Zirconia metering nozzle preparing method adding zirconium sol in two steps

A sizing nozzle and zirconium sol technology, which is applied in the field of two-step addition of zirconium sol to toughen and strengthen the zirconium sizing nozzle preparation field, can solve the problems of short service life and poor thermal shock stability of the sizing nozzle, and reduce porosity, Improved thermal shock resistance, erosion resistance, and improved creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

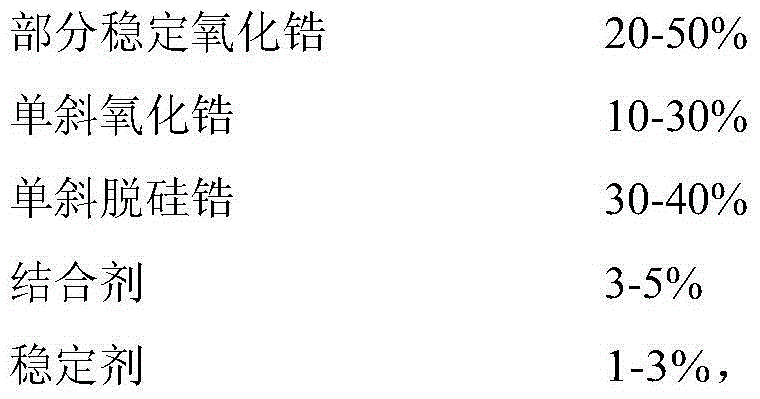

Method used

Image

Examples

Embodiment 1

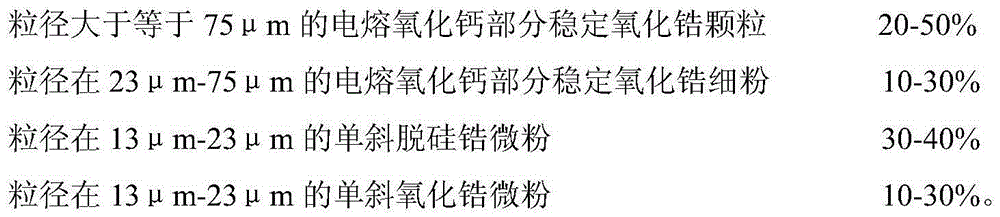

[0029] A two-step preparation method for adding zirconium sol to toughen and strengthen zirconium sizing nozzle, comprising 25% by weight of fused calcium oxide partially stabilized zirconia particles, 20% of fused calcium oxide partially stabilized zirconia fine powder, 35% of monoclinic desilication zirconium powder and 20% of monoclinic zirconia powder are used as raw materials, adding 1% of yttrium oxide as a stabilizer, and then adding 3% of the total weight of materials. Zirconium dioxide sol, A binder composed of dextrin and water, the ratio of each component in the binder is: 66% zirconia sol, 30% water, 4% dextrin, and the solid phase weight content of the zirconia sol is 6%.

[0030] Its preparation steps are as follows:

[0031] 1) Put all the raw materials into the mixer for dry mixing for 4 minutes, then add the binder mainly composed of zirconia sol and wet mix for 5 minutes;

[0032] 2) After the obtained mixture was trapped for 10 hours, it was machine-pressed...

Embodiment 2

[0041]A two-step preparation method for adding zirconium sol to toughen and strengthen zirconium sizing nozzle, which consists of 35% by weight of fused calcium oxide partially stabilized zirconia particles, 25% of fused calcium oxide partially stabilized zirconia fine powder, 30% monoclinic desilication zirconium powder and 10% monoclinic zirconia powder are used as raw materials, and heavy calcium carbonate and light calcium carbonate accounting for 2% of the total weight of raw materials are added as stabilizers. The ratio of each component in the stabilizer It is: 65% heavy calcium carbonate, 35% light calcium carbonate; then add a binder consisting of zirconia sol, phenolic resin, water, and starch accounting for 4% of the total weight of the material, and the proportion of each component in the binder It is: 50% zirconia sol, 2% phenolic resin, 40% water, 8% starch, and the solid phase weight content of zirconia sol is 12%.

[0042] Phenolic resin is an additive to promo...

Embodiment 3

[0049] A two-step preparation method for adding zirconium sol to toughen and strengthen zirconium sizing nozzle, comprising 45% by weight of fused calcium oxide partially stabilized zirconia particles, 10% of fused calcium oxide partially stabilized zirconia fine powder, 35% monoclinic desilication zirconium powder and 10% monoclinic zirconia powder are used as raw materials, and yttrium oxide, heavy calcium carbonate and light calcium carbonate are added as stabilizers accounting for 3% of the total weight of the raw materials. The ratio of the points is: 5% yttrium oxide, 45% heavy calcium carbonate, 50% light calcium carbonate; The proportion of each component in the zirconia sol is: 80% zirconia sol, 17% water, 3% pulp powder, and the solid phase weight content of the zirconia sol is 2%.

[0050] Its preparation steps are as follows:

[0051] 1) Put all the raw materials into the mixer and dry mix for 5 minutes, then add the binder mainly composed of zirconia sol and wet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com