Novel biomass fixed bed combustion boiler capable of operating continuously

A biomass and fixed bed technology, applied in the field of combustion boilers, can solve the problems of large floor space, complicated operation and low combustion efficiency, and achieve the effect of small floor space, simple operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

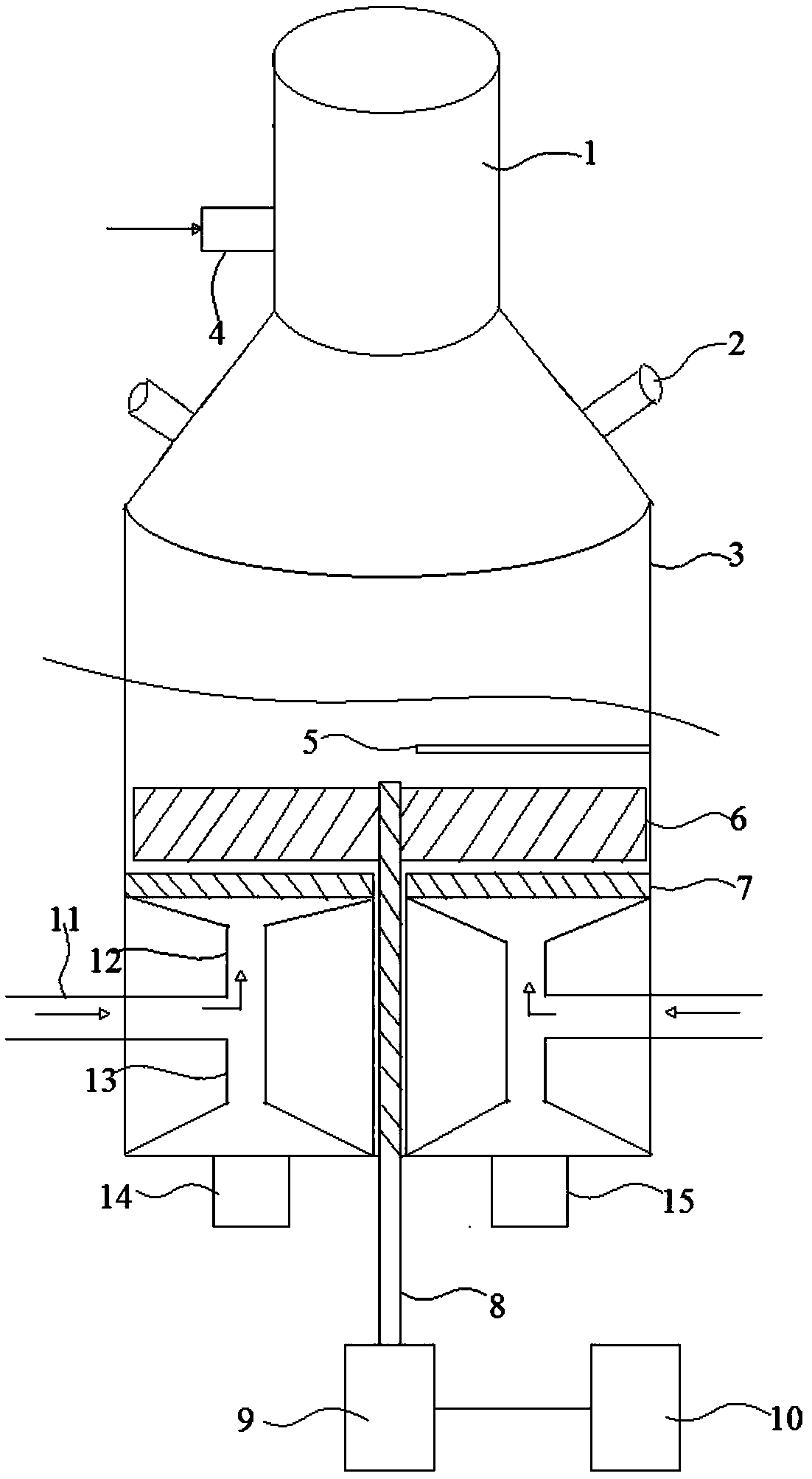

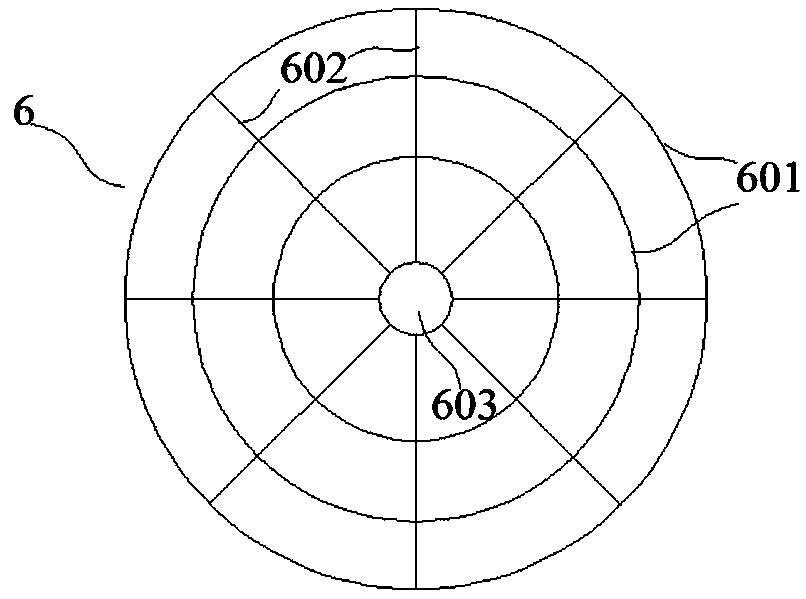

[0041] combine Figure 1-Figure 4 , a novel biomass fixed-bed combustion boiler that can work continuously in this embodiment includes a boiler body 3, the boiler body 3 is composed of a bed and a free space combustion zone, and a fire grate 7 is arranged in the bed, and the fire grate 7. It is divided into an air intake area and an ash discharge area, wherein the air intake area is processed with a blowing hole 706, and an air chamber is provided below it, and an ash discharge chamber is correspondingly provided below the ash discharge area, and an ash discharge port is provided at the bottom of the ash discharge chamber 15. A grid 6 is arranged above the fire grate 7. The grid 6 is used to support the biomass fuel and is connected with the rotary drive mechanism at the bottom of the boiler, and its rotation speed is controlled by the program.

[0042] The biomass material is fed from the upper part of the boiler body 3, and falls on the grille 6 through the evaporation proce...

Embodiment 2

[0044] A new type of biomass fixed-bed combustion boiler that can work continuously in this embodiment is basically the same in structure as in Embodiment 1, the main difference is that the bed in this embodiment is a vertical cylinder, and through a variable cross-section ( figure 1 Inverted cone structure shown in ) transitions to the free space combustion zone, and the side wall of the boiler body 3 corresponding to the variable section is provided with a feed port 2 . Simultaneously, the fire grate 7 of the present embodiment is divided into a plurality of air intake areas and an ash discharge area continuously distributed along the circumferential direction, and the interior of the boiler body 3 is located below the fire grate 7 and is separated from the above air intake area and ash discharge area. Corresponding to different air chambers and ash discharge chambers. The biomass fuel that enters the boiler body 3 through the feed port 2 at the variable cross-section always...

Embodiment 3

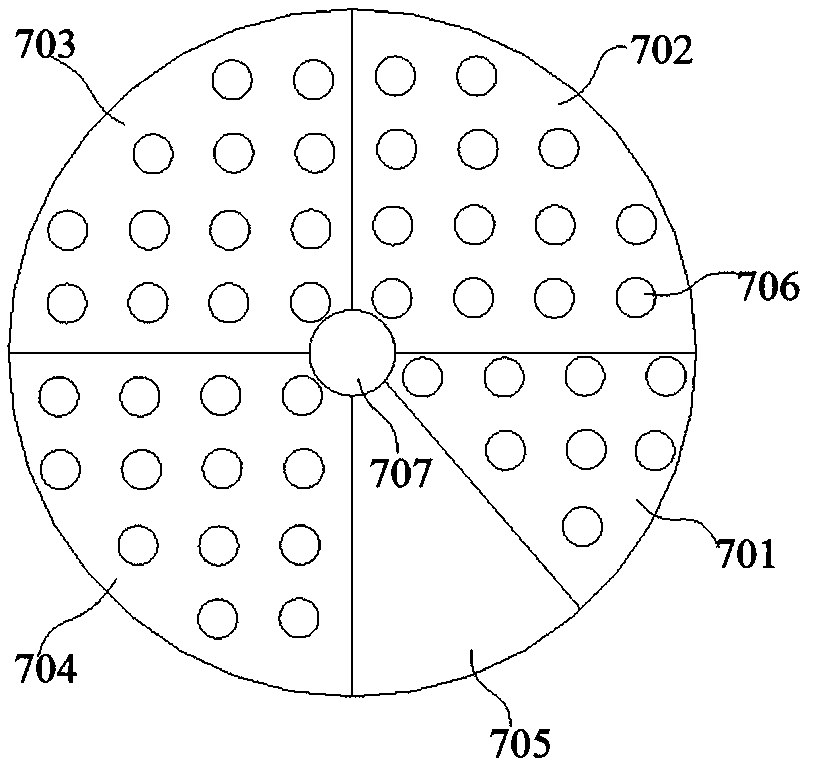

[0048] A new type of biomass fixed-bed combustion boiler that can work continuously in this embodiment has a structure basically the same as that in Embodiment 2, the difference mainly lies in: specifically, as image 3 , Figure 4 As shown, the grate 7 of the present embodiment is divided into five areas continuously distributed along the circumferential direction, wherein the I area 701, the II area 702, the III area 703 and the IV area 704 are all air intake areas, and the V area 705 is the ash discharge area. area (the area inside the furnace body below the fire grate 7 is correspondingly divided into the first air chamber, the second air chamber, the third air chamber, the fourth air chamber and the ash discharge chamber), and the feeding port 2 is set in the same area as the I area 701 corresponds to the upper side wall of the boiler body 3, and the rotation direction of the grid 6 is the same as the distribution direction around the above-mentioned I-V zone. The biomas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com