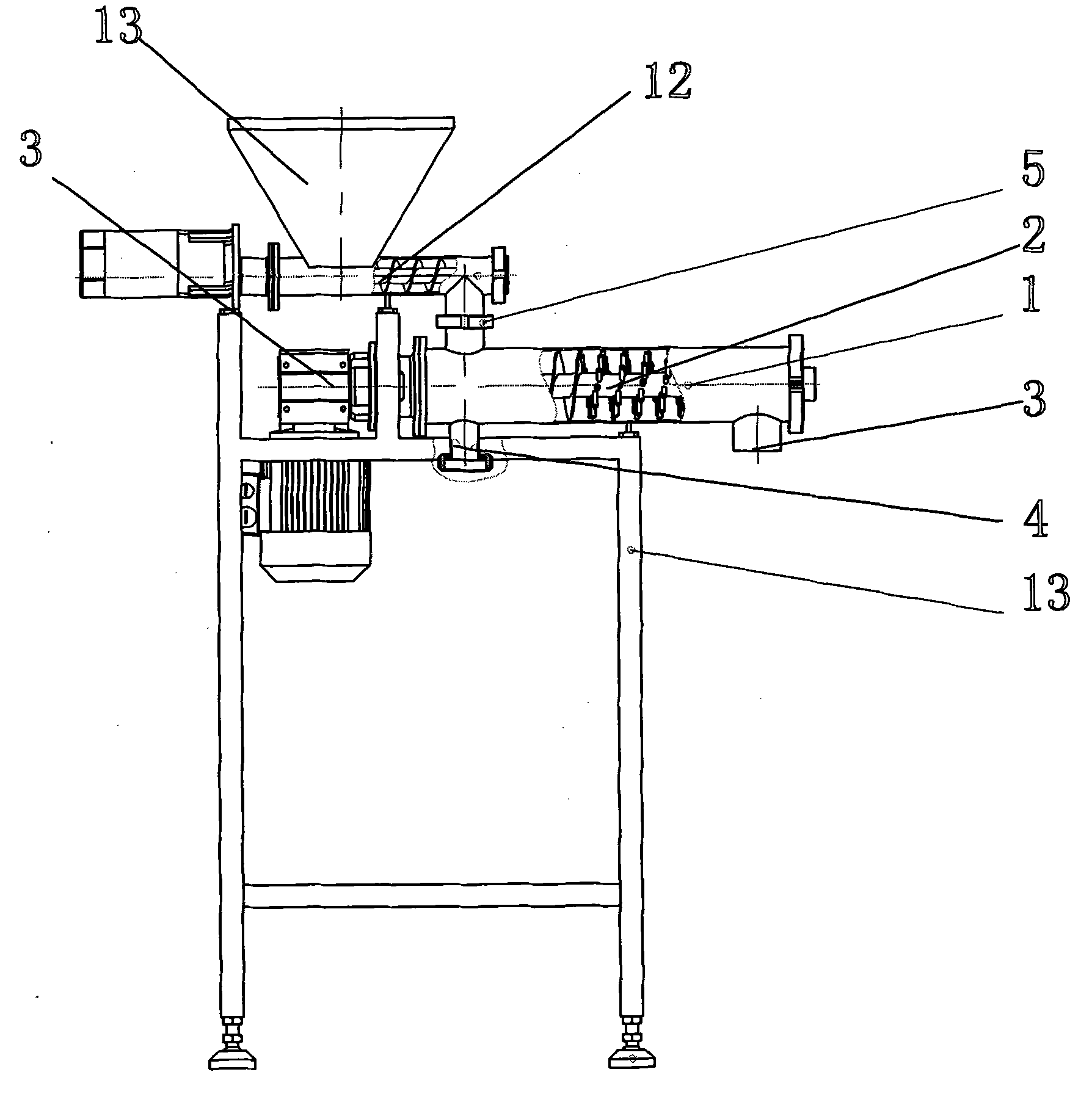

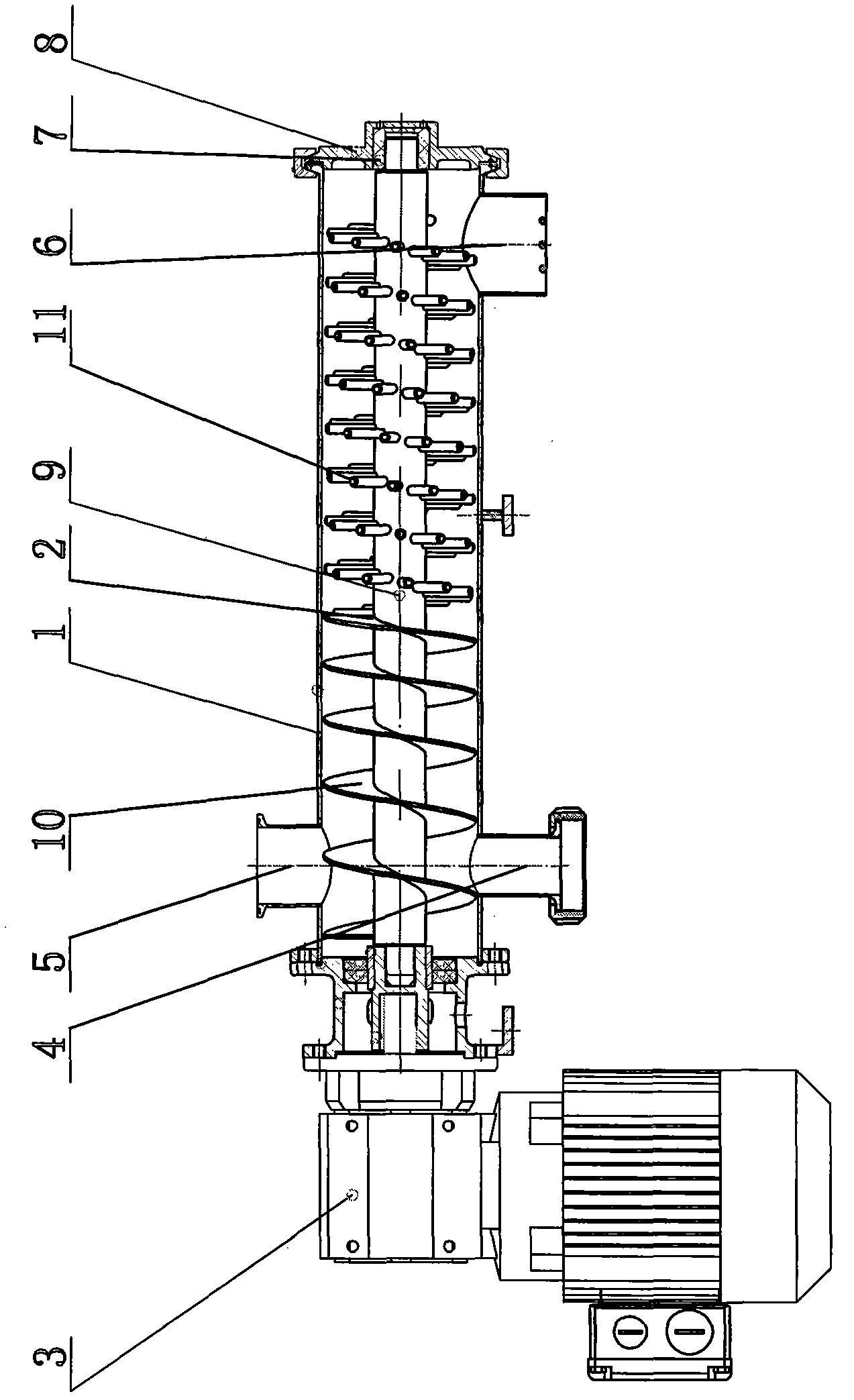

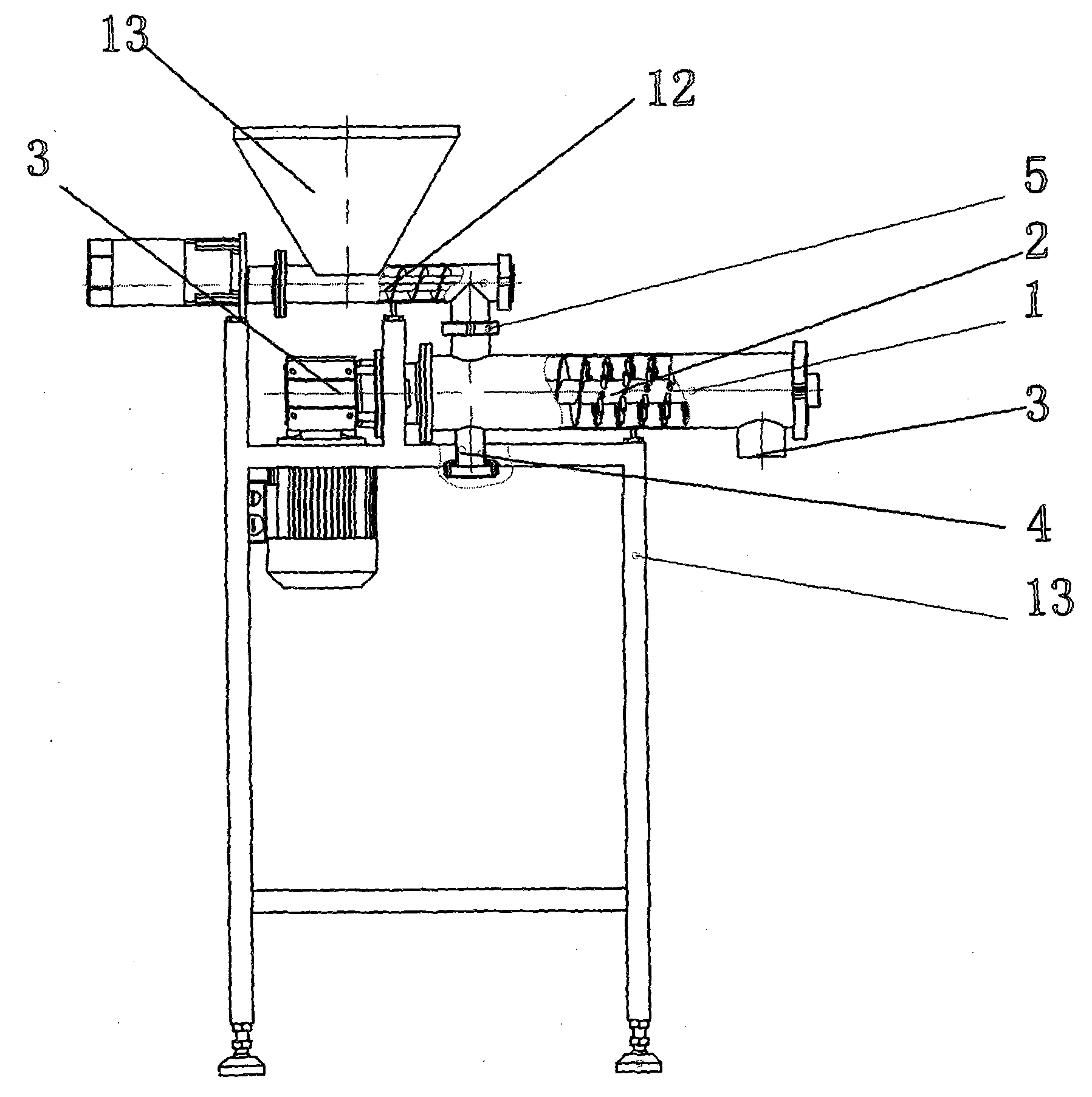

[0010] As shown in the figure, the present invention includes a sleeve 1 arranged on a frame 13, an agitator member 2 arranged in the sleeve 1, a power unit 3 arranged at the front end of the sleeve 1 to drive the agitator member 2 to rotate, the sleeve A liquid material inlet 4 and a solid material inlet 5 are arranged on the front side wall of the barrel 1, a mixed material outlet 6 is arranged on the rear end side wall of the sleeve 1, and an end cover with a bearing 7 is arranged on the rear end surface of the sleeve 1 8. The agitator member 2 includes a rotating shaft 9, a conveying thread 10 arranged at the front section of the rotating shaft 9, a stirring rod 11 arranged on the peripheral surface of the rotating shaft at the rear section of the rotating shaft 9, and the rear end of the rotating shaft 9 is fixed on the bearing 7 of the end cover 8.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com