Isobaric grain-drying tower

A drying tower and grain technology, applied in the field of pressed grain drying tower and grain drying equipment, can solve the problems of cold and hot air medium flow resistance, harsh working environment of the drying tower, affecting the quality of grain after drying, etc. The effect of improving the quality after drying, compact and beautiful appearance, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

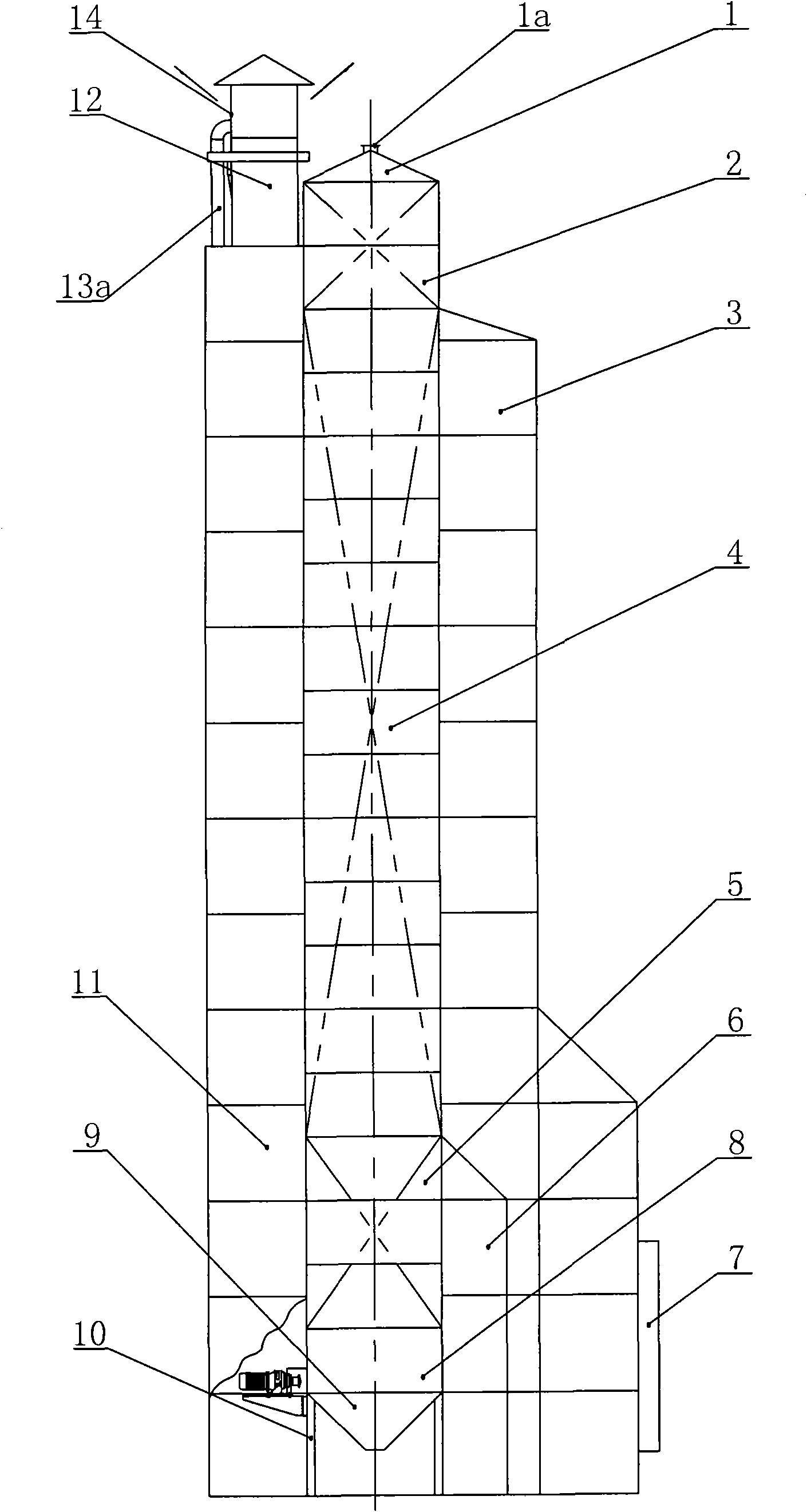

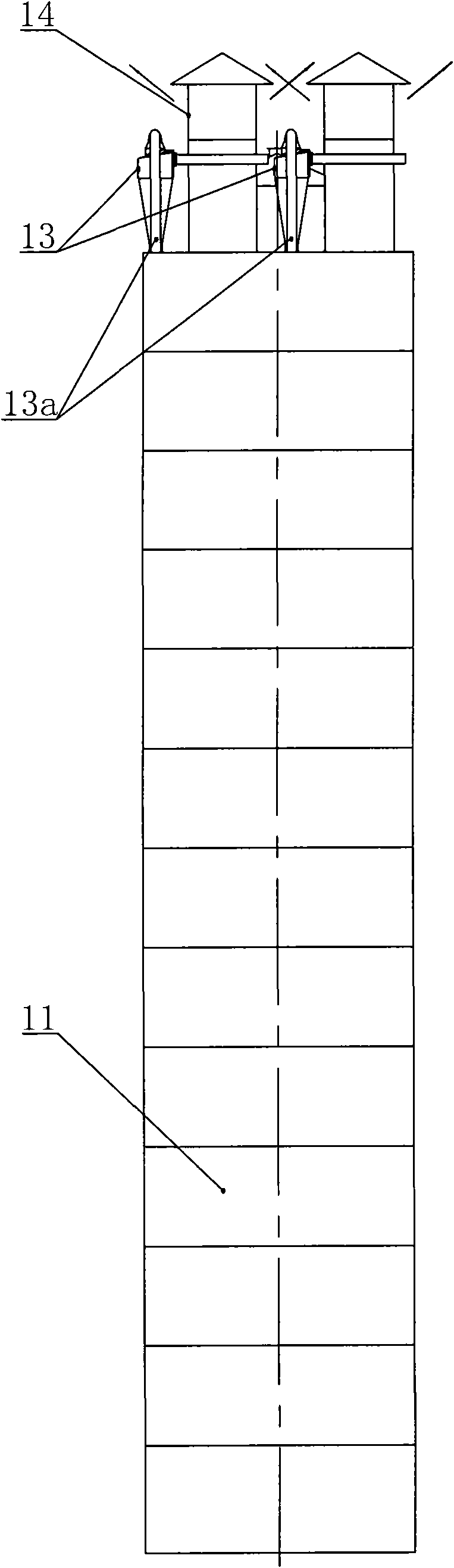

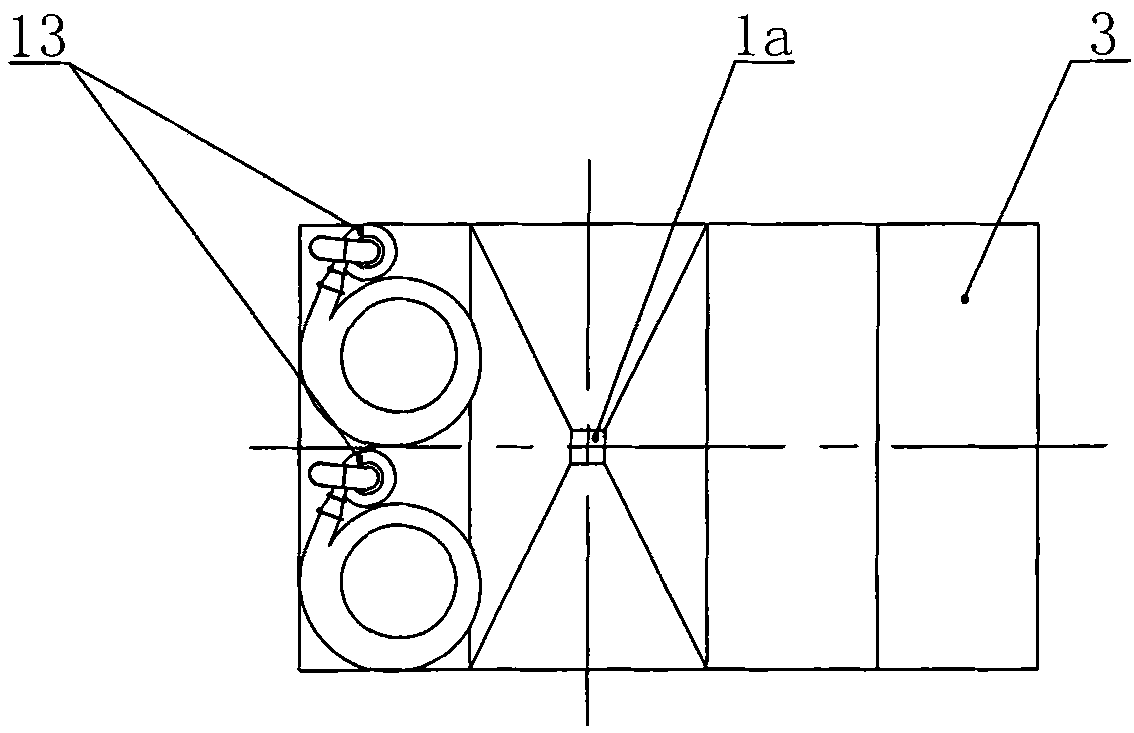

[0019] Figure 1 to Figure 4 Shown is an embodiment of the present invention, the tower body of the isobaric grain drying tower includes a bracket 10, a grain feeding layer 1, a grain storage layer 2, and a drying bin stacked on the bracket 10 in sequence from top to bottom 4. The cooling bin 5 and the grain discharge layer 8, the grain discharge layer 8 is provided with a discharge hopper 9, and the drying bin 4 includes multiple drying layers stacked in sequence, and each drying layer is respectively provided with staggered ventilation boxes, The cooling chamber 5 includes multiple layers of cooling layers stacked one after another, and each cooling layer is respectively provided with ventilation boxes arranged in a staggered manner. The same side of the drying bin 4 and the cooling bin 5 are respectively equipped with a hot air inlet of the drying bin and a cold air inlet of the cooling bin, and the other side is respectively equipped with a hot air outlet of the drying bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com