Middle box automatic cartoning machine

An automatic cartoning machine and middle box technology, which is applied in packaging, conveyor objects, transportation and packaging, etc., can solve the problems of limited manual speed, increased labor cost, and poor production process, and achieves convenient installation and simple structure , Compact and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

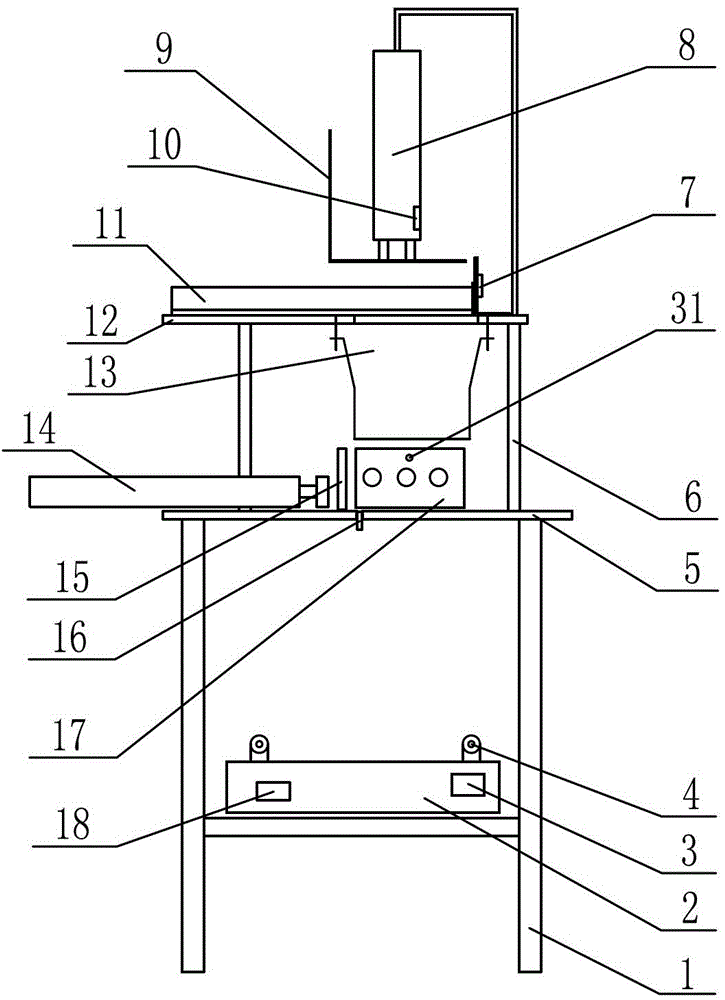

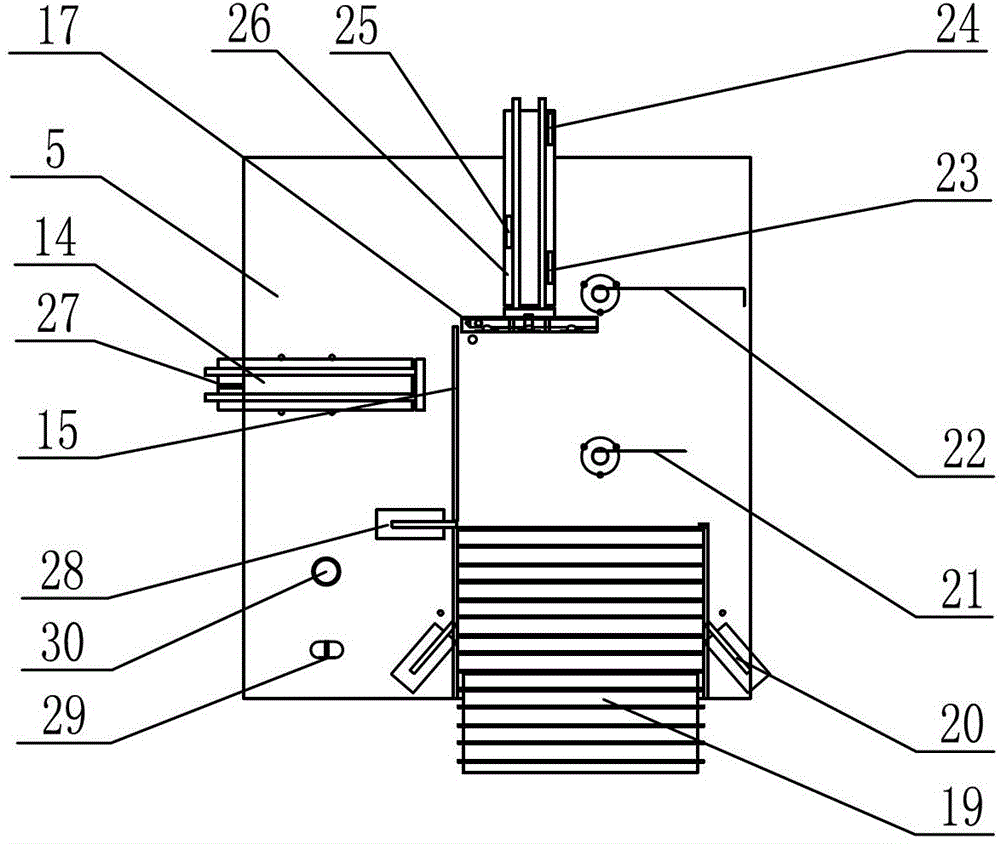

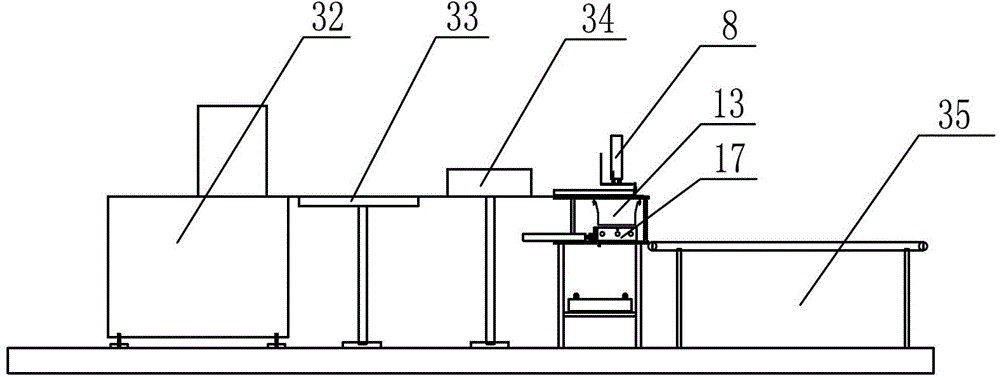

[0025] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0026] Such as figure 1 , figure 2 As shown, the middle box automatic cartoning machine of the present invention includes a body 1, an electrical box 2 is arranged inside the body 1, an upper platform 12 and a lower platform 5 are arranged on the upper part of the body 1, and a pillar is passed between the upper platform 12 and the lower platform 5 6 supports, the upper platform 12 is provided with a box-moving track 11 and a box-pressing cylinder 8, the box-pressing cylinder 8 is arranged above the box-moving track 11, the box-pressing cylinder 8 is connected to the box-pressing plate 9, and the box-pressing plate 9 is in phase with the box-moving track 11 Corresponding; Corresponding box pressing plate 9 is provided with guide groove 13 at the lower part of upper platform 12 openings, and lower platform 5 front ends are provided with box rack 19, and box rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com