Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Change contact angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrowetting device and varifocal lens, optical pickup device, optical recording/reproduction device, droplet operation device, optical element, zoom lens, imaging device, light modulating

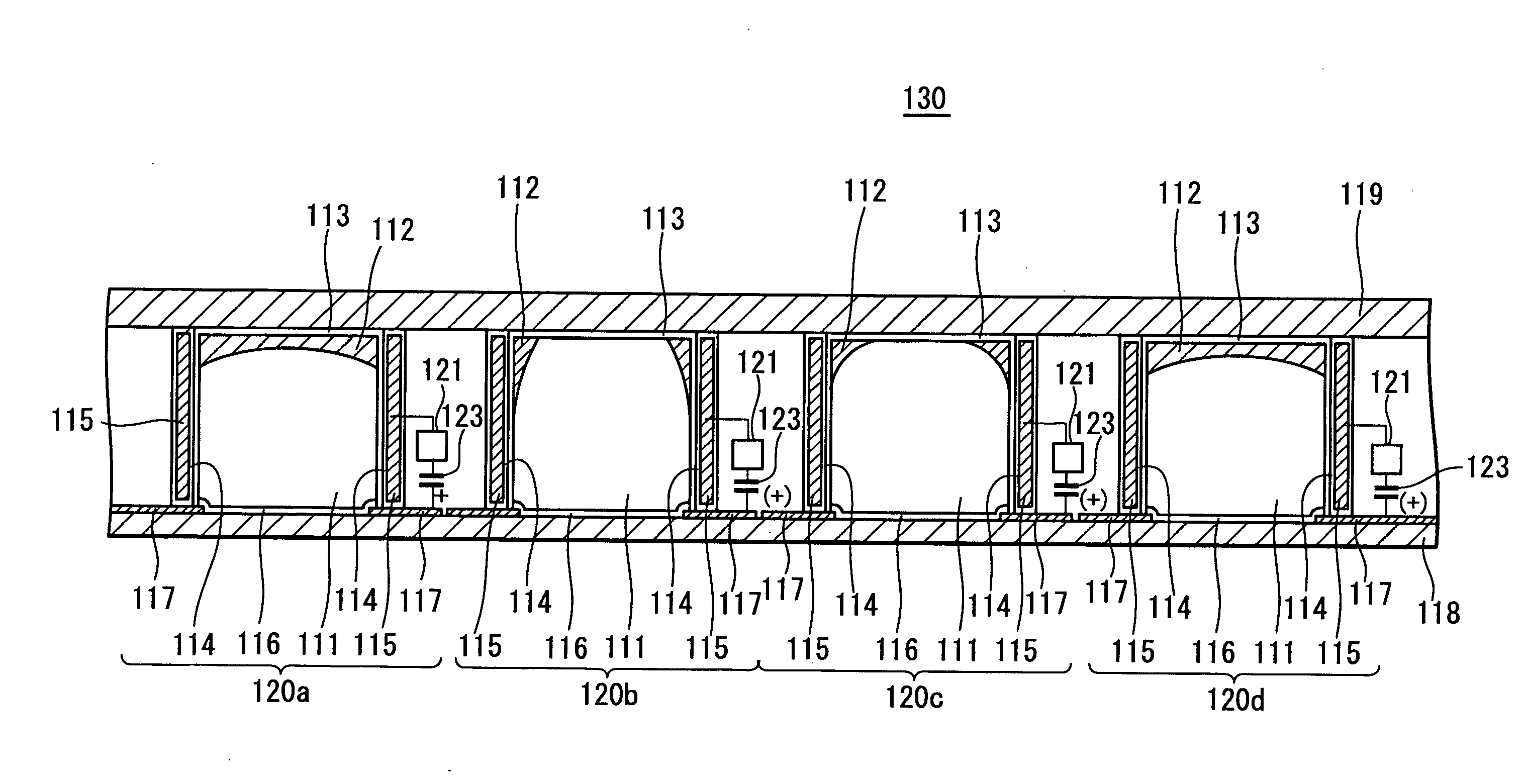

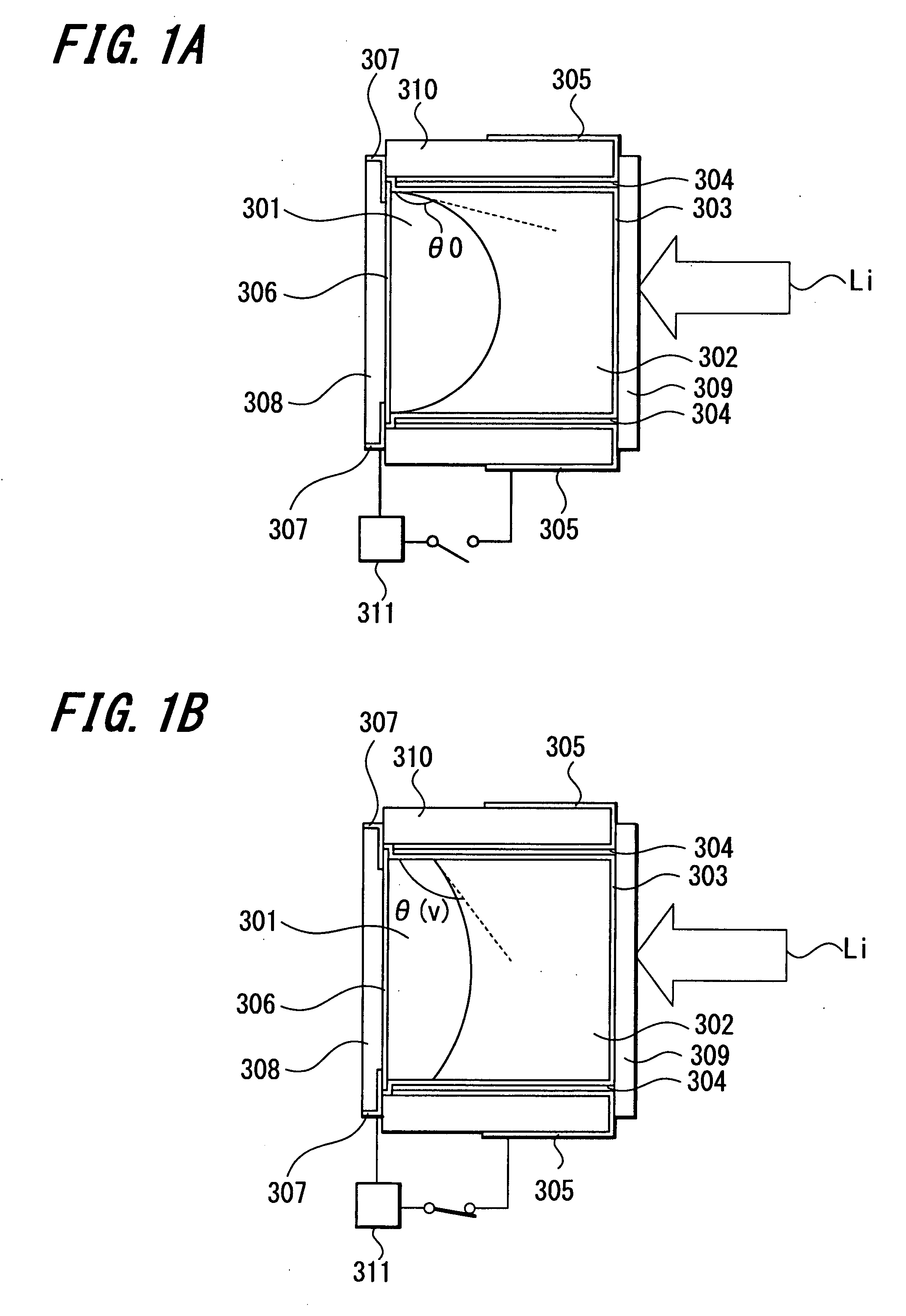

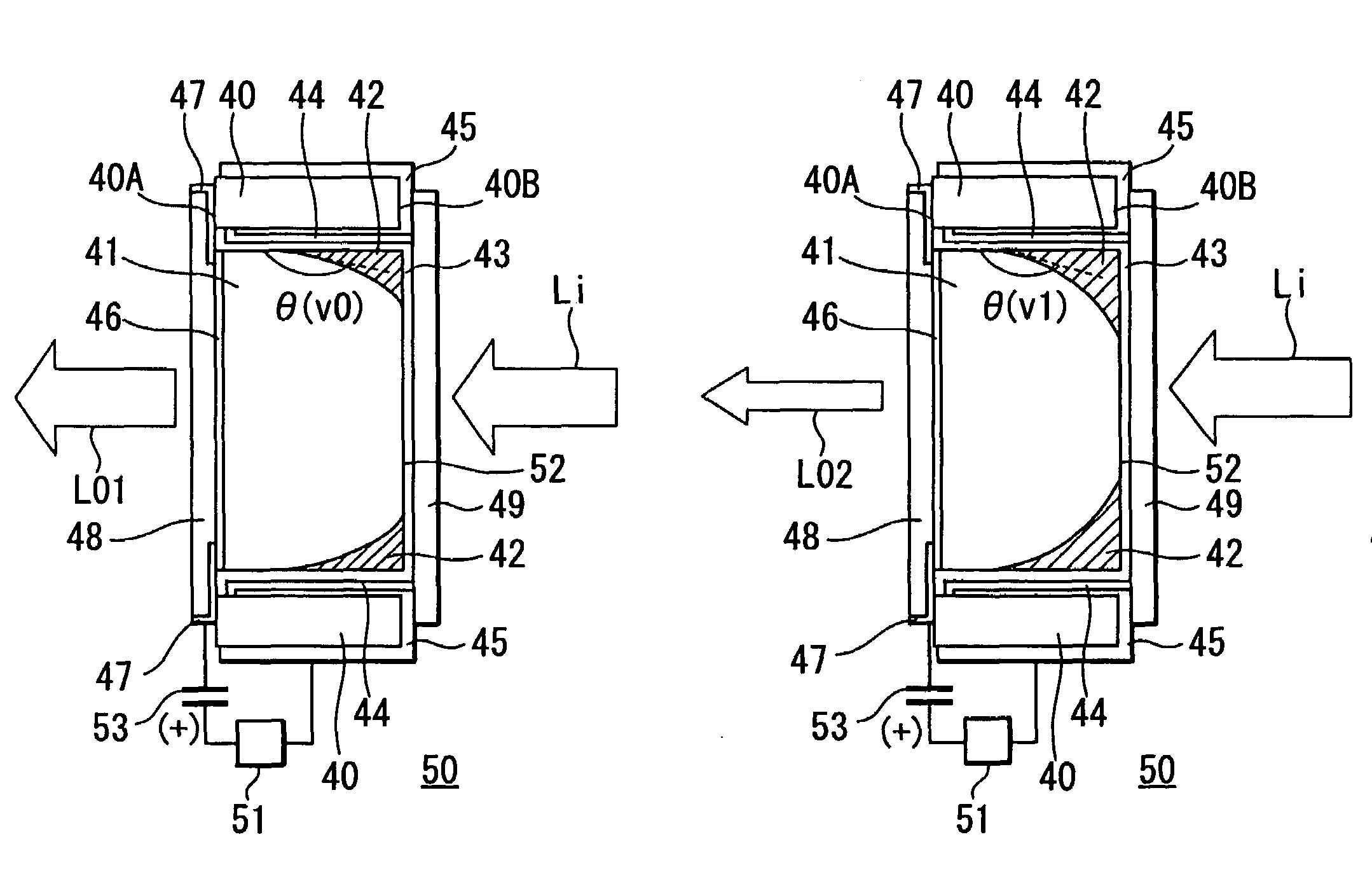

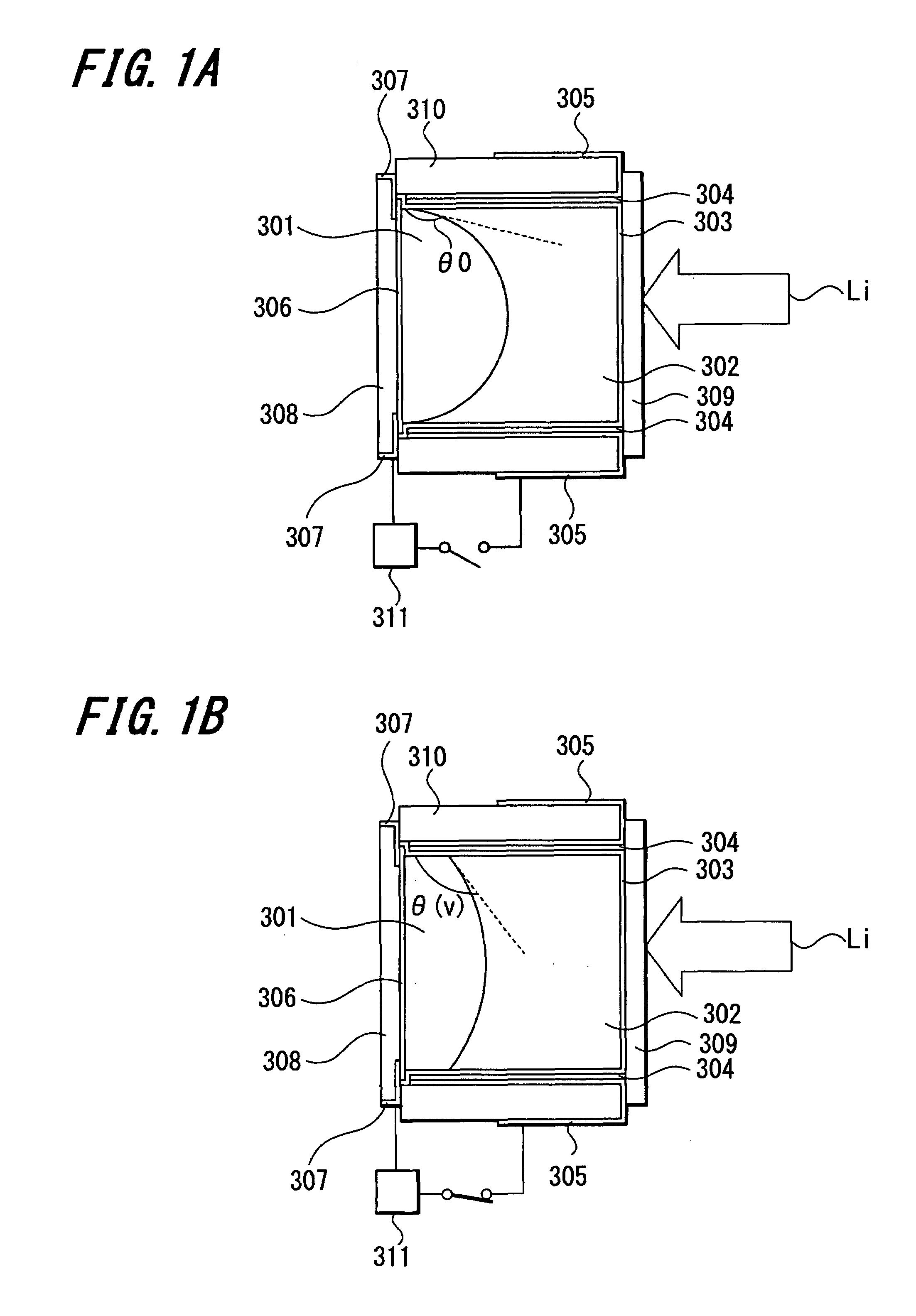

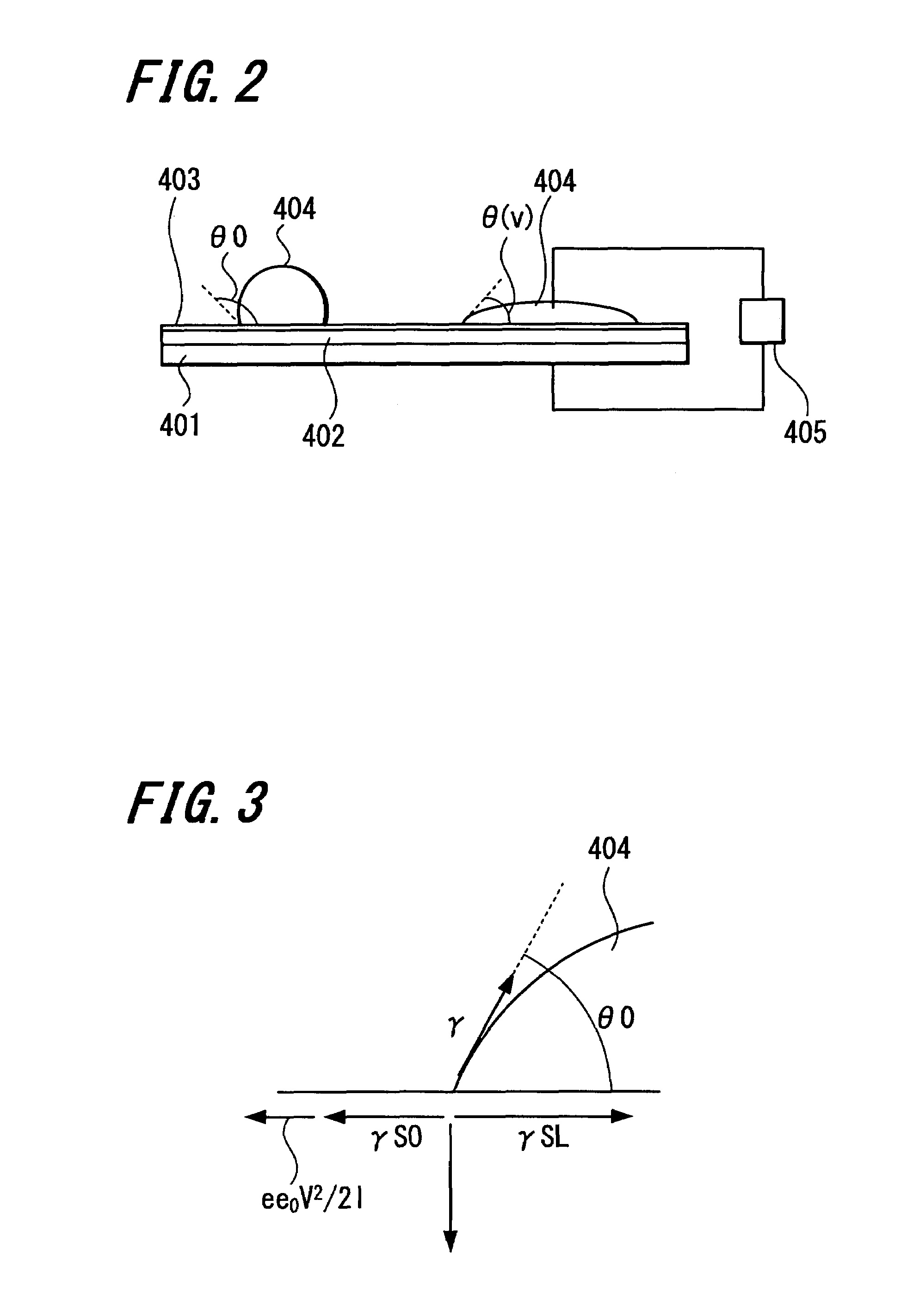

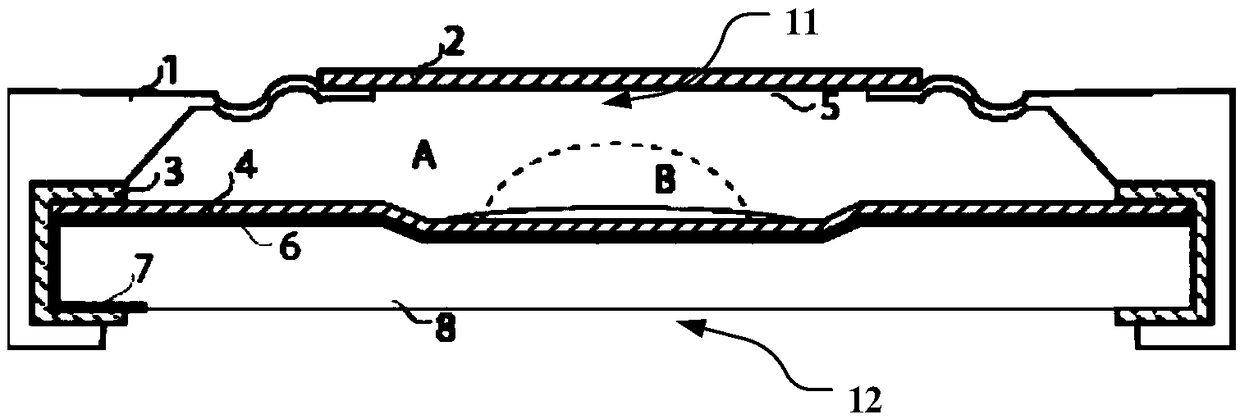

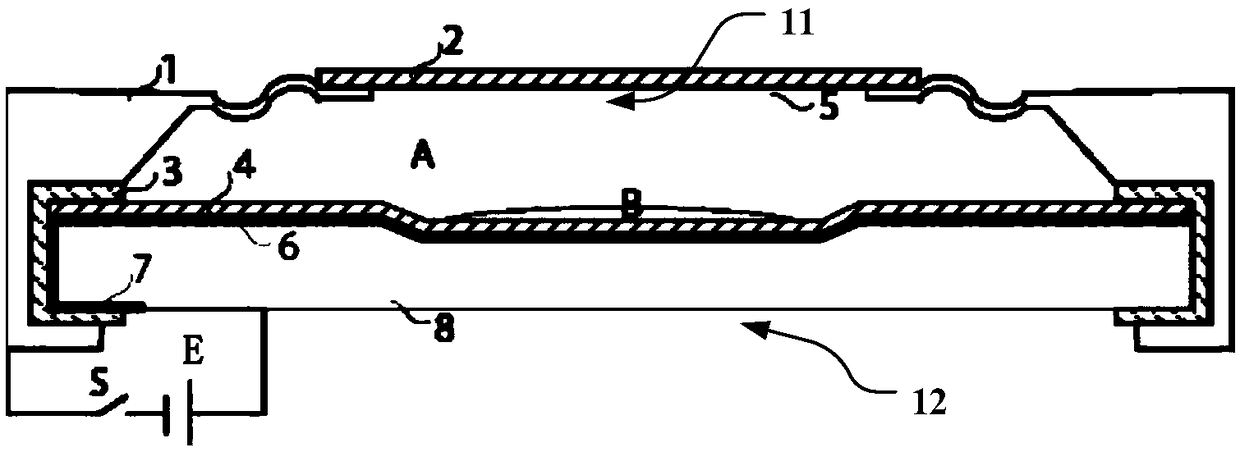

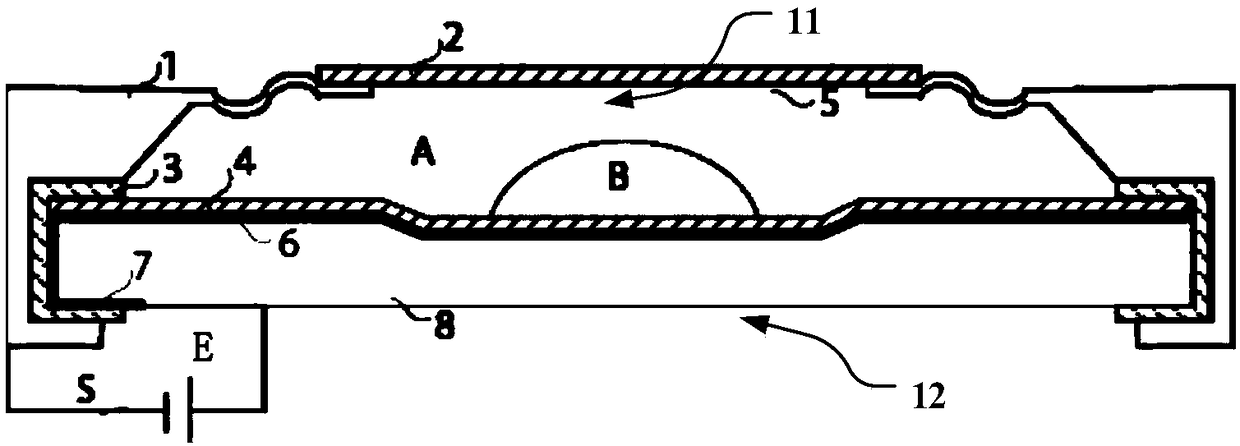

InactiveUS20080100905A1Drive voltage causing an equal change in focal length may be reducedReduce film thicknessPiezoelectric/electrostriction/magnetostriction machinesStatic indicating devicesOptical pickupEngineering

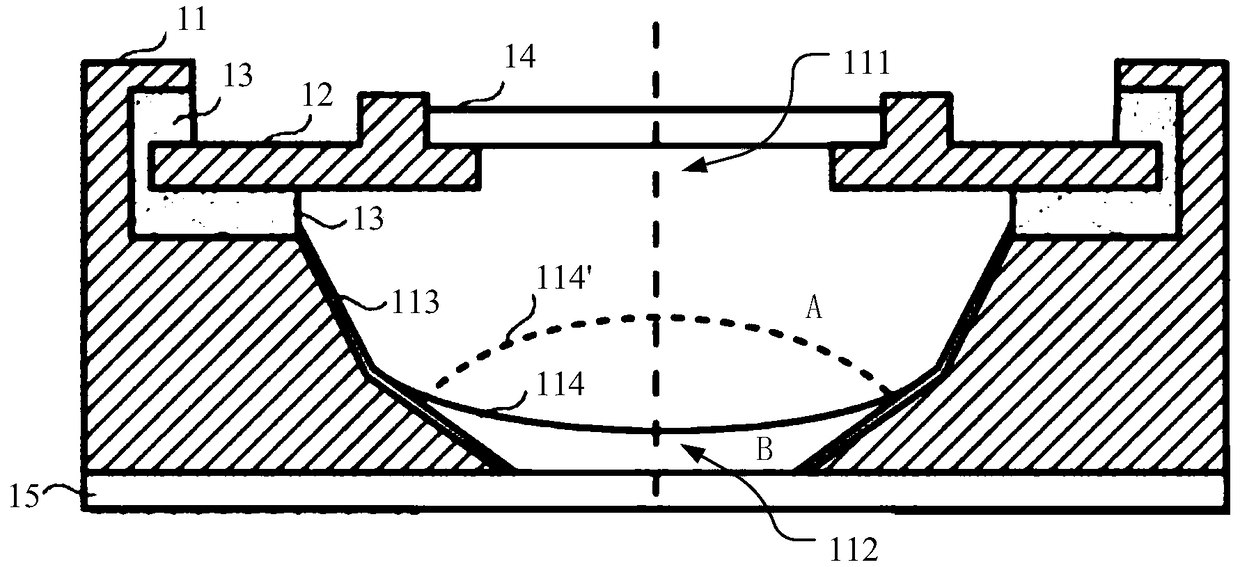

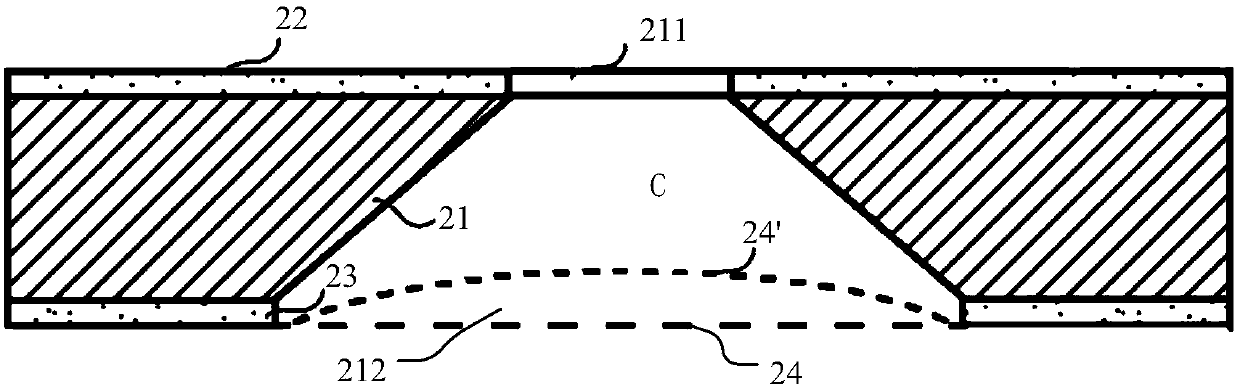

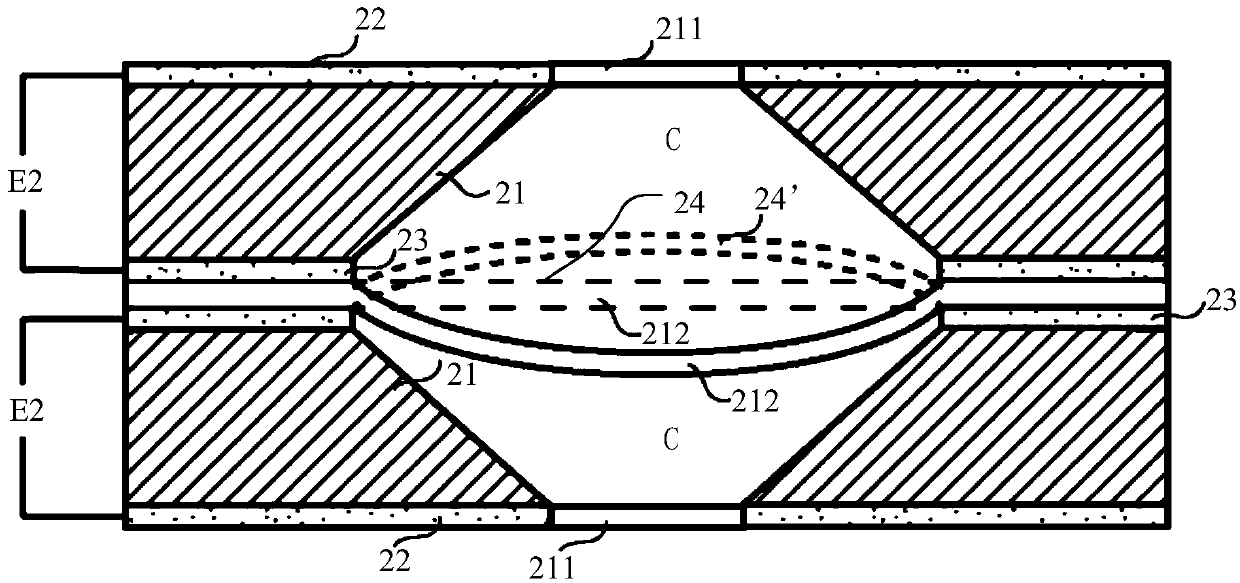

Disclosed is an electrowetting device. The electrowetting device includes a conductive or polar liquid material, and an electrode applying voltage to the liquid material through a dielectric layer. In the electrowetting device, the dielectric layer is formed as an anodized portion made of a metal oxide formed by anodizing the electrode, and a voltage applying unit applying voltage between the electrode and the liquid material and a polar capacitor are placed between the electrode and the liquid material.

Owner:SONY CORP

Electrowetting device and varifocal lens, optical pickup device, optical recording/reproduction device, droplet operation device, optical element, zoom lens, imaging device, light modulating device, and display device using the same

InactiveUS7697187B2Drive voltage causing an equal change in focal length may be reducedReduce film thicknessStatic indicating devicesRecord information storageOptical pickupDisplay device

Disclosed is an electrowetting device. The electrowetting device includes a conductive or polar liquid material, and an electrode applying voltage to the liquid material through a dielectric layer. In the electrowetting device, the dielectric layer is formed as an anodized portion made of a metal oxide formed by anodizing the electrode, and a voltage applying unit applying voltage between the electrode and the liquid material and a polar capacitor are placed between the electrode and the liquid material.

Owner:SONY CORP

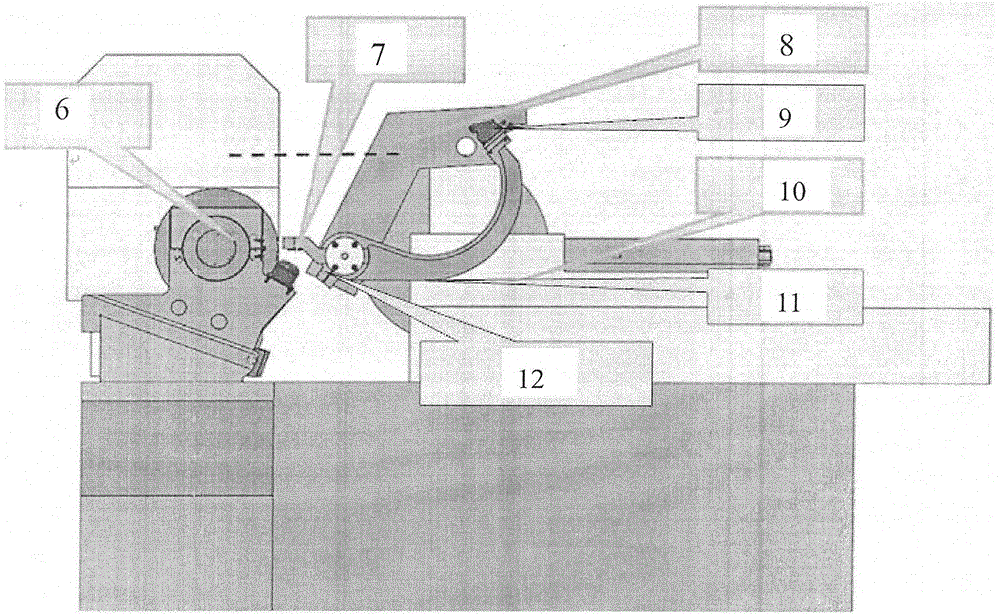

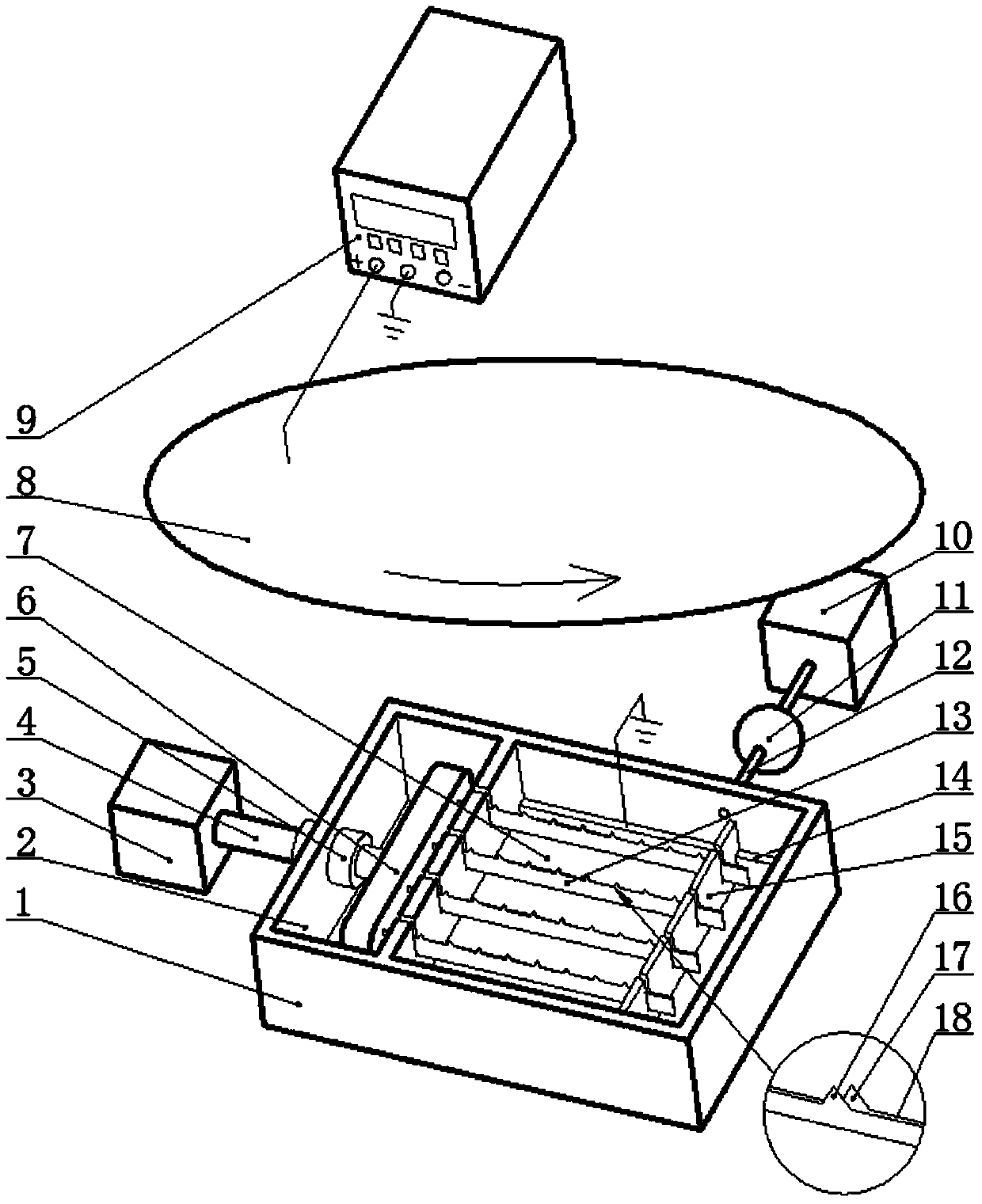

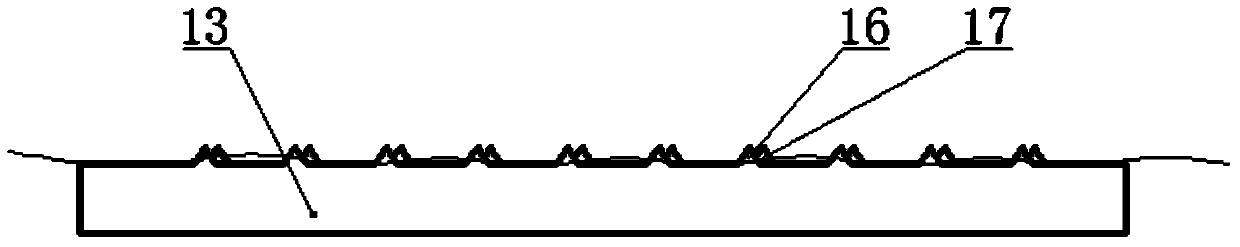

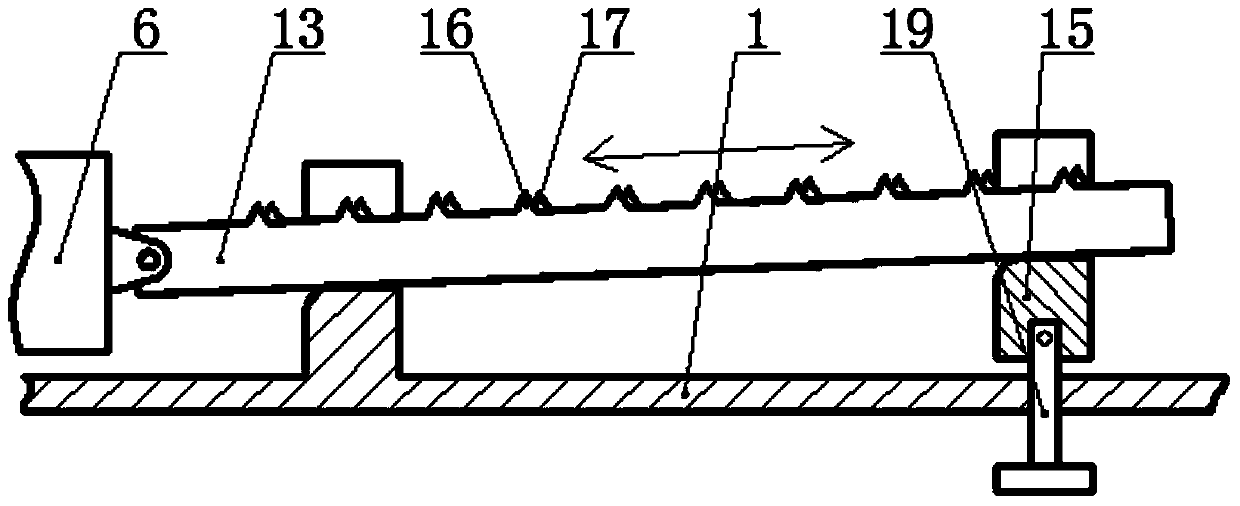

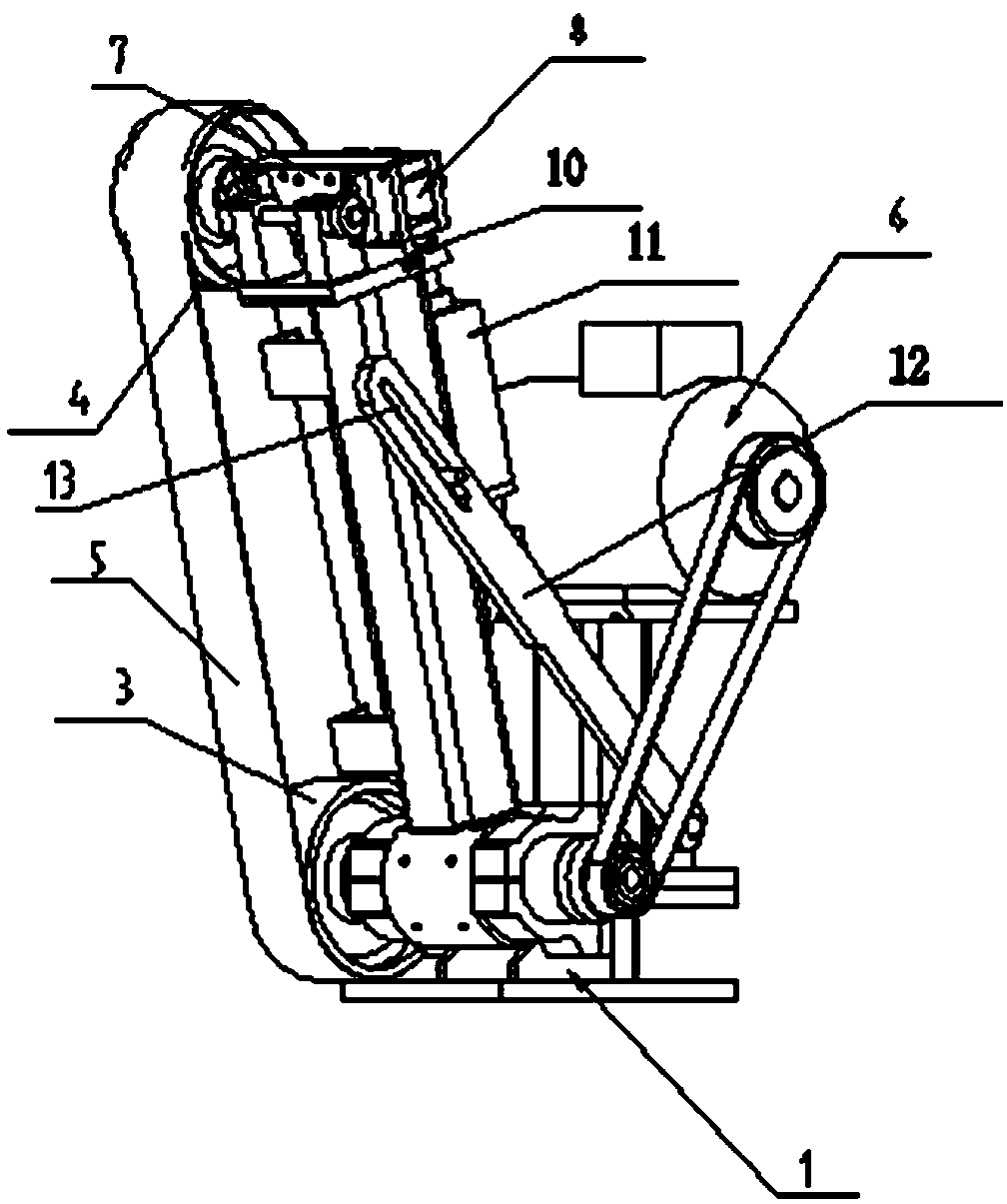

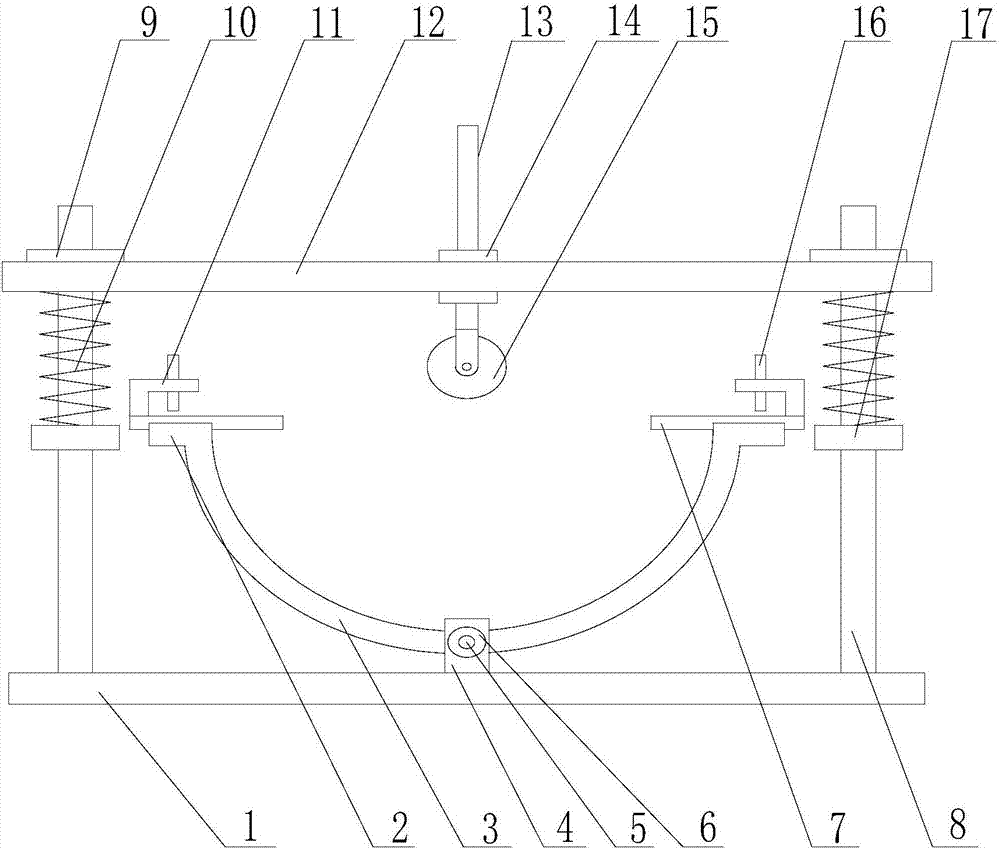

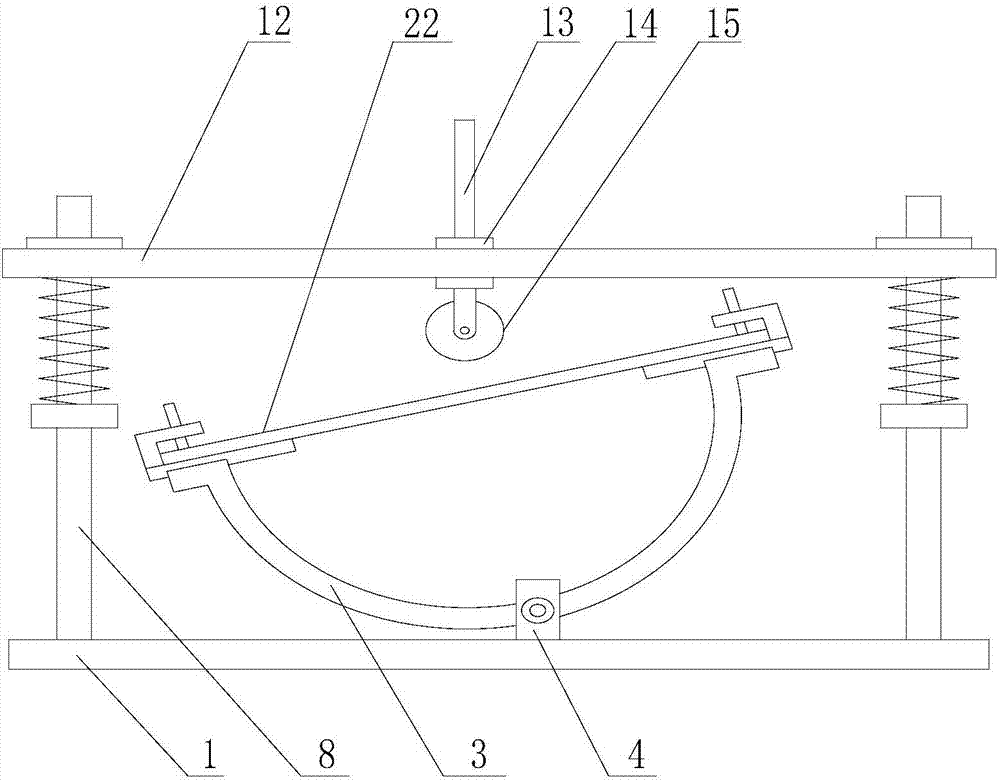

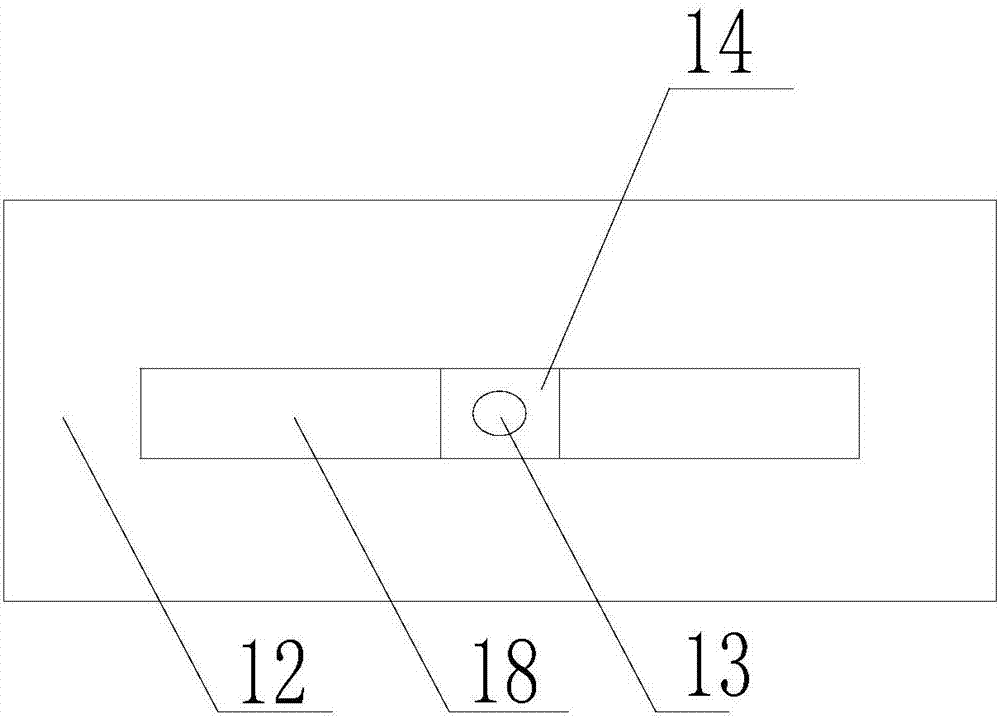

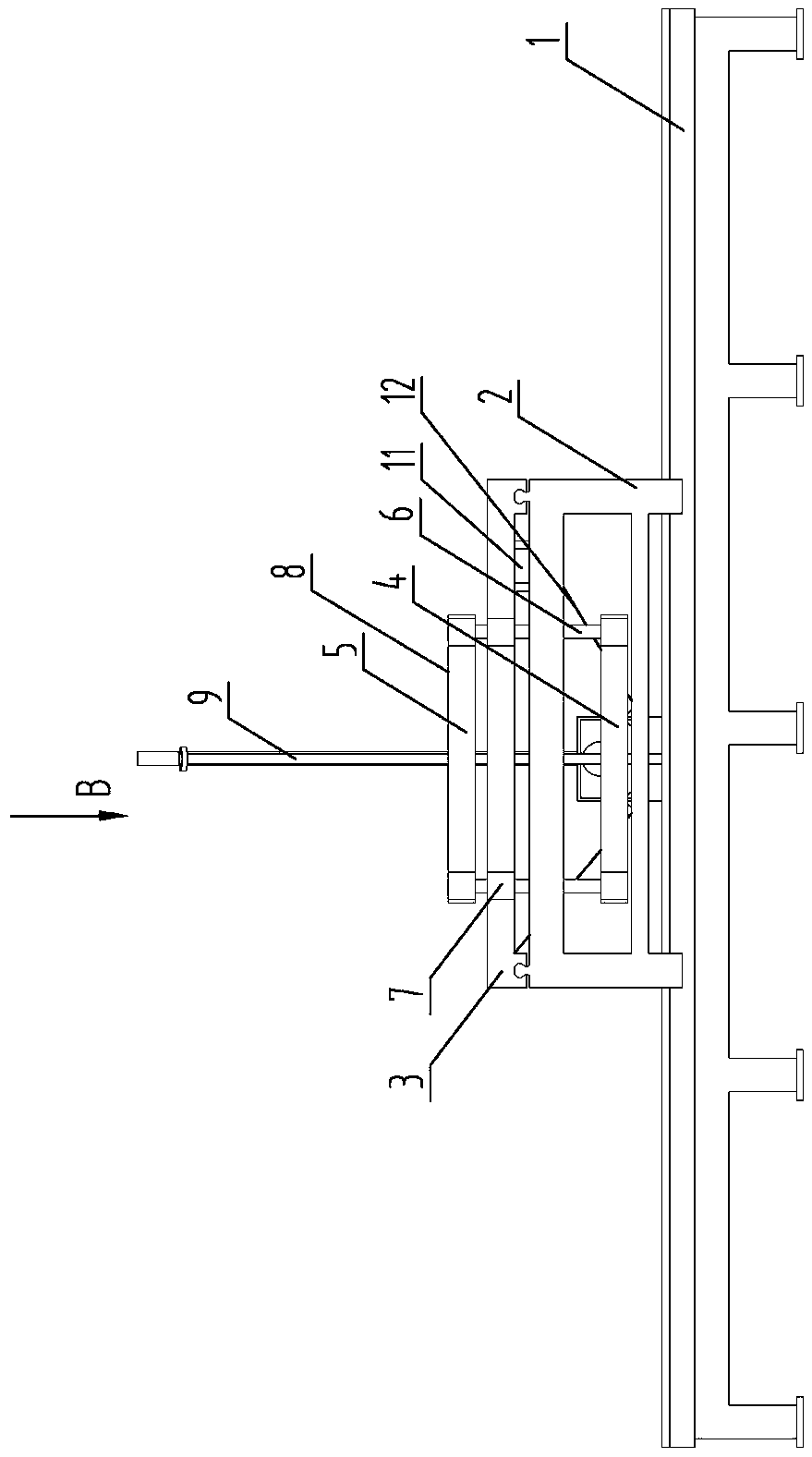

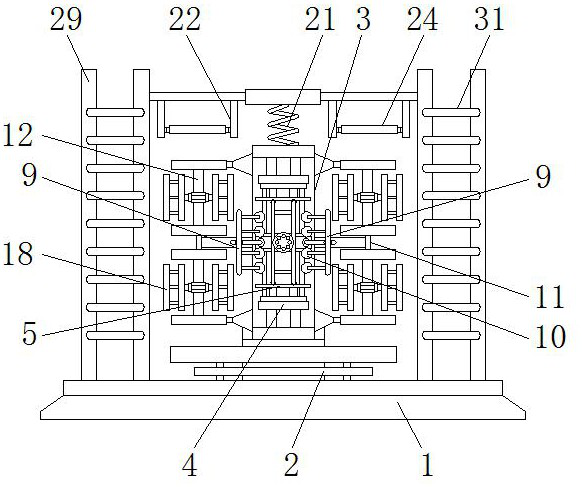

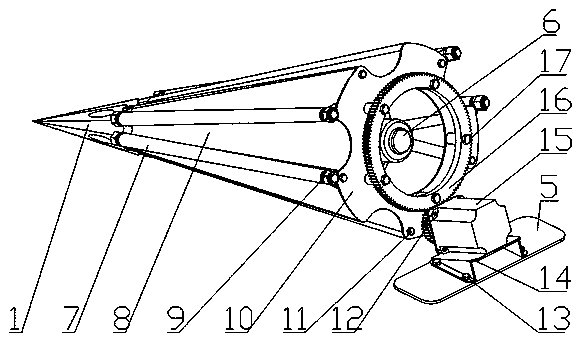

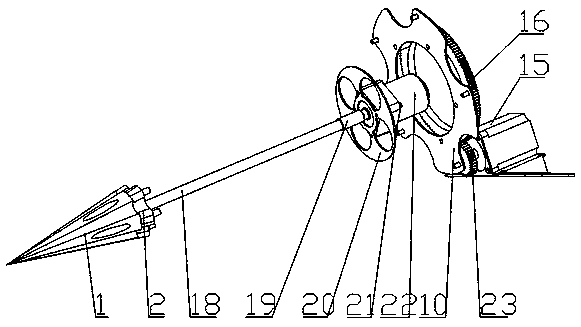

Turning, grinding and polishing all-in-one machine device for rubber roller

InactiveCN105690095AChange contact angleChange contact positionOther manufacturing equipments/toolsDrive wheelEngineering

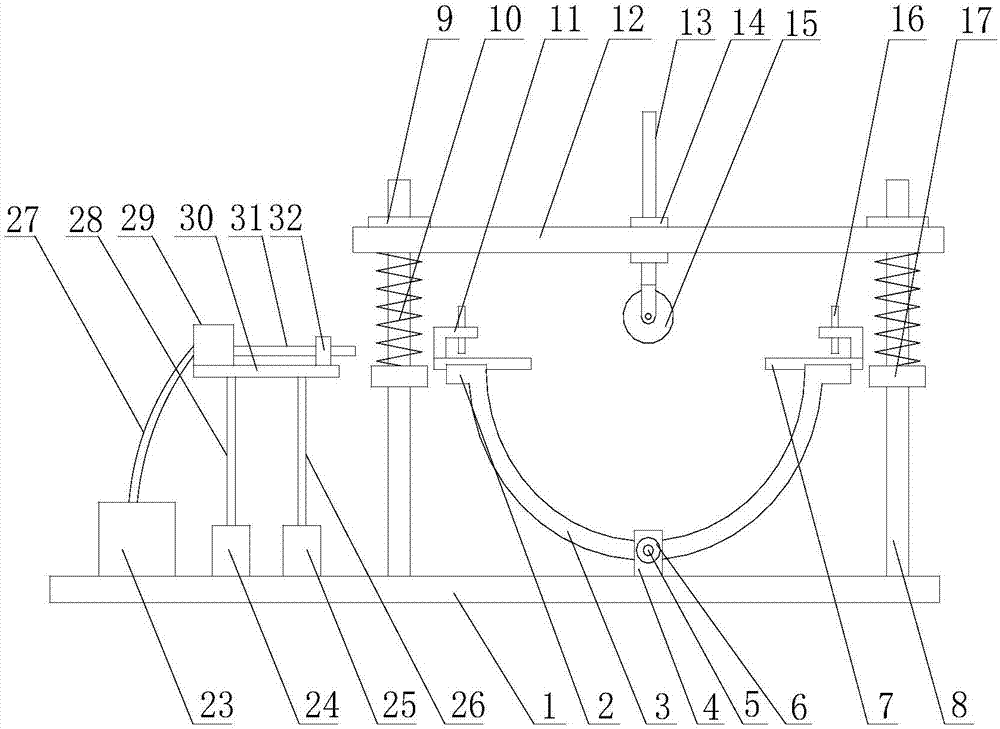

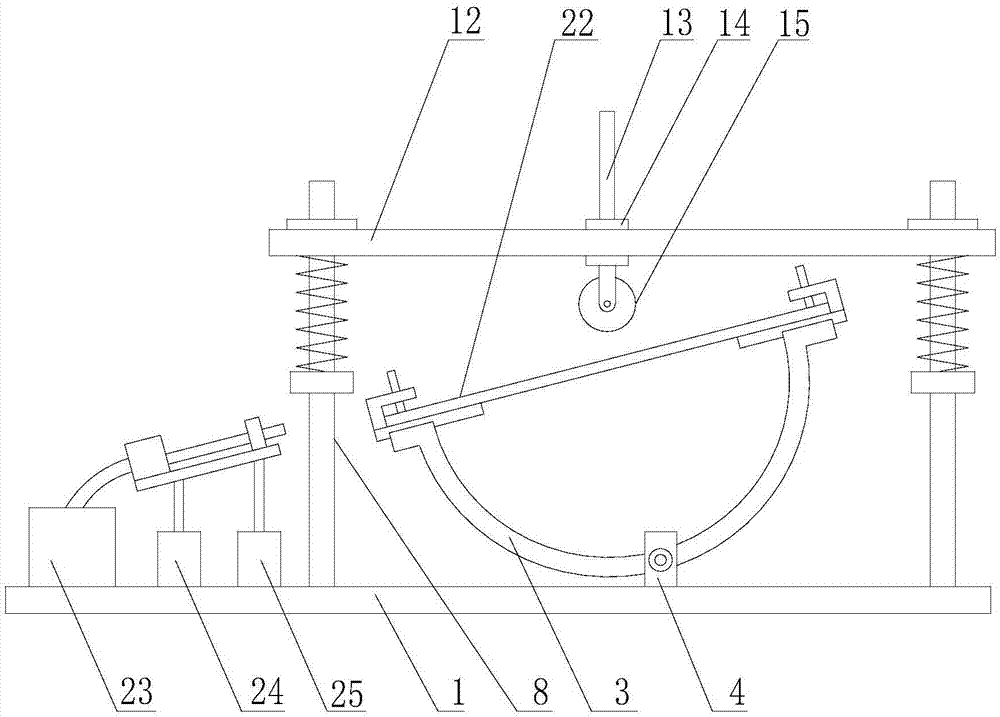

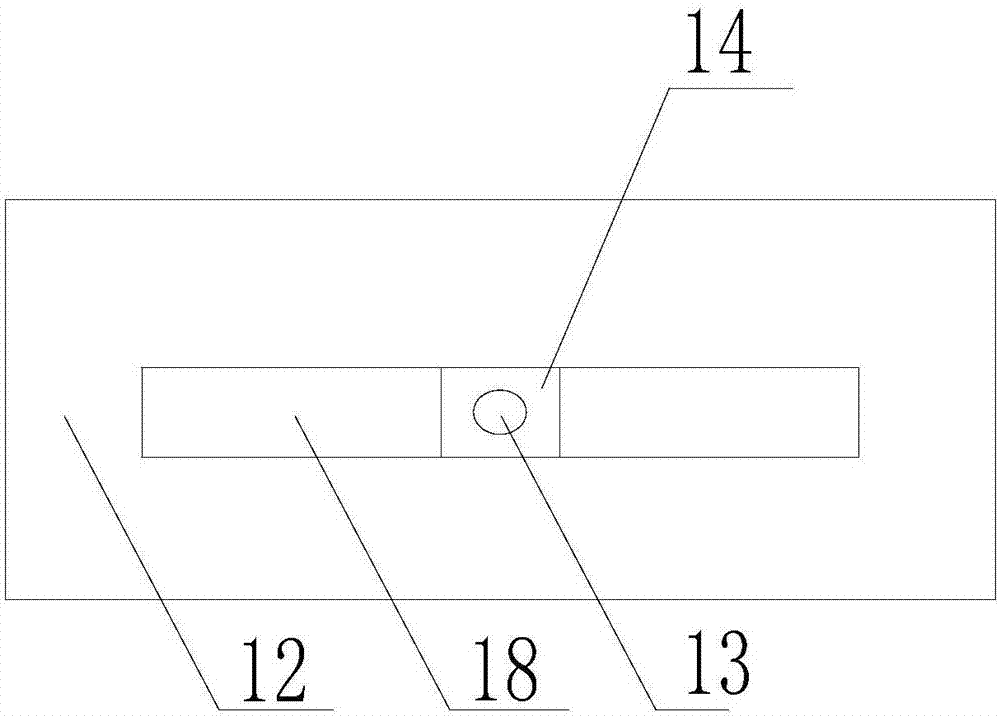

The invention provides a turning, grinding and polishing all-in-one machine device for a rubber roller. By the adoption of the turning, grinding and polishing all-in-one machine device for the rubber roller, turning, grinding through a grinding wheel and polishing through an abrasive belt can be achieved at the same time. According to the turning, grinding and polishing all-in-one machine device for the rubber roller, a turning machine, a grinding machine and a polishing device for the rubber roller are highly integrated, and new functions are additionally achieved based on the grinding machine special for the rubber roller. A power machine head used for making a workpiece rotate is installed at one end of a machine body, and a machine tail is installed at the other end of the machine body; a spindle is arranged on the machine head; one end of the spindle is connected with a chuck, and the other end of the spindle is connected with a power device; a center used for fixing the workpiece is arranged on the machine tail, and the spindle of the machine head and the center of the machine tail are located on the same center line; a measurement device is installed on the upper surface of the machine body; and an annular abrasive belt driving and tensioning device is installed on a workbench. A whole annular abrasive belt can rotate around the axis of a driving wheel, so that the contact angle between the abrasive belt and the workpiece is changed, and accordingly the position, making contact with the workpiece, of the abrasive belt is changed, and different machining requirements are met.

Owner:SUZHOU HONGSUN ELECTROMECHANICAL TECH CO LTD

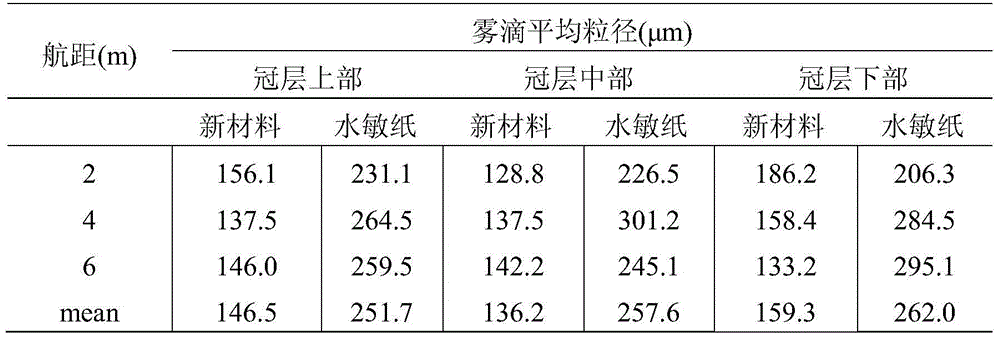

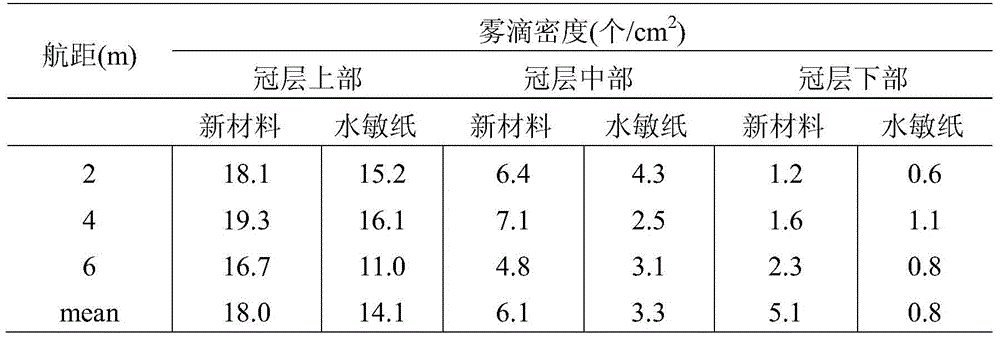

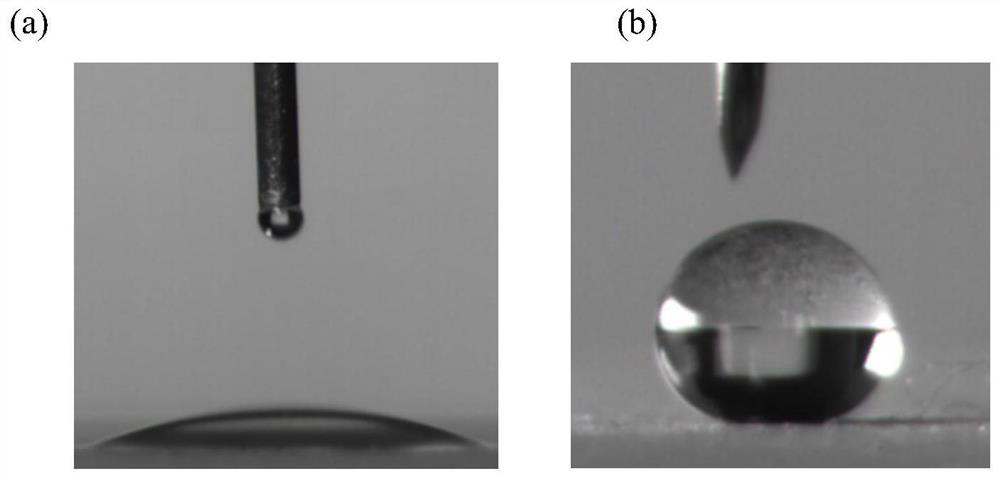

Humidity sensing ceramic, and preparation method and application thereof

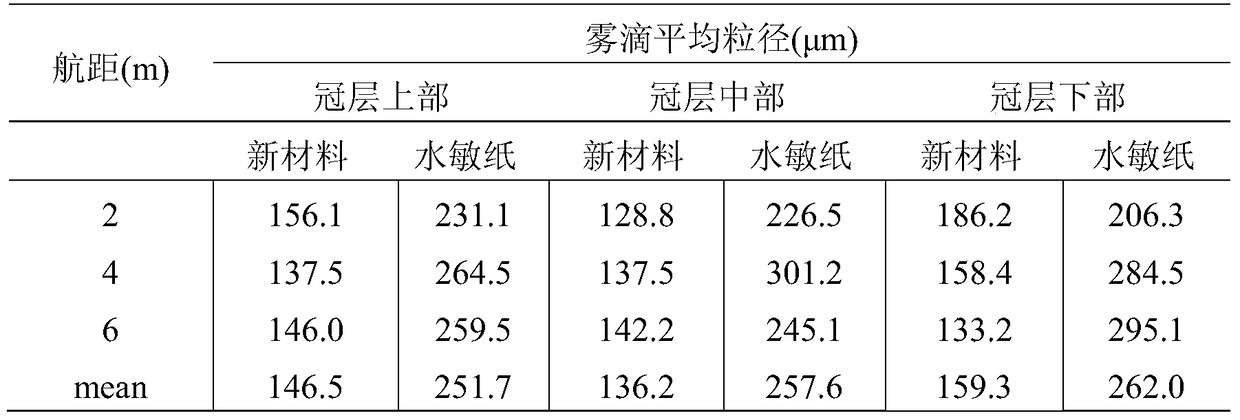

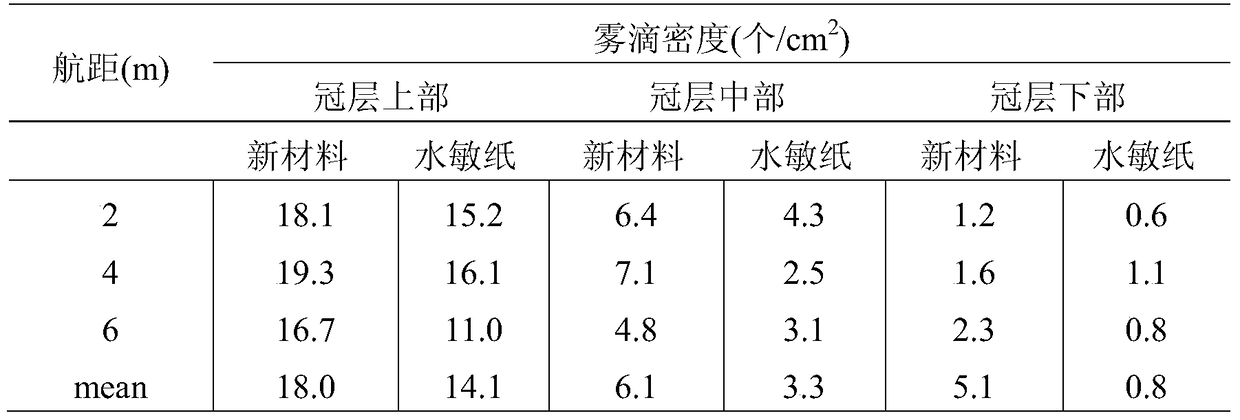

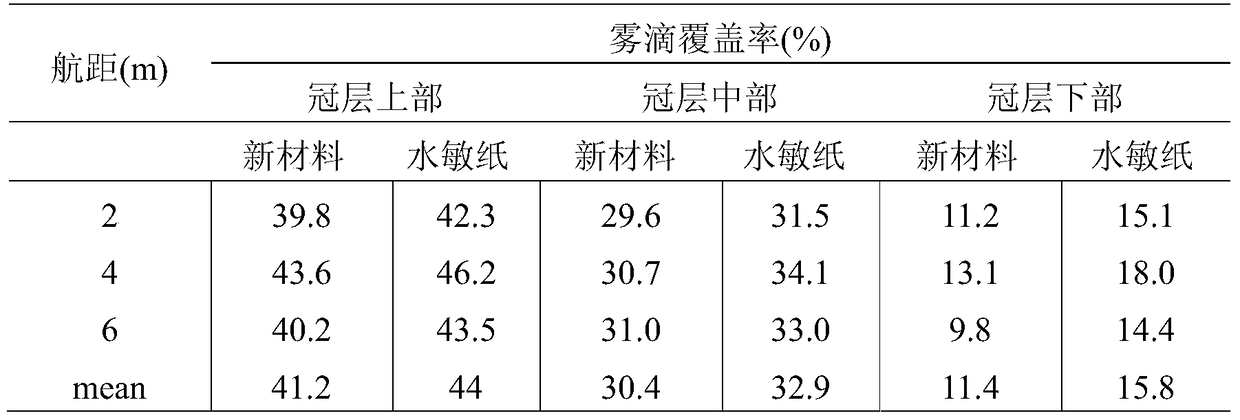

ActiveCN105753509AChange contact angleDiffusion coefficient is smallMaterial analysisElectrical resistance and conductanceCeramic substrate

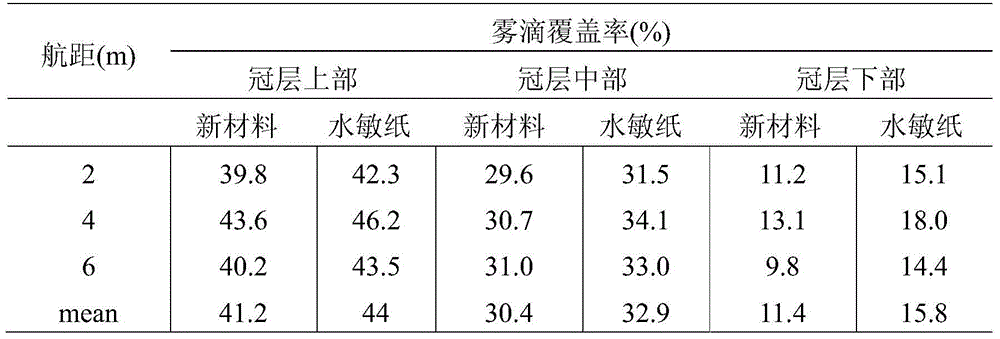

The invention provides a humidity sensing ceramic and a preparation method thereof. An organosilane modification layer is arranged on the surface of a humidity sensing ceramic substrate, and the surface contact angle is 85 to 95 degrees. The organosilane is used for modifying the surface of the humidity sensing ceramic; the contact angle of fog drops deposited on the surface of the ceramic is changed; the diffusion coefficient of the fog drops on the surface of the humidity sensing ceramic is reduced. The invention also discloses a fog drop deposition sensor prepared by the humidity sensing ceramic and application of the fog drop deposition sensor to the unmanned aerial vehicle chemical spraying fog drop deposition characteristic detection. The fog drop deposition sensor provided by the invention has the advantages that information such as fog drop average particle diameter, fog drop density, fog drop covering rate and distribution uniformity can be accurately detected; meanwhile, a detection resistor reflects the relative humidity change; the fog drop deposition quantity comparison conditions of the chemical spraying specific regions can be obtained.

Owner:ZHEJIANG UNIV

Wood processing device for wood packaging box

InactiveCN107350949AChange tilt angleImprove grinding efficiencyEdge grinding machinesPolishing machinesWood plankSawdust

The invention discloses a wood processing device for a wood packaging box. The wood processing device comprises a base; a supporting frame with an upward opening is arranged at the top of the base; the supporting frame can rotate on the base; a dust collecting box, a first driving mechanism and a second driving mechanism are arranged at the top of the base sequentially; the first driving mechanism comprises a first output shaft; the second driving mechanism comprises a second output shaft; a supporting table is arranged at the tops of the first output shaft and the second output shaft; the first output shaft and the second output shaft are connected with the two sides of the bottom of the supporting table separately; a suction fan and a supporting block are arranged at the top of the supporting table; a dust suction pipe parallel to the supporting table is arranged between the supporting block and a blower; one end of the dust suction pipe is connected with the blower; the other end of the dust suction pipe penetrates through the supporting block; and a universal pipe is arranged on the blower and is connected with the dust collecting box. The polishing angle between a polishing roll and a wood board can be adjusted, the polishing quality and precision are improved, and sawdust can be collected.

Owner:成都东友包装有限公司

Fiber felt manufacturing device

InactiveCN103757719AChange contact angleControl the liquid supply speedNew-spun product collectionArtificial thread manufacturing machinesFiberEngineering

The invention provides a fiber felt manufacturing device and relates to fiber felt. The fiber manufacturing device comprises a spinning box, a vibration generating device, a vibration transmitting system, a solution supply system, a collecting device, a high-voltage power supply, inducing pieces and fixing pieces. The interior of the spinning box is divided into a vibration transmitting chamber and a solution trough, the vibration transmitting system is arranged in the vibration transmitting chamber, and the vibration transmitting system is provided with a vibration output shaft, a connecting seat and a vibration transmitting block. The solution supply system is provided with a solution storage tank and a metering pump. The vibration output shaft is fixed to the spinning box through the connecting seat, the shaft end of the vibration output shaft is connected with one end of the vibration transmitting block, and the inducing pieces are hinged to the other end face of the vibration transmitting block. Inducing piece protrusions are arranged on the tops of the inducing pieces, and fixing piece protrusions are arranged on the tops of the fixing pieces. A concave fixing block is arranged in the solution trough, and the fixing pieces are fixed in grooves of the concave fixing block. The metering pump is communicated with the solution trough through a solution supply pipe, solution is supplied to the solution trough through the metering pump, the collecting device is arranged over the solution trough, and the collecting device is electrically connected with the output end of the high-voltage power supply.

Owner:XIAMEN UNIV

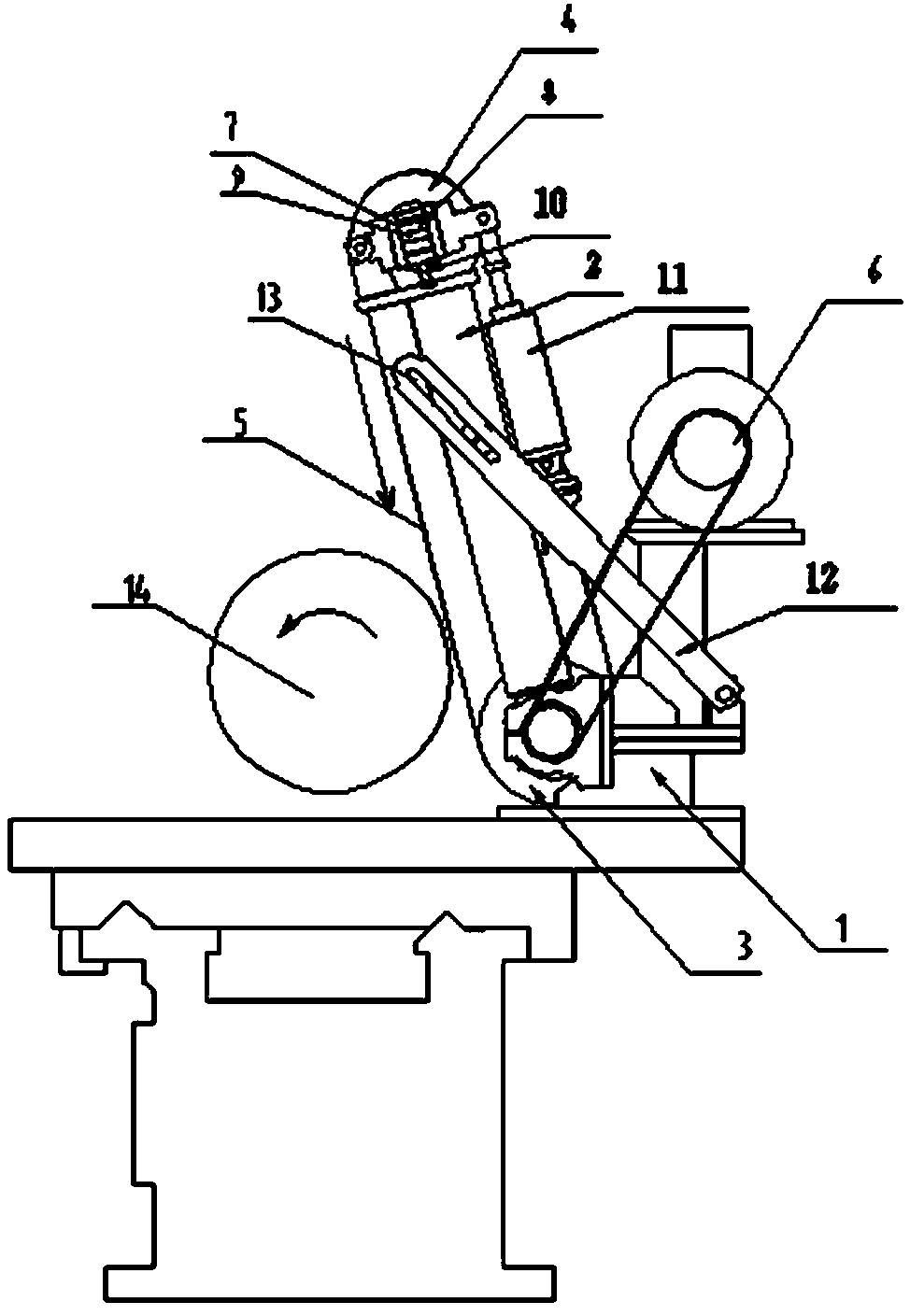

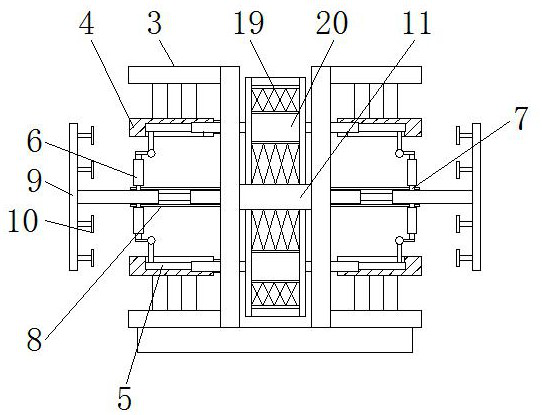

Rubber roller belt sander

The invention discloses a rubber roller belt sander, wherein a long strip-shaped support frame is positioned on a base; a driving wheel can be rotationally positioned at one end of the support frame; a driven wheel can be rotationally positioned at the other end of the support frame; the driving wheel and the driven wheel are arrayed in parallel; a ring-shaped abrasive belt is arranged on the driving wheel and the driven wheel in a sleeving manner; the driving wheel is driven by a motor to rotate; a driven shaft on the driven wheel is inserted in a shaft sleeve at the other end of the support frame; and the driven shaft can be driven by a deviation rectifying adjusting device on the shaft sleeve to rotate around a shaft perpendicular to the axial direction of the driven shaft and the length direction of the ring-shaped abrasive belt. According to the rubber roller belt sander, an adjustment of the axis parallelism of the driving wheel and the driven wheel can be realized, so that the stability of the operation of the abrasive belt can be realized; the tension adjustment of the ring-shaped abrasive belt is convenient, so that the ring-shaped abrasive belt can be adapted to processing of different materials, and the replacement of the ring-shaped abrasive belt is facilitated, the rotation of the whole ring-shaped abrasive belt around an axial line of the driving wheel can be realized, the contact angle of the abrasive belt and a workpiece can be changed, the contact position of the abrasive belt and the workpiece can be changed, and different processing demands can be met.

Owner:昆山诺丹舜蒲胶辊有限公司

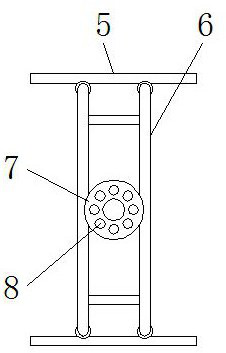

Equipment capable of improving production efficiency of wooden framed cases

InactiveCN107186583AIncrease productivityImprove grinding efficiencyGrinding carriagesGrinding machinesEngineeringMechanical engineering

The invention discloses equipment capable of improving production efficiency of wooden framed cases. The equipment comprises a base, supporting rods are arranged on the top of the base, and a top plate is arranged on the supporting rods. The top plate can move in the axis direction of the supporting rods and is provided with a movable rod. The bottom of the movable rod is provided with a grinding roller for polishing wood. The top of the base is further provided with a connection block. The connection block is provided with a groove and a movable shaft inserted in the groove of the connection block in a penetrating mode. The movable shaft can rotate in the connection block, and is provided with an arc rack being open upwards, and the arc rack can rotate along with the movable shaft. The movable shaft is further provided with a fixing element which is connected with the movable shaft through a thread. The fixing element can fix the movable shaft onto the connection block by being rotated. According to the equipment capable of improving the production efficiency of wooden framed cases, the grinding angle between the grinding roller and a workpiece can be adjusted, trenches in the workpiece can be ground conveniently, and the grinding quality and precision are improved.

Owner:成都东友包装有限公司

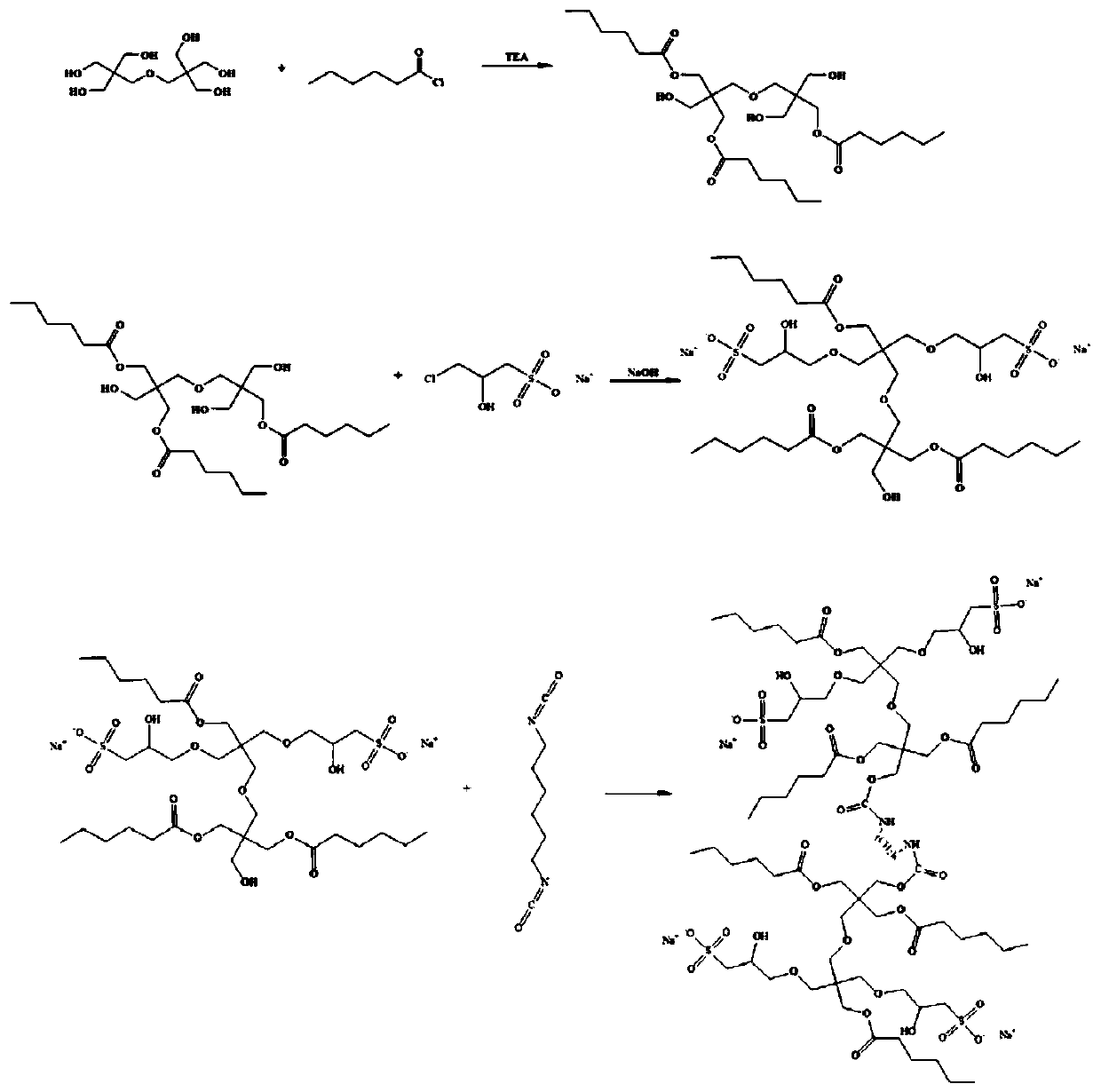

Zooming liquid lens

The invention provides a zooming liquid lens. The diopter of a liquid surface is changed by conducting a shell or a drive electrode to have an electric wetting reaction and / or an inverse piezoelectriceffect. Convenience is brought to miniaturization of an optical zooming system, the focusing range of the optical zooming system is increased, the application scenarios of the optical zooming systemare enlarged and the applicability of the optical zooming system is enhanced.

Owner:上海酷聚科技有限公司

Reverse disc mower

The invention relates to a reverse protective-cover type disc mower. The reverse protective-cover type disc mower comprises a fixed shaft, wherein an outer shell is arranged above and connected with the fixed shaft through a nut; a protective cover is arranged below and connected with the fixed shaft through a nut; a slide disc is arranged below and connected with the protective cover through snaps; the outer end of the fixed shaft is fixed with a rotating hollow shaft through small bearings; the outer end of the rotating hollow shaft is provided with big bevel gears and connected with the outer shell through large bearings; the rotating hollow shaft is interconnected with a dustproof cover and a cutter disc through bolts; cutter seats are fixedly arranged on the cutter disc through pin bolts; an anti-collision spring is arranged between the cutter disc and each cutter seat; and each cutter seat is fixed with a cutter blade through bolts. The reverse protective-cover type disc mower provided by the invention has the characteristics of convenient use, lowered labor intensity, significantly-improved safety, facilitation of long-term and continuous work, high work efficiency, good effect, etc.

Owner:冯逸安

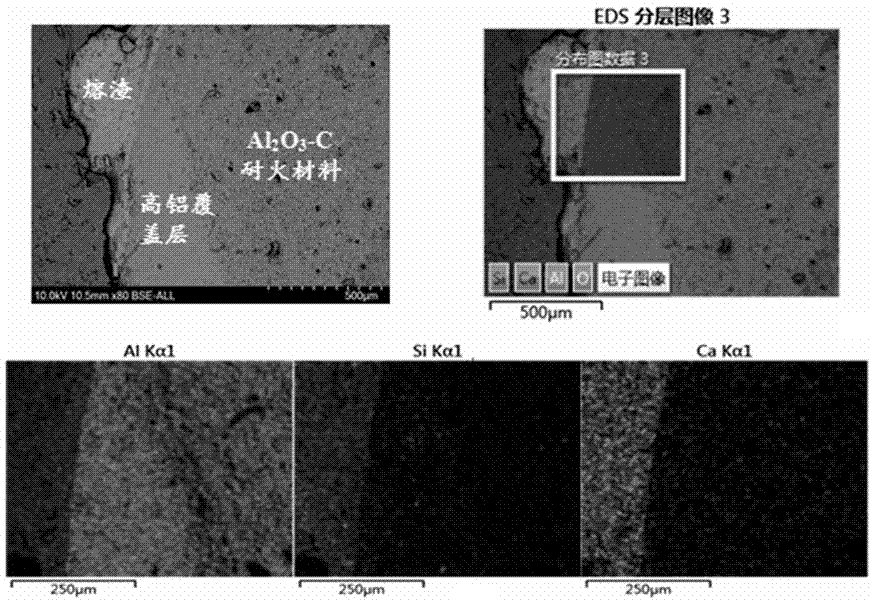

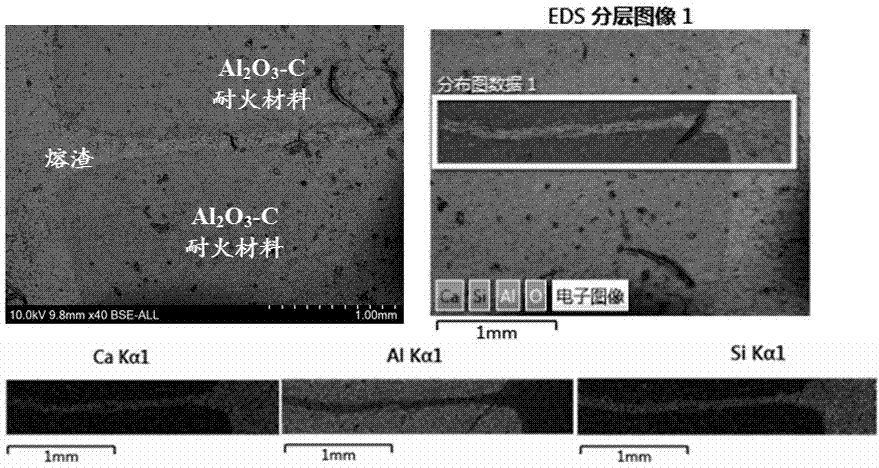

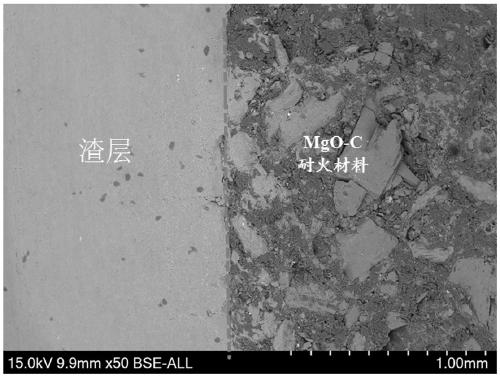

Method for preventing carbon-containing fireproof material from slag erosion

ActiveCN107253865AAchieve physical protectionReduce penetration depthMelt-holding vesselsAlkalinitySlag

The invention discloses a method for preventing carbon-containing fireproof material from slag erosion. Through providing a suitable external voltage for a slag system, the penetration depth f the slag in a fireproof material is delayed, and the physical protection of the fireproof material is realized. The method includes steps of taking aluminum oxide, silica, and calcium oxide as raw materials, and preparing to be the slag powder with alkalinity of 0.8-2.3; heating the mixed powder to 1550-1650 DEG C to melt down; after decarbonization, contacting the carbon-containing fireproof material with slag, and then connecting the fireproof material after decarbonizing treatment and the slag to both electrodes of the power source respectively; electrifying at 0-4V; realizing the protection of carbon-containing fireproof material from slag erosion. The method can effectively inhibit the physical penetration of slag in the carbon-containing fireproof material, significantly improve the slag erosion resistance of the carbon-containing fireproof material, and prolong 3-4 times of the service life of the carbon-containing fireproof material. The method is simple in operation, wide in applicable slag scale, and high in production practical value.

Owner:SUZHOU UNIV

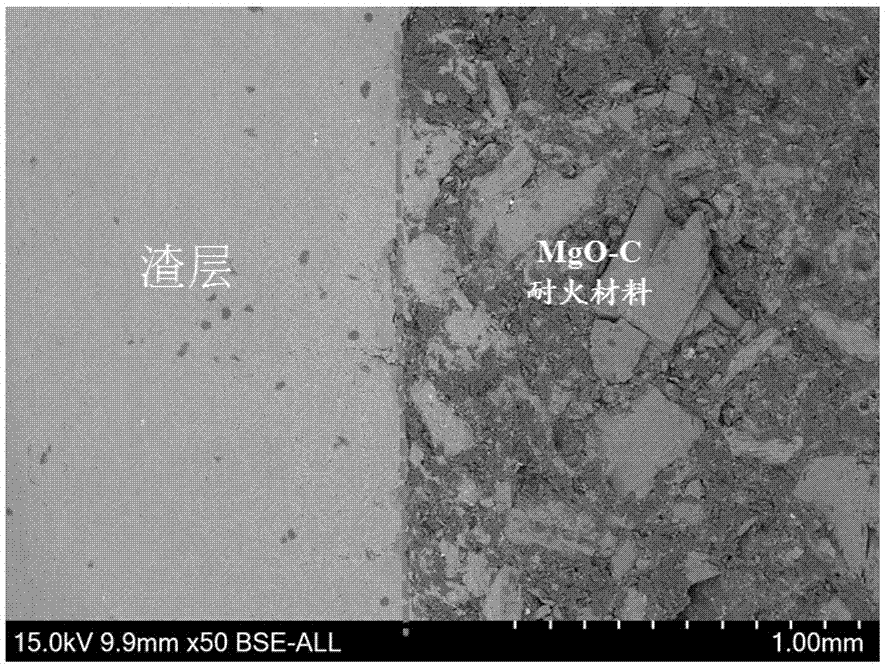

Polysulfonic acid structure surface wetting agent and preparation method thereof

InactiveCN111559970AReduce surface tensionFast wettingOther chemical processesTransportation and packagingPhysical chemistryChloride

The invention discloses a polysulfonic acid structure surface wetting agent and a preparation method thereof. The preparation method comprises the following steps: 1) mixing dipentaerythritol and hexanoyl chloride, stirring and reacting for 2-4 h at the temperature of 30-50 DEG C, cooling to the room temperature, neutralizing, washing with water, extracting, and distilling under reduced pressure to remove the solvent to obtain a viscous liquid intermediate I; 2) adding a first solvent into the viscous liquid intermediate I, adding powdery sodium hydroxide after the viscous liquid intermediateis completely dissolved, stirring and reacting for 0.5-1 h at 25-35 DEG C, then adding sodium 3-chloro-2-hydroxypropyl propanesulfonate into the solution, heating to 80-90 DEG C, reacting for 5-7 h, and carrying out suction filtration to obtain a solid product intermediate II; and 3) adding the solid product intermediate II into a second solvent, adding hexamethylene diisocyanate under magnetic stirring, heating to 40-50 DEG C, reacting for 3-5 h, carrying out suction filtration, and drying to obtain the polysulfonic acid structure surface wetting agent. The preparation method solves the problem of poor spreadability of water on the solid surface.

Owner:宁夏宇航油田工程有限公司

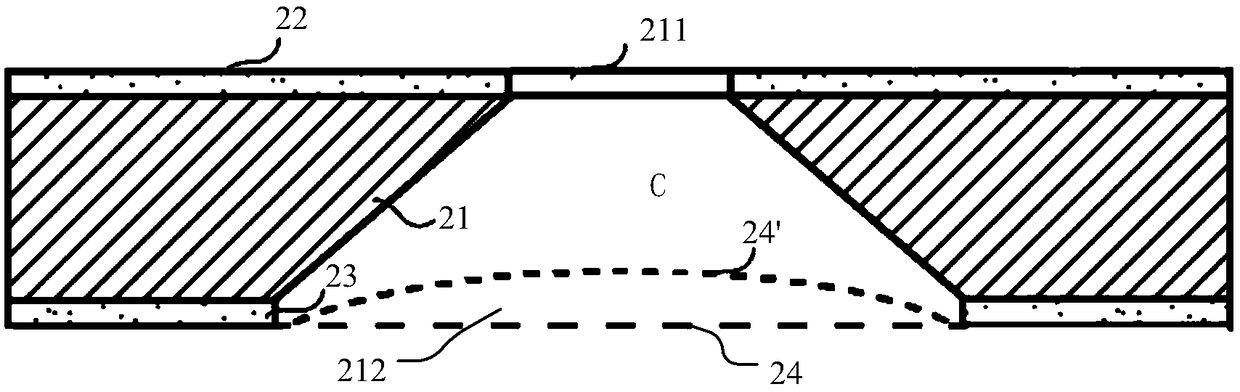

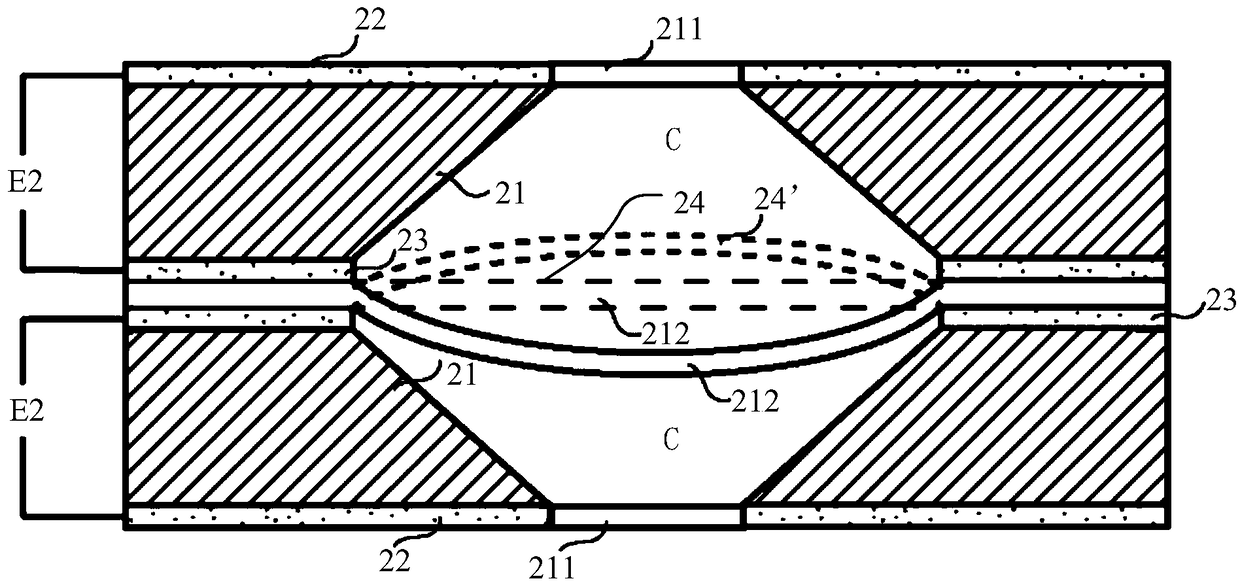

Liquid lens

The invention provides a zoom lens. According to the zoom lens, through an electrowetting reaction and / or an inverse piezoelectric effect of a conducting shell or a driving electrode, the diopter of aliquid surface is changed, it is convenient to make an optical zoom system small, the focusing range of the optical zoom system is expanded, the application scene of the optical zoom system is broadened, and the applicability of the optical zoom system is enhanced.

Owner:上海酷聚科技有限公司

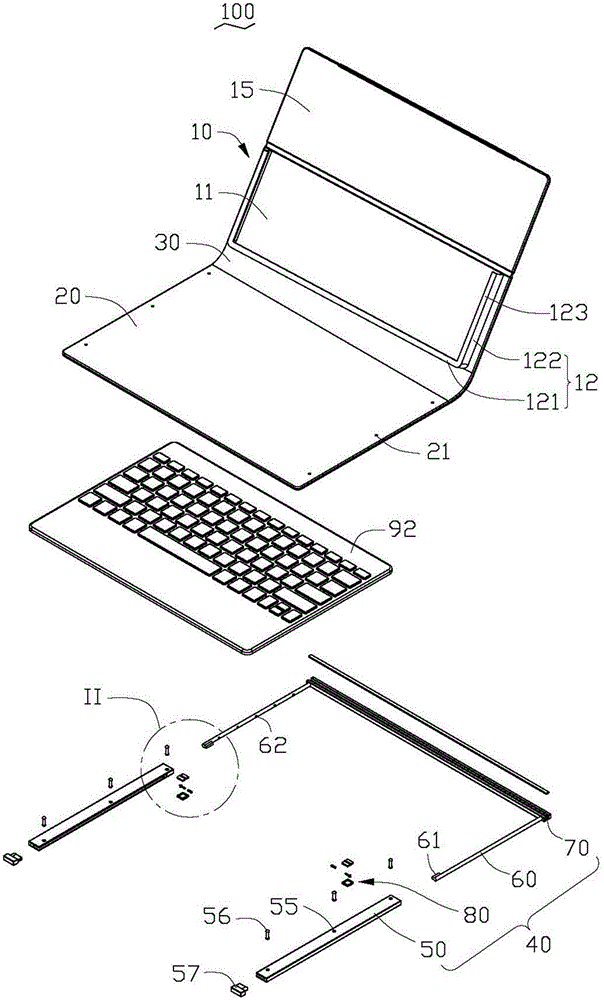

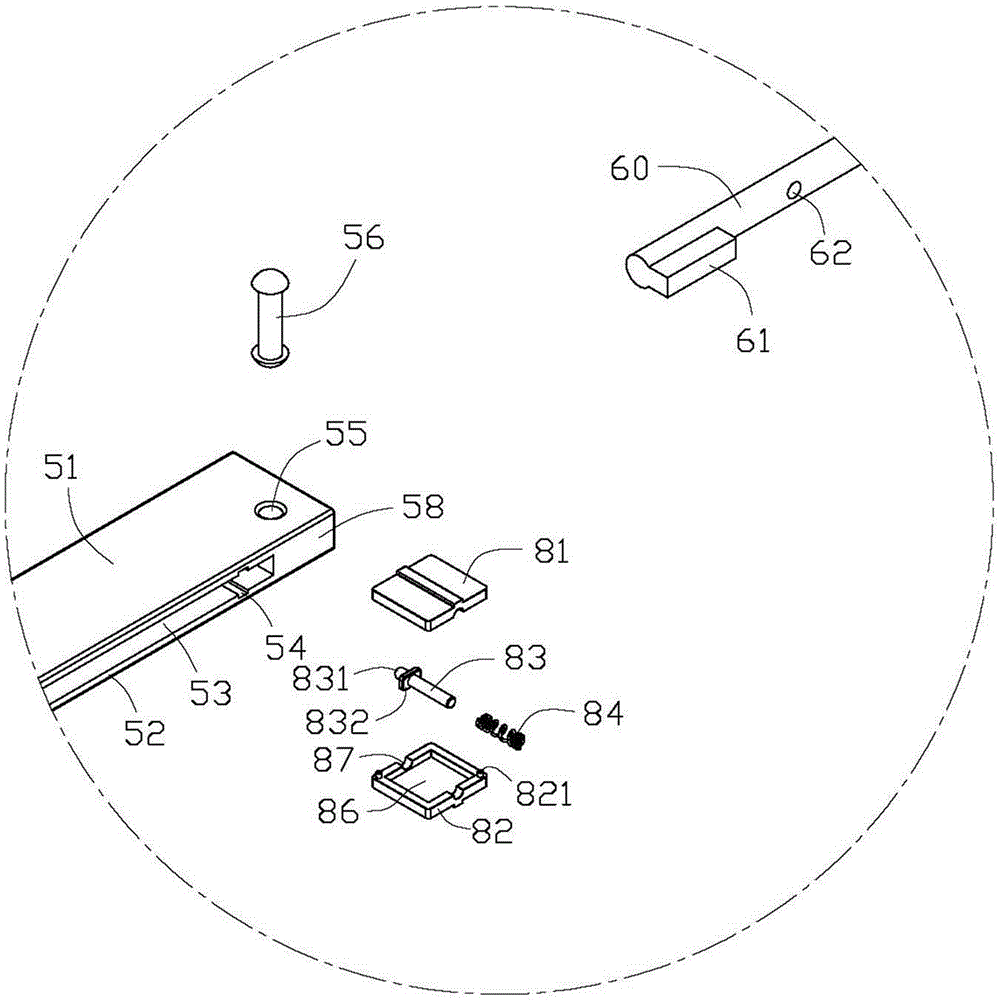

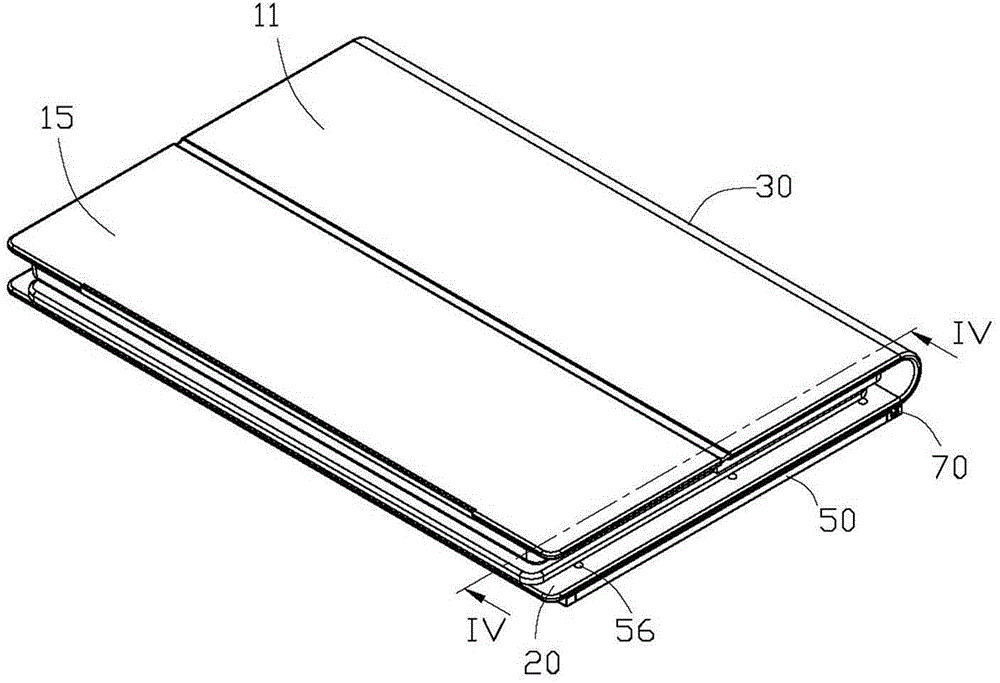

Electronic device protective jacket

InactiveCN104834348AChange in standing positionChange contact angleDigital data processing detailsEngineeringMechanical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Liquid lens and manufacturing method thereof

The invention provides a liquid lens and a manufacturing method thereof. The liquid lens comprises a shell that comprises a first window and a second window; first liquid that is a conductor; second liquid that is an insulator, wherein the first liquid is insoluble in the second liquid; and a substrate connected with the second window, wherein the first liquid and the second liquid are arranged inthe shell, and the second liquid is arranged on the substrate. Through communicating a power source, the shell, the first liquid and the substrate, the first liquid generates an electric wetting effect on touch surfaces with the substrate and the second liquid, the interface curvature between the first liquid and the second liquid is changed, the diopter and focal length of the liquid lens are changed, and thus the effective clear aperture is changed, the miniaturization of the lens module can be achieved, and simultaneous regulation of the focal length and the effective clear aperture of thelens module can be achieved, the application scene is enlarged and the applicability of the application components is improved.

Owner:上海酷聚科技有限公司

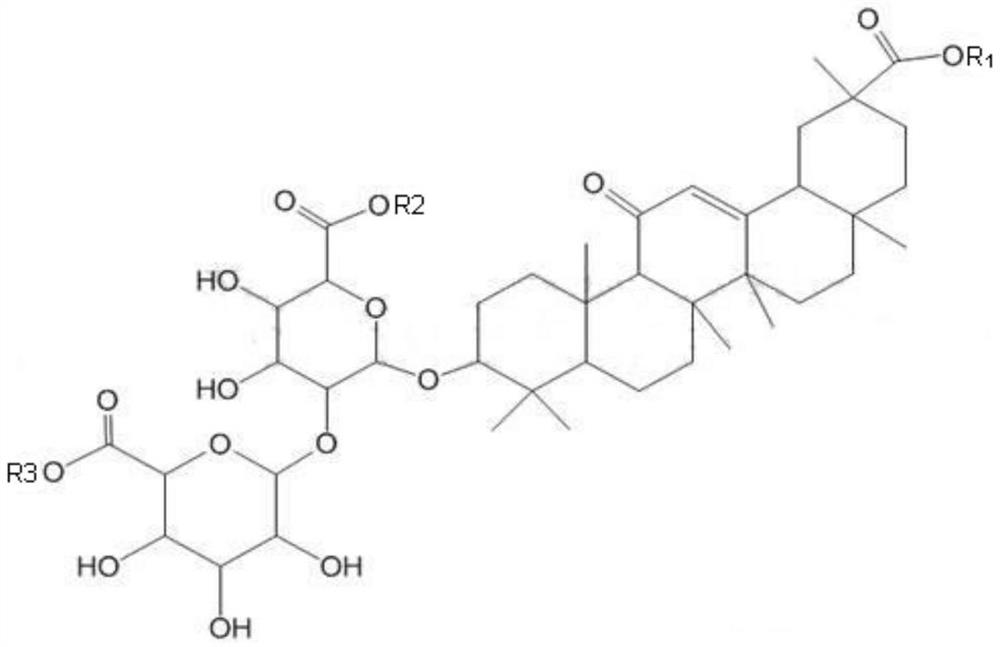

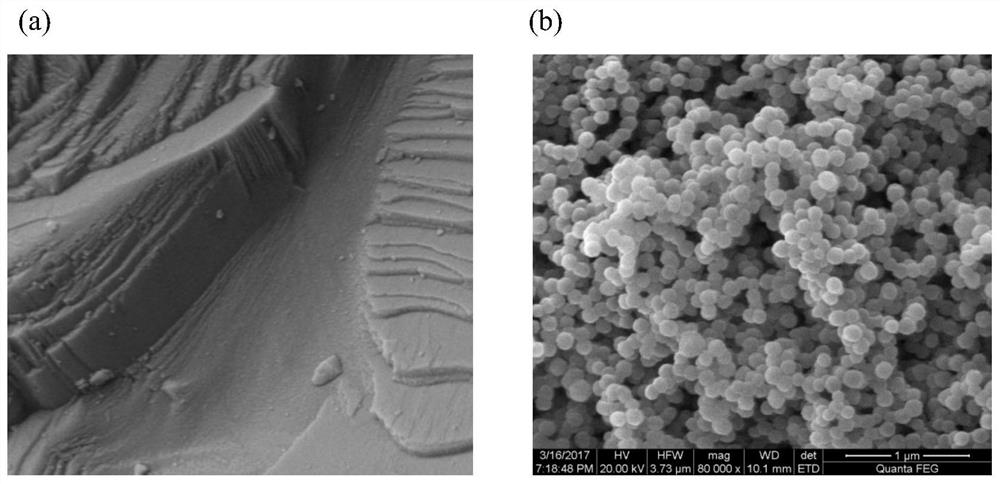

Antibacterial anti-fog spray and its preparation method and application

ActiveCN107722733BWide variety of sourcesImprove adhesionCellulose coatingsBiotechnologyMicrobiology

The invention provides an antibacterial and antifog spray and a preparation method and application thereof. The antibacterial and antifog spray is prepared from the following raw materials in percentage by weight: 0.1 to 2.5% of modified nanocellulose, 0.1 to 2.5% of antibacterial agent, 1 to 5% of Tween series, and the balance of deionized water. The invention also discloses a preparation methodof the antibacterial and antifog spray and application in antibacterial and antifog aspects of automobile glass. The antibacterial and antifog spray has the advantages that by using the TEMPO type modified nanocellulose as a main component, the characteristics of high specific surface area, light weight, biocompatibility and degradability are fully utilized, so that the adhesion force between theantifog spray and a substrate is increased, and the excellent antifog property and antifog time can be stilled ensured after wiping and scouring; because of easiness in breeding of bacteria under thedamp condition, after the antibacterial agent is added into the antifog spray, the antifog function and the antibacterial function are combined, and the stability of the antifog property is improved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

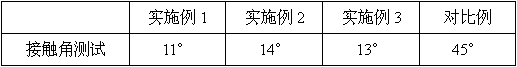

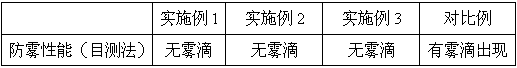

Organosilicon macromolecular composite waterproof gypsum and preparation method thereof

The invention discloses organosilicon macromolecular composite waterproof gypsum and a preparation method thereof and relates to gypsum. The invention provides organosilicon macromolecular composite waterproof gypsum having excellent waterproof performance and a preparation method thereof. The organosilicon macromolecular composite waterproof gypsum is composed of the following raw materials according to mass ratio: 100 parts of desulfurated building gypsum, 0.1-3.0 parts of silane coupling agent, 0.1-1.0 part of multi-hydroxyl polymer and 80 parts of water. The preparation method comprises the steps of: preparing the multi-hydroxyl polymer into aqueous solution to obtain an ingredient A; dissolving a catalyst in water, adding the silane coupling agent, and stirring until the solution is clear to obtain an ingredient B; mixing the ingredient A and the ingredient B with the rest of water, adding the desulfurated building gypsum, mixing, injecting the mixture in a mould, demolding after gypsum is solidified, and drying to obtain the organosilicon macromolecular composite waterproof gypsum.

Owner:金沙卓为环保新材料有限公司

Etching solution for stably etching titanium nitride

PendingCN114350365AGuaranteed etch rateReduce etch rateSurface treatment compositionsThin membraneActive agent

The invention discloses an etching solution for stably etching titanium nitride, which comprises an oxidizing agent, sulfuric acid, a chelating agent, a corrosion inhibitor and a surfactant, and is used for etching films such as titanium nitride and the like under a stirring condition. The etching solution can quickly remove titanium nitride, and has a relatively low etching rate on metals such as tungsten, copper, cobalt and the like and compounds thereof, and low-k dielectric materials, and the etching rate does not fluctuate along with the change of etching time. The pH regulator sorbic acid and the like in the etching solution stabilize the pH of the etching solution, so that the influence on the etching rate and stability of titanium nitride and metal tungsten due to the fluctuation of the pH of the etching solution caused by hydroxyl released by titanium nitride and tungsten in the etching process is avoided; the surface active agent polyacrylamide changes the viscosity, the surface tension and the like of the etching liquid, the corrosion inhibitor protects the metal tungsten, stirring is carried out during etching, substance exchange of reactants between the surface of a wafer and the solution can be increased, and the etching selection ratio of titanium nitride to thin films such as the metal tungsten is ensured.

Owner:湖北兴福电子材料股份有限公司

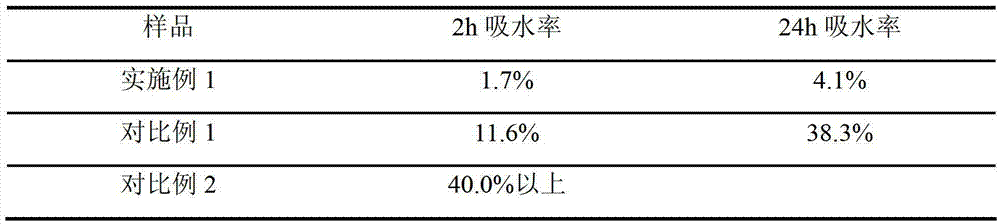

Makeup remover lotion and wet towel

ActiveCN105686973BGood dispersionRefreshing and non-greasyCosmetic preparationsMake-upPolymer scienceActive agent

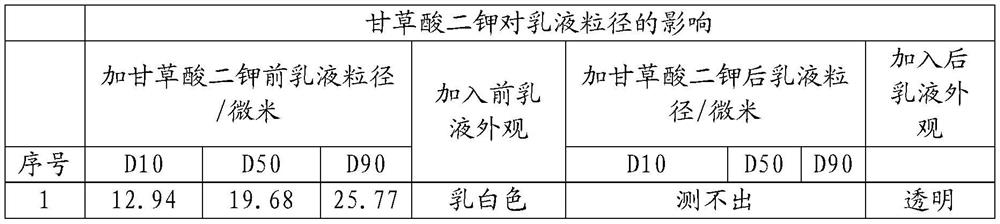

The invention discloses a cleansing lotion and a wet tissue. The cleansing lotion includes an oil phase substance, water, more than one of glycyrrhizic acid or glycyrrhizinate, and a surfactant. The oil phase substance is mixed with the surfactant and licorice Under the action of acid or glycyrrhizinate, it is dispersed in the water to form an isotropic, thermodynamically stable transparent or translucent emulsion. Through the above method, the makeup remover emulsion of the present invention can be durable and stable, improve the efficiency of makeup removal, and is not greasy, and the makeup removal steps of the wet wipes are simple and efficient, and are convenient to carry.

Owner:GOLD HONG YE PAPER

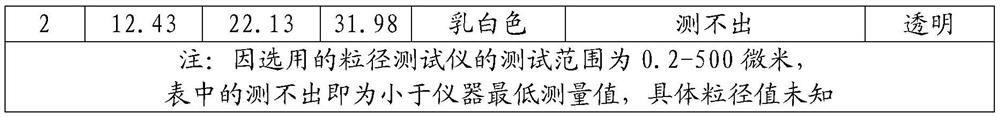

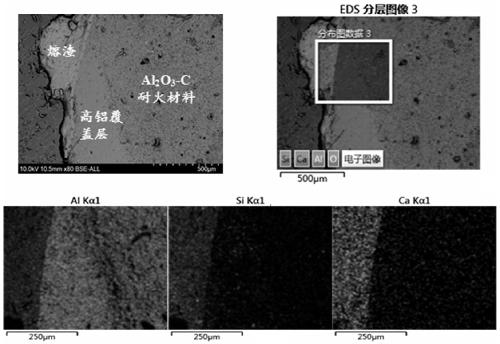

A protection method for carbon-containing refractories against slag erosion

ActiveCN107253865BAchieve physical protectionReduce penetration depthMelt-holding vesselsAlkalinitySlag

The invention discloses a protection method for a carbon-containing refractory material against slag erosion. By providing a suitable external voltage for the slag system, the penetration depth of the slag in the refractory material is slowed down, and the physical protection of the refractory material is realized. Alumina, silica, and calcium oxide are used as raw materials to prepare slag powder with a basicity of 0.8~2.3, and the mixed powder is heated to 1550~1650°C to melt; the carbon-containing refractory is decarburized and mixed with slag Contact, and then connect the decarburized refractory material and slag to the two poles of the power supply; then energize at 0-4V to realize the protection of the carbon-containing refractory material against slag erosion. It can effectively inhibit the physical penetration of slag in carbon-containing refractories, significantly improve the slag intrusion resistance of carbon-containing refractories, and increase the service life of carbon-containing refractories by more than 3 to 4 times. The invention is simple to operate, applicable to a wide range of slag systems, and has high production practical value.

Owner:SUZHOU UNIV

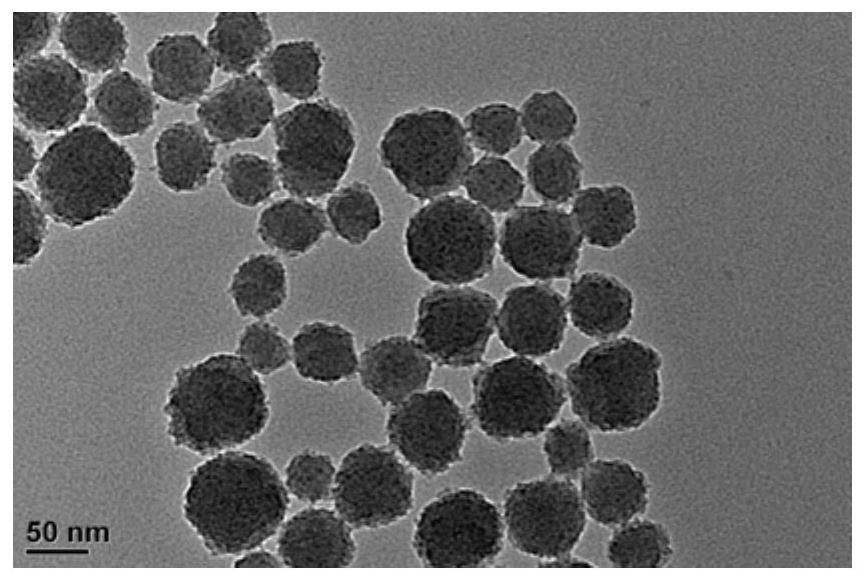

Synergist for water-based drilling fluid and preparation method thereof, water-based drilling fluid and application

ActiveCN111732940BLower free energyRelieve pressureFlushingDrilling compositionParaffin waxSuccinic acid

The present invention proposes a synergist for water-based drilling fluid and its preparation method, water-based drilling fluid and application, and belongs to the technical field of drilling fluid. The synergist is prepared from raw materials including the following parts by weight: sodium styrene sulfonate 15-25 parts, 8-15 parts of allyltrimethylammonium chloride, 2-8 parts of didodecyldimethylammonium bromide, 1-5 parts of n-octyltriethoxysilane, propyl 1-5 parts of triethoxysilane, 1-5 parts of disodium lauryl sulfosuccinate, 10-20 parts of nano silicon dioxide, 8-15 parts of paraffin, etc. The synergist can be used in the preparation of water-based drilling fluid and in the field of shale gas development. It can reduce the free energy of the rock surface, change the contact angle between the water phase or oil phase and the rock reservoir surface, and prevent the water phase or oil phase from entering the reservoir. , And, it can be used as inhibitor, lubricant and oil and gas layer protection agent at the same time. In addition, the synergist has a micro-nano structure, which can achieve full-scale plugging of micro-cracks of different sizes.

Owner:BEIJING SHIDABOCHENG TECH

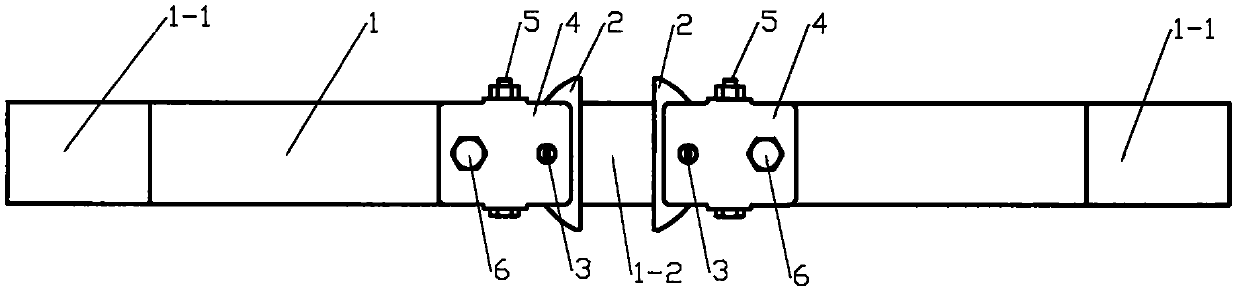

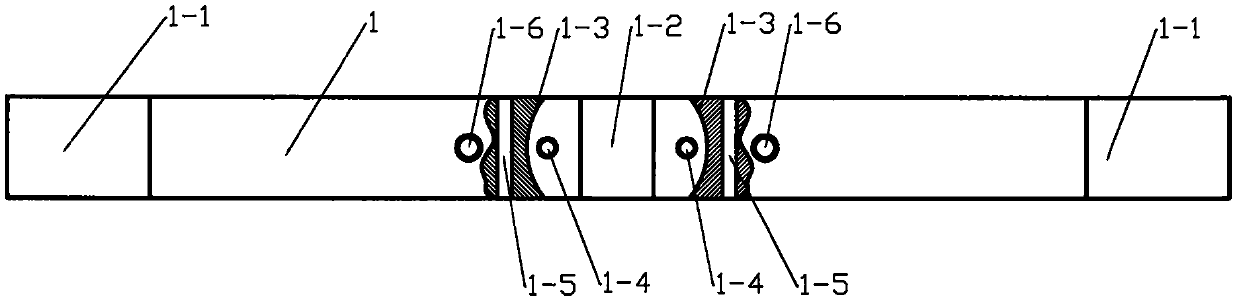

Wear-resistant hooking lock for point rails of external-locking turnout

A wear-resistant hooking lock for point rails of an external-locking turnout mainly consists of a hooking lock (1), wear-resistant blocks (2) and pin shafts (3) arranged at both ends of a U-shaped opening at the middle of the hooking lock, fastening and pressing plates (4), pin bolts (5) and bolts (6). The wear-resistant blocks (2) are respectively mounted along cambered surfaces (1-3) at both ends of the U-shaped opening (1-2) at the middle of the hooking lock (1). When planes (2-1) of the wear-resistant blocks (2) are in close contact with bottom surfaces of the point rails and stressed to generate torsion angles, cambered surfaces (2-2) of the wear-resistant blocks (2) can automatically rotate along the vertical cambered surfaces (1-3) at both ends of the U-shaped opening (1-2), so thatthe planes (2-1) of the wear-resistant blocks (2) can be always in plane contact with the bottom surfaces of the point rails and the wear of the hooking lock to the point rails is reduced. When the size of the wear-resistant blocks (2) on the hooking lock changes because of the wear during the using process and is not in conformity with the requirements, the excessively worn wear-resistant blocks(2) which are arranged at both ends of the U-shaped opening of the hooking lock can be replaced quickly and conveniently to recover a standard state of the hooking lock, so that the safety performance of equipment and the reliability for use are improved and the disturbance to the running of trains is reduced.

Owner:张振坤 +2

Self-walking polishing equipment

ActiveCN109877695AIncrease walking speedSelf-propelledGrinding carriagesPolishing machinesJoystickUniversal joint

The invention discloses self-walking polishing equipment, and belongs to the technical field of wall board prefabrication. The self-walking polishing equipment comprises a base, and is characterized in that a first slide frame capable of moving longitudinally is installed in the base, a second slide frame capable of moving horizontally is installed on the first slide frame, a universal joint is arranged in the second slide frame, a polishing machine is installed in the universal joint, a joystick capable of extending to the upper part of the second slide frame is fixed to the polishing machine, and the joystick can drive the polishing machine to rotate in the universal joint. The self-walking polishing equipment can drive the second slide frame to move in a two-dimensional plane through the friction force between the polishing machine and a wall board, so that the walking speed of the polishing machine adapts to the friction force, and the friction force is directly related to the polishing effect; when a better polishing effect is achieved, the walking speed of the polishing machine is obviously slowed down, the polishing quality is enabled to be controllable, a better combinationpoint of polishing efficiency and quality is achieved, the self-walking of the polishing machine is further realized, and the walking energy is saved.

Owner:山东省滨州市坤合建筑工程有限公司

Organosilicon macromolecular composite waterproof gypsum and preparation method thereof

Owner:金沙卓为环保新材料有限公司

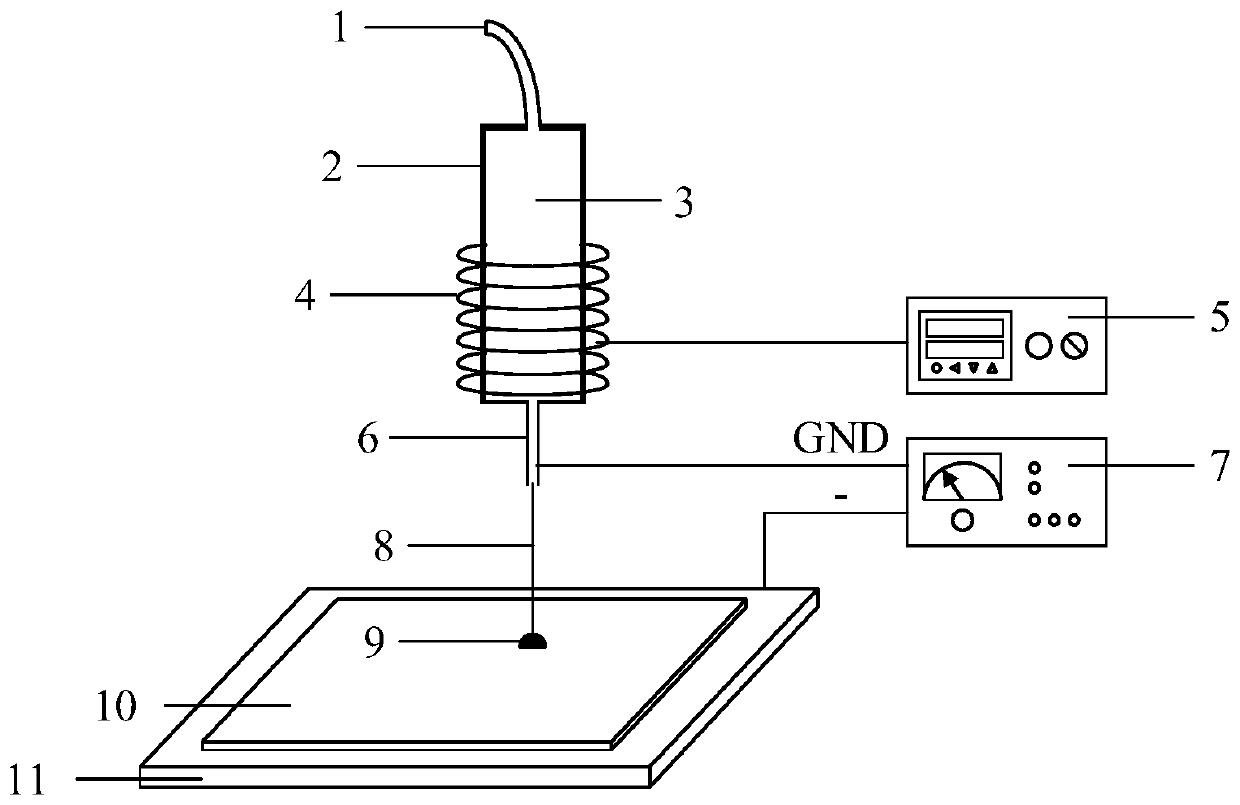

Fabrication method of microsphere resonator based on electrohydrodynamic spray printing

ActiveCN107632346AAvoid easy cloggingChange hydrophilic/hydrophobicCoupling light guidesMicrosphereHigh pressure

The invention provides a fabrication method of a microsphere resonator based on electrohydrodynamic spray printing, and relates to an optical micro-cavity. An air pipe is connected with an air pump, and a melt polymer raw material is provided for a metal storing pipe; a hanging drop is formed at a nozzle of a metal micro-channel; a heater and the metal storing pipe are tightly attached, the temperature of the melt polymer raw material in the metal storing pipe is adjusted through a temperature controller, additives are then added to the melt polymer raw material, a switch of a high-voltage power supply is turned on, the voltage of an electrode plate is adjusted to -600V, the hanging drop is ejected on a collection plate due to the effect of an electric field force, the nozzle of the metalmicro-channel is connected with a grounding terminal of the high-voltage power supply, and the electrode plate is connected with a negative voltage terminal of the high-voltage power supply; and whenthe high-voltage power supply outputs a specified voltage, the drop at the nozzle of the metal micro-channel is spray printed on the collection plate in the manner of a melt polymer jet flow to form amicro-drop having a certain contact angle with the collection plate, and the solid-phase microsphere resonator is obtained after cooling and solidification.

Owner:XIAMEN UNIV

A manufacturing method of microsphere resonator cavity based on electrohydrodynamic jet printing

ActiveCN107632346BAvoid easy cloggingChange hydrophilic/hydrophobicCoupling light guidesResonant cavityTemperature control

Owner:XIAMEN UNIV

An underwater fixed-point binding and fixed joint monitoring pile for an underwater robot

ActiveCN109015752BGood side supportImprove stabilityManipulatorUnderwater equipmentHydraulic cylinderMarine engineering

The invention discloses an underwater fixed-point binding and fixed joint monitoring pile for an underwater robot, which includes a base and a side bracket. A base plate is installed above the base, and a docking platform is arranged above the base plate. The inner side of the underwater robot is equipped with a cladding frame, and the side brackets are respectively located on the left and right sides of the base. The underwater fixed-point binding and fixed joint monitoring pile of the underwater robot realizes the ability of the pile body to the underwater robot through the setting of the docking platform. For the structural purpose of binding, fixing and docking, the support plate is used to provide support for the vertical strut, and also provides structural support for the telescopic action of the hydraulic telescopic rod. The stability of the moving action and the straightness of the action, the hydraulic cylinder controls the hydraulic telescopic rod to do the hydraulic telescopic action, and moves the vertical strut horizontally, and uses the smooth movement of the vertical strut to provide outward pushing force for the underwater robot, assisting Robots work.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

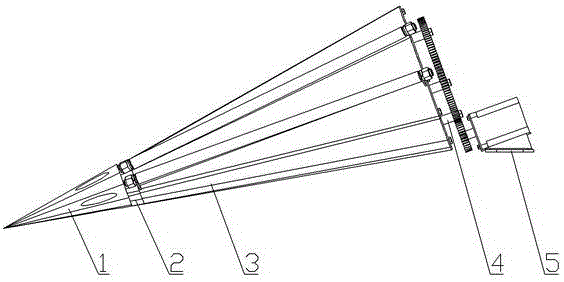

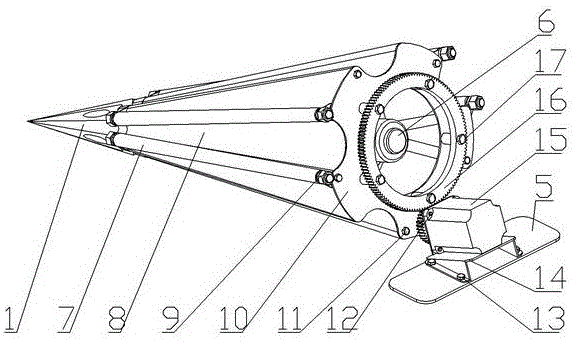

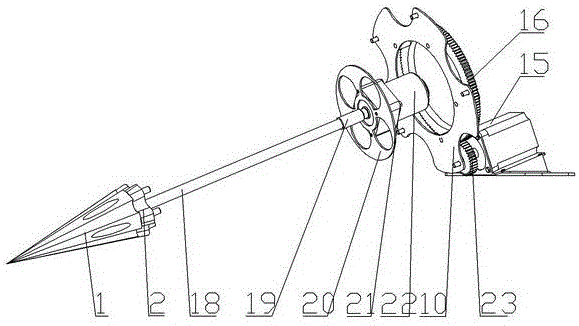

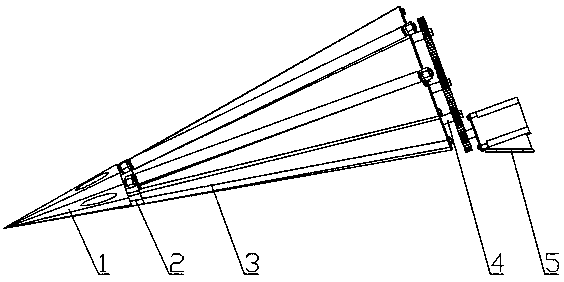

Rotary-cutting bionic intelligent corn harvesting divider

ActiveCN106550657AGood for rotary cutting forceImprove feeding efficiencyOutside dividersDrive shaftGear wheel

The invention discloses a rotary-cutting bionic intelligent corn harvesting divider. The rotary-cutting bionic intelligent corn harvesting divider comprises a dividing awl, a dividing shoulder, a dividing body, a reversing mechanism, a header frame and a speed control mechanism. The dividing awl is fixed on the top of the dividing shoulder through a transmission shaft, the dividing shoulder is fixed on the top of the dividing body through double end studs, the reversing mechanism is fixed on the header frame through third bolts, the speed control mechanism is fixed on a second engine base through fifth bolts, dividing rollers are fixed on a corrugated housing through nuts, a tooth ring seat is fixed on the bottom of the corrugated housing through first bolts, the second engine base is fixed in the corrugated housing, a gear is fixed on a stepping motor, the gear is externally engaged with a tooth ring, the tooth ring is fixed on the tooth ring seat through fourth bolts, transition fillets are uniformly distributed on the external surface of the corrugated housing, and the ratio of the top recess diameter to the bottom recess diameter is equal to the ratio of top protrusion diameter to bottom protrusion diameter. The working speed and working angle of the rotary-cutting bionic intelligent corn harvesting divider can be adjusted, straw wound on the surface of the divider is few, and soil adhering to the surface of the divider is few.

Owner:SHANDONG JUMING MASCH CO LTD

A kind of moisture-sensitive ceramic and its preparation method and application

ActiveCN105753509BReduce spreadReduce calculation errorsMaterial analysisElectrical resistance and conductanceRelative humidity

The invention provides a humidity sensing ceramic and a preparation method thereof. An organosilane modification layer is arranged on the surface of a humidity sensing ceramic substrate, and the surface contact angle is 85 to 95 degrees. The organosilane is used for modifying the surface of the humidity sensing ceramic; the contact angle of fog drops deposited on the surface of the ceramic is changed; the diffusion coefficient of the fog drops on the surface of the humidity sensing ceramic is reduced. The invention also discloses a fog drop deposition sensor prepared by the humidity sensing ceramic and application of the fog drop deposition sensor to the unmanned aerial vehicle chemical spraying fog drop deposition characteristic detection. The fog drop deposition sensor provided by the invention has the advantages that information such as fog drop average particle diameter, fog drop density, fog drop covering rate and distribution uniformity can be accurately detected; meanwhile, a detection resistor reflects the relative humidity change; the fog drop deposition quantity comparison conditions of the chemical spraying specific regions can be obtained.

Owner:ZHEJIANG UNIV

Rotary cutting bionic intelligent corn harvesting divider

ActiveCN106550657BGood for rotary cutting forceImprove feeding efficiencyOutside dividersDrive shaftGear wheel

The invention discloses a rotary-cutting bionic intelligent corn harvesting divider. The rotary-cutting bionic intelligent corn harvesting divider comprises a dividing awl, a dividing shoulder, a dividing body, a reversing mechanism, a header frame and a speed control mechanism. The dividing awl is fixed on the top of the dividing shoulder through a transmission shaft, the dividing shoulder is fixed on the top of the dividing body through double end studs, the reversing mechanism is fixed on the header frame through third bolts, the speed control mechanism is fixed on a second engine base through fifth bolts, dividing rollers are fixed on a corrugated housing through nuts, a tooth ring seat is fixed on the bottom of the corrugated housing through first bolts, the second engine base is fixed in the corrugated housing, a gear is fixed on a stepping motor, the gear is externally engaged with a tooth ring, the tooth ring is fixed on the tooth ring seat through fourth bolts, transition fillets are uniformly distributed on the external surface of the corrugated housing, and the ratio of the top recess diameter to the bottom recess diameter is equal to the ratio of top protrusion diameter to bottom protrusion diameter. The working speed and working angle of the rotary-cutting bionic intelligent corn harvesting divider can be adjusted, straw wound on the surface of the divider is few, and soil adhering to the surface of the divider is few.

Owner:SHANDONG JUMING MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com