A protection method for carbon-containing refractories against slag erosion

A technology of refractory materials and slag, which is applied in the field of metallurgical refractories to achieve the effects of easy operation, increased contact angle, and increased viscosity of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

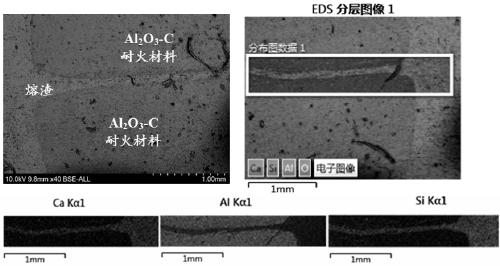

[0034] A slag with an alkalinity of 0.8 was prepared according to the ingredients shown in Table 1, and the slag was placed in a graphite crucible and heated in a high-temperature resistance furnace to melt. When the temperature reaches 1550℃, keep it for 20min to even the slag composition. Aluminium carbon brick (φ10×25mm 2 ) As the anode connected to the positive pole of the DC power supply, another molybdenum rod is connected to the negative pole of the power supply to form the cathode (reversely connected to the DC power supply, that is, the molybdenum rod and refractory material are respectively connected to the positive and negative poles of the DC power supply to form the system The anode and cathode are compared), the cathode molybdenum rod and anode refractory material sample are immersed in the slag for 5mm, the DC power supply is turned on, the voltage of the tank is adjusted to 3V, and the sample is taken out after powering on for 30 minutes. Observe the two conditio...

Embodiment 2

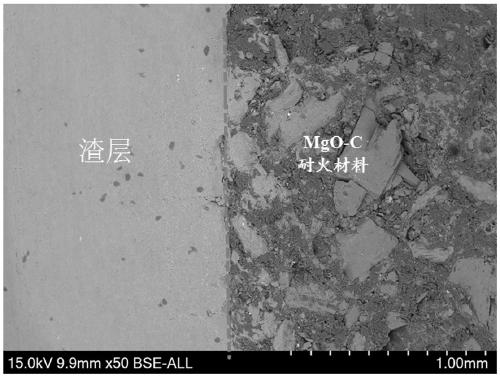

[0037] A slag with an alkalinity of 0.8 was prepared according to the ingredients shown in Table 1, and the slag was placed in a graphite crucible and heated in a high-temperature resistance furnace to melt. When the temperature reaches 1550℃, keep it for 20min to even the slag composition. Will be fixed on the molybdenum rod magnesia carbon brick (φ10×25mm 2 ) As the cathode connected to the negative pole of the DC power supply, another molybdenum rod is connected to the positive pole of the power supply to form the anode. The anode molybdenum rod and the cathode refractory sample are immersed in the slag for 5mm, the DC power supply is turned on, and the tank voltage is adjusted to 4V. The sample was taken out after 30 minutes of electrification, and the corrosion condition of the surface of the two magnesia carbon refractories was observed.

[0038] SEM is used to observe the interface corrosion of the cathodic protected MgO-C refractory under the conditions of the present inv...

Embodiment 3

[0040] A slag sample with an alkalinity of 2.3 was prepared according to the ingredients shown in Table 1, and the mixed powder was placed in a graphite crucible and heated in a high-temperature resistance furnace to melt. When the temperature reaches 1650℃, keep it for 20min to even the slag composition. Connect the decarburized aluminum-carbon refractories and molybdenum rods to the positive and negative electrodes of the DC power supply, respectively, immerse the molybdenum rods and refractory samples into the slag for 5mm, turn on the DC power supply, adjust the tank voltage to 2V, and take out the samples after 60 minutes of power on. Observe the corrosion status of the refractory surface.

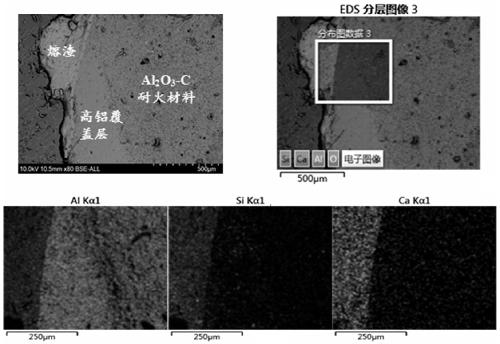

[0041] After 60 minutes of treatment, the surface shape of the refractory material is relatively regular, as attached Figure 4 Shown. Using SEM and EDS to observe the cross-section of the aluminum-carbon refractory material, it can be found that the thickness of the dense aluminum oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com