Packing auger device special for biomass particle burner

A biomass particle and burner technology, applied in the direction of combustion method, combustion equipment, combustion air/fuel supply, etc., can solve the problem of single function, and achieve the effect of multiple functions, novel structure, and sufficient and uniform combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

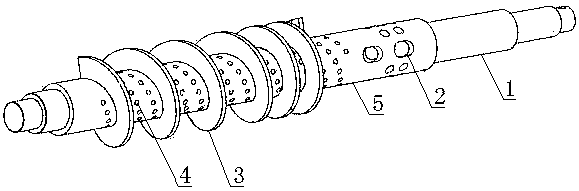

[0009] as attached figure 1 A special auger device for a biomass pellet burner is shown, which is composed of a main shaft 1 and a hollow shaft 5, the front end of the main shaft 1 is connected to the hollow shaft 5, and the outer periphery of the rear end of the hollow shaft 5 is provided with several air inlets 2, The outer periphery of the front end is uniformly covered with air outlet holes 4 , and the outer periphery of the hollow shaft 5 is provided with helical blades 3 .

[0010] When this embodiment is used, the auger device is installed in the feed pipe of the biomass pellet burner, and the auger device is driven by a motor to evenly and accurately deliver the biomass pellet fuel to the combustion chamber of the burner to ensure that the fuel Supply, the wind blown by the blower enters through the air inlet 2 at the rear end of the hollow shaft 5, blows out from the air outlet hole 4 at the front end of the hollow shaft 5, and rotates and sends air to the combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com