Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Burn evenly and fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

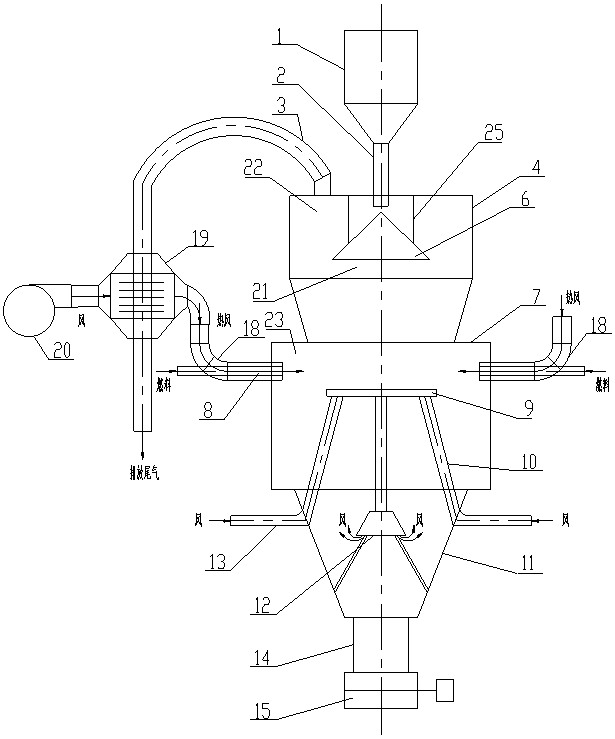

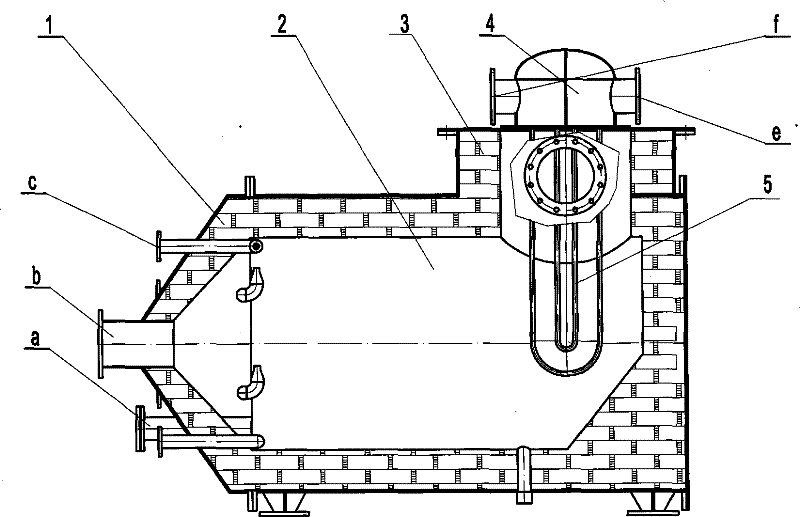

Incineration treatment method for domestic refuse

ActiveCN101761928AReduce dosageAchieve recyclingCement productionIncinerator apparatusSlagCalcination

The invention provides an incineration treatment method for domestic refuse. The method comprises: having an incinerator arranged between a rotary kiln and a decomposing furnace; introducing tertiary hot air into a wind tower of the incinerator and baking an incinerator body; crushing domestic refuse with the water content less than 20 percent into refuse material 50 to 80 millimeters in particle size and guiding the refuse material into the incinerator body through an electronic control feeder of the incinerator; allowing a material level meter to send a feedback signal to stop adding the refuse material when a refuse material layer is 50 millimeters away from a material separation body; drying the refuse material; burning, decomposing and gasifying organic substances in the refuse material through the tertiary hot air out of a multi-layer air outlet of a central air pipe; ensuring that the temperature in the incinerator body is above 850 DEG C; discharging produced flue gas to the decomposing furnace through a smoke outlet; ensuring that the decomposing furnace reaches a temperature of above 900 DEG C and is in an alkaline atmosphere; and further neutralizing acidic flue gas. Refuse ash-slag is discharged through an electrical vibrating material discharger, sent into the rotary kiln, and is taken as raw material burden for cement production to participate in calcination, so that the aim of treating domestic refuse in a 'harmless, amount-reducing and resource-recovering' way is achieved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

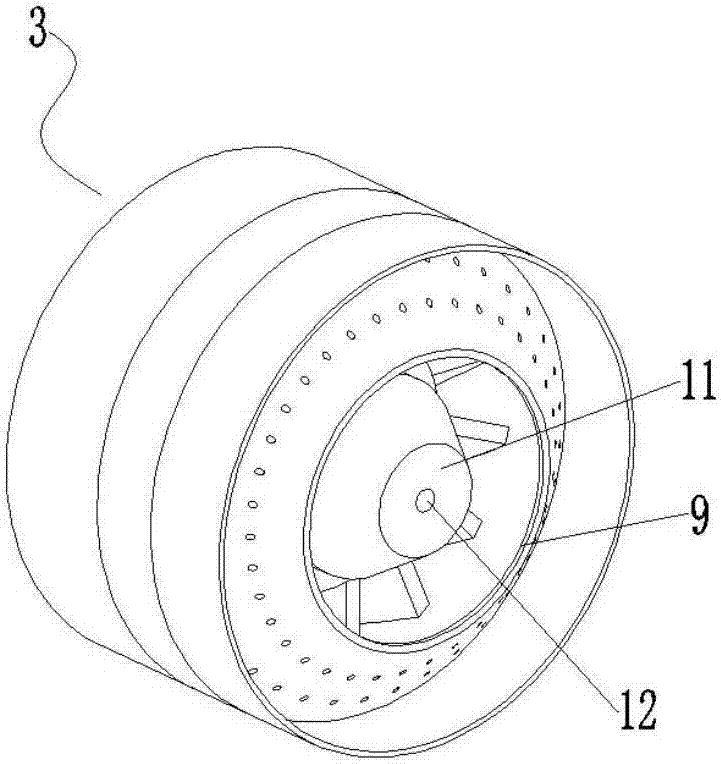

Gasification combustor of industrialized alcohol-based fuel

A gasification combustor of industrialized alcohol-based fuel comprises a combustor body. A hollow soaking gasifier is arranged on the portion, on one side of a fire outlet, of an inner cavity of the combustor body. A combustion assembly is arranged outside the hollow soaking gasifier. Gasified alcohol-based fuel is ignited and combusted through the combustion assembly. Flame penetrates through the hollow soaking gasifier to be sprayed out of the fire outlet. An electric heating element and a gasification pipe are arranged in the hollow soaking gasifier. The electric heating element is used for initially heating a soaking device. One end of the gasification pipe extends out of the hollow soaking gasifier and the combustor body to form an inlet of the gasification pipe so that alcohol-based liquid fuel can be input, and the other end of the gasification pipe extends out of the hollow soaking gasifier to form a gasification conveying pipe so that gasified alcohol-based liquid fuel can be output to the combustion assembly in the combustor body to be ignited. A draught fan connector is additionally arranged on the combustor body; because of entrance of combustion air, flame penetrates through the hollow soaking gasifier after initially-gasified alcohol-based fuel is combusted, it is ensured that alcohol-based fuel is unceasingly and uniformly gasified and sufficiently combusted, and the requirement of industrial combustion is met.

Owner:CHONGQING DAWEI ENERGY

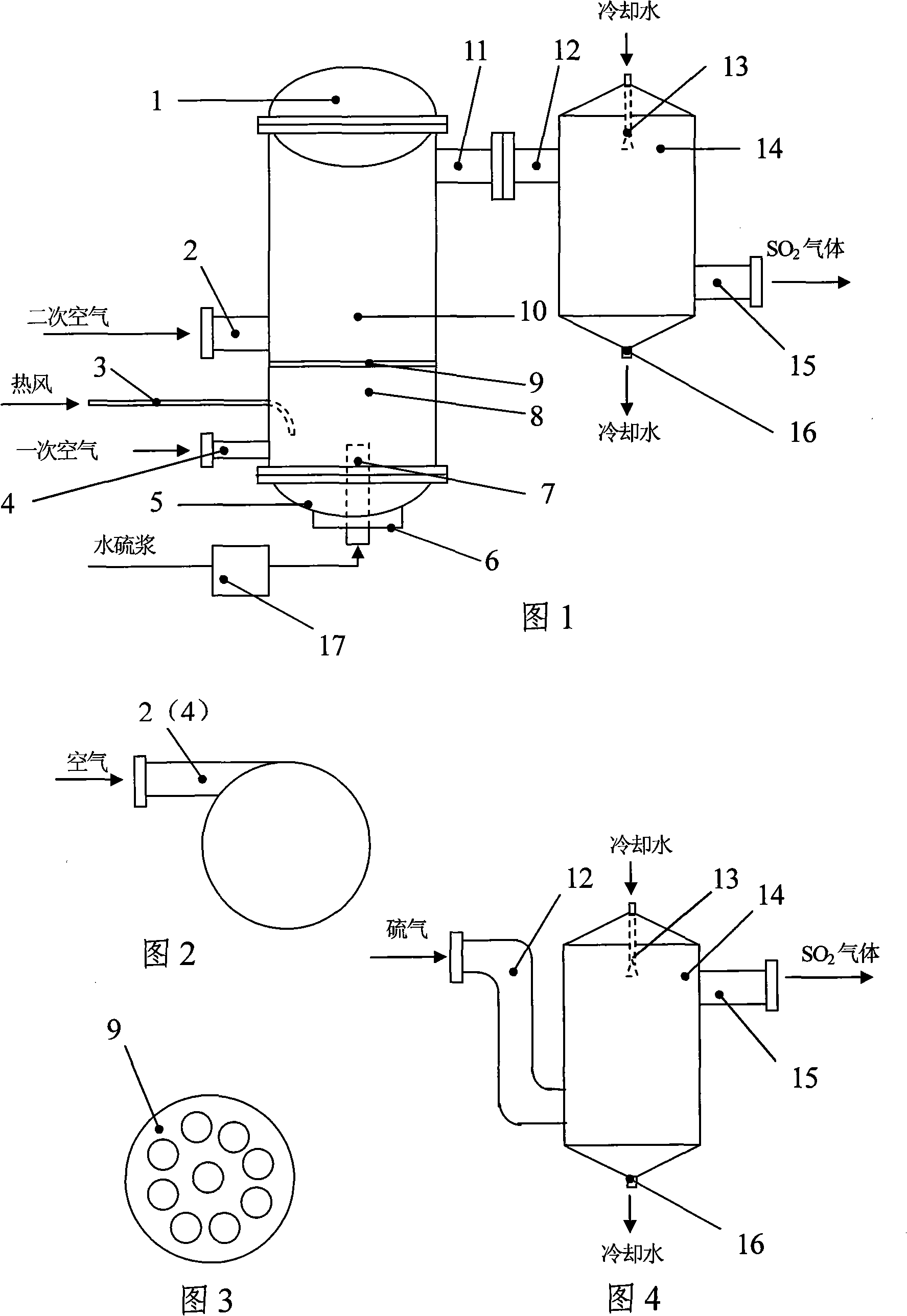

Method and apparatus for preparing sulphur dioxide gas

The invention discloses a method for generating sulfur dioxide gas and a device thereof. The method takes water-sulfur slurry as raw material, the water-sulfur slurry is successively and automatically fed into a primary combustion chamber by a feeding device, firstly the water-sulfur slurry is vaporized by pumping in a small amount of primary air, then secondary air is added in so as to lead sulfur to be fully burned and to generate SO2 gas, furthermore, the SO2 gas is cooled so as to prepare purified sulfur gas. The water-sulfur slurry is emulsion colloid sulfur or suspended sulfur solution, which is prepared by mixing sulfur particles with water. The device used for producing the sulfur dioxide gas comprises a brimstone furnace which consists of a combustion chamber, a safety hood and a lower base, and a SO2 gas cooling device, wherein, the combustion chamber is a vertically cylindrical vessel, the middle part of the vessel is provided with a porous separator which divides the combustion chamber into a primary combustion chamber and a secondary combustion chamber, wherein, the bottom of the primary combustion chamber is provided with a feeding device, a heating device and a ignition device, and the lower parts of the primary combustion chamber and the secondary combustion chamber are respectively provided with a primary air inlet duct and a secondary air inlet duct. The content of sublimed sulfur in the SO2 gas generated by using the method and the device is zero or is close to zero, and no or very little SO3 is generated.

Owner:黄永春 +1

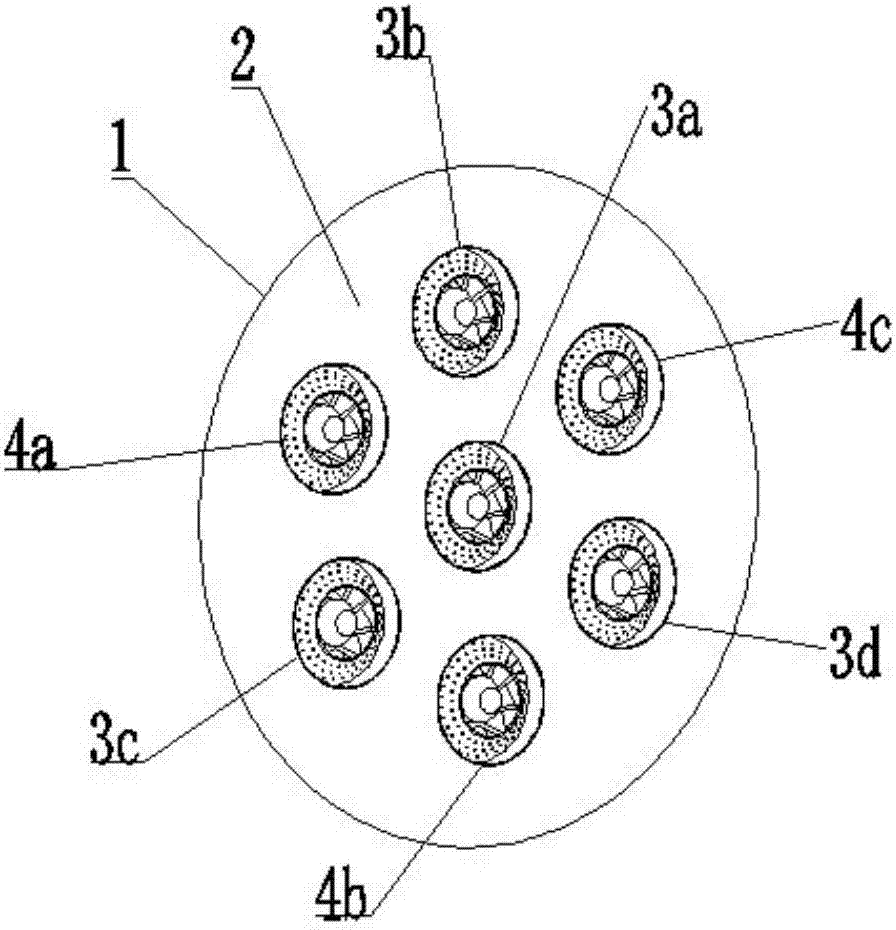

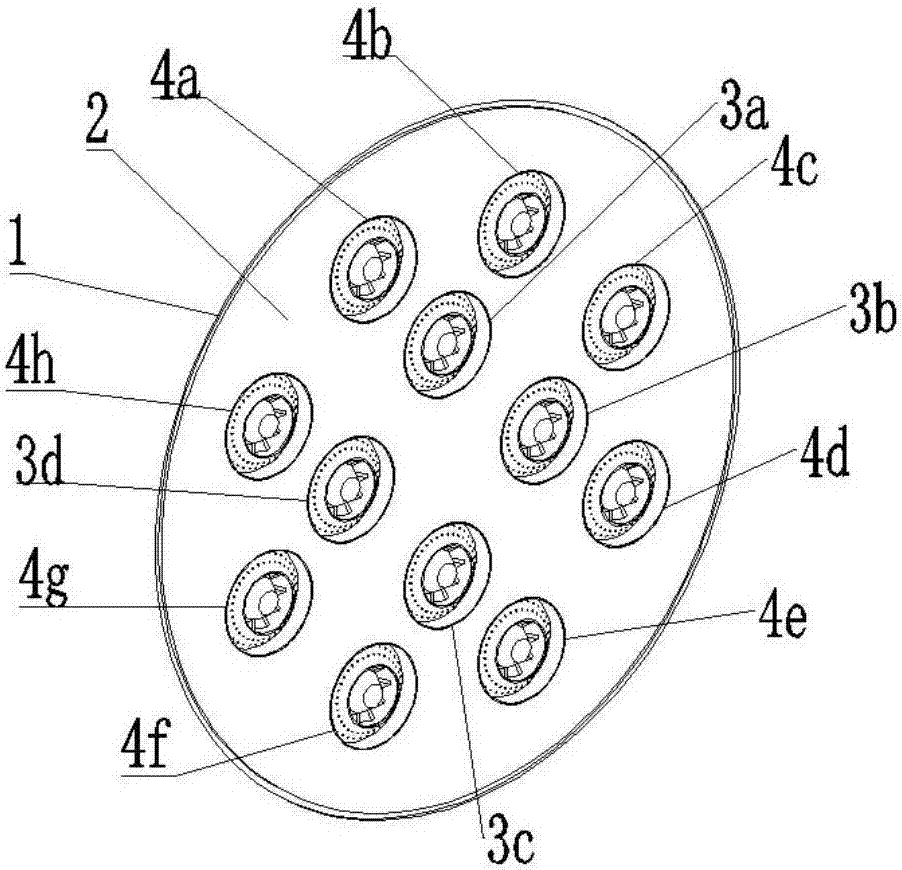

Lean oil multipoint direct injection head for low-pollution combustion chamber of gas turbine

ActiveCN107143880AInhibit nitrogen oxidesBurn evenly and fullyContinuous combustion chamberSpontaneous combustionCombustion chamber

The invention discloses a lean oil multipoint direct injection head for a low-pollution combustion chamber of a gas turbine. The lean oil multipoint direct injection head is composed of multiple swirl nozzle molds of the same structure. A secondary combustion stage is composed of a swirl nozzle mold located in the center and three swirl nozzle molds circumferentially and evenly distributed along the center swirl nozzle mold at equal distance. A primary combustion stage is composed of swirl nozzle molds alternate with the three swirl nozzle molds of the secondary combustion stage. The primary combustion stage and the secondary combustion stage can be independently controlled, and it is guaranteed that the combustion chamber can stably work in a wide working state. A lean oil direct injection combustion technology is adopted, a nozzle outlet is flushed with a swirl flow air outlet, the nozzle molds work in a non-premixed combustion manner, the phenomena of spontaneous combustion and tempering can be avoided, and the risk of oscillating combustion is reduced. The working equivalence ratio of the nozzle molds ranges from 0.6 to 0.8, it is guaranteed that the temperature of a combustion area is low and combustion is stable, and generated thermal nitric oxide is effectively reduced. Pollutant emissions are few, and the lean oil multipoint direct injection head is simple in structure and suitable for the low-pollution combustion chamber of the gas turbine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

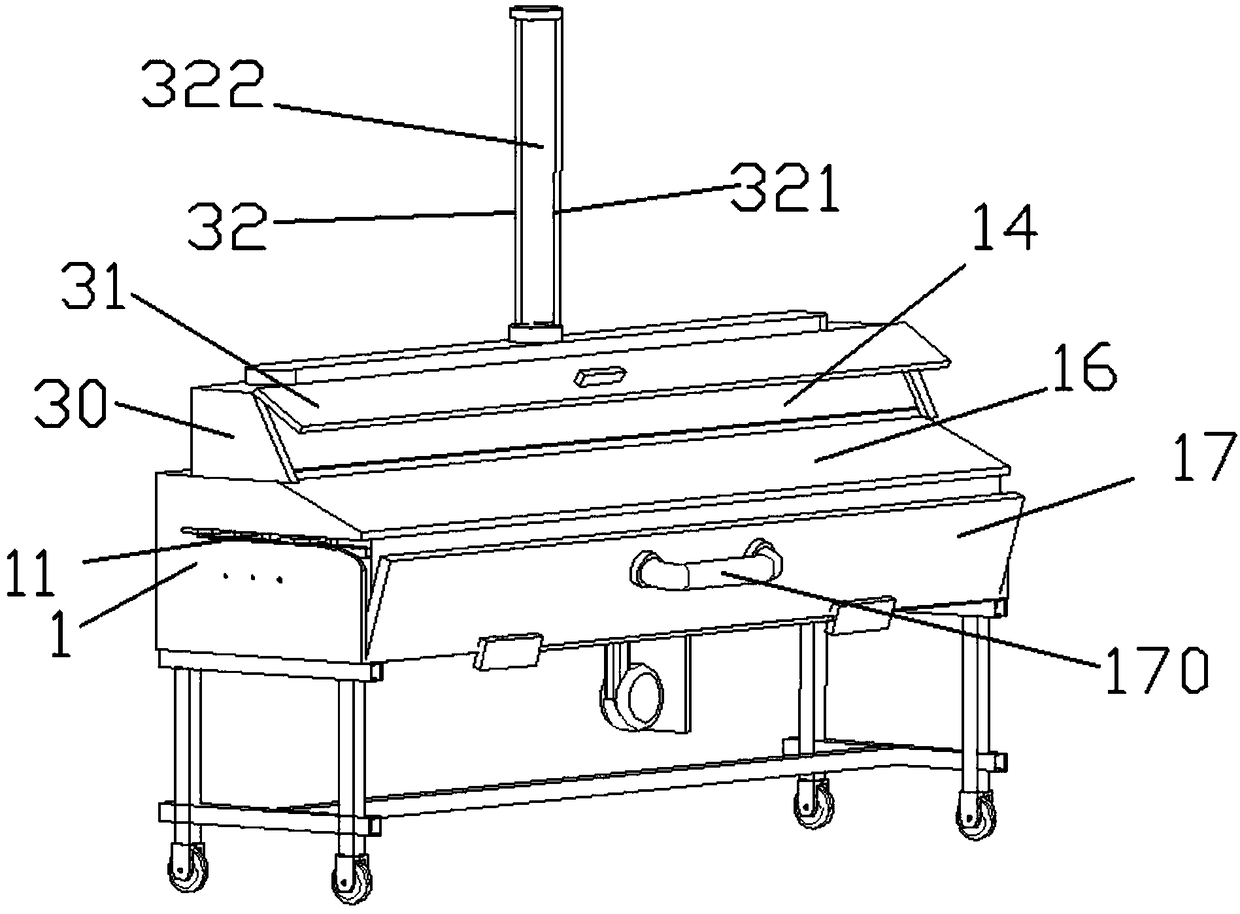

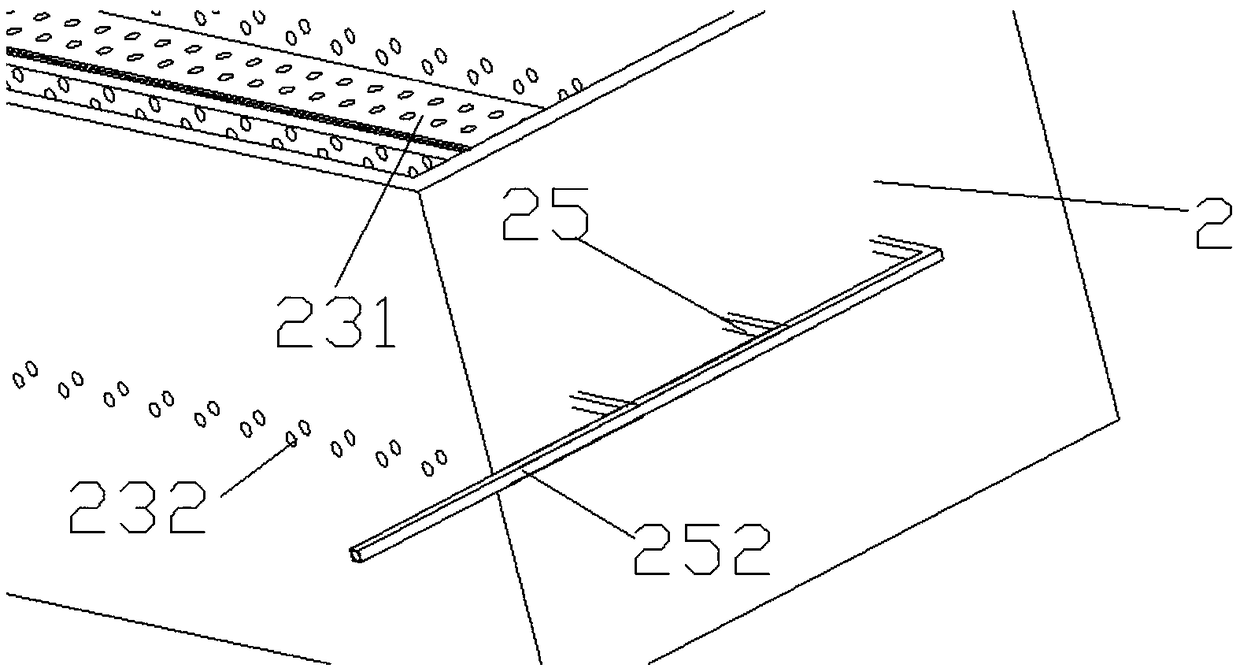

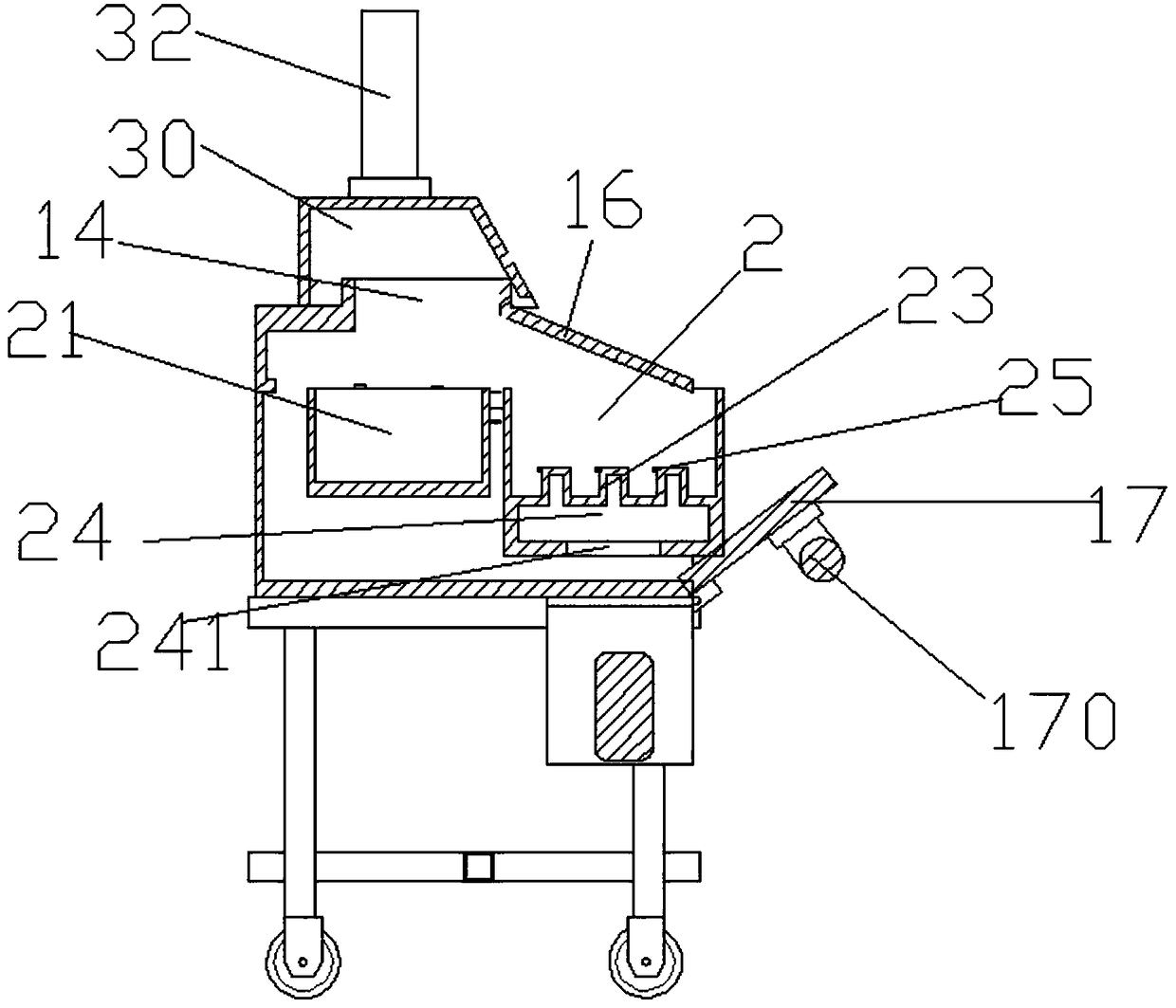

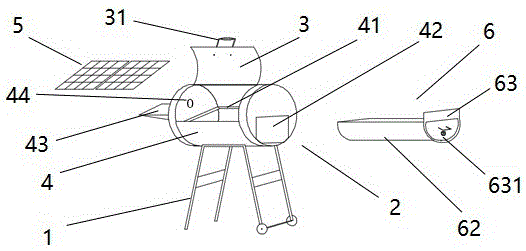

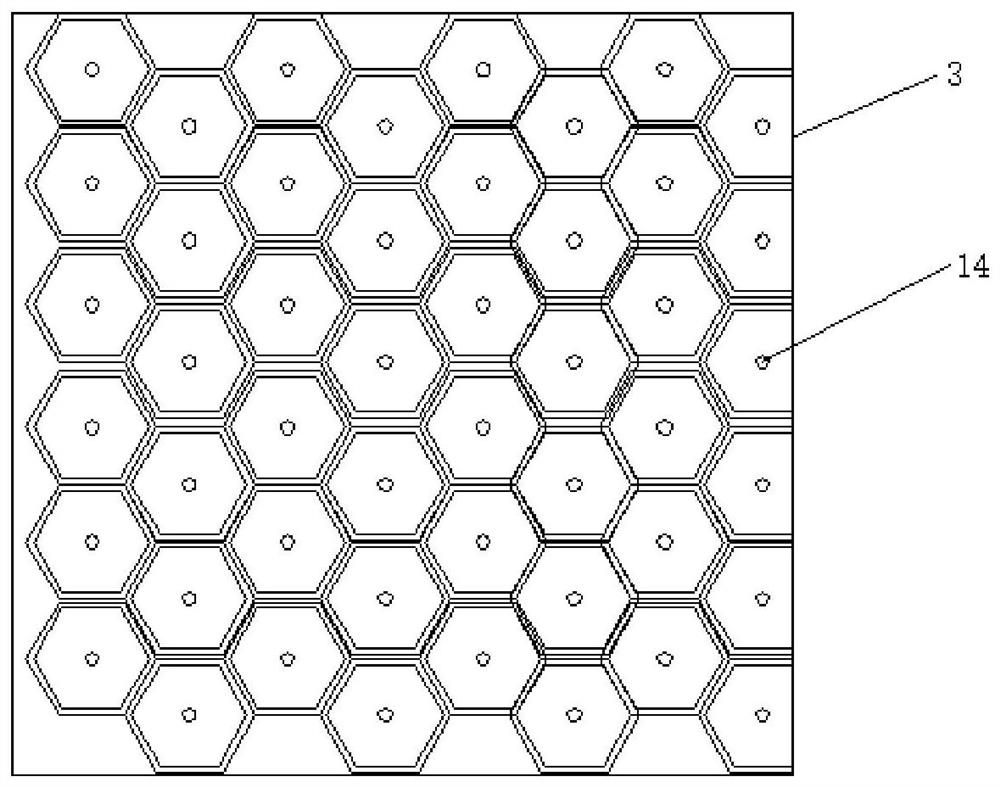

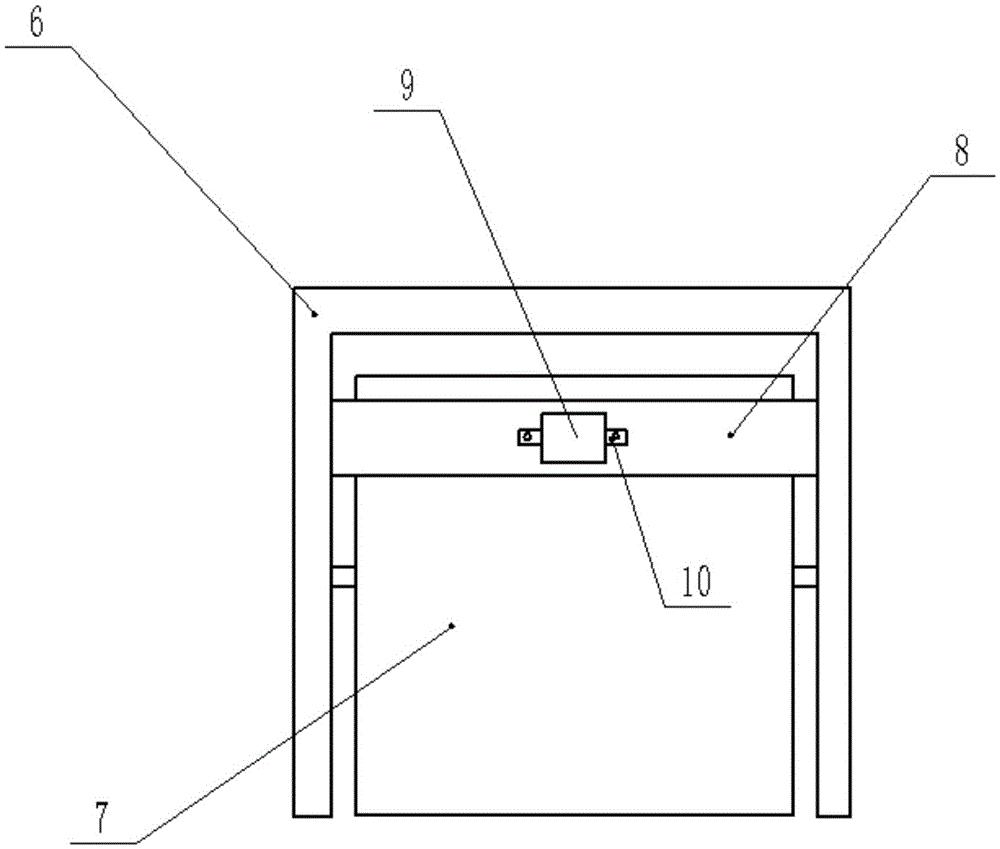

Environment-friendly energy-saving efficient smokeless barbecue oven utilization method

InactiveCN108143303AImprove combustion efficiencyEnsure safetyRoasters/grillsCombustionThermal insulation

The invention relates to an environment-friendly energy-saving efficient smokeless barbecue oven utilization method. A smokeless barbecue oven comprises a barbecue oven body, a bottom supporting frame, slide rails, a charcoal cavity, an oil receiving groove, an air blower and an oven side cover. The barbecue oven body is made of a metal sheet material by welding and internally coated with a refractory material, and a thermal insulation layer is sandwiched between the refractory material and the metal outer wall. The charcoal cavity and the oil receiving groove are positioned on the slide railsand similar to drawer structures to make it convenient to take out the charcoal cavity to replace charcoal, an air passage is positioned below the charcoal cavity and downwardly connected with the external air blower, and the air passage is provided with a plurality of pores for solving the problem of heat nonuniformity of a barbecue operating port due to different charcoal combustion speeds caused by wind distribution nonuniformity in barbecuing. The bottom supporting frame is positioned below the barbecue oven body, and universal traveling wheels with brakes are arranged at the bottom of the supporting frame. The smokeless barbecue oven is convenient to ignite, and charcoal ash is less prone to flying, so that cleanness is achieved; by an air passage device, uniformity in charcoal combustion is improved, and high charcoal utilization rate is realized.

Owner:淄博萃智工业设计咨询有限公司

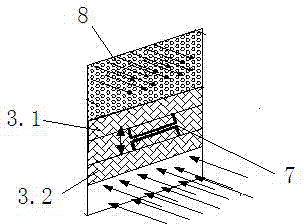

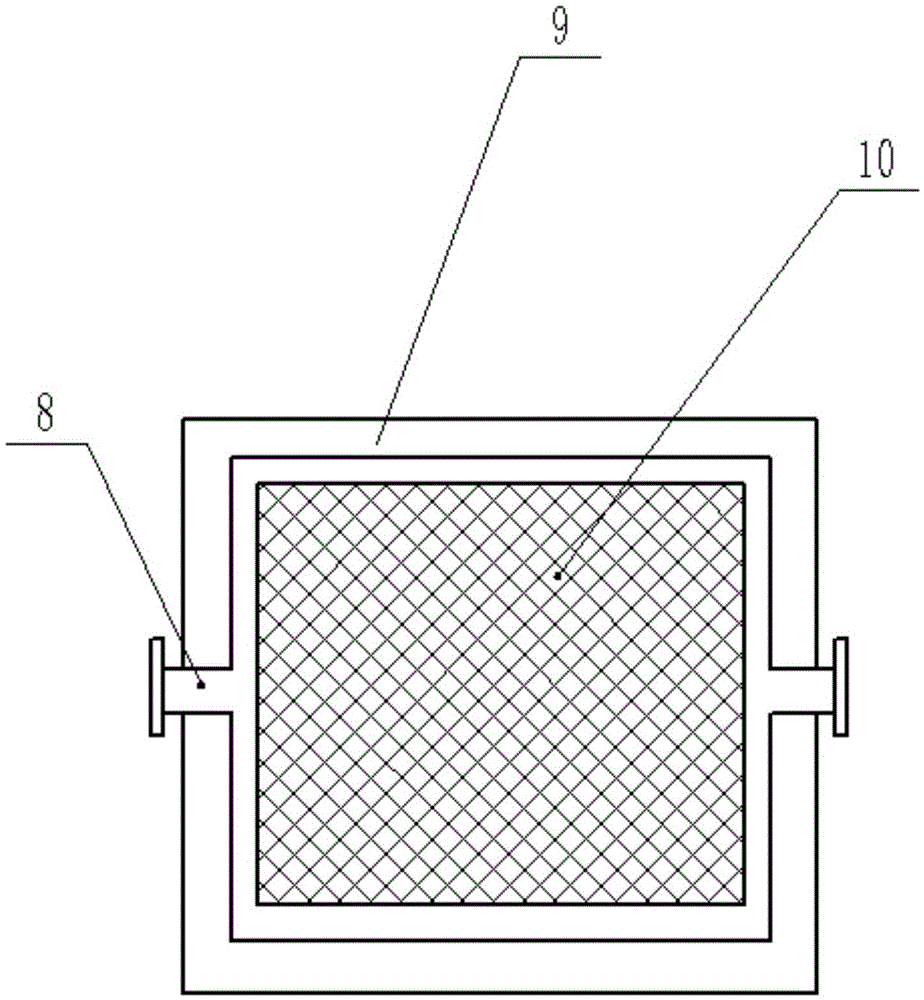

Method and device for fast preparing white activated rice hull ash

InactiveCN102730702AAccelerated dissipationControl ingressSilicaSolid waste disposalTemperature controlEngineering

The invention relates to method and device for fast preparing white activated rice hull ash. The method comprises the following steps: (1) carrying out diluted acid pretreatment on rich hulls for 2-24 hours; (2) washing the rice hulls subjected to diluted acid pretreatment for many times, and removing impurities in the rice hulls; and (3) directly placing the washes rice hulls into an incineration basket, and incinerating in a furnace body, controlling the grate temperature of the furnace body at the temperature of 600-800 DEG C, and preparing rice hull ash with 50 nanoscale particles, wherein the content of amorphous silica achieves more than 90%, the amorphous silica is white and evenly distributed, and the rich hull ash is loosely stacked. The device comprises an insulating furnace body, the incineration basket, a temperature controller, a thermocouple temperature sensor, a resistance wire, an adjustable air inlet and an adjustable air outlet. The method and the device can be used for fast producing white activated rice hull ash capable of substituting silica fume.

Owner:FUZHOU UNIV

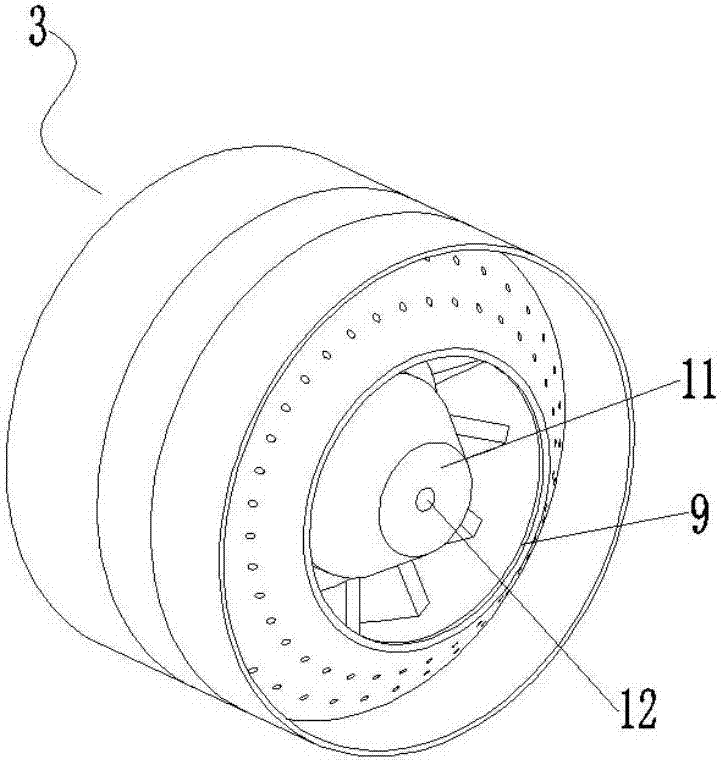

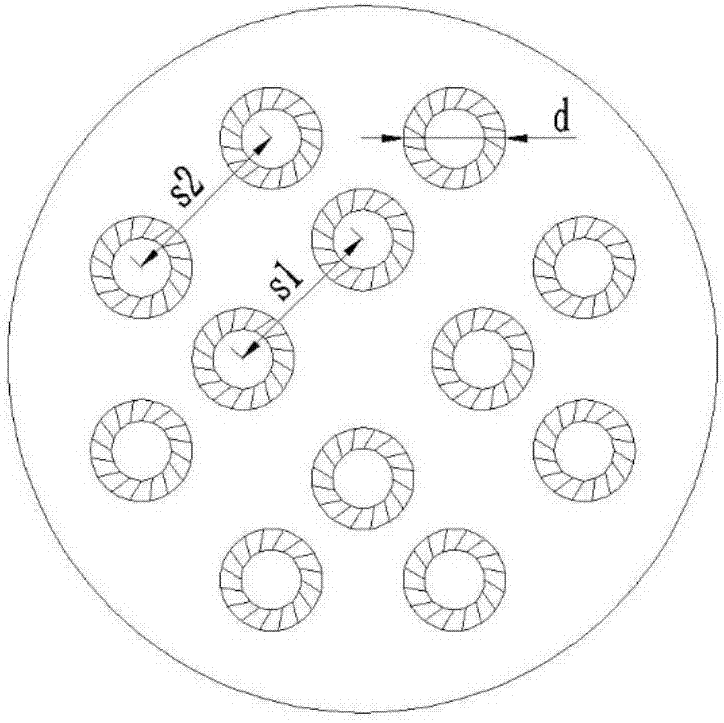

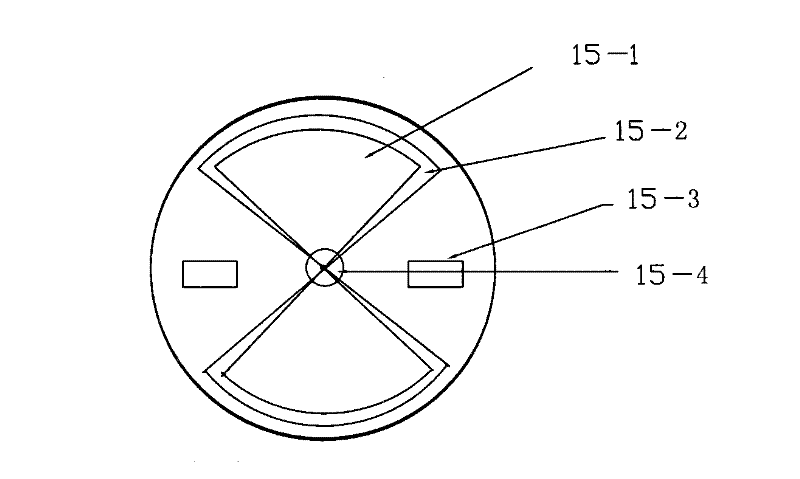

Multipoint direct injection head structure for low-pollution combustion chamber of gas turbine

ActiveCN107143881ABurn evenly and fullyIncrease oil supply pressureContinuous combustion chamberSpontaneous combustionCombustion chamber

The invention discloses a multipoint direct injection head structure for a low-pollution combustion chamber of a gas turbine. Multiple secondary combustion stage swirl nozzle molds and primary combustion stage swirl nozzle molds of the same structure are adopted for being evenly distributed and fixedly connected in the circumferential direction of the center of a combustion chamber head flange, and the primary combustion stage swirl nozzle molds are located on the periphery of the secondary combustion stage swirl nozzle molds in the circumferential direction. An air flow path of the swirl nozzle molds is formed by an air inlet, a swirl flow channel, an annular swirl flow air straight channel, an annular swirl flow air convergence channel and a swirl flow air outlet, and speed distribution with the inner side lower than the outer side in the radial direction is formed at the swirl flow air outlet. A fuel oil flow path is formed by a fuel oil inlet, a nozzle and a nozzle outlet. The nozzle outlet is flushed with the swirl flow air outlet, the nozzle molds work in a non-premixed combustion manner, the phenomena of spontaneous combustion and tempering are avoided, and the risk of oscillating combustion is reduced. The temperature of a combustion area is low, combustion is stable, and generated thermal nitric oxide is effectively reduced. Pollutant emissions are few, and the multipoint direct injection head structure is suitable for the low-pollution combustion chamber of the gas turbine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

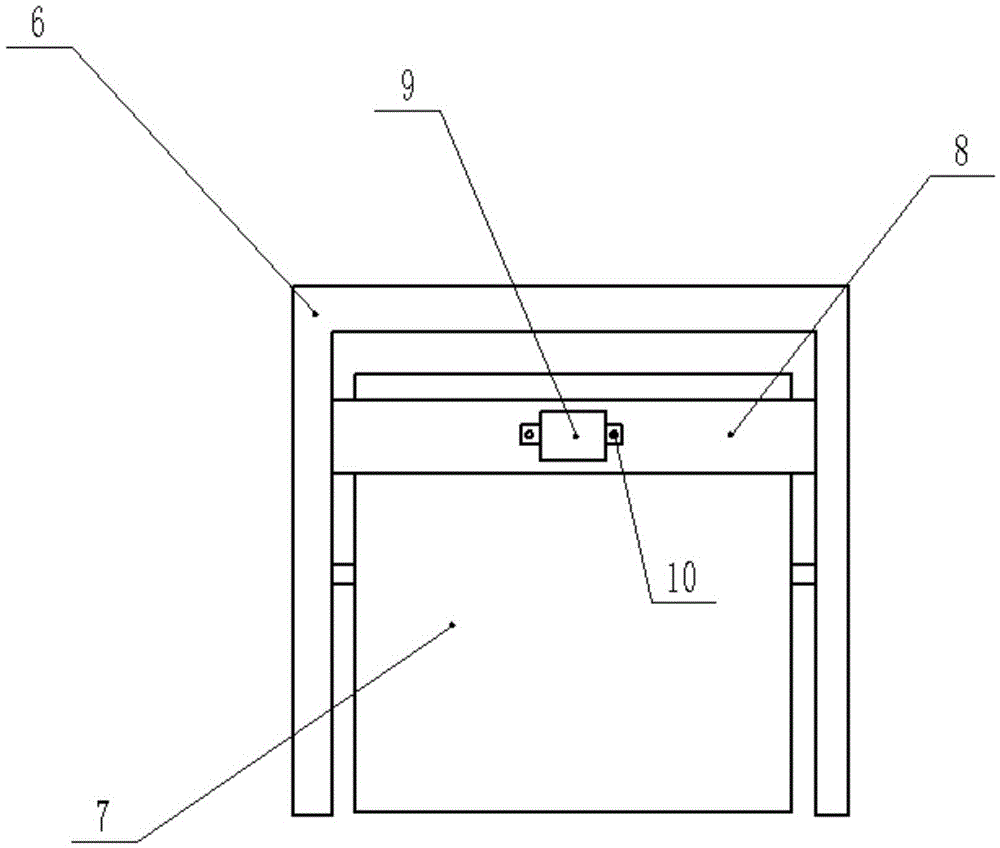

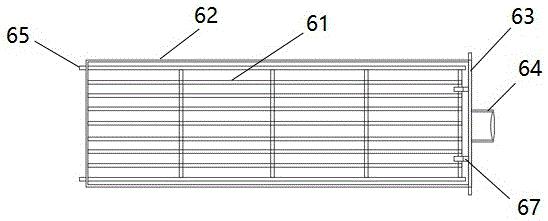

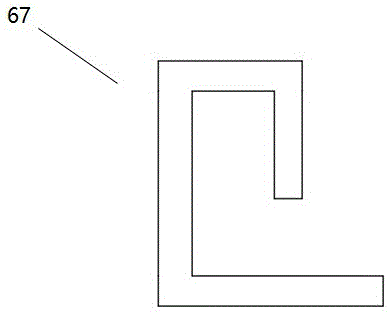

Smokeless barbeque oven with efficient and environment-friendly function

InactiveCN108209611AImprove combustion efficiencyEnsure safetyClimate change adaptationEngineeringAir blower

The invention relates to a smokeless barbeque oven with an efficient and environment-friendly function. The smokeless barbeque oven comprises an oven body, a bottom support, a slide rail, a charcoal groove, an oil connecting groove, an air blower and an oven side cover. The oven body is formed by welding metal sheets, a refractory material fits the inner side, and a heat preservation layer is sandwiched between the refractory material and the metal outer wall. The charcoal groove and the oil connecting groove are formed in the slide rail and are similar to drawers, the charcoal groove is conveniently taken out for replacing charcoal, an air channel is located below the charcoal groove, the air blower is connected to the lower portion of the air channel, and multiple small holes are formedin the upper portion of the air channel to solve the problems that the burning velocity of the charcoal is inconstant and heat of a barbeque operating opening is not uniform when the wind distributionis not uniform during barbequing. The bottom support is located below the barbeque oven, and universal walking wheels with brakes are arranged at the bottom of the bottom support. The smokeless barbeque oven facilitates ignition, charcoal ashes do not easily rise, the smokeless barbeque oven is hygienic, the device of the air channel makes the charcoal more uniformly burned, and the charcoal utilization rate is high.

Owner:淄博萃智工业设计咨询有限公司

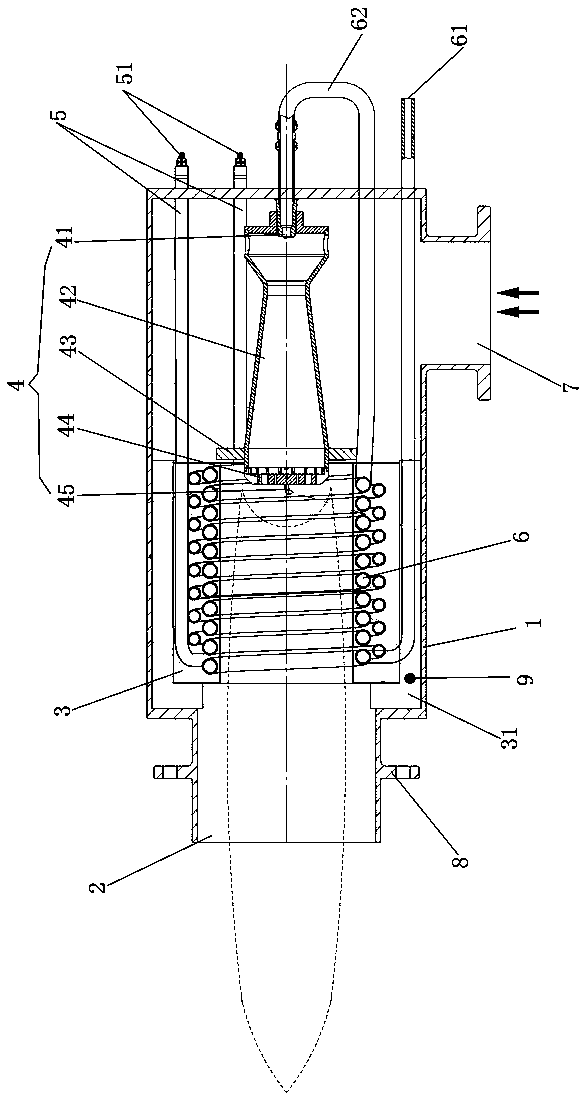

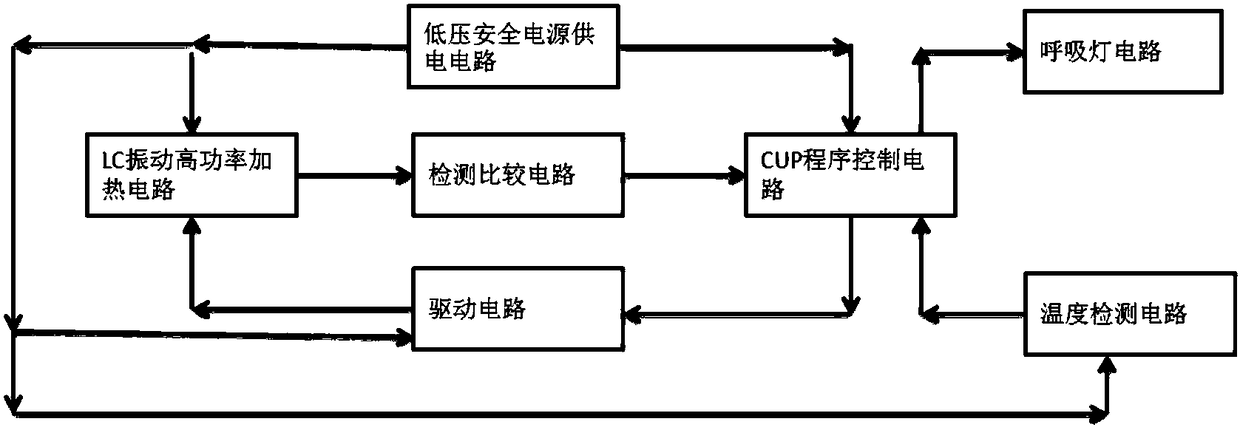

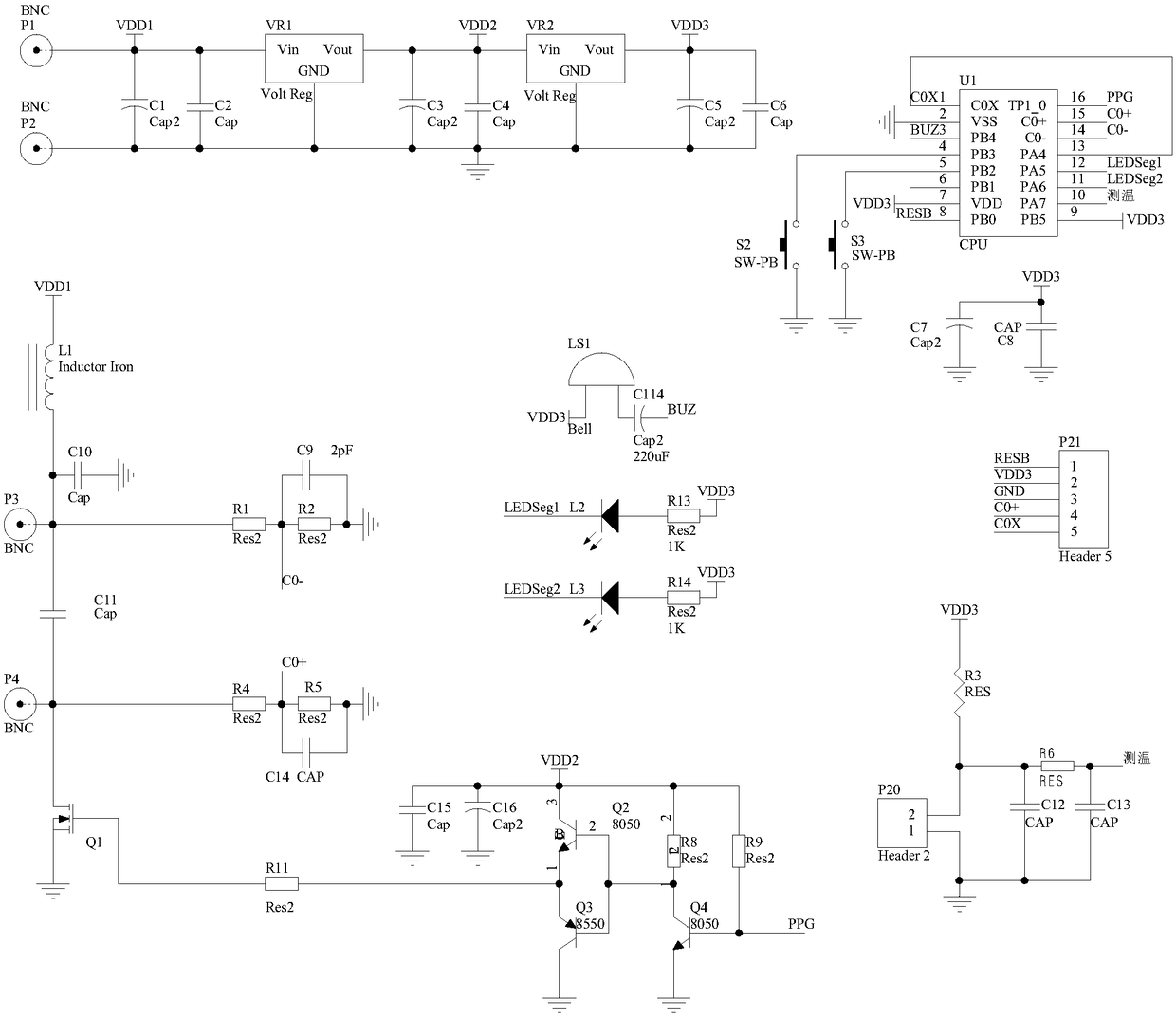

Electronic cigarette controller based on direct-current low-voltage electromagnetic heating technology

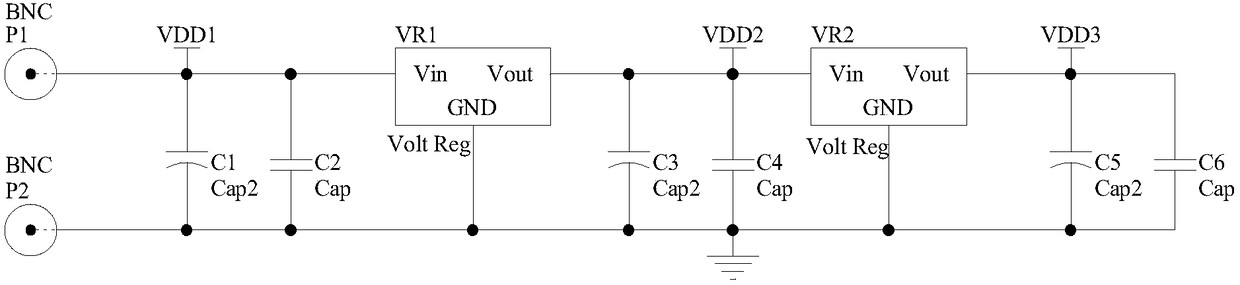

PendingCN108420117ABurn evenlyBurn evenly and fullyTobacco devicesTemperature control using electric meansCapacitanceLow voltage

The invention discloses an electronic cigarette controller based on a direct-current low-voltage electromagnetic heating technology. The electronic cigarette controller based on the direct-current low-voltage electromagnetic heating technology includes a CPU, a power supply, an LC vibration high-power heating circuit and a comparison circuit; the LC vibration high-power heating circuit includes acapacitor C10, a capacitor C11, an inductor L1 and an external heating coil, wherein the inductor L1 is connected with the capacitor C10, the capacitor C11 and a resistor R1 in the comparison circuit;one end of the capacitor C10 is connected with the inductor L1, the capacitor C11 and the resistor R1 in the comparison circuit; one end of the capacitor C11 is connected with the inductor L1, the capacitor C10, a connector P3 and the resistor R1 in the comparison circuit, and the other end of the capacitor C11 is connected with the drain electrode of an MOS tube Q1 of a drive circuit, a connector P4 and a resistor R4 in the comparison circuit; the external heating coil is connected to the connector P3 and the connector P4 separately. According to the electronic cigarette controller based onthe direct-current low-voltage electromagnetic heating technology, the direct-current power supply is adopted, IH heating is adopted to control output, and therefore a heater warms rapidly and heats uniformly.

Owner:SHUNDE POLYTECHNIC

Control method for air-fuel ratio of pusher heat accumulating type heating furnace

InactiveCN106370021AImprove heating qualityReduce build thicknessControl devices for furnacesSurface oxidationAir–fuel ratio

The invention discloses a control method for air-fuel ratio of a pusher heat accumulating type heating furnace, and aims to solve the problem of a conventional heat accumulating type heating furnace that the air-fuel ratio is not controlled. The control method is characterized in that a middle plate heat accumulating type heating furnace is divided into four combustion sections of a heating section I, a heating section II, a heating section III and a soaking section; the air-fuel ratio of the heating section I and the heating section II is 0.75 to 0.85; the air-fuel ratio of the heating section III is 0.70 to 0.80; and the air-fuel ratio of the soaking section is 0.70 to 0.75. According to the control method, through adjusting the ratio of air to gas in the heating furnace, full combustion of gas in the furnace is guaranteed, heat is effectively released, and the heating quality of billet steel is improved; through reasonably setting the air-fuel ratio, the amount of residual air in the furnace is decreased, the thickness of oxidized scales generated on the surface of the billet steel is decreased, the scale removing difficulty is reduced, the burning loss of the surface of the billet steel is reduced, and the yield of the billet steel is increased; and on the other hand, through optimizing the ratio, the fuel is fully and uniformly burnt, the energy consumption is reduced, the changing frequency of a heat accumulator is reduced, and the service cycle of the heating furnace is prolonged.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

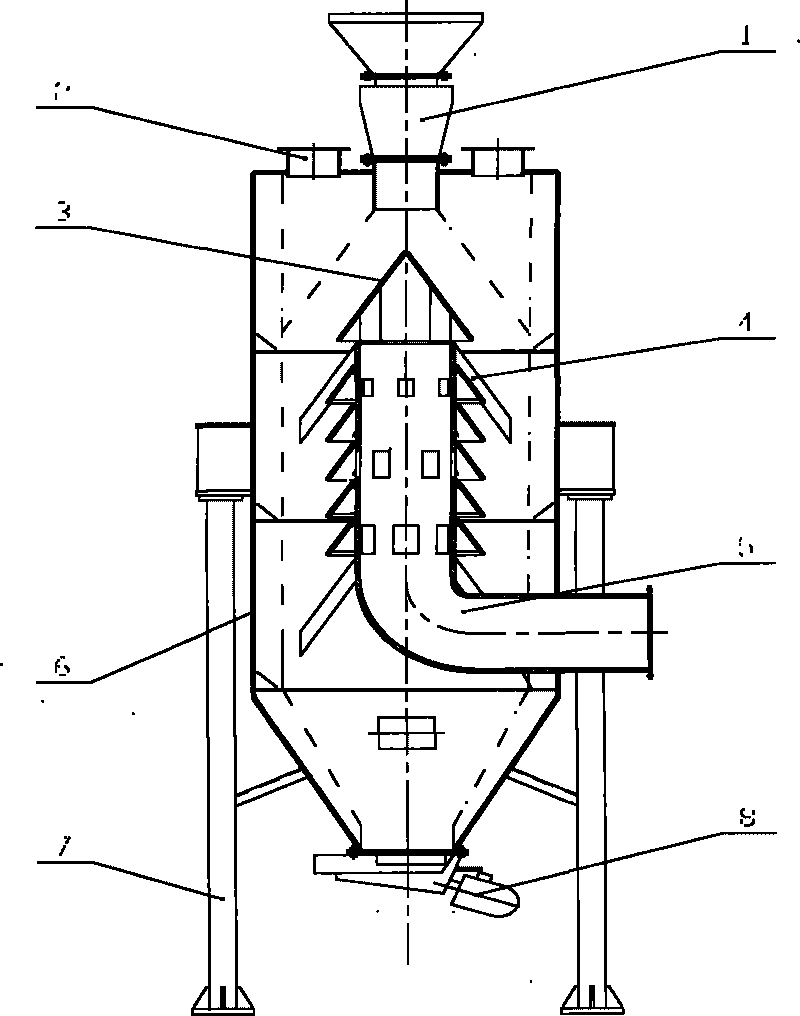

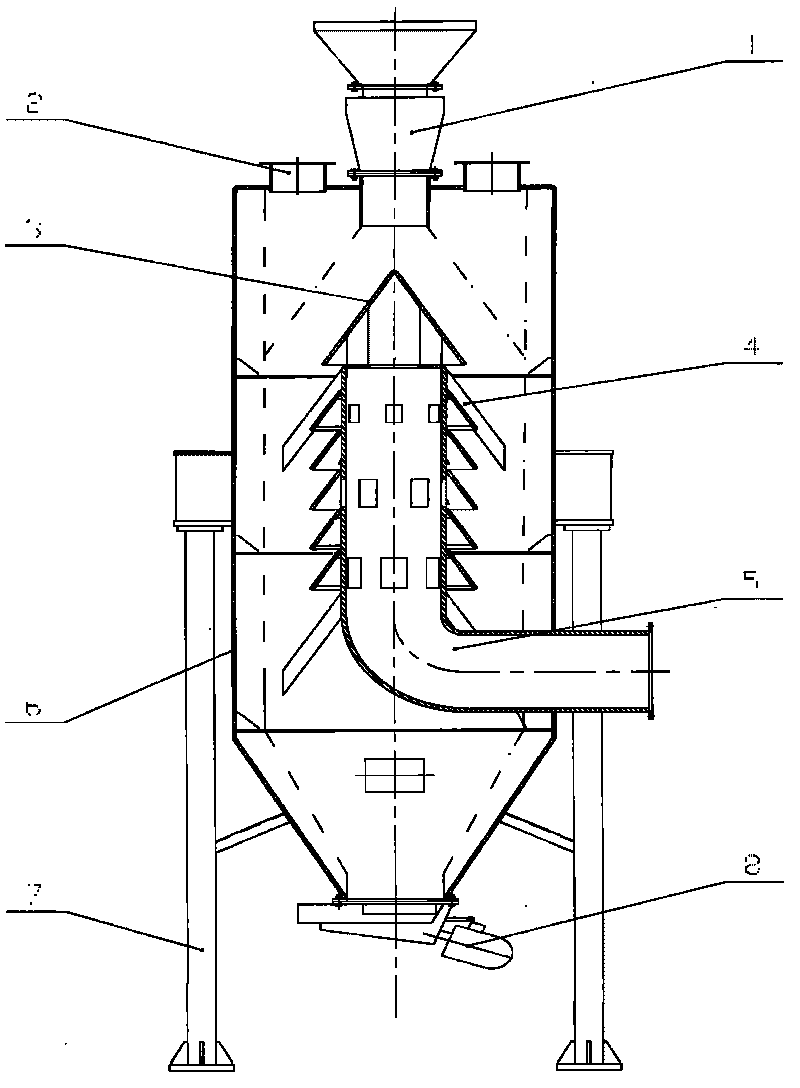

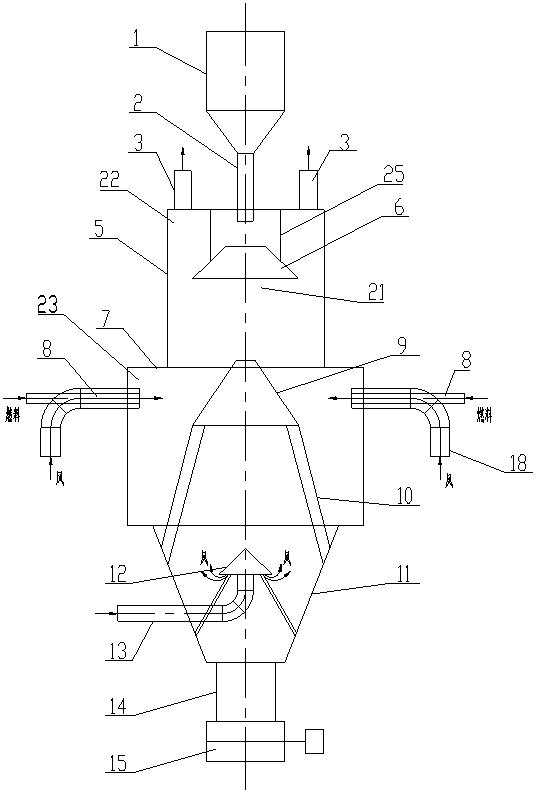

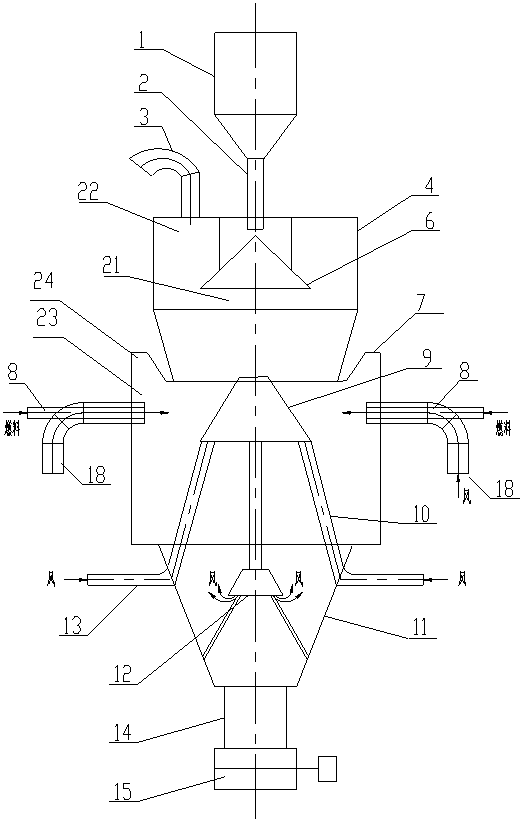

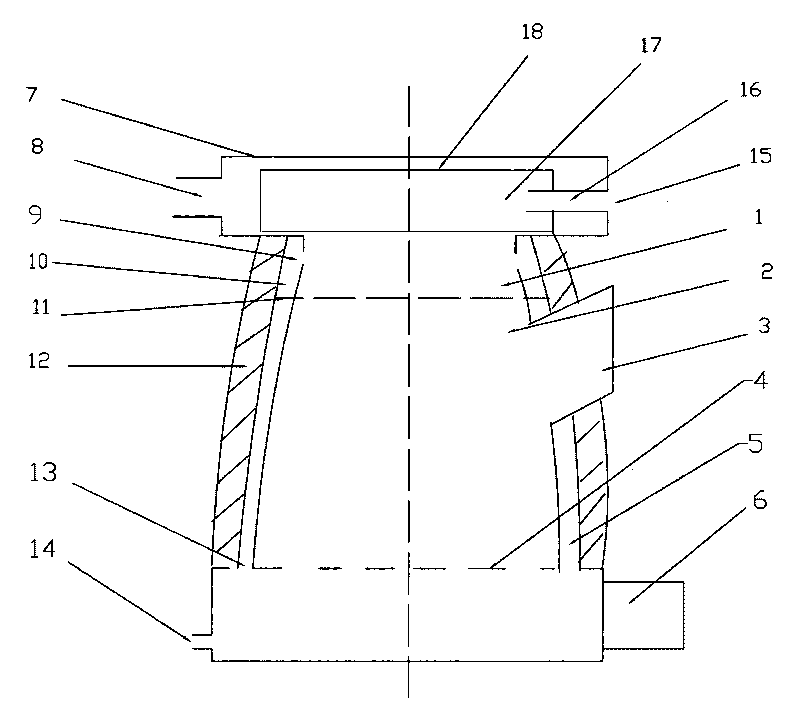

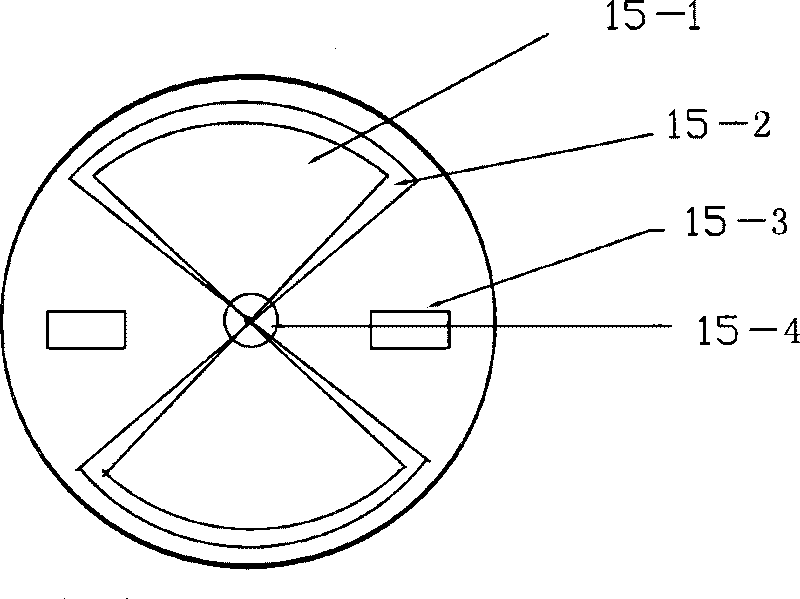

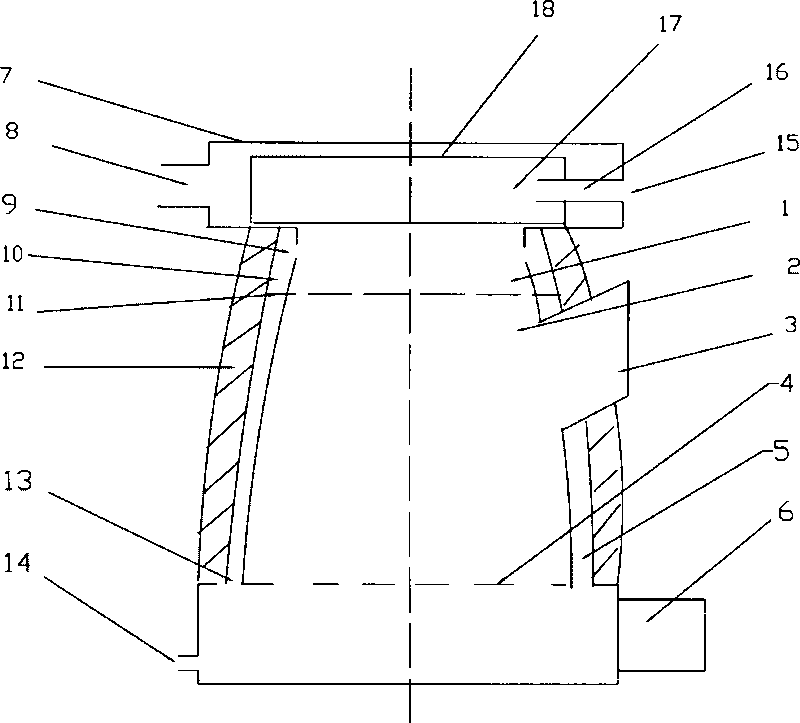

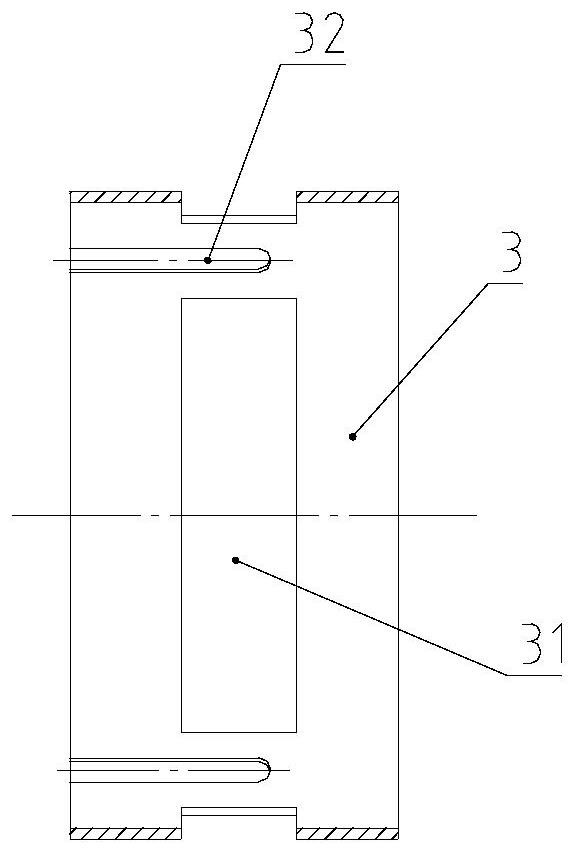

Industrial calcination shaft kiln

PendingCN108088236AEqual temperatureEasy to achieve uniform temperature requirementsControl devices for furnacesVertical furnacesCombustionPulp and paper industry

The invention discloses an industrial calcination shaft kiln. According to the industrial calcination shaft kiln, gas, liquid or power are taken as fuel, the calcination temperature is more even, theproduct quality is better, energy conservation and environmental protection are achieved, the automation degree is high, and massive or granular or ball-shaped materials can be calcined. The industrial calcination shaft kiln comprises a cylinder body, a material adding device used for adding materials to the interior of the cylinder body and an exhaust device used for exhausting tail gas are arranged on the upper portion of the cylinder body; a combustion-supporting wind device used for sending combustion-supporting wind to the interior of the cylinder body and an unloading device used for discharging the material in the cylinder body are arranged on the lower portion of the cylinder body, at least a sudden-changed section is arranged at the position, between the material adding device andthe combustion-supporting wind device, of the cylinder body, the size of the part, on the upper portion of the sudden-changed section, of an inner cavity of the cylinder body is small in the horizontal direction, the size of the part, on the lower portion of the sudden-changed section, of the inner cavity of the cylinder body is large in the horizontal direction, and when the materials flow downwards in the cylinder body, a cavity which the materials cannot reach naturally is formed on the lower portion of the sudden-changed section; and an outlet of a combustion nozzle in a fuel combustion device communicates with the cavity, and materials are sprayed out from the combustion nozzle.

Owner:NANJING SUYE CALCIUM IND TECH

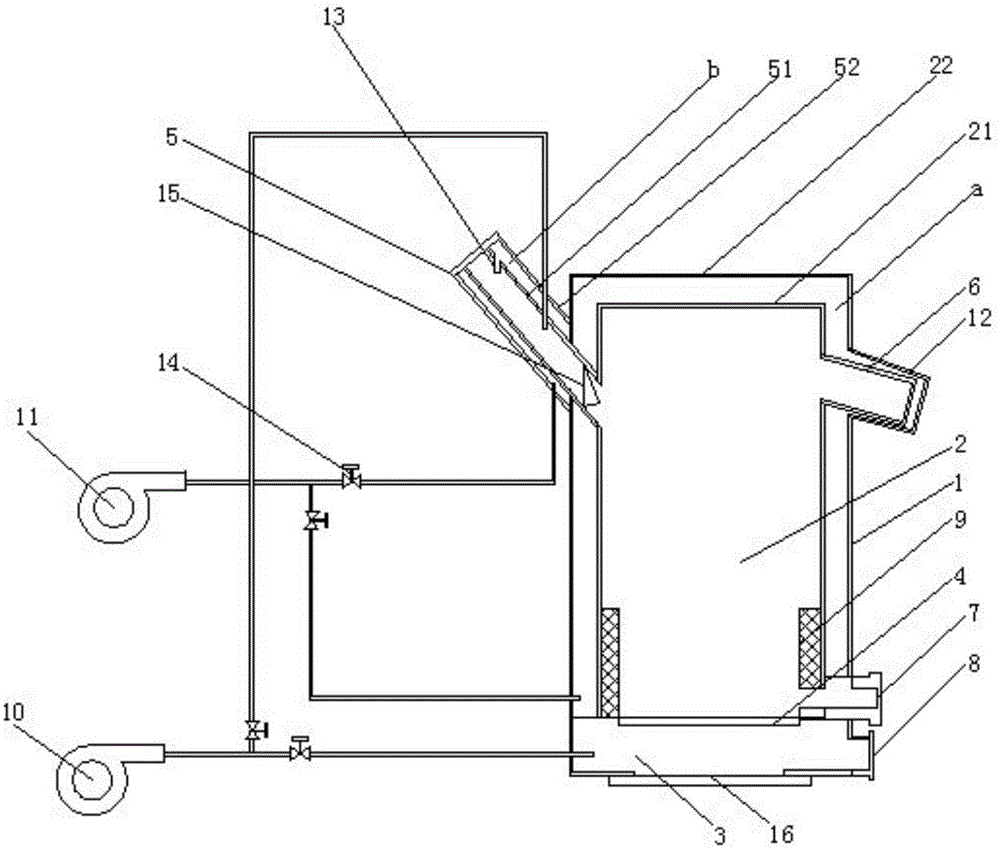

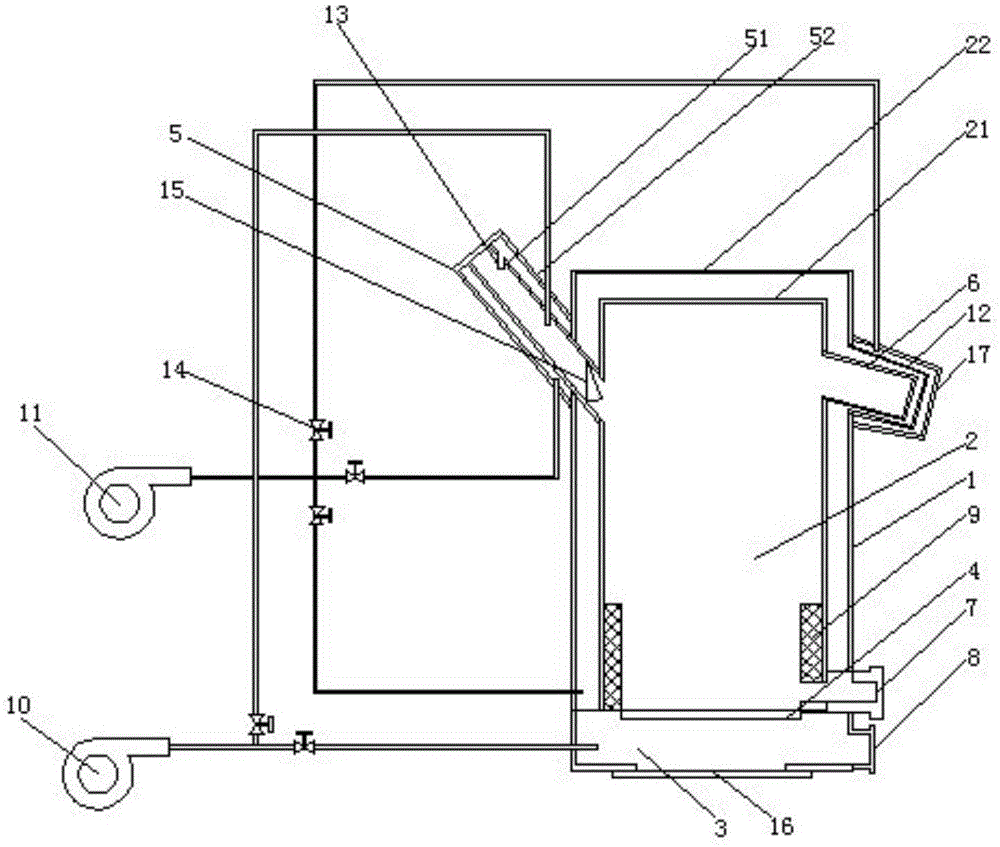

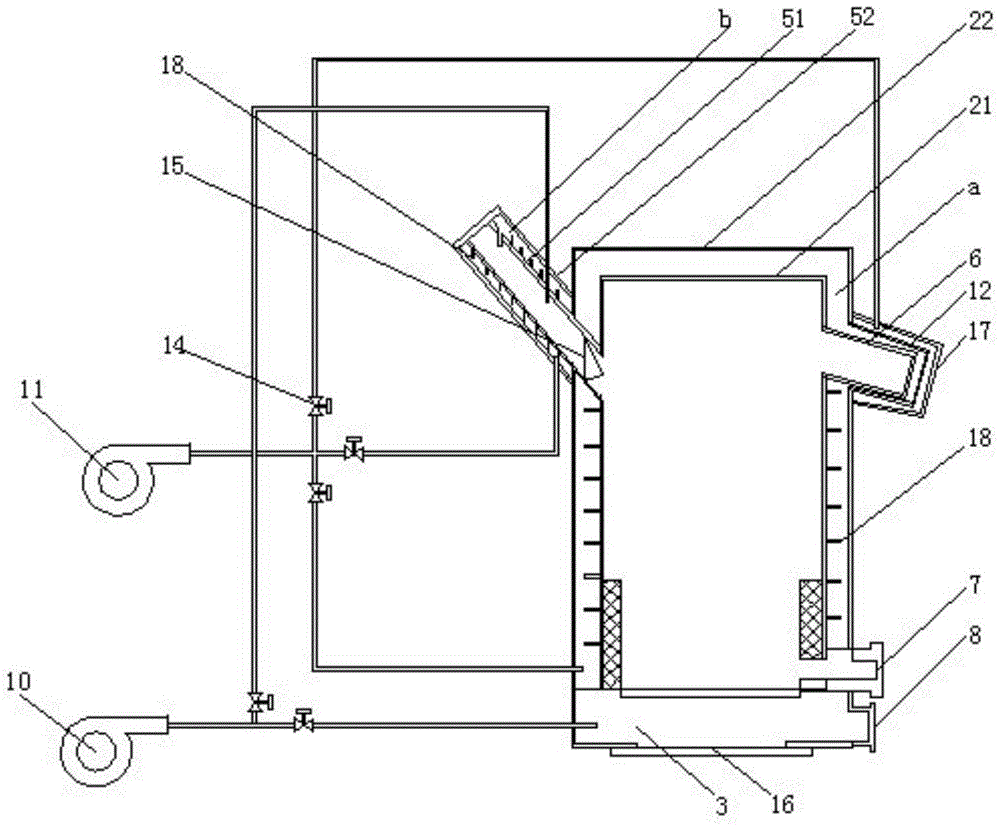

Biomass gasification burner

InactiveCN104566339AEfficient use ofExtended service lifeSolid fuel combustionChamber doorsCombustionEngineering

The invention discloses a biomass gasification burner. The biomass gasification burner comprises a furnace; a movable grate in the furnace divides the furnace into a furnace chamber and an ash chamber; the upper side of the furnace is provided with a feeding device and burner ports; the furnace chamber comprises an inner liner and an outer liner; a gap a is reserved between the inner liner and the outer liner; the burner port is communicated with the inner liner; the outer liner is welded with two layers of burner ports with similar structures in clearance fit; the feeding device has an inner layer structure and an outer layer structure; a gap b is reserved between the inner layer structure and the outer layer structure; the gap b is communicated with a feeding device passage through a guide hole; the inner layer structure is communicated with the inner liner; the outer layer structure is fixedly welded to the outer wall of the outer liner; the gap b is not communicated with the gap a; the biomass gasification burner also comprises a primary fan and a secondary fan; the primary fan is communicated with the feeding device passage and the ash chamber through a pipeline; and the secondary fan is communicated with the gap a and the gap b through a pipeline. The biomass gasification burner is reasonable in structure, large in power, sufficient in combustion, high in heat efficiency, low in emission, convenient to installat, small in occupied space and low in operation cost.

Owner:王海峰

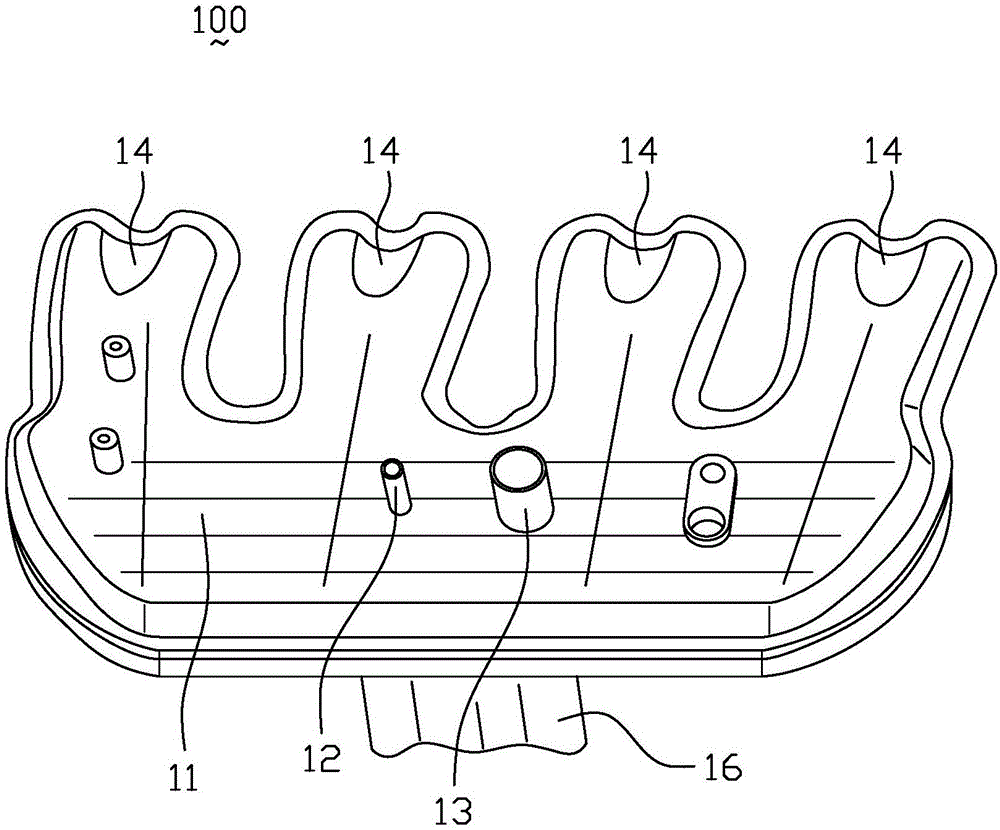

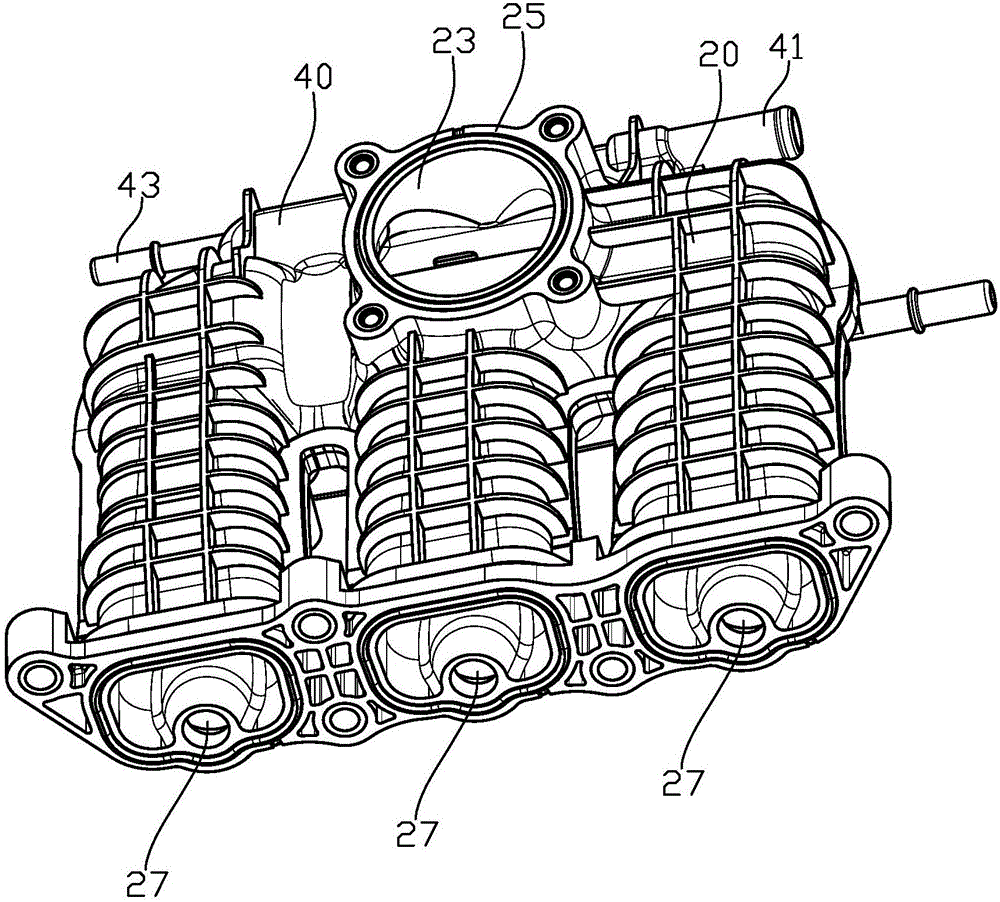

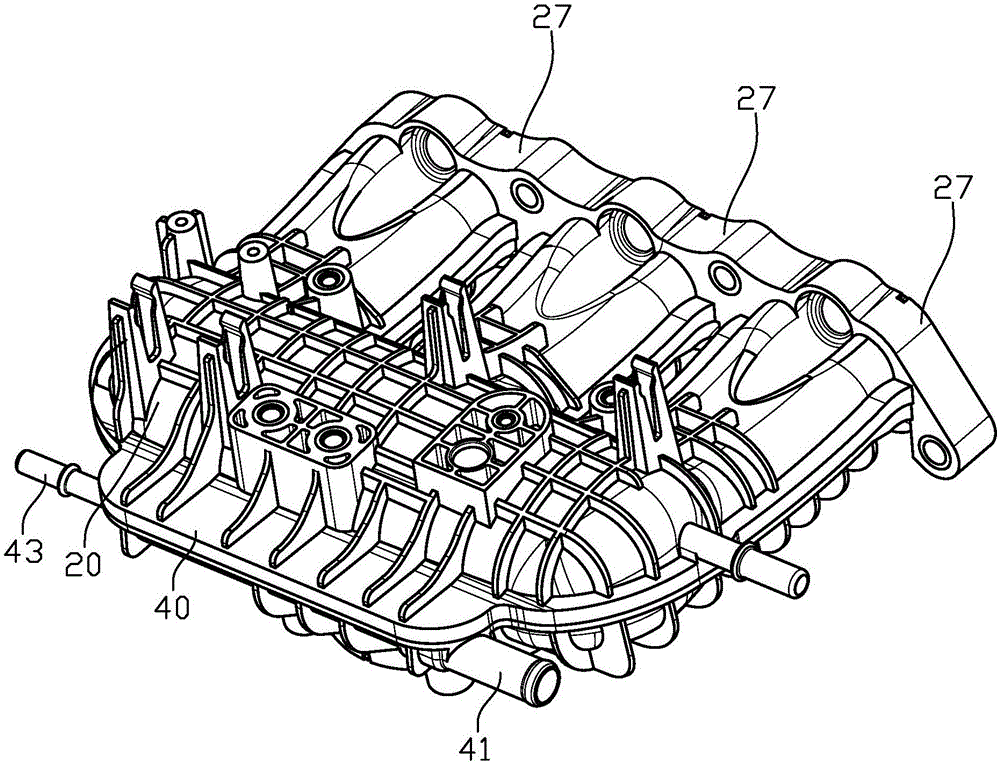

Air inlet manifold of engine and engine

ActiveCN106150793AMix well and evenlyEnsure uniformity of combustionCombustion-air/fuel-air treatmentMachines/enginesEngineeringElectromagnetic valve

The invention provides an air inlet manifold of an engine and the engine comprising the air inlet manifold. A pressure stabilizing cavity and an auxiliary cavity adjacent to the pressure stabilizing cavity are formed in the air inlet manifold of the engine. The pressure stabilizing cavity communicates with the auxiliary cavity. The pressure stabilizing cavity is connected with an air outlet pipe. The air outlet pipe is connected with an air cylinder of the engine. The auxiliary cavity is connected with a crankcase ventilation pipe connector and a carbon tank electromagnetic valve pipe connector. A partition plate is arranged between the pressure stabilizing cavity and the auxiliary cavity. At least one communication hole is formed in the partition plate. The pressure stabilizing cavity communicates with the auxiliary cavity through the communication holes. By the adoption of the air inlet manifold of the engine, crankcase waste gas, fuel steam and fresh air which enter the air inlet manifold can be evenly mixed, and condensate water in a crankcase ventilation system is prevented from flowing into an electronic throttle valve.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

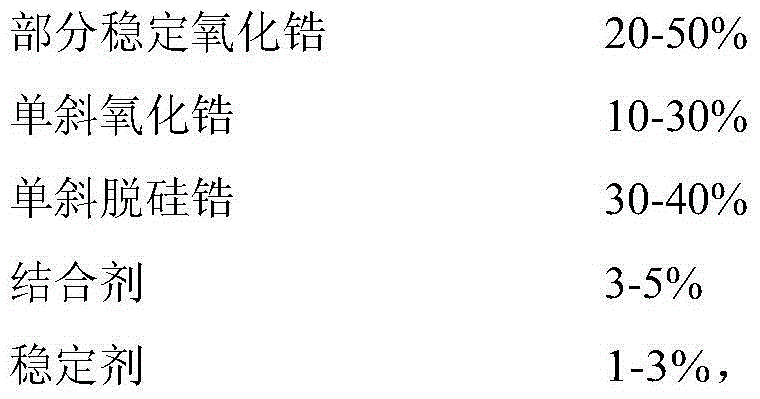

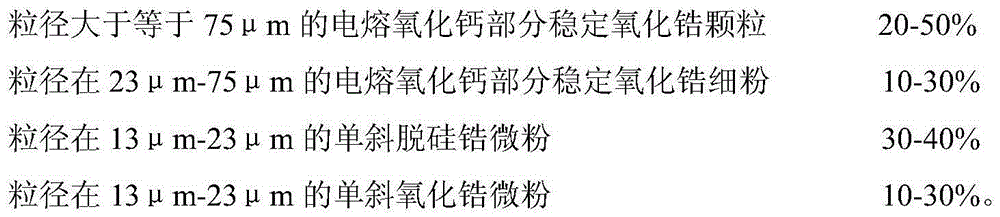

Zirconia metering nozzle preparing method adding zirconium sol in two steps

The invention provides a zirconia metering nozzle preparing method adding zirconium sol in two steps. The method includes steps of material mixing, compression moulding, drying, sintering, and vacuum soaking. The mixed materials comprise 20-50% by weight of partially-stable zirconia, 10-30% by weight of monoclinic zirconia, 30-40% by weight of monoclinic silicon-removed zirconium, 1-3% by weight of a stabilizing agent, and 3-5% by weight of a binding agent that including zirconia sol. In the subsequent vacuum soaking step, a sintered product is added into the zirconia sol and subjected to vacuumizing and soaking. According to the method, nanometer zirconia is introduced by a manner of adding the zirconium sol in two steps. The nanometer zirconia decomposed by utilization of the zirconium sol has functions of resisting high temperature, stress-induced transformation toughening and microcrack toughening, thus enhancing the washing resistance, corrosion resistance and thermal shock resistance of the zirconia metering nozzle, prolonging the service lifetime of the metering nozzle, and increasing the working efficiency of a continuous casting machine.

Owner:CENT SOUTH UNIV

Method for rolling whole leaf rolled cigar

ActiveCN101125029ABeautiful cross sectionBurn evenly and fullyCigar manufactureEngineeringMechanical engineering

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

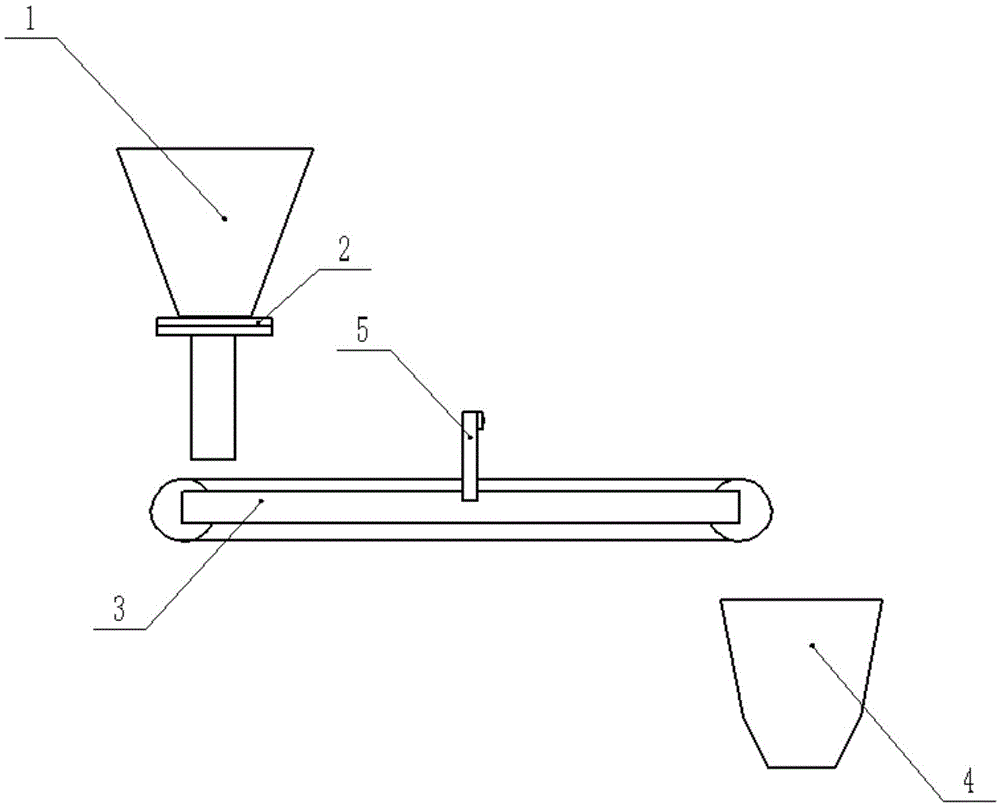

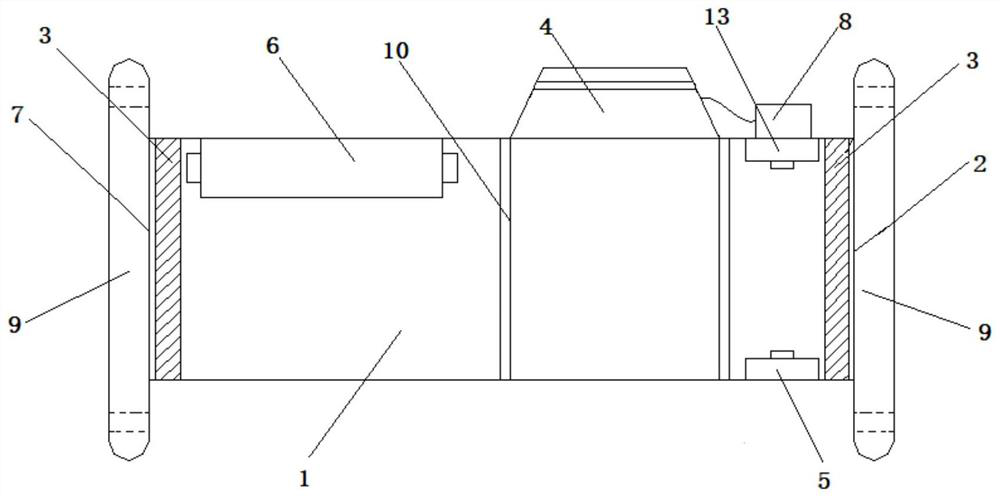

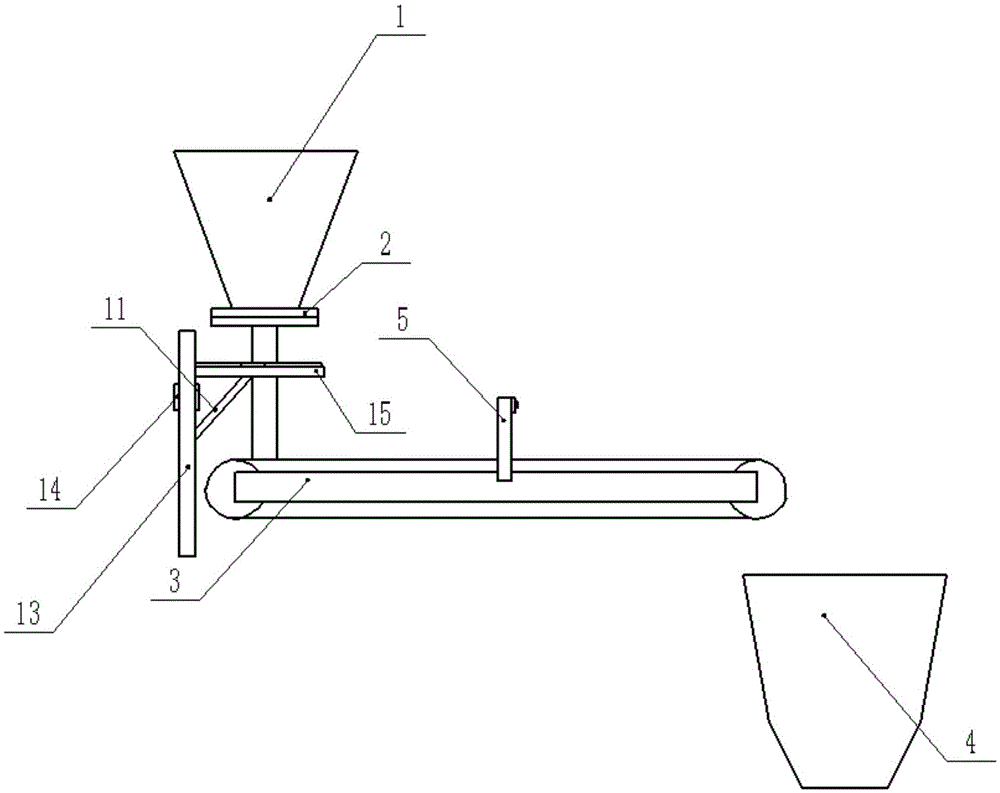

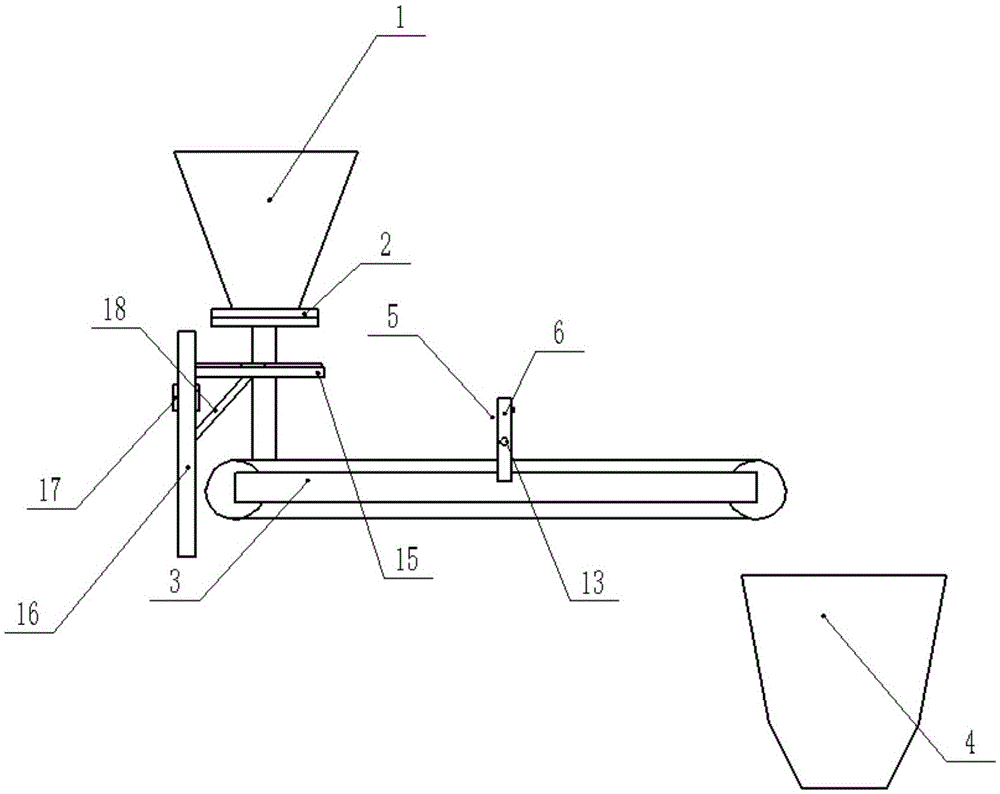

Coal-adding system

InactiveCN106885262ASimple system structureBurn evenly and fullyHeating arrangementLump/pulverulent fuel feeder/distributionSystem structureCoal

The invention discloses a coal feeding system, which comprises a coal feeding bunker, an outlet of the coal feeding bunker is provided with a flapper valve, a conveyor belt device is arranged under the coal feeding bunker, and a drying furnace is arranged at the end of the conveyor belt device , the middle part of the conveyor belt device is provided with a material blocking device, the material blocking device includes a support frame connected to the conveyor belt device, a baffle plate is hingedly connected to the support frame, and a mounting plate is connected to the upper part of the support frame, An air cylinder is connected to the middle of the mounting plate, and an air cylinder that can push out the baffle is also connected above the support frame. The system has a simple structure, can evenly and quickly add coal into the drying furnace, and burn fully and evenly.

Owner:CHONGQING KINGLONG FINE STRONTIUM CHEM

Small barbecue range

The invention discloses a small barbecue range which comprises a support frame and an oven, wherein the oven is arranged on the support frame and comprises an upper cover, a lower shell, a barbecue wire mesh and a charcoal tray; the upper cover is articulated with the lower shell; a barbecue wire mesh placement plate is arranged on the lower shell; the barbecue wire mesh is arranged on the barbecue wire mesh placement plate; an opening is formed in the side surface of the lower shell; the charcoal tray penetrates through the opening and is arranged in the lower shell; the charcoal tray is composed of a charcoal mesh and an ash collecting tray; one side wall of the ash collecting tray is arranged into a side cover structure; the side cover is matched with the opening; a charcoal tray handle is arranged at the outer side of the side cover; the charcoal mesh is arranged in the ash collecting tray, and is in a structure of transversely and vertically welding a plurality of metal strips alternately; two metal strips are provided with protruding ends; the ash collecting tray is connected with the side cover; through holes matched with the protruding ends are formed in the side wall, opposite to the side cover, of the ash collecting tray; a charcoal mesh clamping groove is formed in the inner side of the side cover; the charcoal mesh is clamped in the charcoal mesh clamping groove. The small barbecue range has the advantages of small size and simple structure; due to the design of the charcoal mesh clamping groove, the charcoal tray is relatively convenient and fast to use.

Owner:JIANGSU FEINIDI METAL PROD

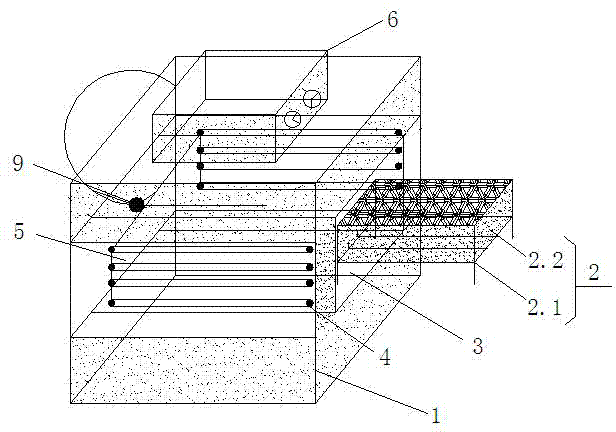

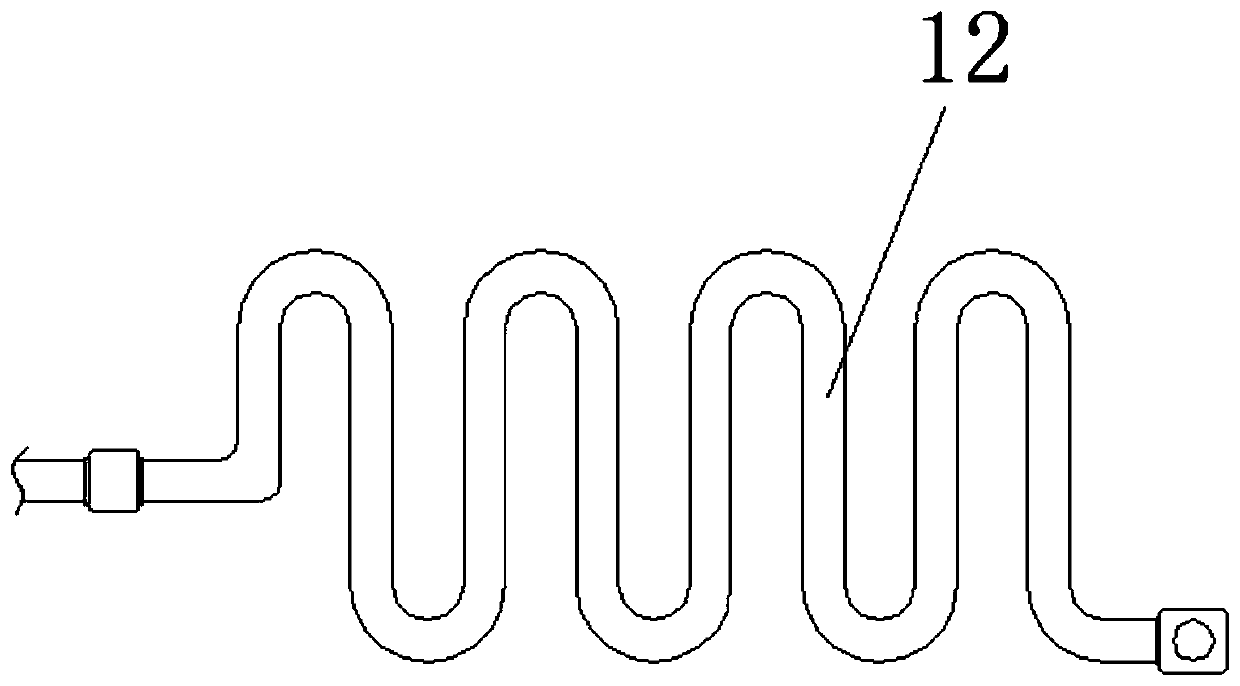

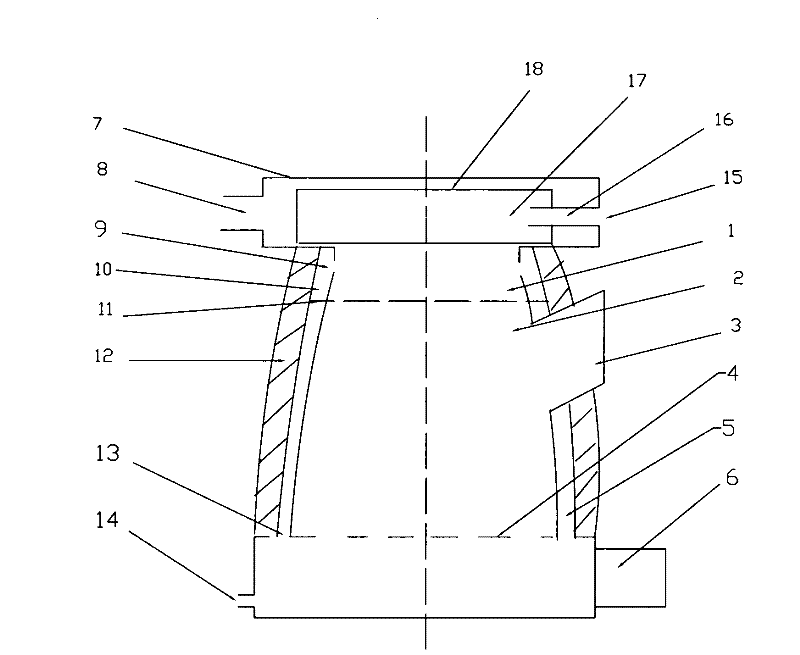

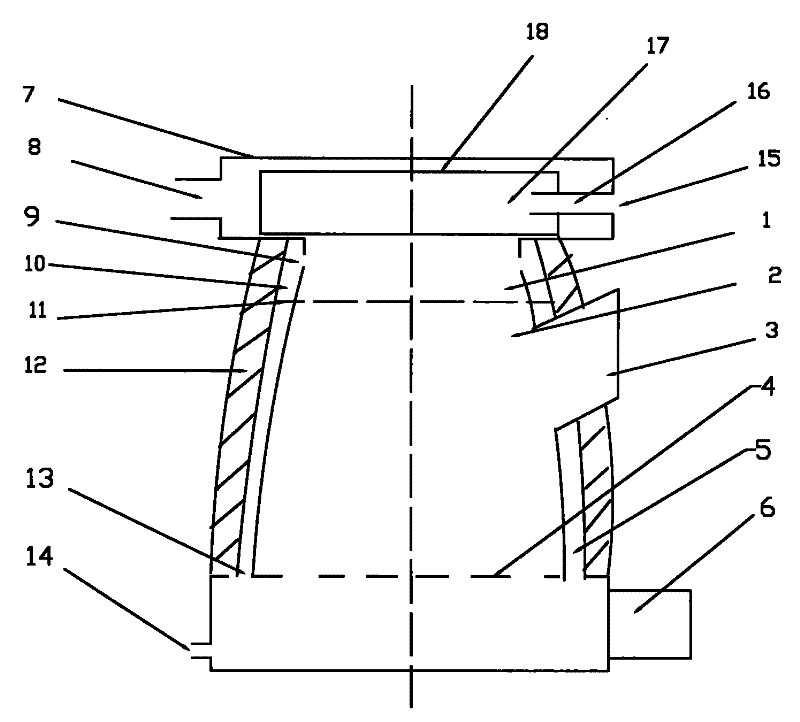

Far infrared hot pipe type vapor and water dual-purpose heating stove and method of use thereof

The invention discloses a far infrared heat-pipe steam-water dual-purpose heating furnace, pertaining to the field of heat energy. The far infrared heat-pipe steam-water dual-purpose heating furnace comprises a clinker chamber (1), a coal charging gate (2), a secondary blast pipe, a tuyere (3), an inner boiler drum (4), an external boiler drum (5), a furnace discharging pipe, a collecting box (6), a horizontal water-cycle pipe (7), a deformed high-temperature heat pipe (8), a steam collecting and distributing cylinder (9), a main steam-supply pipe, a flue-gas tube (11), a heat-pipe preheating water tank (12), a dust-preventing deformed moderate-temperature heat pipe (13), a dust cleaning door, a blow-off pipe (15), a far infrared high-temperature radiation energy-saving dope (16), an electrode drum, a fluid level gage (17), a short-water alarming electrode (18), an electromagnetic float switch (19), a water-replenishing pipe (20) and a blower (21). The secondary blast pipe and tuyere (3) are arranged above the coal charging gate (2); the deformed high-temperature heat pipe (8) is arranged in the furnace; the heat-pipe preheating water tank (12) and the dust-preventing deformed moderate-temperature heat pipe (13) are arranged at a flue-gas outlet; the far infrared high-temperature radiation energy-saving dope (16) is coated on the metal surfaces of the inner boiler drum (4), the furnace discharging pipe and collecting box (6), the horizontal water-cycle pipe (7), the deformed high-temperature heat pipe (8), the heat-pipe preheating water tank (12) and the dust-preventing deformed moderate-temperature heat pipe (13). The deformed high-temperature heat pipe (8) arranged in the furnace reclaims the high temperature flue gas produced during burning into the furnace. The heat-pipe preheating water tank (12) and the dust-preventing deformed moderate-temperature heat pipe (13) arranged at the flue-gas outlet jointly prevent dust and flue-gas from transgressing.

Owner:肖建选

Biomass semi-gasification furnace and manufacturing method thereof

InactiveCN101737808AEliminate dead endsReduce resistanceDomestic stoves or rangesLighting and heating apparatusAir volumeEngineering

The invention discloses a biomass semi-gasification furnace comprising a burner, a vaporizing chamber, a filling mouth, a flame bridge, an ash receiving and ventilating chamber, a secondary air inlet channel, a panel fire surrounding cover and a flue, a circumference space, an insulating layer, a fireproof ring, an air blower mouth and the like. The invention prefabricates accessories, such as the burner, the vaporizing chamber, the panel fire surrounding cover, the flue, the filling mouth, the secondary air inlet channel, the flame bridge and the like which have different specifications and are matched as well as prefabricates square or round metal furnace periphery or cooking bench periphery built by bricks and mud; all accessories are connected, and the insulating layer is built by fire clay. The invention eliminates a dead space formed on the joint of the burner and the vaporizing chamber and increases the flammable gas rising flowability; secondary air inlet is high-temperature wind so as to greatly improve combustion-supporting efficiency; third air inlet supplements the insufficiency of secondary supply air rate when fuel with a higher gas production rate is burnt, so that biomass raw material can be more evenly and completely burnt. The accessory of the product of the invention can be produced in a standardized and industrialized mode, thus lowering cost and bringing convenience for popularizing products.

Owner:山西炜轩科技有限公司

Novel biomass fixed bed combustion boiler capable of operating continuously

ActiveCN108916860ACompact structureEasy to operateSolid fuel combustionAir/fuel supply for combustionCombustionFixed bed

The invention discloses a novel biomass fixed bed combustion boiler capable of operating continuously, and belongs to the technical field of combustion boilers. The Novel biomass fixed bed combustionboiler capable of operating continuously comprises a boiler body which is composed of a bed layer and a free space combustion section; the bed layer is mainly composed of a fire grate and a grid; thefire grate is divided into an air feeding zone and an ash discharging zone, the air feeding zone is provided with air flowing holes, an air chamber is arranged below the air flowing holes in a corresponding mode, and an ash discharging chamber is arranged below the ash discharging zone in a corresponding mode; and the grid is arranged above the fire grate and connected with a rotation driving mechanism located at the bottom of the boiler, and the rotation speed of the grid is controlled by the program. According to the novel biomass fixed bed combustion boiler capable of operating continuously, the staying time of biomass fuel in the boiler is controlled through motion of the grid, and continuous boiler operation is ensured. The boiler is compact in overall structure, the combustion efficiency of the biomass fuel can be effectively improved, compared with traditional grate-fired furnaces, the boiler has the outstanding characteristics of being small in occupied area, easy to operate, low in building cost and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Natural gas energy conservation and emission reduction device

PendingCN112555919ABurn evenly and fullyDomestic stoves or rangesLighting and heating apparatusPollutant emissionsEnvironmental engineering

The invention discloses a natural gas energy conservation and emission reduction device. The natural gas energy conservation and emission reduction device comprises a pipe body, a carbon dioxide filter, a gas flowmeter, a carbon dioxide sensor and a controller. A gas inlet is formed in one end of the pipe body, a gas outlet is formed in the other end of the pipe body, the gas flowmeter and the carbon dioxide sensor are arranged at the end, close to the gas inlet, of an inner cavity of the pipe body, the carbon dioxide filter is arranged in the middle of the inner cavity, and the controller isarranged on the outer surface of the pipe body. The gas flowmeter detects the gas amount of natural gas introduced into the inner cavity from the gas inlet, the carbon dioxide sensor detects the carbon dioxide gas amount in the natural gas introduced into the inner cavity, and the controller calculates the carbon dioxide concentration according to the carbon dioxide gas amount and the gas amount of the natural gas. According to the device, the problems that in the prior art, the purity of the natural gas in a pipeline is not high in the conveying and using process of the natural gas, combustion is insufficient, pollutant emission is intensified, and the device is very unreasonable are solved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Coal-adding system with screening function

Owner:CHONGQING KINGLONG FINE STRONTIUM CHEM

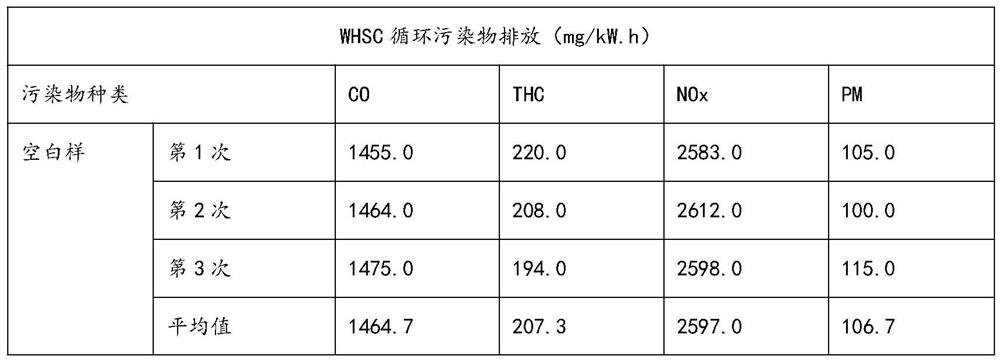

Clean environment-friendly diesel oil and preparation method thereof

PendingCN114164027AIncrease the degree of atomizationPrevent covalent coalescenceLiquid carbonaceous fuelsFuel additivesKetoneFuel oil

The invention provides clean and environment-friendly diesel oil. The clean and environment-friendly diesel oil comprises the following raw material components: 90-97 wt% of diesel oil; and 3 to 10 wt% of a liquid nanodetergent. According to the clean and environment-friendly diesel oil disclosed by the invention, a small amount of special bead liquid nano detergent is added into common diesel oil (generally used for national six-standard diesel oil in market gas stations) to improve the overall performance of a diesel oil product, and the diesel oil product does not contain harmful elements (the product does not contain forbidden components such as aldehyde and ketone, and does not contain heavy metals such as sulfur, nitrogen and the like); clean diesel oil is formed from a pure petroleum-based physical method product additive (a non-chemical method), and the effects of improving efficiency, saving oil, cleaning carbon and reducing emission are achieved by changing the physical performance of the fuel oil; the oil quality is greatly improved, and the cetane number of the oil is obviously increased; the oil sensitivity is good, the engine resonance phenomenon is eliminated, kinetic energy output is stable, and oil consumption is reduced; and sufficient combustion of oil in the engine is realized, so that emission of automobile exhaust pollutants is reduced.

Owner:SINOCHEM ENERGY SAVING ENVIRONMENTAL PROTECTION HLDG BEIJING +1

Combustion chamber of environment-friendly high-efficiency gas water heater

InactiveCN109827174AIncrease burn rateBurn fullyFluid heatersGaseous fuel burnerCombustion chamberNuclear engineering

The invention relates to the technical field of smart homes and discloses a combustion chamber of an environment-friendly high-efficiency gas water heater. The combustion chamber comprises an outer shell. One side of the bottom of the front side of an inner cavity of the outer shell is in threaded connection with a frequency conversion fan. An air inlet of the frequency conversion fan penetrates through and extends to the bottom end of one side of the outer portion of the outer shell. The bottom of the front side of the inner cavity of the outer shell is in threaded connection with a gas mixing chamber. An air outlet of the frequency conversion fan communicates with one side of an inner cavity of the gas mixing chamber. Through arrangement of the frequency conversion fan, the gas mixing chamber and a gas pipeline, the combustion chamber of the environment-friendly high-efficiency gas water heater conducts full and even mixing on natural gas and air in advance before the natural gas isnot combusted, and the natural gas can be fully combusted. Compared with diffusion combustion of an existing gas water heater, the combustion chamber has the advantages that the high temperature can be generated through complete premixed combustion, and the combustion efficiency of the natural gas is higher; consumption of natural gas is effectively reduced; and moreover, waste gas such as carbondioxide can only be generated during combustion of the natural gas and does no harm to human bodies.

Owner:付福来

Screening-type coaling system

The invention discloses a screening-type coaling system. The system comprises a coaling bin. An outlet of the coaling bin is provided with a gate valve. A conveyor belt device is arranged below the coaling bin. The tail end of the conveyor belt device is provided with a drying furnace. The middle part of the conveyor belt device is provided with a material blocking device. The material blocking device comprises a support frame connected with the conveyor belt device. The inside of the support frame is provided with a chute, in which a baffle plate is arranged. The side surface of the baffle plate is provided with multiple penetrating holes. The support frame is provided with a connecting hole. The connecting hole and the penetrating holes are connected through a connecting rod. A lifting column is further arranged on the baffle plate. A screening device is further arranged below the coaling bin. The screening device comprises a fixing rack, on which a vibration motor is arranged. A fixing frame is further arranged on the fixing rack and detachably provided with a coal sieve. The screening-type coaling system has following beneficial effects: the screening-type coaling system is simple and capable of uniformly and rapidly adding coal into the drying furnace; coal is burned fully and uniformly; and large coal blocks can be screened out.

Owner:CHONGQING KINGLONG FINE STRONTIUM CHEM

Biomass semi-gasification furnace and manufacturing method thereof

InactiveCN101737808BEliminate dead endsReduce resistanceDomestic stoves or rangesLighting and heating apparatusEngineeringAir blower

The invention discloses a biomass semi-gasification furnace comprising a burner, a vaporizing chamber, a filling mouth, a flame bridge, an ash receiving and ventilating chamber, a secondary air inlet channel, a panel fire surrounding cover and a flue, a circumference space, an insulating layer, a fireproof ring, an air blower mouth and the like. The invention prefabricates accessories, such as the burner, the vaporizing chamber, the panel fire surrounding cover, the flue, the filling mouth, the secondary air inlet channel, the flame bridge and the like which have different specifications and are matched as well as prefabricates square or round metal furnace periphery or cooking bench periphery built by bricks and mud; all accessories are connected, and the insulating layer is built by fire clay. The invention eliminates a dead space formed on the joint of the burner and the vaporizing chamber and increases the flammable gas rising flowability; secondary air inlet is high-temperature wind so as to greatly improve combustion-supporting efficiency; third air inlet supplements the insufficiency of secondary supply air rate when fuel with a higher gas production rate is burnt, so that biomass raw material can be more evenly and completely burnt. The accessory of the product of the invention can be produced in a standardized and industrialized mode, thus lowering cost and bringing convenience for popularizing products.

Owner:山西炜轩科技有限公司

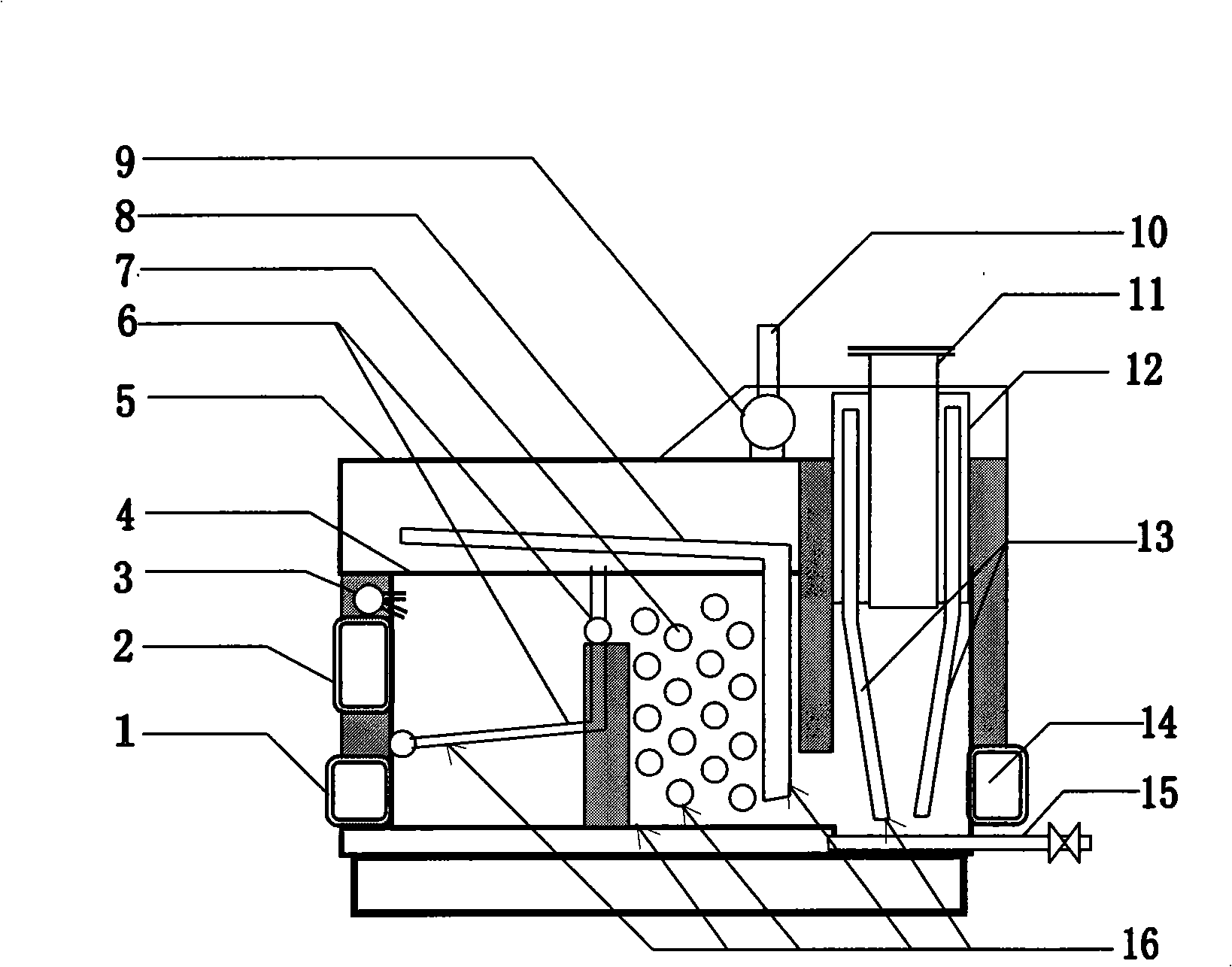

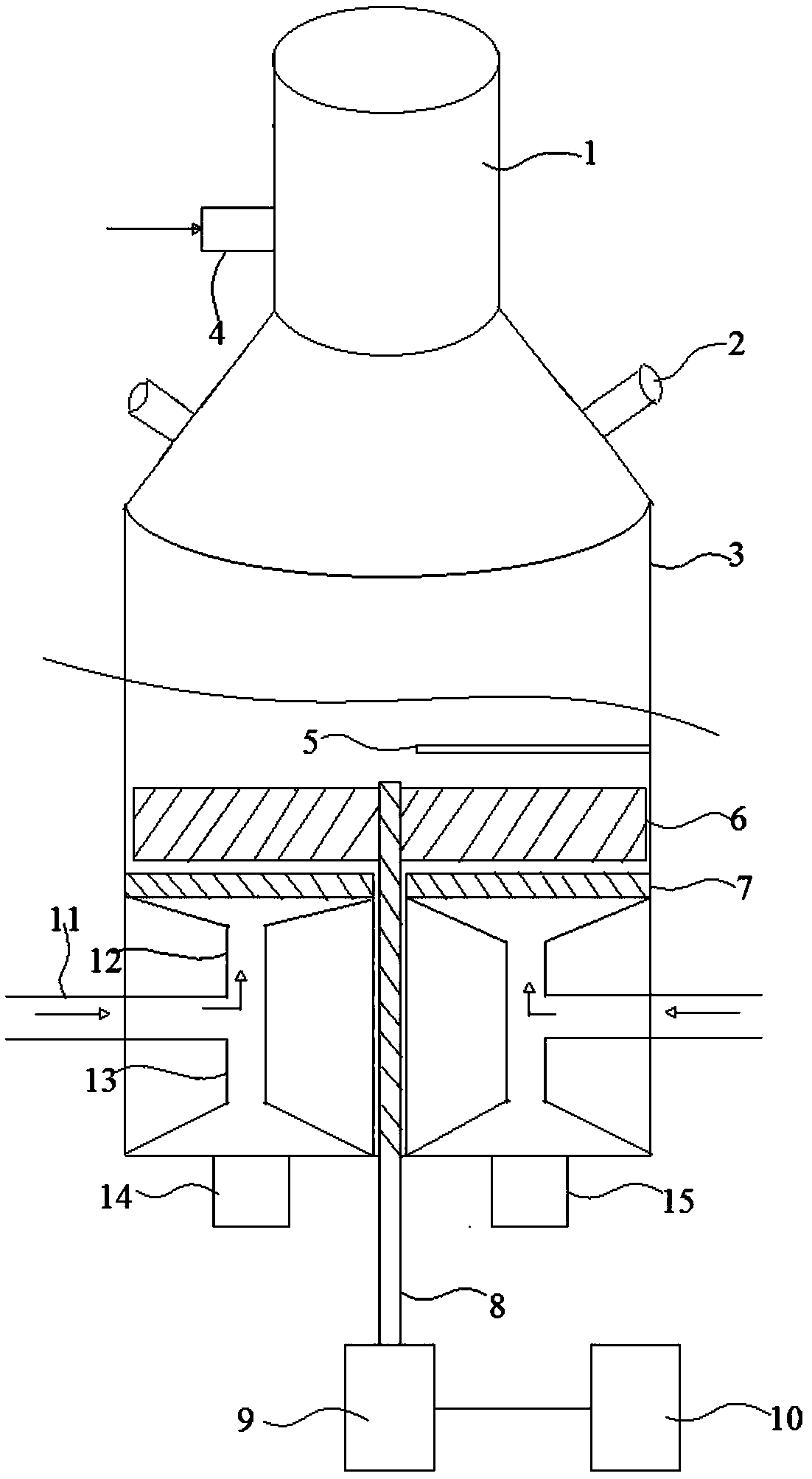

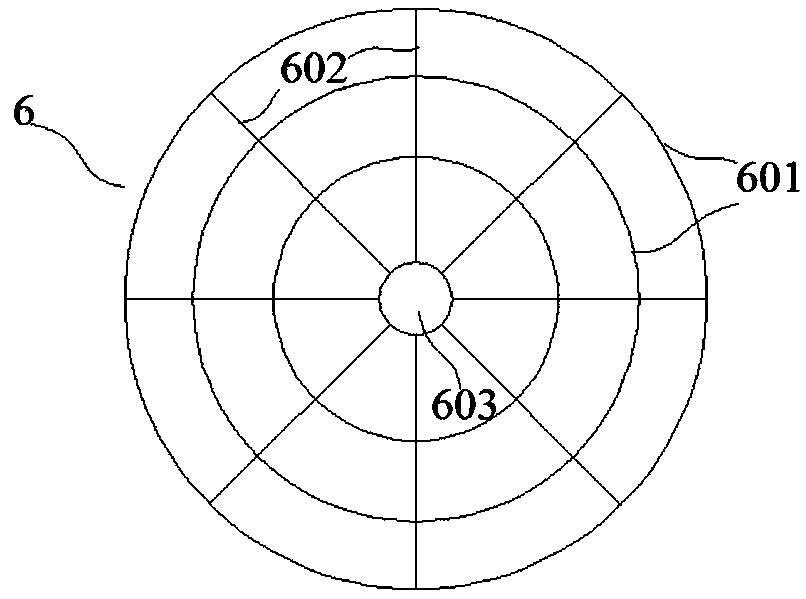

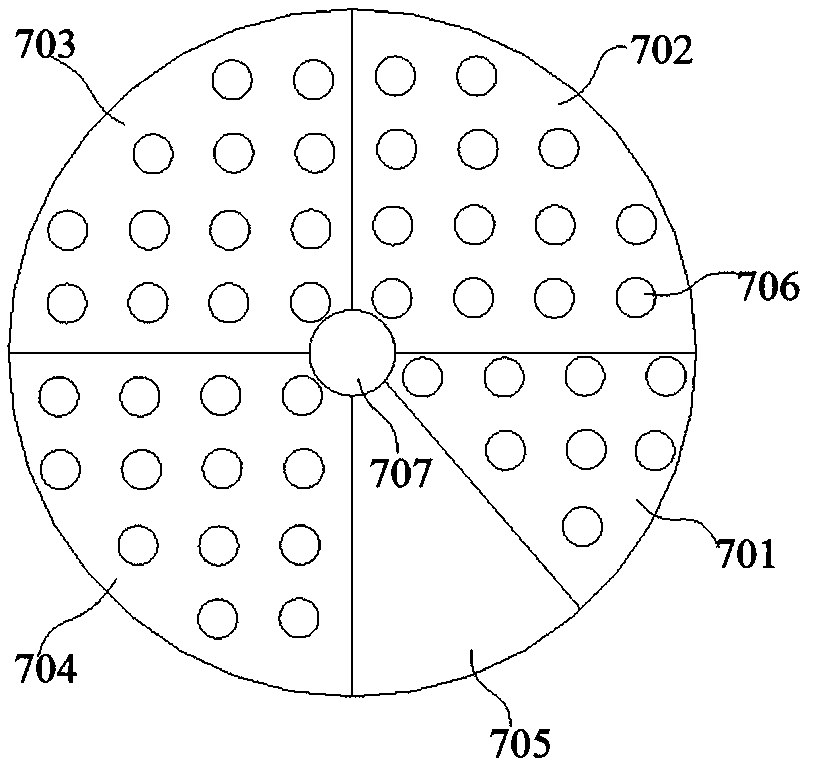

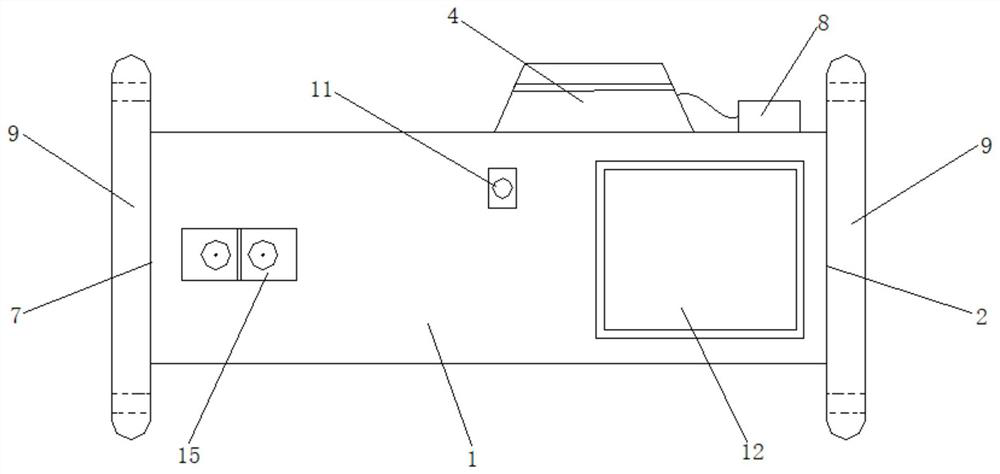

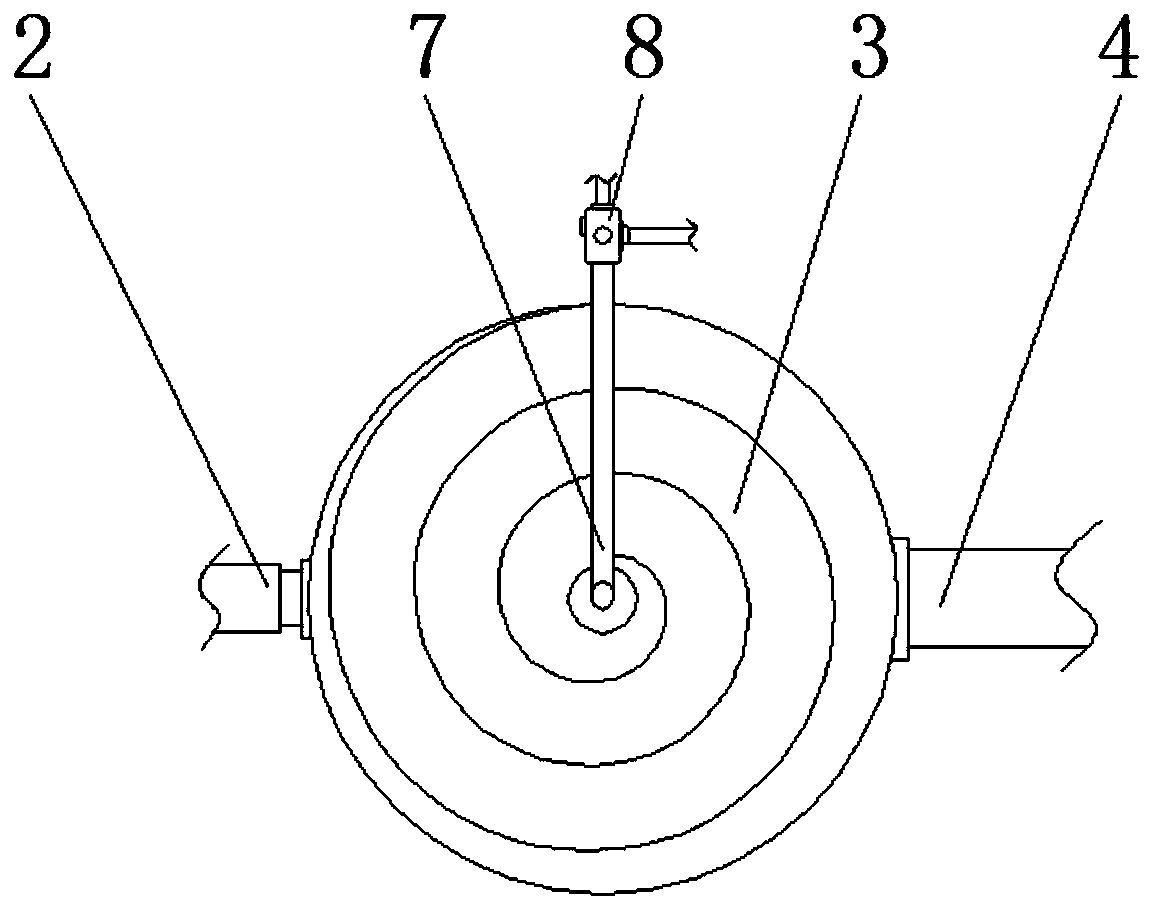

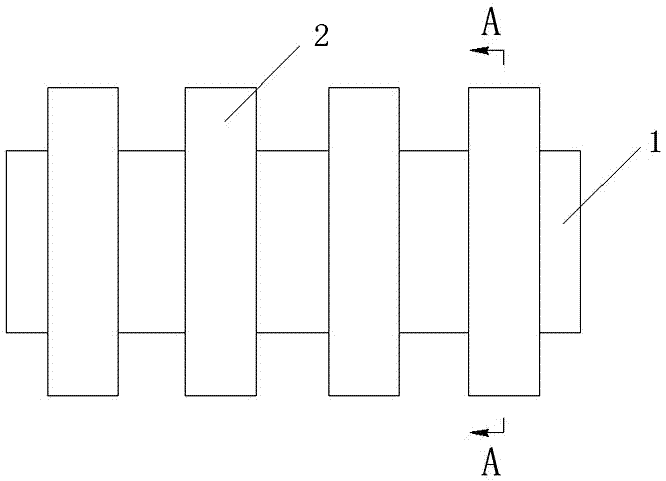

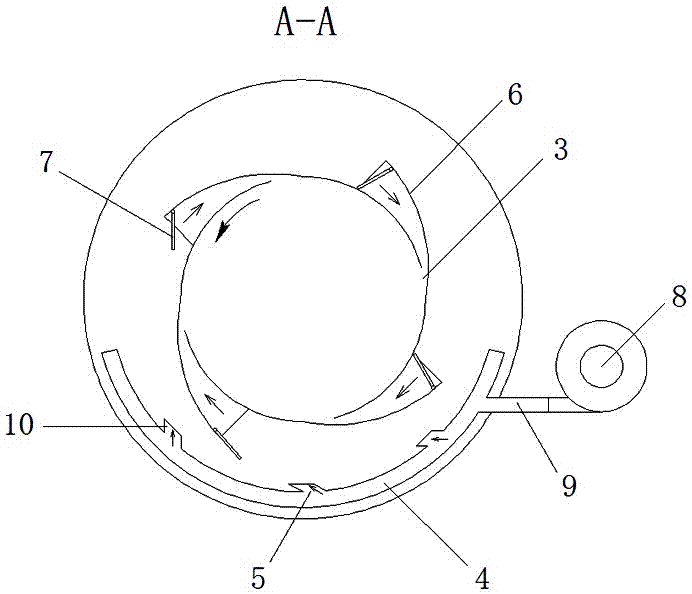

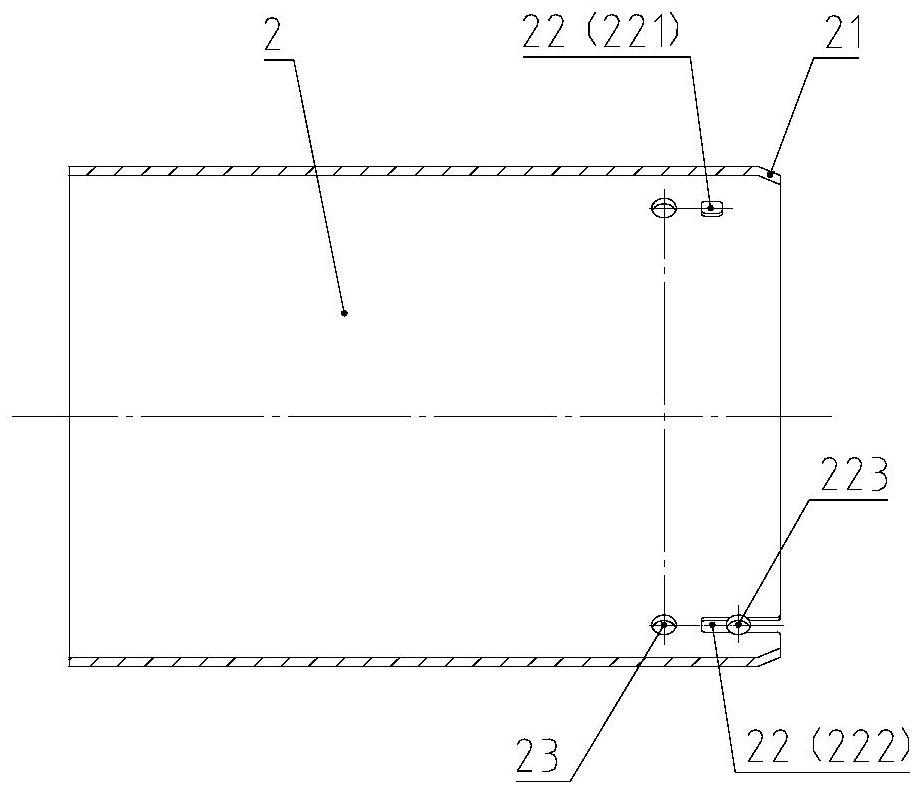

Incinerator dynamic turbulent flow rotational flow device and working method thereof

ActiveCN106979523ASimple structureReasonable designIndirect carbon-dioxide mitigationIncinerator apparatusEnvironmental engineeringMechanical engineering

The invention relates to an incinerator dynamic turbulent flow rotational flow device and a working method thereof. The incinerator dynamic turbulent flow rotational flow device comprises a self-rotating incinerator, wherein a plurality of annular shells are arranged on the periphery of the incinerator in the axial direction in a sleeving manner; a plurality of air inlets are formed in the circumferential part of the incinerator body at intervals, and the annular shells are positioned at the circumferential part of the incinerator body; arc-shaped air distribution pipes positioned below the incinerator are arranged in the annular shells; a plurality of air inlets are formed in the upper sides of the air distribution pipes at intervals; an ox horn shaped air inlet guide shell is arranged at each air inlet in each annular shell; the smaller ends of the air inlet guide shells are in butt joint with the air inlets; and the air inlet direction of the air inlet guide shells is opposite to the rotating direction of the incinerator. The incinerator dynamic turbulent flow rotational flow device is simple in structure and reasonable in design; the air is blown in the hearth of the incinerator through the air inlets in the circumferential part of the incinerator body to feed oxygen turbulence, so that sufficient oxygen supply and complete mixing are ensured; and in addition, the wind blown into the incinerator can form a rotational flow, so that the air can be uniformly distributed, uniform and sufficient combustion can be ensured, and emission of primary pollutant is chocked.

Owner:广东纳翕燚资源综合利用科技有限公司

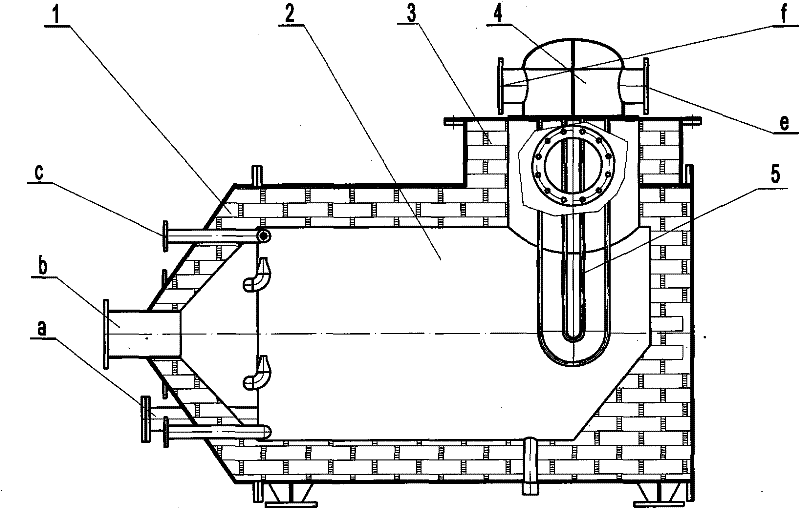

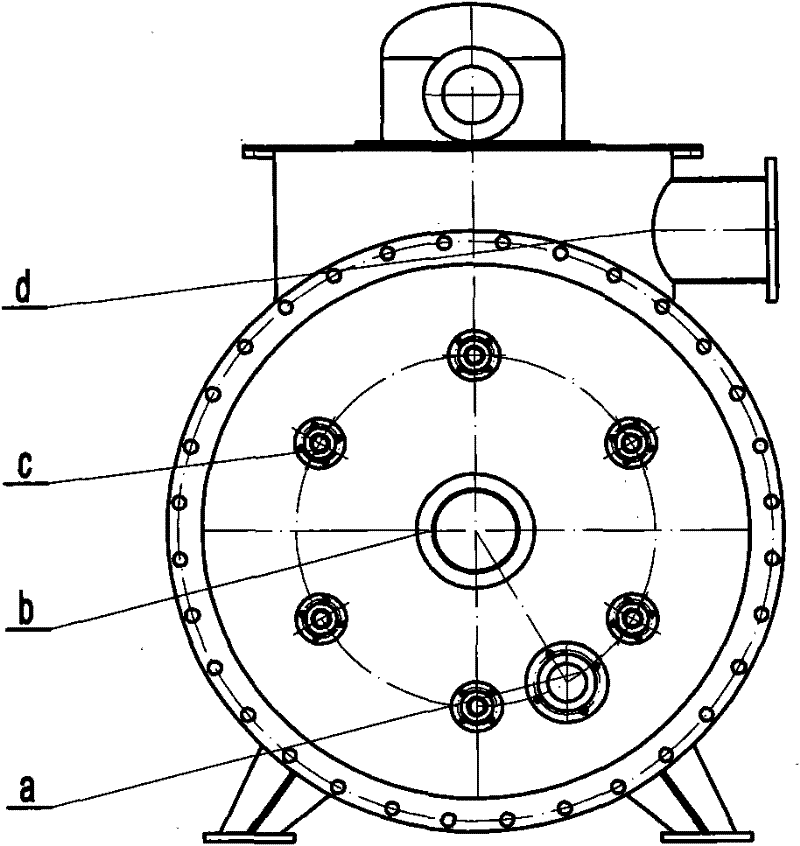

Hot-blast recuperative furnace of biomass generating system

InactiveCN102095209BAvoid high temperature corrosionBurn fullyDomestic stoves or rangesLighting and heating apparatusCombustionFlue gas

The invention relates to a hot-blast recuperative furnace of a biomass generating system, and belongs to the technical field of a heat exchange device. A cylindrical kettle body of the recuperative furnace is arranged horizontally, wherein a burning opening is arranged in the center of one end of the recuperative furnace, and a chimney section with a hot blast outlet is extended upwards on the other end of the recuperative furnace; a heat exchanger stretching into the cylindrical kettle body from top to bottom is inserted into the chimney section; the heat exchange section of the heat exchanger is U-shaped, and the two ports on the upper part of the heat exchanger are respectively communicated with a heat exchange medium inlet and a heat exchange medium outlet which are exposed outside the chimney section; a group of air distribution openings passing through the cylindrical kettle body are distributed at the periphery of the burning opening; outlets on the inner ends of the air distribution openings are tangentially distributed along a heat-insulating wall of the cylindrical kettle body, and a preset helical angle is formed in the direction of the outlets. The outlets on the innerends of the air opening are provided with the helical angle along the heat-insulating wall, so that air can be sufficiently and uniformly mixed with flue gas to realize the ideal combustion-supporting function to lead the burning more sufficient, and realize the function of steadying the flame in the center at the same time. In addition, the flame and the heat-insulating wall of the cylindrical kettle body are separated, so the heat-insulating effect is enhanced and the heat-insulating wall is prevented from being corroded at high temperature.

Owner:南通海鹰机电集团有限公司

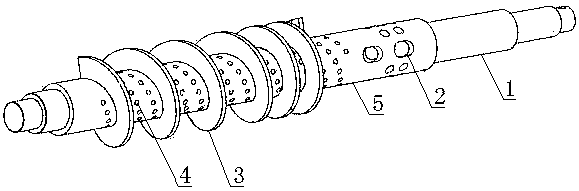

Packing auger device special for biomass particle burner

PendingCN108167856ABurn evenly and fullyReasonable designFuel feeding arrangementsAir/fuel supply for combustionSpiral bladeEngineering

A packing auger device special for a biomass particle burner is composed of a main shaft and a hollow shaft. The front end of the main shaft is connected with the hollow shaft. The periphery of the rear end of the hollow shaft is provided with a plurality of air inlets, the periphery of the front end of the hollow shaft is evenly provided with air outlet holes in a dense manner, and the peripheryof the hollow shaft is provided with spiral blades. The packing auger device special for the biomass particle burner has the beneficial effects that the design is reasonable, the structure is novel, multiple functions are achieved, when the spiral blades are used for forwards pushing and conveying materials, air is rotationally supplied into a burning chamber of the burner to help burning, the straw particle fuel can be burned sufficiently and evenly, pollution discharge is reduced, fuel is saved, and the cost is reduced.

Owner:SHANDONG YUAN QUAN MACHINERY

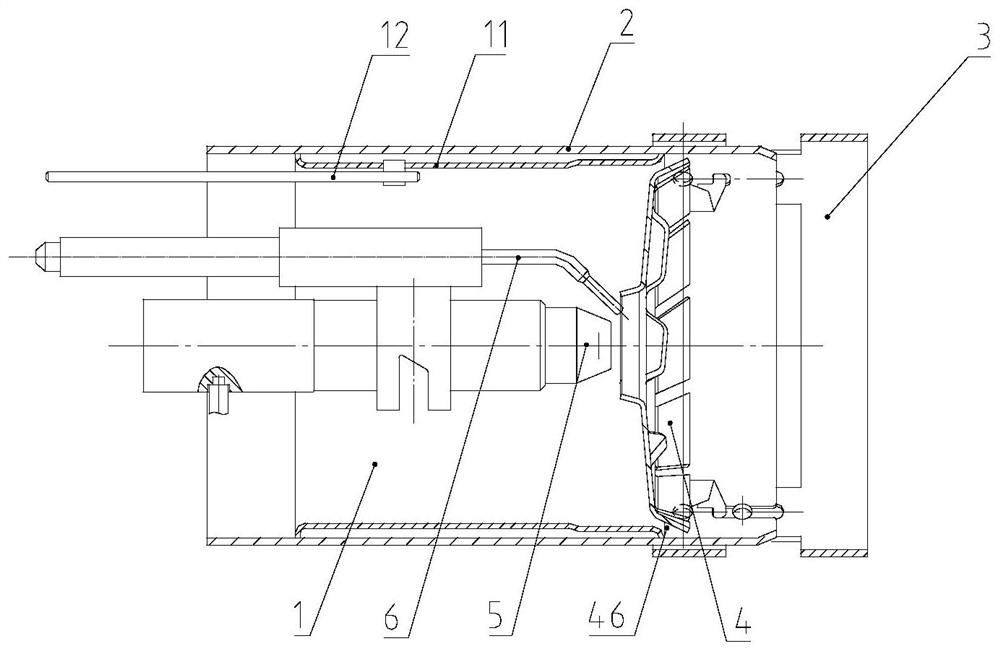

Combined device and control method for realizing low nitrogen short flame combustion of diesel burner

ActiveCN114165782BChange the form of combustionShort flameBurnersIndirect carbon-dioxide mitigationLow nitrogenFlue gas

The present application relates to the field of burners, and in particular, to a combined device and a control method for realizing low-nitrogen short flame combustion of diesel burners. The combined device includes an adjustment device, a combustion cylinder, an end cylinder, a double swirl flame stabilization disc, a nozzle and an ignition assembly. The end cylinder is fixed at the front end of the combustion cylinder, the double swirl flame stabilization disc is fixed inside the front end of the combustion cylinder, and the adjustment device is installed in the combustion cylinder. Inside the middle section of the barrel, the nozzle is fixed inside the middle section of the combustion barrel, and the adjusting device, the combustion barrel, the end barrel, the double swirl flame stabilization disc and the nozzle are all coaxial. The application changes the combustion air distribution ratio, strengthens the air supply guidance and ejected flue gas recirculation combustion, increases the swirl air distribution intensity on the premise of ensuring flame stability, increases the turbulence of the oil mist flame, and shortens the flame length. Strengthen air disturbance, enhance oil and gas mixing effect, and inhibit NO x It strengthens the air gathering effect on the flame and shortens the flame length; ejects the high temperature flue gas back to participate in the secondary combustion and reduces NO x emissions.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com