Method and apparatus for preparing sulphur dioxide gas

A sulfur dioxide and gas technology, applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve problems such as difficult control of SO2 production, irregular pH value of sulfur smoked juice, difficult control of sublimated sulfur, etc., to improve cooling effect, relatively uniform proportion, and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method of producing sulfur dioxide gas. The raw material used in this method is water-sulfur slurry, which is continuously and automatically fed into the sulfur-burning furnace through a feeding device, and a small amount of primary air is introduced to vaporize the water-sulfur slurry, and then secondary air is added to fully burn sulfur to form SO 2 gas, then SO 2 Gas cooling produces sulfur gas without SO 3 Purify sulfur gas; said water sulfur slurry is latex sulfur formed by mixing granular sulfur and water. In the water sulfur slurry, the weight percentage of sulfur and water is 40:60, which can also be increased or decreased to 35:65~60: 40; In addition, by adjusting the ratio of sulfur to water, the combustion temperature of water-sulfur slurry in the combustion chamber can be set at a certain value within 900°C to 1300°C, and within 900°C to 1300°C is exactly the sulfur combustion process. The temperature range in which sulfur oxides are produced.

[0034]...

Embodiment 2

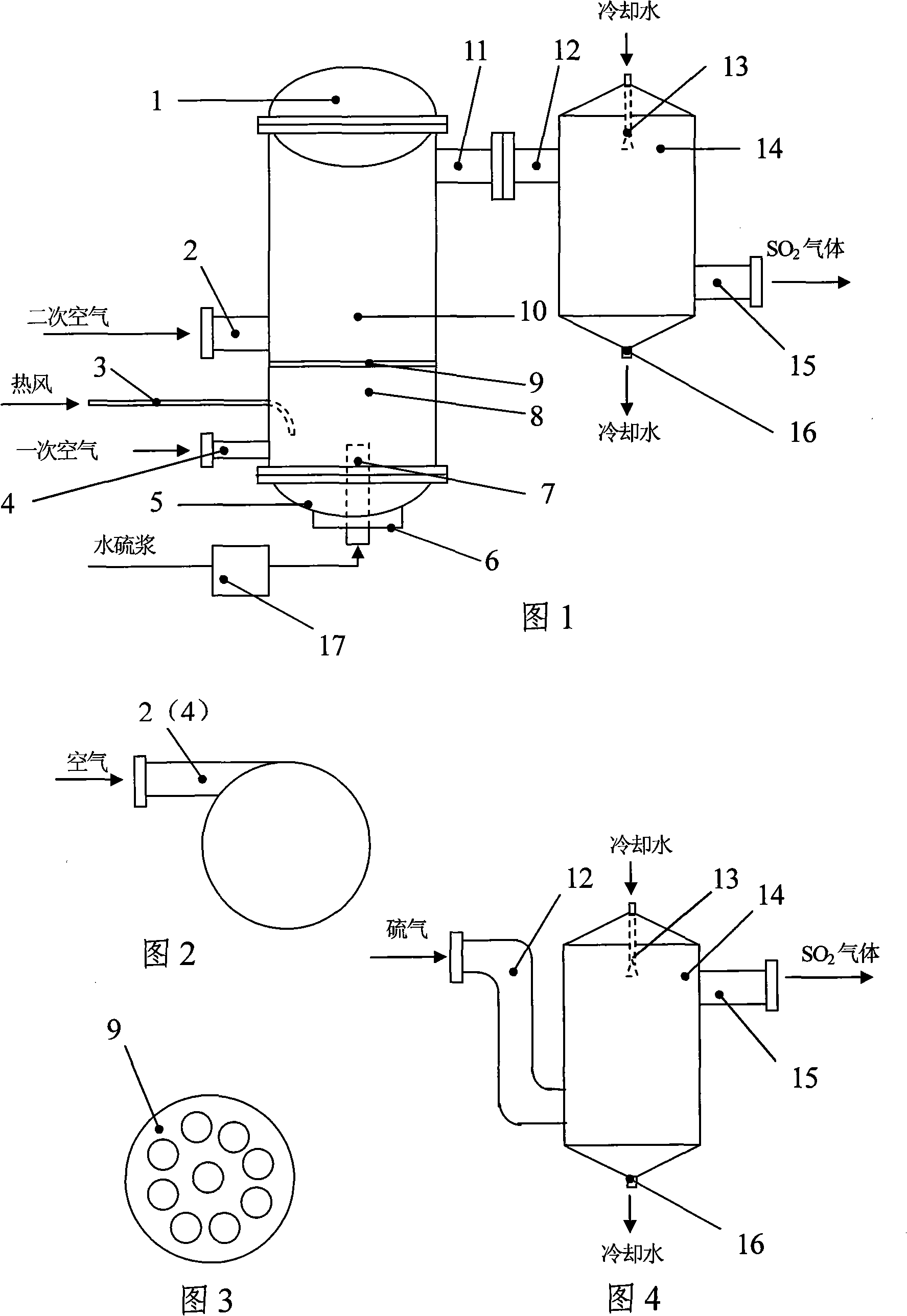

[0037] A device for producing sulfur dioxide gas. The device is a supporting device for a method for producing sulfur dioxide gas described in Embodiment 1 of the present invention. It is a sulfur burning furnace composed of a combustion chamber, a safety cover 1 and a lower bottom 5 that are sealed and connected with it. 2 The gas cooling device is formed, and the combustion chamber is a vertical cylindrical container, and a porous dividing plate 9 (referring to Fig. 3) is arranged in the middle of the vertical cylindrical container to divide the combustion chamber into a primary combustion chamber 8 and a secondary combustion chamber 10. The ignition device is a hot air pipe 3 with a diameter of 0.5 to 2 cm installed on the bottom side of the primary combustion chamber. The lower part of the primary combustion chamber 8 has a primary air inlet pipe 4 connected tangentially to the furnace wall of the combustion chamber. The secondary combustion The lower part of the chamber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com