Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Compact and beautiful appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

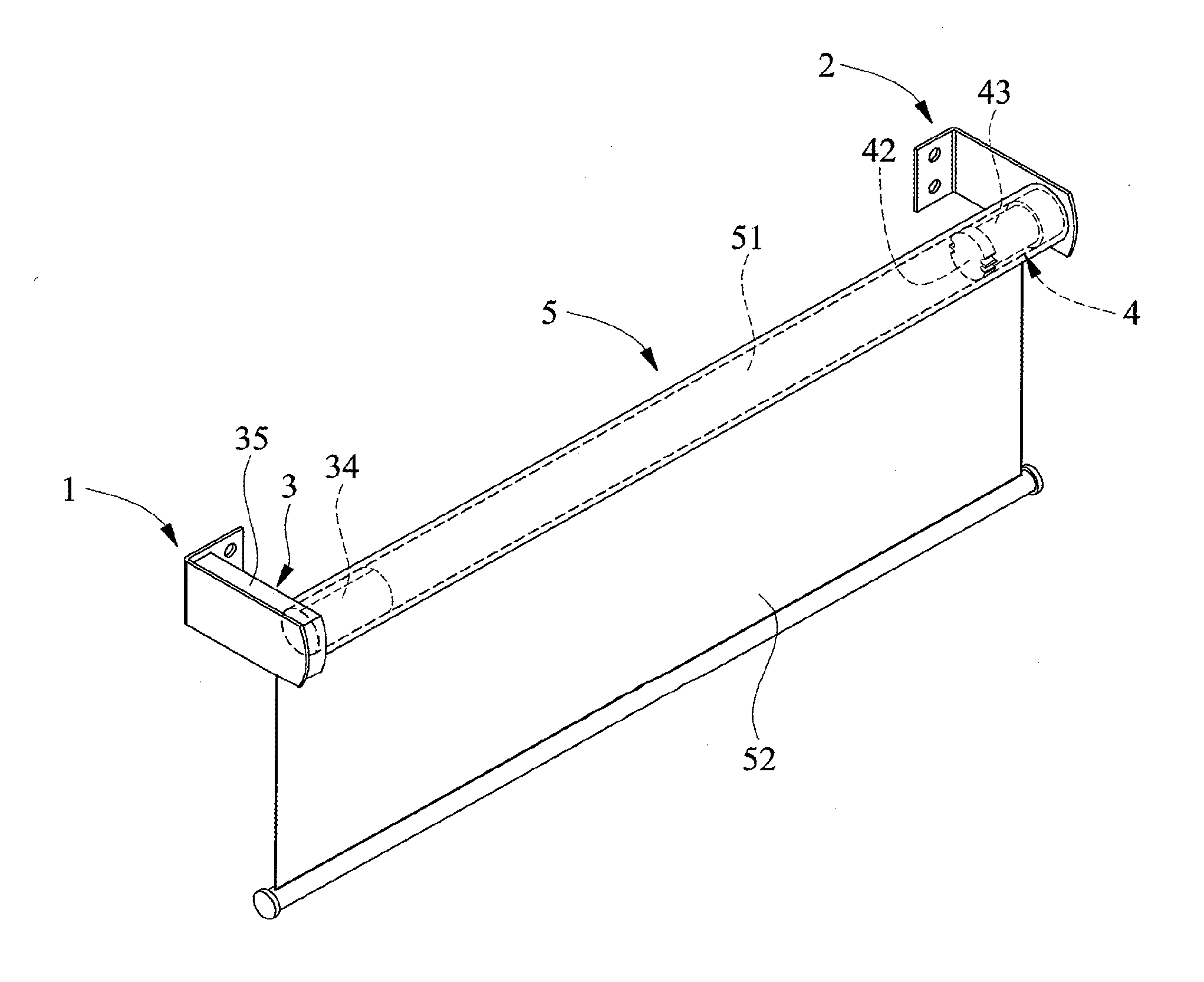

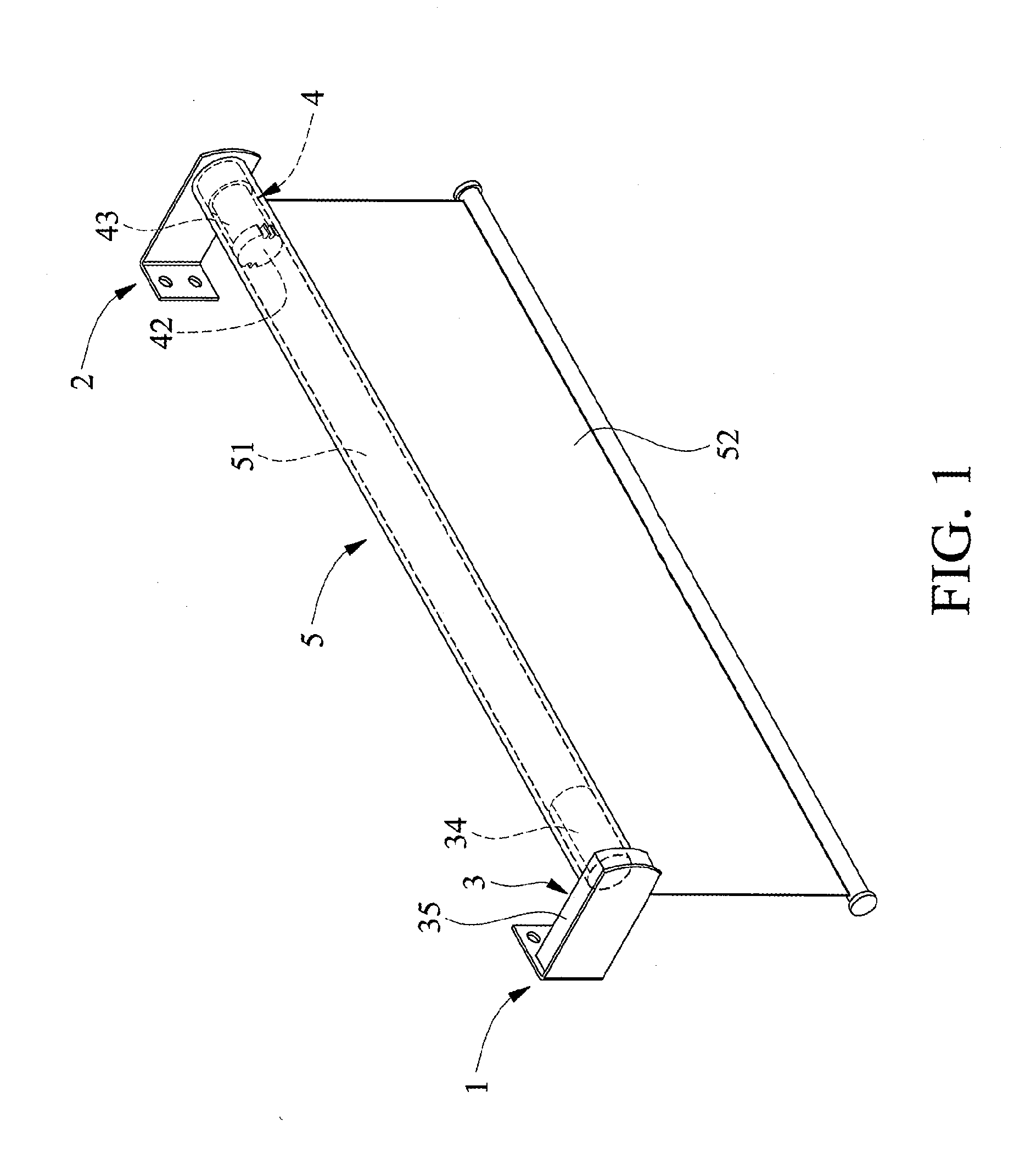

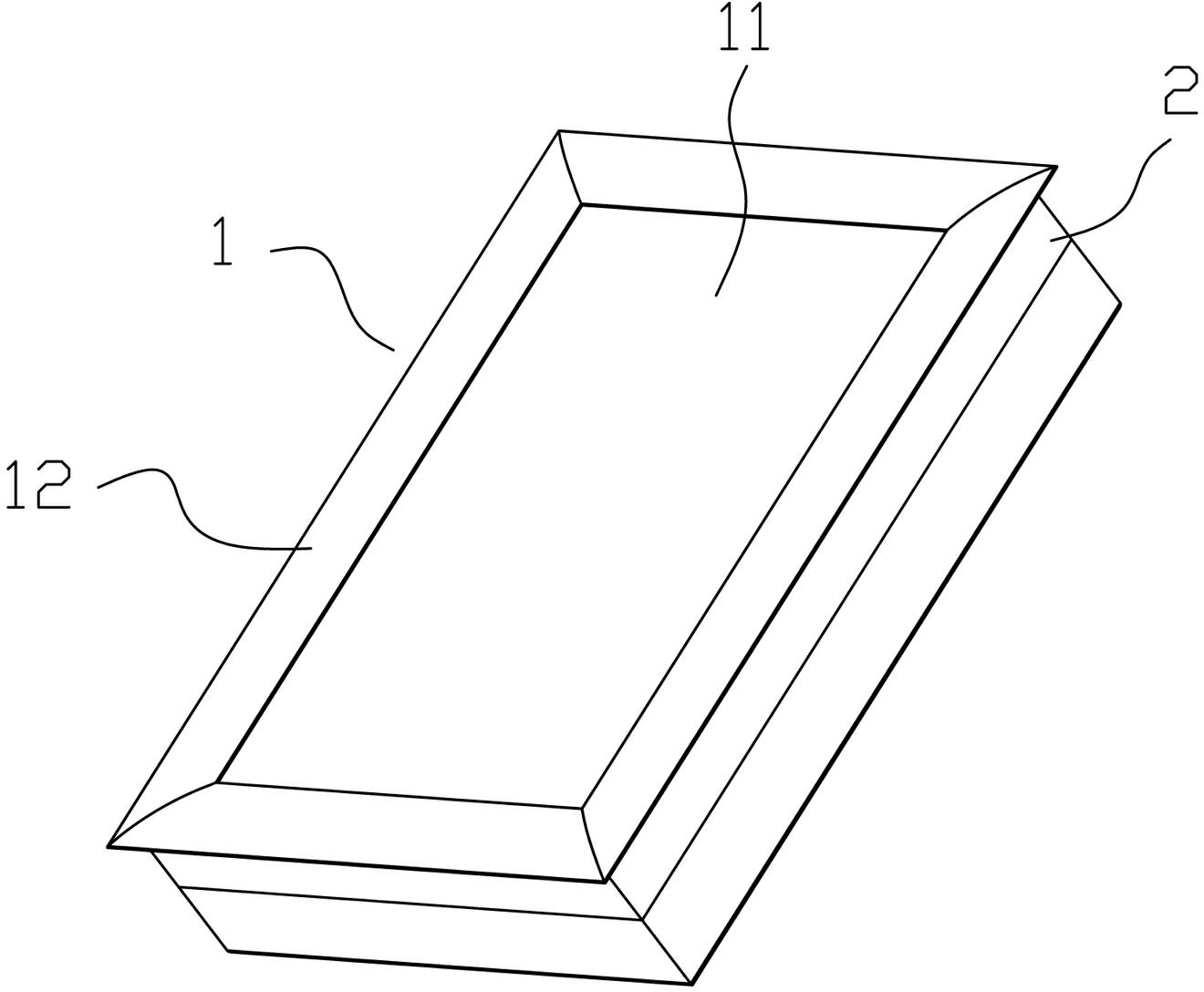

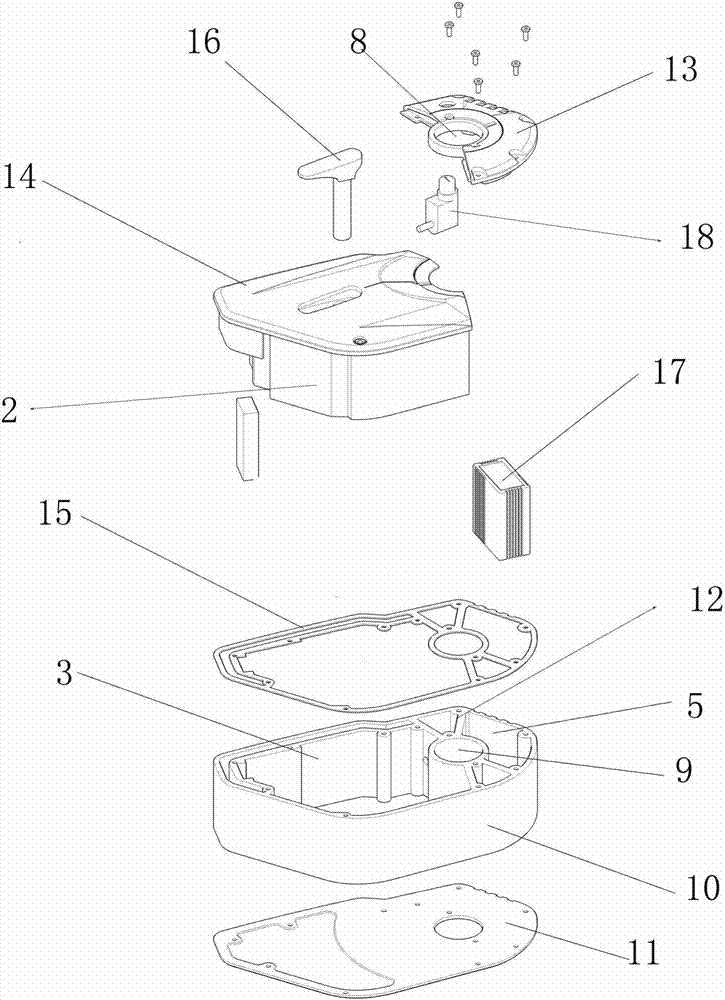

Automatic roller shade

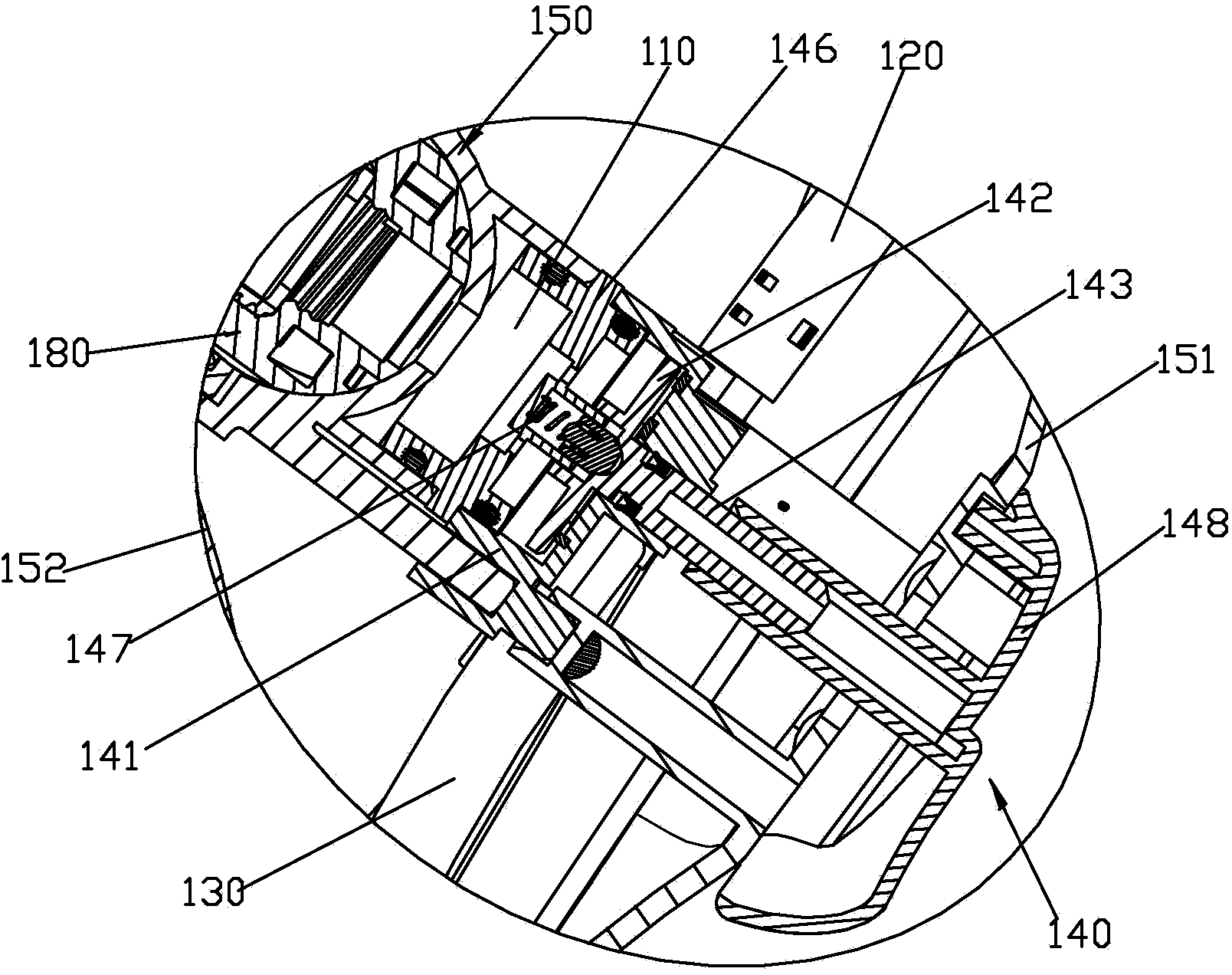

An automatic roller shade includes a shade body rotatably mounted to between a first and a second mounting bracket; a stop mechanism mounted in an end of a roller of the shade body; and a driving mechanism mounted in another opposite end of the roller. The stop mechanism includes a winding element connected to the roller and a spiral spring element having an end connected to the winding element. The spiral spring element enables a balance between a force for lifting or winding a shade fabric of the shade and the gravitational force lowering or unwinding the shade fabric. The driving mechanism at the other end of the roller can adopt a micro motor as a power source and the micro motor can be invisibly located inside the roller, enabling the automatic roller shade to have reduced power consumption and manufacturing cost while having a compact and esthetic appearance.

Owner:CHICOLOGY

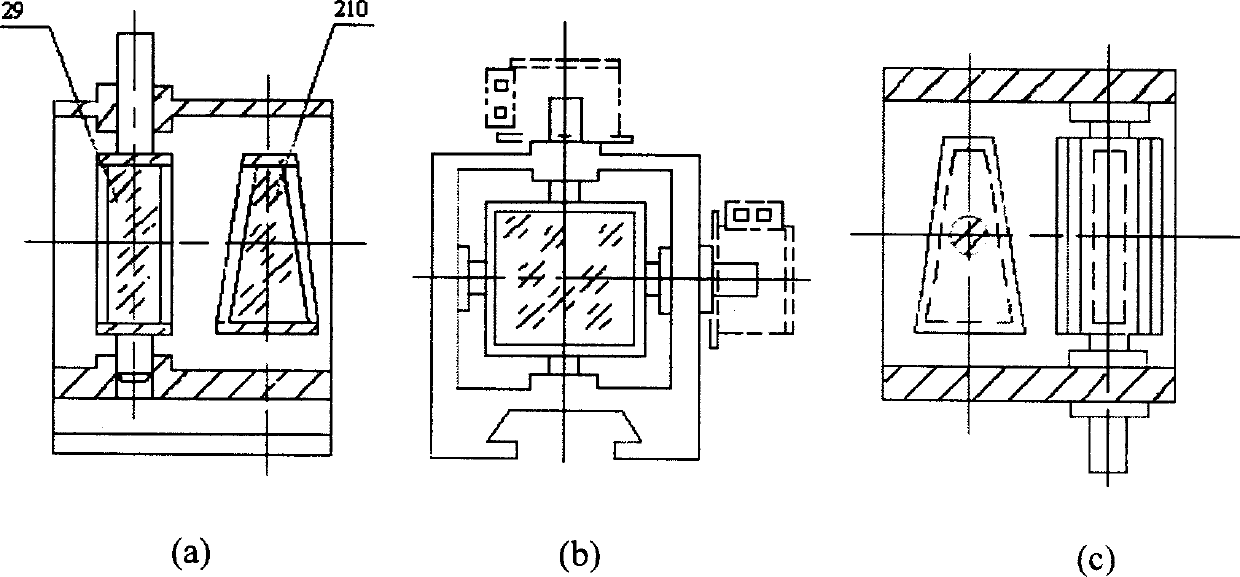

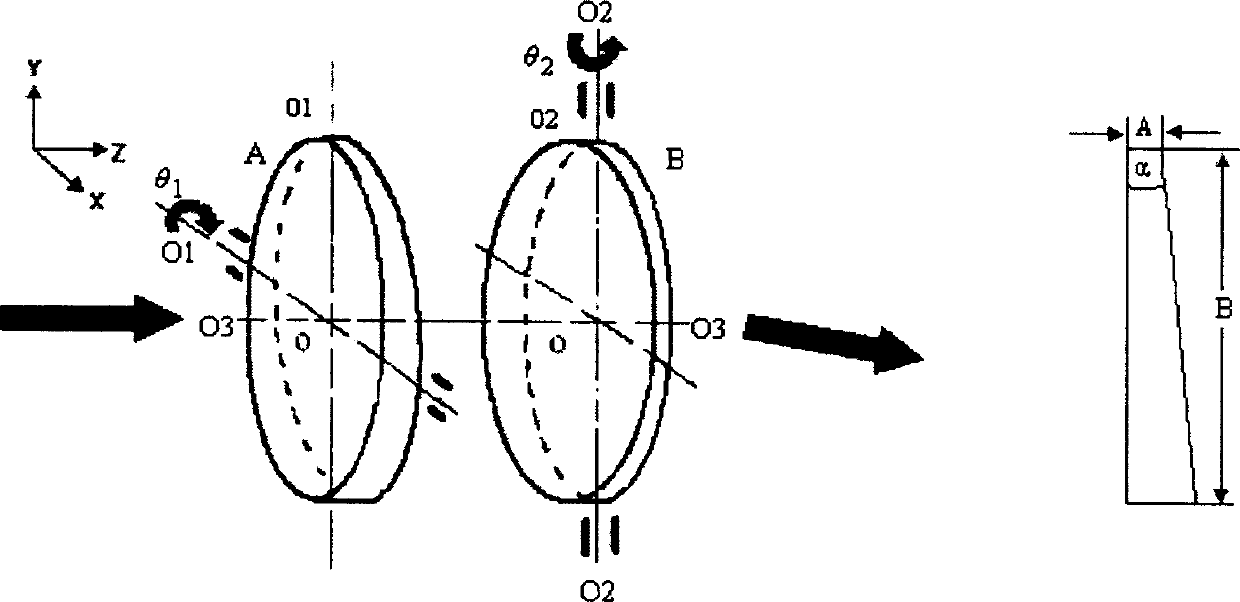

Light-beam offset mechanic apparatus with double light wedges

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

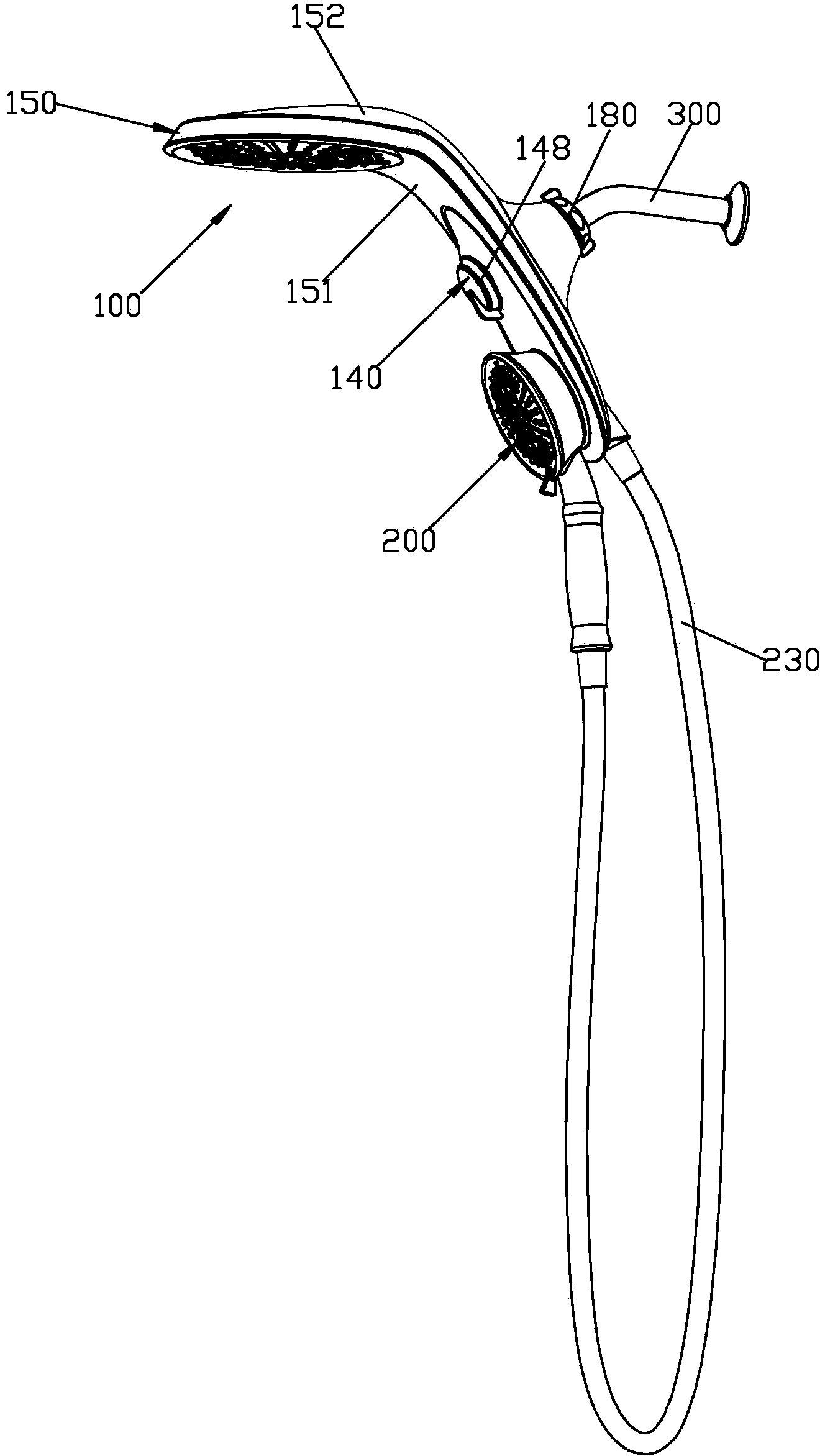

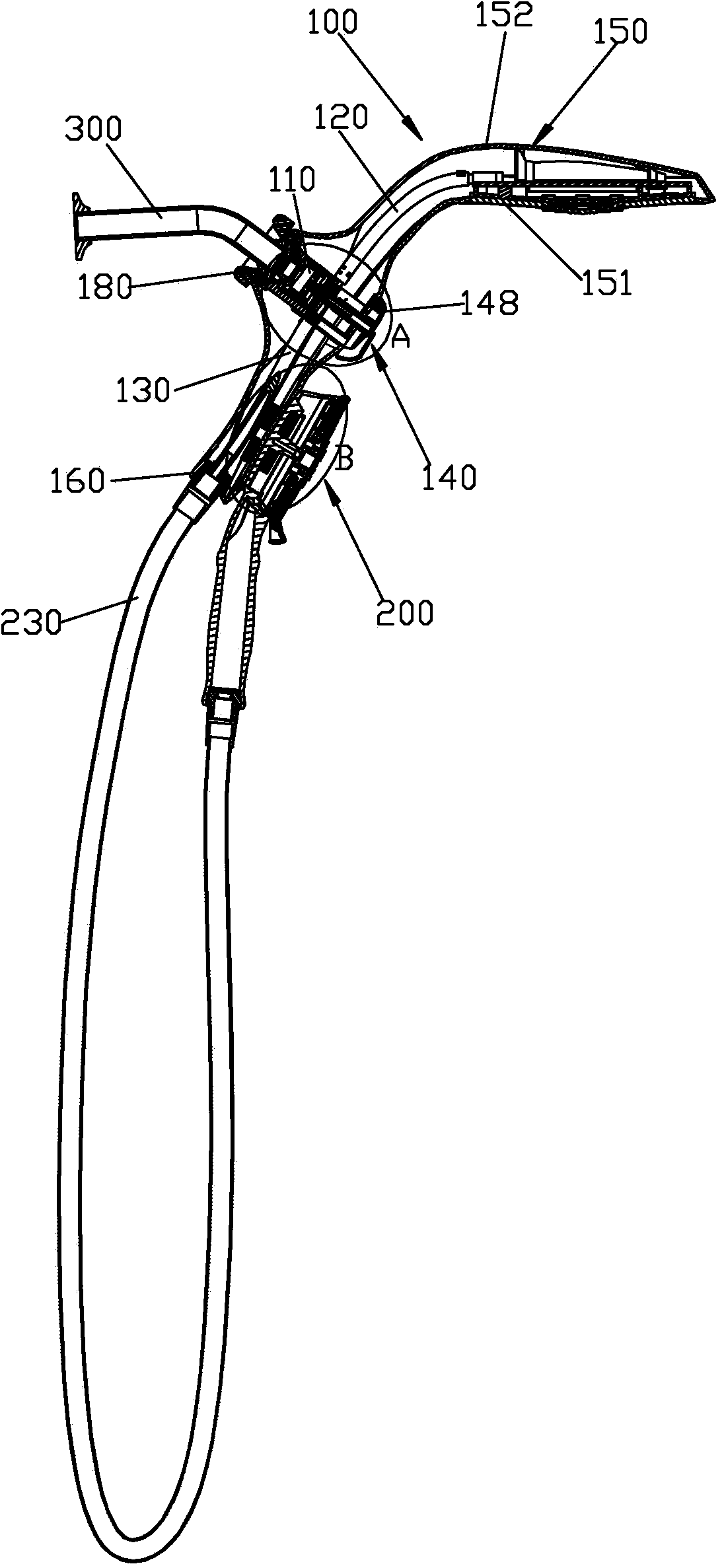

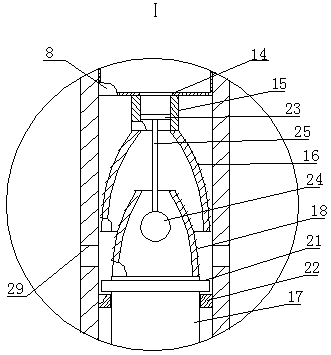

Shower system with combination of overhead shower and handheld shower

The invention discloses a shower system with combination of an overhead shower and a handheld shower. The shower system comprises the overhead shower which can spray water in at least two ways and the handheld shower. The overhead shower is provided with a water inlet passage communicated with a water supply source and a first water distributing passage in one-to-one correspondence with each way of water spray. The overhead shower is further provided with a second water distributing passage. The handheld shower is communicated with the second water distributing passage through an outer hose. A switching mechanism is disposed at the overhead shower. Water passage switching can be achieved by the switching mechanism in coordination with the water inlet passage, the first water distributing passage and the second water distributing passage. The optional water distributing passage can be selected to be communicated with the water inlet passage through water passage switching. The shower system has the advantages that water spray ways of the overhead shower can be selected through the switching mechanism, overall cost is lowered greatly, and the shower system is convenient and fast in switching, simple in overall structure, and outstanding in style.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

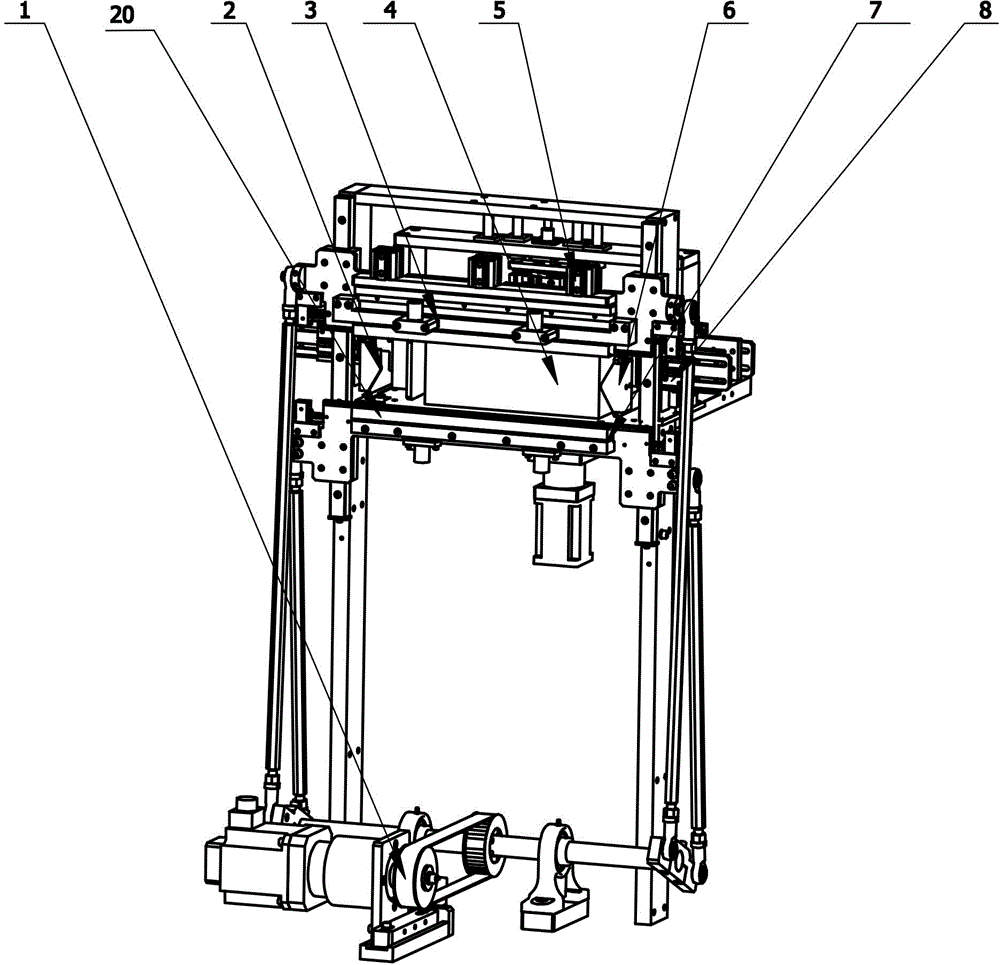

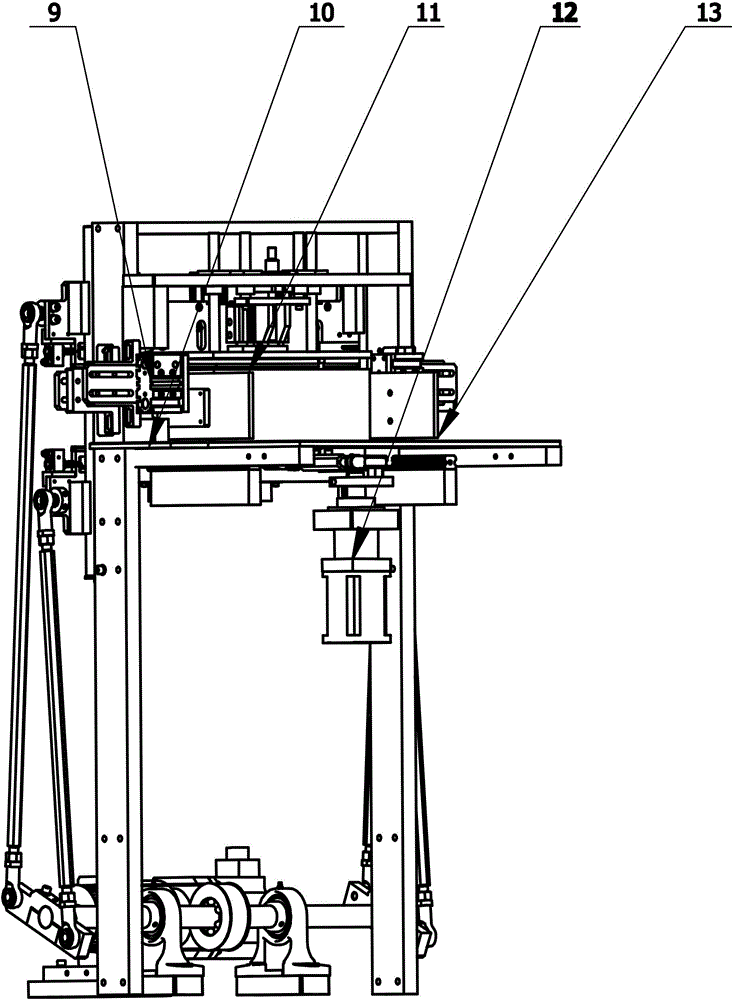

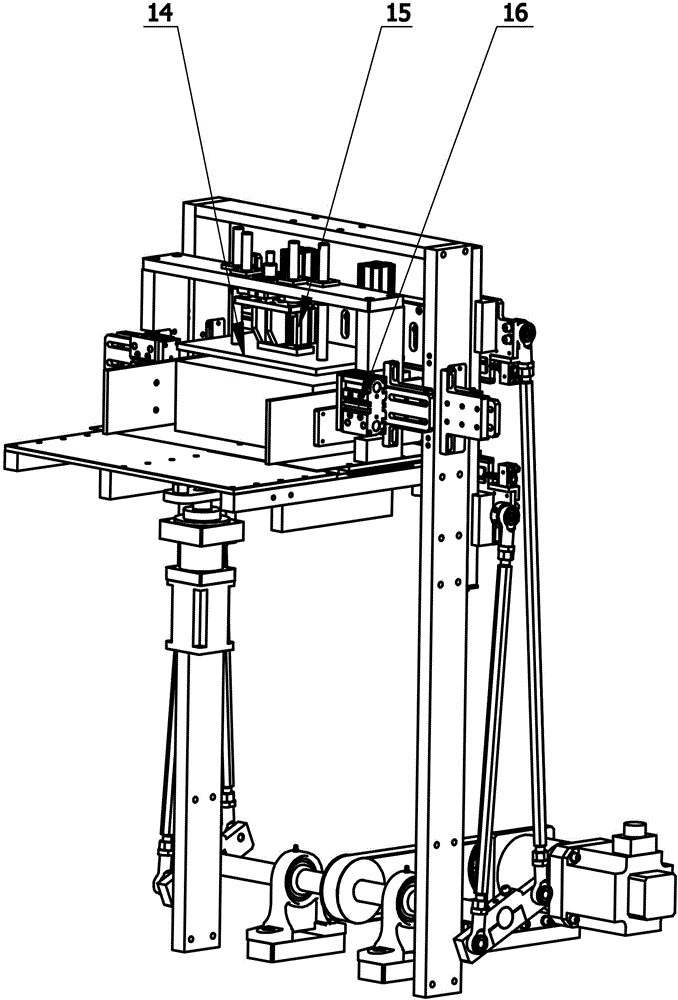

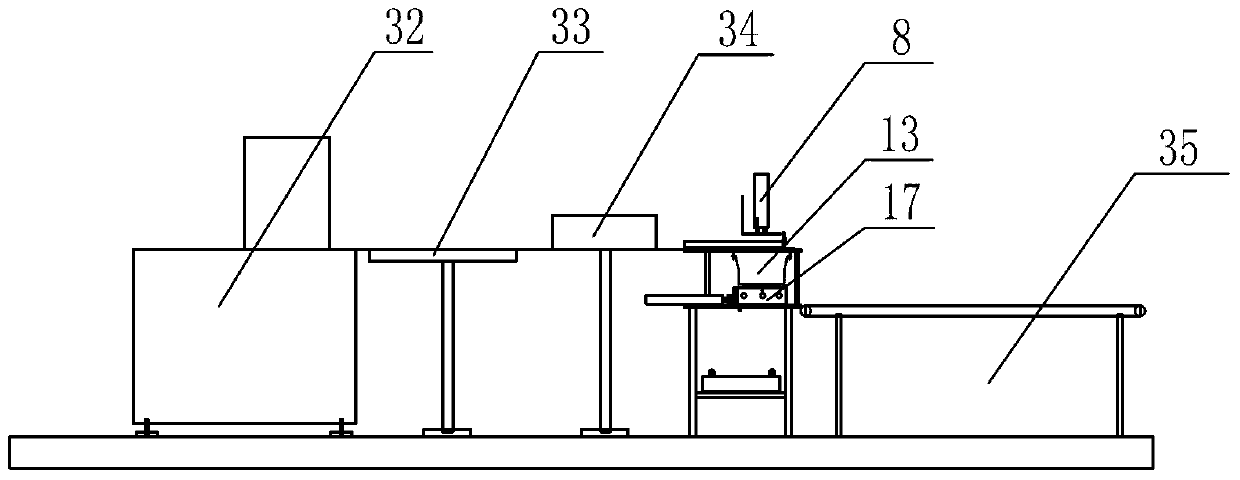

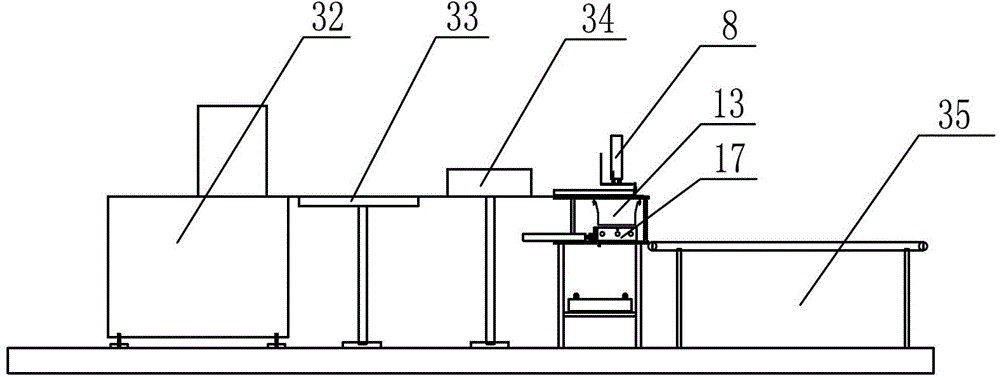

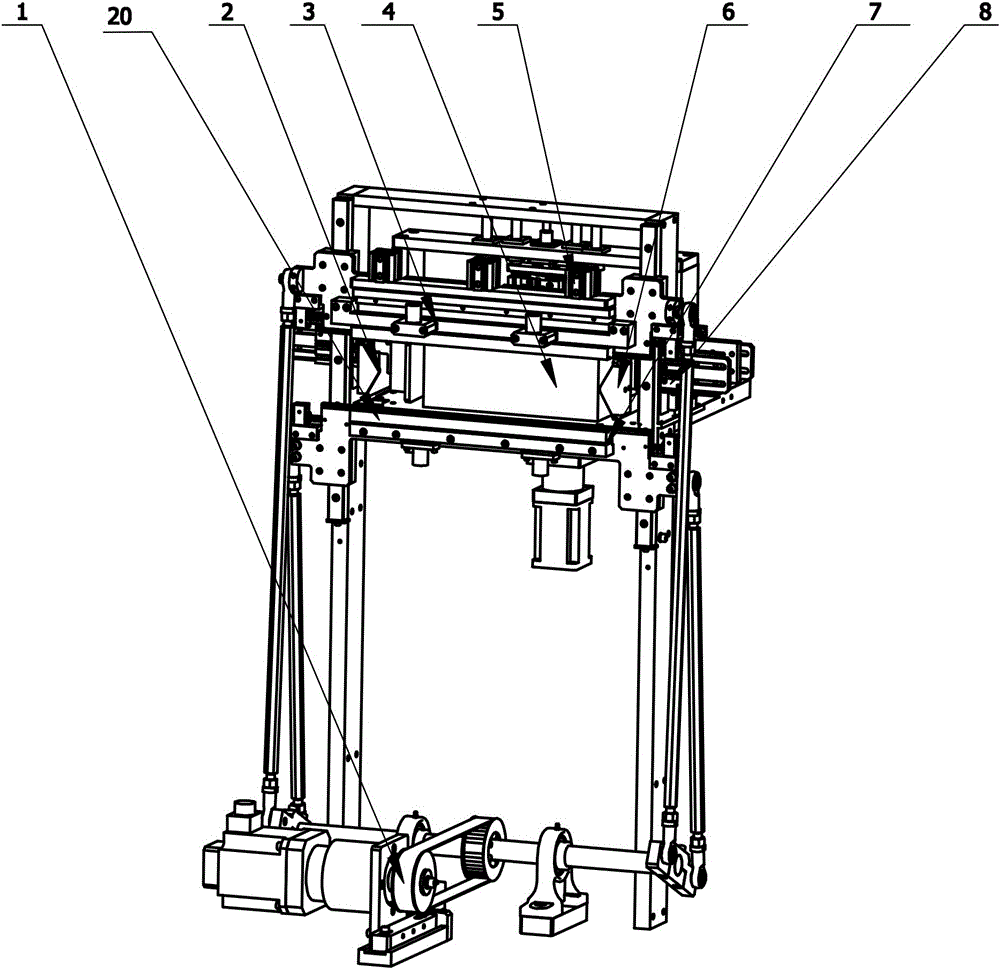

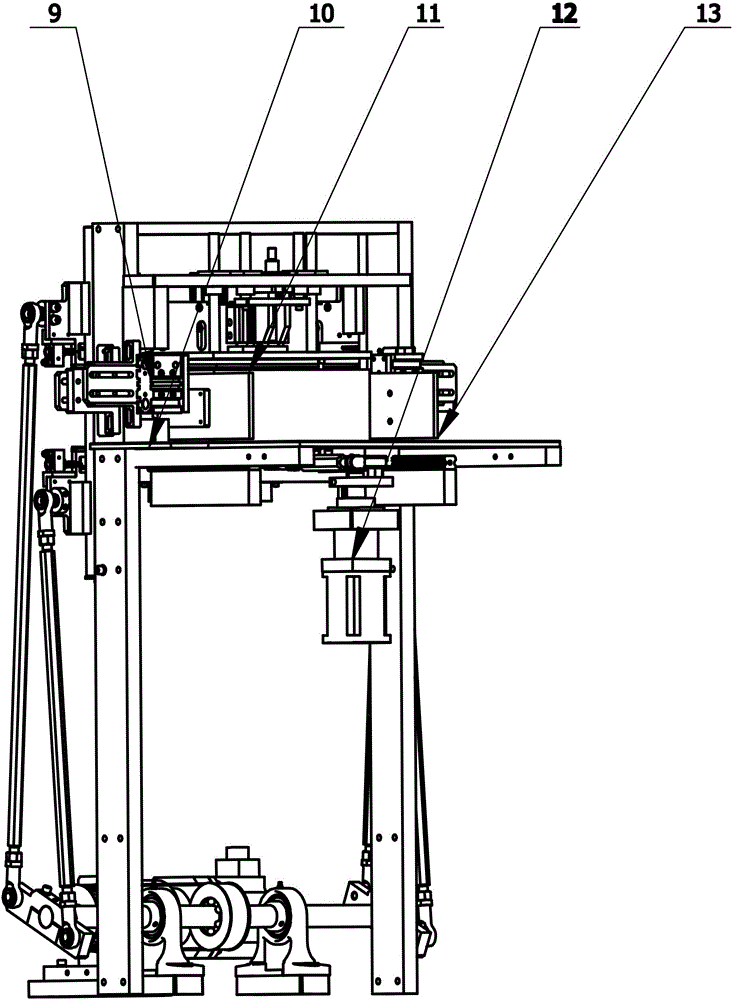

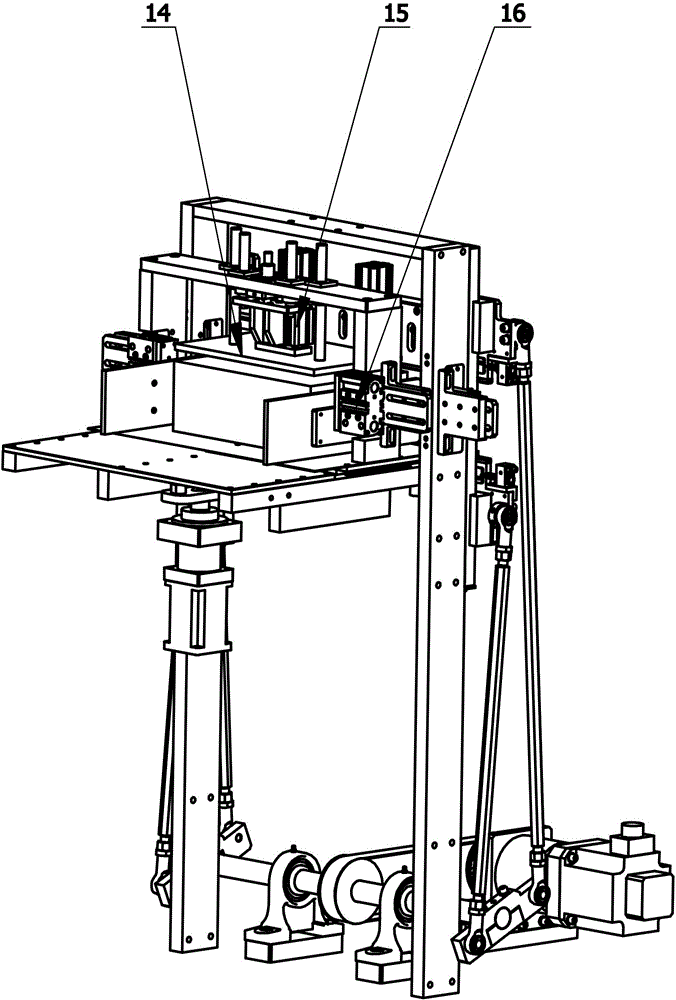

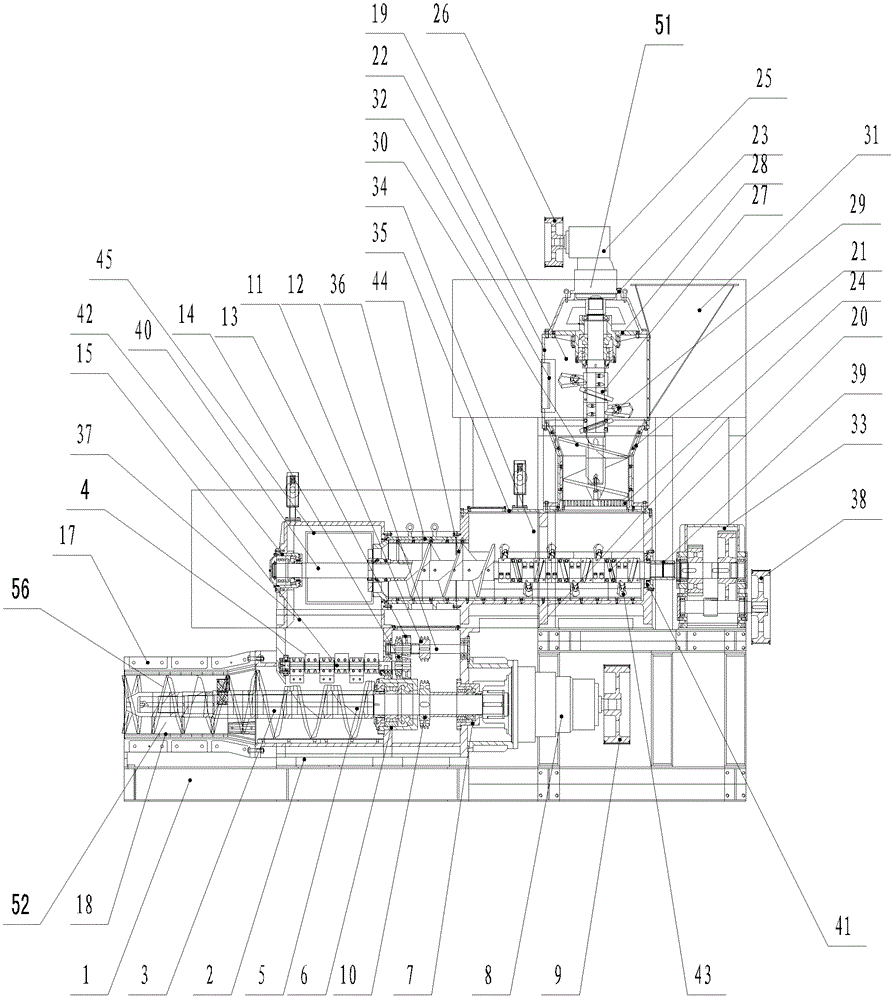

Novel packaging equipment and novel packaging method

ActiveCN104058136ACompact and beautiful appearanceFirm and beautiful shapeWrapper folding/bending apparatusWrapper twisting/gatheringPack materialMechanical engineering

Owner:XIAMEN GACHN TECH

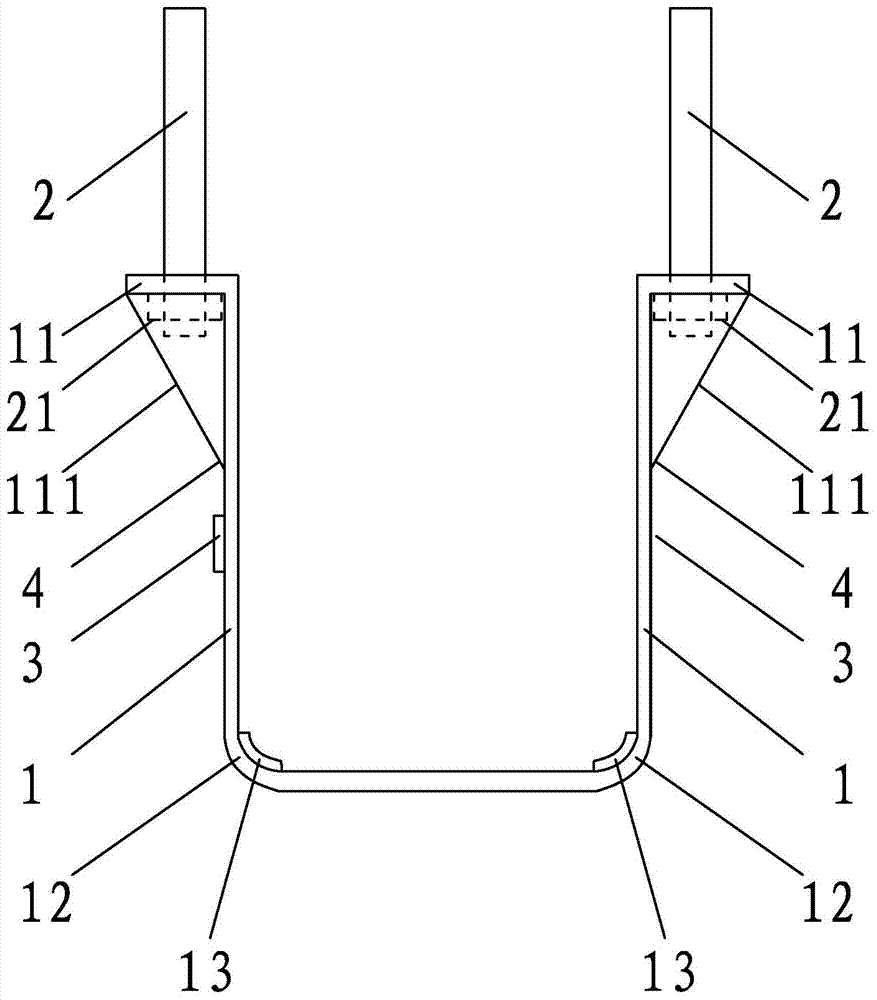

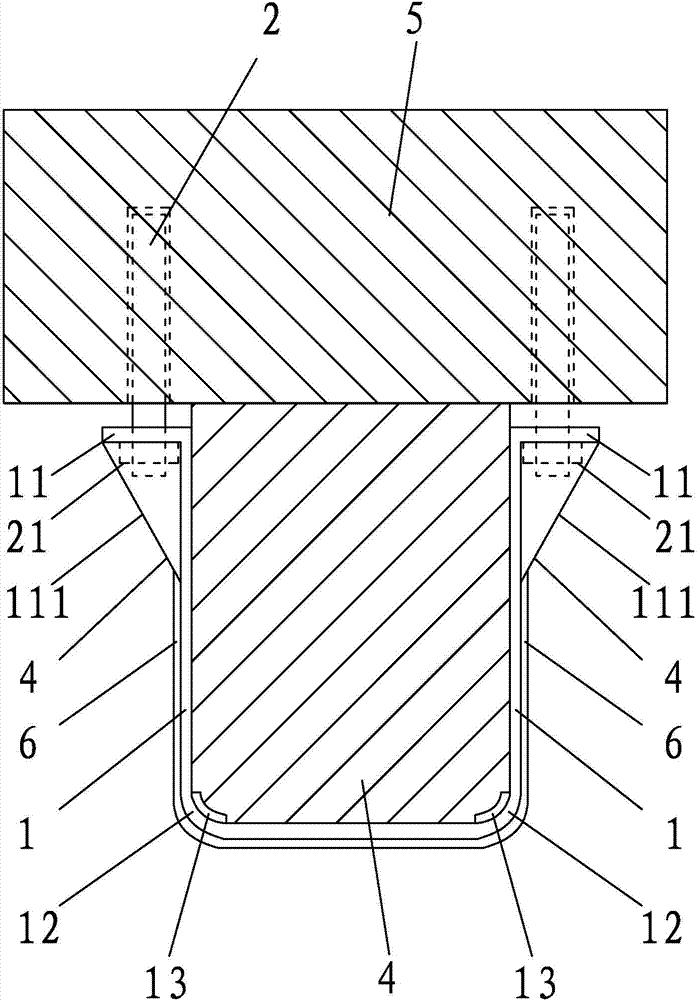

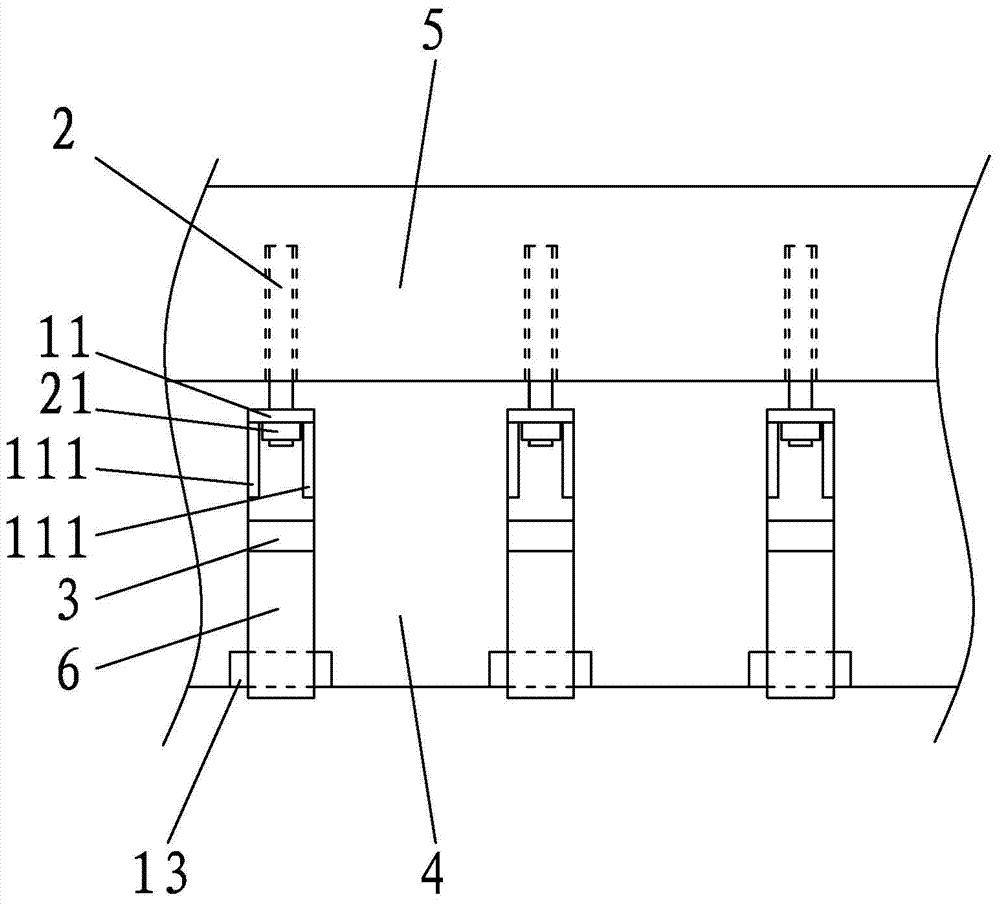

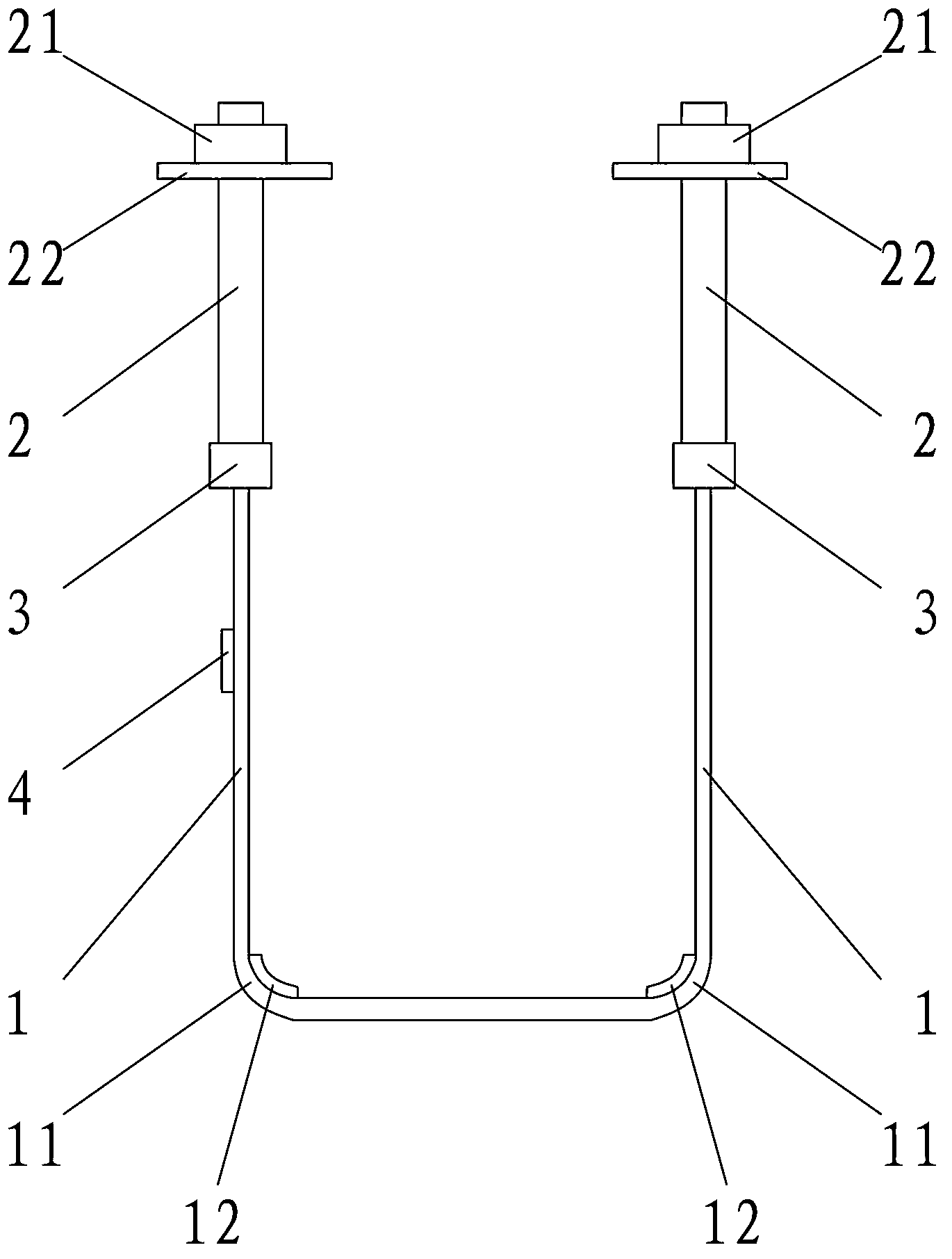

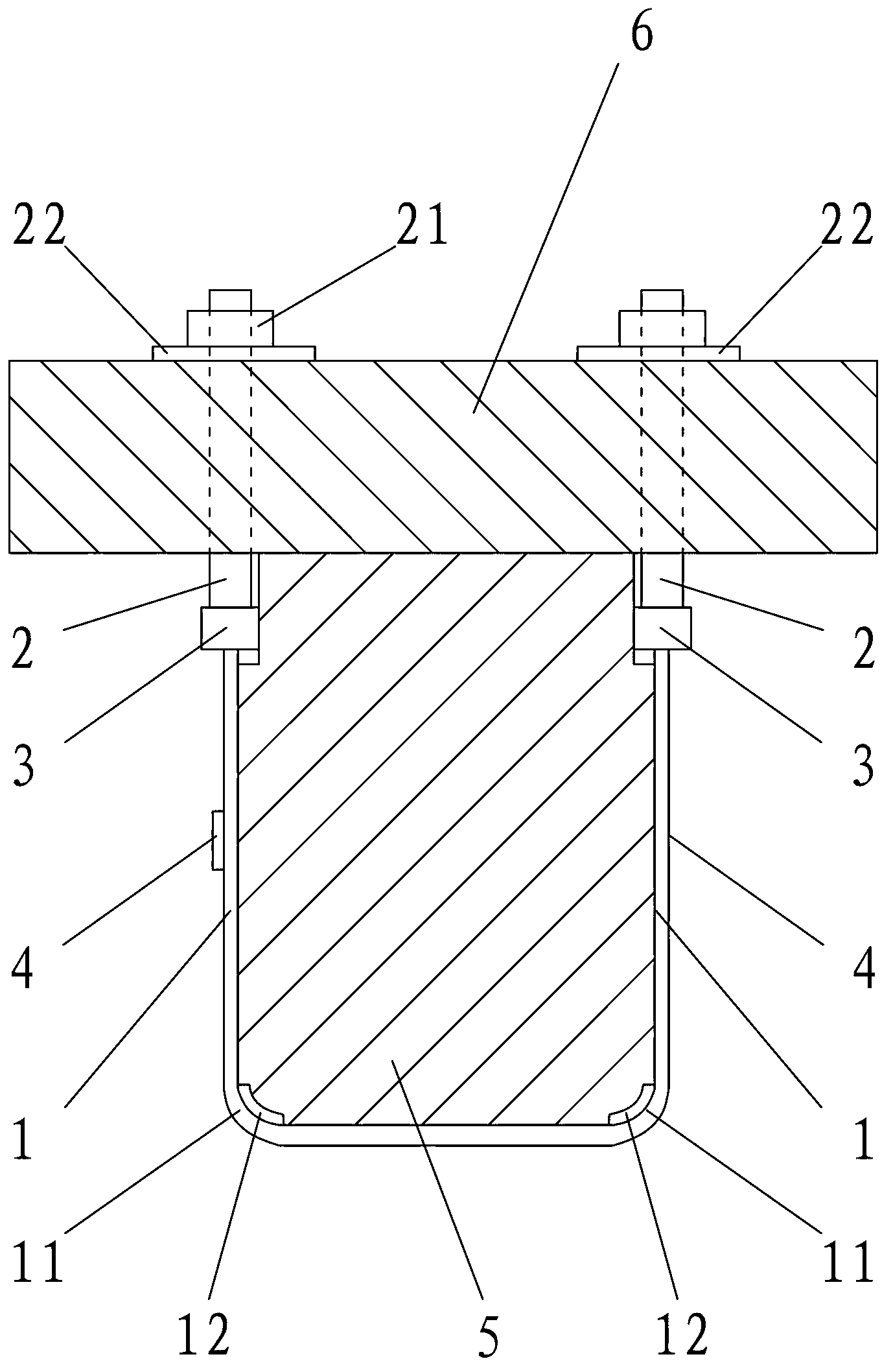

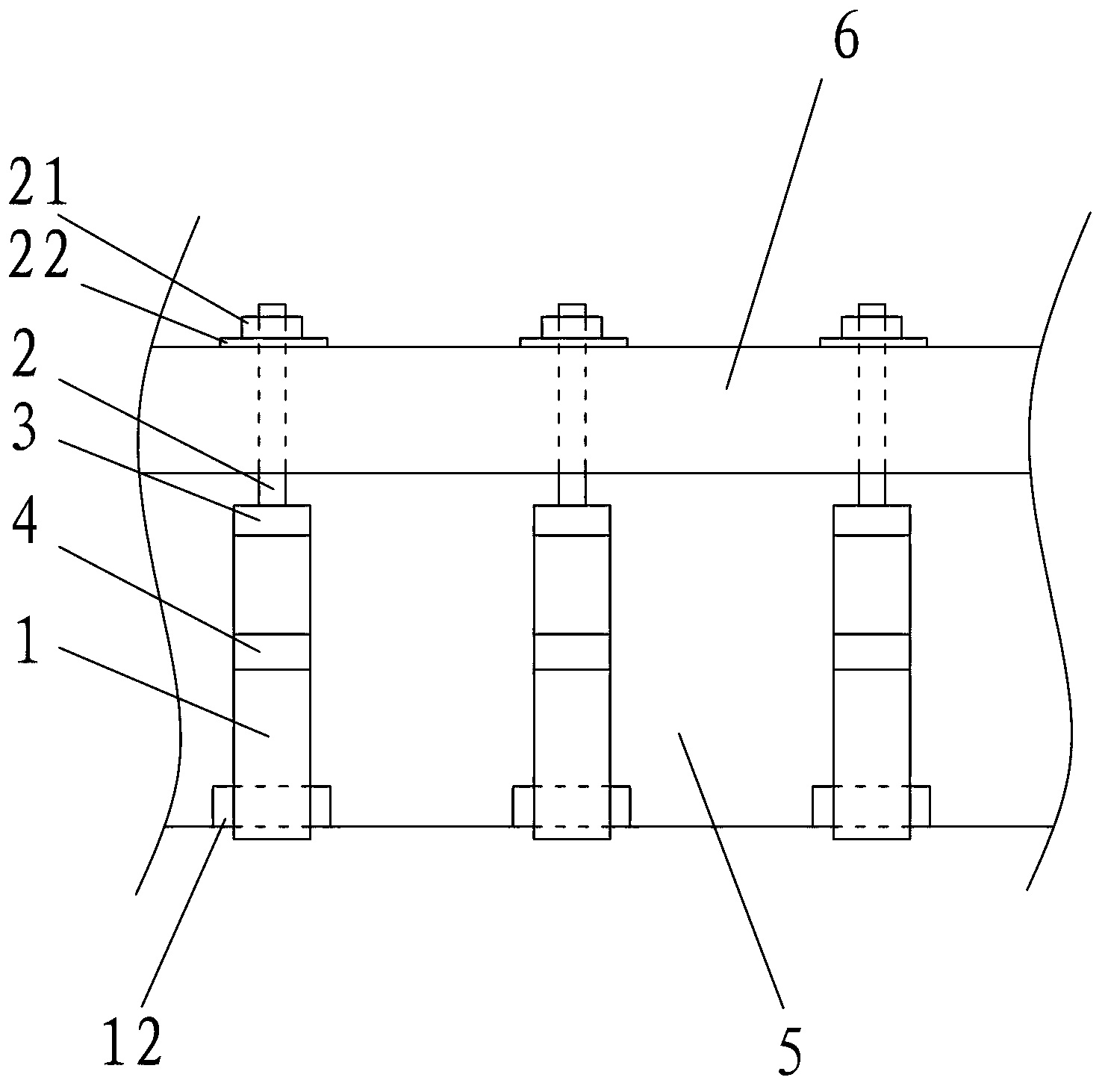

Method for constructing fastening device of reinforced concrete girder and floor slab

InactiveCN104847129AIncreased shear strengthAvoid Stress Hysteresis EffectsBuilding repairsHysteresisFloor slab

The invention provides a novel reinforcement device for a reinforced concrete beam and a floor slab, which comprises an U-shaped steel hoop part tightening the reinforced concrete beam from bottom to top, and two bolt parts respectively penetrating the floor slab to be fixedly connected with two ends of the steel hoop part, wherein nuts of the bolt parts, which are screwed on the bolt parts, are positioned above the floor slab. Due to the adoption of the technical scheme, the reinforced concrete beam and the floor slab are pre-tightened and locked together through matching of the steel hoop parts and the bolt parts. Compared with the prior art, stress hysteresis effect caused by a traditional reinforcement device can be effectively avoided, the anchoring validity is maintained, the reinforcement effect is effectively ensured, and the shear strength of the reinforced concrete beam is improved. Moreover, the structure is easy to realize, the appearance is compact and beautiful, and the comprehensive practicability is strong. The invention further provides a construction method of the novel reinforcement device, the steps are concise and clear, and the implementation efficiency of the novel reinforcement device can be effectively improved.

Owner:HUAQIAO UNIVERSITY +1

Novel reinforcement device for reinforced concrete beam and floor slab and construction method thereof

InactiveCN103306214AIncreased shear strengthAvoid Stress Hysteresis EffectsBuilding repairsBridge erection/assemblyHysteresisFloor slab

The invention provides a novel reinforcement device for a reinforced concrete beam and a floor slab, which comprises an U-shaped steel hoop part tightening the reinforced concrete beam from bottom to top, and two bolt parts respectively penetrating the floor slab to be fixedly connected with two ends of the steel hoop part, wherein nuts of the bolt parts, which are screwed on the bolt parts, are positioned above the floor slab. Due to the adoption of the technical scheme, the reinforced concrete beam and the floor slab are pre-tightened and locked together through matching of the steel hoop parts and the bolt parts. Compared with the prior art, stress hysteresis effect caused by a traditional reinforcement device can be effectively avoided, the anchoring validity is maintained, the reinforcement effect is effectively ensured, and the shear strength of the reinforced concrete beam is improved. Moreover, the structure is easy to realize, the appearance is compact and beautiful, and the comprehensive practicability is strong. The invention further provides a construction method of the novel reinforcement device, the steps are concise and clear, and the implementation efficiency of the novel reinforcement device can be effectively improved.

Owner:HUAQIAO UNIVERSITY +1

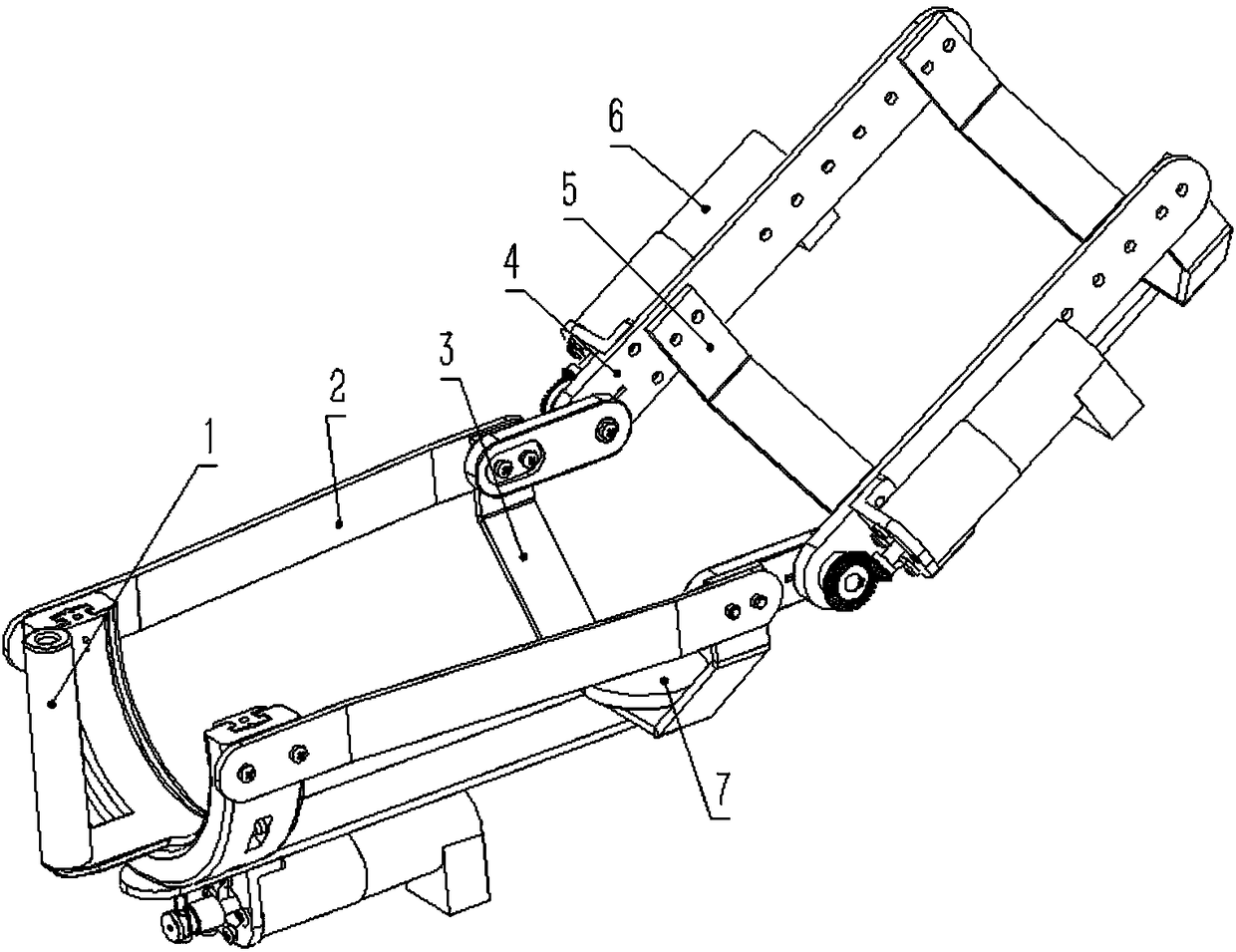

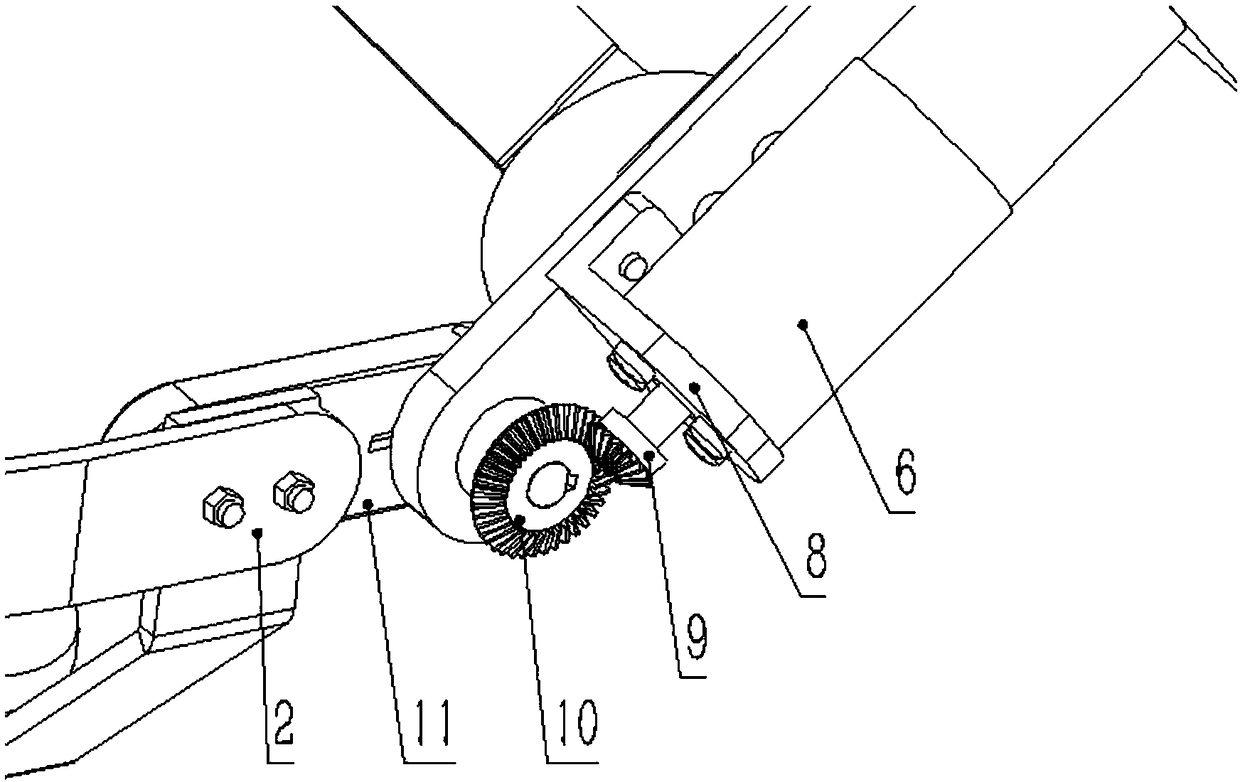

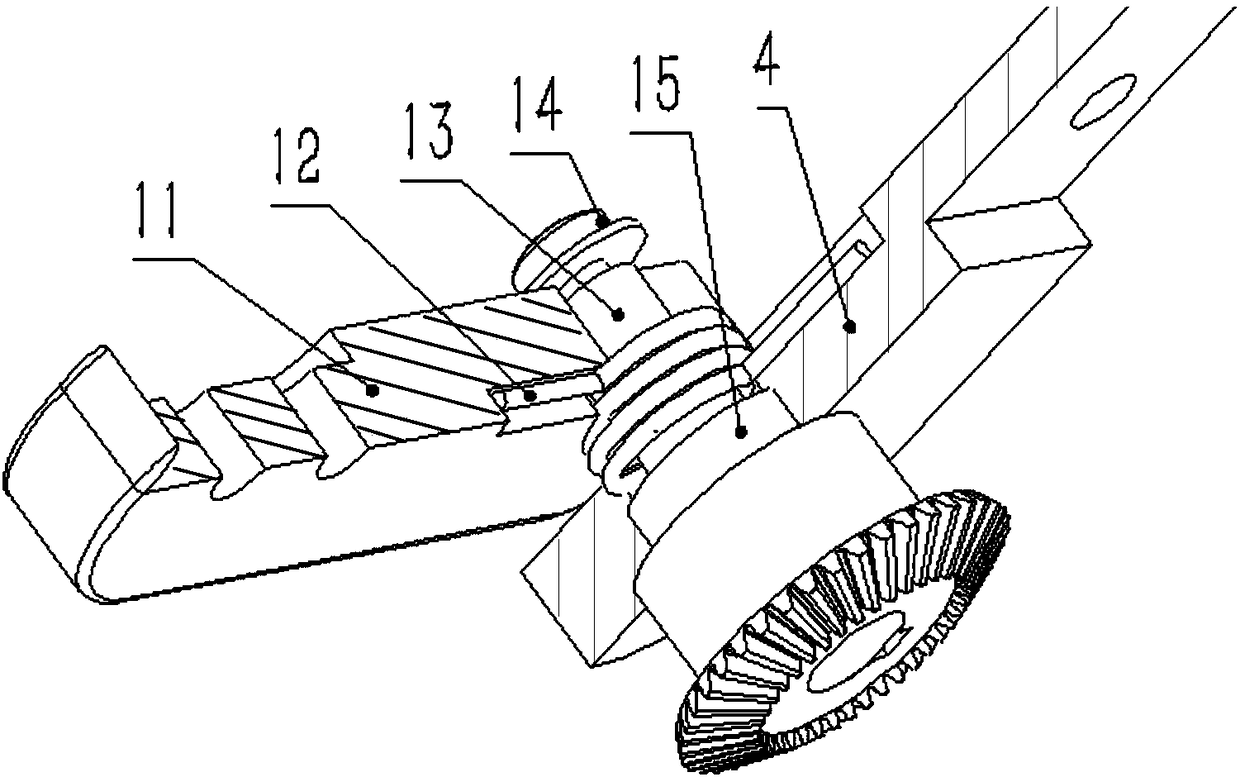

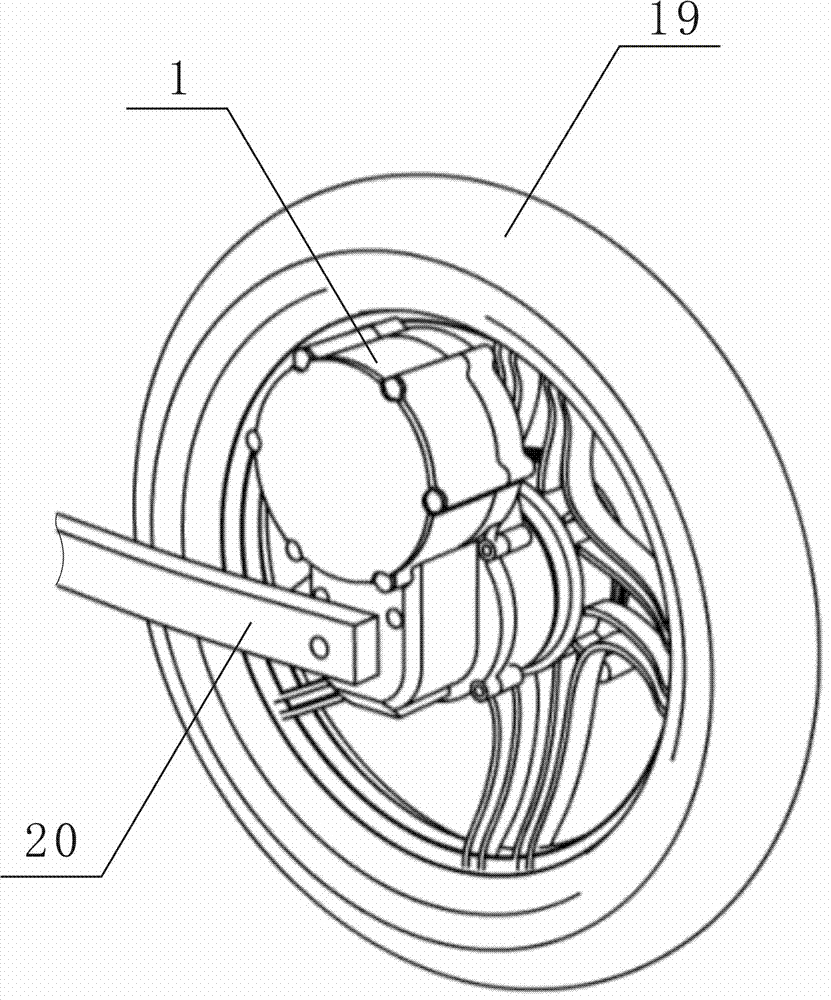

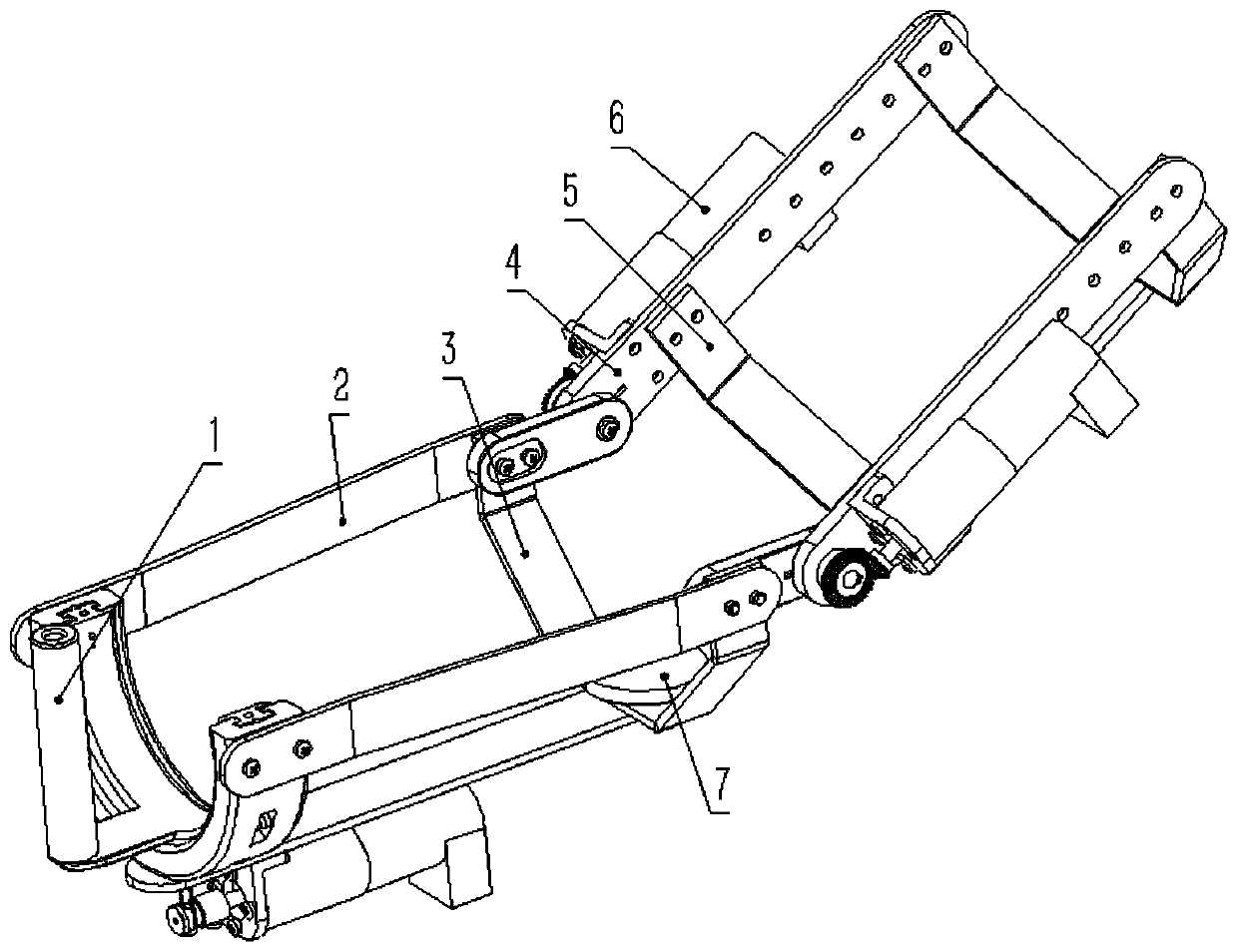

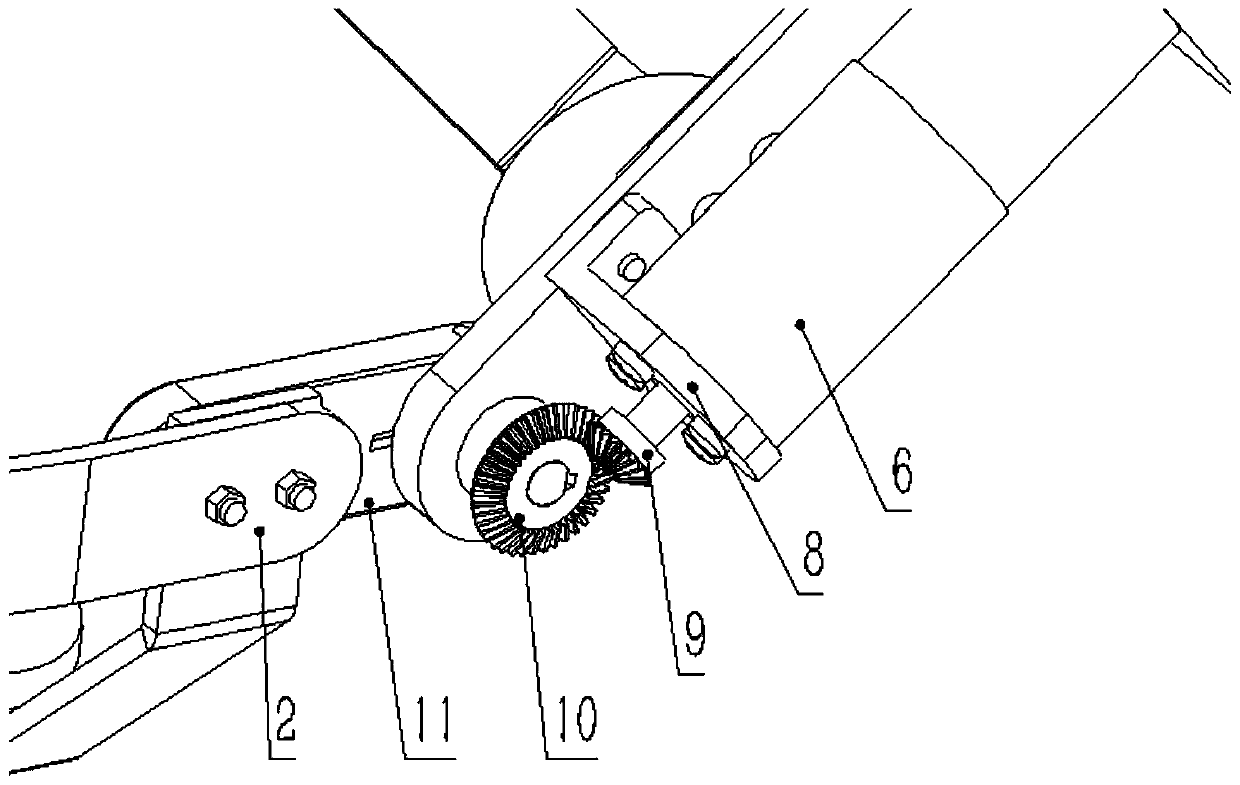

Wearable forearm active rehabilitation training exoskeleton device with myoelectric perception

ActiveCN108524192AEasy to wearGuaranteed experienceDiagnosticsChiropractic devicesPattern perceptionDrive motor

The invention requests protection of a wearable forearm active rehabilitation training exoskeleton device with myoelectric perception and belongs to robot field. The wearable forearm active rehabilitation training exoskeleton device consists of an exoskeleton support, a forearm rotation mechanism, an elbow flexion-extension mechanism, a driving motor and a myoelectric signal acquisition device, and can achieve the active rehabilitation training with two degrees of freedom for elbow flexion-extension and arm rotation. A large forearm support is easier to wear with a semi-open structure, and themyoelectric signal acquisition device is embedded in a key position of lining to collect arm myoelectric signals during the process of the rehabilitation training, and then motor movements of each joint can be adjusted according to the muscle tension, improving the security and efficiency of training. The forearm rotation mechanism adopts two sets of motor-bevel gear transmission, achieving forearm flexion-extension movements through synchronous coordinated movements of two motors. The forearm rotation mechanism adopts the driving mode of wire, and the forearm rotation angle is 180 degrees. The wearable forearm active rehabilitation training exoskeleton device with the myoelectric perception is more convenient, safer and more effective in rehabilitation training and can be widely used inhospitals, communities and families.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

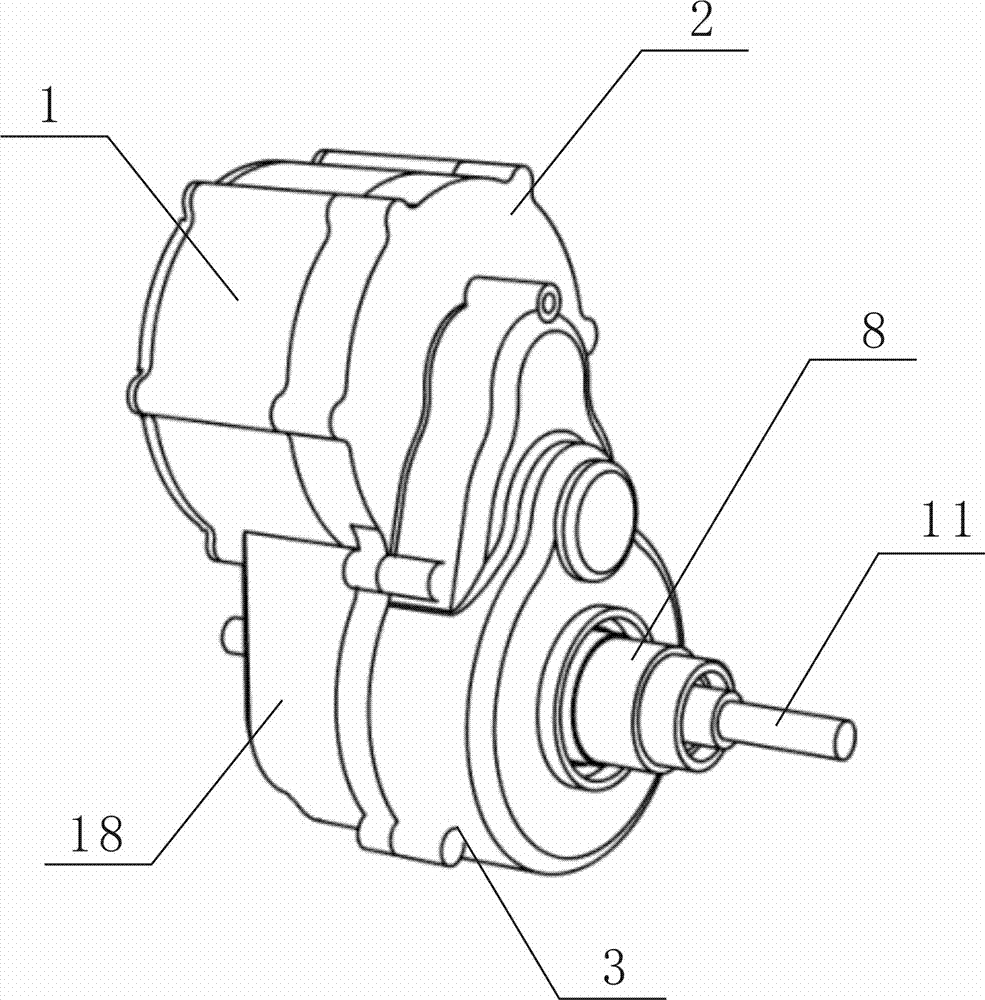

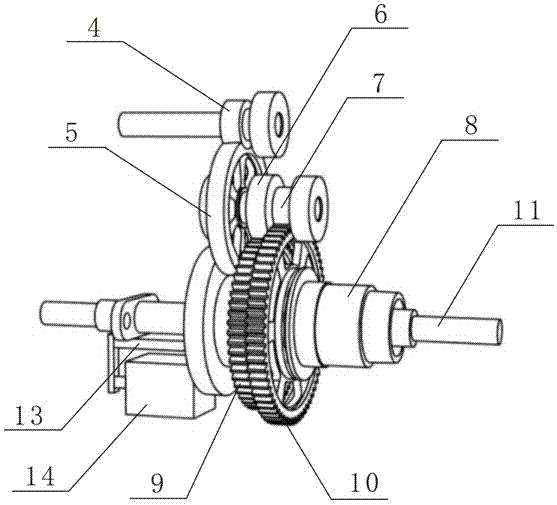

Drive device of electric motor car

InactiveCN102826191ACompact structureEasy to installWheel based transmissionToothed gearingsLow speedEngineering

The invention discloses a drive device of an electric motor car. The drive device comprises a shell, a motor, a speed change mechanism and a gear-shifting self-holding electromagnet, wherein the speed change mechanism comprises an output shaft sleeve, a high-speed driven gear and a low-speed driven gear are sleeved on the output shaft sleeve, and mutually matched ratchet mechanisms are arranged between the output shaft and the high-speed driven gear and between the output shaft sleeve and the low-speed driven gear. The drive device also comprises a wheel axle, wherein the output shaft sleeve is sleeved on the wheel axle through a bearing, a gear-shifting shaft sleeve capable of moving along the axial direction is sleeved on the wheel axle, the gear-shifting shaft sleeve is matched with the ratchet wheel mechanism by moving the gear shifting shaft sleeve, thus switching between high speed and low speed can be realized. The drive device provided by the invention has the advantages of high gear shifting speed, accuracy and reliability, convenience for maintenance, capability of automatically carrying out power upgrading, low cost, and capability of increasing bearing capacity of the electric motor car.

Owner:CHONGQING CHENGMOU TECH CO LTD

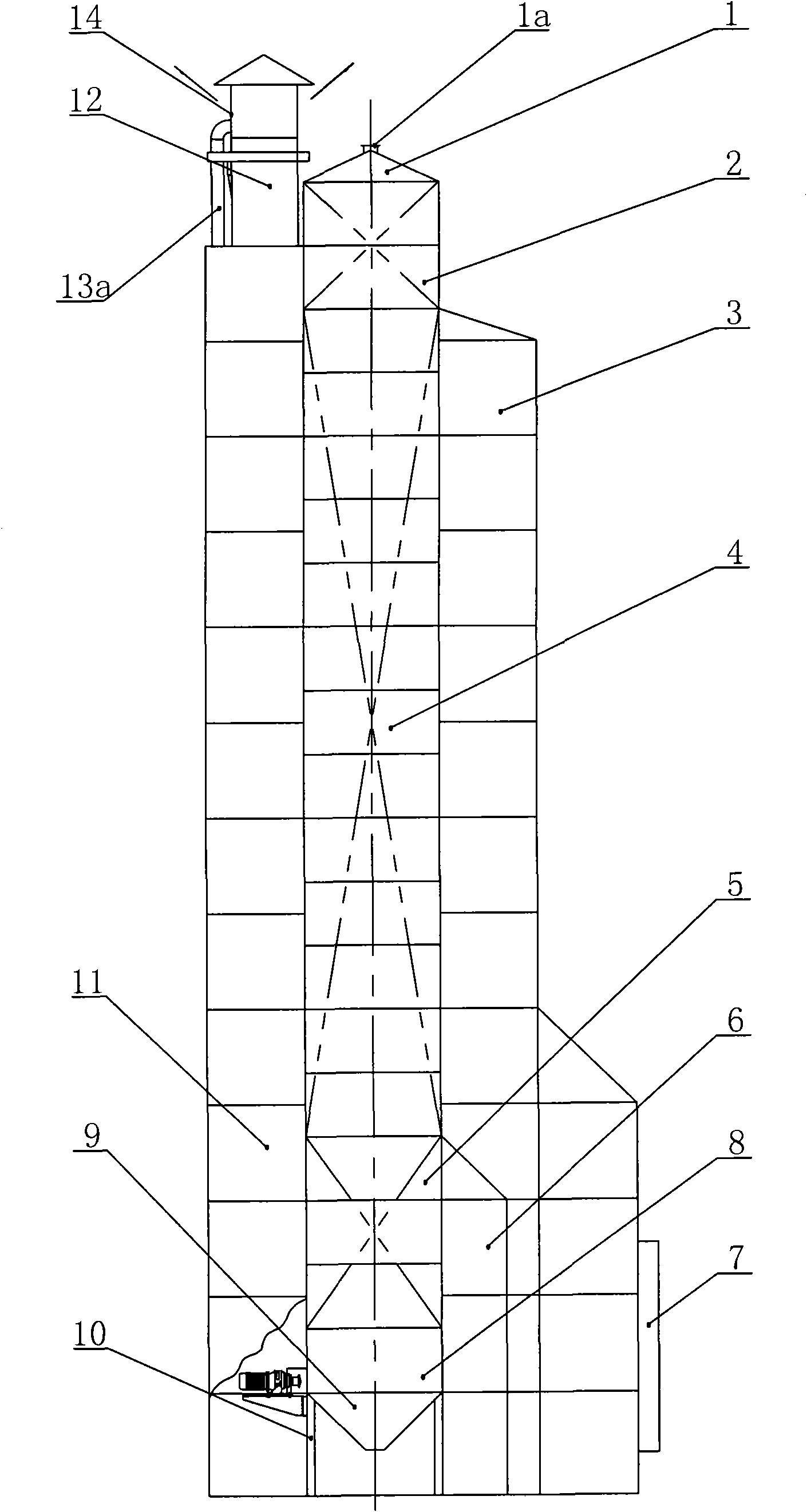

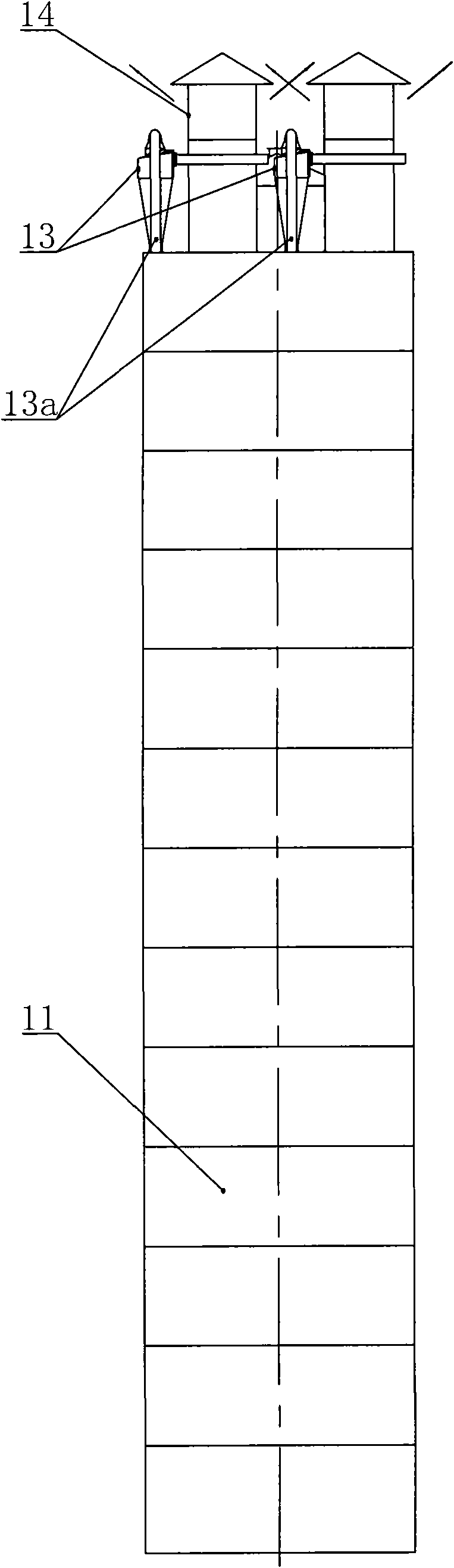

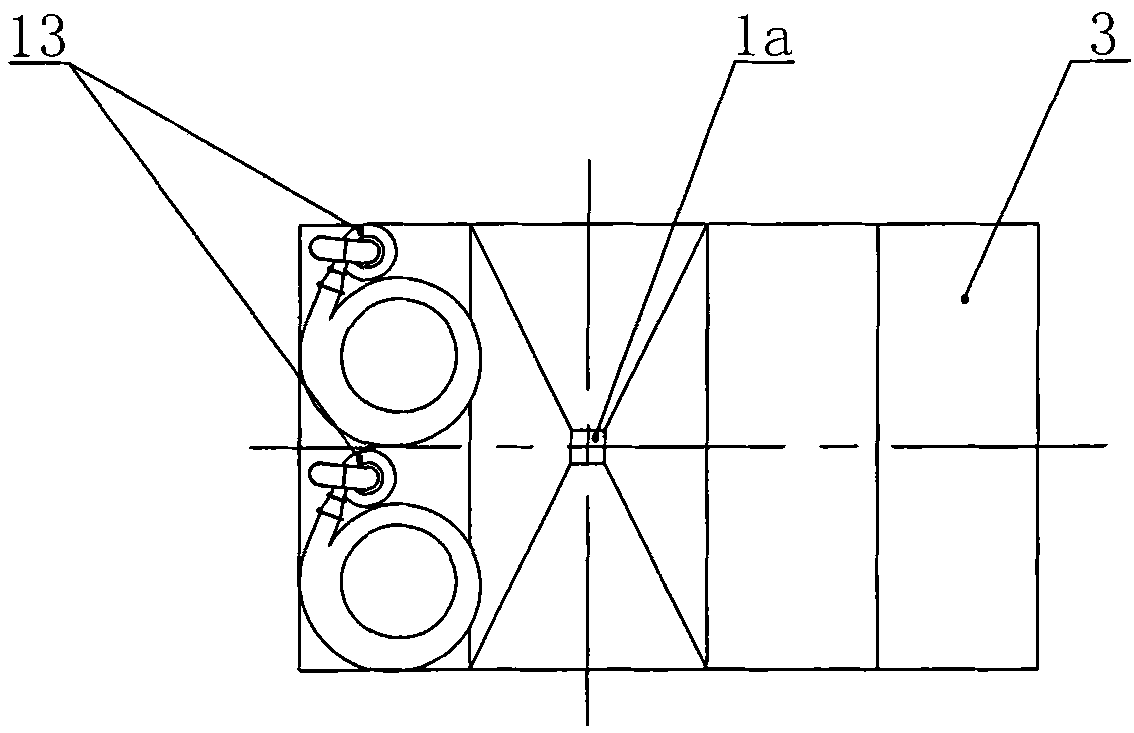

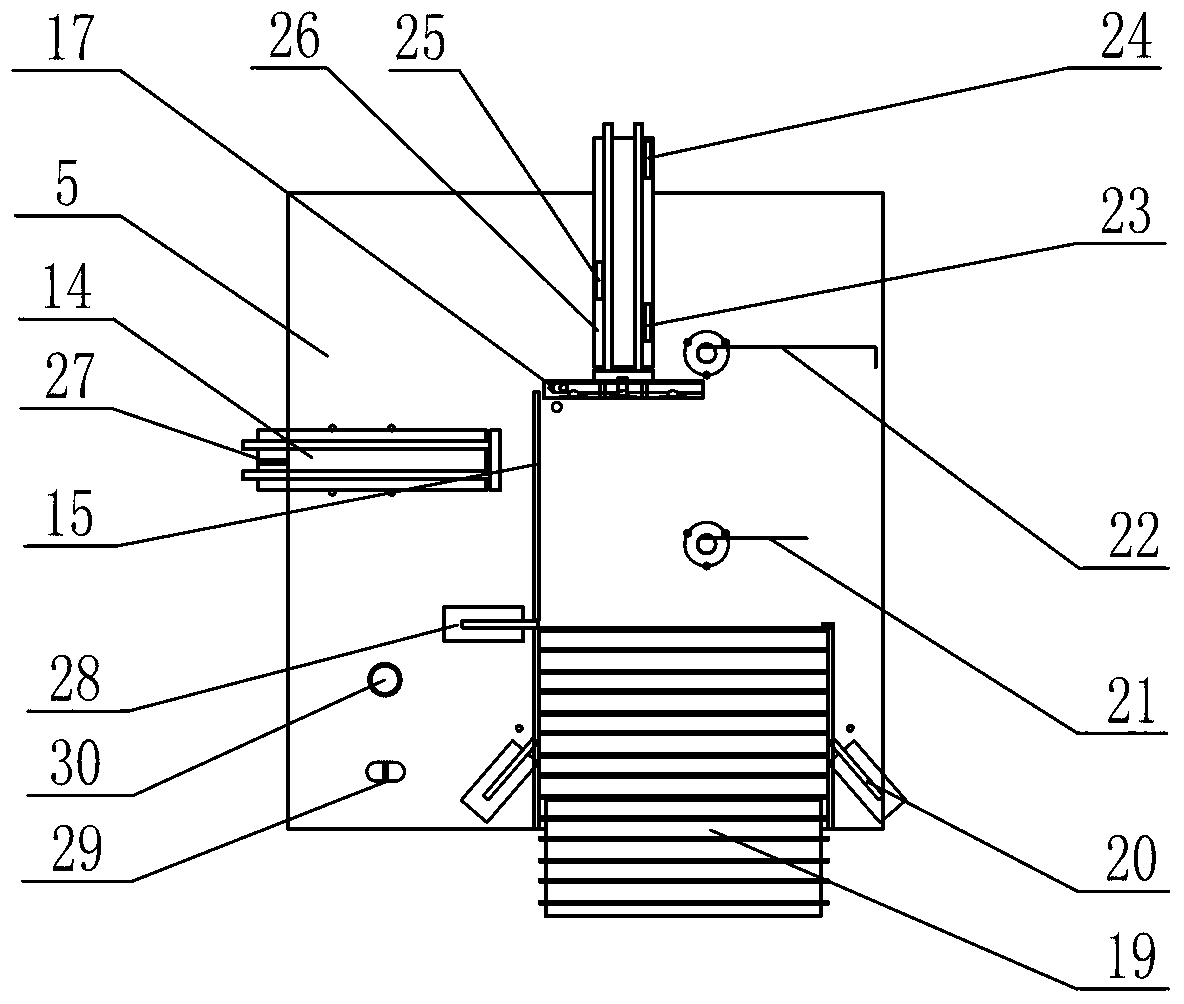

Isobaric grain-drying tower

InactiveCN101911969ASmall sizeCompact and beautiful appearanceSeed preservation by dryingElectric machineryExhaust gas

The invention discloses an isobaric grain-drying tower, belonging to the field of grain machinery. The tower body comprises a grain feeding layer, a grain storing layer, a drying bin, a cooling bin and a grain discharging layer which are laminated sequentially from top to bottom, wherein one side of the tower body is provided with a hot wind channel and a cold wind channel which are respectively as equal wide as the tower body; the other side of the tower body is provided with an exhaust gas channel as equal wide as the tower body; the cold wind channel is arranged at the inner side the hot wind channel; the lower end of the cold wind channel is provided with an atmosphere inlet; the upper side of the cold wind channel is provided with a cold wind outlet of the cold wind channel; the cold wind outlet of the cold wind channel is abutted with a cold wind inlet of the cooling bin; the lower end of the hot wind channel is provided with a hot wind inlet of a heat source; the upper end side of the hot wind channel is provided with a hot wind outlet of the hot wind channel; the hot wind outlet of the hot wind channel is abutted with the hot wind inlet of the drying bin; the cold wind outlet of the cooling bin and the hot wind outlet of the drying bin is respectively abutted with an exhaust gas channel; and the upper end of the exhaust gas channel is provided with an exhaust fan and an ash separating and discharging system. The wind resistance and the motor power consumption of the drying tower are small, and the wind quantity and the wind pressure of the hot wind or the cold wind are uniform, therefore, the quality of the dried grains is excellent.

Owner:JIANGSU MUYANG GRP CO LTD

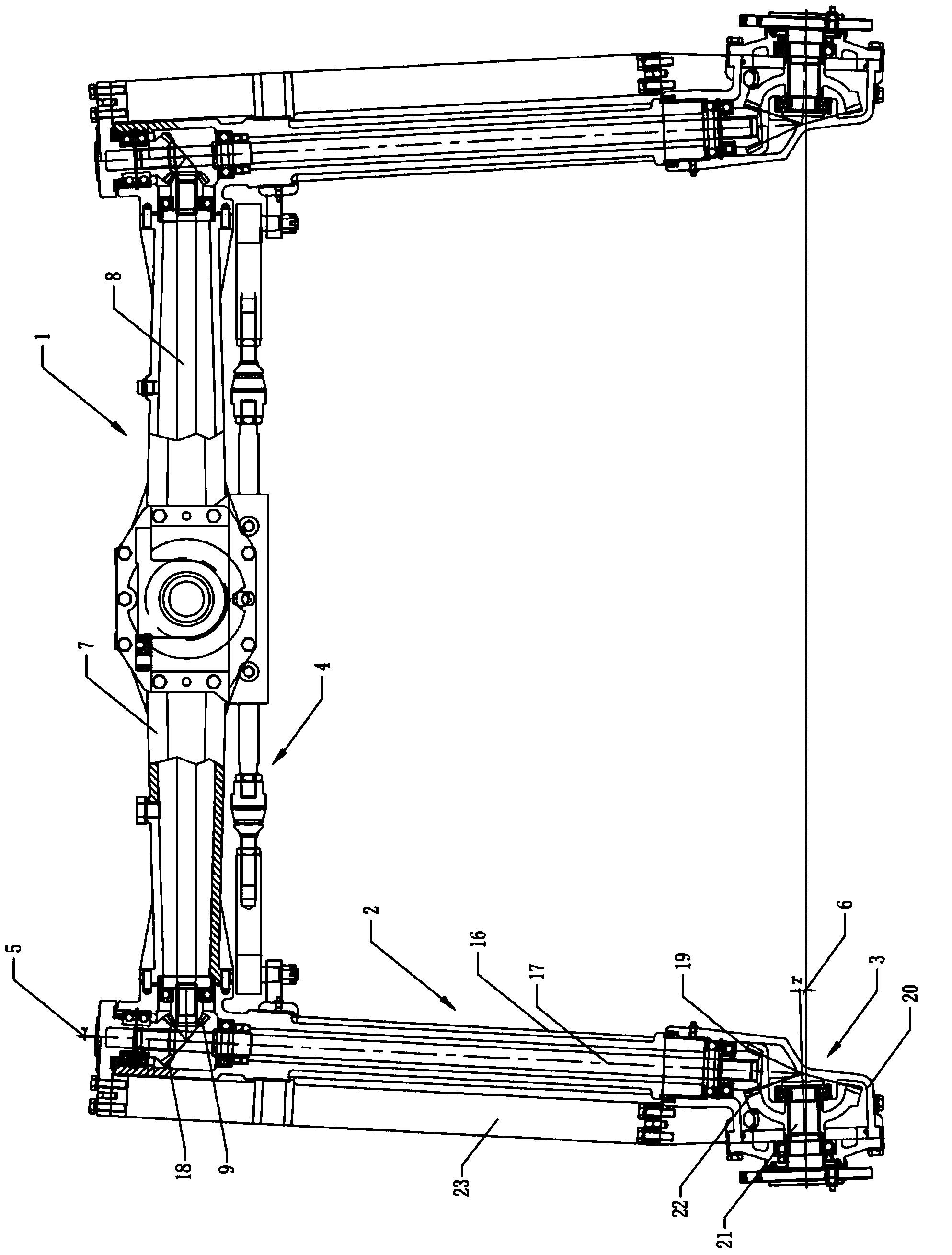

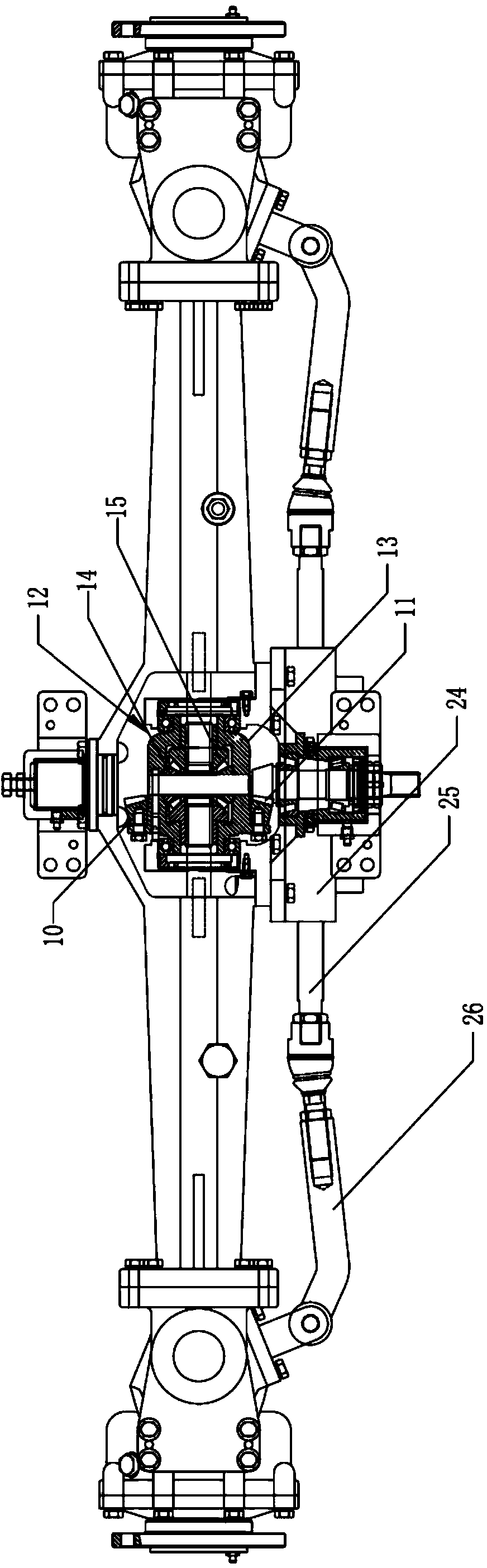

Hydraulic steering four-wheel drive axle of plant protection machine

InactiveCN104163199AThe overall structure is reasonableCompact and beautiful appearanceSteering linkagesControl devicesFour-wheel driveFastener

The invention provides a hydraulic steering four-wheel drive axle of a plant protection machine. The axle comprises a horizontal main reduction gear box assembly, the two ends of the main reduction gear box are respectively and rotatably provided with a vertical knuckle assembly, the two knuckle assemblies are symmetrically arranged, the tail end of each knuckle assembly is provided with a tail end transmission assembly through a fastener, a steering mechanism used for driving the two knuckle assemblies to steer is arranged between the two knuckle assemblies and the main reduction gear box, a first included angle is formed between a knuckle pin shaft of the two knuckle assemblies and the vertical direction, and a second included angle is formed between a tail end drive shaft of the two tail end transmission assemblies and the horizontal direction. The axle is reasonable in structure and compact and attractive in appearance, passing ability is obviously improved during field work, steering, supporting and connection are firm, reliable and flexible, a tail end structure mode is improved, and passing ability is optimized.

Owner:QINGZHOU MAITE AXLE MFG

Simply marinated spiced yak meat and processing method thereof

The invention provides a simply marinated spiced yak meat and a processing method thereof. The processing method is characterized in that yak meat is the main raw material, the auxiliary materials comprise white sugar, salt, soy sauce, and spices; and the processing method comprises steps of rolling, kneading, marinating, vacuum packing, cooking, sterilizing, cooling, and storing. The prepared spiced yak meat is compact, beautiful, tender, and soft, the fragrance is rich, the taste is good, and the flavor is unique. Moreover, the processing technology is simple, the production period is short, and the spiced yak meat can be massively produced through streamlined production.

Owner:青海五三六九生态牧业科技有限公司

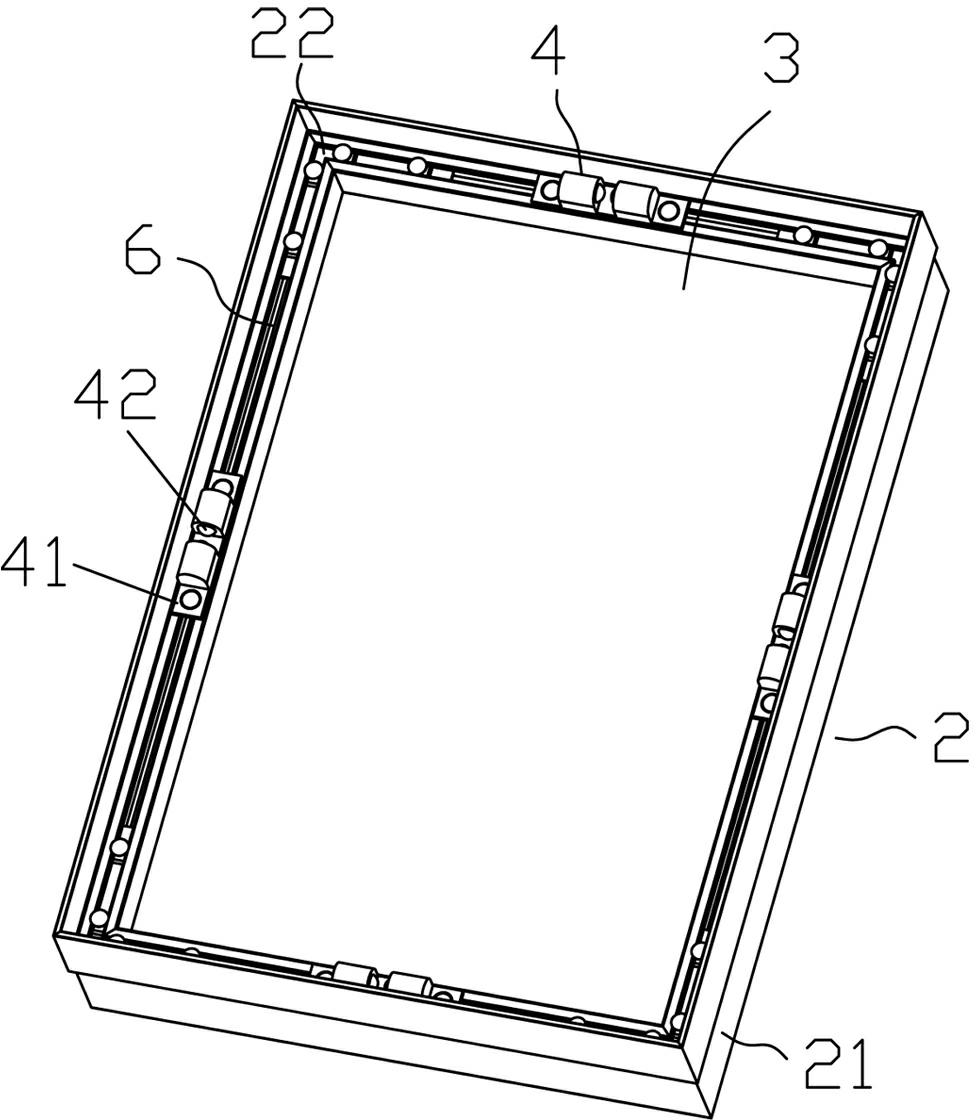

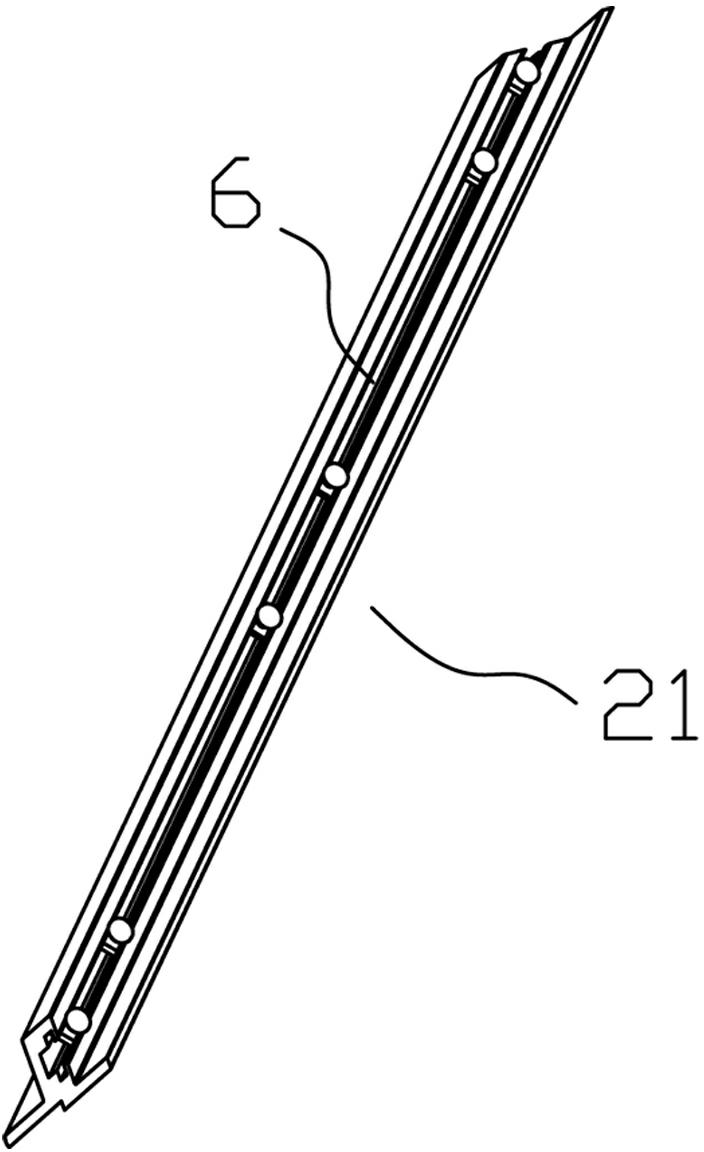

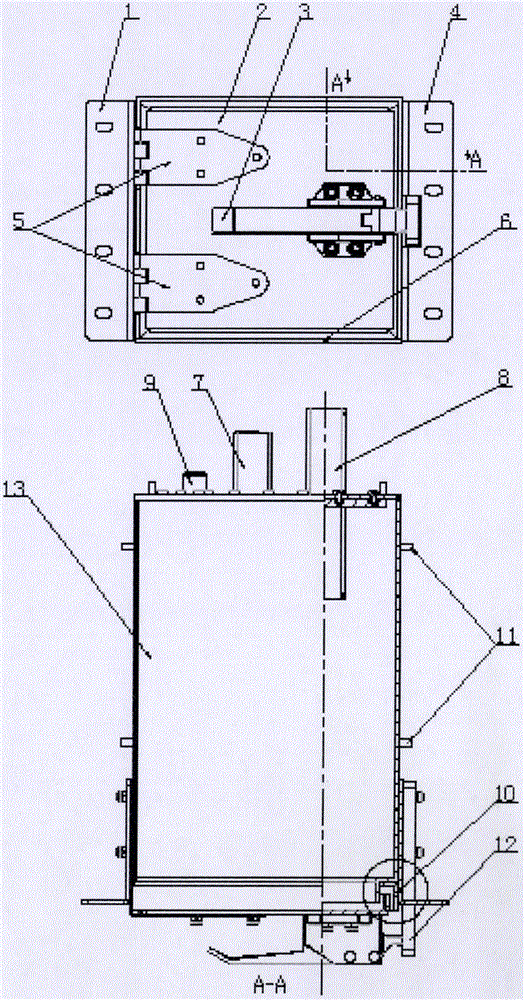

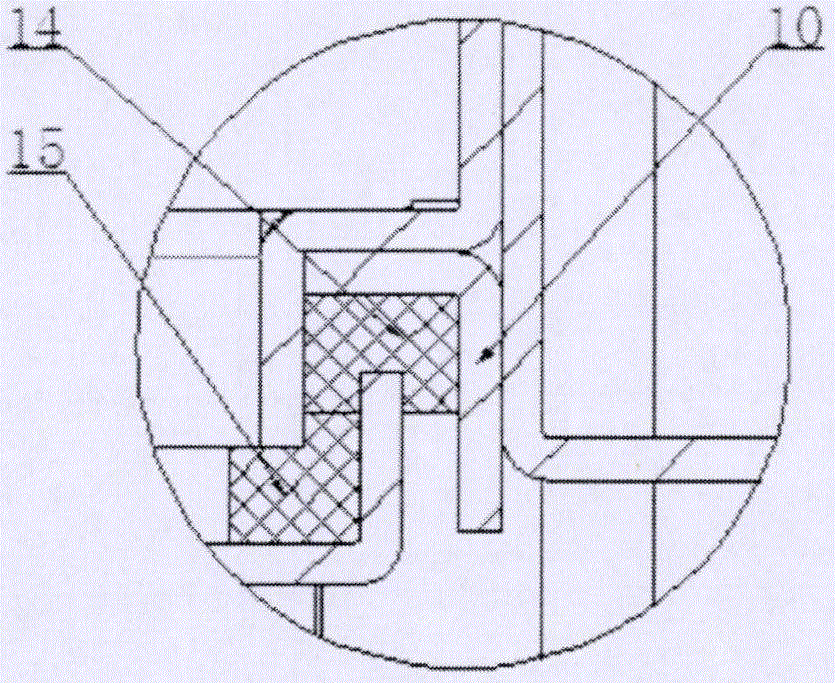

Wall-embedded mounting system for operation panel

ActiveCN102523719ASolve matching problemsFirmly connectedCasings/cabinets/drawers detailsSupport structure mountingComputer moduleEngineering

The invention discloses a wall-embedded mounting system for an operation panel. The wall-embedded mounting system comprises a panel module, as well as a pre-mounting framework and a mounting chamber which are used for being embedded in a wall; the panel module is mounted on the pre-mounting framework in a clamping manner through a movable plug-in mounting structure constituted by a clamping male seat and a clamping female seat; the mounting chamber is arranged below the pre-mounting framework; and electronic elements of the operation panel are mounted in a cavity formed by the panel module, the pre-mounting framework and the mounting chamber. The wall-embedded mounting system is simple in structure, structurally solves the problem of matching between the mounting structure of the operation panel and the peripheral wall body, and has a beautiful and compact appearance on the whole after the operation panel is mounted; besides, the panel module and the pre-mounting framework can be connected conveniently, and when maintenance or service is required, circuits of the internal electronic elements can be debugged or modified conveniently by dismounting the panel module, so that the operation is convenient and fast, and superhigh efficiency can be achieved.

Owner:珠海昊星自动化系统有限公司

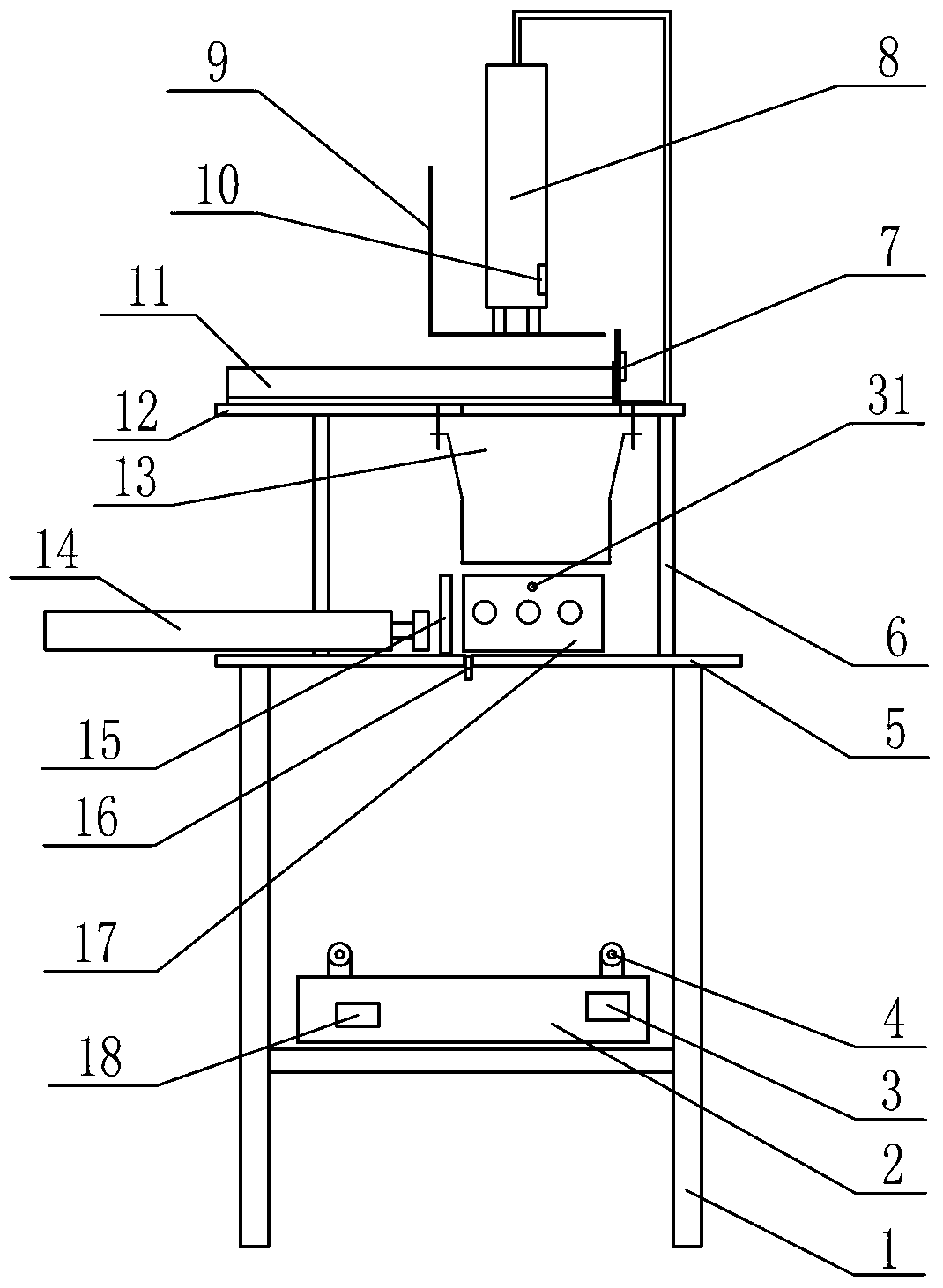

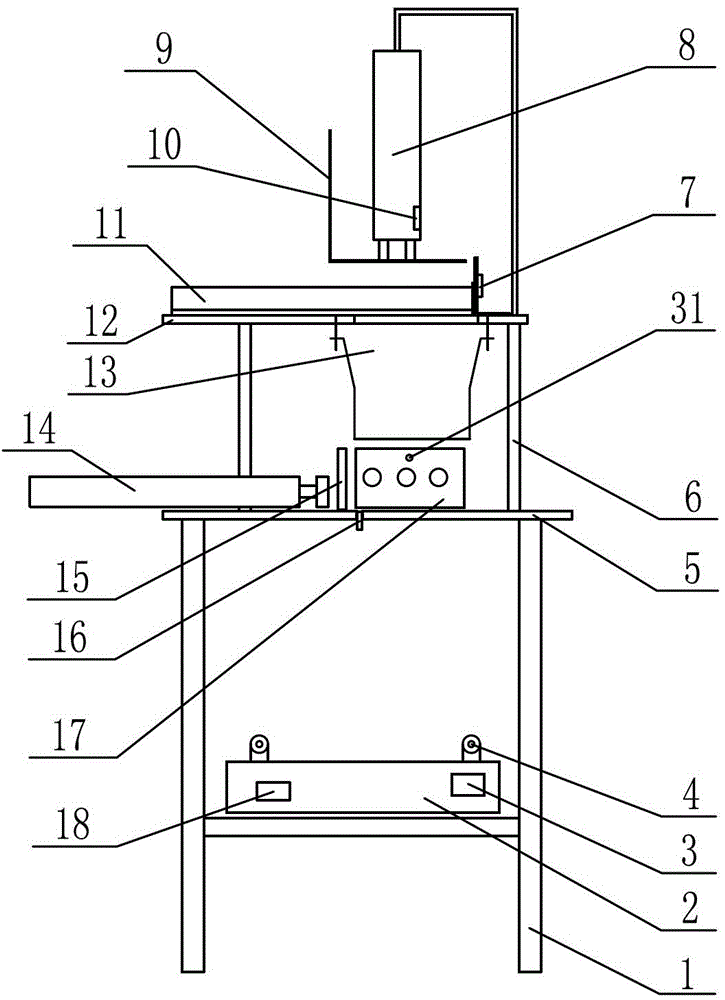

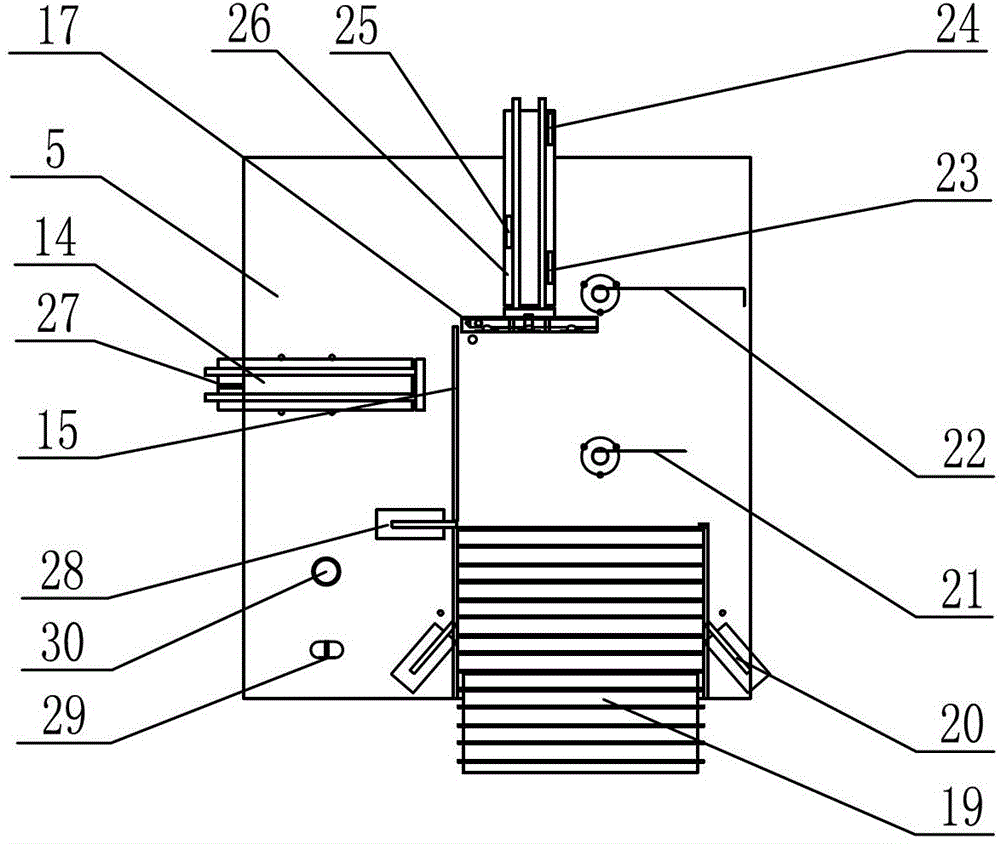

Automatic box packing machine for middle boxes

ActiveCN103274084AHigh degree of automationImprove running accuracyPackagingConveyor partsManufacturing lineMechanical field

The invention relates to an automatic box packing machine for middle boxes, and belongs to the field of product packing machinery. The automatic box packing machine for the middle boxes comprises a machine body, wherein an electrical cabinet is arranged in the machine body, an upper platform and a lower platform are arranged on the upper portion of the machine body, a box moving rail and a box pressing air cylinder are arranged on the upper platform, the box pressing air cylinder is connected with a box pressing plate, a guide groove which corresponds to the box pressing plate is arranged at the bottom of the upper platform, a box placing frame is arranged at the front end of the lower platform, a rail plate is arranged on one side of the box placing frame, a box blocking air cylinder is arranged in front of the box placing frame, a box sucking air cylinder is arranged at the rear end of the lower platform, the box sucking air cylinder is connected with a box sucking plate, the box sucking plate is attached to the tail end of the rail plate, a box opening locating air cylinder is arranged on one side of the box sucking air cylinder, a box opening air cylinder is arranged between the box opening locating air cylinder and the box placing frame, a first box pushing air cylinder is arranged corresponding to the position between the box sucking plate and the box placing frame, and is arranged on the left side of the rail plate, and a starting switch and a power switch are arranged on one side of the box placing frame. The automatic box packing machine for the middle boxes is high in degree of automation, good in stability, simple in equipment structure, compact in appearance, reasonable in design, convenient to install, good in practicability, capable of being installed to be applied to various production lines.

Owner:REYOUNG PHARMA

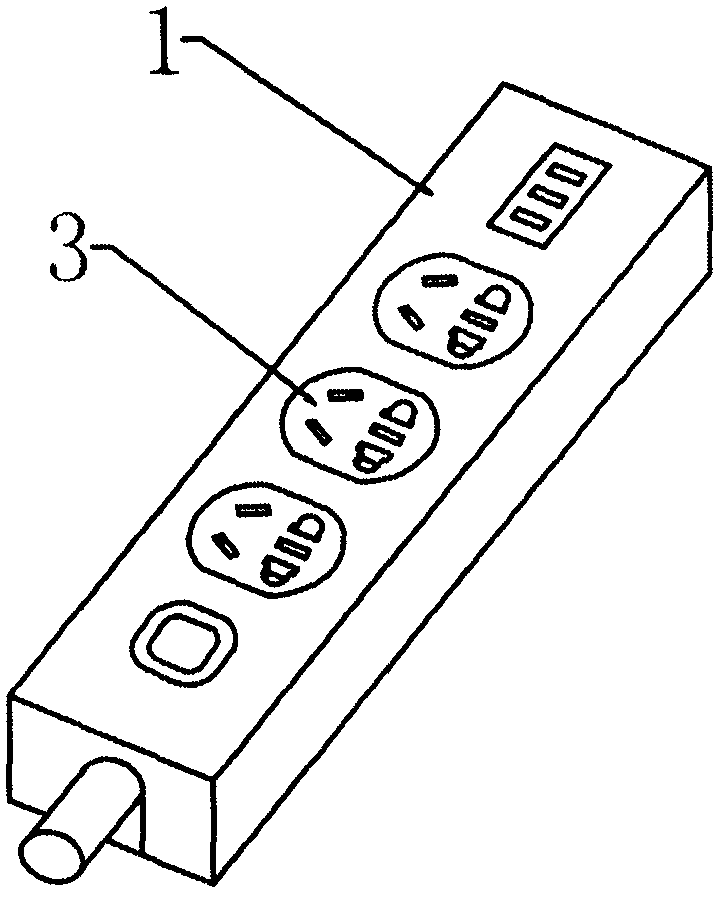

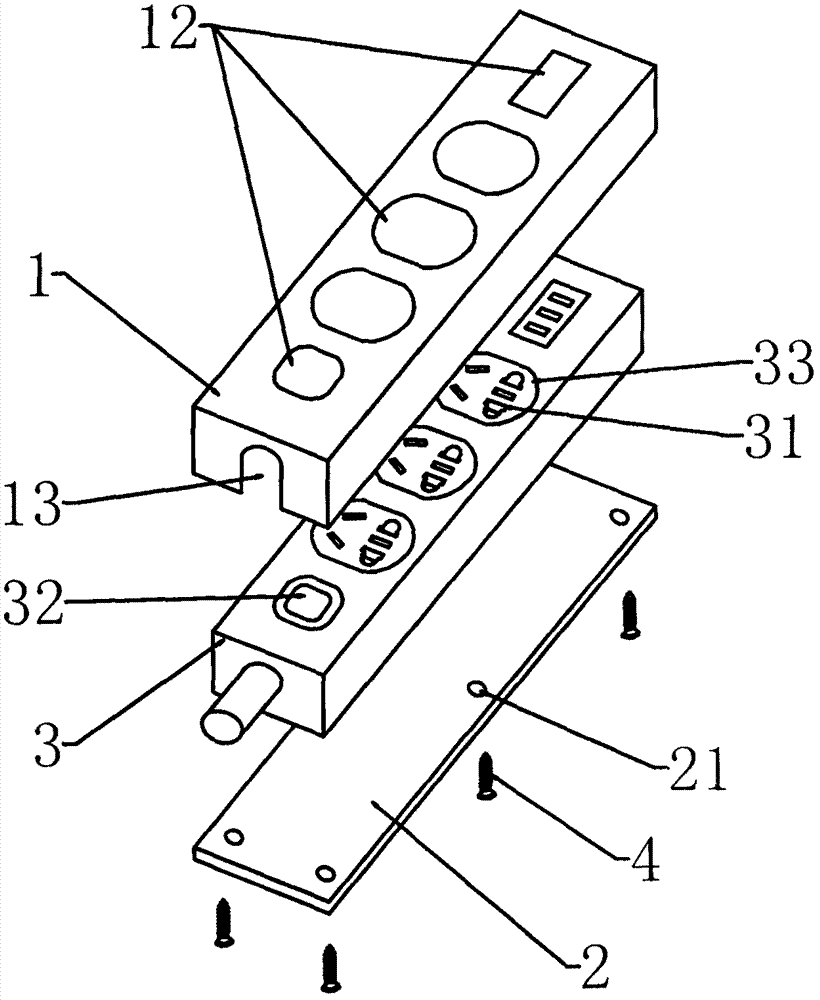

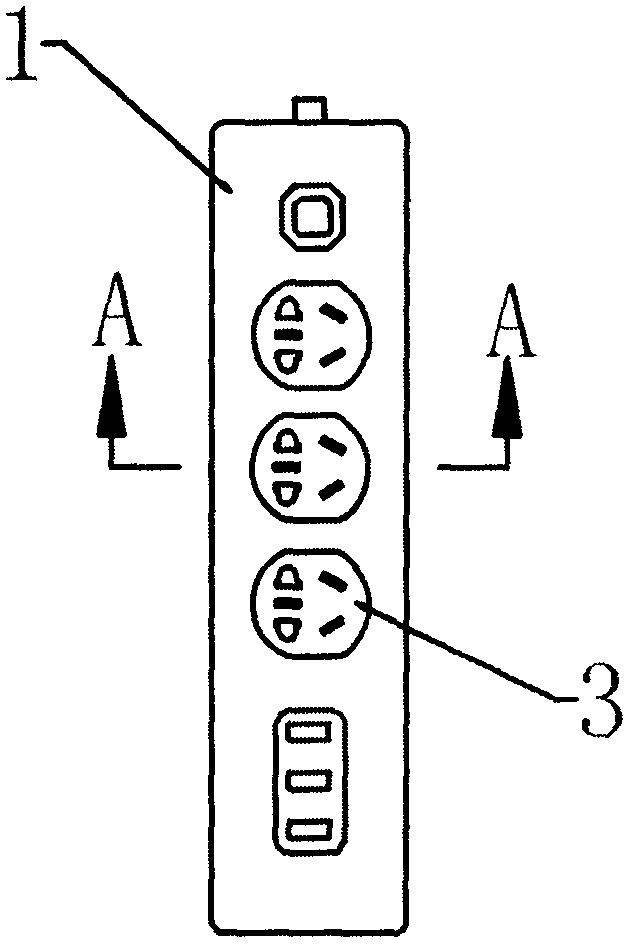

Outer coat for patch board and patch board

PendingCN106953193APrevent agingAvoid damage and leakageCoupling contact membersPatch panelHome appliance

The invention relates to the field of household electrical appliances, and provides an outer coat for a patch board and the patch board. The outer coat for the patch board comprises a box body and a bottom plate, the bottom plate cooperates with the box body, the bottom plate is detachably connected with the box body, the box body is three-dimensional, at least one accommodating chamber accommodating patch boards are arranged in the box body side by side, an upper end face of the box body is provided with through holes corresponding to sockets, a switch and other function members of the patch board, and a side wall of each accommodating chamber is provided with a through groove for a patch board bus to pass through. The patch board is used with the over coat for the patch board, protruding parts are disposed at positions of the sockets of the patch board, shapes of the protruding parts match shapes of the through holes, and heights of the protruding parts are not less than a thickness of a top wall of the box body. The patch board with the over coat comprises the over coat for the patch board and the patch board used with the over coat for the patch board.

Owner:NINGBO DIMINGSI ELECTRONICS

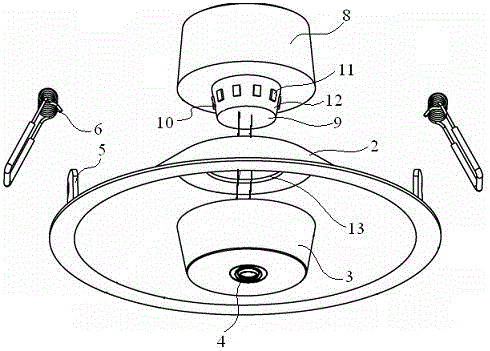

Pyroelectric infrared induction type LED (Light-Emitting Diode) lamp

InactiveCN106482002AIngenious structural designEasy to disassemble, assemble, repair and replaceElectrical apparatusElectric circuit arrangementsVoltage converterElectricity

The invention relates to a pyroelectric infrared induction type LED (Light-Emitting Diode) lamp. The pyroelectric infrared induction type LED lamp comprises a heat-conducting aluminium base, a horn-shaped reflecting cover, a U-shaped light diffusing cover, an LED integrated package light source, a pyroelectric infrared sensor, an infrared induction controller and a driving power supply; the LED integrated package light source is arranged at a front-end boss of the heat conducting base; the driving power supply and the infrared induction controller are both arranged in a cavity; the front-end boss of the heat conducting base is in threaded connection with the horn-shaped reflecting cover; the light diffusing cover is arranged on the front-end boss and covers the LED integrated package light source; the pyroelectric infrared sensor is arranged in the centre of the front end of the light diffusing cover in an exposed manner; the LED integrated package light source is connected with an output end of the infrared induction controller; the pyroelectric infrared sensor is connected with an input end of the infrared induction controller; the infrared induction controller is electrically connected with the driving power supply; and the infrared induction controller comprises a voltage converter and an infrared induction IC (Integrated Circuit) chip. According to the pyroelectric infrared induction type LED lamp, safe, energy-saving, environment-friendly and user-friendly lighting functions of turning on the lamp when a person comes and turning off the lamp when the person leaves can be realized.

Owner:NANJING ROUTER SOFTWARE

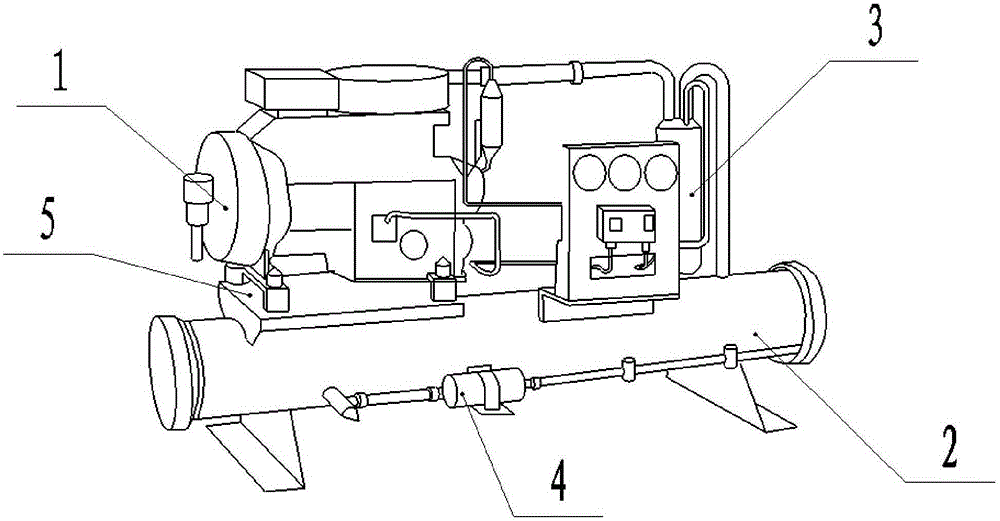

Efficient and energy-saving power system for refrigeration house

InactiveCN105157314AEasy to replaceReduce connectionsLighting and heating apparatusStationary refrigeration devicesControl theoryRefrigerant

An efficient and energy-saving power system for a refrigeration house comprises a power circulation device which comprises a compressor and a condenser. A temperature sensor and a pressure sensor are arranged in the compressor. A temperature sensor and a pressure sensor are arranged in the condenser, a fixing plate is arranged on the condenser, and the compressor is connected with the condenser through the fixing plate. At least one damping device is arranged in the position where the compressor and the condenser are connected. The temperature sensor in the condenser is connected with the temperature sensor in the compressor. After the compressor and the condenser are integrally mounted, the connection portion of a refrigeration system is omitted, the risk of failures is lowered, and accordingly capacity adjustment in a large range can be performed, and high adaptability to the change of loads is achieved; refrigerants of an exhaust tube can enter a condenser assembly rapidly for cooling after the compressor is shortened; produced loads are reduced by about 20%, mounting space of the refrigeration house occupied by the efficient and energy-saving power system is reduced, and the application range is wide; due to the shortening of a pipeline, refrigerants are recycled rapidly, the efficacy is high, power is reduced, noise is small, and energy and power are saved.

Owner:LIUZHOU SANNONG TECH

Middle box automatic cartoning machine

ActiveCN103274084BHigh degree of automationImprove running accuracyPackagingConveyor partsCartoning machineEngineering

The invention relates to an automatic box packing machine for middle boxes, and belongs to the field of product packing machinery. The automatic box packing machine for the middle boxes comprises a machine body, wherein an electrical cabinet is arranged in the machine body, an upper platform and a lower platform are arranged on the upper portion of the machine body, a box moving rail and a box pressing air cylinder are arranged on the upper platform, the box pressing air cylinder is connected with a box pressing plate, a guide groove which corresponds to the box pressing plate is arranged at the bottom of the upper platform, a box placing frame is arranged at the front end of the lower platform, a rail plate is arranged on one side of the box placing frame, a box blocking air cylinder is arranged in front of the box placing frame, a box sucking air cylinder is arranged at the rear end of the lower platform, the box sucking air cylinder is connected with a box sucking plate, the box sucking plate is attached to the tail end of the rail plate, a box opening locating air cylinder is arranged on one side of the box sucking air cylinder, a box opening air cylinder is arranged between the box opening locating air cylinder and the box placing frame, a first box pushing air cylinder is arranged corresponding to the position between the box sucking plate and the box placing frame, and is arranged on the left side of the rail plate, and a starting switch and a power switch are arranged on one side of the box placing frame. The automatic box packing machine for the middle boxes is high in degree of automation, good in stability, simple in equipment structure, compact in appearance, reasonable in design, convenient to install, good in practicability, capable of being installed to be applied to various production lines.

Owner:REYOUNG PHARMA

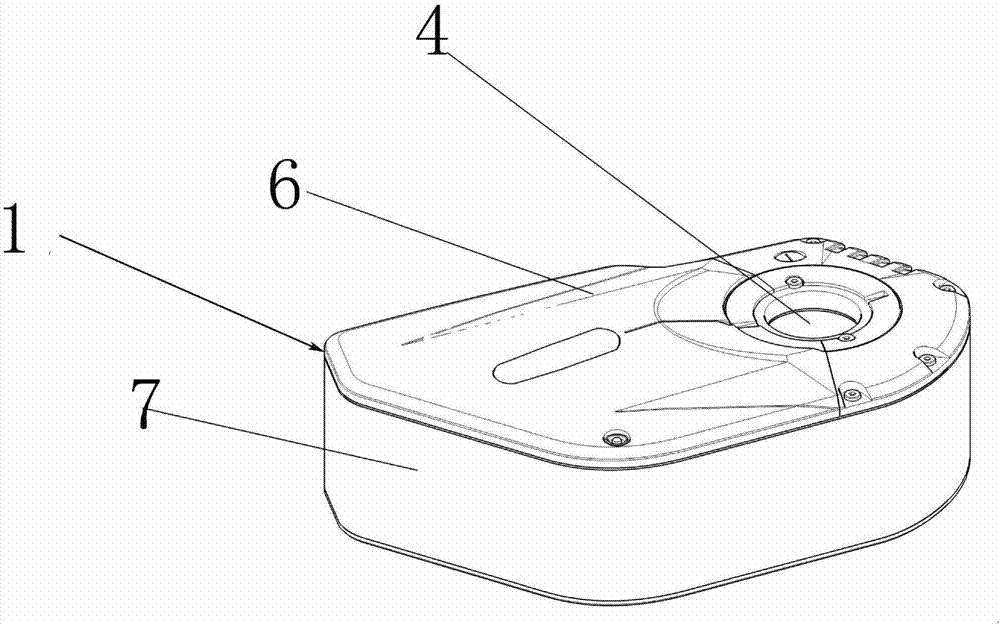

Center battery box

PendingCN107123759ACompact and beautiful appearanceEasy to installCell lids/coversEngineeringElectric bicycle

The invention provides a center battery box, belongs to the technical field of electric bicycle accessories, and solves the problem that the existing battery box is inconvenient to mount. The center battery box is arranged in the position of a bottom bracket of an electric bicycle, and comprises a main body; a first containing tank for containing a unit battery cell module is formed inside the main body; a center shaft hole is formed in the main body; the center shaft hole penetrates through the main body; and the shape and size of the center shaft hole are matched with those of a center shaft arranged in the position of the bottom bracket. The center battery box ensures that a battery and a controller are integrated on a battery box, and the center shaft hole matched with the center shaft in the position of the bottom bracket of the electric bicycle is formed in the battery box, so that the shape of the electric bicycle adopting the center battery box is more compact and attractive; a controller cover plate and a battery box cover plate are provided, so that a battery pack and the controller are convenient to dismount, replace and maintain; and the center battery box increases the difficulty in stealing the battery after being applied to the electric bicycle, thereby having an anti-burglary function. The center battery box is more convenient to mount and more stable in quality.

Owner:JINHUA FEIRUI VEHICLE CO LTD

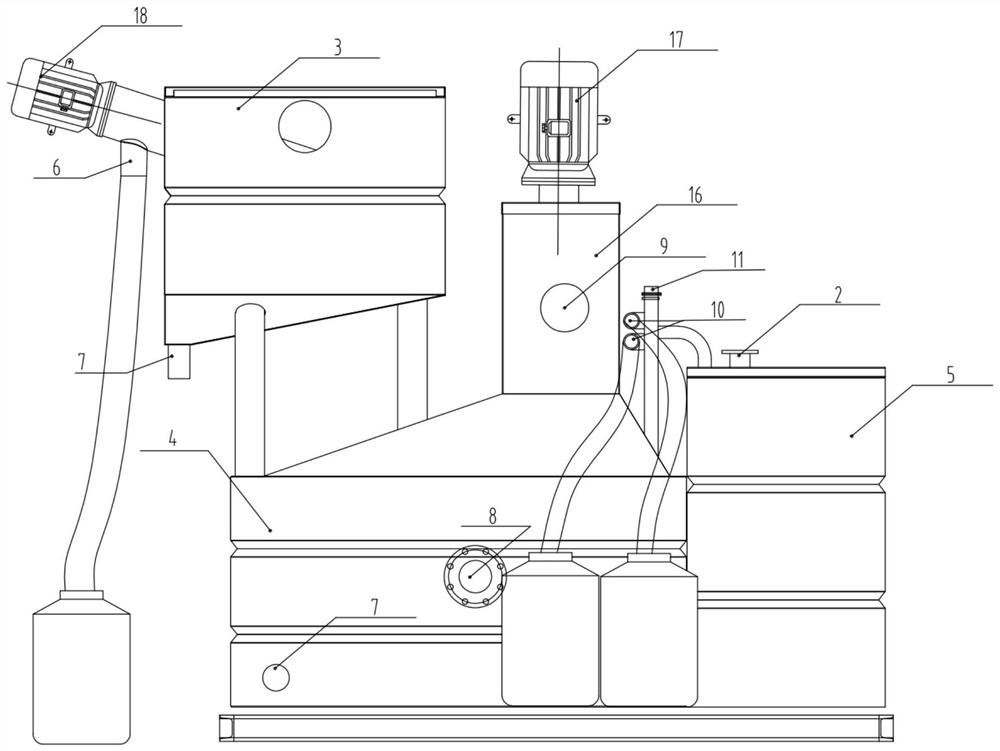

Oil separation equipment

PendingCN111874992AAuto Quick GatherSave installation spaceFatty/oily/floating substances removal devicesLiquid separationTemperature controlSludge

Oil separation equipment is disclosed. The equipment comprises a residue-liquid separation tank, an oil-water separation tank, an oil storage tank and a sewage lifting tank, wherein a liquid outlet ofthe residue-liquid separation tank is communicated with a liquid inlet of the oil-water separation tank, the bottom of the residue-liquid separation tank is arranged in an inverted cone shape, a sludge discharge port is formed in the cone bottom of the inverted cone, the upper portion of the oil-water separation tank is arranged in a right cone shape, the upper part of the right cone shape is communicated with the oil storage tank, an oil outlet of the oil storage tank is externally connected with a waste oil collecting barrel through a pipeline to discharge oil; a stirring device, a heatingdevice and a temperature control device are arranged in the oil storage tank; a water outlet of the oil-water separation tank is connected with a water inlet of the sewage lifting tank. The equipmentintegrates an automatic oil separation function, an electric heating constant-temperature function and an automatic sewage forced drainage function, is ingenious in design and excellent in configuration, and is special equipment for oil separation and forced drainage of underground restaurant wastewater. The whole process is automatic and integrally designed, oil separation, forced drainage and auxiliary heating are integrated, installation and operation are easy, the appearance is compact and attractive, and the basement installation space is reduced.

Owner:上海双解泵业制造有限公司

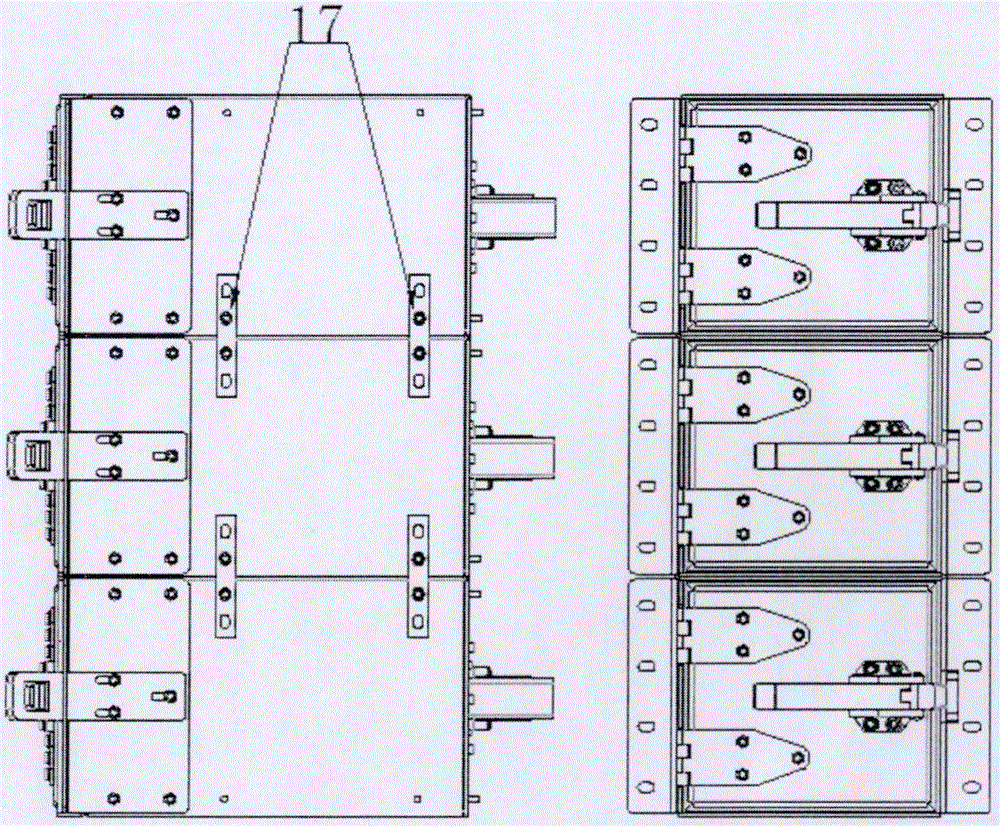

Stackable multipurpose shielding case

PendingCN106604625ACompact and beautiful appearanceEasy to carryScreening casingsEngineeringMechanical engineering

Owner:杭州永谐科技有限公司

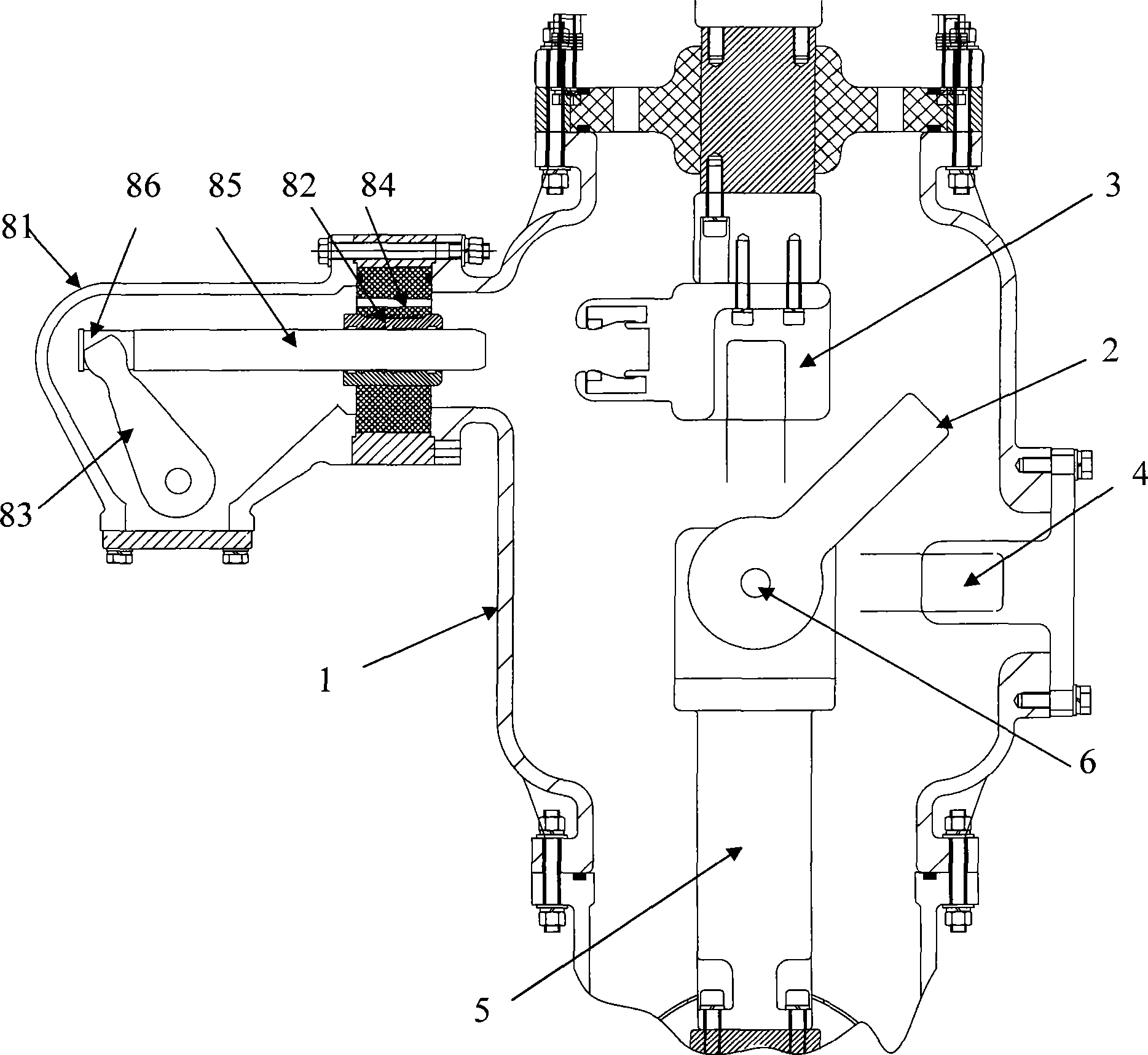

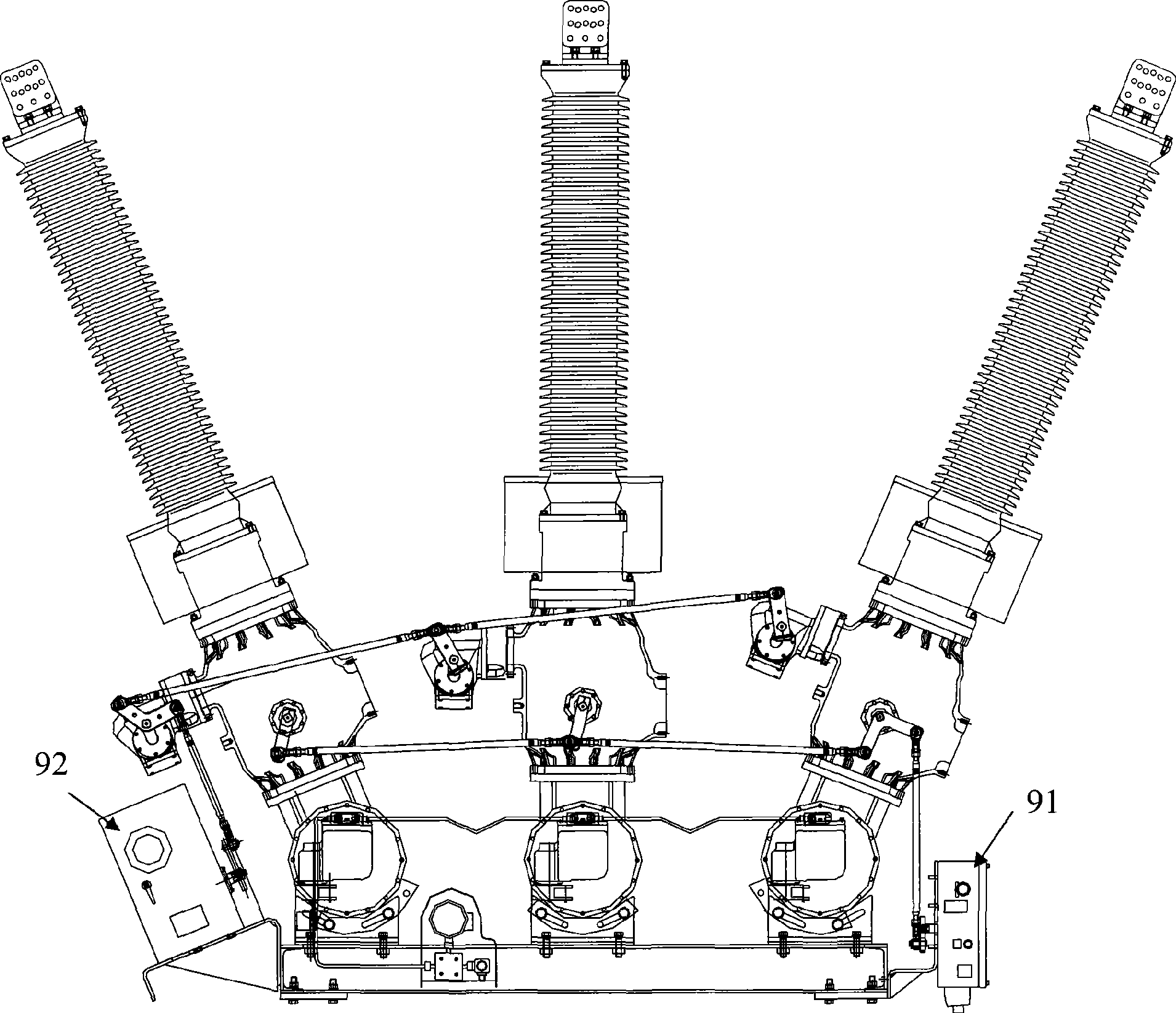

126KV composite combine electric appliance

InactiveCN101483323ALow costSave spaceSwitchgear arrangementsSubstation/switching arrangement casingsState of artElectrical equipment

The present invention discloses a 126KV compound composite apparatus which aims to solve problems like complex structure and great volume in prior art. The invention comprises an air chamber by isolating switch housing, wherein a dynamic contact, a isolation switch static contact and a ground switch static contact are set in the air chamber; the ground switch static contact is set on one side of the air chamber and forms a phase angle of 90 DEG with the isolation switch; the dynamic contact is set between the isolation switch static contact in rotatable way and the ground switch static contact through a controlled shaft. In the above structure, the isolation switch and the ground switch adopt three working positions composite structure, opening and closing of the isolation switch and the ground switch can be done with only one operating mechanism without interlock between the isolation switch and the ground switch, hence cost is reduced and space is saved, and the rapid ground switch and the isolation switch share one air chamber. Compared with traditional structure appearance, the invention is provided with small volume, good-look and compact appearance.

Owner:国电博纳(北京)电力设备有限公司

A new type of packaging equipment and packaging method

ActiveCN104058136BCompact and beautiful appearanceFirm and beautiful shapeWrapper folding/bending apparatusWrapper twisting/gatheringEngineeringMechanical engineering

Owner:XIAMEN GACHN TECH

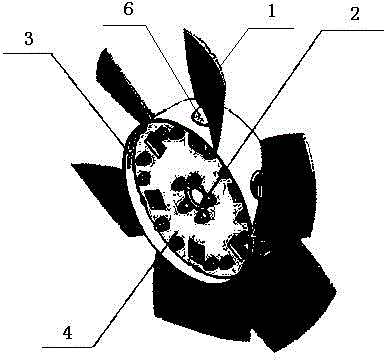

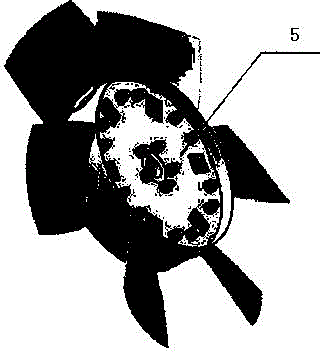

Hub for axial flow fan

InactiveCN104100568ASimple structureCompact and beautiful appearancePump componentsPumpsEngineeringStructural engineering

Owner:WEIHAI CREDITFAN VENTILATOR

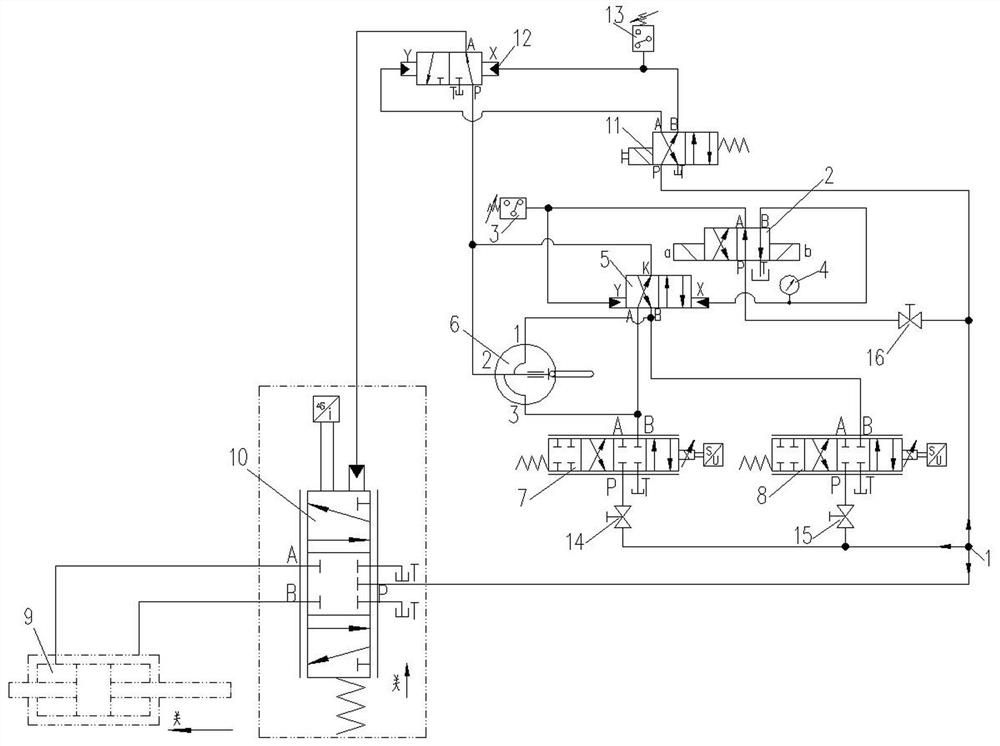

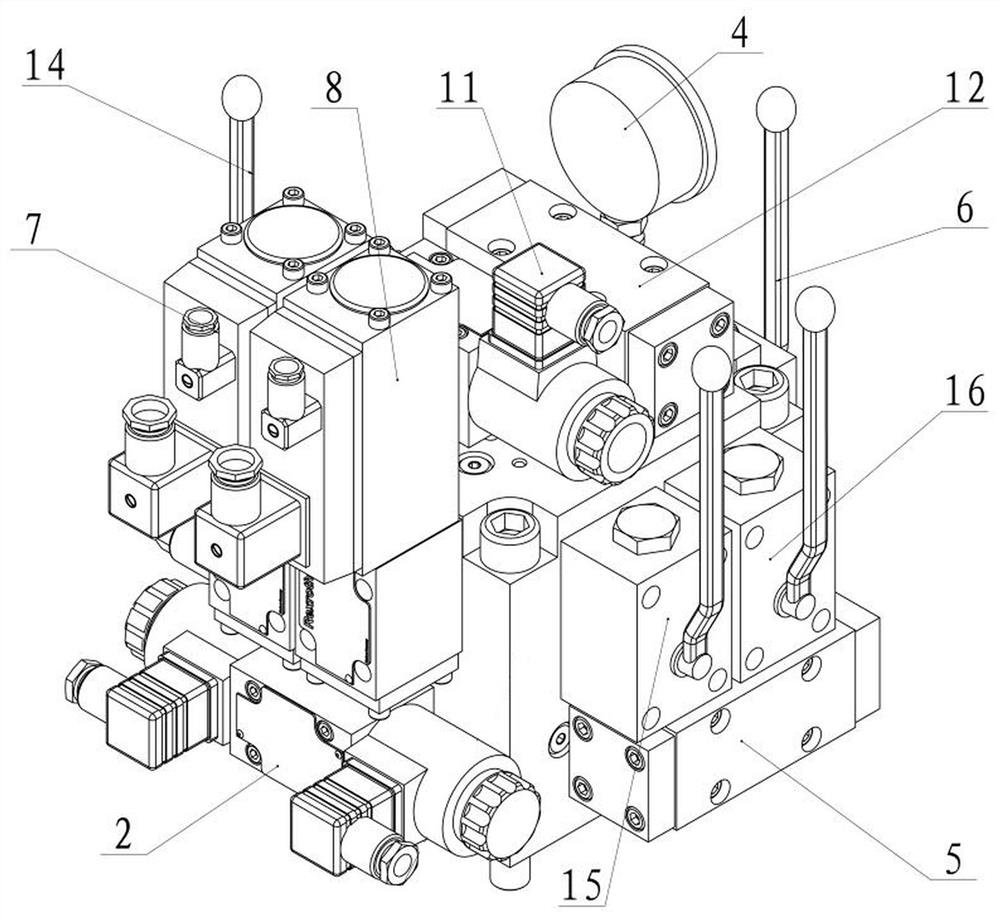

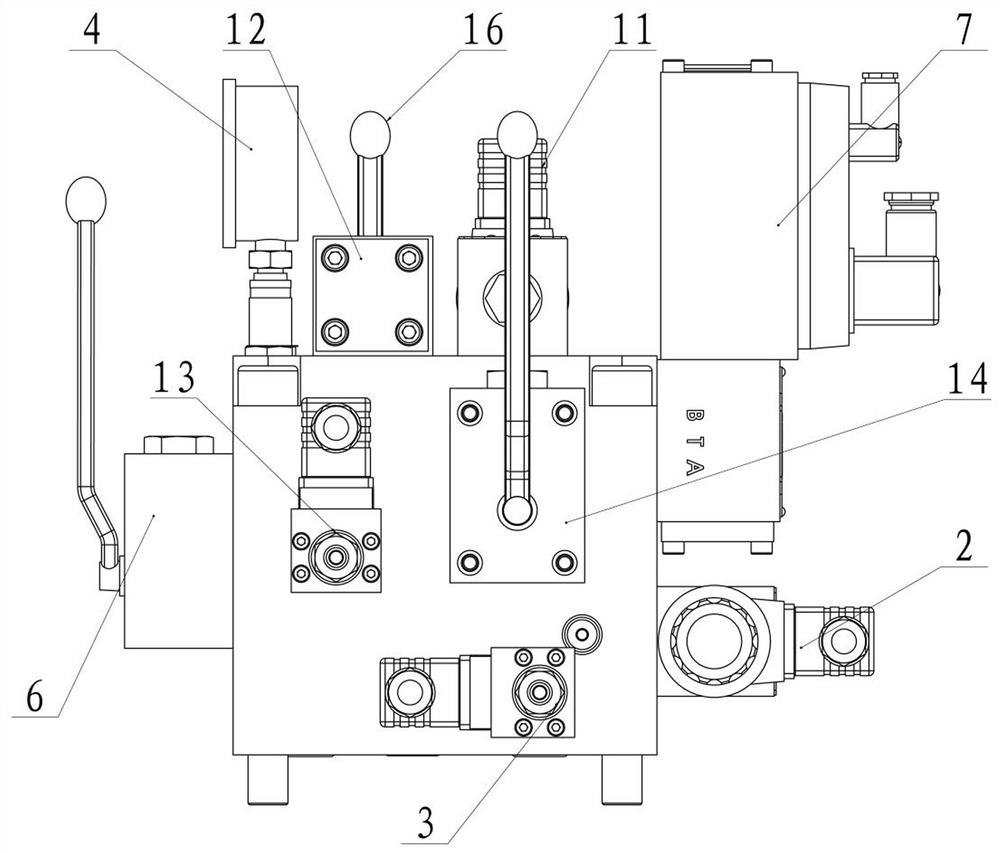

A control method of a hydraulic speed regulating system with manual automatic switching

ActiveCN111336151BImprove reliabilityRealize online maintenanceFluid-pressure actuator safetyServomotor componentsAutomatic controlSpeed control system

The present invention relates to the technical field of hydraulic systems, in particular to a control method of a hydraulic speed regulating system with manual automatic switching. The output port of the hydraulic signal output proportional valve 2 is connected with the upper control chamber of the main pressure distribution valve, cooperates with the spring in the lower control chamber of the main pressure distribution valve, controls the main valve spool to move up and down, and controls the opening and closing of the guide vane servomotor. closure. Through the control method, the problems of unreliable operation of the hydraulic speed regulating system and difficulties in finding and eliminating faults can be effectively solved.

Owner:DONGFANG ELECTRIC AUTOMATIC CONTROL ENG CO LTD

Sintered ceramsite and method prepared from phosphorus tailings as main raw material

ActiveCN106747600BSolve pollutionSolve resource problemsCeramic materials productionCeramicwarePhosphateSlag

The invention discloses a method for preparing sintered ceramsite by using phosphate tailings as a main raw material. The method comprises the following steps of crushing the phosphate tailings and steel slag, then adding pulverized fuel ash into an obtained first mixture, and afterwards, adding water into an obtained second mixture to carry out wet grinding, so as to obtain slurry of which the median particle size is less than 5 microns; adding a binder and carbon powder into the slurry, putting an obtained third mixture into a granulator to obtain a raw-material ball; naturally drying the raw-material ball for 6h to 8h at a room temperature, placing the raw-material ball in an electric heating constant-temperature blast drying box, and carrying out constant-temperature drying and aging for 8h to 10h, so as to obtain a semi-finished-product ball; placing the semi-finished-product ball at a preheating zone of a rotary kiln, and preheating the semi-finished-product ball for 30min to 40min at 600 to 850 DEG C, so as to obtain a finished-product ball; placing the finished-product ball at a high-temperature zone of the rotary kiln, calcining the finished-product ball at 1,140 to 1,250 DEG C for 40min to 80min, and then naturally cooling the finished-product ball to the room temperature to subsequently obtain the sintered ceramsite. According to the sintered ceramsite and the method, the potential activity of raw materials is sufficiently excited by adopting the wet grinding; the mill-dust pollution generated during oven drying and dry drying is avoided; the environmental pollution and the resource waste of the stockpiling of the phosphate tailing are reduced to a great extent; the sintered ceramsite prepared by the method has water resistance, high strength, heat resistance and fire resistance, and can be widely used for building structure and landscape.

Owner:HUBEI UNIV OF TECH

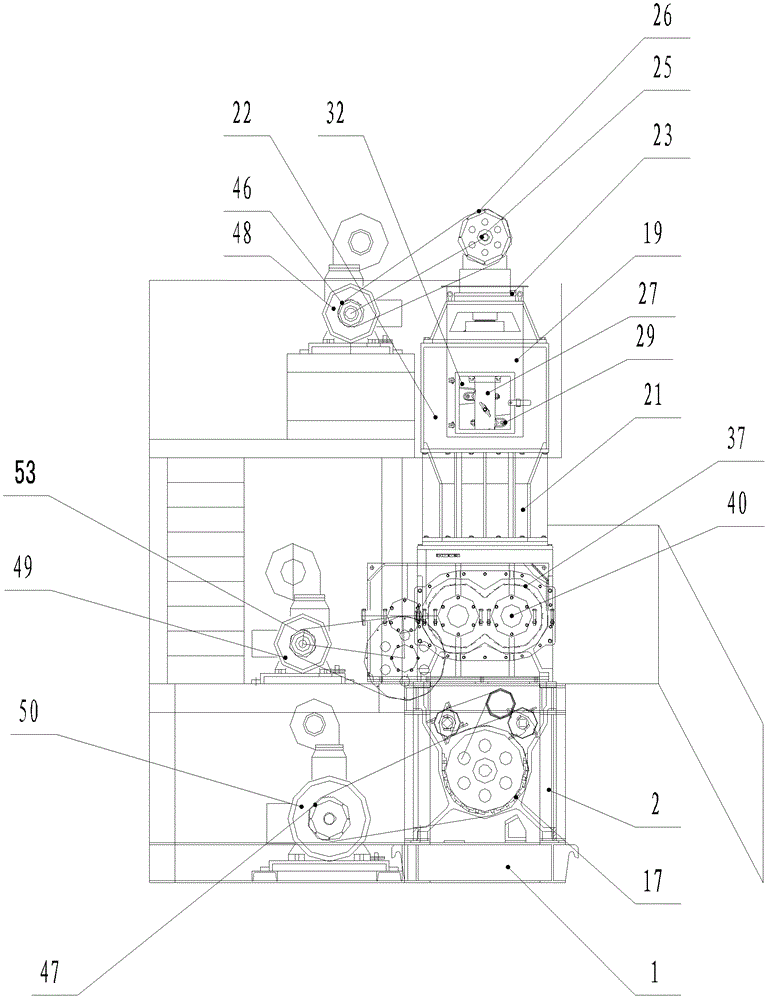

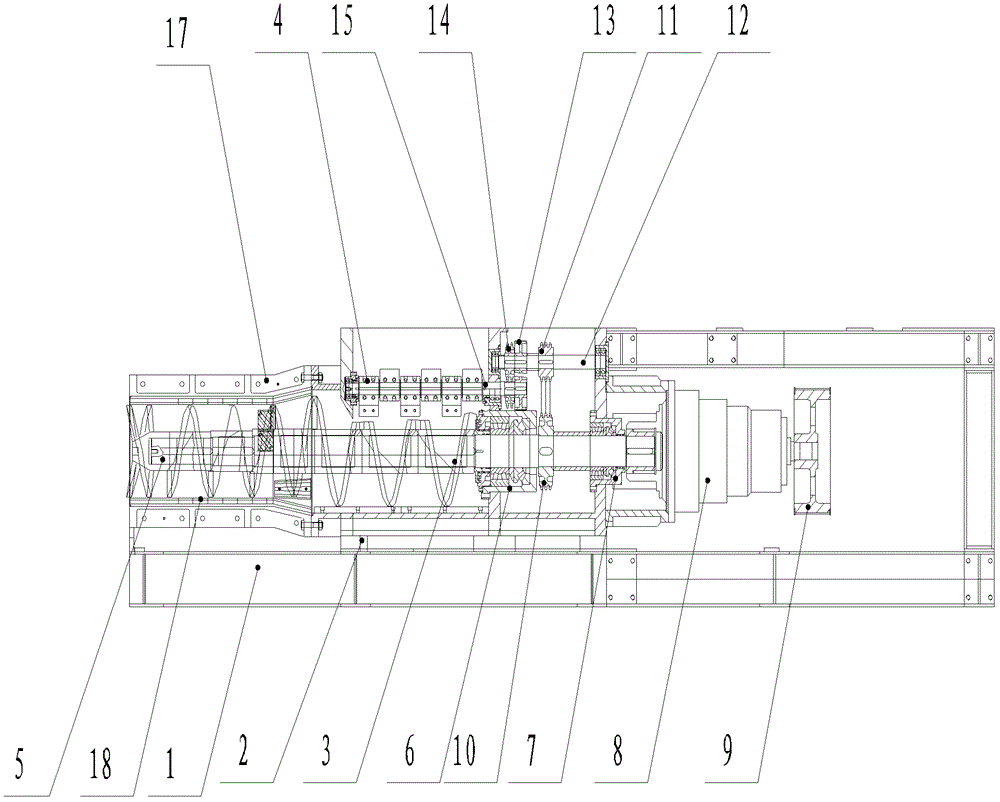

Novel terracotta extruding machine

ActiveCN102248586BIncrease productivityImprove lubrication statusCeramic shaping apparatusSludgePulp and paper industry

The invention provides a novel terracotta extruding machine, which comprises a base, wherein a lathe bed is arranged on the base; a motor I, a motor II and a motor III are arranged on the lathe bed in turn from top to bottom; an upper stirring device and a lower extruding device are arranged on the lathe bed; the upper stirring device is composed of an upright stirring part and a horizontal stirring part; the lower end of the upright stirring part is vertically connected to the upper end of the horizontal stirring part; the lower extruding device is composed of an extruding part and a sludge pressing part; the upper end of the sludge pressing part is connected to the lower end of the horizontal stirring part; the sludge pressing part is located above the extruding part; the sludge pressing part and the extruding part are both arranged in the lathe body; and an outlet end of the extruding part is connected to a planer sludge separating cylinder. In the novel terracotta extruding machine, three motors are used for simultaneously driving the stirring parts and the extruding part to work, thereby increasing the stirring intensity. When the upper stirring device is at fault or the fed material is excessive, the stirring parts are easily stopped, the extruding vacuum degree is promoted, the extruding pressure is increased, the moisture contained in terracotta is reduced and the unnecessary trouble is reduced for the subsequent process.

Owner:SHAANXI BAOSHEN MACHINERY GROUP

High-strength air cylinder cover with heat dissipation function

The invention discloses a high-strength air cylinder cover with a heat dissipation function. The high-strength air cylinder cover comprises an air cylinder cover top plate, an air cylinder cover bottom surface, exhaust ports, valve lug sets and an oil passage. An oil sprayer hole is formed in the center of the air cylinder cover top plate; the exhaust ports are formed to correspond to a pluralityof air cylinders and configured to gather outlets of the exhaust ports into the air cylinder cover; the exhaust ports are provided with push rod holes; protruding side walls are arranged on the peripheries of the top faces of the valve lug sets correspondingly; a plurality of reinforcing ribs are arranged between the side wall of each valve lug set and the air cylinder cover top plate; and the oilpassage is positioned in the inner side, in the arranging direction of the air cylinders, of the air cylinder cover. According to the air cylinder cover, the temperature of lubricating oil is effectively decreased, the strength and performance of the air cylinder cover are improved, the appearance is compact and attractive, and the reinforcing ribs are additionally arranged on the air cylinder cover, so that the local strength of all parts of the air cylinder cover is enhanced.

Owner:青岛众和盛农用机械有限公司

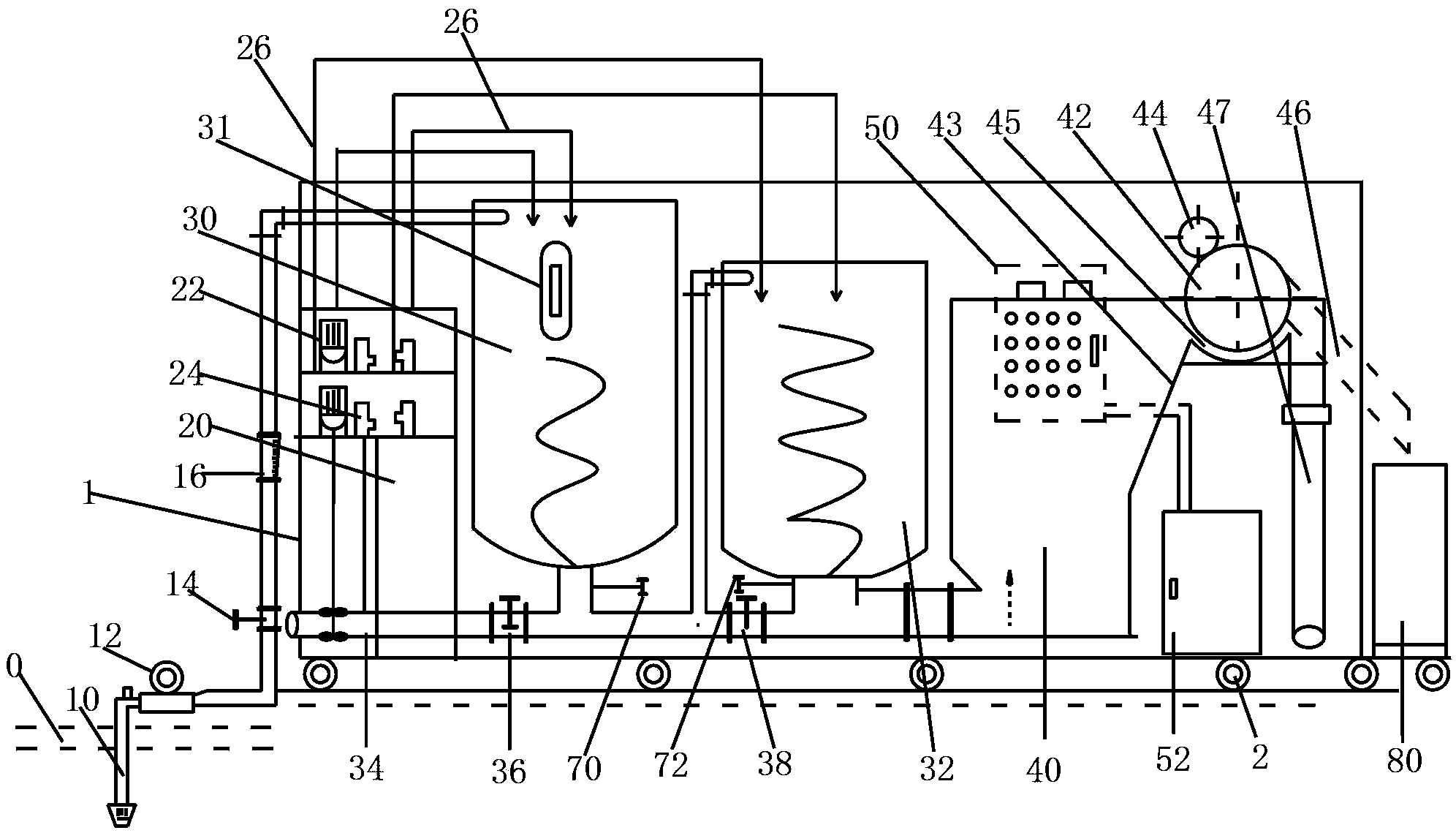

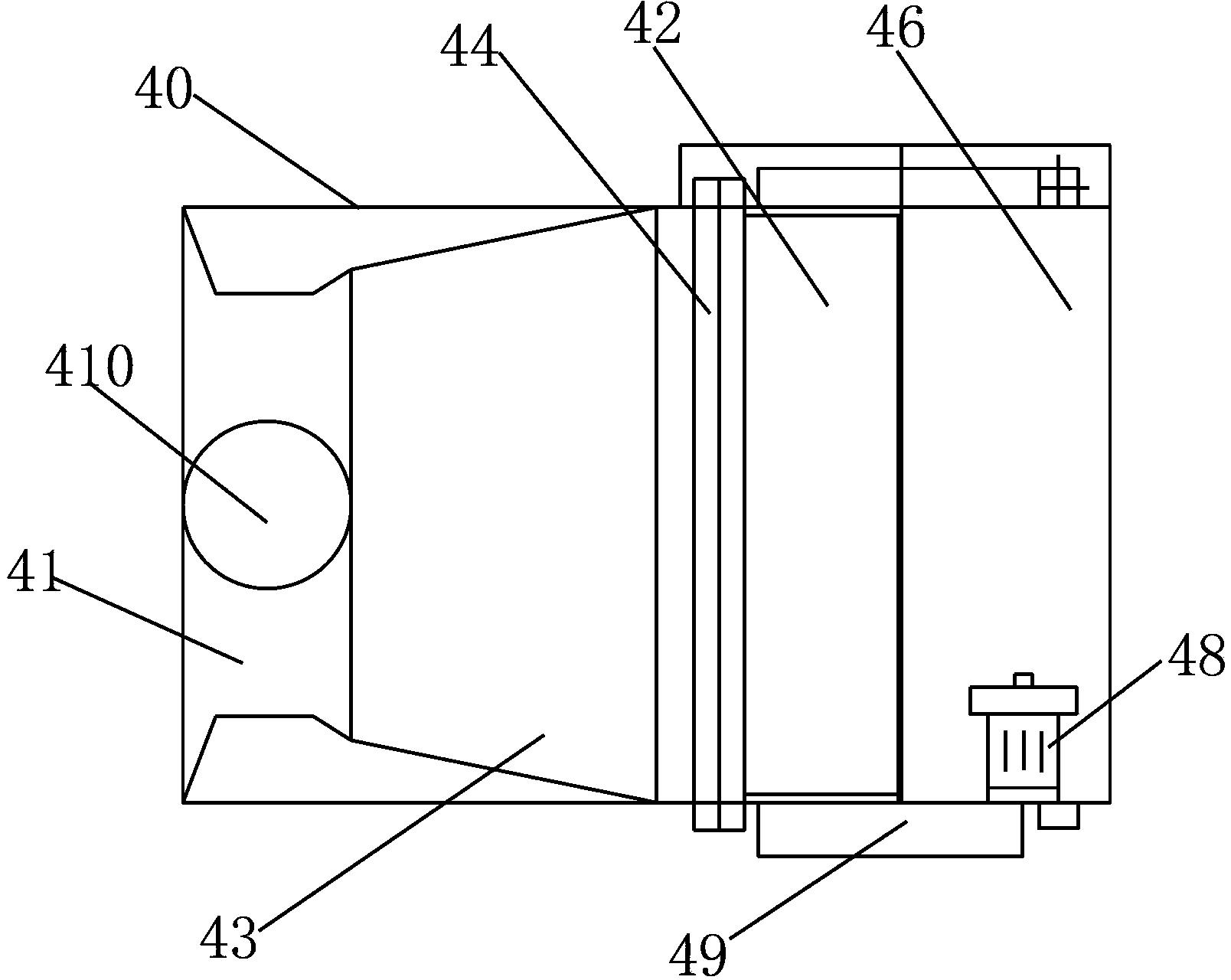

Multifunctional integral sewage purifier and using method thereof

InactiveCN103058339BLarge amount of processingSmall footprintWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationElectric controlWater treatment

The invention discloses a multifunctional integral sewage purifier and a using method thereof. The multifunctional integral sewage purifier comprises a main body and a roller wheel for supporting the main body to move, wherein the main body comprises a water inlet metering unit, a medicine adding unit, a physical-chemical reaction unit, a detecting unit, a mud-water separating unit and an electric control unit, wherein the physical-chemical reaction unit, the detecting unit, the mud-water separating unit and the electric control unit are connected with the water inlet metering unit and the medicine adding unit. According to the multifunctional integral sewage purifier disclosed by the invention, a multi-level medicine adding mode is adopted; the movement is free; the water treatment capacity is large; the floor space is small; the appearance is compact and beautiful; the investment cost is low; SS (Stainless Steel), phosphor, BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand), ammonia, nitrogen, peculiar smell, algae, chromaticity, metal ion as well as oil and sewage in the water can be removed, so that emission indexes of national sewage treatment can be achieved.

Owner:徐献荣 +1

Wearable forearm active rehabilitation training exoskeleton device with myoelectric sensing

ActiveCN108524192BEasy to wearGuaranteed experienceDiagnosticsChiropractic devicesEngineeringPattern perception

The invention requests protection of a wearable forearm active rehabilitation training exoskeleton device with myoelectric perception and belongs to robot field. The wearable forearm active rehabilitation training exoskeleton device consists of an exoskeleton support, a forearm rotation mechanism, an elbow flexion-extension mechanism, a driving motor and a myoelectric signal acquisition device, and can achieve the active rehabilitation training with two degrees of freedom for elbow flexion-extension and arm rotation. A large forearm support is easier to wear with a semi-open structure, and themyoelectric signal acquisition device is embedded in a key position of lining to collect arm myoelectric signals during the process of the rehabilitation training, and then motor movements of each joint can be adjusted according to the muscle tension, improving the security and efficiency of training. The forearm rotation mechanism adopts two sets of motor-bevel gear transmission, achieving forearm flexion-extension movements through synchronous coordinated movements of two motors. The forearm rotation mechanism adopts the driving mode of wire, and the forearm rotation angle is 180 degrees. The wearable forearm active rehabilitation training exoskeleton device with the myoelectric perception is more convenient, safer and more effective in rehabilitation training and can be widely used inhospitals, communities and families.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

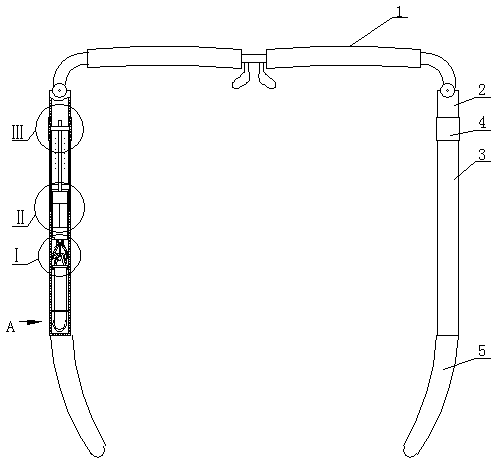

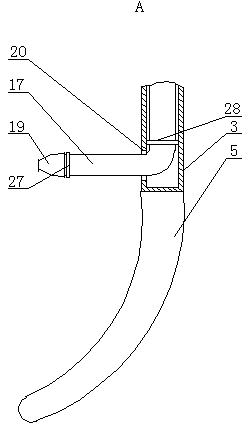

Hearing equipment with sound tube plug connection

A hear device having an acoustic tube plug connection, including glasses, each leg of the glasses includes a first straight tube,a second straight pipe, a casing, and a hanging lug bending rod, the lower end of the first straight pipe is connected with the upper end of the second straight pipe through a sleeve, the first straight pipe, the second straight pipe, and the sleeve are coaxial, the outer periphery of the lower end of the first straight pipe and the outer periphery of the upper end of the second straight pipe are provided with a first annular groove, both the first straight tube andthe second straight tube are inserted into the inside of the sleeve at a first annular groove, sleeve clasps are fixed at the first annular grooves of the first straight pipe and the second straight pipe, an annular clasp grooves are arranged at the inner wall of the sleeve near the upper and lower ends, the clasp is inserted and matched with the corresponding annular clasp groove, a cylindrical shell is arranged in the second straight pipe, and the shell can move back and forth along the length direction of the second straight pipe. The invention skillfully combines the hearing aid device with the eyes, has a compact and beautiful appearance, can fold the ear parts at any time, and can adjust the sound output volume of the ear parts through a mechanical adjustment method.

Owner:DONGGUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com