Rubber roller belt sander

A technology of abrasive belt polishing and rubber rollers, which is applied in the field of abrasive belt machines, can solve problems such as difficulty in ensuring consistent tension of the abrasive belt, non-parallel driving wheels and driven wheels, inconsistent polishing surfaces, etc., to achieve changing contact positions, high linear speed, The effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

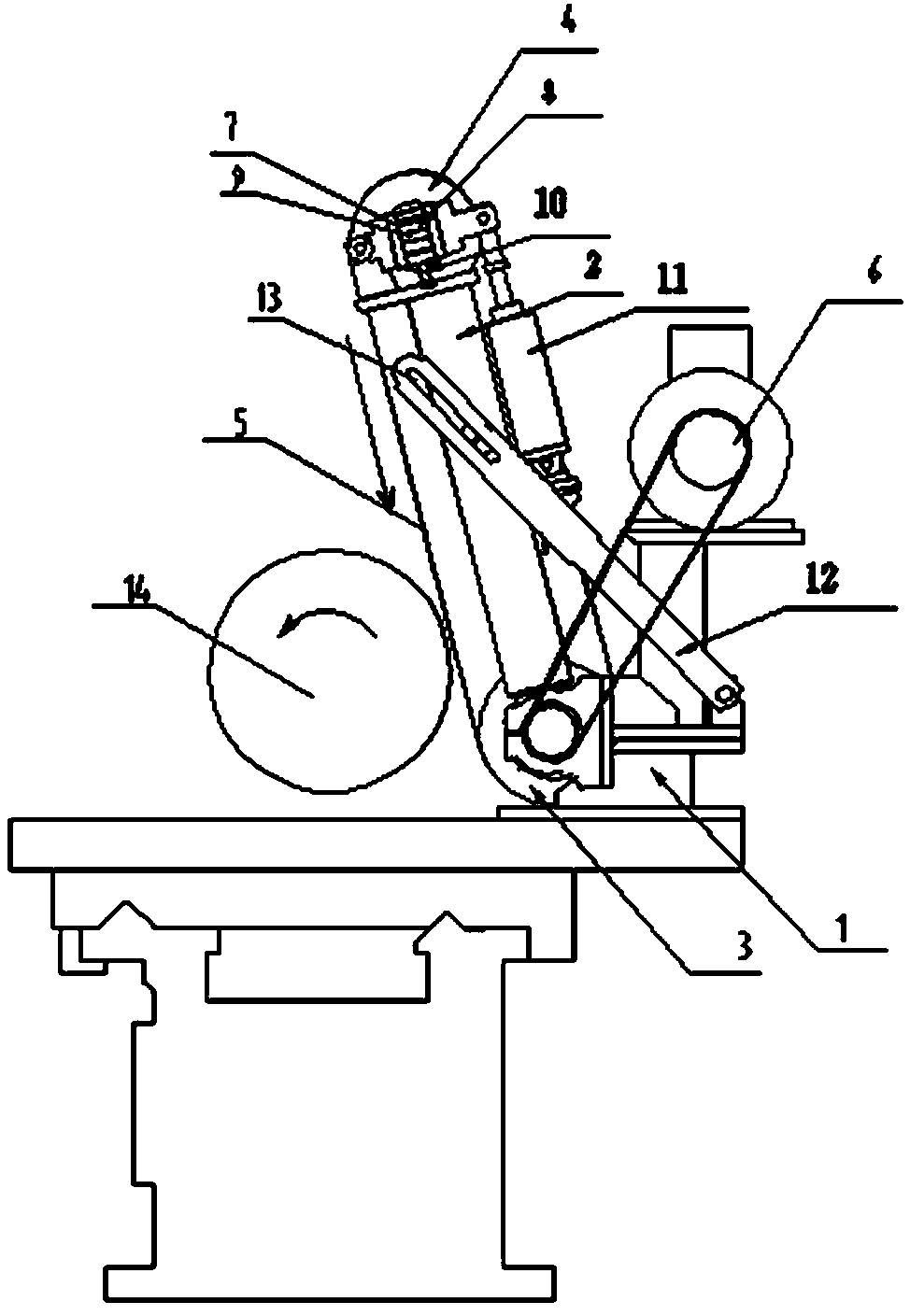

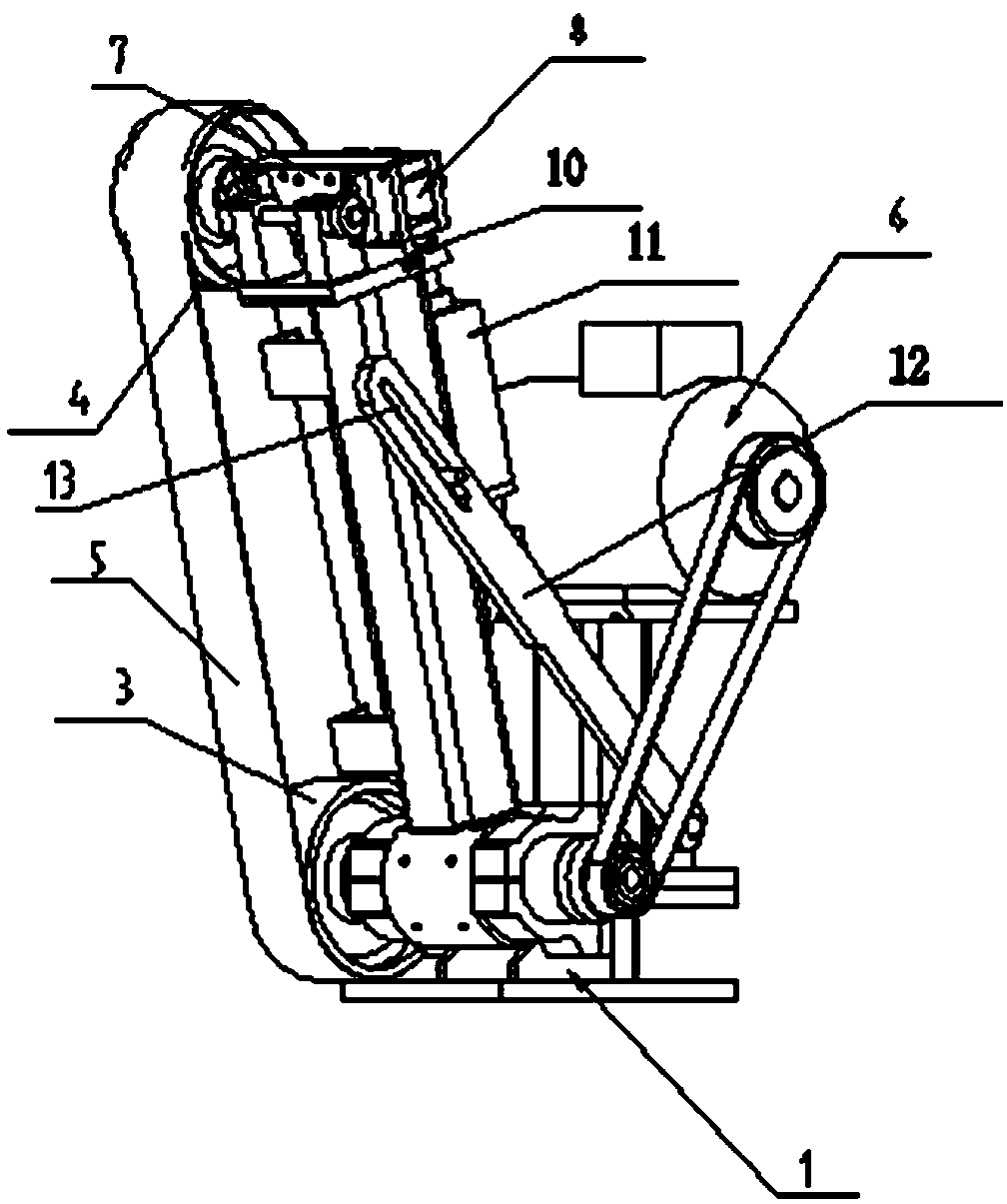

[0016] Embodiment: A rubber roller abrasive belt polishing machine, comprising a base 1, a support frame 2, a driving wheel 3, a driven wheel 4, an annular abrasive belt 5 and a motor 6, and the elongated support frame 2 is positioned on the base 1, and the driving wheel The wheel 3 is rotatably positioned at one end of the support frame 2, and the driven wheel 4 is rotatably positioned at the other end of the support frame 2. The axes of the driving wheel 3 and the driven wheel 4 are arranged in parallel. The motor 6 drives the driving wheel 3 to rotate, the other end of the support frame 2 is provided with a shaft sleeve 7, the driven wheel 4 is provided with a driven shaft 8, the driven shaft 8 is inserted in the shaft sleeve 7, and the shaft sleeve 7 is provided with There is a deviation correction adjustment device, which can drive the driven shaft 8 to rotate around an axis perpendicular to its axial direction and the length direction of the annular abrasive belt 5 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com